Abstract

People with disabilities often face challenges like moving around independently and depending on personal caregivers for daily life activities. Traditional assistive devices are universally accepted by these communities, but they are designed with one-size-fits-all approaches that cannot adjust to individual human sizes, are not easily customized, and are made from rigid materials that do not adapt as a person’s condition changes over time. This systematic review examines the integration of smart materials, sensors, actuators, and 3D/4D printing technologies in advancing assistive devices, with a particular emphasis on mobility aids. In this work, the authors conducted a comparative analysis of traditional devices with commercially available innovative prototypes and research stage assistive devices by focusing on smart adaptable materials and sustainable additive manufacturing techniques. The results demonstrate how artificial intelligence drives smart assistive devices in hospital decentralized additive manufacturing, and policy frameworks agree with the Sustainable Development Goals, representing the future direction for adaptive assistive technology. Also, by combining 3D/4D printing and AI, it is possible to produce adaptive, affordable, and patient centered rehabilitation with feedback and can also provide predictive and preventive healthcare strategies. The successful commercialization of adaptive assistive devices relies on cost effective manufacturing techniques clinically aligned development supported by cross disciplinary collaboration to ensure scalable, sustainable, and universally accessible smart solutions. Ultimately, it paves the way for smart, sustainable, and clinically viable assistive devices that outperform conventional solutions and promote equitable access for all users.

1. Introduction

People having mobility challenges and physical disabilities such as Parkinson’s disease, spinal cord injuries (SCI), multiple sclerosis, amyotrophic lateral sclerosis, cerebral palsy, and muscular dystrophy have to live a hard life with less confidence and complex challenges like pressure sores and endure chronic pain and fatigue. It includes impaired mobility and muscle control, making routine activities, such as sitting, standing, dressing, eating, and moving independently, difficult without assistance. Patients with mobility impairments generally experience one of two basic types of disability: progressive disabilities, which involve a gradual physical decline over time, and static disabilities, which remain stable but still necessitate ongoing adaptation [1]. Additionally, societal misconceptions [2], employment barriers, and financial hardship further erode their quality of life, whereas assistive technologies (ATs) [3], tailored rehabilitation, and inclusive policies are crucial in empowering individuals to regain autonomy [4]. Actual equity demands not just providing medical help but also eliminating the unfair attitudes and systems that strip people of their dignity and choice of career [5,6].

There is a need to study and evaluate a wide range of devices, software, support, and assistive services designed to improve lifestyle, daily activities, manage chronic conditions, enhance health, and promote functional independence for individuals with disabilities and chronic conditions [7]. Assistive devices (ADs) [8,9], including mobility aids, communication devices, hearing aids, and adaptive equipment, have increased control in daily life activities for patients with disabilities. In recent times, smart materials (SMs) and artificial intelligence (AI) have transformed these technologies.

Beyond physical devices, for effective adoption and long term usability, personalized assessments, training, cost, aesthetics, comfort, ease of maintenance, and control are critical fields that need to be focused on. After addressing gaps in mobility [10], communication, and self-care assistive devices, users will be able to overcome barriers and actively participate in education, employment, and social life without relying on others for support. However, to unlock the transformative potential of AT, there is a need for inclusive policies and equitable distribution. The United Nation’s convention on the rights of persons with disabilities [11] strongly supports the opportunities for exercising personal choice and living independently within the community for persons with disabilities. Rehabilitation and treatment of disabled patients, even with minor injuries and disabilities, is an essential yet underestimated aspect of global healthcare. During 2019 alone, approximately 2.41 billion individuals, representing one third of the world’s population, required rehabilitation services, marking a striking 63% rise since 1990 [12]. Musculoskeletal disorders, notably low back pain, sports injuries, and military rehabilitation, emerged as the main reason for rehabilitation practices. To address this issue, three key actions should be undertaken: elevating rehabilitation within health policy agendas, securing sustainable funding, and integrating rehabilitation services into primary healthcare departments.

Previous reviews have mainly focused on material development, fabrication strategies, and general biomedical applications of 3D/4D printing [13,14]. In contrast, this work addresses a specific research gap by integrating both 3D and 4D printing with their application domains, emphasizing their role in ADs. This perspective provides a user centered and clinical focus that distinguishes this review from [13], which concentrates on magnetically responsive memory polymers, and [14], which discusses 4D printing primarily as a technology.

1.1. Statistics on Global Disability

The World Health Organization (WHO) [15] has extensively documented the global crisis in access to ADs. According to the 2022 global report on AT, almost one billion people with minor or major disabilities are living without any access to AT, whereas an estimated 2.5 billion people need at least one device for assisting in motion, such as wheelchairs, prosthetics, and hearing aids; yet nearly 1 billion people remain without access to these products. This gap is severe in countries having low and middle incomes, where healthcare systems often lack the infrastructure and funding to provide these life changing technologies. The report emphasizes that if no action is taken, the issue will continue to grow, particularly as aging populations increase the demand for mobility and sensory aid.

The WHO identifies 50 essential assistive products, such as wheelchairs, hearing aids, and communication devices, from the priority assistive products list [16] to meet global needs, yet despite the critical role of these technologies, 80% of countries still lack national policies to ensure their role in providing accessibility of these devices to all age groups. There is a report on disability in 2011 [17] by the WHO, which was later updated in 2023, highlighting that 50% of individuals with disabilities cannot afford essential ADs. As a result, many are forced to rely on outdated, inexpensive, and makeshift solutions, which restrict their independence, thereby limiting their adaptability, and provide only limited support. Additionally, the report emphasizes how societal stigma and poor policies marginalize disabled individuals.

Certain types of minor disabilities are becoming common in children; as per the report [18], an estimated 240 million children worldwide are living with disabilities. However, 75% of them lack access to basic ADs. Hence, 50% of them will not attend school, as they require ADs for mobility and psychological support. UNICEF and WHO call for global action on inclusive policies, increased funding, and strengthened international cooperation to ensure that no child is left behind.

In May 2018, there was a resolution, World Health Assembly 71.8 [19], passed by an assembly representing health professionals, urging countries to improve access to AT. This resolution calls for its inclusion in universal health coverage and the creation of a global report on access to AT, utilizing worldwide research and experience. WHO must also report progress made in 2022 and future purposes for 2026 and 2030. These reports will highlight the large gap in access to AT but also show a way to improve the situation. They call on governments, researchers, and industry leaders to focus on creating affordable solutions, making policies more inclusive, and ensuring that AT is part of universal healthcare. By working together, they can help more people obtain the devices and provide moral, ethical, and financial support for better lives.

1.2. Limitations of Traditional Assistive Devices

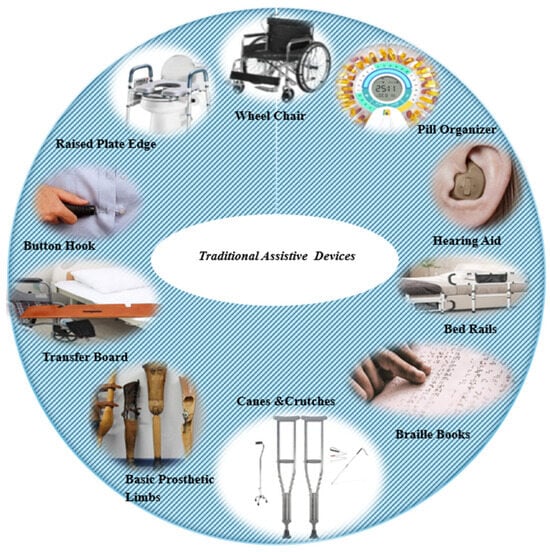

The traditional ADs, shown in Figure 1, such as manual wheelchairs, basic hearing aids, white canes, and bare prosthetic limbs, have long been used by individuals with disabilities [20]. These devices are affordable and straightforward, with prices ranging from as low as USD 20 for white canes to several thousand dollars for prosthetic limbs. These traditional aids, which had a greater impact in the past, now have numerous limitations. As technology advances, there is a corresponding need for the development of these devices as well. For example, manual wheelchairs [21] require physical strength to propel, whereas basic hearing aids merely amplify sound without offering advanced features such as Bluetooth connectivity and noise cancellation. Similarly, white canes are effective for basic navigation but lack the real time feedback and navigation assistance found in modern bright canes. Prosthetic limbs, though offering basic functionality, do not offer the precision, adaptability, and control provided by advanced bionic and myoelectric limbs [22]. Devices like raised toilet seats and walkers, while providing essential support, offer limited customization and are fixed in their design. In contrast, advanced technologies such as smart toilets and robotic walkers are more adaptable, utilizing sensors, AI, and SMs. Grab bars and crutches, although reliable, often work without the aid of smart sensors (SSs). In contrast, ergonomic innovations, such as bright grab bars and crutches, reduce strain. Bed rails and shower chairs are also effective but lack the motorized and automated adjustments seen in modern solutions. Devices like long reach grabbers and sock aids are simple and cost effective but do not offer the precision and motorized control found in advanced ADs; also, button hooks and utensil cuffs are functional but lack the multi-functionality available in modern adaptive wearables. Braille books, while still crucial, are bulky compared to digital Braille displays [23], having greater flexibility. Pill organizers and transfer boards remain useful, but they are far less sophisticated compared to bright medication dispensers and motorized lift systems.

Figure 1.

Traditional ADs.

Overall, traditional ADs (see Table 1), while foundational and accessible, cannot compete with the flexibility, adaptability, and customization offered by advanced technologies. New technologies, such as SMs and SSs, and customized 3D-printed devices [24,25] are helping people with disabilities live more independently and comfortably in ways that traditional ADs were never able to [26]. However, globally, access to smart ADs [27], durability, customer satisfaction, cost, and acceptance by healthcare professionals and patients still need to be addressed.

Table 1.

Widely adopted traditional ADs.

The challenges of high costs and limited accessibility in ADs are often due to the expensive materials, technology, and manufacturing processes involved [28]. Additionally, the distribution networks in these regions can be inefficient, and a lack of local suppliers may lead individuals to rely on expensive imports. In terms of static designs, many traditional ADs are based on one-size-fits-all models that do not account for the unique and evolving needs of individual users. These devices often have limited customization options, meaning that once a device is purchased, it cannot be easily adjusted and adapted to changes in the patient’s condition and preferences. For example, a wheelchair with a fixed seat and armrest configuration might not be comfortable for all users, especially as their mobility needs change over time [29,30]. Similarly, prosthetic limbs, which often come in fixed designs, may not provide sufficient flexibility to adapt to the varying levels of activity and functionality required by the user. The lack of adaptability in these devices results in a situation where users may have to settle for a suboptimal solution, leading to decreased comfort, functionality, and independence. Both the high costs and limited access of advanced, customizable, and adaptive ATs pose significant barriers for people having disabilities.

The combination of these factors makes it even more challenging for individuals with disabilities to lead independent, dignified lives, highlighting the need for innovation in both affordable pricing and more adaptable, user required designs [28].

1.3. Commercially Used Advanced ADs: Current Functioning, Limitations and Future Implementations

This subsection discusses several commercially available ADs, examining their current functionalities, limitations, and potential future developments aimed at improving and expanding their applications. These ADs have undergone rigorous industry validation, secured patent protection, and are now subject to continuous annual enhancements. An overview of these devices is also presented in Table 2.

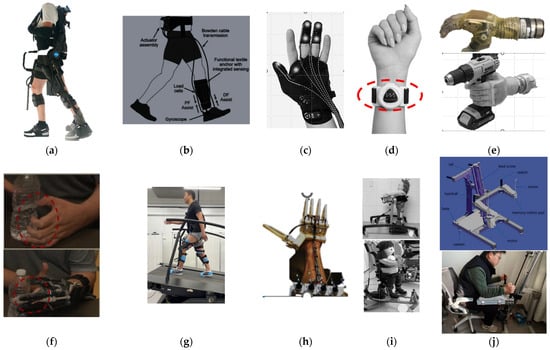

1. The EksoNR [31] exoskeleton has been utilized to assist patients with neurological impairments in regaining mobility through guided standing and walking rehabilitation (Figure 2a). The most important characteristics include sensor adaptive algorithms, which ensure safe and effective therapy but also involve high costs, limiting accessibility for smaller clinics and those treating diverse patient anatomies [32,33]. Due to advancements in manufacturing techniques, users and health professionals also demand human body dimension based exoskeleton components, AI-controlled tele-rehabilitation, and 4D-printed SMs, which pose future challenges.

2. The ReWalk [34,35] is a motorized, wearable exoskeleton enabling mobility, walking, stair climbing, and ramp navigation for people with spinal problems. Adaptive gait control, clearance by the Food and Drug Administration (FDA) for personal use, and overground mobility are essential performance parameters. In contrast, limited battery life, restricted adaptability for varying levels of paralysis, uneven terrain, and fast transitions from sitting to standing are challenges for future researchers [36]. Stroke patients were trained with a soft exosuit (Figure 2b) for almost two months to test the effects of gait training. Clinical and biomechanical performance were measured and paved the way for adopting exosuits for post-rehabilitation of stroke patients [37]. At the same time, real-time adaptability to muscle fatigue can be improved by using 4D-printed shape memory alloys (SMAs) and self-adjusting structures. Modular designs of brain controlled exoskeletons could also revolutionize mobility for individuals with paralysis.

3. Carbon hand (Figure 2c) is a soft robotic glove, which is designed to provide grip strength for individuals with hand weakness. It utilizes flexible actuators and pressure sensors to detect grip intent and provide proportional assistance, enabling tasks such as holding utensils, tools, and domestic items. It also features intuitive control over shelf sizing. Soft materials wear out over time, have a moderate grip force, which is unsuitable for heavy lifting, and lack finger independence, which are the current challenges [38]. Personalized glove liners for deformed and atrophied hands, 4D smart textiles that integrate haptic feedback, and AI-controlled grip prediction sensors for individual finger movement could bridge current gaps, making it viable for high precision and critical tasks.

4. Neuro Node [39] can control AT with the help of muscle signals and head/limb motions. It is a wireless wearable sensor designed for patients with extremely critical SCI. It is a universal control interface for all digital devices. A study [40] uses neuro node technology (Figure 2d) to test the speed and accuracy of an eye gaze augmentative and alternative communication system with dwell selection (extended gaze) compared to eye gaze combined with electromyography switching, a method designed for users with disabilities that limit independence and communication. Limited precision for multiple tasks, dependence on residual muscle and neck movement, skin irritation, grip assistance problems, and relying on external devices for physical function are current challenges. Eye-tracking hybrid modes, combined with 3D-printed, softer, and more breathable materials, as well as durable direct neural interfaces, can enable seamless control for users with paralysis.

5. LUKE Arm [41] is an advanced prosthetic limb, that is designed for upper arm amputees, focusing on replacing limb function rather than rehabilitating movement, offering multi-articulating joints and intuitive control. Weight and bulkiness compared to biological arms, as well as the lack of full tactile feedback, can restrict fine motor tasks, such as handling fragile items, which are the functional improvements required in the most recent model of 3D- and 4D-printed materials, touch sensation, and closing. A modern six degree of freedom (DOF) LUKE Arm (Figure 2e) is used in a study to achieve natural and precise control of the arm using a modified Kalman filter (a smart control system) [42]. Predictive motion control and battery free power solutions, as well as brain machine interfaces, serve as future challenges. If researchers succeed in solving these issues, it will enable the LUKE Arm to behave more like a real human arm.

6. The HERO (Hand Extension Robot Orthosis) glove (Figure 2f) is an assistive device for heart patients with severe hand impairment, using artificial tendons driven by a linear actuator to enable finger grasping and assisting users in relearning hand movements through automated finger flexion triggered by inertial sensors. Insufficient force for heavy objects, lack of individual finger control, dependency on residual arm movement, and severe spasticity are current trends missing in this glove [43,44]. Three-dimensional printed tendon systems, 4D printed self-stiffening materials, and hybrid control for users with minimal limb mobility, learning user specific movement patterns with the help of AI, could personalize rehabilitation and make this device a modern and adaptive control.

7. Myo suit [45] is a soft exo muscle that uses artificial tendons and elastic bands, and it is designed for users with lower limb weakness who retain some walking ability but fatigue quickly. It lacks adaptive AI control, and no ankle support is available [46]. A study involved experimental evaluation of lower limb joint kinematics and electromyography patterns in healthy subjects walking with and without the Myo suit (Figure 2g) during level overground and incline treadmill walking [47]. Three-dimensional printed elastic actuators and sensors, such as neuro nodes, could improve responsiveness by combining Myo suit’s soft robotics with functional electrical stimulation, among other future challenges for this device.

8. Exo glove is a tendon driven actuation system embedded in flexible polymers. The most important drawback is the dependency on residual muscle signals, which is challenging for high level amputations [48,49]. Advances in pressure sensitive skin, which enhance sensory feedback, and neural lace interfaces may enable direct brain control, serving as a viable alternative for advanced prosthetic hands. Similarly, in order to achieve effective finger rehabilitation, lightweight exo gloves (Figure 2h) using nitinol shape memory alloy (SMA) actuators have been fabricated [50], then numerically simulated and experimentally verified as well. Hence, remote therapy will be achieved using smart actuators combined with telerehabilitation to print small, efficient wearable devices that can help patients recover better.

9. Qolo rehabilitation system is a mobility aid designed for individuals with difficulties in walking and standing. These rehabilitation devices consist of numerous sensors that help in adjusting supports. The human machine interface has been used for rehabilitation sessions. Currently, due to the high-level of advanced digital technology, it has limited home use [51]. Although this system is advanced, personalized rehabilitation based on patient progress, affordable modular supports utilizing 3D and 4D materials, and remote therapist monitoring via cloud data are some improvements that can be made to make this device completely compatible with all kinds of digital advancements needed according to modern digital protocols. To achieve quality of life for children with cerebral palsy, dynamic standing and static standing designs (Figure 2i) were studied over a 4-month period, and dynamic standing was preferred, while more personalized standing care was preferred for each patient [52].

10. The able chair is a hybrid mobility device that transitions from wheelchairs to assisted walking. It consists of a seated support system with motorized walking actuators and balance aids to prevent falls. It promotes rehabilitation, reduces pressure sores, and improves cardiovascular health. It is not designed for long distance mobility, such as wheelchairs; that is why it is less portable than soft exosuits. Additionally, it requires residual leg strength, which is also suitable for cases of complete paralysis, although with some limited applications [53]. Seat and walker components are tailored to individual body shapes using advanced 3D and 4D printed materials and shapes, then adjust support levels based on real time fatigue and terrain data from neural network predictions, serving as a foundation for future modifications in this hybrid chair. Standing up is always a problem for elderly patients; a compact design prototype (Figure 2j) was developed and experimentally validated with four volunteers involved. This design supports the arms of elderly patients using the lifting mechanism allows simple hand and arm engagement after standing [54].

Figure 2.

Commercially available ADs: (a) Ekso NR exoskeleton [33]; (b) ReWalk exosuit [37]; (c) Carbon hand [38]; (d) A neuro node device placed on the forearm to measure when the index finger bends [40]; (e) LUKE Arm [42]; (f) HERO glove assistive tasks for paralyzed patient [43]; (g) Myo suit [47]; (h) Fabricated SMA actuator exo glove [50]; (i) Static and dynamic standing design assistive device [52]; (j) Sit to stand movement AD (CAD and experimental model) [54]. (Figures reproduced from external sources retain their original copyright. Reuse permissions were granted under the creative commons licenses (CC BY 4.0).) (https://creativecommons.org/licenses/by/4.0/ accessed on 10 April 2025).

Table 2.

Commercially available ADs.

Table 2.

Commercially available ADs.

| No. | Type of Device (Year Updated) | Potential Application of 3D/4D Printing Technologies | Material | Actuator, Sensors, Applications |

|---|---|---|---|---|

| 1 | Ekso NR [31] is a robotic exoskeleton for limbs (2023) | Limited 3D shell with future 4D potential with smart materials application. | Aluminum, carbon fiber | Motion sensors, AI-linked circuits |

| 2 | ReWalk personal 6.0 [35] is an exoskeleton for paraplegic patients (2022) | 3D printed braces are possible | Aluminum, polycarbonate | Gyroscope, tilt sensors |

| 3 | Carbon hand [38] is smart grip assist glove. (2024) | 3D glove shells; soft robotics future | Silicone, textile blend | Pneumatic actuators, sensors |

| 4 | Neuro node trilogy [39] is a neural input interface (2022) | Minimal 3D use, flexible PCBs in future | Composite plastic, medical gel | Electromyography sensors, capacitive electronics |

| 5 | LUKE Arm [41] is an advanced prosthetic arm (2023) | 3D sockets; 4D joints future applications | Titanium, silicone, carbon fiber | Neural interfaces, pressure sensors |

| 6 | HERO glove [43,44] is a rehab glove (2022) | 3D finger modules; 4D soft robotics future | Neoprene, nylon | Flex sensors, IMU tracking |

| 7 | Myo suit [45] soft exosuit for legs (2024) | 3D fit shells; 4D fabrics in research | Smart textiles, carbon fabric | Smart stretch sensors, textile circuits |

| 8 | Exo glove poly II [49] is a soft hand exosuit (2023) | Fully 3D printable; 4D in exploration | TPU, nylon, silicone | Pneumatic actuators, embedded sensors |

| 9 | Qolo [51] rehabilitation system is used for sit to stand movements (2022) | 3D frame; 4D seat research ongoing | Aluminum, plastic | McKibben type soft, compliant actuators, load sensors, IMU and pressure sensors |

| 10 | Able chair [53] is a smart power wheelchair (2023) | 3D seat shells; 4D cushion materials in R and D | Aluminum, memory foam | Electric motors, joint position and EMG sensors |

1.4. Breakthroughs in ADs from Academia and Lab Studies

The devices listed in Table 2 represent commercially established technologies. There are some other studies that focused on optimization methodology, such as in [55], where a step approach was employed: first, Kano model is used to identify user demands; second, design elements are obtained using the analytic hierarchy process; and last, a fuzzy comprehensive evaluation technique is used to obtain the best-performing scheme. Another novel omnidirectional Ex robot, WANDER [56], is developed using a preference optimization method for walking aids with multifunctional properties.

On the other hand, Table 3 provides a brief comparison of devices that are currently emerging technologies. The details of these devices are primarily sourced from recent research publications and prototypes. As innovation in manufacturing processes is increasing, there are a lot of prototypes being developed and tested in research institutions and in medical facilities. Some of the applications related to our study will be discussed here.

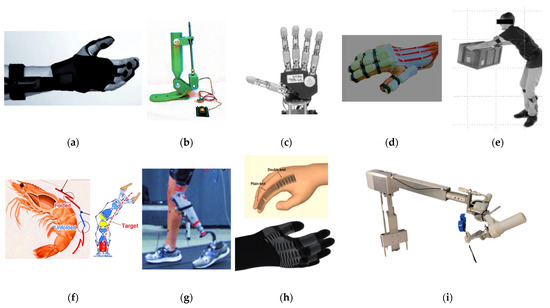

- SEM glove (Figure 3a) is a motor assisted glove designed for patients with upper limb movement deficiencies [57]. This glove increased the pinch strength of patients when tested on almost 30 hospitalized patients.

- A pilot study [58] was performed on a soft and light textile based exo boot designed to reduce the metabolic effort during walking. A comparative study involving the torque generated by this innovative lightweight assistive device at different pressures and ankle angles is also being performed. In order to enhance the naturalness of single DOF commercial devices, a lightweight, autonomous two DOF ankle prosthesis (Figure 3b) consisting of a screw drive actuator and microcontroller has been developed and tested [59]. Experimental and FEA simulations pave the way for real-world locomotion, whereas future work will focus on fatigue and impacts.

- Neurobotics [60] elbow exoskeleton is designed for patients recovering from stroke and has also been verified with experimental studies. In order to drive a multi DOF anthropomorphic prosthetic hand emulator (Figure 3c), a novel two DOF myoelectric controller using principal components analysis was employed [61]. Twelve participants used two differential EMG (electromyography) channels to grasp, move, and release different objects. They also measured how well and how fast they completed tasks and tracked their improvement over three consecutive days.

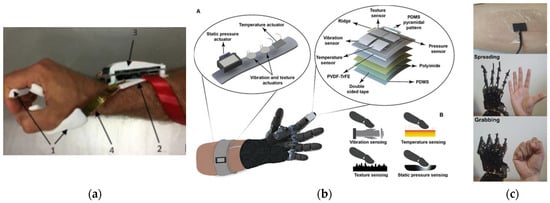

- A unique heat cured rubber silicon fabrication process is used to fabricate a voice-controlled flex tendon glove-III, a hand exoskeleton designed for holding and grasping objects. This study also involved a mobile phone app controlled by voice control an object based admittance controller for gripping and grasping. This device was also validated with experimental verification on a healthy user [62]. Similarly, for developing a new rehabilitation glove, a novel actuator design [63] aligned with human finger anatomy and motion was created and tested using soft materials with 3D printed manufacturing technology (Figure 3d). Kinematic models for the index and little finger actuators were developed from pressure and link lengths, and forward kinematics was used for workspace estimation. Finally, the results were verified with anatomical motion and experiments, and glove ergonomics were assessed.

- SPEXOR [64] is an exoskeleton design for improving workplace ergonomics for healthy patients. This exoskeleton is designed to support the spinal cord, unlike other exoskeletons, which were designed for limb assistance and rehabilitation. So, this study focuses on preventive medical assistance. So, in order to manage and prevent low back pain, biomechanical principles have been studied [65]. This research consists of modeling and optimization of spinal exoskeleton interaction (Figure 3e) with the human body, and also the design and development of a passive system with effective control system assistance has been evaluated.

- A novel bio inspired fish like structure having a bionic spine with variable stiffness [66] can be used to create a bionic spine for more natural and energy efficient movement in ADs such as soft exoskeletons and prosthetic limbs. This novel study demonstrates the effectiveness of bio-inspired structures with advantages of adaptability, responsiveness, and better natural motion efficiency. So, by using a flexible bionic spine that can adjust stiffness depending on patient requirements, ADs offer a valuable solution. There is another study in which a multi-stable origami exoskeleton (Figure 3f) is developed, inspired by shrimp exoskeletons, in order to achieve flexible, rigid arrangements [67].

- Power knee [68] is one of the advanced prosthetic knees available with the first microprocessor motor power, so it will give smooth, natural motion, as this advanced prosthetic consists of sensors as well, so it will also reduce user effort and can be used for climbing as well. A novel strategy has been developed by integrating a powered knee prosthesis (Figure 3g) with a control system [69]. This system provides passive behavior during activities requiring minimal power and delivers powered assistance for movements demanding active knee actuation. This intelligent control system is also verified experimentally by making a comparison of a nominally passive system with a conventional passive microprocessor-controlled knee prosthesis.

- The multifunctional elbow brace is designed to treat elbow joint problems with both heat therapy and mechanical pressure. This device [70] is also being experimentally verified on human participants. Knitted SMA fabric provides comfort for daily use, and SMA changes shape when heated, giving smart properties to the fabric, so heating therapy, muscle contraction for joint movement, and mobility assistance to the elbow are achieved after testing on human participants, satisfying the aim of achieving multiple functional outputs. Since COVID-19, numerous strategies and studies have been implemented for increasing the role of robotic technologies in healthcare while keeping patient care, safety, and clinical efficiency as priorities. Recent studies have explored the potential application of knitted shape memory alloys in soft wearable robots, where a flexible knitted shape memory alloy actuator has been developed for a rehabilitation glove [71]. Also, to achieve a realistic patient’s finger range of motion (Figure 3h), both plain and double-knit modules were used.

- Similarly, robots have been used in spinal surgeries to perform simple tasks, but this robotic system (Figure 3i) performs autonomous laminectomy (spinal bone removal to release pressure from the spinal cord). In an experimental approach [72], an advanced robotic system is being used to perform surgeries on four human bodies donated for research, performance metrics were measured and compared with professional surgeons’ outcomes and standards; hence, precise execution is reported.

Below mentioned Table 3 provides a brief comparison of devices explained above, concerning advanced additive manufacturing techniques that are currently emerging, their working principle, and SMs’ potential in these devices.

Figure 3.

ADs from academia and lab studies. (a) SEM glove [57]; (b) Two DOF ankle prosthesis [59]; (c) robotic hand [61]; (d) 3D-printed rehabilitation glove [63]; (e) SPEXOR monitoring system [65]; (f) multi-stable origami exoskeleton [67]; (g) power knee and control system [69]; (h) knitted SMA actuator rehabilitation glove [71]; (i) robotic arm with a Jamshidi needle for spinal surgery [73]. (Figures reproduced from external sources retain their original copyright.) Reuse permissions were granted under creative commons licenses (CC BY 4.0).) (https://creativecommons.org/licenses/by/4.0/ accessed on 20 April 2025).

Table 3.

Innovative prototypes and research stage ADs.

Table 3.

Innovative prototypes and research stage ADs.

| No. | Type of Device | Working Principle | Limitations | 3D Printing Material Potential and Application | SMs Potential | Potential Applications of 3D/4D Printing Technologies | Advantages Over Conventional Materials |

|---|---|---|---|---|---|---|---|

| 1 | SEM Glove [57] works as a hand rehab device for stroke patients | Soft actuators for finger motion | Limited grip force, no tactile feedback | TPU/Elastomers | Shape memory polymers | Self-stiffening finger joints for variable resistance | Patient required design and size, adaptive grips |

| 2 | Exo Boot [58] is ankle rehab device | Portable assistance | Bulky, short battery life | Carbon fiber composites | Piezoelectric polymers | Energy-harvesting sole foams | Adjustable strap systems, Solar powered gait adaptation |

| 3 | Powered elbow exo skeleton [60] works for arm rehab for SCI disabilities | Torque-controlled spasticity management | Rigid joints restrict motion | Titanium alloys | Liquid crystal elastomers | Stiffness adjusting cuffs based on EMG signals | Torque personalization, neural interface integration |

| 4 | Flexo tendon glove [62] gives hand rehab | Fluidic tendons for adaptive grip | Slow response, leakage risks | Flexible photopolymers | Self-healing hydrogels | Microfluidic channels with leak proof coatings | Predefined grip modes, closed loop pressure control |

| 5 | SPEXOR [64] spinal exoskeleton provides spinal support | Passive lower back load reduction | No active assistance | Nylon 12 | Auxetic metamaterials | Lattice structures for dynamic spinal alignment | Sizing only |

| 6 | Bionic spine [66] helps in full-body mobility | Neural implant for exoskeleton control | Invasive surgery | Biocompatible resins | Conductive 4D hydrogels | Self-expanding electrode arrays | Surgical precision |

| 7 | Power knee [68,74,75] provides knee rehab | Energy recycling exosuit | Heavy, noisy | PETG/PLA composites | Electroactive polymers | Energy harvesting knee hinges | Gait pattern tuning, Silent piezoelectric actuation |

| 8 | Smart braces [70,76] provides knee and ankle support | SMA dynamic bracing | Slow response | NiTi alloys | Thermo-responsive polymers | Terrain-responsive stiffness modulation | Joint specific tuning, predicted stiffness adjustment |

| 9 | Spine surgery assists robotic system for works [72,77] | Robotic scoliosis correction | Restricted mobility | PEEK polymers | Growth adaptive scaffolds | Expandable braces for child development | Curve specific correction, pediatric growth accommodation |

As discussed in Section 1, this review first establishes the global statistics on disability and the urgent need for assistive technologies (ATs), followed by an assessment of the limitations of traditional devices. It then examines commercially established smart devices and subsequently highlights recent laboratory breakthroughs, each addressed in separate sections to provide clarity on material usage, technological adoption, and functional capabilities. By structuring the discussion in this way, the study not only compares devices across different stages of maturity but also emphasizes how materials, design innovations, and policy frameworks interact to shape accessibility. Unlike previous reviews, which often focus narrowly on sensor actuator integration, material combinations, and isolated performance parameters, this work presents a comprehensive synthesis that bridges global policy perspectives, affordability, and patient centered design with technical advancements. In doing so, it provides a holistic roadmap for how innovations in advanced materials and additive technologies can be aligned with policy and accessibility goals, paving the way for more inclusive and scalable AT solutions. As a result, this review performs a critical comparative analysis that explicitly connects material properties and manufacturing techniques to functional outcomes, accessibility, and scalability. We identify and analyze a crucial paradigm shift: the move away from rigid, centralized manufacturing towards AI-driven, decentralized, and on demand production models (e.g., 3D/4D printing in hospitals) as the key to overcoming the systemic barriers of cost, customization, and equitable access detailed in Section 1.1 and Section 1.2. By evaluating both commercial devices (Section 1.3) and academic breakthroughs (Section 1.4) against this same framework, this review reveals previously unrecognized trends and critical gaps, most notably the disconnect between high performance laboratory innovations and the requirements for sustainable, policy aligned, and globally scalable commercialization. Ultimately, this work provides a unique roadmap for guiding future research, development, and policy toward creating clinically viable and universally accessible adaptive assistive technologies.

2. Methodology

2.1. Research Questions

The PICO framework has been used to explore the role of emerging technologies, such as materials adaptive behavior properties, sensors, actuators, and 3D and 4D printing, in the design and performance of ADs. In this phase, population (P) represents users of ADs, exposure and intervention (I) are the current available ADs, the comparison (C) are the alternatives, such as smart materials, 3D/4D printing, sensors, and actuators (C), whereas outcome (O) represents improved customization, performance, cost efficiency, adaptability, biomechanical alignment, and accessibility to all kinds of people. Depending on this framework, we have developed the following research questions for our systematic review.

- How can 3D and 4D printing technologies improve the traditional ADs by considering customization, cost, adaptability factors, and performance for mobility assistance such as walking, standing, and grasping? And how will these technologies be able to fully replace conventional devices in the healthcare industry?

- How can smart sensors (SSs) be integrated into ADs with a focus on recent research prototypes and commercial applications? How do different types of actuators increase smart functionality and self-regulated motion in ATs to ensure smooth and efficient mobility support?

- How do different 3D printing technologies used for producing ADs affect their quality and performance? How is decentralized additive manufacturing of ADs in hospitals possible, patient acceptance, and overall productivity in digital healthcare systems improved?

- What kind of smart materials are essential for mobility aids and prosthetics? Are there any successful applications of smart materials in mobility aids with improved adaptability and biomechanical performance?

- In what ways can actuators, sensors, and 3D/4D printing be harnessed to design adaptive and affordable ADs aligned with individual biomechanics?

- What are the primary technical, economic, and regulatory barriers that exist for establishing 3D and 4D printing technologies in healthcare facilities? Smart material (SM) reliability, lab scale success vs. scalability, performance metrics of ADs, small decentralized economic production, availability in rural regions, and FDA/CE approvals are key factors to be followed.

- How effective are commercially available smart ADs, such as prosthetic and orthotic devices, in achieving improved gait, posture, and quality of life, and how can emerging technologies push these outcomes further?

- Which design strategies and engineering models best support the co-optimization of mechanical and biomechanical performance in ATs, integrating 3D/4D printing, sensors, and actuators, through collaborative, multidisciplinary approaches and data sharing?

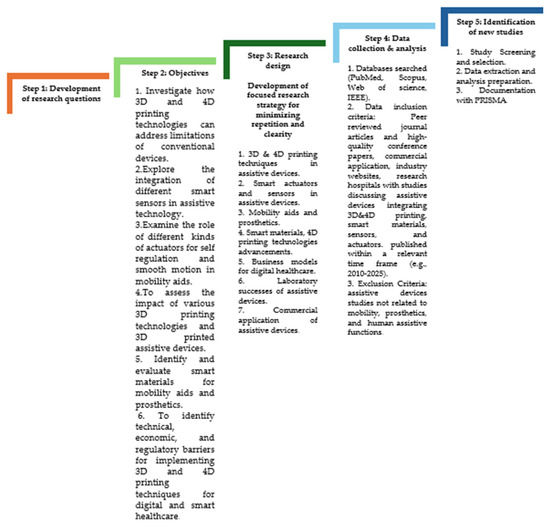

2.2. Development of Research Objectives and Methodology for Research Studies Analysis

The research questions outlined above aim to clearly define our objectives in exploring recent advancements in ATs. They emphasize evolution beyond traditional ADs by focusing on enhanced customization, cost-effectiveness, adaptability, and biomechanical performance. We also want to evaluate the performance of laboratory scale innovations and their potential for full scale adoption in the healthcare industry. Figure 4 illustrates an overview of the methodology adopted during the systematic review process to facilitate a clearer, unbiased understanding of our study and ensure its accuracy. This will result in comprehensive research, enabling healthcare professionals, engineers, and industrialists to make decisions based on reliable information. To implement a medical device, specific protocols must be met. Additionally, we require research evidence, clinical proficiency, and patient preferences, which is why evidence based and experimentally verified digital health devices are our focus. We will discuss advanced ADs produced in research hospitals, commercially available and laboratory success comparisons, with a focus on ATs that are easily implemented, customer-satisfied devices, and their components, such as sensors, adaptable materials, actuators, and advancements in 3D/4D printing in recent years.

Figure 4.

Steps for the methodology adopted for review.

2.3. Inclusion/Exclusion Criteria of Research Studies and Reports

This review was built on a foundation of primary research evidence. To ensure our findings were comprehensive and robust, we used a multifaceted strategy for collecting data: Core Evidence (Primary Research): The main body of our analysis is based on 130 primary research articles. These provided the original data that we synthesized to draw our conclusions. Supporting Context (Review Articles): We consulted 33 existing review articles, but only to help shape our research question and provide background context in the introduction and discussion. Their data was not included in our final analysis to avoid simply repeating previous summaries. Mitigating Bias (Grey Literature): To capture valuable data that is not always published in academic journals, we included 53 pieces of “grey literature,” such as technical reports from universities and documents from agencies like the WHO and UNICEF. These sources were only used when they contained unique, unpublished information (e.g., specific performance metrics, internal program data, or policy guidelines) relevant to our research question. In these cases, they were treated as primary evidence. This approach, recommended by the Cochrane Handbook, helps minimize publication bias and ensures a more complete picture of the available evidence.

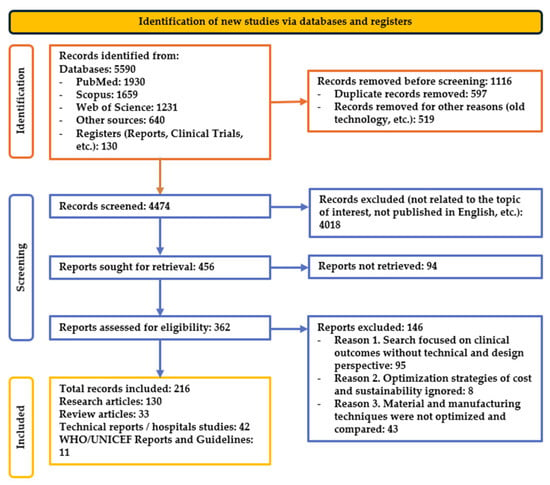

2.4. PRISMA Flow Chart

Figure 5 reports the PRISMA (Preferred Reporting Items for Systematic Reviews and Meta-Analyses) flow chart, which represents the screening process of this study. To make this process transparent, a mapped research approach in the form of a flowchart has been implemented. It consists of steps that represent how many studies were processed, identified at the start, then screened for the final analysis, along with reasons for inclusion and exclusion. Grey literature, including technical reports, theses, and institutional documents, was considered when it provided original data relevant to our research question. While excluded from the final evidence synthesis, these sources helped to shape the research framework, identify gaps, and ensure a comprehensive overview of the field.

Figure 5.

PRISMA flow chart.

3. Functional Components in ADs: Recent Advancements

3.1. Actuators in ADs

Actuators help components in ADs to move, control, and interact by converting an input, depending on application type, such as electrical energy, hydraulic energy, and pneumatic energy, into an output, which is mechanical energy. In ADs, actuators assist human motion, thereby improving independence and performance in daily life activities, including prosthetics, orthotics, mobility aids, and rehabilitation robotics. Powered prosthetic limbs, motorized wheelchairs, and robotic exoskeletons work with the help of electrical actuators, named as electrical motors, DC motors, and servo motors. Another essential type of actuator for high force output in heavy-duty exoskeletons and advanced prosthetic knees is hydraulic actuators; as their name suggests, they use hydraulic fluid pressure to create strong but smooth movements. However, most of the time, they require pumps and reservoirs, which typically consist of large bulk quantities of actuators. Pneumatic actuators are lighter than hydraulic actuators because they use compressed air, which is commonly found in wearable ADs for flexible motion. The force output of McKibben pneumatic artificial muscles is analyzed to achieve efficient muscle design by a detailed comparison of design parameters. Finite element simulation and artificial neural network techniques were used to verify real test data [78]. There have been examples of actuators being developed using SMs in clinical studies. Most of the actuators have used SMAs and piezoelectric materials. SMAs can change shape in response to a heat stimulus within their designed working environment, making them adaptable and multifunctional. In contrast, piezoelectric materials produce small displacements in response to an electrical stimulus. These types of smart actuators generate the required actuation without needing any external power. Soft actuators represent another type of actuator that is commonly found in ADs that utilize soft materials, such as polymers. In order to achieve flexibility, strength, and speed, a novel bioinspired soft actuator design is experimentally validated, showing an excellent biomimetic design, paving the way for future applications in soft robotic limbs [79]. Soft actuators have four further types: pneumatic, hydraulic, tendon-driven, and dielectric elastomer systems that help patients with mobility assistance and also in later stages of rehabilitation [80]. In addition to these, there are some other emerging actuator technologies as well, like ionic polymer metal composites [81], bend easily when a small amount of electricity is applied because ions move inside them, offering advantages like biocompatibility and silent operation, but have some drawbacks like low force output, slow response, and environmental sensitivity. Twisted and coiled polymer actuators [82], usually made from nylon and polyethylene fibers, change shape in response to heat, their contracting ability is fast when exposed to heat; providing high stroke and low cost, but complex thermal management is one of the key problems in these devices. Liquid crystal elastomers (LCEs) [83] are one of the most advanced and efficient actuators, having reversible significant shape changes directly in response to changes in heat and light, making them highly sensitive and with impressive theoretical work density, but complex fabrication and significant control challenges are limiting these to research laboratories. The overall comparison of these actuators explains that actuators in soft hand exoskeletons have improved the range of motion for patients. Adaptive ankle-foot orthoses have reduced walking effort by 12% for patients with cerebral palsy. As this is the next generation phase of ADs, energy inefficiency, control delays, material durability, and cost are key challenges for advanced actuators. Actuators are the backbone of ADs; therefore, for next-generation ADs, there is a need to transform them from passive devices to smart, interactive ones. In Table 4 below is reported a brief comparison of some advanced actuators in ADs.

Table 4.

Advanced actuators in ADs.

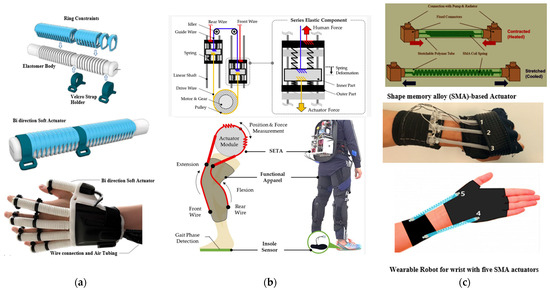

Figure 6a illustrates the bi-directional soft pneumatic actuator [87], produced using 3D-printed molds and silicone rubber, reinforced with polyethylene rings, lightweight, and sized to match human fingers. Integrated with sensors and control, it enables safe, controllable, and bidirectional motion for assistive hand robotics. Figure 6b presents a series elastic tendon actuator (SETA) [88], where linear springs and wire actuation provide smooth, controlled knee assistance in an exosuit. This elastic tendon actuator generates torque through front and rear wires during knee flexion, also measuring forces with wire tension. Compliance is introduced through linear springs, allowing slight joint movement, and a single motor drives both wires with two series elastic components sliding along linear shafts. Each SEC, preloaded to 50% of maximum deformation with four compression springs, transmits motor power from the input to the front or rear wires. Figure 6c presents shape memory alloy spring-shaped, muscle-like actuators [89] that contract when heated electrically, providing actuation without bulky motors. In Figure 6c, actuators are placed strategically around the wrist; contraction of actuators on the palm side (4, 5) produces flexion, while those on the dorsal side (1, 2, 3) cause extension. Similarly, actuators near the little finger side (1, 4) generate ulnar deviation, and those near the thumb side (3, 5) induce radial deviation. By selectively activating combinations of these actuators, the device enables not only single-axis movements but also complex wrist motions.

Figure 6.

Actuators in ADs. (a) Bi-directional pneumatic soft actuator in wearable soft robotic hand [87]; (b) series elastic tendon actuator (SETA) in knee exosuit actuator using linear springs and encoder feedback for compliant, adaptive stair climbing assistance [88]; (c) SMA coil actuator with coil shaped SMA for high contraction and force in soft wrist assistive device [89].

While actuators independently serve as the backbone of advanced ADs, their true potential emerges when integrated with sensors and produced using sustainable advanced fabrication technologies. For example, actuators alone can enable motion, but when coupled with sensor feedback, for example, using EMG, pressure, and motion sensors, they allow for adaptive control in prosthetics and exoskeletons. Furthermore, 3D printing technologies enable the customization and lightweight design of actuator housings and transmission systems, ensuring improved comfort and usability for patients. Emerging smart actuators based on shape memory alloys (SMA), dielectric elastomers, and liquid crystal elastomers can be directly integrated with sensor arrays, resulting in self-regulating, adaptive ADs. This integration represents the shift from passive mechanical components to smart, interactive systems that dynamically respond to user needs and environmental contexts. This concept promotes some components of actuators to be printed with conventional 3D-printed materials and then some with smart materials for a combination of active and passive motion. In order to explain this concept in detail, some advanced sensors and manufacturing techniques are explained in further sections.

3.2. Sensors in ADs

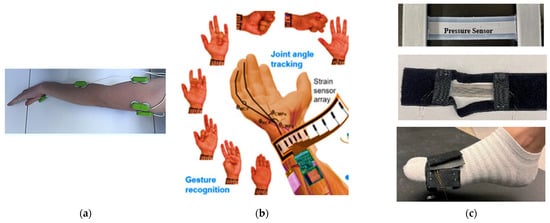

Sensors typically operate by detecting changes in their environment and converting them into readable values [90]. Sensors detect physical changes and convert them into analog and digital outputs, which can be displayed, monitored, and processed by other devices, depending on the application. Sensors provide a link between the physical parameters, as input values, and the logical parameters, as output values [91]. It works for IoT [92] by collecting, analyzing, and processing environmental data, then providing efficient monitoring, management, and control with the help of other devices. So, almost every assistive device consists of transducers that convert the signal from input to output, and then we have actuators that use these outputs as their input to perform required tasks, such as motion or force transfer. In ADs, sensors are used for different applications; even 3D printing technology has been used to produce smart sensors as well [93]. There are various types of sensor classification, classified by power requirement as active sensors that require external power for operation. In contrast, passive sensors work without external power. Another type of sensor depends on how they detect changes in the environment, meaning their detection principle, such as chemical, electrical, and radioactive methods for measuring environmental changes. Sensors are also classified on the working principle of conversions, meaning how they convert input into output, with massive applications in ADs, for example, converting heat to voltage in thermoelectric sensors. However, the last classification type encompasses both analog and digital sensors, depending on the type of output required from them. ADs used in neurological, musculoskeletal, cardiopulmonary, and pediatric rehabilitation are using accelerometers, gyroscopes, and magnetometers as sensors. All three types are inertial measurement units, strain sensors, and pressure sensors, such as those found in the insoles of ADs, on mats, in wearable devices and exoskeletons [94], and electromyography sensors for intramuscular devices. Electrocardiography (ECG), electrodermal activity, photoplethysmography, temperature sensors, and respiration sensors are utilized in the field of physiology, alongside haptic, auditory, and visual modalities, which operate on the principle of biofeedback [95]. Also during grasping action [96], a Bayesian sensor fusion algorithm was used to analyze the data from each sensor independently. Four surface EMG sensors (Figure 7a) were utilized to measure muscular signals during sequential grasping actions, resulting in a more reliable and easier-to-maintain design, providing a flexible design while still providing intent detection precision and reduced maintenance requirements. In electronic travel aids, sensors such as cameras, sonar, and laser scanners [97,98] have been utilized. In order to measure the force applied and to detect the user’s intention to stand, researcher [99] involves initial feasibility testing of sit-to-stand devices that utilize pressure sensors, thereby promoting adaptive assistance. This resulted in the sensor-integrated device being feasible, offering promising usability and providing potential benefits for safer and easier standing. An advanced wearable electronic patch [100] is also used, which adheres directly to the skin of the forearm and hand, and it is composed of an array of tiny sensors made from laser-induced graphene (Figure 7b). When patients move their fingers and hands, sensors will detect sensitive muscle movements and skin deformations (myography). To track the complex poses and gestures of the entire hand and forearm, data is recorded and then processed. There is another advanced camera, the Intel RealSense D400f depth camera [101], that can be used for advanced detection techniques. It consists of an IR pass filter that blocks visible light and captures only infrared. It will increase depth sensitivity in challenging environments, such as obstacle detection and navigation for smart wheelchairs in bright outdoor settings. This promotes contactless gesture control for mobility limited users, visually impaired navigation systems for spatial mapping, and home lighting that prevents patients from falling. To achieve comfortable and real time wearable gait monitoring, a novel, flexible microchannel pressure sensor (Figure 7c) has been designed from a soft elastomer containing a microchannel filled with liquid metal Galinstan [102]. This sensor features a flexible electrode that changes capacitance when a footstep deforms the microchannel, resulting in highly sensitive and stable pressure values. These advanced sensors can work very efficiently in rehabilitation and other mobility ADs due to their excellent step timing, pressure patterns, and center of pressure trajectory compared to piezoresistive alternatives and other rigid sensors.

Figure 7.

Sensors in ADs. (a) EMG sensors (green boxes) on participants arms [96]; (b) laser-induced graphene sensors for sensitive hand movements and gesture detection [100]; (c) microchannel pressure sensor application in a gait monitoring system [102].

The functionality of sensors in ADs is amplified when integrated with smart actuators and sustainable advanced fabrication methods. Sensors provide the critical feedback loop by monitoring biomechanical signals, physiological parameters, and environmental changes, which actuators then convert into precise motion and assistance. For instance, pressure sensors in gait-monitoring devices can guide actuators in exoskeletons to adjust step assistance in real time. Similarly, 3D printing allows for embedding flexible, lightweight sensors directly into wearable devices, enhancing comfort and accuracy while minimizing bulk. When combined with smart materials, such as piezoelectric and graphene sensors, the integration fosters the development of ADs that are not only responsive but also predictive, enabling proactive rehabilitation and assistance tailored to individual users.

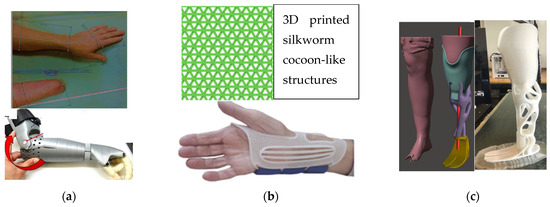

3.3. D-Printed ADs

3D printing technology is revolutionizing ATs by enabling highly customizable, affordable, and functional replacements for the human body [25]. Three-dimensional printing produces digital scanning and modeling, ensuring a comfortable fit with 3D-printed sensors [93], user-specified components, and actuators [32,103]. It utilizes lightweight, durable materials and rapid prototyping, enabling quick adjustments and iterative improvements [104], hence increasing enhanced mobility and responsiveness. In [105], a case report is studied using a comparative approach to examine a 3D-printed transradial prosthesis (Figure 8a) compared to a standard one. The wrist–hand orthoses (Figure 8b) and lattice geometries were fabricated using material extrusion technology equipped with a direct drive extruder suitable for soft materials, which are melted and extruded through a nozzle to create custom lattice geometries and orthoses layer by layer [106]. There is also research that revolutionizes the production of lower limb prostheses by using 3D printing combined with digital design and structural optimization. In this study a single monocoque device (Figure 8c) is printed using fused filament fabrication, with careful selection of materials for prototyping and load bearing applications, enabling rapid iteration and patient-specific customization. Ultimately, the study provides a practical roadmap for making prosthetic devices accessible to underserved populations, reducing both economic and geographic barriers while maintaining quality, comfort, and functionality [107]. The standard device performed better functionally, offering strength, durability, and fine control. In contrast, the 3D-printed prosthesis offered significantly higher patient satisfaction due to its comfort, lighter weight, and customizable appearance. Also, a brief comparison of 3D-printed technologies is presented, highlighting applications and potential in ADs.

Figure 8.

Three-dimensional printed ADs. (a) 3D-printed arm prosthesis produced using photogrammetry [105]; (b) 3D-printed orthosis [106]; (c) 3D-printed monocoque design transtibial prosthesis (unibody structure instead of multiple parts) [107].

3.3.1. Fused Deposition Modeling (FDM)

It is a widely used additive manufacturing technique in which a heated nozzle fabricates 3D ADs by extruding thermoplastic filaments, depositing material layer by layer. FDM techniques have significant importance in ADs and prosthetics [108], where customization, lightweight designs, and cost-effectiveness are paramount [109]. Examples include prosthetic sockets, ankle–foot orthoses, and exoskeletons, which feature variable patient-specific design [110] and sizing tailored with the help of 3D scanning and FDM’s design flexibility [111]. FDM also offers great transformative potential, achieving consistent quality demands, rigorous parameter control, and material innovation. Nozzle temperature, thickness, and interlayer bonding are critical processing parameters. Material selection, primarily composed of PLA, ABS, and TPU, among others, significantly influences mechanical performance, including warping, residual stresses, and poor interlayer adhesion [112]. However, there are several limitations, such as reduced strength along layer lines due to anisotropic behavior and surface roughness, necessitating postprocessing. AI-driven parameter optimization, as well as carbon fiber reinforced filaments, are future improvements that are needed to make ADs printed by FDM stronger and more durable.

3.3.2. Selective Laser Sintering and Melting (SLS and SLM)

It is a powder-based manufacturing method that produces ADs with complex geometries without support structures. It uses a laser to selectively polymerize powders, such as polyamide, polypropylene, and composites, layer by layer. Material properties, printing orientation, and inherent porosity resulting from incomplete sintering impact the mechanical performance of 3D-printed ADs [113]. SLS-printed ADs have better strength and surface finish compared to FDM, although they face challenges such as limited material options, high costs, and the need for parameter optimization [114]. Selective laser melting (SLM) and electron beam melting (EBM) were used to fabricate titanium frameworks for implant supported fixed prostheses [115].

Factors, such as laser power, thickness of layer, and speed, critically affect the mechanical behavior of 3D-printed ADs [116], while also assessing defects like incomplete sintering, which results in incomplete durability. To achieve robust additive manufacturing practices, there is a need for advanced material models, future advancements in polymer blends, powder recycling, process refinement, and simulation techniques to bridge the gap between SLS fabrication and functional performance.

3.3.3. Stereolithography and Digital Light Processing

SLA (stereolithography) and DLP (digital light processing) use UV and laser to cure liquid photopolymer resin layer by layer into a solid 3D-printed assistive device. DLP has been used to fabricate complex, customized structures for tissue engineering, prosthetics, and implants [117]. Eco-friendly materials reduce environmental impact by developing bio-based, recyclable, and biodegradable photopolymer resins, as well as innovations such as vitrimers and water-soluble supports, to minimize waste [118]. This technique has great potential for producing advanced assistive technology.

3.3.4. Material Jetting (MJ)

It is a high-precision additive manufacturing technology that deposits and cures droplets of photopolymers to create a 3D-printed assistive device [119]. It includes material diversity, including photopolymers, waxes, and emerging composites, with advantages such as exceptional resolution, multimaterial capabilities, and easy support removal [120]. Limitations, such as material brittleness, post-processing requirements, and high costs, are key points to consider for future applications of ADs printed with quality and strength [121]. Customized pediatric and prosthetic limb socket liners, anatomical fitting models, and other assistive devices have been produced by using material jetting techniques in research laboratories [119]. Improved printhead precision and novel material formulations are state-of-the-art advancements needed to make this technology sustainable in biomedical applications.

3.3.5. Laser Powder Bed Fusion (LPBF)

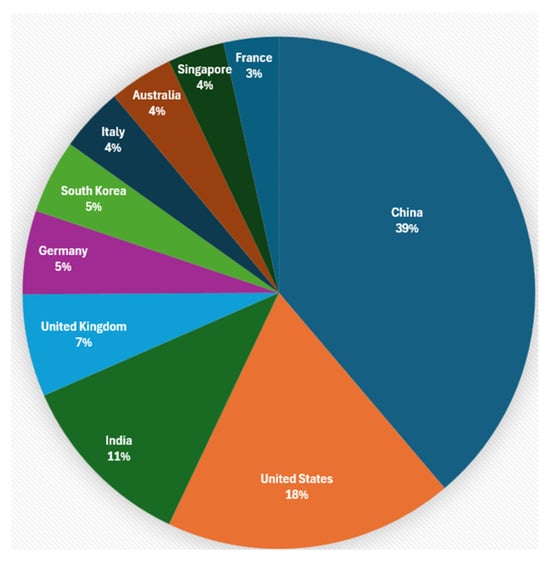

LPBF builds parts, layer by layer, from metal powder to produce complex ADs. This technique offers excellent design flexibility with minimal waste and the ability to produce strong prosthetic sockets and hand frameworks, wheelchair components, and cranial implants [122]. LPBF is ideal for customized, low-volume, and highly complex prosthetics and mobility aids, with hybrid approaches emerging to combine their strengths. Factors such as material, design complexity, production volume, and post-processing requirements need to be discussed and addressed [123]. There is research [123] that discusses LPBF and electron beam melting (EBM) [124]; these techniques are being used to create bone replacements. LPBF provides precise and smoother surfaces, while EBM results in parts with reduced internal stress and the ability to handle more challenging metals, such as titanium. In Table 5 below is reported a global impact of 3D printing in academic hospitals.

Table 5.

Global impact of 3D printing in academic hospitals.

3D printing technologies extend beyond structural customization to serve as a platform for integrating actuators and sensors within a single device. For example, prosthetic sockets produced through 3D printing can be directly integrated with flexible pressure sensors, while actuator housings and transmission components can be printed simultaneously using lightweight and durable polymers. This approach reduces assembly complexity and cost accommodates users’ aesthetic preferences, since many wear these devices on a daily basis, hence improving overall reliability. Furthermore, 3D printing supports iterative prototyping of sensor actuator combinations, enabling rapid personalization for users. The future of ADs lies in merging these printed structures with smart materials that inherently provide sensing and actuation, creating multifunctional devices that are lightweight, affordable, and patient-specific. Thus, 3D printing acts as the convergence hub for bringing actuators, sensors, and smart materials together into integrated, intelligent AD systems. Thus, 3D printing serves as a convergence hub for integrating actuators, sensors, and smart materials into cohesive and intelligent assistive device systems. Beyond the technical advantages, the adoption of this approach also calls for supportive policy frameworks that enable in-hospital production, streamline regulatory approval, and ensure patient safety. At the same time, advances in smart materials such as self-healing polymers and biocompatible composites can further enhance device performance, durability, and user comfort, highlighting the need for coordinated efforts between engineering innovation and healthcare policy.

3.3.6. Challenges

One of the primary challenges in developing and implementing new devices is navigating complex regulatory frameworks, which can delay approval and market entry. Additionally, ensuring high manufacturing quality and minimizing defects remain critical hurdles, particularly when scaling up production from laboratory prototypes to commercial products. Moreover, the long-term success of these innovations depends on establishing sustainable and economically viable business models [132] that support widespread adoption while addressing environmental and societal impacts.

Agencies like the FDA and the European Medicines Agency (EMA) are the primary regulatory bodies overseeing medical products, innovations, new devices, and testing protocols, including 3D-printed medical devices and pharmaceuticals [133]. Advancing medical innovations while balancing patient safety is a critical factor; however, delays in approval methods and standards can impact the global adoption of 3D-printed medical solutions. A study [134] discusses the FDA’s guidance, which classifies 3D-printed medical devices by risk and requires process validation and good manufacturing practices even in research hospital laboratories [135]. According to the available literature and regulatory bodies, a lack of clear pathways and old strategies are the key challenges for new device approvals.

The requirements, such as time-intensive biocompatibility testing and dependency on historically safe materials, necessitate the use of limited, available FDA-approved polymers with less flexible material properties, including durability, sterilization compatibility, high development costs, degradation, and biocompatibility issues. Additionally, there are limited approved data available for specialized fields, such as heart valves and bone grafts. These barriers hinder innovation and favor well-established polymers, despite their potential limitations.

Layer by layer manufacturing processes, such as FDM and SLA, create steplike rough structures that can disturb the surrounding tissues. These rough surfaces affect mechanical performance by creating stress concentrations. Processes such as chemical vapor smoothing, mechanical polishing, and plasma treatment serve as post-processing techniques to ensure smooth surfaces for devices like prosthetics [136,137].

If the removal of support material is not performed carefully, it can introduce sharp protrusions that damage tissue and internal arteries [138]. Manual trimming, ultrasonic cleaning, and solvent baths are finishing techniques. There is a common challenge in printing techniques that are using resin printed devices contain toxic uncured monomers and metal particles from the nozzles, which can lead to inflammation and cytotoxicity. Heat treatments and washing in isopropanol are required to eliminate harmful residues [139].

Weak interlayer bonding results in weak anisotropic strength, consequently unsuitable for loading applications, such as orthopedic implants [140]. Annealing, epoxy infiltration, and hydrothermal aging are techniques required to post-process these defects after printing. Degradation of polymers under standard sterilization methods is also a significant issue for 3D-printed devices used in the human body. Autoclaving and gamma irradiation result in warping of thermoplastics and embrittling of materials. To address these issues, methods include using sterilization resistant polymers (e.g., PEEK), applying ethylene oxide gas for heat-sensitive devices, and adding surface coatings to seal and protect the material.

Devices like cranial plates and dental aligners sometimes have poor fit and functional failure, which are mostly due to shrinkage, warping, and swelling during printing [141]. Hydrostatic pressurization for reshaping warped parts, precision machining, and design software compensation improve the dimensional and size fit errors for customized devices. Most biomedical devices require bioactive properties for tissue integration; however, materials like PLA and ABS are inert and lack these properties [142,143]. To introduce bioactivity, coating a 3D-printed device with materials like hydroxyapatite, which promotes bone growth, immersing devices in collagen solutions, and plasma treatment have been used as finishing techniques. There are two types of porosity expected in 3D-printed ADs: porosity resulting from printing defects and intentional porosity, such as in scaffolds. For refining pore size and shape, chemical etching is performed, along with surface modifications such as RGD peptide coatings and infiltration with biocompatible sealants, which will provide mechanical strength and biological performance [144].

Aesthetic defects, such as visible layer lines, uneven color distribution, and textures, may be unacceptable for some patients, particularly in the case of prosthetics and wearable devices. Biocompatible painting, dyeing, and coating enhance aesthetics while maintaining functionality. Most of the time, patients need prosthetic limbs with smooth, skin-like finishes for psychological impact. Hence, post-processing techniques and finishing methods are indispensable for devices like ADs, as these devices are used daily by patients. Additionally, these techniques convert raw 3D ADs into safe, functional, and regulatory compliant medical devices, so post-processing remains a cornerstone of biomedical device fabrication and application.

Smart service models are revolutionizing healthcare by effectively integrating medical resources. Decentralization of any 3D-printed medical facility promotes flexibility, resulting in lower costs, easier access, and increased sustainability and competition from decentralized small manufacturing units. On-demand production, combined with a small investment, motivates healthcare departments to shift production technology from centralized factories to research teaching hospitals and laboratories, producing user-friendly, customized, and perfectly sized ADs. To streamline workflows, we need collaborative ecosystems that include hospitals, engineers, material experts, and policy regulators, as well as effective digital platforms for sharing data and knowledge. Additionally, reduced costs and improved accessibility can be achieved through subscription models for digital innovation and updates, as well as outsourcing small mobile 3D printing units and on-demand manufacturing. Advanced materials like biocompatible polymers and bioinks improve functionality and economic efficiencies, also converting complex, expensive processes into sustainable processes economically, like the real-life example of Align Technology [145], which uses 3D printing to make custom-fit clear braces for teeth, and Stryker [146], which uses 3D printing to design as well as to test medical device.

Intellectual property disputes over open-source designs, standardization gaps in achieving effective decentralized production, and regulatory hurdles remain significant challenges. Sustainability, achieved by using recyclable materials, ensuring secure data sharing, and scaling bioprinting, is a future recommendation for a digital sustainable healthcare business. Complex innovations have been achieved by utilizing hybrid systems that combine robotics and nanotechnology, as exemplified by the case of drug-eluting stents. Collaborative policy frameworks, an ethical approach, training, and the satisfaction of healthcare professionals are necessary to realize the full potential behind [147].

3.4. Four-Dimensional Printing Technology in ADs

A significant amount of research and studies has been conducted to make 3D printing more sustainable and accessible, which is opening doors for strategies like interdisciplinary research, detailed approaches to studying new material properties like smart and adaptive properties, and process design, ultimately leading to the evolution of 4D printing. Four-dimensional printing is an additive manufacturing process where products like ADs dynamically transform over time, concerning the fourth dimension, in response to stimuli, types of stimuli depending on the type of materials and applications, such as temperature, position, moisture, and light. Hence, 4D printing revolves around stimuli-responsive materials, also known as smart materials (SMs), such as thermal activation, pH changes, humidity, and light driven actuation, as well as composite systems that enable multi-responsive behavior for unique applications.

Four-dimensional printing produces self-adjusting and self-assembling structures and smart structures, making 4D-printed ADs the most advanced next-generation medical devices. However, there are numerous challenges, as with every new technology, such as scalability, biocompatibility, precise spatiotemporal control, and material durability. Multi-responsive materials, computational modeling, integration for intelligent systems, and interdisciplinary innovation are key factors to consider for future advancements in 4D printing [148]. Applications such as adaptive tissue engineered scaffolds, drug delivery systems triggered by physiological conditions, self-adjusting implants, and invasive surgical tools are key examples of the transformative potential of 4D printing for ADs [149]. The combination of electroactive polymers and ionic polymers, along with advanced 3D printing methods, produces structures with smart properties that can change their shape and then adapt their functions in response to electrical signals. These materials can allow programmable, voltage-driven movement, such as bending, twisting, and expanding, which can be tailored for various applications, including the manipulation of delicate objects in soft robotic grippers, stents that adjust to human body conditions, and airplane wings that morph mid-flight [150]. Biomimetic materials, such as those that mimic collagen and bone, are being used in training hospitals and research institutions [151]. These materials include hydrogels, which are water responsive, shape memory polymers, which are temperature responsive; and stimuli responsive ceramics. Stents produced with SMs can expand and contract in response to vascular conditions and release drugs to prevent restenosis, whereas as traditional stents are static scaffolds. Implants that release therapeutics in response to biomarkers work as glucose-sensitive insulin drug delivery systems, and adaptive pacemakers and neural interfaces that adjust to physiological signals work as neurological and cardiac devices are some recent examples of 4D printing applications across medical sectors.

3.5. Smart Materials (SMs)