Path Tracking Control for Underground Articulated Vehicles with Multi-Timescale Predictive Modeling

Abstract

1. Introduction

- (1)

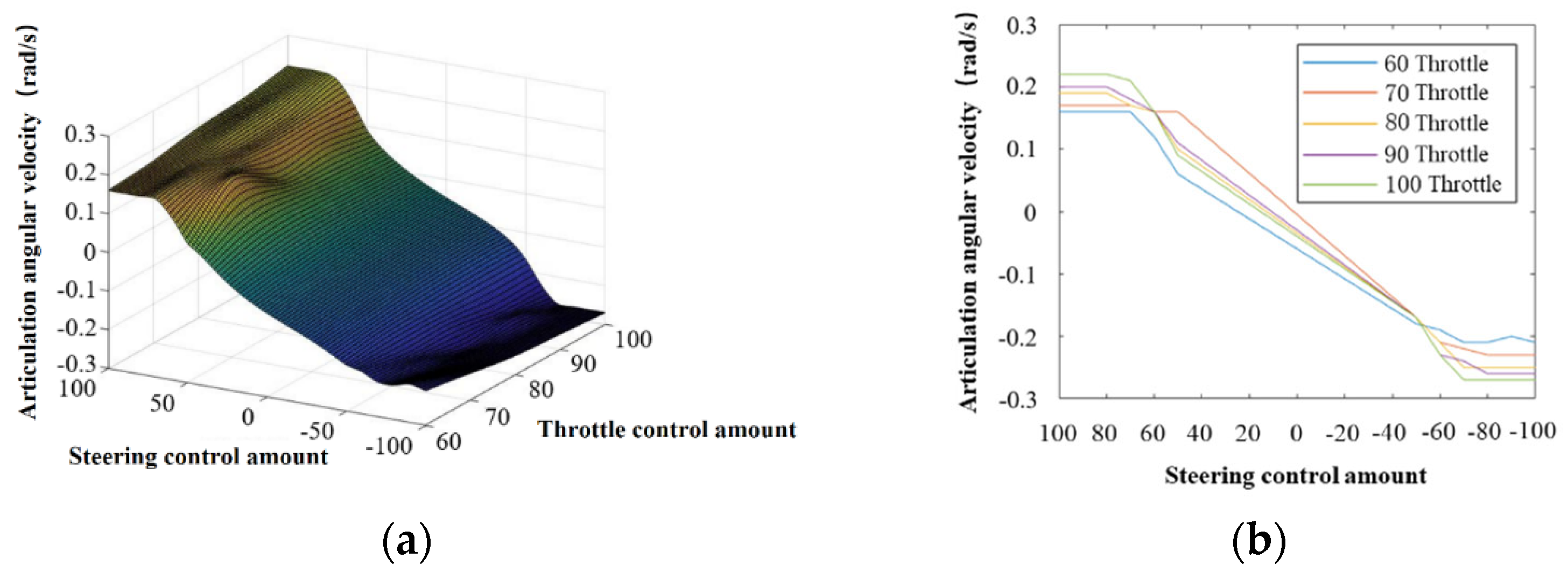

- This study develops a comprehensive dynamic model for articulated vehicles by integrating two key components. First, a nonlinear hydraulic steering control system is established, explicitly incorporating steering resistance to more accurately capture the real system behavior. Second, a throttle–steering coupling module is constructed based on extensive real-vehicle experimental data, effectively characterizing the interaction between throttle input and steering response. The integrated model provides a more accurate representation of the complex motion characteristics of articulated vehicles, and its engineering applicability has been validated through field tests in actual mining operations.

- (2)

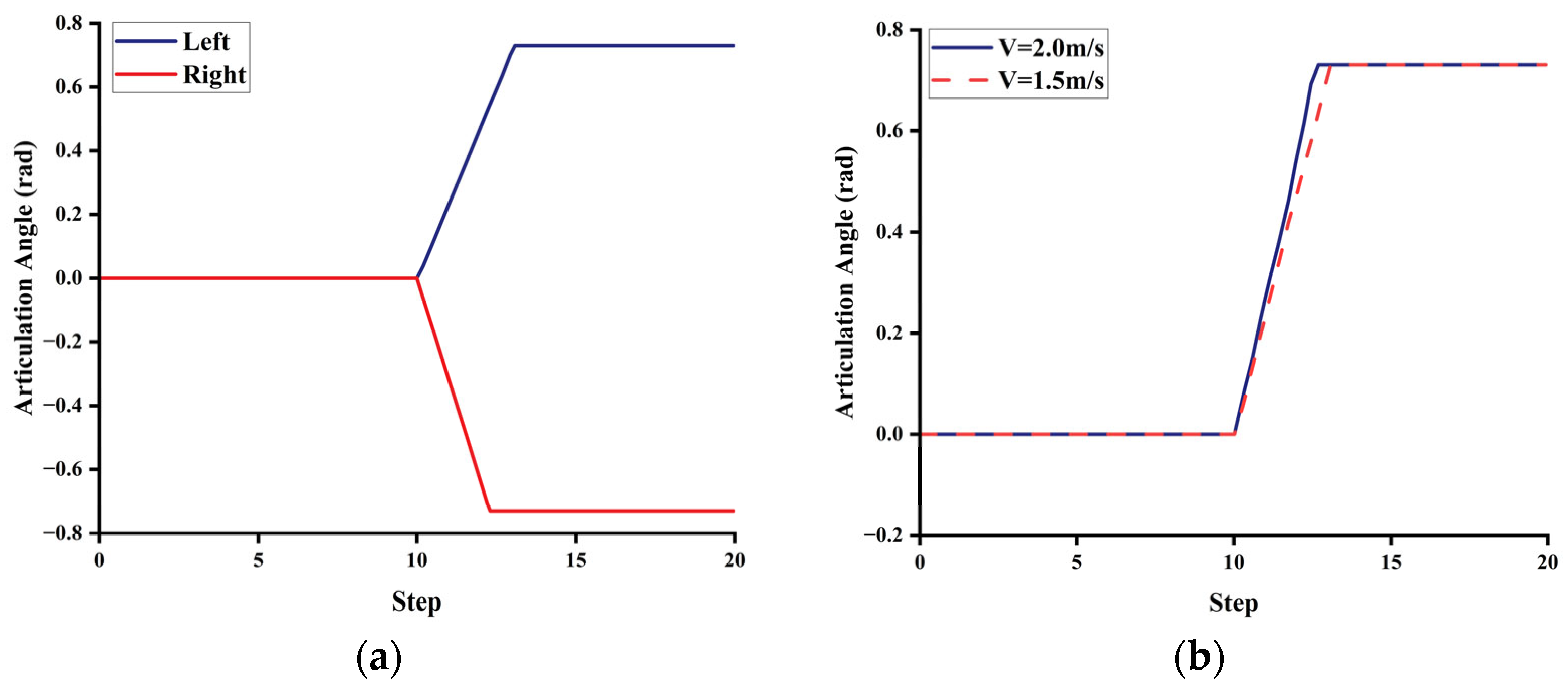

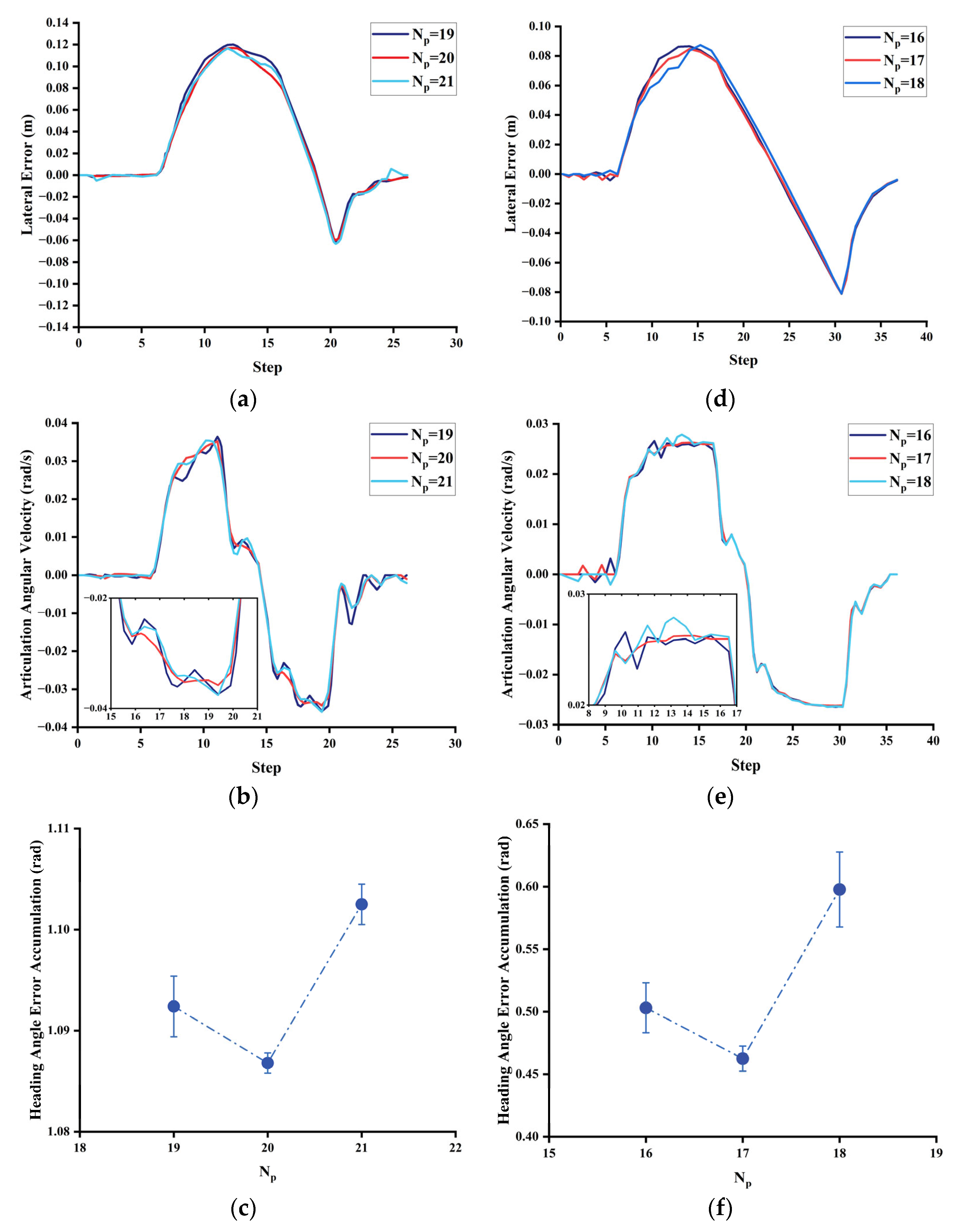

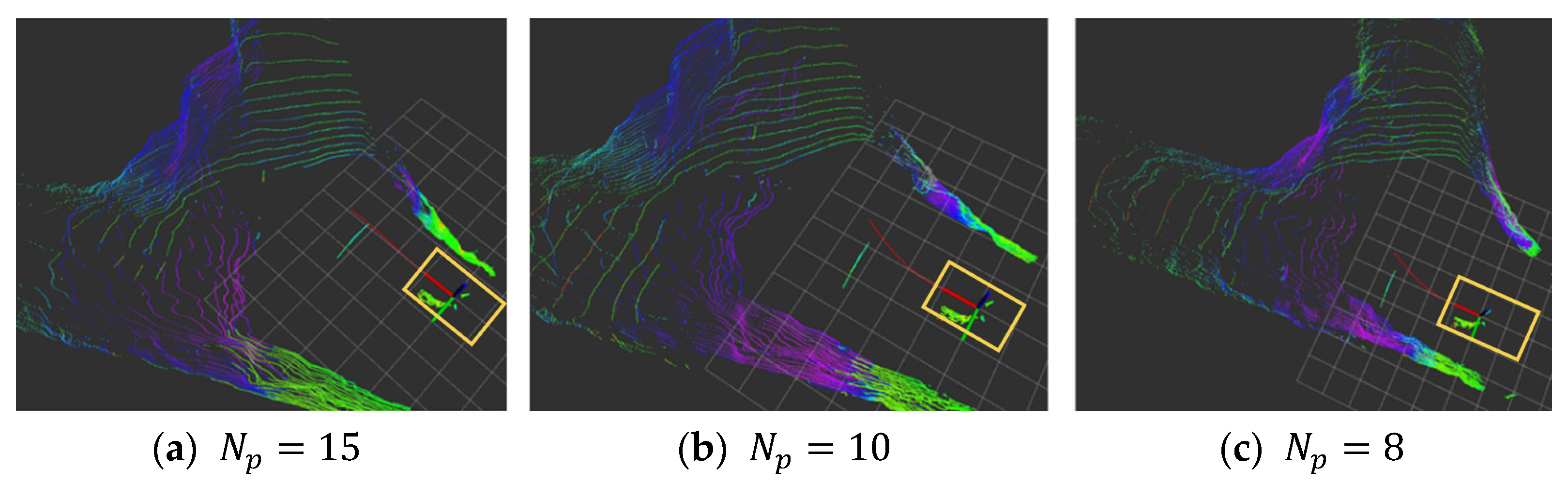

- We propose a MTS-NMPC algorithm, which represents an innovative application for articulated vehicles. This algorithm dynamically incorporates the influence of path curvature and maximum vehicle speed on the steering process, enabling adaptive adjustment of the prediction horizon to enhance path-tracking accuracy. In contrast, conventional MPC/NMPC approaches rely on a fixed prediction horizon. Systematic experiments were conducted to quantify the mapping relationship among vehicle speed, path curvature, and the optimal prediction horizon.

- (3)

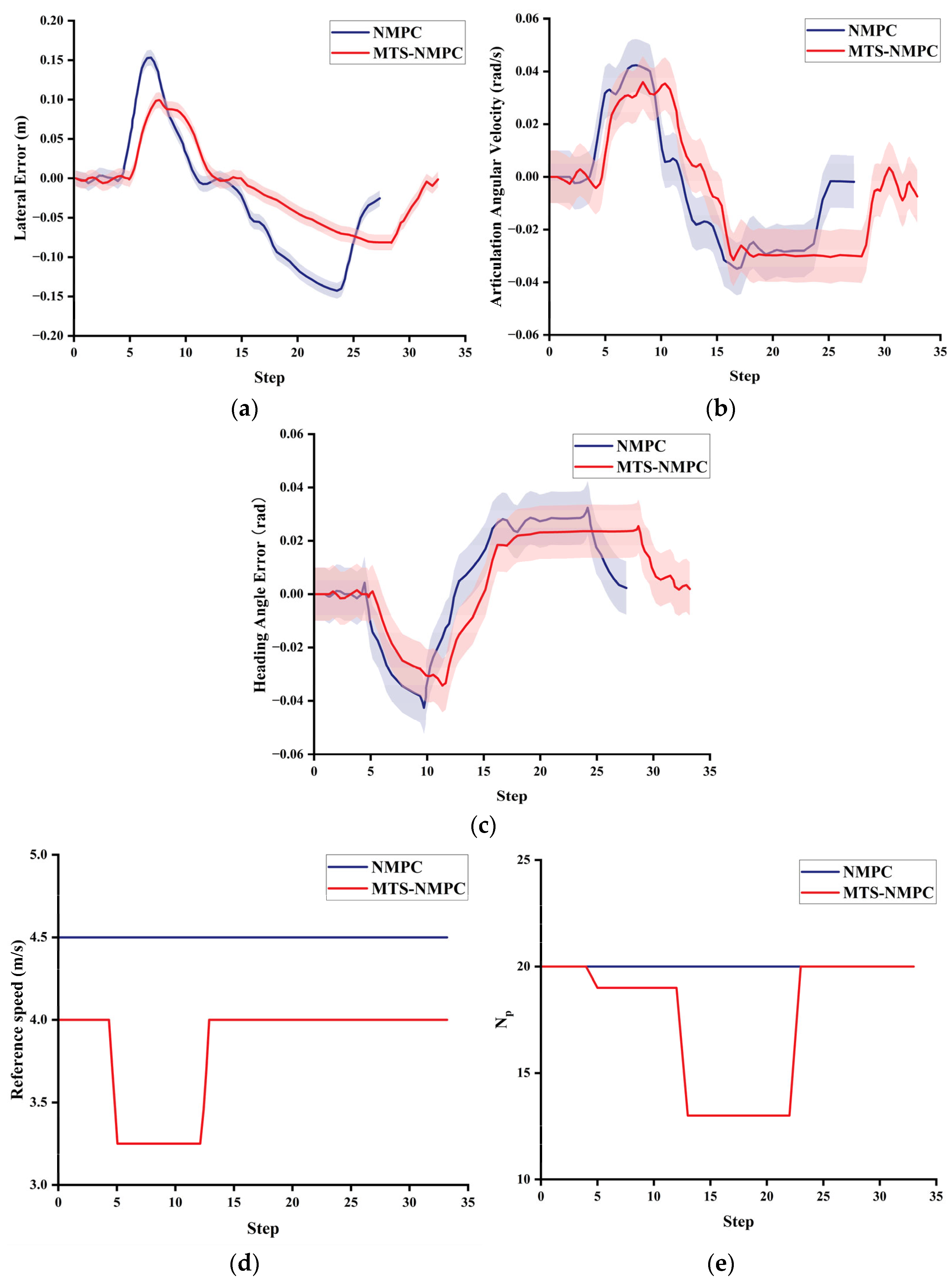

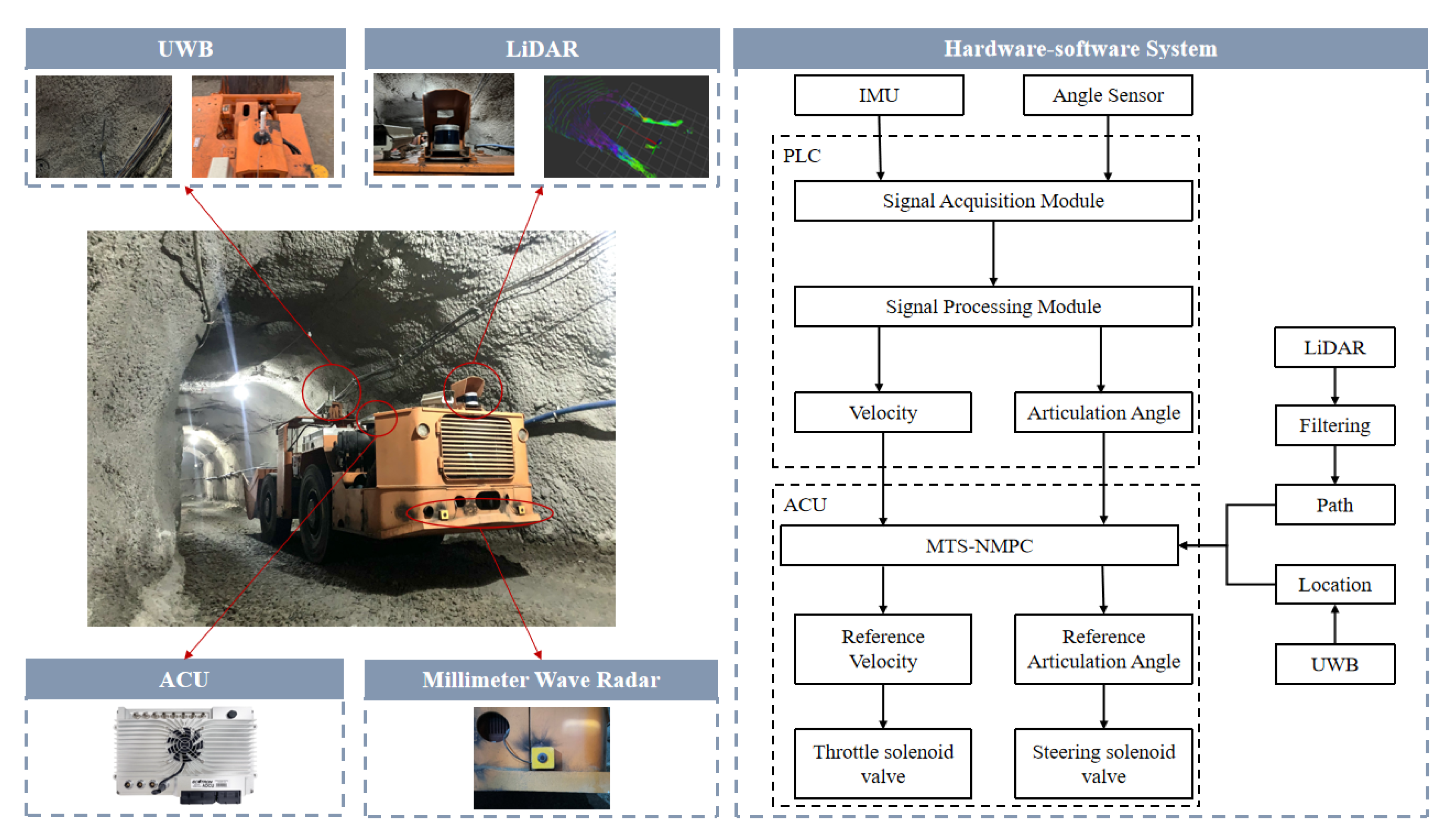

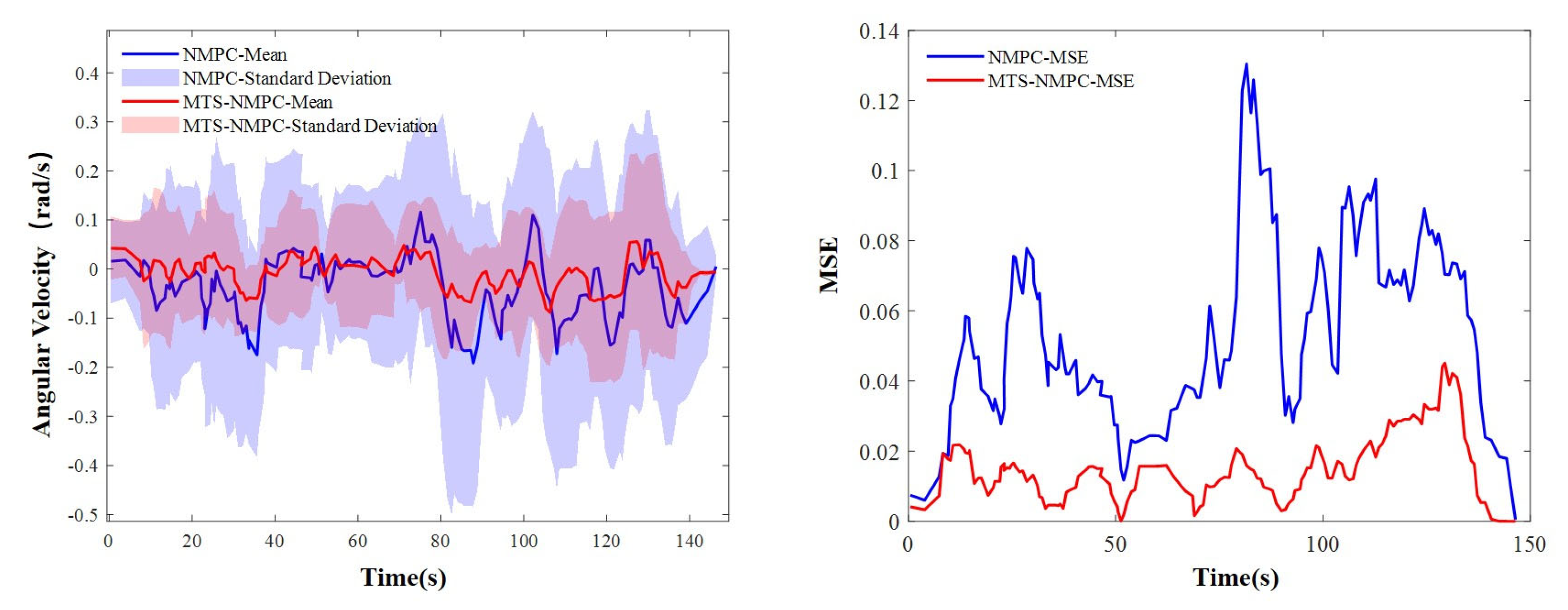

- Real-world path-tracking experiments were carried out in the challenging environment of an underground mine at a depth of 645 m to validate the effectiveness of the proposed MTS-NMPC algorithm. The test results demonstrate that the algorithm exhibits excellent robustness and tracking accuracy under realistic operating conditions, achieving significant reductions of 35% and 17% in the maximum lateral tracking error and heading deviation, respectively, while effectively suppressing rotational speed fluctuations at the articulated joint. These findings confirm its practical engineering value for controlling articulated vehicles in complex mining scenarios.

2. Modeling and Control Framework for Articulated Vehicle Path Tracking

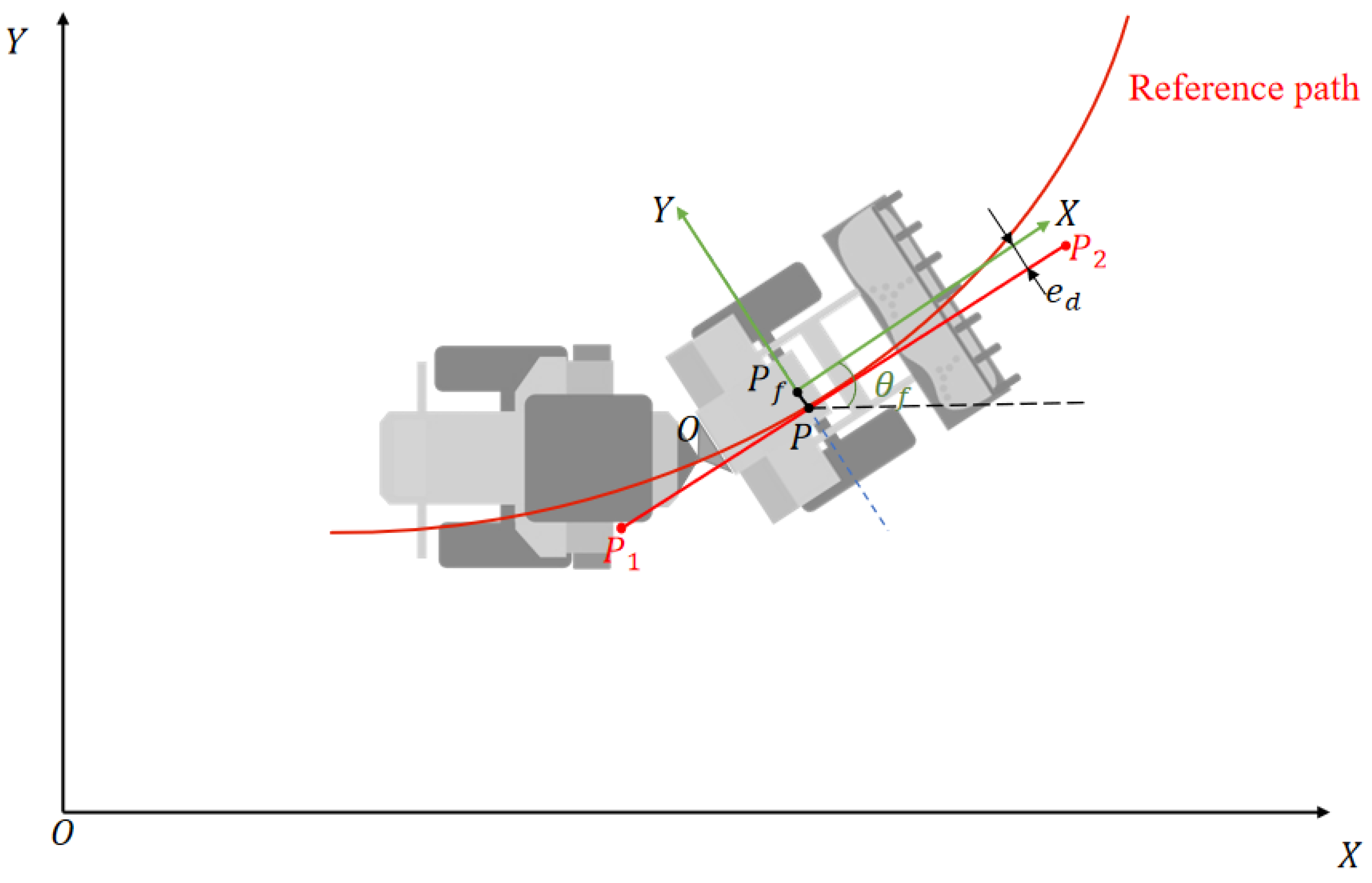

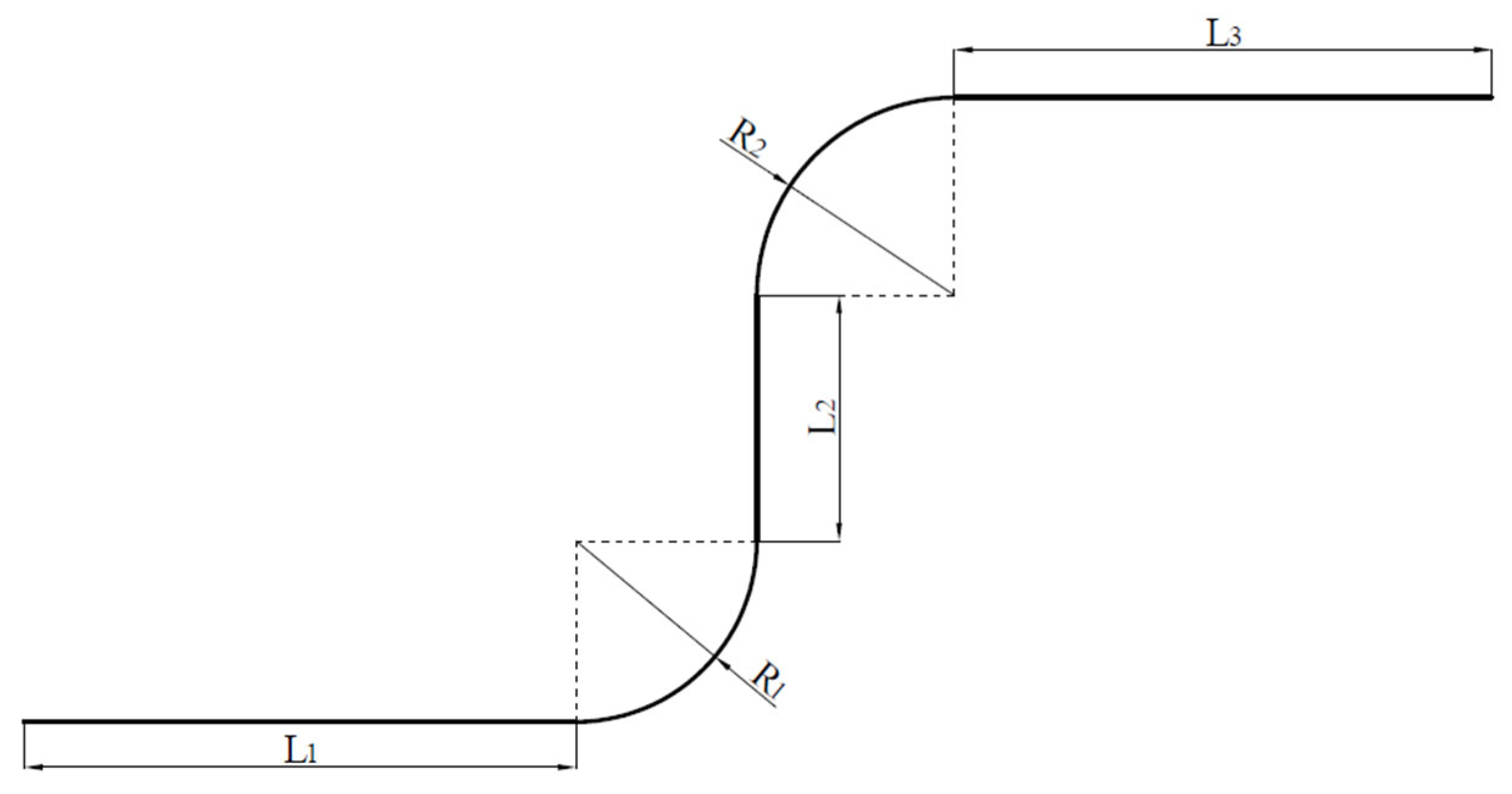

2.1. Articulated Vehicle Path Tracking Model

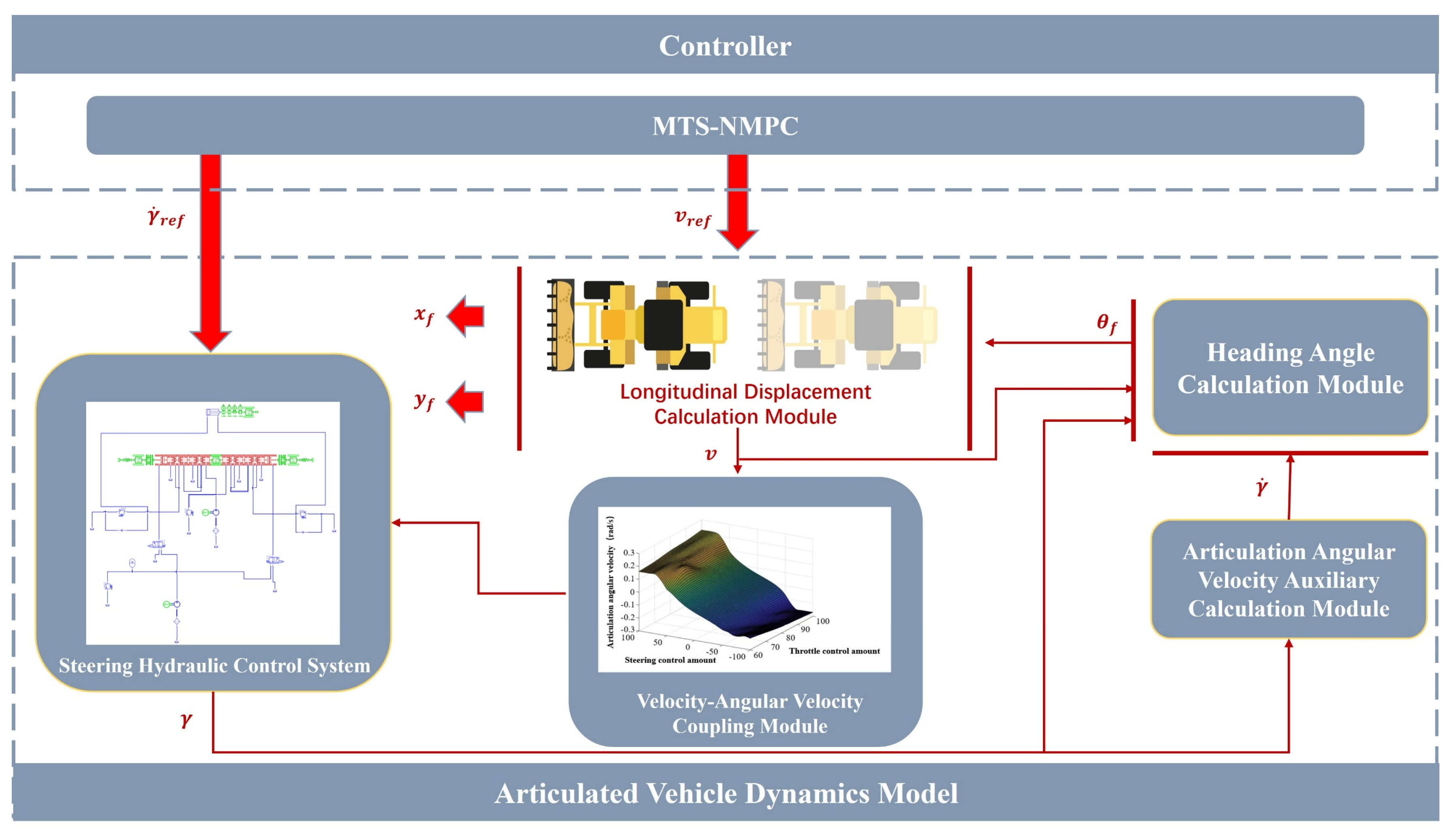

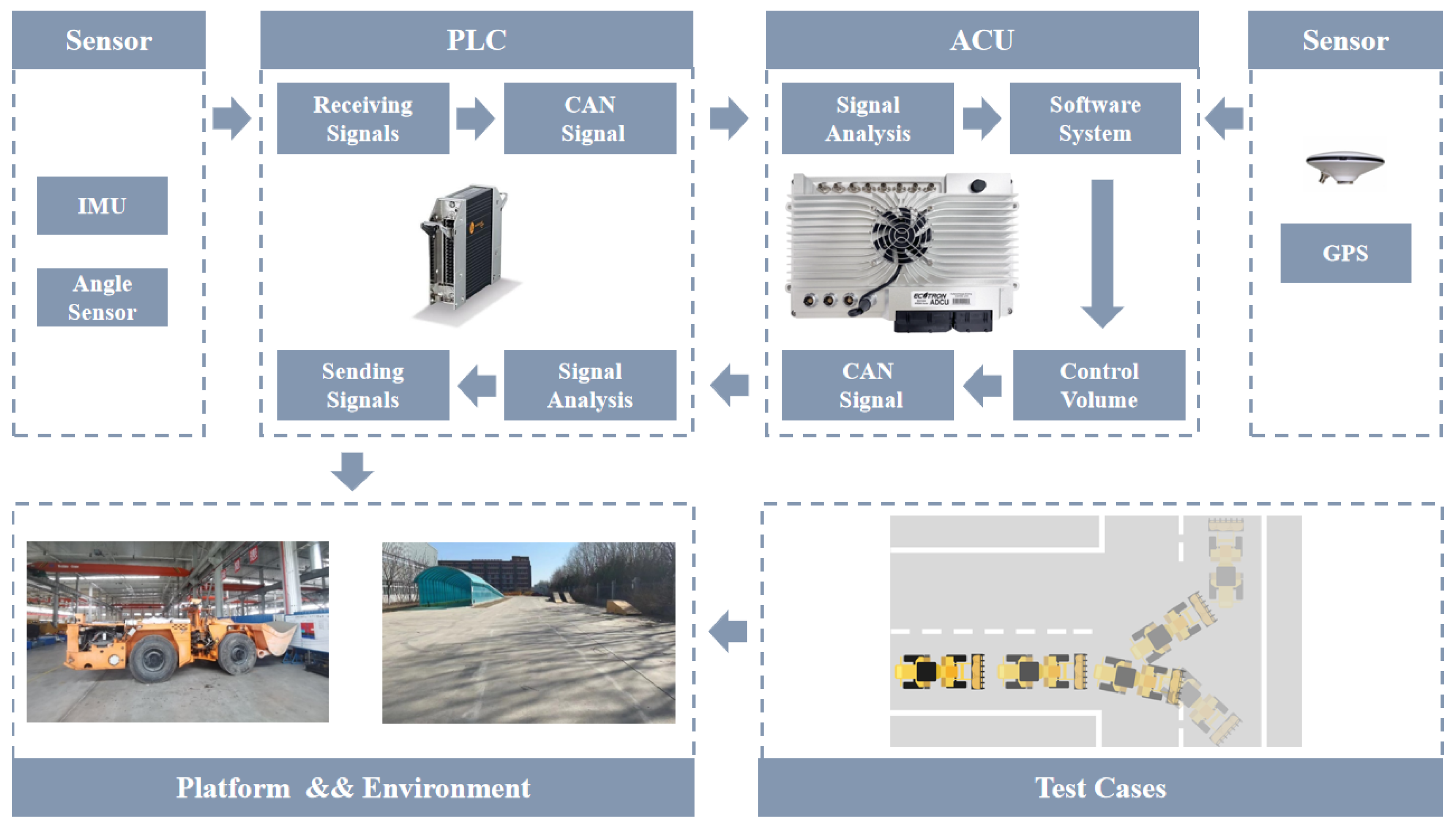

2.2. Overall Framework of the MTS-NMPC Path Tracking System

3. Modeling of Articulated Vehicle Dynamics

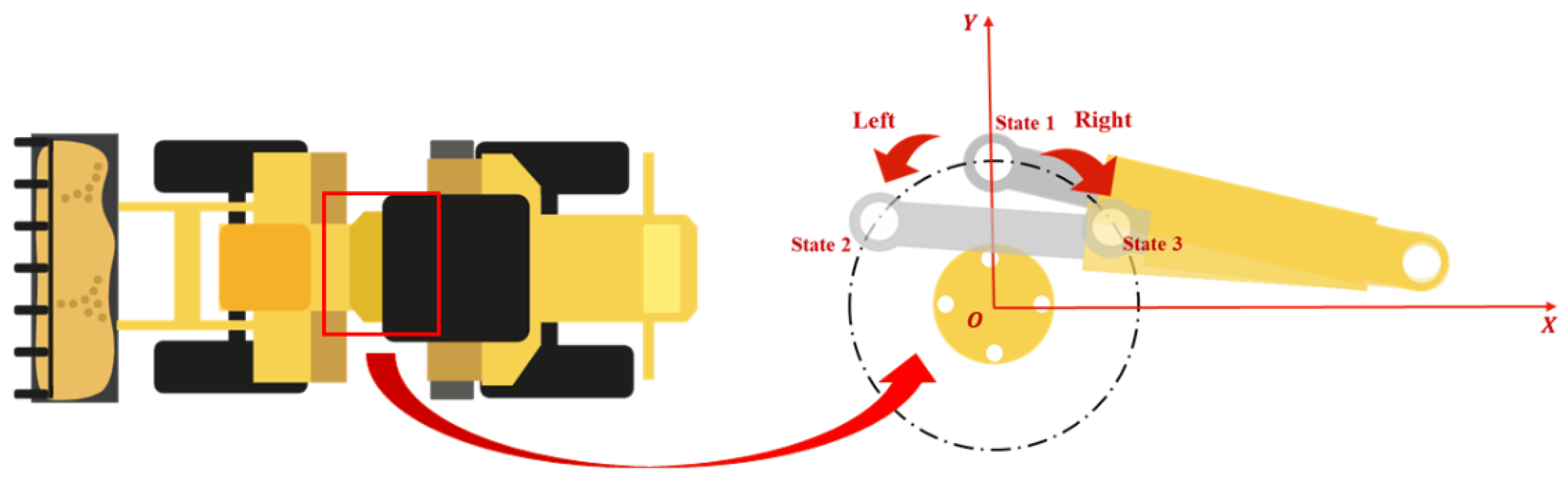

3.1. Steering Resistance Analysis

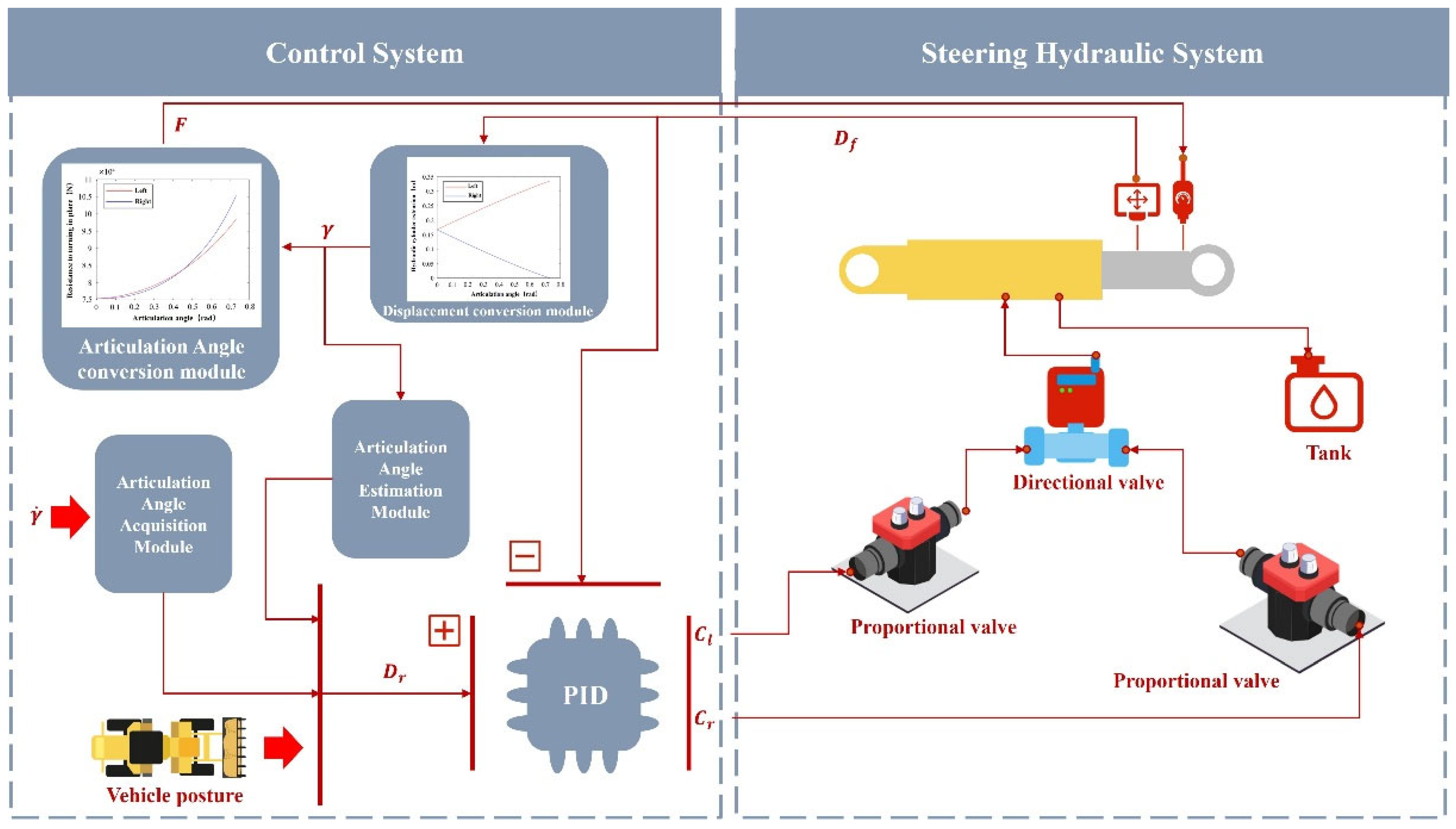

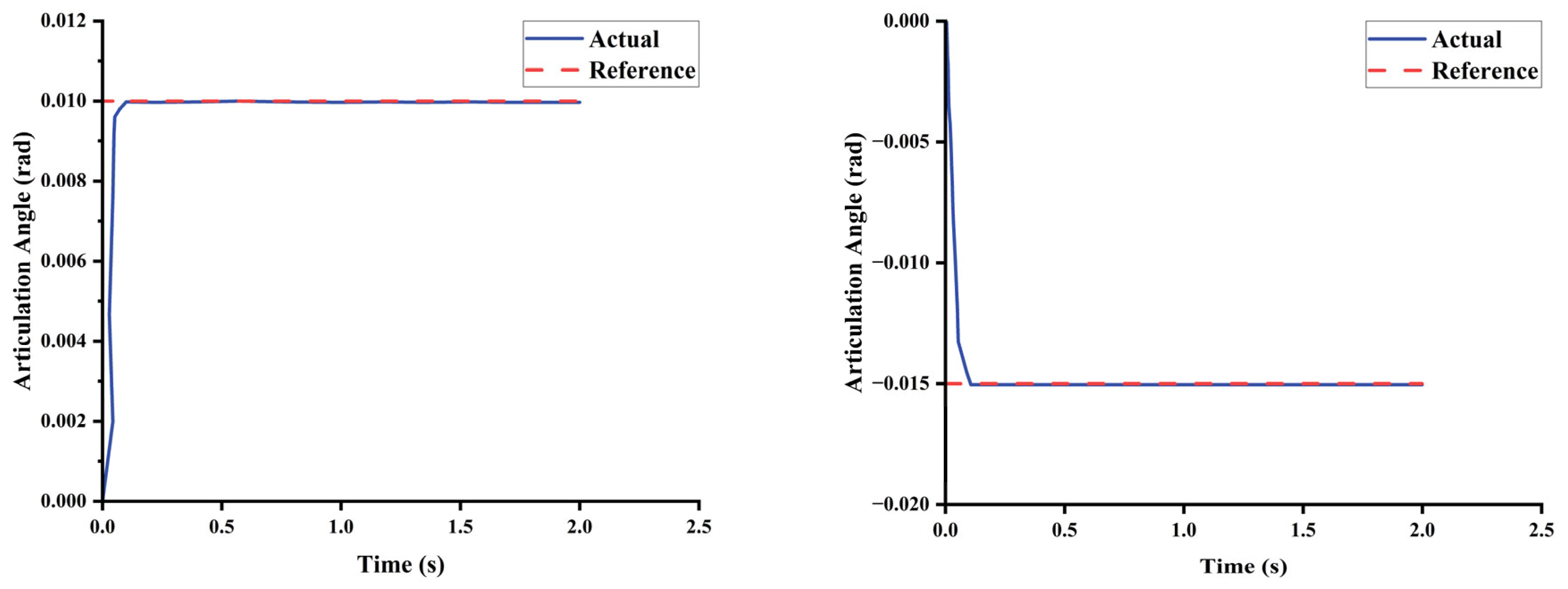

3.2. Modeling of the Steering Hydraulic Control System

3.3. Dynamic Response Characteristics of Articulated Vehicles

4. Multi-Timescale Nonlinear Model Predictive Path Tracking Control

4.1. MTS-NMPC-Based Controller

4.2. Validation and Performance Evaluation of the MTS-NMPC Algorithm for Articulated Vehicle Path Tracking

| Algorithm 1: Curvature-Adaptive prediction horizon and reference speed adjustment in MTS-NMPC. | |

| Step | Description |

| Input | Vehicle state , reference path , maximum horizon , maximum allowable speed , sampling time |

| Output | Prediction horizon , reference speed , optimal control |

| Initialization | Set previous horizon . This is used for warm-starting the MTS-NMPC optimization at the first step. |

| 1. Curvature assessment | Compute maximum curvature within look-ahead window along . Compute the corresponding radius . |

| 2. Prediction horizon and reference speed computation | Calculate prediction horizon and reference speed using quadratic formulas:

Ensure and . |

| 3. Warm-start strategy | If , truncate the previous optimal sequence.

If , extend the sequence with reference-based guess. Else, shift the previous sequence. |

| 4. Optimization | Solve MTS-NMPC with horizon and reference speed using warm-start initialization. Apply soft constraints to ensure feasibility. |

| 5. Control execution | Apply the first control element . Update . |

5. Real-World Validation of MTS-NMPC in an Underground Mining Environment

6. Discussion

7. Conclusions

7.1. Validation of Steering Model Accuracy and Control Performance Enhancement

7.2. Adaptive Advantages and Performance Improvements of the Multi-Timescale Method

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| MTS-NMPC | Multi-Time-Scale-Nonlinear Model Predictive Control |

| NMPC | Nonlinear Model Predictive Control |

| AV | Articulated Vehicle |

| ATV | All-Terrain Vehicle |

| AMPC | Adaptive Model Predictive Controller |

| FAR | Front Axle Reference |

| AR | Adaptive Reference |

| SRP-LMPC | Single Reference Point-Linear Model Predictive Control |

| MRP-LMPC | Multiple Reference Points-Linear Model Predictive Control |

| VTF | Virtual Terrain Field of Dynamic Simulation |

| ASV | Articulated Steering Vehicle |

References

- Qu, J.; Zhang, Z.; Qin, Z.; Guo, K.; Li, D. Applications of Autonomous Navigation Technologies for Unmanned Agricultural Tractors: A Review. Machines 2024, 12, 218. [Google Scholar] [CrossRef]

- Yao, Q.; Tian, Y.; Wang, Q.; Wang, S. Control Strategies on Path Tracking for Autonomous Vehicle: State of the Art and Future Challenges. IEEE Access 2020, 8, 161211–161222. [Google Scholar] [CrossRef]

- Chu, S.; Xie, Z.; Wong, P.K.; Li, P.; Li, W.; Zhao, J. Observer-based gain scheduling path following control for autonomous electric vehicles subject to time delay.Vehic. Syst. Dyn. 2021, 60, 1602–1626. [Google Scholar] [CrossRef]

- Zhang, C.; Gao, G.; Zhao, C.; Li, L.; Li, C.; Chen, X. Research on 4WS Agricultural Machine Path Tracking Algorithm Based on Fuzzy Control Pure Tracking Model. Machines 2022, 10, 597. [Google Scholar] [CrossRef]

- Deshmukh, D.; Kumutham, A.R.; Pratihar, D.K.; Deb, A.K. Accurate Path Tracing of a Tracked Robot: A Modified PID Approach with Slip Compensation. Eng. Res. Express 2025, 7, 015203. [Google Scholar] [CrossRef]

- Cui, D.; Wang, G.; Zhao, H.; Wang, S. Research on a Path-Tracking Control System for Articulated Tracked Vehicles. J. Mech. Eng. Stroj. Vestn. 2020, 66, 311–324. [Google Scholar] [CrossRef]

- Dou, F.; Huang, Y.; Liu, L.; Wang, H.; Meng, Y.; Zhao, L. Path planning and tracking for autonomous mining articulated vehicles. Int. J. Heavy Veh. Syst. 2019, 26, 315–333. [Google Scholar] [CrossRef]

- Huang, Y.; Tian, Z.; Jiang, Q.; Xu, J. Path Tracking Based on Improved Pure Pursuit Model and PID. In Proceedings of the 2020 IEEE 2nd International Conference on Civil Aviation Safety and Information Technology, Weihai, China, 14–16 October 2020. [Google Scholar]

- Hu, C.; Ru, Y.; Li, X.; Fang, S.; Zhou, H.; Yan, X.; Liu, M.; Xie, R. Path tracking control for brake-steering tracked vehicles based on an improved pure pursuit algorithm. Biosyst. Eng. 2024, 242, 1–15. [Google Scholar] [CrossRef]

- Hu, K.; Cheng, K. Trajectory Planning for an Articulated Tracked Vehicle and Tracking the Trajectory via an Adaptive Model Predictive Control. Electronics 2023, 12, 1988. [Google Scholar] [CrossRef]

- Sun, N.; Zhang, W.; Yang, J. Integrated Path Tracking Controller of Underground Articulated Vehicle Based on Nonlinear Model Predictive Control. Appl. Sci. 2023, 13, 5340. [Google Scholar] [CrossRef]

- Meng, Y.; Gan, X.; Bai, G. Path following control of underground mining articulated vehicle based on the preview control method. Chin. J. Eng. 2019, 41, 662–671. [Google Scholar]

- Zhou, B.; Su, X.; Yu, H.; Guo, W.; Zhang, Q. Research on Path Tracking of Articulated Steering Tractor Based on Modified Model Predictive Control. Agriculture 2023, 13, 871. [Google Scholar] [CrossRef]

- Awad, N.; Lasheen, A.; Elnaggar, M.; Kamel, A. Model predictive control with fuzzy logic switching for path tracking of autonomous vehicles. ISA Trans. 2022, 129, 193–205. [Google Scholar] [CrossRef] [PubMed]

- Rokonuzzaman, M.; Mohajer, N.; Nahavandi, S. Effective adoption of vehicle models for autonomous vehicle path tracking: A switched MPC approach. Vehic. Syst. Dyn. 2022, 61, 1236–1259. [Google Scholar] [CrossRef]

- Stano, P.; Montanaro, U.; Tavernini, D.; Tufo, M.; Fiengo, G.; Novella, L.; Sorniotti, A. Model predictive path tracking control for automated road vehicles: A review. Annu. Rev. Control 2023, 55, 194–236. [Google Scholar] [CrossRef]

- Wang, M.; Niu, C.; Wang, Z.; Jiang, Y.; Jian, J.; Tang, X. Model and Parameter Adaptive MPC Path Tracking Control Study of Rear-Wheel-Steering Agricultural Machinery. Agriculture 2024, 14, 823. [Google Scholar] [CrossRef]

- Tang, X.; Yan, Y.; Wang, B.; Zhang, L. Adaptive Articulation Angle Preview-Based Path-Following Algorithm for Tractor-Semitrailer Using Optimal Control. Sensors 2022, 22, 5163. [Google Scholar] [CrossRef]

- Yu, H.; Zhao, C.; Li, S.; Wang, Z.; Zhang, Y. Pre-Work for the Birth of Driver-Less Scraper (LHD) in the Underground Mine: The Path Tracking Control Based on an LQR Controller and Algorithms Comparison. Sensors 2021, 21, 7839. [Google Scholar] [CrossRef]

- Liu, J.; Zhao, X.; Guo, H.; Chen, H. Tractor Semi-trailer Modeling and Regional Path Tracking Control Strategy. In Proceedings of the 2020 Chinese Automation Congress (CAC), Shanghai, China, 6–8 November 2020; pp. 1961–1966. [Google Scholar]

- Zhang, Z.; Xie, L.; Lu, S.; Wu, X.; Su, H. Vehicle yaw stability control with a two-layered learning MPC. Vehic. Syst. Dyn. 2022, 61, 423–444. [Google Scholar] [CrossRef]

- Lee, T.; Jeong, Y. A Tube-Based Model Predictive Control for Path Tracking of Autonomous Articulated Vehicle. Actuators 2024, 13, 164. [Google Scholar] [CrossRef]

- Rahman, S.; Gordon, T.; Gao, Y.; Henderson, L.; Liu, Q.; Laine, L. Automated steering control for improved path tracking and stability of articulated heavy goods vehicles. Vehic. Syst. Dyn. 2024, 62, 1–21. [Google Scholar] [CrossRef]

- Chen, X.; Cheng, J.; Hu, H.; Shao, G.; Gao, Y.; Zhu, Q. A Novel Fuzzy Logic Switched MPC for Efficient Path Tracking of Articulated Steering Vehicles. Robotics 2024, 13, 134. [Google Scholar] [CrossRef]

- Bai, G.; Liu, S.; Zhou, B.; Huang, J.; Zheng, Y.; Elham, E. Path Tracking for Electric Mining Articulated Vehicles Based on Nonlinear Compensated Multiple Reference Points Linear MPC. World Electr. Veh. J. 2024, 15, 427. [Google Scholar] [CrossRef]

- He, Y.; Wu, J.; Xu, F.; Liu, X.; Wang, S.; Cui, G. Path Tracking Control Based on T-S Fuzzy Model for Autonomous Vehicles with Yaw Angle and Heading Angle. Machines 2024, 12, 375. [Google Scholar] [CrossRef]

- de Lima, M.L.; Camponogara, E.; Odloak, D.; Jordanou, J.P. Satisficing Infinite-Horizon Model Predictive Control. J. Process Control 2025, 150, 103423. [Google Scholar] [CrossRef]

- Li, Y.; Dong, W.; Zheng, T.; Wang, Y.; Li, X. Scene-Adaptive Loader Trajectory Planning and Tracking Control. Sensors 2025, 25, 1135. [Google Scholar] [CrossRef]

- Xu, L.; Hou, J.; Yan, X.; Liu, M.; Zhang, J.; Tao, Y. Research on Path Tracking of Intelligent Hybrid Articulated Tractor Based on Corrected Model Predictive Control. World Electr. Veh. J. 2025, 16, 161. [Google Scholar] [CrossRef]

| Parameter | Value |

|---|---|

| Spool outer diameter | 19 mm |

| Valve stem diameter | 9 mm |

| Spool mass | 1 kg |

| Spring stiffness | 8 N/mm |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, L.; Zhao, X.; Sun, Z.; Kang, Y. Path Tracking Control for Underground Articulated Vehicles with Multi-Timescale Predictive Modeling. Actuators 2025, 14, 477. https://doi.org/10.3390/act14100477

Liu L, Zhao X, Sun Z, Kang Y. Path Tracking Control for Underground Articulated Vehicles with Multi-Timescale Predictive Modeling. Actuators. 2025; 14(10):477. https://doi.org/10.3390/act14100477

Chicago/Turabian StyleLiu, Lei, Xinxin Zhao, Zhibo Sun, and Yiting Kang. 2025. "Path Tracking Control for Underground Articulated Vehicles with Multi-Timescale Predictive Modeling" Actuators 14, no. 10: 477. https://doi.org/10.3390/act14100477

APA StyleLiu, L., Zhao, X., Sun, Z., & Kang, Y. (2025). Path Tracking Control for Underground Articulated Vehicles with Multi-Timescale Predictive Modeling. Actuators, 14(10), 477. https://doi.org/10.3390/act14100477