Revolutionizing Patient Care: A Comprehensive Review of Recent Advances in Flexible Printed Heaters for Wearable Medical Applications

Abstract

1. Introduction

2. Materials for Flexible Printed Heaters

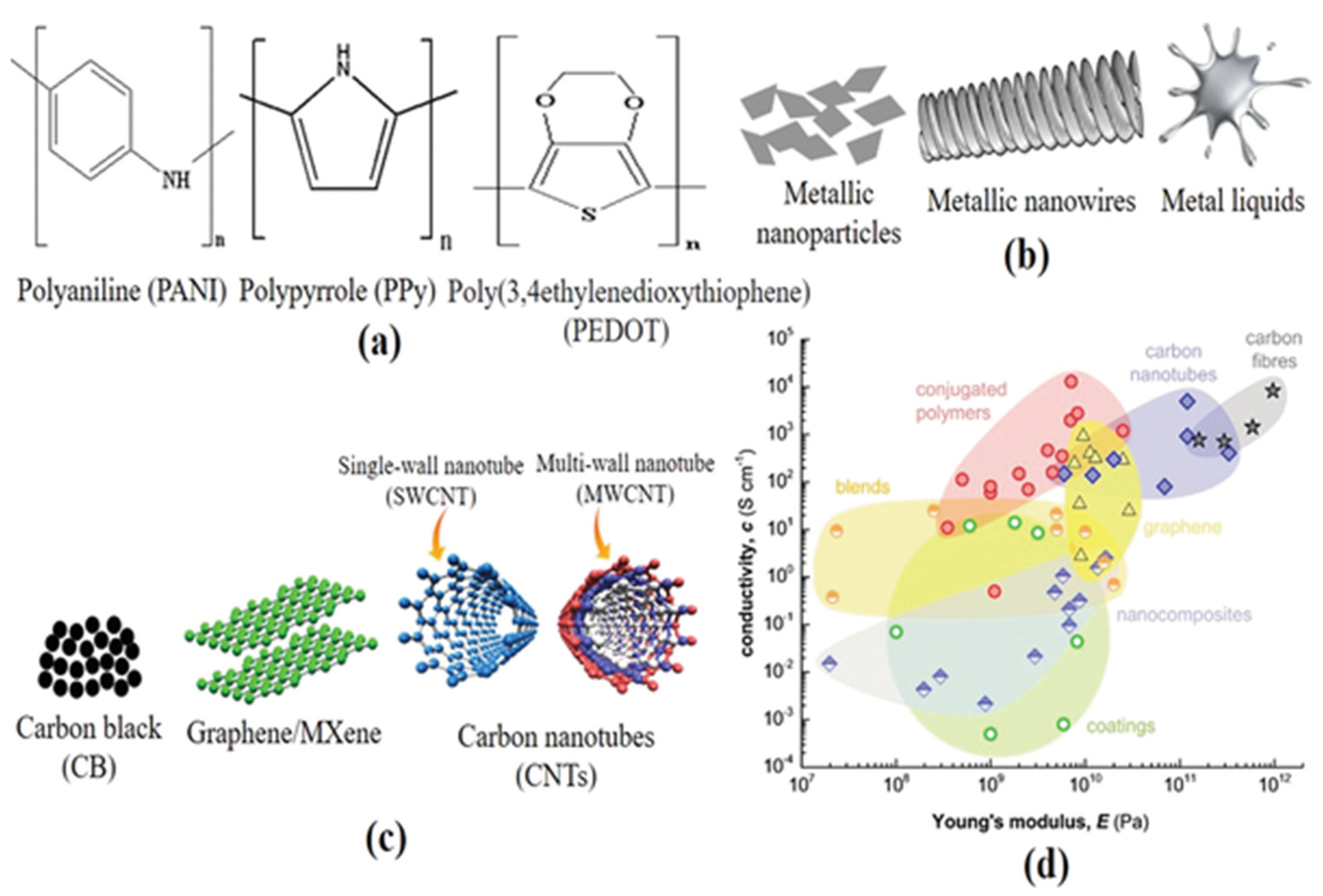

2.1. Conductive Materials

2.1.1. Metallic Conductive Materials

2.1.2. Carbon-Based Conductive Materials

2.1.3. Conductive Polymers

2.1.4. Hybrid Conductive Materials

2.2. Substrate Materials

2.2.1. Flexible Plastic Films

2.2.2. Stretchable Elastomers

2.2.3. Textiles

3. Flexible Printed Heater Fabrication Methods

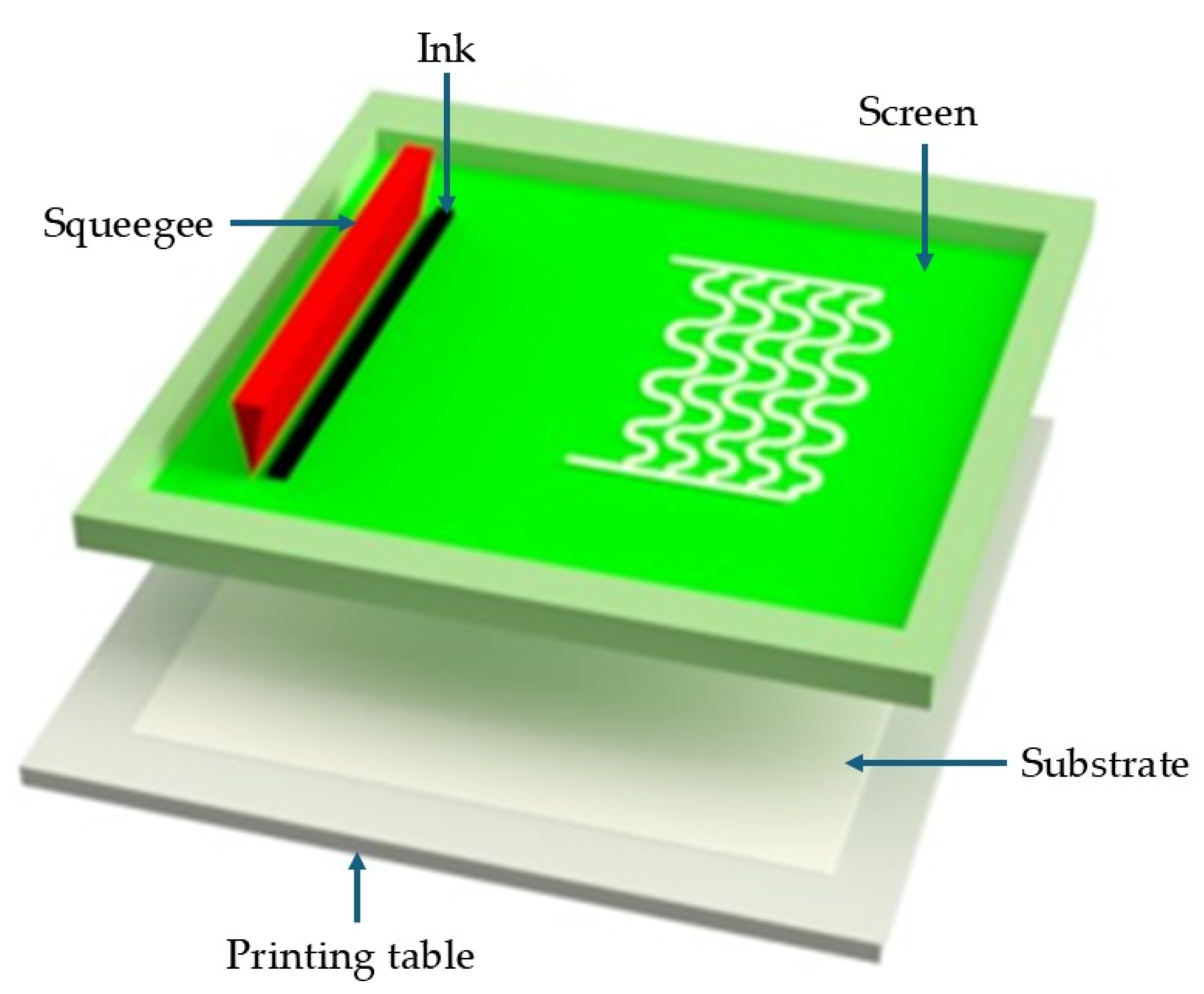

3.1. Screen Printing

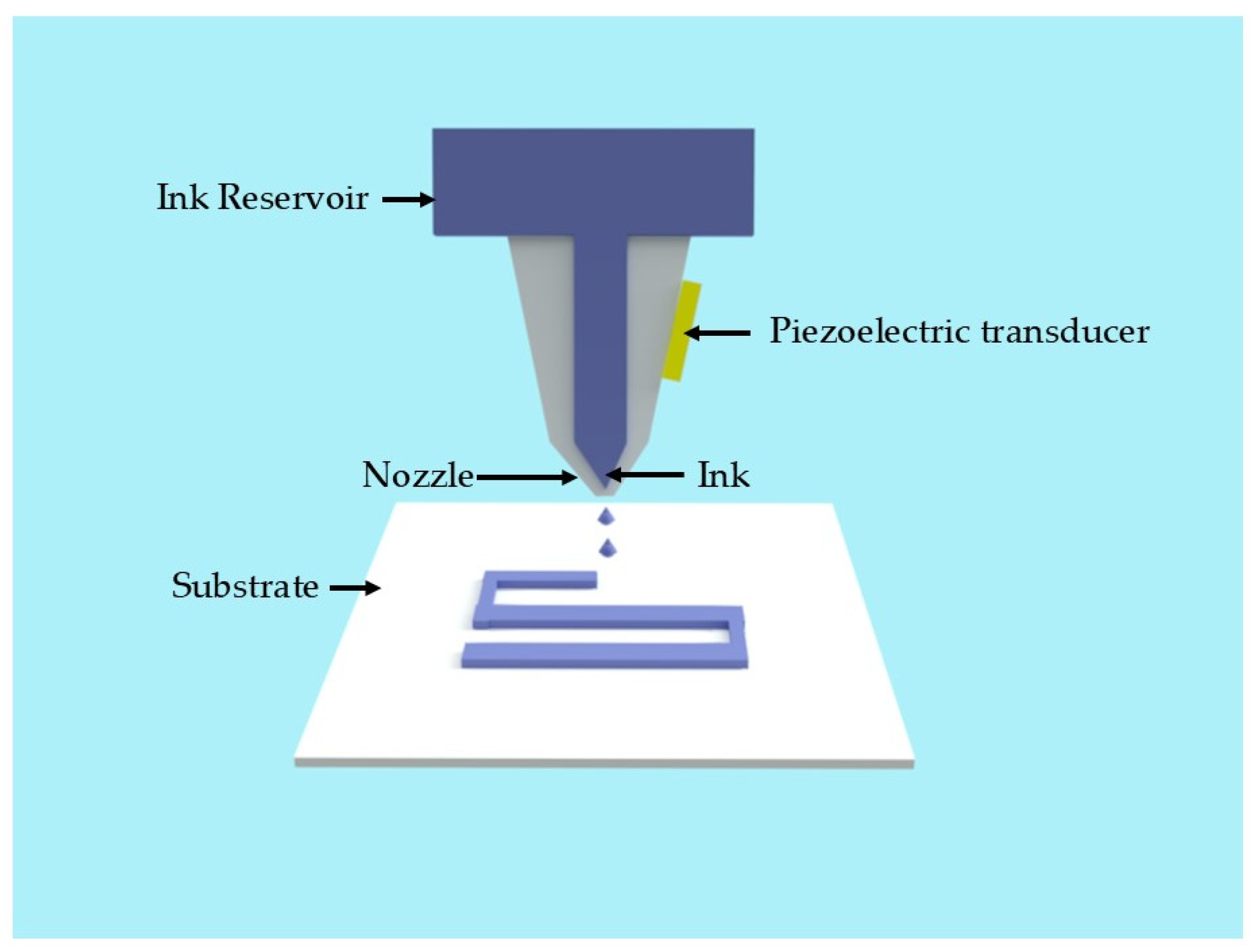

3.2. Inkjet Printing

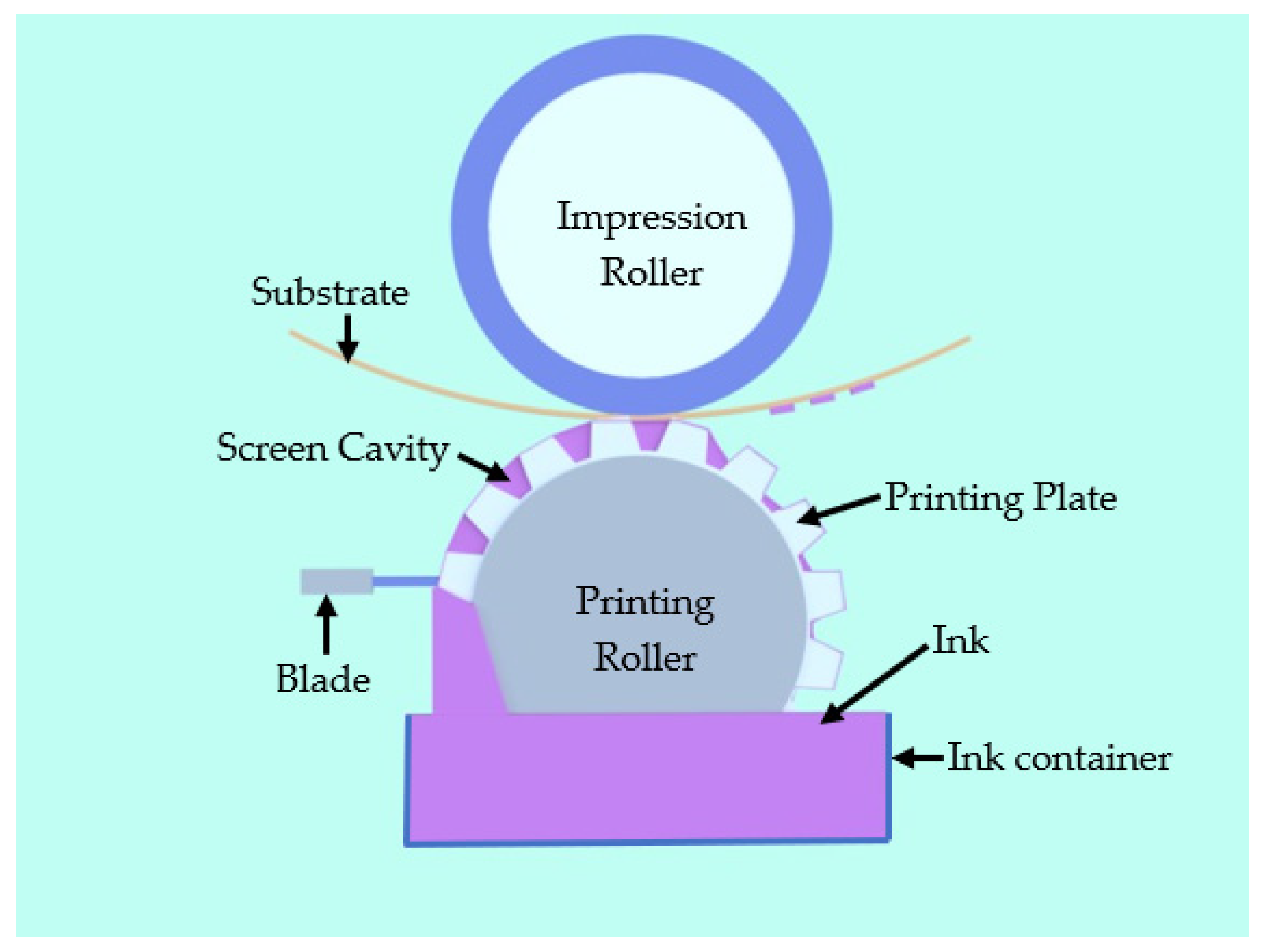

3.3. Role-to-Role Gravure Printing

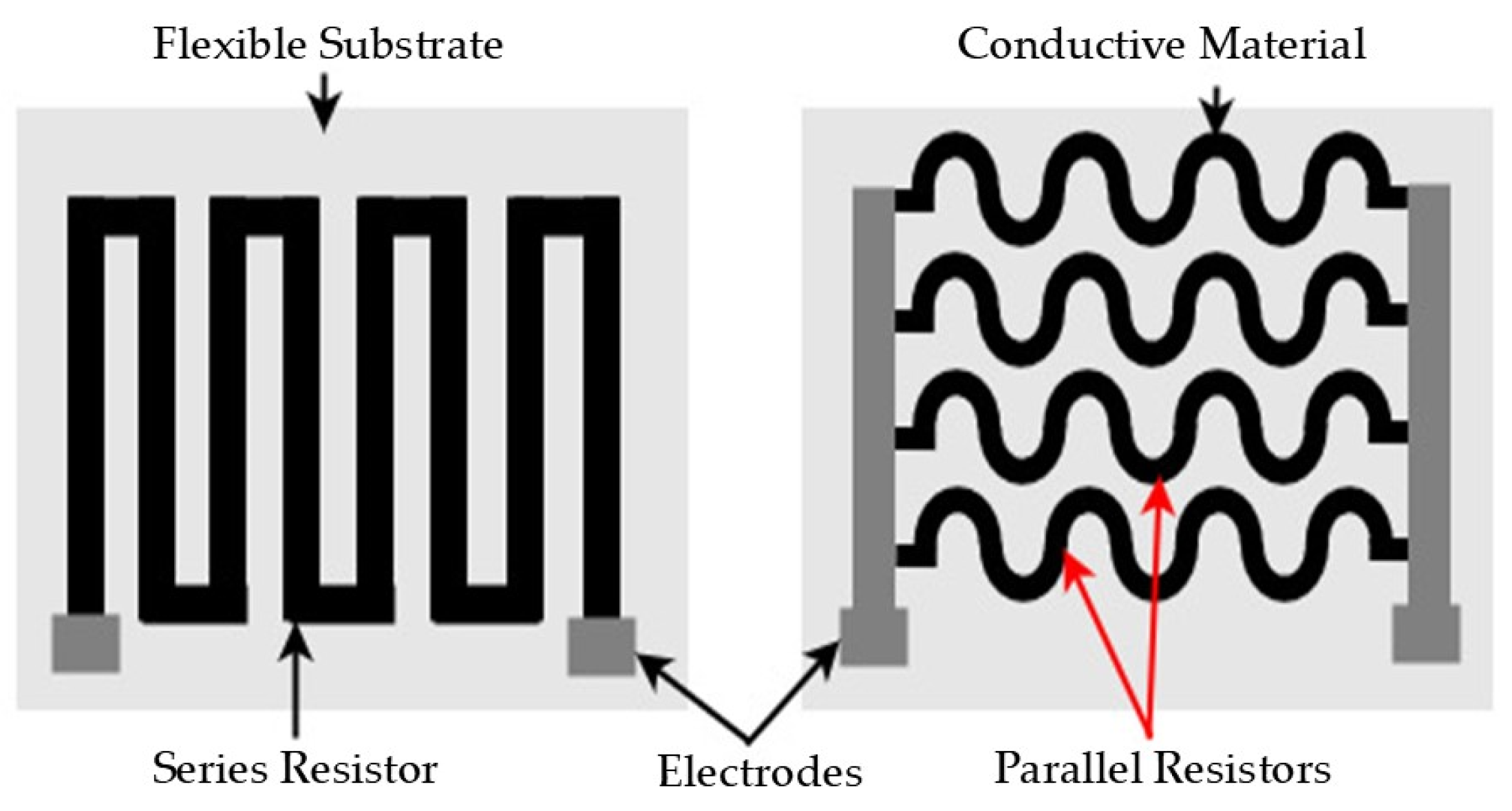

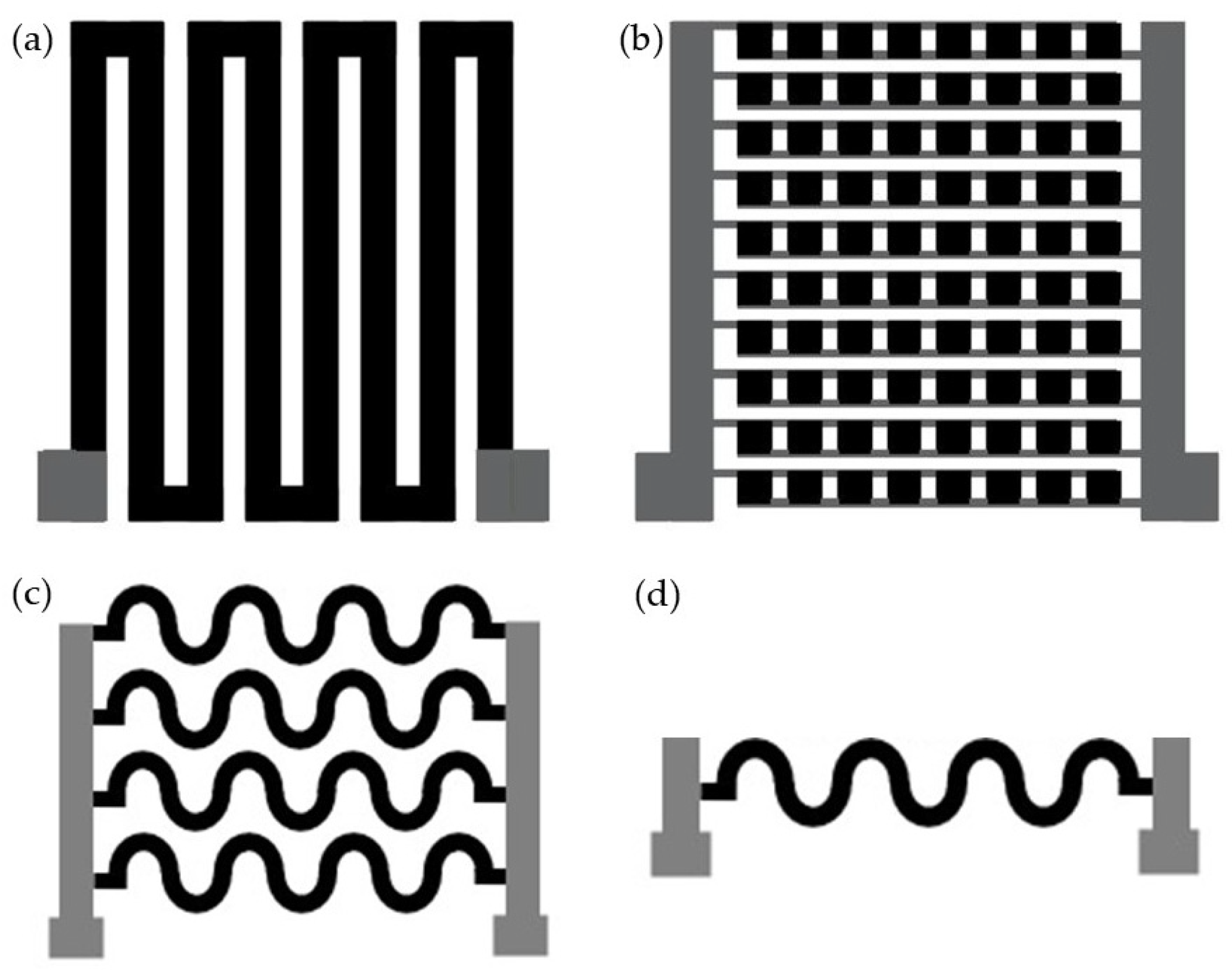

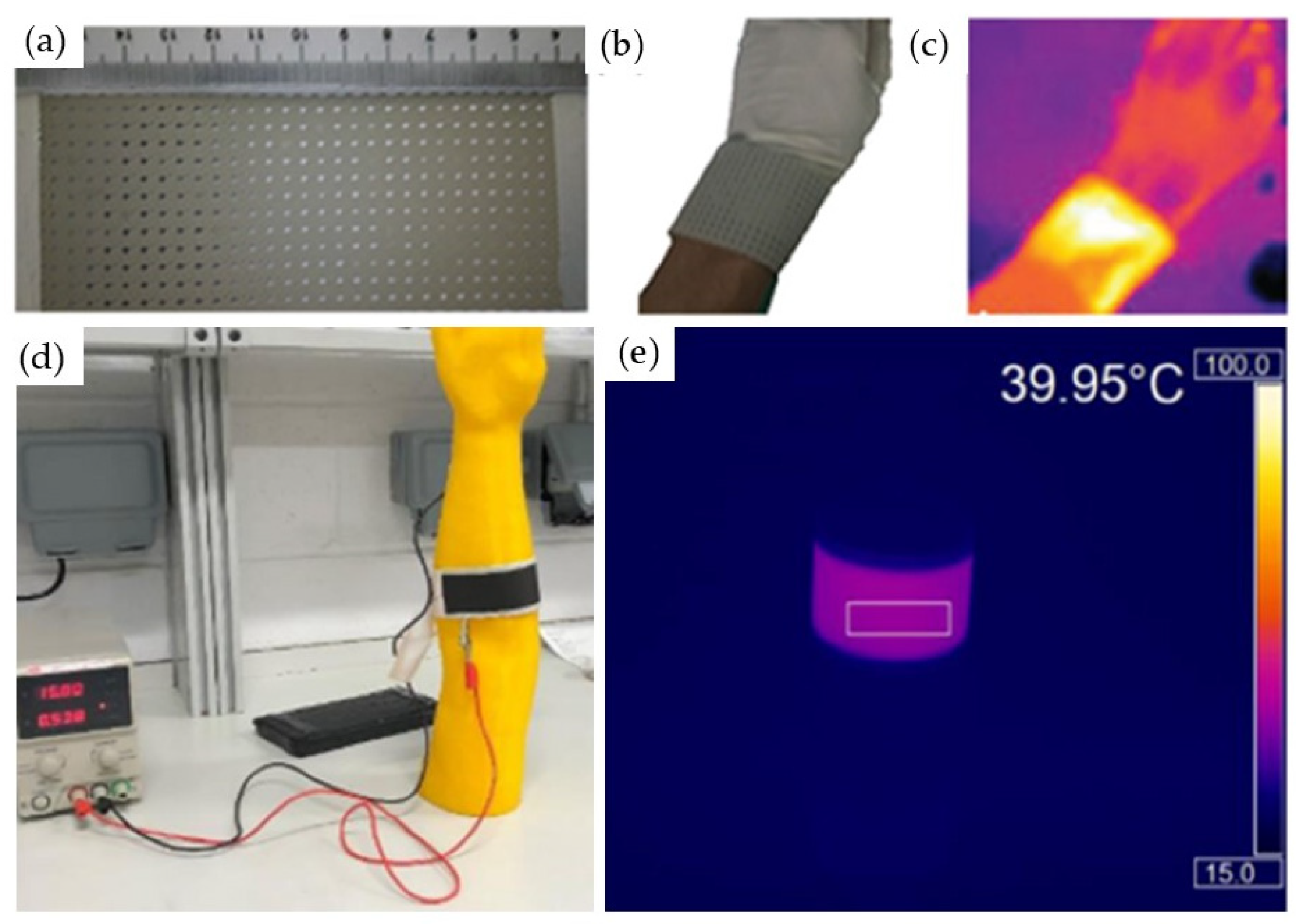

4. Flexible Printed Heater Design and Temperature Control Mechanisms

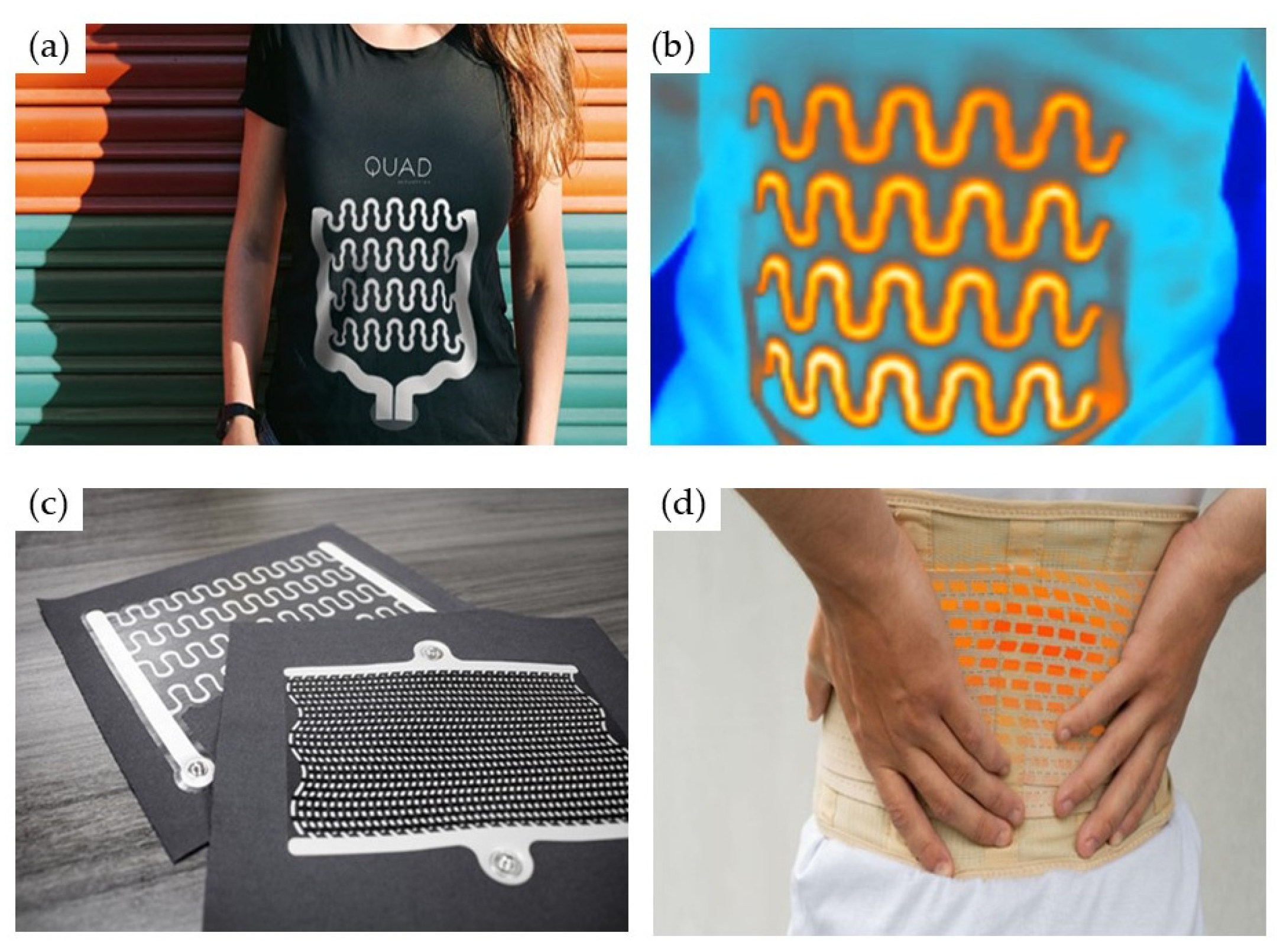

5. Medical Applications and Performance Analysis of Flexible Printed Heaters

5.1. Medical Applications

5.2. Performance Analysis

6. Challenges

7. Future Directions and Opportunities

- Exploring novel conductive materials with excellent electrical and thermal conductivity at a self-regulating temperature close to human body temperature could increase the performance of the wearable heater and its usability for wearable medical applications. Additionally, incorporating biodegradable and recyclable materials in the development of FPHs is essential for addressing sustainability concerns.

- Exploring the potential integration of shape memory materials and origami-inspired designs holds significant promise for enhancing the adaptability and functionality of FPHs. Shape memory materials can undergo reversible shape changes in response to temperature variations, allowing for adaptive heating solutions that conform to the body’s contours for optimal contact and therapeutic effectiveness [105]. Considering a novel origami tessellation approach could also advance FPHs in terms of flexibility and comfort [106,107].

- Incorporating vital sign monitoring sensors could advance the wearable printed heater to enable measurement of important parameters such as body temperature, oxygen saturation, respiration rate, heart rate, and others for effective medical follow-up.

- Intelligent textiles and smart heating fabrics that integrate sensors and actuators play a vital role in advancing wearable heaters. Intelligent textiles can adapt to the wearer’s body temperature and environmental conditions, providing customized heating solutions that enhance comfort. Smart heating fabrics can adjust heat levels based on the user’s physiological responses, optimizing therapeutic effectiveness.

- Multidisciplinary collaboration among researchers, healthcare professionals, industry, and regulatory bodies will enable the development of a regulatory standard for wearable printed heaters for medical applications.

- Conducting clinical trials and validation studies to demonstrate the efficacy, safety, and cost-effectiveness of printed heaters for specific medical applications is another critical step in this process. This will facilitate the utilization of FPHs for medical applications.

8. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Van Tellingen, C.; Va Tukiegn, C. Hyperthermia in ancient Rome—or nonpharmaceutical management of heart failure in antiquity. Neth. Heart J. 2006, 14, 397. [Google Scholar]

- Chinyere Celine, N.; Ugochukwu Clifford, I. A Review of Heat Therapy in African Traditional Medicine. J. Health Environ. Res. 2020, 6, 87. [Google Scholar] [CrossRef]

- What Evidence Exists that Describes the Safe Application of Heat Therapy in A Healthcare Context? 2016. Available online: http://www.muhclibraries.ca/Documents/RR_Final-Report_Heat-Application_JAN2016.pdf (accessed on 29 April 2024).

- Yildirim, N.; Filiz Ulusoy, M.; Bodur, H. The effect of heat application on pain, stiffness, physical function and quality of life in patients with knee osteoarthritis. J. Clin. Nurs. 2010, 19, 1113–1120. [Google Scholar] [CrossRef]

- Cao, T.; Shi, X.L.; Zou, J.; Chen, Z.G. Advances in conducting polymer-based thermoelectric materials and devices. Microstructures 2021, 1, 2021007. [Google Scholar] [CrossRef]

- Weingand, K. The Physiologic Basis and Clinical Applications of Cryotherapy and Thermotherapy for the Pain Practitioner. Pain Physician 2004, 7, 395. [Google Scholar] [CrossRef]

- Freiwald, J.; Magni, A.; Fanlo-Mazas, P.; Paulino, E.; de Medeiros, L.S.; Moretti, B.; Schleip, R.; Solarino, G. A Role for Superficial Heat Therapy in the Management of Non-Specific, Mild-to-Moderate Low Back Pain in Current Clinical Practice: A Narrative Review. Life 2021, 11, 780. [Google Scholar] [CrossRef] [PubMed]

- Clijsen, R.; Stoop, R.; Hohenauer, E.; Aerenhouts, D.; Clarys, P.; Deflorin, C.; Taeymans, J. Local Heat Applications as a Treatment of Physical and Functional Parameters in Acute and Chronic Musculoskeletal Disorders or Pain. Arch. Phys. Med. Rehabil. 2022, 103, 505–522. [Google Scholar] [CrossRef]

- Kok, H.P.; Cressman, E.N.K.; Ceelen, W.; Brace, C.L.; Ivkov, R.; Grüll, H.; ter Haar, G.; Wust, P.; Crezee, J. Heating technology for malignant tumors: A review. Int. J. Hyperth. 2020, 37, 711. [Google Scholar] [CrossRef]

- Dunne, E.A.; O’Donnell, C.P.F.; Nakstad, B.; McCarthy, L.K. Thermoregulation for very preterm infants in the delivery room: A narrative review. Pediatr. Res. 2024, 95, 1448–1454. [Google Scholar] [CrossRef] [PubMed]

- Demtse, A.G.; Pfister, R.E.; Nigussie, A.K.; McClure, E.M.; Ferede, Y.G.; Tazu Bonger, Z.; Mekasha, A.; Demisse, A.G.; Gidi, N.W.; Metaferia, G.; et al. Hypothermia in Preterm Newborns: Impact on Survival. Glob. Pediatr. Health 2020, 7. [Google Scholar] [CrossRef]

- Fenta, B.; Biyazin, T.; Dagnaw, Y.; Dewey, R.S.; Yetwale, A. Neonatal hypothermia and associated factors in preterm neonates admitted to neonatal intensive care units in southwest Ethiopia. J. Neonatal Nurs. 2023, 29, 307–312. [Google Scholar] [CrossRef]

- Petrofsky, J.; Berk, L.; Bains, G.; Khowailed, I.A.; Hui, T.; Granado, M.; Laymon, M.; Lee, H. Moist Heat or Dry Heat for Delayed Onset Muscle Soreness. J. Clin. Med. Res. 2013, 5, 416. [Google Scholar] [CrossRef]

- Chang, W.Y.; Liu, H.H.; Huang, D.W.; Chou, Y.Y.; Ou, K.L.; Wang, C.H.; Dai, N.T.; Tzeng, Y.S. Severe burn injury from the common Asian practice of heat application in patients with diabetic neuropathy. Int. Wound J. 2022, 19, 845. [Google Scholar] [CrossRef]

- Mun, J.H.; Jeon, J.H.; Jung, Y.J.; Jang, K.U.; Yang, H.T.; Lim, H.J.; Cho, Y.S.; Kim, D.; Hur, J.; Kim, J.H.; et al. The Factors Associated with Contact Burns from Therapeutic Modalities. Ann. Rehabil. Med. 2012, 36, 688. [Google Scholar] [CrossRef] [PubMed]

- Gosselin, T.K. Thermal wounds following heating pad use. Clin. J. Oncol. Nurs. 2003, 7, 87–88. [Google Scholar] [CrossRef] [PubMed]

- Özgenel Ege, G.Y.; Özcan, M. Heating-pad burn as a complication of abdominoplasty. Br. J. Plast. Surg. 2003, 56, 52–53. [Google Scholar] [CrossRef]

- Lowe, W.; Chaitow, L. Thermal modalities as treatment aids. In Orthopedic Massage, 2nd ed.; Elsevier: Amsterdam, The Netherlands, 2009; pp. 27–42. [Google Scholar] [CrossRef]

- Bahadir, S.K.; Sahin, U.K.; Bahadir, S.K.; Sahin, U.K. A Wearable Heating System with a Controllable e-Textile-Based Thermal Panel. In Wearable Technologies; IntechOpen: Rijeka, Croatia, 2018. [Google Scholar] [CrossRef]

- Caya, M.V.C.; De Pano, C.J.R.; Magpayo, J.G.S. Development of Wearable Wireless Heating E-Textile using Conductive Threads for Thermotherapy. In Proceedings of the 2020 IEEE 12th International Conference on Humanoid, Nanotechnology, Information Technology, Communication and Control, Environment, and Management (HNICEM), Manila, Philippines, 3–7 December 2020. [Google Scholar] [CrossRef]

- Maurya, S.K.; Das, A.; Kumar, B. Optimization of Heating Performance of the Rib-Knitted Wearable Heating Pad. Eng. Proc. 2023, 30, 1. [Google Scholar] [CrossRef]

- De Mey, G.; Özçelik, M.; Schwarz, A.; Kazani, I.; Hertleer, C.; Van Langenhove, L.; Gürsoy, N.Ç. Designing of conductive yarn knitted thermal comfortable shirt using battery operated heating system. Text. Appar. 2014, 24, 26–29. [Google Scholar]

- Liu, Q.; Tian, B.; Luo, C.; Liang, J.; Wu, W. Printed Flexible Heaters-Based Thermotherapy Platform for Multiduty Thermal Management. Adv. Mater. Technol. 2020, 5. [Google Scholar] [CrossRef]

- Fang, S.; Wang, R.; Ni, H.; Liu, H.; Liu, L. A review of flexible electric heating element and electric heating garments. J. Ind. Text. 2022, 51, 101S–136S. [Google Scholar] [CrossRef]

- The Basics of Flexible Printed Heaters|Machine Design. Available online: https://www.machinedesign.com/leaders/medical-design/article/21159616/the-basics-of-flexible-printed-heaters (accessed on 31 January 2024).

- Islam, M.R.; Afroj, S.; Beach, C.; Islam, M.H.; Parraman, C.; Abdelkader, A.; Casson, A.J.; Novoselov, K.S.; Karim, N. Fully printed and multifunctional graphene-based wearable e-textiles for personalized healthcare applications. iScience 2022, 25, 103945. [Google Scholar] [CrossRef]

- Claypole, A.; Claypole, J.; Leeder, J.; Stevens, G.; Johnson, F.; Bezodis, N.; Parker, M.; Claypole, T.; Gethin, D.; Kilduff, L. Large area, stretchable, wearable, screen-printed carbon heaters for use in elite sport. J. Coat. Technol. Res. 2023, 20, 261–273. [Google Scholar] [CrossRef]

- Ye, C.; Zhao, L.; Yang, S.; Li, X. Recent Research on Preparation and Application of Smart Joule Heating Fabrics. Small 2024, 20, 2309027. [Google Scholar] [CrossRef] [PubMed]

- Mohammed, M.A.; Basirun, W.J.; Rahman, N.M.M.A.; Salleh, N.M. Electrochemical applications of nanocellulose. In Nanocellulose Based Composites for Electronics; Elsevier: Amsterdam, The Netherlands, 2021; pp. 313–335. [Google Scholar] [CrossRef]

- Van Langenhove, L.; Puers, R.; Matthys, D. Intelligent textiles for protection. In Textiles for Protection; Elsevier: Amsterdam, The Netherlands, 2005; pp. 176–195. [Google Scholar] [CrossRef]

- Barbhuiya, S.; Das, B.B.; Idrees, M. Thermal energy storage in concrete: A comprehensive review on fundamentals, technology and sustainability. J. Build. Eng. 2024, 82, 108302. [Google Scholar] [CrossRef]

- Heat Transfer Coefficient|Shop HVAC Products. Available online: https://www.broughtoneap.co.uk/hvac/articles/heat-transfer-coefficient/ (accessed on 4 November 2024).

- Liu, T.; Mauter, M.S. Heat transfer innovations and their application in thermal desalination processes. Joule 2022, 6, 1199–1229. [Google Scholar] [CrossRef]

- Smith, D.R.; Fickett, F.R. Low-Temperature Properties of Silver. J. Res. Natl. Inst. Stand. Technol. 1995, 100, 119. [Google Scholar] [CrossRef] [PubMed]

- Tomotoshi, D.; Kawasaki, H. Surface and Interface Designs in Copper-Based Conductive Inks for Printed/Flexible Electronics. Nanomaterials 2020, 10, 1689. [Google Scholar] [CrossRef] [PubMed]

- Zheng, Y.; Huang, X.; Chen, J.; Wu, K.; Wang, J.; Zhang, X. A review of conductive carbon materials for 3d printing: Materials, technologies, properties, and applications. Materials 2021, 14, 3911. [Google Scholar] [CrossRef]

- Silver—Energy Education. Available online: https://energyeducation.ca/encyclopedia/Silver (accessed on 21 February 2024).

- Tiwari, N.; Ankit; Rajput, M.; Kulkarni, M.R.; John, R.A.; Mathews, N. Healable and flexible transparent heaters. Nanoscale 2017, 9, 14990–14997. [Google Scholar] [CrossRef]

- Zhang, J.; Ahmadi, M.; Fargas, G.; Perinka, N.; Reguera, J.; Lanceros-Méndez, S.; Llanes, L.; Jiménez-Piqué, E. Silver Nanoparticles for Conductive Inks: From Synthesis and Ink Formulation to Their Use in Printing Technologies. Metals 2022, 12, 234. [Google Scholar] [CrossRef]

- Shukla, D.; Liu, Y.; Zhu, Y. Eco-friendly screen printing of silver nanowires for flexible and stretchable electronics. Nanoscale 2023, 15, 2767–2778. [Google Scholar] [CrossRef]

- Zeng, P.; Tian, B.; Tian, Q.; Yao, W.; Li, M.; Wang, H.; Feng, Y.; Liu, L.; Wu, W. Screen-Printed, Low-Cost, and Patterned Flexible Heater Based on Ag Fractal Dendrites for Human Wearable Application. Adv. Mater. Technol. 2019, 4, 1800453. [Google Scholar] [CrossRef]

- Zhu, Y.; Deng, Y.; Yi, P.; Peng, L.; Lai, X.; Lin, Z. Flexible Transparent Electrodes Based on Silver Nanowires: Material Synthesis, Fabrication, Performance, and Applications. Adv. Mater. Technol. 2019, 4, 1900413. [Google Scholar] [CrossRef]

- Yuan, Y.G.; Zhang, S.; Hwang, J.Y.; Kong, I.K. Silver Nanoparticles Potentiates Cytotoxicity and Apoptotic Potential of Camptothecin in Human Cervical Cancer Cells. Oxid. Med. Cell. Longev. 2018, 2018, 6121328. [Google Scholar] [CrossRef]

- Lee, J.H.; Youn, D.Y.; Luo, Z.; Moon, J.Y.; Choi, S.J.; Kim, C.; Kim, I.D. Cu Microbelt Network Embedded in Colorless Polyimide Substrate: Flexible Heater Platform with High Optical Transparency and Superior Mechanical Stability. ACS Appl. Mater. Interfaces 2017, 9, 39650–39656. [Google Scholar] [CrossRef]

- Wang, P.; Yuan, Y.; Xu, K.; Zhong, H.; Yang, Y.; Jin, S.; Yang, K.; Qi, X. Biological applications of copper-containing materials. Bioact. Mater. 2021, 6, 916–927. [Google Scholar] [CrossRef] [PubMed]

- Lee, J.G.; Lee, J.H.; An, S.; Kim, D.Y.; Kim, T.G.; Al-Deyab, S.S.; Yarin, A.L.; Yoon, S.S. Highly flexible, stretchable, wearable, patternable and transparent heaters on complex 3D surfaces formed from supersonically sprayed silver nanowires. J. Mater. Chem. A 2017, 5, 6677–6685. [Google Scholar] [CrossRef]

- Celle, C.; Mayousse, C.; Moreau, E.; Basti, H.; Carella, A.; Simonato, J.P. Highly flexible transparent film heaters based on random networks of silver nanowires. Nano Res. 2012, 5, 427–433. [Google Scholar] [CrossRef]

- Pang, S.; Hernandez, Y.; Feng, X.; Müllen, K.; Pang, S.; Hernandez, Y.; Feng, X.; Müllen, K. Graphene as Transparent Electrode Material for Organic Electronics. Adv. Mater. 2011, 23, 2779–2795. [Google Scholar] [CrossRef]

- Xie, Y.; Wang, X. Thermal conductivity of carbon-based nanomaterials: Deep understanding of the structural effects. Green Carbon 2023, 1, 47–57. [Google Scholar] [CrossRef]

- Wang, Y.; Weng, G.J. Electrical conductivity of carbon nanotubeand graphene-based nanocomposites. In Micromechanics and Nanomechanics of Composite Solids; Springer: Berlin/Heidelberg, Germany, 2017; pp. 123–156. [Google Scholar] [CrossRef]

- Kim, S.B.; Kim, C.H.; Lee, S.Y.; Park, S.J. Carbon materials and their metal composites for biomedical applications: A short review. Nanoscale 2024, 16, 16313–16328. [Google Scholar] [CrossRef] [PubMed]

- Al Faruque, M.A.; Syduzzaman, M.; Sarkar, J.; Bilisik, K.; Naebe, M. A Review on the Production Methods and Applications of Graphene-Based Materials. Nanomater 2021, 11, 2414. [Google Scholar] [CrossRef] [PubMed]

- Cao, Q.; Rogers, J.A. Ultrathin Films of Single-Walled Carbon Nanotubes for Electronics and Sensors: A Review of Fundamental and Applied Aspects. Adv. Mater. 2009, 21, 29–53. [Google Scholar] [CrossRef]

- He, Q.; Tian, Y.; Wu, Y.; Liu, J.; Li, G.; Deng, P.; Chen, D. Facile and ultrasensitive determination of 4-nitrophenol based on acetylene black paste and graphene hybrid electrode. Nanomaterials 2019, 9, 429. [Google Scholar] [CrossRef] [PubMed]

- Aleksandrova, M.; Mateev, V.; Iliev, I. Behavior of Polymer Electrode PEDOT:PSS/Graphene on Flexible Substrate for Wearable Biosensor at Different Loading Modes. Nanomaterials 2024, 14, 1357. [Google Scholar] [CrossRef] [PubMed]

- Li, Z.; Gong, L. Research Progress on Applications of Polyaniline (PANI) for Electrochemical Energy Storage and Conversion. Materials 2020, 13, 548. [Google Scholar] [CrossRef] [PubMed]

- Humpolicek, P.; Kasparkova, V.; Saha, P.; Stejskal, J. Biocompatibility of polyaniline. Synth. Met. 2012, 162, 722–727. [Google Scholar] [CrossRef]

- Foroughi, J.; Ghorbani, S.; Peleckis, G.; Spinks, G.; Wallace, G.; Wang, X.-L.; Dou, S. The mechanical and the electrical properties of conducting polypyrrole fibers. J. Appl. Phys. 2010, 107, 103712. [Google Scholar] [CrossRef]

- Slejko, E.A.; Carraro, G.; Huang, X.; Smerieri, M. Advances in the Fabrication, Properties, and Applications of Electrospun PEDOT-Based Conductive Nanofibers. Polymers 2024, 16, 2514. [Google Scholar] [CrossRef] [PubMed]

- Kim, I.; Woo, K.; Zhong, Z.; Lee, E.; Kang, D.; Jeong, S.; Choi, Y.M.; Jang, Y.; Kwon, S.; Moon, J. Selective Light-Induced Patterning of Carbon Nanotube/Silver Nanoparticle Composite to Produce Extremely Flexible Conductive Electrodes. ACS Appl. Mater. Interfaces 2017, 9, 6163–6170. [Google Scholar] [CrossRef]

- Cao, M.; Wang, M.; Li, L.; Qiu, H.; Yang, Z. Effect of Graphene-EC on Ag NW-Based Transparent Film Heaters: Optimizing the Stability and Heat Dispersion of Films. ACS Appl. Mater. Interfaces 2018, 10, 1077–1083. [Google Scholar] [CrossRef] [PubMed]

- Pillai, P.S.; Athira, B.S.; Varghese, H.; Agarwal, S.; Kumar, B.; Alagirusamy, R.; Das, A.; Surendran, K.P.; Chandran, A. A resistive ink based all-printed fabric heater integrated wearable thermotherapy device. J. Mater. Sci. Mater. Electron. 2023, 34, 1261. [Google Scholar] [CrossRef]

- Tian, B.; Wu, W. Printed Stretchable Multifunctional E-textile for Wearable electronics. In Proceedings of the 2021 5th IEEE Electron Devices Technology & Manufacturing Conference (EDTM), Chengdu, China, 8–11 April 2021. [Google Scholar] [CrossRef]

- From Experiment to Final Print: Understanding Self-Regulation PTC Heaters. Available online: https://www.techblick.com/post/from-experiment-to-final-print-understanding-self-regulation-ptc-heaters (accessed on 18 April 2024).

- Repon, M.R.; Mikučionienė, D. Progress in Flexible Electronic Textile for Heating Application: A Critical Review. Materials 2021, 14, 6540. [Google Scholar] [CrossRef] [PubMed]

- How Substrates and Inks Impact In-Store Marketing|Imagine. Available online: https://theimaginegroup.com/insights/printer-primer-part-3-how-substrates-and-inks-impact-in-store-marketing (accessed on 30 April 2024).

- Kim, P.K.; Chung, S.I.; Ha, T.G.; Jung, K. Transparent flexible heater with nano amorphous pattern. J. Micromech. Microeng. 2019, 29, 115010. [Google Scholar] [CrossRef]

- Xie, S.; Li, T.; Xu, Z.; Wang, Y.; Liu, X.; Guo, W. A high-response transparent heater based on a CuS nanosheet film with superior mechanical flexibility and chemical stability. Nanoscale 2018, 10, 6531–6538. [Google Scholar] [CrossRef]

- Zhang, N.; Huang, C.; Wan, S.; Kang, L.; Hu, M.; Zhang, Y.; Wu, X.; Zhang, J. A Novel Flexible Silver Heater Fabricated by a Solution-Based Polyimide Metalization and Inkjet-Printed Carbon Masking Technique. ACS Appl. Electron. Mater. 2019, 1, 928–935. [Google Scholar] [CrossRef]

- Bobinger, M.R.; Romero, F.J.; Salinas-Castillo, A.; Becherer, M.; Lugli, P.; Morales, D.P.; Rodríguez, N.; Rivadeneyra, A. Flexible and robust laser-induced graphene heaters photothermally scribed on bare polyimide substrates. Carbon N. Y. 2019, 144, 116–126. [Google Scholar] [CrossRef]

- Wang, Y.; Li, K.; Li, X.; Cui, H.; Liu, G.; Xu, H.; Wu, X.; Yao, W.; Zhong, B.; Huang, X.; et al. Electro-thermally driven flexible robot arms based on stacking-controlled graphite nanocomposites. Carbon N. Y. 2019, 152, 873–881. [Google Scholar] [CrossRef]

- Çaykara, T.; Sande, M.G.; Azoia, N.; Rodrigues, L.R.; Silva, C.J. Exploring the potential of polyethylene terephthalate in the design of antibacterial surfaces. Med. Microbiol. Immunol. 2020, 209, 363–372. [Google Scholar] [CrossRef] [PubMed]

- Lin, J.; Su, J.; Weng, M.; Xu, W.; Huang, J.; Fan, T.; Liu, Y.; Min, Y. Applications of flexible polyimide: Barrier material, sensor material, and functional material. Soft Sci. 2023, 3, 2. [Google Scholar] [CrossRef]

- An, B.W.; Gwak, E.J.; Kim, K.; Kim, Y.C.; Jang, J.; Kim, J.Y.; Park, J.U. Stretchable, Transparent Electrodes as Wearable Heaters Using Nanotrough Networks of Metallic Glasses with Superior Mechanical Properties and Thermal Stability. Nano Lett. 2016, 16, 471–478. [Google Scholar] [CrossRef] [PubMed]

- Sun, W.J.; Xu, L.; Jia, L.C.; Zhou, C.G.; Xiang, Y.; Yin, R.H.; Yan, D.X.; Tang, J.H.; Li, Z.M. Highly conductive and stretchable carbon nanotube/thermoplastic polyurethane composite for wearable heater. In Composites Science and Technology; Elsevier: Amsterdam, The Netherlands, 2019; p. 181. [Google Scholar] [CrossRef]

- Zheng, S.G.; Liu, X.; Guo, Z.; Li, Y.; Zhou, B.; Zheng, G.; Li, T.; Yan, C.; Cheng, C.; Dai, K.; et al. Continuously prepared highly conductive and stretchable SWNT/MWNT synergistically composited electrospun thermoplastic polyurethane yarns for wearable sensing. J. Mater. Chem. C 2018, 6, 2258. [Google Scholar] [CrossRef]

- Xu, T.; Shen, W.; Lin, X.; Xie, Y.M. Mechanical Properties of Additively Manufactured Thermoplastic Polyurethane (TPU) Material Affected by Various Processing Parameters. Polymers 2020, 12, 3010. [Google Scholar] [CrossRef] [PubMed]

- Miranda, I.; Souza, A.; Sousa, P.; Ribeiro, J.; Castanheira, E.M.S.; Lima, R.; Minas, G. Properties and applications of PDMS for biomedical engineering: A review. J. Funct. Biomater. 2022, 13, 2. [Google Scholar] [CrossRef]

- Ariati, R.; Sales, F.; Souza, A.; Lima, R.A.; Ribeiro, J. Polydimethylsiloxane composites characterization and its applications: A review. Polymers 2021, 13, 4258. [Google Scholar] [CrossRef] [PubMed]

- Huang, Y.; Peng, C.; Li, Y.; Yang, Y.; Feng, W. Elastomeric polymers for conductive layers of flexible sensors: Materials, fabrication, performance, and applications. Aggregate 2023, 4, e319. [Google Scholar] [CrossRef]

- Gray, B.L. The Textile is the Substrate: Challenges of Direct-on-Fabric Wearables. In Proceedings of the 2023 IEEE International Flexible Electronics Technology Conference (IFETC), San Jose, CA, USA, 13–16 August 2023. [Google Scholar] [CrossRef]

- Flexible Printed Heaters: A Revolution In Heating Technology. Available online: https://almaxeis.com/flexible-printed-heaters/ (accessed on 16 April 2024).

- Sachyani Keneth, E.; Kamyshny, A.; Totaro, M.; Beccai, L.; Magdassi, S. 3D Printing Materials for Soft Robotics. Adv. Mater. 2021, 33, 2003387. [Google Scholar] [CrossRef]

- Li, P.; Zhang, Y.; Zheng, Z. Polymer-Assisted Metal Deposition (PAMD) for Flexible and Wearable Electronics: Principle, Materials, Printing, and Devices. Adv. Mater. 2019, 31, 1902987. [Google Scholar] [CrossRef] [PubMed]

- Han, Y.; Cui, Y.; Liu, X.; Wang, Y. A Review of Manufacturing Methods for Flexible Devices and Energy Storage Devices. Biosensors 2023, 13, 896. [Google Scholar] [CrossRef] [PubMed]

- Buga, C.; Viana, J.C.; Buga, C.; Viana, J.C. Inkjet Printing of Functional Inks for Smart Products. In Production Engineering and Robust Control; IntechOpen: Rijeka, Croatia, 2022. [Google Scholar] [CrossRef]

- You, M.; Zhong, J.; Hong, Y.; Duan, Z.; Lin, M.; Xu, F. Inkjet printing of upconversion nanoparticles for anti-counterfeit applications. Nanoscale 2015, 7, 4423–4431. [Google Scholar] [CrossRef]

- Szentgyörgyvölgyi, R. 12—Gravure Printing. In Printing on Polymers; Izdebska, J., Thomas, S., Eds.; William Andrew Publishing: Amsterdam, The Netherlands, 2016; pp. 199–215. ISBN 978-0-323-37468-2. [Google Scholar]

- Liu, Q.; Tian, B.; Liang, J.; Wu, W. Recent advances in printed flexible heaters for portable and wearable thermal management. Mater. Horizons 2021, 8, 1634–1656. [Google Scholar] [CrossRef]

- Kim, H.; Lee, S. Characterization of Electrical Heating Performance of CFDM 3D-Printed Graphene/Polylactic Acid (PLA) Horseshoe Pattern with Different 3D Printing Directions. Polymers 2020, 12, 2955. [Google Scholar] [CrossRef] [PubMed]

- Film Heater|User Interfaces|Quad Industries. Available online: https://www.quad-ind.com/printed-electronics/film-heaters/ (accessed on 15 April 2024).

- Arc Length Formula—Formula to Calculate Arc Length with Solved Examples PDF|PDF|Distance|Angle. Available online: https://www.scribd.com/document/482691601/Arc-Length-Formula-Formula-To-Calculate-Arc-Length-With-Solved-Examples-pdf (accessed on 15 April 2024).

- Physics LibreTexts. 10.3: Resistors in Series and Parallel. Available online: https://phys.libretexts.org/Bookshelves/University_Physics/University_Physics_(OpenStax)/University_Physics_II_-_Thermodynamics_Electricity_and_Magnetism_(OpenStax)/10%3A_Direct-Current_Circuits/10.03%3A_Resistors_in_Series_and_Parallel (accessed on 15 April 2024).

- Power Output of Flexible Heaters—Calculations and Temperature. Available online: https://www.epectec.com/flexible-heaters/power-output.html (accessed on 15 April 2024).

- Palaniyappan, T.K.; Yadav, V.; Ruchira; Tayal, V.K.; Choudekar, P. PID Control Design for a Temperature Control System. In Proceedings of the 2018 International Conference on Power Energy, Environment and Intelligent Control (PEEIC), Greater Noida, India, 13–14 April 2018; pp. 632–637. [Google Scholar] [CrossRef]

- Best Mechanisms to Control Flexible Heater Temperatures. Available online: https://blog.epectec.com/best-mechanisms-to-control-flexible-heater-temperatures (accessed on 16 April 2024).

- Swansea Technology Helps Power Top British Athletes to Tokyo Success—Swansea University. Available online: https://www.swansea.ac.uk/press-office/news-events/news/2021/09/swansea-technology-helps-power-top-british-athletes-to-tokyo-success.php (accessed on 27 March 2024).

- The Importance of Flexible Heaters in the Medical Industry. Available online: https://blog.epectec.com/the-importance-of-flexible-heaters-in-the-medical-industry (accessed on 27 March 2024).

- Three Uses for Flexible Printed Heaters in the Medical Industry. Available online: https://butlertechnologies.com/blog/flexible-printed-heaters-medical-industry (accessed on 27 March 2024).

- Smart Textiles|Printed Electronics|Quad Industries. Available online: https://www.quad-ind.com/printed-electronics/smart-textiles/ (accessed on 2 May 2024).

- Li, Z.; Zhang, X.; Shan, J.; Liu, C.; Guo, X.; Zhao, X.; Yang, H. Facile fabrication of large-scale silver nanowire transparent conductive films by screen printing. Mater. Res. Express 2022, 9, 066401. [Google Scholar] [CrossRef]

- Tian, B.; Liu, Q.; Luo, C.; Feng, Y.; Wu, W.; Tian, B.; Liu, Q.; Luo, C.; Feng, Y.; Wu, W. Multifunctional Ultrastretchable Printed Soft Electronic Devices for Wearable Applications. Adv. Electron. Mater. 2020, 6, 1900922. [Google Scholar] [CrossRef]

- Shan, X.C.; Sunappan, V.; Salam, B.; Lok, B.K. Roll-to-Roll Gravure Printing of Electric Heaters on Polymeric Substrates. In Proceedings of the 2020 IEEE 22nd Electronics Packaging Technology Conference (EPTC), Singapore, 2–4 December 2020; pp. 210–212. [Google Scholar] [CrossRef]

- Cen, Z.H.; Shan, X.C.; Salam, B.; Lai, W.L.; Lok, B.K. Design of Flexible Printed Heater to Improve Uniform Heating. In Proceedings of the 2019 IEEE 21st Electronics Packaging Technology Conference (EPTC), Singapore, 4–6 December 2019; pp. 649–653. [Google Scholar] [CrossRef]

- Pisani, S.; Genta, I.; Modena, T.; Dorati, R.; Benazzo, M.; Conti, B. Shape-Memory Polymers Hallmarks and Their Biomedical Applications in the Form of Nanofibers. Int. J. Mol. Sci. 2022, 23, 1290. [Google Scholar] [CrossRef] [PubMed]

- Misseroni, D.; Pratapa, P.P.; Liu, K.; Kresling, B.; Chen, Y.; Daraio, C.; Paulino, G.H. Origami engineering. Nat. Rev. Methods Prim. 2024, 4, 40. [Google Scholar] [CrossRef]

- Merces, L.; Ferro, L.M.M.; Thomas, A.; Karnaushenko, D.D.; Luo, Y.; Egunov, A.I.; Zhang, W.; Bandari, V.K.; Lee, Y.; McCaskill, J.S.; et al. Bio-Inspired Dynamically Morphing Microelectronics toward High-Density Energy Applications and Intelligent Biomedical Implants. Adv. Mater. 2024, 36, 2313327. [Google Scholar] [CrossRef] [PubMed]

| Conductive Material | Substrate | Printing Method | Size (cm2) | Power Supply (v) | Saturation Temperature (°C) | Response Time (s) | Power (W) | Durability | Ref. |

|---|---|---|---|---|---|---|---|---|---|

| AgFDs | PET | Screen printing | 12 × 5 | 5 | 38.3 | 35 | - | Stable after 2000 bending cycles | [41] |

| Silver–carbon composite ink | PE | Screen printing | 5 × 5 | 5 | 50 | 60 | 0.811 | Maintained excellent performance under various bending radii | [62] |

| Nanocarbon ink with silver busbar | PET/TPU | Screen printing | 15 × 4 | 9 | 40 | 120 | 3.78 | Temperature decreases with applications of nominal strains | [27] |

| AgNW conductive ink | PET | Screen printing | 5 × 5 | 4 | 55 | 80 | 1.86 | Shows stable performance | [101] |

| Ag NWs/ PEDOT:PSS | PET | Inkjet printing | 5 × 2 | 6 | 85 | 30 | - | Less than 20% resistance variation after 10,000 bending cycles | [102] |

| AgFDs | Textile | Screen printing | 3 × 0.4 | 1 | 89 | 100 | - | Workable strain range of 105% | [63] |

| Silver particle-based ink | TPU/PET | R2R gravure printing | 9.8 × 4.3 | 4 | 78 | 240 | 6.67 | [103] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nemomssa, H.D.; Bossuyt, F.; Vandecasteele, B.; De Pauw, H.; Gidi, N.W.; Bauwens, P. Revolutionizing Patient Care: A Comprehensive Review of Recent Advances in Flexible Printed Heaters for Wearable Medical Applications. Actuators 2025, 14, 1. https://doi.org/10.3390/act14010001

Nemomssa HD, Bossuyt F, Vandecasteele B, De Pauw H, Gidi NW, Bauwens P. Revolutionizing Patient Care: A Comprehensive Review of Recent Advances in Flexible Printed Heaters for Wearable Medical Applications. Actuators. 2025; 14(1):1. https://doi.org/10.3390/act14010001

Chicago/Turabian StyleNemomssa, Hundessa Daba, Frederick Bossuyt, Bjorn Vandecasteele, Herbert De Pauw, Netsanet Workneh Gidi, and Pieter Bauwens. 2025. "Revolutionizing Patient Care: A Comprehensive Review of Recent Advances in Flexible Printed Heaters for Wearable Medical Applications" Actuators 14, no. 1: 1. https://doi.org/10.3390/act14010001

APA StyleNemomssa, H. D., Bossuyt, F., Vandecasteele, B., De Pauw, H., Gidi, N. W., & Bauwens, P. (2025). Revolutionizing Patient Care: A Comprehensive Review of Recent Advances in Flexible Printed Heaters for Wearable Medical Applications. Actuators, 14(1), 1. https://doi.org/10.3390/act14010001