1. Introduction

This article describes the process of designing and implementing an electrohydraulic air load simulation system for the testing of aerospace actuators. The work is part of the development of the Iron Bird shown in

Figure 1, as a collaboration between Saab AB and Linköping University. An Iron Bird is a vital part of the validation procedure of the flight control system [

1,

2,

3], and enables ground testing, which reduces cost and risk. Increased ground testing is also a response to a growing complexity of aircraft systems [

4]. The Iron Bird usually also includes hydraulics, landing gear, and necessary computers. Moreover, the benefit of integrated testing and flight simulations provided by an Iron Bird is stressed by [

5] for the purpose of actuator health monitoring. The platform referred to here, however, is strictly a research test rig for energy management studies. Studies on the test rig include hydraulic and electric actuation, hydraulic and electric power generation and distribution, and power management. The actuation system in particular is one of the key technologies in the transition towards more electric aircraft, with traditional servohydraulic actuators, electrohydrostatic actuators, and electromechanical actuators as alternatives for future aircraft [

6]. The test rig allows one to perform a hardware-in-the-loop simulation of complete missions or different manoeuvres anywhere in the flight envelope.

The purpose of the air load simulation system is to apply realistic loads on the actuators under test and resemble the hinge moment on the control surface caused by the aerodynamic loads. This is carried out by controlling the applied force in a closed loop considerably faster than the response of the test object. The performance requirements are high so as to not interfere with the test results. The challenge lies in designing a system that can handle a large operating range, with both high forces and high speed, with good performance and accuracy. Actuators are specified to handle extreme scenarios in case of failure or combat manoeuvres where the hinge loads become very high. But, for the majority of the mission, the actuator only operates at partial loads [

7]. The inherent property of hydraulic systems where the oil compression gives a rise in the pressure means that there is an interaction between the test object and the air load system. Every time the test object initiates a movement, the oil in the air load system cylinder is compressed, which causes a disturbance to the force controller. This is one of the main challenges with electrohydraulic force control.

The development of Iron Bird test rigs and the challenges with hydraulic force control is documented in the literature, with various approaches to the problem, as well as common denominators. The concept of the modular Iron Bird [

8,

9,

10] allows for the adaptation to different actuators and layouts by the use of independent functions: structure, test or load system, test equipment (aeroplane systems to be tested). Hardware-in-the-loop simulation together with a cockpit simulator enables an even more integrated test environment [

11]. The load system is used for the aerodynamic and inertial loads simulation and excitation on the test object, and is typically an electrohydraulic system. This is a versatile solution found in different applications, other than aerospace testing, due to the offered power density and controllability [

12].

The force control problem with electrohydraulic actuators is challenging due to the many nonlinear effects, such as servo valve null lap characteristics, hysteresis, threshold, friction, and structural compliance, as well as the high load velocity requirements for several applications [

13]. General considerations when designing a force control system are to select proper components and to use linear analysis for the control design and nonlinear simulation for final tuning [

13,

14]. The model should include the hydraulic capacitance, servo valve characteristics, digital effects, mechanical compliance, and hydraulic supply system [

15]. Other considerations are that the servo valve performance has a direct influence on the force control performance, increasing the cylinder compliance by adding additional volumes reduces the force error, and an increased leakage between the force cylinder chambers improves the velocity disturbance rejection and high-frequency damping. PI controllers should be avoided due to limit cycle oscillations caused by static nonlinearities. It is suggested to implement a force set point and speed compensation instead.

Speed compensation through a feed-forward control link is widely proven to be a successful approach for improving the control performance during the dynamic testing of actuators [

16,

17,

18]. In [

19], a feed-forward link is developed together with a state-space controller and a Luenberger state observer to further improve the performance. The test rig for the M-346 jet trainer adopts feed-forward compensation since the speed is high, which negatively affects the tracking performance. The speed is measured and used to calculate the servo valve input. Proportional and derivative feedback are used together with an integrator in the control path, where adaptive gains are used to make the controller independent of operating conditions. Acceleration feedback is also used to improve low-frequency tracking and complex filters are required to cancel out noise in the speed signal. A by-pass valve improves the performance by reducing the gain in the servo valve null region and can be used for further tuning. An important aspect is also the structural stiffness; if too low, it can cause a delay in the measured force signal, resulting in an unstable system [

20].

Although various forms of the classical PID controller with a feed-forward link are widespread with good performance, there are several other techniques that improve performance. A nonlinear model predictive controller is applied to the force control of a modular Iron Bird and integrated with a flight simulator that generates the reference force [

21]. The tracking performance is improved compared to a PID controller but the computational burden does not allow for real-time implementation with low-cost hardware. A synchronisation controller to suppress motion disturbance that matches the dynamics of the actuator system is developed in [

22]. An adaptive update law handles parameter uncertainties using model reference adaptive control. Robust control techniques are applied to handle plant parameter uncertainties such as servo valve flow gain, natural frequency, and damping. An example is the quantitative feedback theory (QFT) controller [

23,

24]. This allows one to have fixed controller gains while still being robust, and has successfully been demonstrated on electrohydraulic force control systems. A nonlinear QFT controller is designed to overcome deficiencies in linearised models [

25]. Both a robust feedback controller and a speed compensator are designed using the same QFT framework to improve tracking performance. The controller is implemented in an HIL flight simulator. A pre-filter further shapes reference tracking. QFT control design is used in [

26], where also a flexible hose is used to increase the hydraulic compliance, which makes the system less difficult to control.

Friction in the load cylinder can deteriorate the tracking performance. A cylinder with hydrostatic bearings is a good option with very low internal friction [

16]. Control performance can also be improved by including a friction compensator in the control loop [

27,

28]. Hysteresis is another nonlinear phenomenon with negative impact and can cause limit cycle oscillations. The hysteresis can come from the electromagnetic hysteresis in the servo valve, and a multi-term lead controller was proposed to quench the cycles and improve the controller’s performance in [

29].

This work takes theory to practice by presenting practical considerations and the experience gained when developing, implementing, and integrating the air load simulation system for two different test objects, one servohydraulic actuator (SHA) and one electromechanical actuator (EMA), with different performance requirements. This work is a continuation from [

30]. An extensive model-based analysis is given to support the design process. Several considerations, including ones from the literature, are analysed and implemented to handle practical implications. The main approach is to adopt the method of a feed-forward controller based on the estimation of the cylinder speed while increasing the hydraulic capacitance of the air load system, and a proportional feedback loop. This allows one to increase the gain without affecting control loop stability, while the increased capacitance also reduces the effect from the test objects’ movement. The cylinder speed is estimated from a model where an optimisation routine is used to tune model parameters and different filters are used to handle imperfections in the integration.

This article starts by describing the Iron Bird and how the air load system interacts with the flight simulator and test objects in

Section 2. The design process, requirements definition, and installation are described in

Section 3. The nonlinear model is explained in

Section 4, while the linear modelling and analysis, control design, and simulation results are found in

Section 5. The implementation and practical considerations are analysed in

Section 6, together with results from testing in the Iron Bird. The conclusions are finally described in

Section 7.

6. Implementation and Results

This section presents the implementation of the air load simulation system controllers, the tuning process, and how practical implications are handled. The same controller structure as in the simulations is implemented. The basic setup is to use the same control gain, which is slightly tuned during testing, to find a good performance while maintaining a stable system. Mainly step response and sine wave inputs to the actuator are used to generate the force reference signal, which is proportional to the measured actuator position. Different gains on the force reference are used throughout the tuning process. The final step is to integrate the force controller with the flight simulator and evaluate its performance.

Results from the tuning process are excluded since it is straightforward. The subsequent subsections focus on the implementation of key functions to increase performance and the final results with the flight simulator.

6.1. Speed Estimation Optimisation

The air load system force controller’s performance is very dependent on the accuracy and performance of the feed-forward link. The key is to accurately estimate the DUT’s speed together with the inverse flow function of the servo valve. Since the DUT’s position is measured with external sensors, several techniques were investigated that involve filtering of the position signal and simplified representations of the DUT, similar to what is shown in

Figure 11. However, the most accurate result has shown to be through representing the DUT by physical modelling. An optimisation routine is applied to find the model parameters by comparing to tests of the actual DUT.

6.1.1. Servohydraulic Actuator

The SHA is based on the nonlinear flow–pressure relation and a second-order transfer function in order to include the dynamic characteristics of the actuator control loop. The model is implemented as shown in

Figure 16.

The transfer function

is defined as Equation (

10), with resonance

and damping coefficient

.

The flow–pressure relation

is defined according to Equation (

11). The coefficients define the flow–pressure relation, where

, the oil density is

kg/m

3,

A is the piston area, and the supply pressure

is set to 210 bar. The measured force

F is an input to the model, as well as the commanded position

. A saturation block limits the maximum and minimum valve position. A delay is placed at the command signal. This is used for tuning the model when implemented in the real-time system.

Optimisation is applied to find model parameters. There are several possible algorithms, e.g., using least-square methods or particle swarm optimisation [

33,

34], which have proven to give good results on DC motor model parameters. The optimisation in this work uses the ComplexRF routine, see [

35], to find the parameters

,

w,

, max valve position, and min valve position. The optimisation is set up to minimise the error between the measured and simulated actuator position. The test data are a series of step responses with different amplitudes in both directions in order to capture the static and dynamic characteristics. A sample of the test is shown in

Figure 17.

The speed estimation model is slightly modified when implemented in the real-time system. Instead of using the estimated position as the feedback signal, the actual measured position is used. This prevents any deviation between the estimated position and measured position erroneously estimating the speed.

6.1.2. Electro-Mechanical Actuator

The approach that was found to give satisfying results was to develop a DC-equivalent model of the EMA in combination with a model of the controller implemented in the EMA’s control unit. The model cannot be too computationally heavy as it would require too high a performance of the real-time system. Any high-frequency dynamics are therefore excluded. Equations (

12)–(16) describe the model, where

is the motor torque,

the torque constant,

the motor inertia,

B the viscous friction coefficient,

i the motor current,

the motor speed,

the motor angle,

x the actuator position,

the external load on the ball screw, and

L the ball-screw lead.

The model of the controller is a cascaded controller including the motor speed control loop and the actuator position control loop, according to

Figure 18. In reality, the EMA also has an inner-current controller that is neglected due to the very fast dynamics involved.

The optimisation routine is this set up for tuning the motor inertia, viscous friction coefficient, and torque constant. The measured data are derived from a combination of step commands and running the flight simulator since the force control performance is very sensitive to the accuracy of the speed estimation. The results from the optimisation are shown in

Figure 19.

6.1.3. Implementation of the Feed-Forward Link and Speed Estimation Models

When the feed-forward link is finally implemented in the real-time system, a gain scales the actual contribution. If the feed-forward link is perfectly matched, it would not be necessary to have the feedback signal, apart from the dynamic characteristics, which the feed-forward link does not account for. By applying a rather slow sine wave command signal at the DUT to avoid triggering any dynamics and applying a load proportional to the DUT’s position, the feed-forward link’s contribution is slightly tuned by varying the gain so that the feedback control signal is minimised. The feed-forward signal is also slightly biased to compensate for a small asymmetry in the servo valve. An example is seen in

Figure 20, where the feedback signal is close to zero. The noise from the signal is discussed below.

To demonstrate the effect of the accuracy of the speed estimation, the model of the EMA has been optimised with two different measurements. Since the model is merely a representation of the actual system, there will always be some discrepancy between the model and the actual test object. This turned out to be the case here.

Figure 21 illustrates when the speed estimation is optimised to a step response against when it is optimised to the flight simulator’s command inputs, which do not yield the exact same behaviour. The test case highlights a very low load for an EMA step command but shows that a very good force control performance is achievable when the feed-forward link is very accurate. For higher loads, but still roughly only 6% of the total load actuator’s capacity, the inaccuracy of the speed estimation has a much lower negative impact and can be considered negligible.

Another technique that has been adopted to tune the feed-forward link is by slightly delaying the command signal to the speed estimator model. This was applied for the SHA side by 5 ms, where the estimated speed was slightly ahead of the actual speed, causing the servo valve to open slightly too early. The delay resulted in an improved performance.

6.2. Filter Techniques

The increased cylinder volume size using external containers on the EMA side does not generate a homogeneous volume for each cylinder chamber. Ideally, a longer cylinder would have given the desired effect, but connecting the containers through the valve block and hoses gives a certain disconnection between the cylinder and containers, i.e., dynamically, there are two volumes connected through a resistance. This means that the high-frequency content of the control signal will see a small volume, making the system unstable since the control gain is adapted for a system with large volumes. This is seen from the measurement in

Figure 22, where, in figure a), the feedback signal is the measured force, which results in an unstable system. The implementation is shown in

Figure 23.

Two pressure sensors are installed in the vicinity of the containers. This signal’s characteristics are much more affected by the larger volume size, even for high-frequency content, than the force signal. By using the measured load pressure as feedback, the system becomes stable. The downside is that the load pressure is not exactly the same as the measured force due to internal friction inside the load cylinder. This is seen in

Figure 22b, where there is a discrepancy between the load pressure and force. To overcome this, a filter is used that mixes the high-frequency content from the load pressure signal and the low-frequency content from the force signal. This stabilises the controller since the large volumes affect the high-frequency spectrum by increasing the stability margins, as shown in the previous analysis, while the control accuracy is improved in the low-frequency spectrum since the controller follows the measured force.

To further improve the quality of the signal and remove unwanted noise, an extended Kalman filter (EKF) is implemented, which is the nonlinear version of the Kalman filter, since the hydraulic system is nonlinear in nature. It was realised during testing that the control performance is sensitive to the quality of the feedback signal. Noise was fed back through the controller, with an audible noise as a result. This noise could, e.g., come from the pump pulsation, which is at a relatively low frequency since the pump runs at a low speed when the required flow is low. The EKF effectively removed the noise to such an extent that the performance was improved.

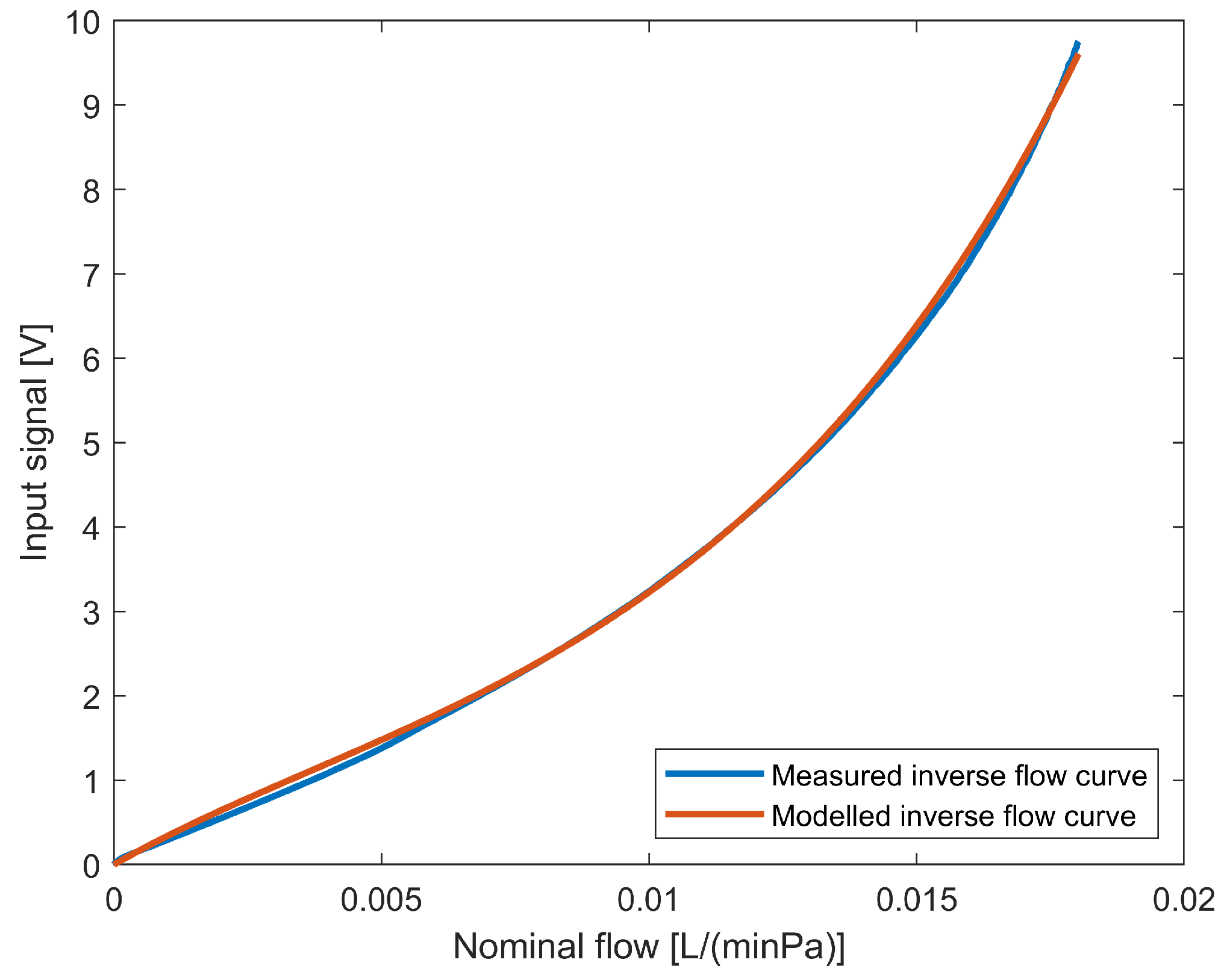

Figure 22b shows all the elements in the signal: the force, the load pressure, the high-pass filter content, the mix filter signal, and the extended Kalman filter signal. The implementation of the EKF follows the same principle as in

Section 4 but is somewhat reduced. The nonlinear set of system derivatives are defined by Equations (

17) and (20). The valve’s dynamic response of the spool position

is, here, assumed to be of first order, where

U is the input signal and

the response time. A nonlinear valve opening curve is assumed as defined by Equation (19).

The set of equations are transformed into discrete form. Defining

,

,

, and

yields the following set of Equations (

21) and (22), where

is the time step (0.1 ms in the real-time system) and

k is the index for the current step:

The extendend Kalman filter also requires the Jacobian,

J, to compute the next time step. It is defined according to Equations (

23)–(27).

The load system on the EMA side option B follows a different approach. The idea is to reduce the restriction between the cylinder chambers and the containers as much as possible by avoiding valve blocks with internal passages and hoses. The solution is seen in

Figure 6, where a new set of block adapters are manufactured that allows the containers to sit right below the cylinder in direct connection to the cylinder chamber ports. The internal passage is as large as the hydraulic connectors allow for. For this case, it is possible to use the measured force as a feedback signal together with the EKF without any mix filter. However, as it turns out, the mix filter improves the performance even for this case. The results are shown in

Figure 24, where the case without the mix filter, and the measured force as feedback, shows a larger overshoot. Interestingly, studying the load pressure shows how the static friction from the valve affects the system’s behaviour. The force felt by the test object and measured by the force sensor is the sum of the load pressure and the cylinder’s friction. However, the force controller acts on the load pressure by controlling the servo valve. Since the friction is part of the equation, the load pressure acts initially in the opposite direction to the reference force to compensate for the friction’s behaviour.

6.3. Model Validation and Performance Evaluation

The complete model is validated here against the step response command of the flight actuators. The validation gives confidence in the results of the air load system’s performance. The force control performance is also evaluated for sine sweep inputs from the flight actuator. The force reference is proportional to the measured flight actuator position. Besides model validation, the results also reveal the force control system’s performance under different conditions.

6.3.1. SHA Side

Figure 25 shows the validation of the force control model on the SHA side with both a light and a heavy load for a step command to the flight actuator. The simulated force and valve positions follow the measured values well, particularly for the heavy load, where friction, servo valve null-position tolerances, and flow disturbance have little effect on the control performance. The DUT controls the reference and reaches 63% of its final value within 90 ms for its maximum performance (for small amplitude inputs where no speed saturation is reached). However, it reaches 63% of its maximum velocity within 13 ms, which causes the flow disturbance. The force controller’s ability to track the reference with good performance indicates that the expected design performance is reached; see

Section 5.

The performance for a sine sweep input of the flight actuator is shown in

Figure 26 for two different frequency inputs at 0.2 Hz and 1 Hz.

6.3.2. EMA Side

The EMA side is validated in the same way.

Figure 27 shows the results of the test case when the feed-forward link is optimised for this specific case. The model represents the implemented system well for both the low- and high-load case. Again, it is the DUT dictating the reference response, which reaches its final value within 30 ms. The force controller’s ability to follow the reference well is an indication that the expected design performance is reached.

The performance for a sine sweep input of the flight actuator is shown in

Figure 28 for two different frequency inputs of 0.2 Hz and 1 Hz.

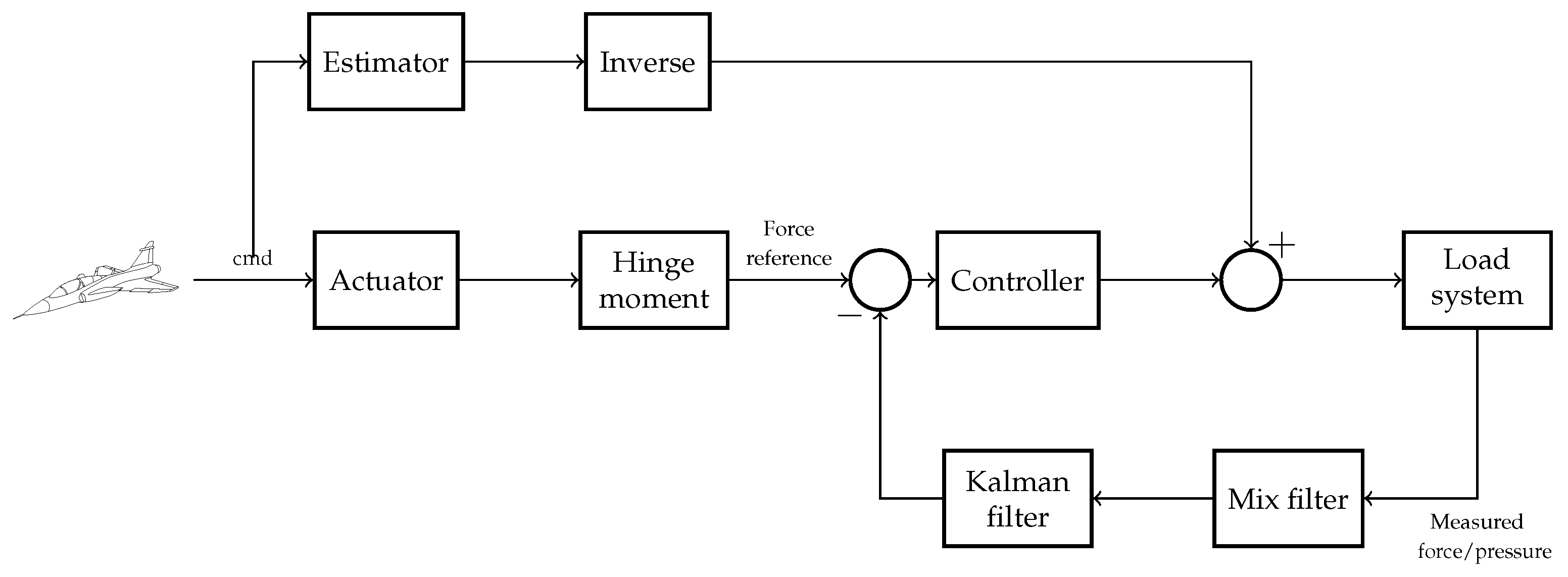

6.4. Integration Results

The final integration with the flight simulator and implementation of the control structure for the EMA are depicted in

Figure 29. The only difference for the SHA side is that the load pressure is directly used as feedback without any filters since the load cell signals were too noisy to be used in the control loop. Based on pre-configured flight manoeuvres, the flight simulator calculates the control surface positions, which are converted into commanded positions for the physical flight actuators. The measured flight actuator positions are fed to the hinge moment calculation, where it is converted to a flight actuator load and acts as the reference to the force controller. The hinge moment is scaled to the physical flight actuator’s max load. A maximum hinge moment,

, is assumed for each control surface to scale the load according to Equation (

28), where

l is the hinge arm length,

is the maximum allowed actuator load, and

R is the ratio between the flight actuator and load actuator.

Testing the air load system together with the flight simulator is carried out by simulating a roll and pitch manoeuvre at an altitude of 5000 m and at Mach 0.7. The performance of the SHA and EMA side is shown in

Figure 30. Even if the loads are low, at only 10% of the stall load, the air load system has no problem following the reference signal. The force reference is different for both sides due to the different scaling.

6.5. Possible Improvements

There are a few points to mention where further improvements might be possible. One is the servo valve’s response. Even if a high response valve has been used, there are faster valves on the market. A faster valve would shift the system’s crossover frequency higher on the frequency scale, effectively increasing stability and the possibility of increasing the controller gain.

It was shown how an increased cylinder volume is an effective means to reduce the impact from the flow disturbance. How the increased volume is installed also affects the solution’s effectiveness. The best solution would be to increase the cylinder chambers or increase the cylinder’s port size so that two external containers can be installed without any disruption in the flow.

The cylinder’s friction is an objective for improvement by either using a compensation link or hydrostatic bearings, as mentioned in the literature. A possible solution might be to remove the internal sealing completely, if possible, at the cost of increased pump flow. For testing, this might be an acceptable cost.

By introducing the load pressure in the control loop, any flow pulsations from the supply system have a negative impact. Flow pulsations should be reduced as much as possible, or sould be shifted to a higher-frequency spectrum. Since the supply system in the test rig is driven by an electric motor, the pump speed is typically low since the needed flow is low when running only one actuator. The supply system is sized for running all actuators in the rig simultaneously.

Finally, as mentioned in the literature, a by-pass valve increases the damping and reduces the system gain at the servo valve null region. This could further shape the tracking response, but an integral in the control loop or a compensation link in the feed-forward path would be necessary. The latter could be tuned in the same way as explained in this work.