Dissimilar Resistance Welding of NiTi Microwires for High-Performance SMA Bundle Actuators

Abstract

1. Introduction

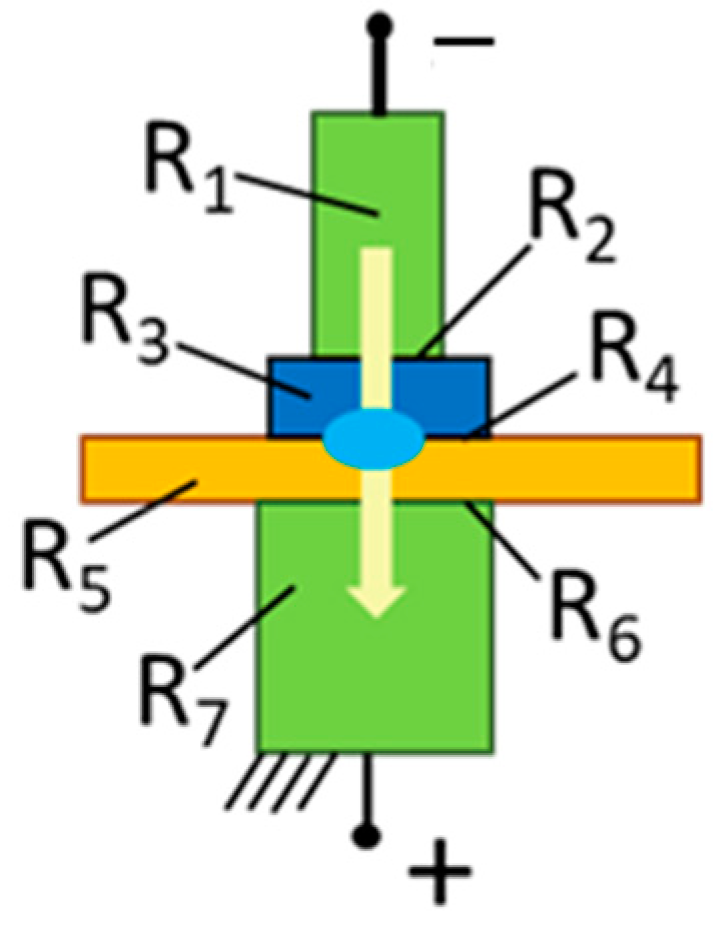

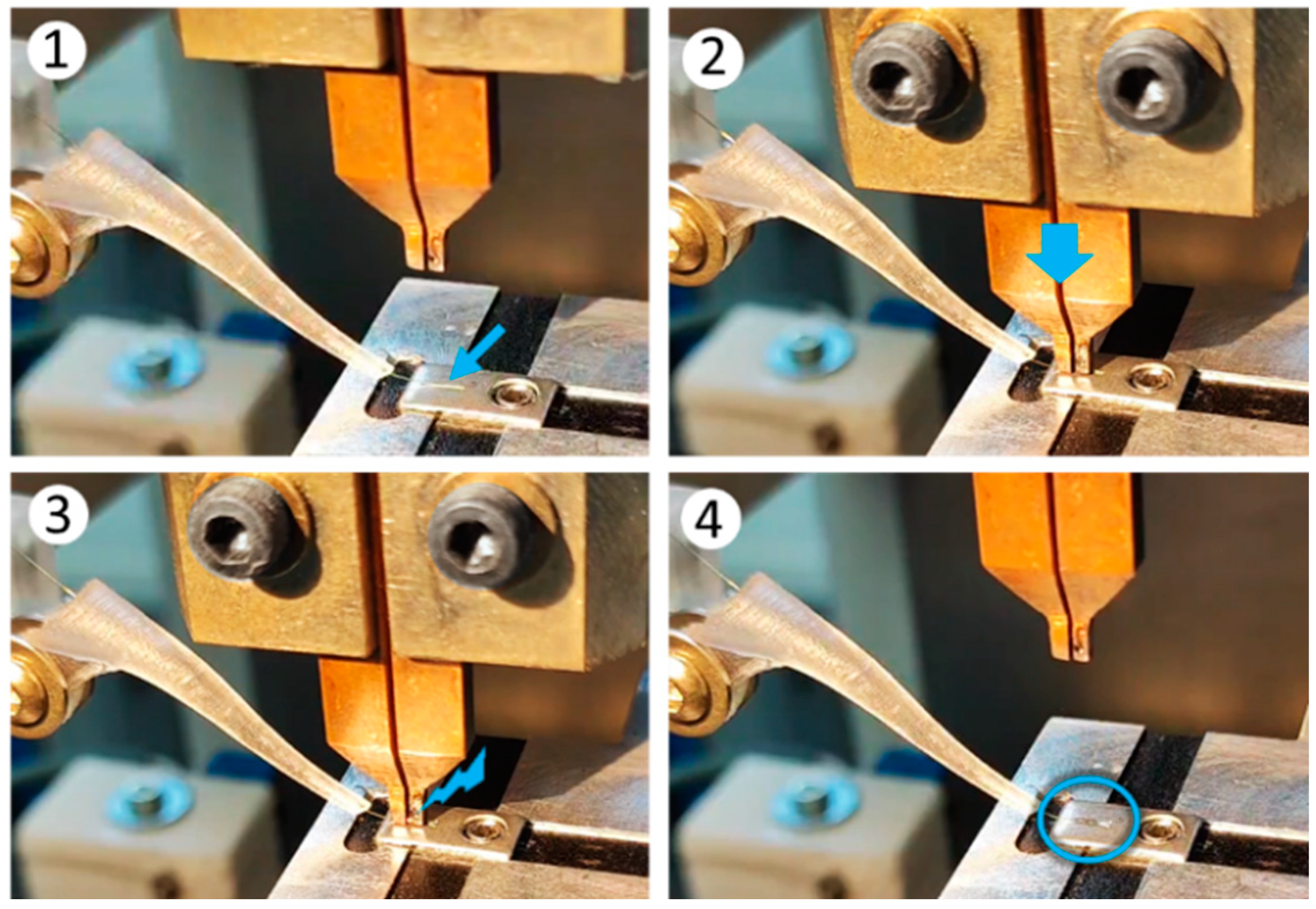

2. Materials and Methods

3. Results and Discussion

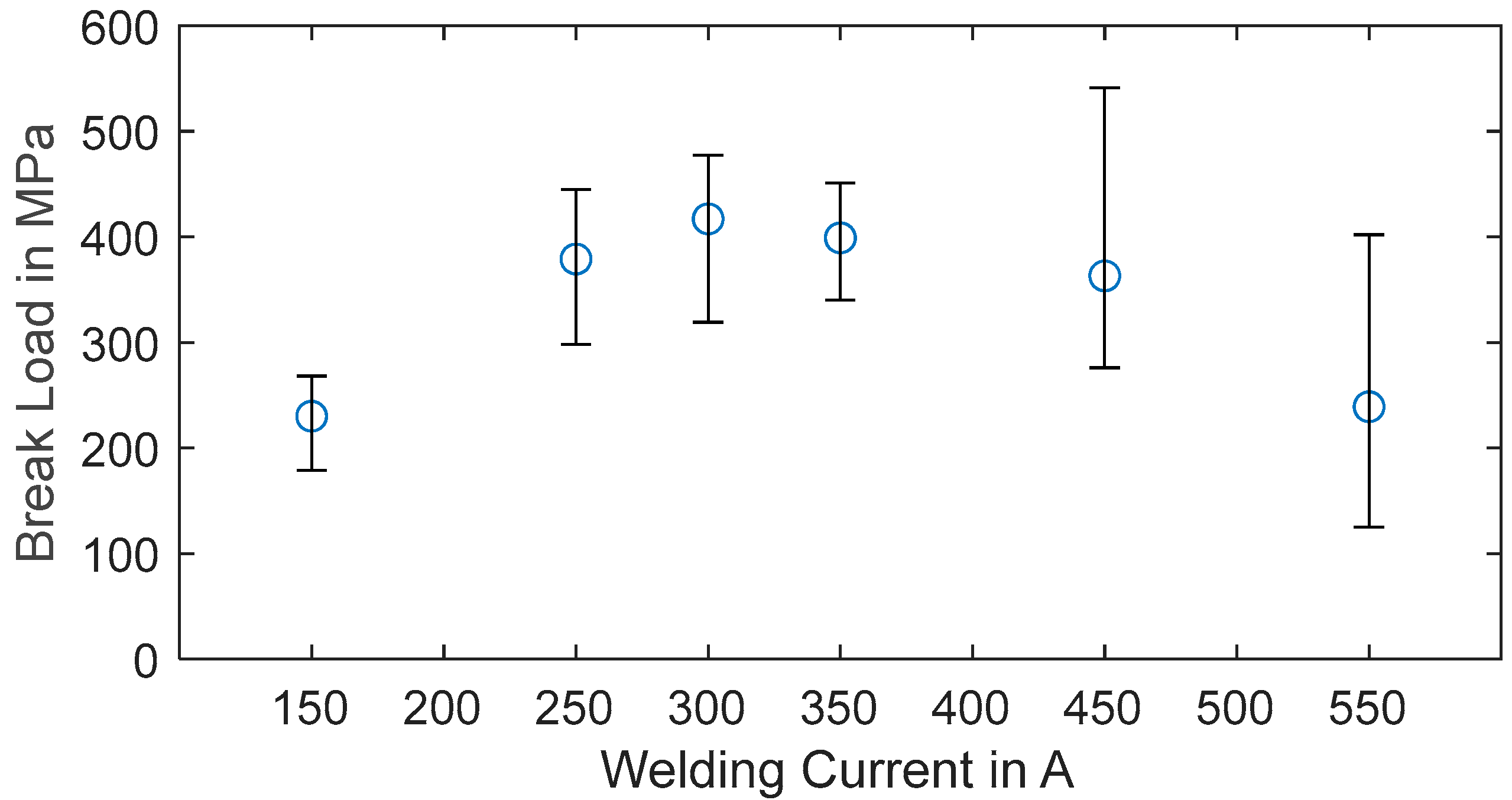

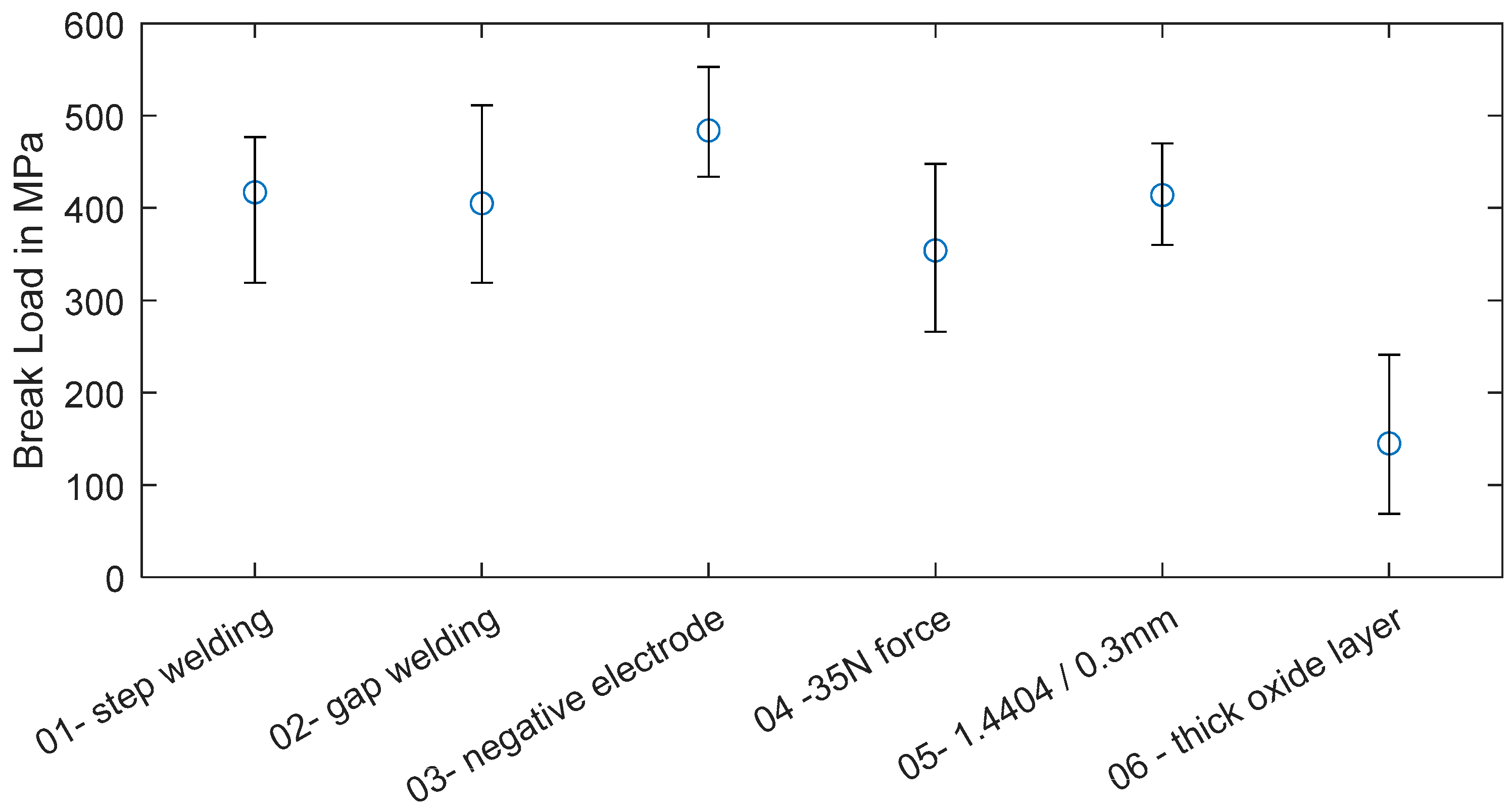

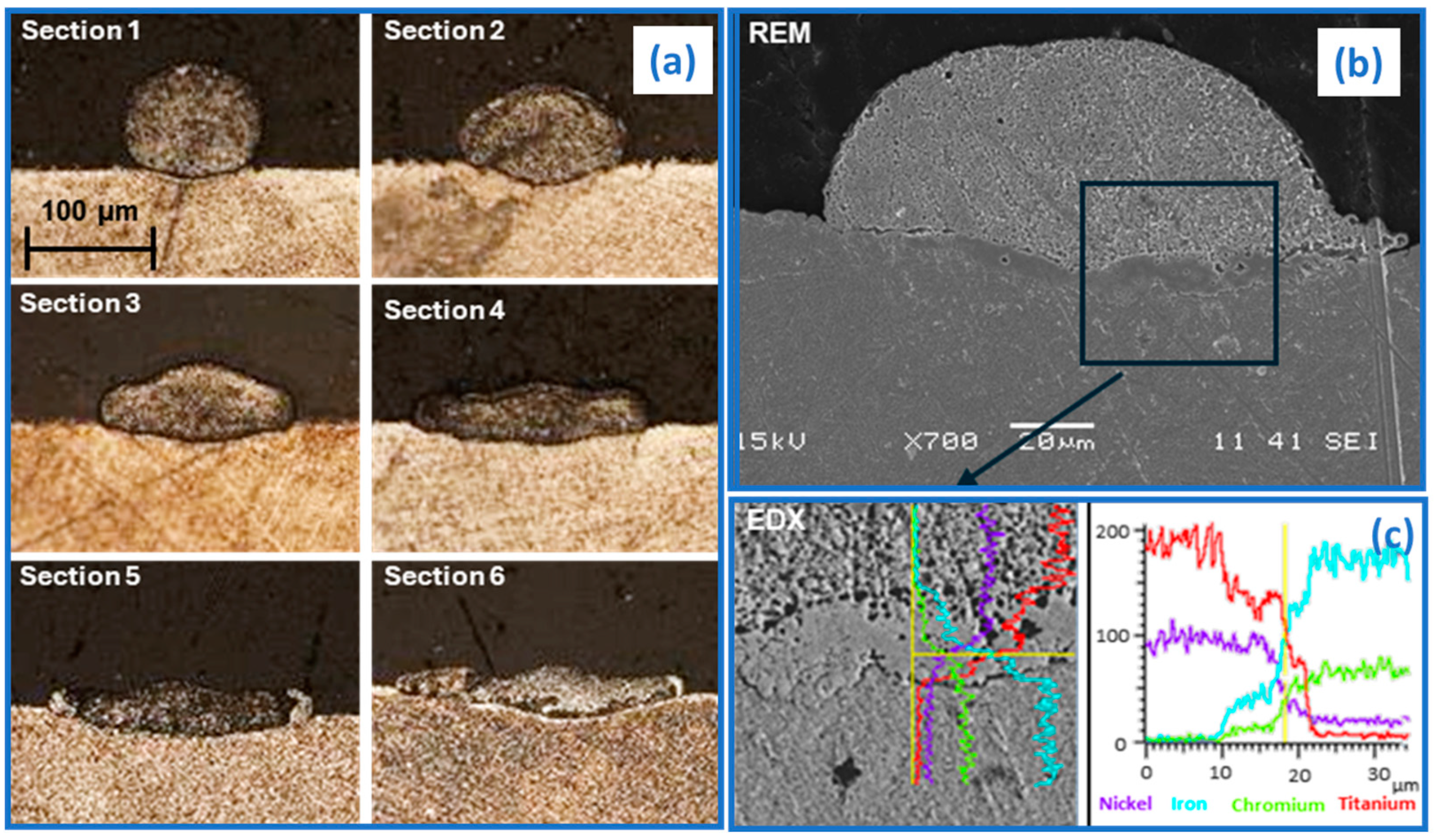

3.1. Parameter Study: Evaluation and Discussion

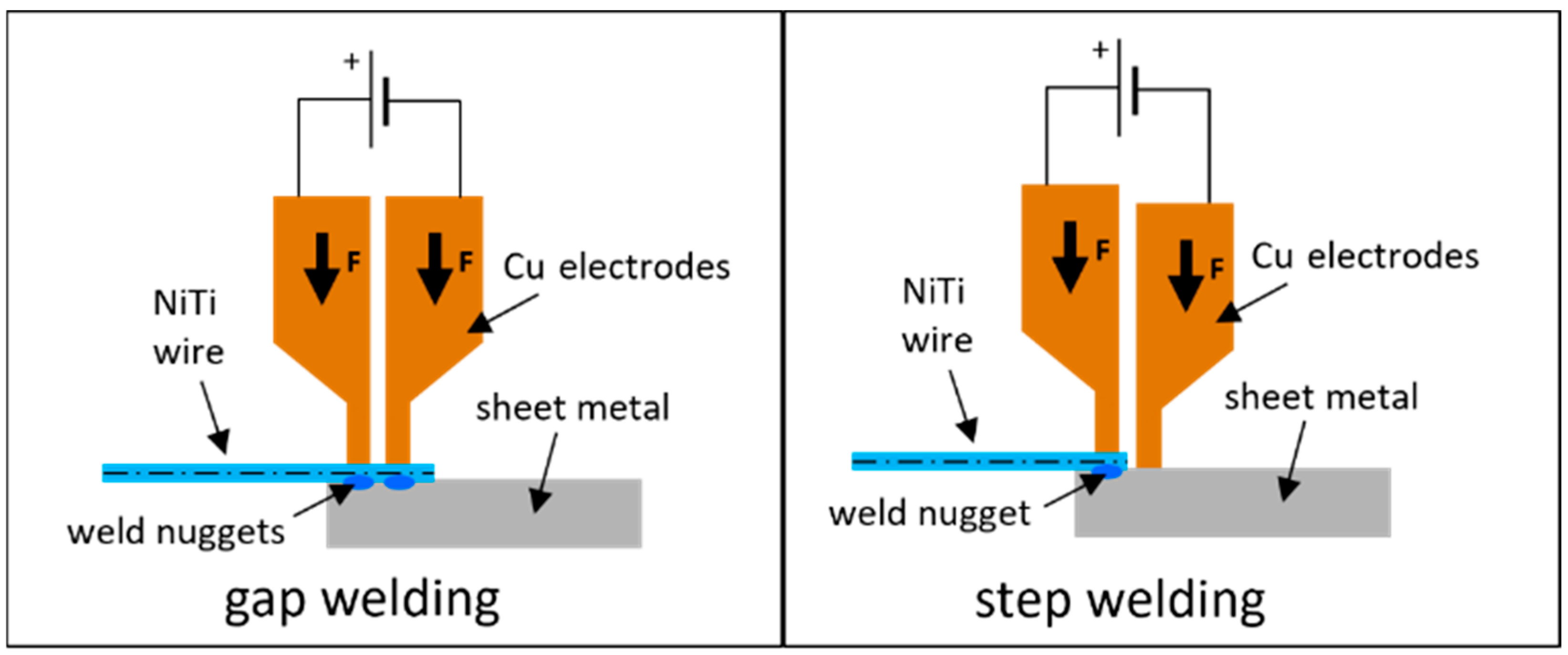

- Gap welding;

- Welding with a negative electrode, step welding;

- Pressure force reduced to 35N, step welding;

- Sample 1.4404 with 0.3 mm thickness, step welding;

- Thicker oxide layer on NiTi wire, step welding.

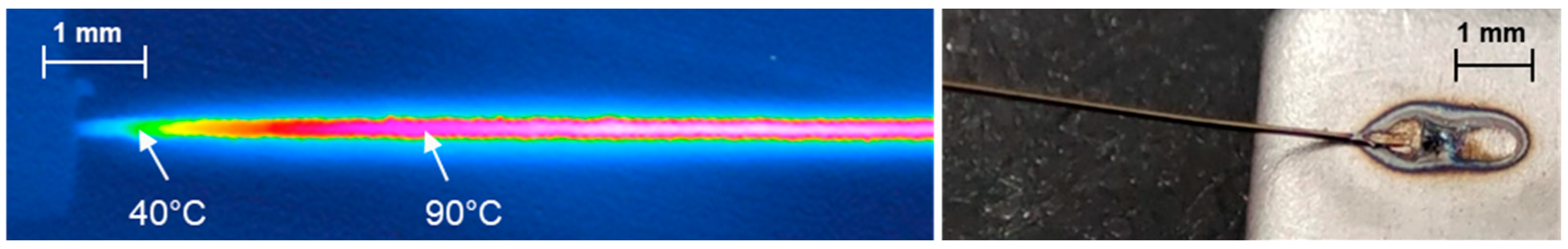

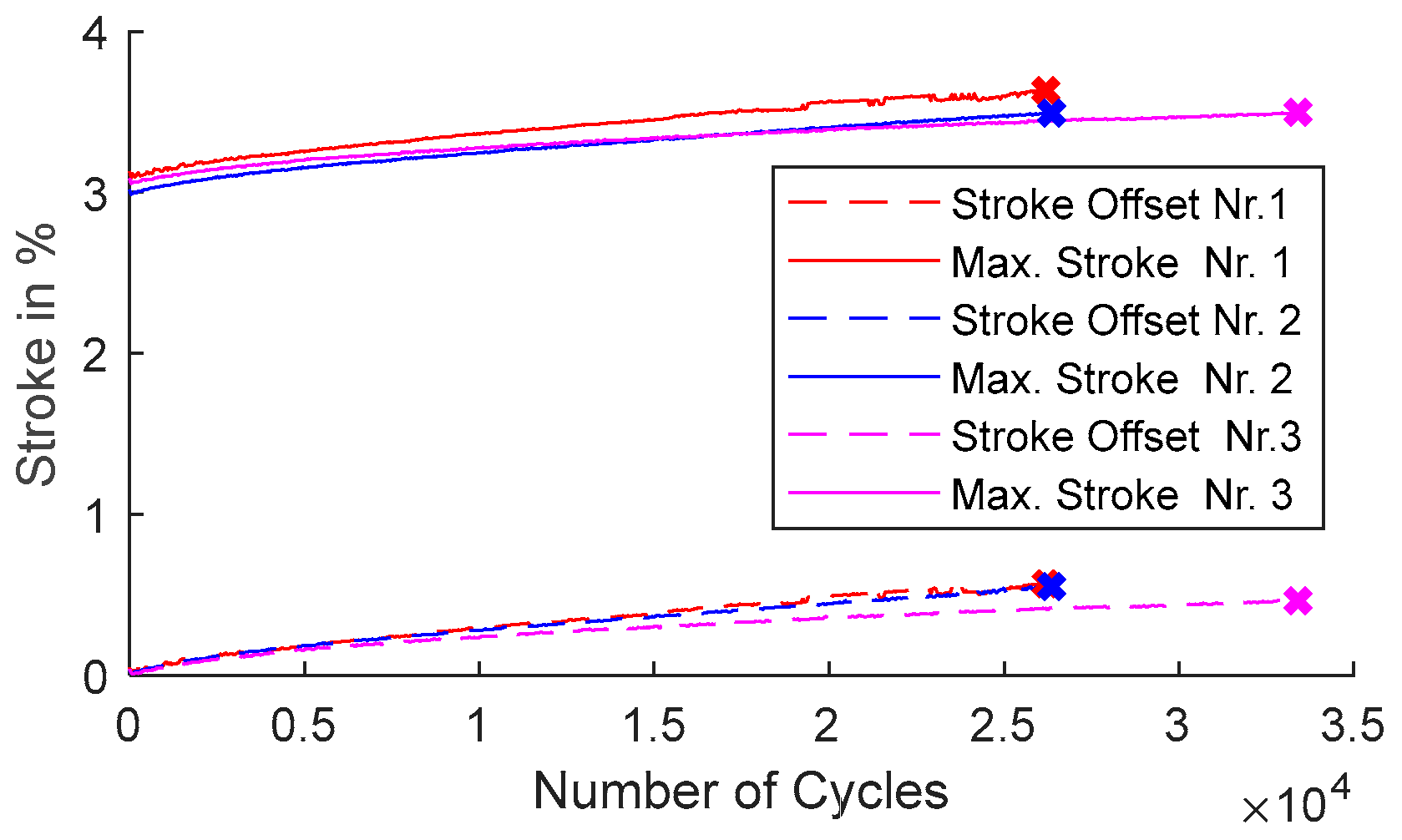

3.2. Welded SMA Bundle Actuators

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Janocha, H.; Bonertz, T.; Pappert, G. Unkonventionelle Aktoren: Eine Einführung; Oldenbourg Wissenschaftsverlag: München, Germany, 2013. [Google Scholar]

- Prechtl, J.; Seelecke, S.; Motzki, P.; Rizzello, G. Self-Sensing Control of Antagonistic SMA Actuators Based on Resistance-Displacement Hysteresis Compensation. In Proceedings of the ASME 2020 Conference on Smart Materials, Adaptive Structures and Intelligent Systems, SMASIS, Online, 15 September 2020. [Google Scholar] [CrossRef]

- Kirsch, S.-M.; Welsch, F.; Bevilacqua, D.; Naso, D.; Seelecke, S.; Rizzello, G.; Motzki, P. SMA Antagonistic-Micro-Wire Bundle: First Measurement Results. In Proceedings of the ASME 2020 Conference on Smart Materials, Adaptive Structures and Intelligent Systems, Online, 15 September 2020. [Google Scholar] [CrossRef]

- Williams, E.; Elahinia, M.H. An Automotive SMA Mirror Actuator: Modeling, Design, and Experimental Evaluation. J. Intell. Mater. Syst. Struct. 2008, 19, 1425–1434. [Google Scholar] [CrossRef]

- Britz, R.; Motzki, P. Analysis and evaluation of bundled SMA actuator wires. Sens. Actuators A Phys. 2022, 333, 113233. [Google Scholar] [CrossRef]

- Simone, F.; Rizzello, G.; Seelecke, S.; Motzki, P. A Soft Five-Fingered Hand Actuated by Shape Memory Alloy Wires: Design, Manufacturing, and Evaluation. Front. Robot. AI 2020, 7, 608841. [Google Scholar] [CrossRef]

- Buehler, W.J.; Gilfrich, J.V.; Wiley, R.C. Effect of Low-Temperature Phase Changes on the Mechanical Properties of Alloys near Composition TiNi. J. Appl. Phys. 1963, 34, 1475–1477. [Google Scholar] [CrossRef]

- Buehler, W.J.; Wang, F.E. A summary of recent research on the nitinol alloys and their potential application in ocean engineering. Ocean Eng. 1968, 1, 105–120. [Google Scholar] [CrossRef]

- Duerig, T.; Pelton, A.; Stöckel, D. An overview of nitinol medical applications. Mater. Sci. Eng. A 1999, 273–275, 149–160. [Google Scholar] [CrossRef]

- Adler, P.; Yu, W.; Pelton, A.; Zadno, R.; Duerig, T.; Barresi, R. On the tensile and torsional properties of pseudoelastic NiTi. Scr. Met. et Mater. 1990, 24, 943–947. [Google Scholar] [CrossRef]

- Lagoudas, D.C. Shape Memory Alloys; Springer: Boston, MA, USA, 2008; Volume 1. [Google Scholar] [CrossRef]

- Wang, S.; Shi, Y.; Li, Y.; Lin, H.; Fan, K.; Teng, X. Solid-state refrigeration of shape memory alloy-based elastocaloric materials: A review focusing on preparation methods, properties and development. Renew. Sustain. Energy Rev. 2023, 187, 113762. [Google Scholar] [CrossRef]

- Hou, H.; Simsek, E.; Ma, T.; Johnson, N.S.; Qian, S.; Cissé, C.; Stasak, D.; Al Hasan, N.; Zhou, L.; Hwang, Y.; et al. Fatigue-resistant high-performance elastocaloric materials made by additive manufacturing. Science 2019, 366, 1116–1121. [Google Scholar] [CrossRef]

- Schmidt, M.; Schütze, A.; Seelecke, S. Scientific test setup for investigation of shape memory alloy based elastocaloric cooling processes. Int. J. Refrig. 2015, 54, 88–97. [Google Scholar] [CrossRef]

- Bruederlin, F.; Ossmer, H.; Wendler, F.; Miyazaki, S.; Kohl, M. SMA foil-based elastocaloric cooling: From material behavior to device engineering. J. Phys. D: Appl. Phys. 2017, 50, 424003. [Google Scholar] [CrossRef]

- Curtis, S.M.; Gugat, J.L.; Bumke, L.; Dengiz, D.; Seigner, L.; Schmadel, D.; Lazarus, N.S.; Quandt, E. Thin-Film Superelastic Alloys for Stretchable Electronics. Shape Mem. Superelasticity 2023, 9, 35–49. [Google Scholar] [CrossRef]

- Dengiz, D.; Goldbeck, H.; Curtis, S.M.; Bumke, L.; Jetter, J.; Quandt, E. Shape Memory Alloy Thin Film Auxetic Structures. Adv. Mater. Technol. 2023, 8, 2201991. [Google Scholar] [CrossRef]

- Oliveira, J.; Miranda, R.; Fernandes, F.B. Welding and Joining of NiTi Shape Memory Alloys: A Review. Prog. Mater. Sci. 2017, 88, 412–466. [Google Scholar] [CrossRef]

- Kannan, T.D.B.; Ramesh, T.; Sathiya, P. A Review of Similar and Dissimilar Micro-joining of Nitinol. JOM 2016, 68, 1227–1245. [Google Scholar] [CrossRef]

- Gugel, H.; Schuermann, A.; Theisen, W. Laser welding of NiTi wires. Mater. Sci. Eng. A 2007, 481–482, 668–671. [Google Scholar] [CrossRef]

- Gugel, H.; Theisen, W. Laserstrahlschweißen von Mikrodrähten aus Nickel-Titan-Formgedächtnislegierungen und austenitischem Stahl. Mater. Werkst. 2007, 38, 489–493. [Google Scholar] [CrossRef]

- Zeng, Z.; Panton, B.; Oliveira, J.P.; Han, A.; Zhou, Y.N. Dissimilar laser welding of NiTi shape memory alloy and copper. Smart Mater. Struct. 2015, 24, 125036. [Google Scholar] [CrossRef]

- Rodrigues, L.F.A.; Amorim, F.A.; Grassi, E.N.D.; dos Santos, P.L.L.; de Araújo, C.J. TIG spot welding applied to NiTi shape memory wires optimized by factorial design. Int. J. Adv. Manuf. Technol. 2022, 121, 7749–7762. [Google Scholar] [CrossRef]

- Li, J.; Panton, B.; Mao, Y.; Vivek, A.; Daehn, G. High strength impact welding of NiTi and stainless steel wires. Smart Mater. Struct. 2020, 29, 105023. [Google Scholar] [CrossRef]

- Barcellona, A.; Fratini, L.; Palmeri, D.; Maletta, C.; Brandizzi, M. Friction stir processing of Niti shape memory alloy: Microstructural characterization. Int. J. Mater. Form. 2010, 3, 1047–1050. [Google Scholar] [CrossRef]

- Tam, B.; Pequegnat, A.; Khan, M.I.; Zhou, Y. Resistance Microwelding of Ti-55.8 wt pct Ni Nitinol Wires and the Effects of Pseudoelasticity. Met. Mater. Trans. A 2012, 43, 2969–2978. [Google Scholar] [CrossRef]

- Shamsolhodaei, A.; GhateiKalashami, A.; Safdel, A.; Midawi, A.; Elbestawi, M.; Peng, P.; Zhou, Y. Resistance spot welding of NiTi shape memory alloy sheets: Microstructural evolution and mechanical properties. J. Manuf. Process. 2022, 81, 467–475. [Google Scholar] [CrossRef]

- Delobelle, V.; Delobelle, P.; Liu, Y.; Favier, D.; Louche, H. Resistance welding of NiTi shape memory alloy tubes. J. Mech. Work. Technol. 2013, 213, 1139–1145. [Google Scholar] [CrossRef]

- Zhang, K.; Shamsolhodaei, A.; Ghatei-Kalashami, A.; Oliveira, J.; Zang, C.; Schell, N.; Li, J.; Midawi, A.; Lopes, J.; Yan, J.; et al. Revealing microstructural evolution and mechanical properties of resistance spot welded NiTi-stainless steel with Ni or Nb interlayer. J. Mater. Sci. Technol. 2024, 180, 160–173. [Google Scholar] [CrossRef]

- Scholtes, D.; Zaeh, R.; Schmidt, M.; Motzki, P.; Faupel, B.; Seelecke, S. Resistance Welding of NiTi Actuator Wires. In Proceedings of the ACTUATOR 2018: 16th International Conference on New Actuators, Bremen, Germany, 25–27 June 2018; pp. 500–504. [Google Scholar]

- Mosley, M.J.; Mavroidis, C. Design and Control of a Shape Memory Alloy Wire Bundle Actuator. In Proceedings of the ASME 2000 International Design Engineering Technical Conferences and Computers and Information in Engineering Conference, Volume 7B: 26th Biennial Mechanisms and Robotics Conference, Baltimore, MD, USA, 10–13 September 2000; American Society of Mechanical Engineers: New York, NY, USA, 2000; pp. 973–979. [Google Scholar] [CrossRef]

- Kratz, R.; Stelzer, M.; von Stryk, O. Macroscopic Sma Wire Bundle Actuator/Sensor System: Design, Measurement, Control Approach. IFAC Proc. Vol. 2006, 39, 1054–1058. [Google Scholar] [CrossRef]

- Britz, R.; Welsch, F.; Kirsch, S.M.; Simone, F.; Schmidt, M.; Motzki, P.; Seelecke, S. SMA Wire Bundles—Mechanical and Electrical Concepts. In Proceedings of the ACTUATOR 2018: 16th International Conference on New Actuators, Bremen, Germany, 25–27 June 2018; pp. 1–4. [Google Scholar]

- Pfeifer, M. Manufacturing Process Considerations. In Materials Enabled Designs; Elsevier: Amsterdam, The Netherlands, 2009; pp. 115–160. [Google Scholar] [CrossRef]

- SAES Group. SmartFlex Springs and Wires. Available online: https://www.saesgetters.com/wp-content/uploads/sites/8/2024/01/SmartFlex-wires.pdf (accessed on 26 September 2024).

- Amada Miyachi America. Fundamentals of Small Parts Resistance Welding. Available online: https://www.amadaweldtech.eu/sites/default/files/images/knowlegdebase/AMYA Fundamentals Resistance Welding 03-16.pdf (accessed on 8 March 2024).

- Deutsches Kupferinstitut. CuSn6. Available online: https://kupfer.de/wp-content/uploads/2019/11/CuSn6-1.pdf (accessed on 8 March 2024).

- Deutsches Kupferinstitut. CuZn30. Available online: https://kupfer.de/wp-content/uploads/2019/11/CuZn30-1.pdf (accessed on 8 March 2024).

- Jury, A.; Balandraud, X.; Heller, L. Thermal Conductivity and Specific Heat Capacity of Austenite and Stress-Induced Martensite in Superelastic NiTi at Ambient Temperature. Int. J. Thermophys. 2023, 44, 162. [Google Scholar] [CrossRef]

- Scholtes, D.; Seelecke, S.; Motzki, P. Electro-thermo-mechanical characterization of shape memory alloy wires for actuator and sensor applications—Part 1: The effects of training. Eng. Rep. 2024, e12867. [Google Scholar] [CrossRef]

- Eagar, T.W. Resistance Welding: A Fast, Inexpensive and Deceptively Simple Process. In Proceedings of the 3rd International Conference on Trends in Welding Research, Gatlinburg, TN, USA, 1–5 June 1992; David, S.A., Vitek, J.M., Eds.; ASM International: Gatlinburg, TN, USA, 1992; pp. 347–351. [Google Scholar]

- Deng, L.; Li, Y.; Cai, W.; Haselhuhn, A.S.; Carlson, B.E. Simulating Thermoelectric Effect and Its Impact on Asymmetric Weld Nugget Growth in Aluminum Resistance Spot Welding. J. Manuf. Sci. Eng. 2020, 142, 091001. [Google Scholar] [CrossRef]

- Mayer, J.; Molitor, P.; Goergen, Y.; Motzki, P. Design of a Modular Lifespan Test Bench for Shape Memory Alloy Wires. In Proceedings of the ASME 2022 Conference on Smart Materials, Adaptive Structures and Intelligent Systems, Dearborn, MI, USA, 12–14 September 2022. [Google Scholar] [CrossRef]

- Saes Getters. SmartFlex® Wire. Available online: www.saesgroup.com (accessed on 17 April 2024).

- Scholtes, D.; Seelecke, S.; Rizzello, G.; Motzki, P. Design of a Compliant Industrial Gripper driven by a Bistable Shape Memory Alloy Actuator. In Proceedings of the ASME 2020 Conference on Smart Materials, Adaptive Structures and Intelligent Systems, SMASIS, Online, 15 September 2020. [Google Scholar] [CrossRef]

- Scholtes, D.; Seelecke, S.; Motzki, P. Development of a Bistable SMA Actuated Industrial Gripper Based on a Compliant Design. In Proceedings of the ACTUATOR—International Conference and Exhibition on New Actuator Systems and Applications, Online, 17–19 February 2021; pp. 181–184. [Google Scholar]

- Scholtes, D.; Seelecke, S.; Motzki, P. Design of a lightweight SMA driven parallel gripper for collaborative robots. In Proceedings of the SPIE Smart Structures and Materials + Nondestructive Evaluation and Health Monitoring, Active and Passive Smart Structures and Integrated Systems XVII, 124830K, Long Beach, CA, USA, 12–16 March 2023; SPIE: Long Beach, CA, USA, 2023. [Google Scholar] [CrossRef]

- CASMART 4th Design Challenge. Available online: https://www.casmart.org/home/student-design-challenges/casmart-4th-design-challenge (accessed on 17 April 2024).

- Pirritano, C.; Gorges, T.; Britz, R.; Scholtes, D.; Zimmer, L.; Preetz, J.; Goergen, Y.; Motzki, P. Fully Integrated Rotary Motor Based on Antagonistic Shape Memory Alloy Wire Bundles. In Proceedings of the ASME 2023 Conference on Smart Materials, Adaptive Structures and Intelligent Systems, SMASIS, Austin, TX, USA, 11–13 September 2023. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Scholtes, D.; Zäh, R.-K.; Faupel, B.; Seelecke, S.; Motzki, P. Dissimilar Resistance Welding of NiTi Microwires for High-Performance SMA Bundle Actuators. Actuators 2024, 13, 400. https://doi.org/10.3390/act13100400

Scholtes D, Zäh R-K, Faupel B, Seelecke S, Motzki P. Dissimilar Resistance Welding of NiTi Microwires for High-Performance SMA Bundle Actuators. Actuators. 2024; 13(10):400. https://doi.org/10.3390/act13100400

Chicago/Turabian StyleScholtes, Dominik, Ralf-Kilian Zäh, Benedikt Faupel, Stefan Seelecke, and Paul Motzki. 2024. "Dissimilar Resistance Welding of NiTi Microwires for High-Performance SMA Bundle Actuators" Actuators 13, no. 10: 400. https://doi.org/10.3390/act13100400

APA StyleScholtes, D., Zäh, R.-K., Faupel, B., Seelecke, S., & Motzki, P. (2024). Dissimilar Resistance Welding of NiTi Microwires for High-Performance SMA Bundle Actuators. Actuators, 13(10), 400. https://doi.org/10.3390/act13100400