Comparative Study of IGBT and SiC MOSFET Three-Phase Inverter: Impact of Parasitic Capacitance on the Output Voltage Distortion

Abstract

:1. Introduction

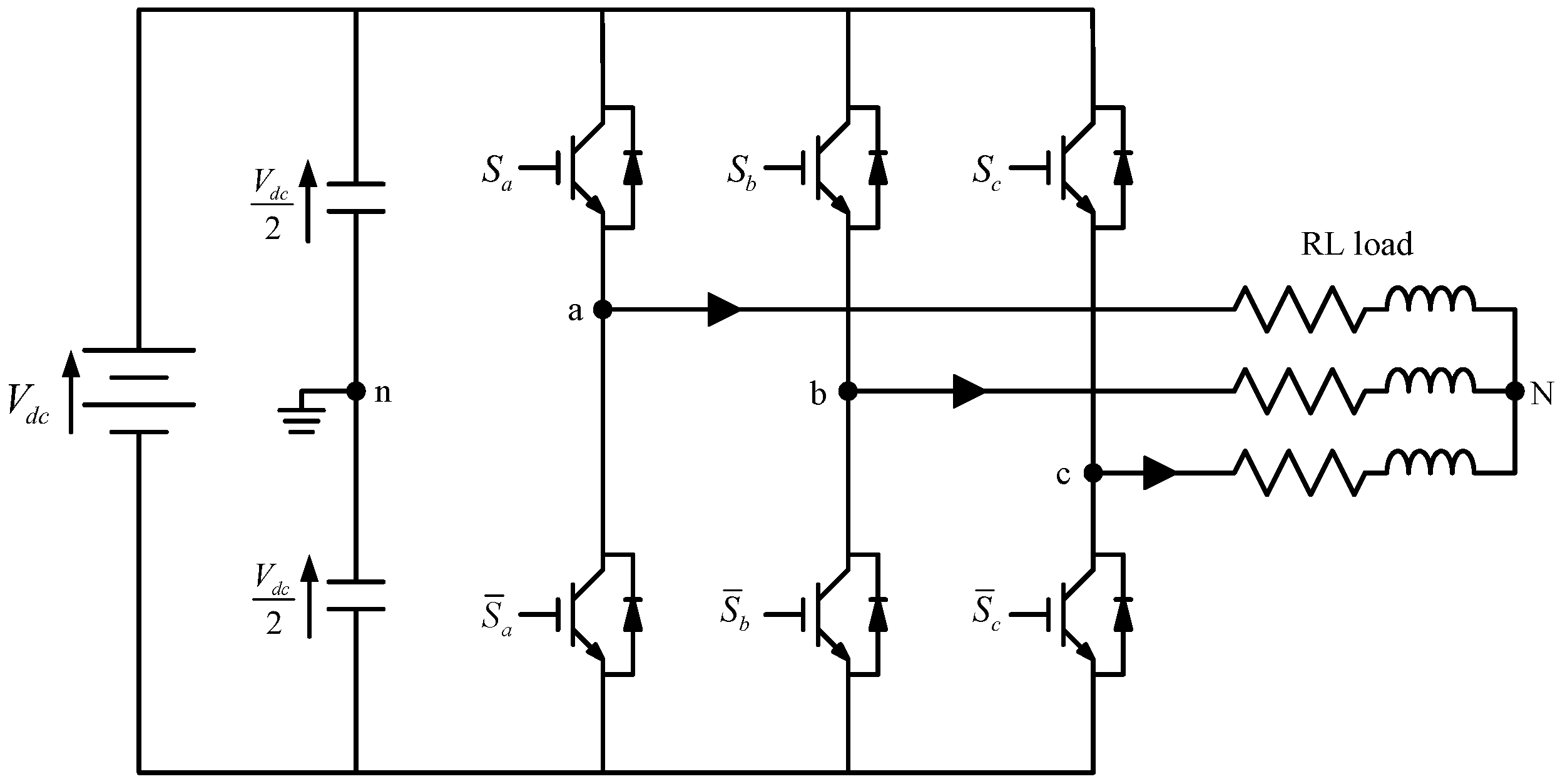

2. Analytical Modeling of a Three-Phase Voltage Source Inverter and Imperfections

2.1. Three-Phase Voltage Source Inverter Modeling

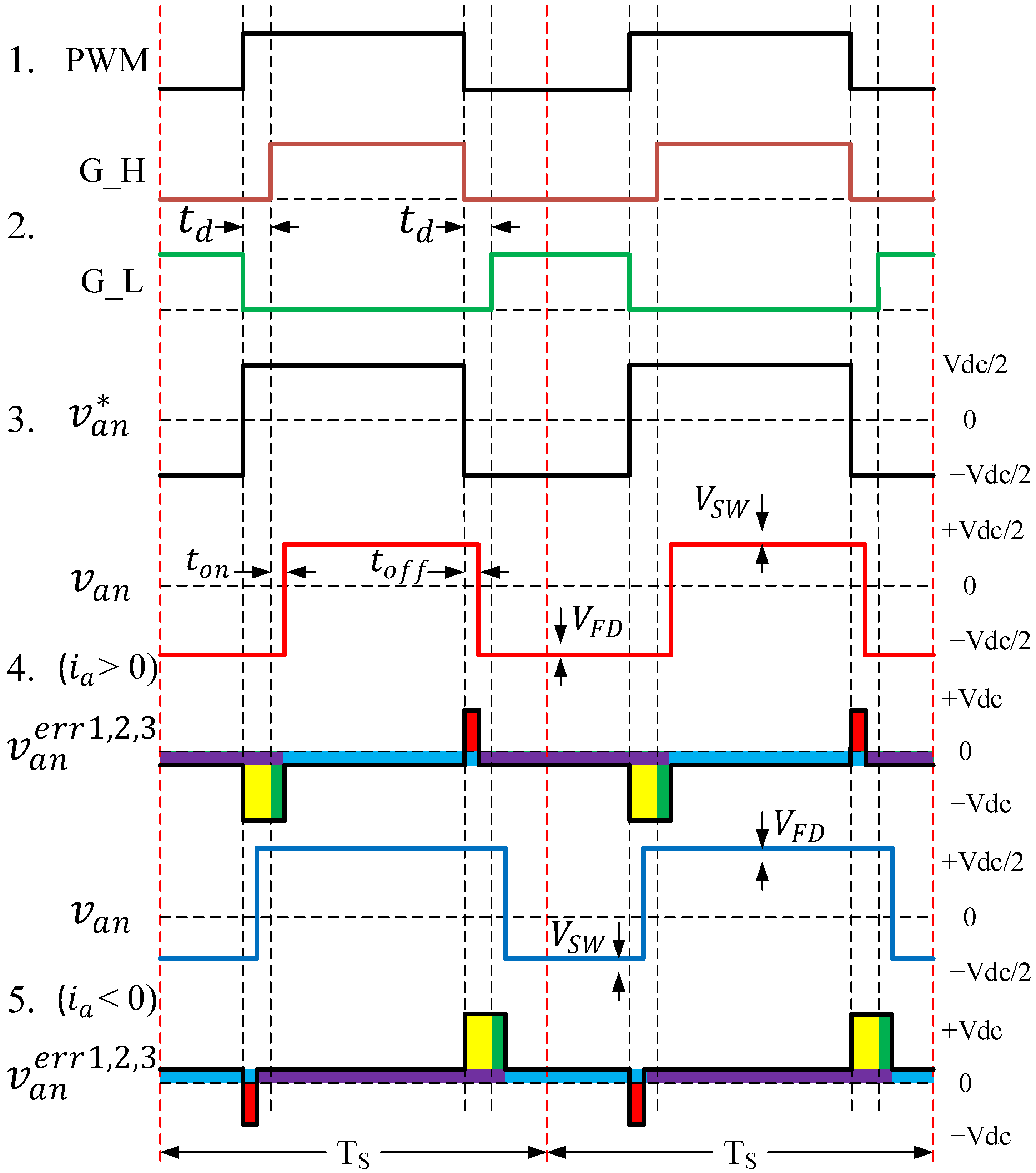

2.2. Analytical Modeling of Imperfections

- is the average voltage drop over one modulation period (PWM) due to dead times;

- is the average voltage drop due to component switching times;

- is the average voltage drop due to voltage drops across power switches;

- is the average voltage drop caused by the effects of parasitic capacitances.

2.2.1. Dead Time Effect

2.2.2. Rising Time and Falling Time Effect

2.2.3. Consideration of Voltage Drops in Components

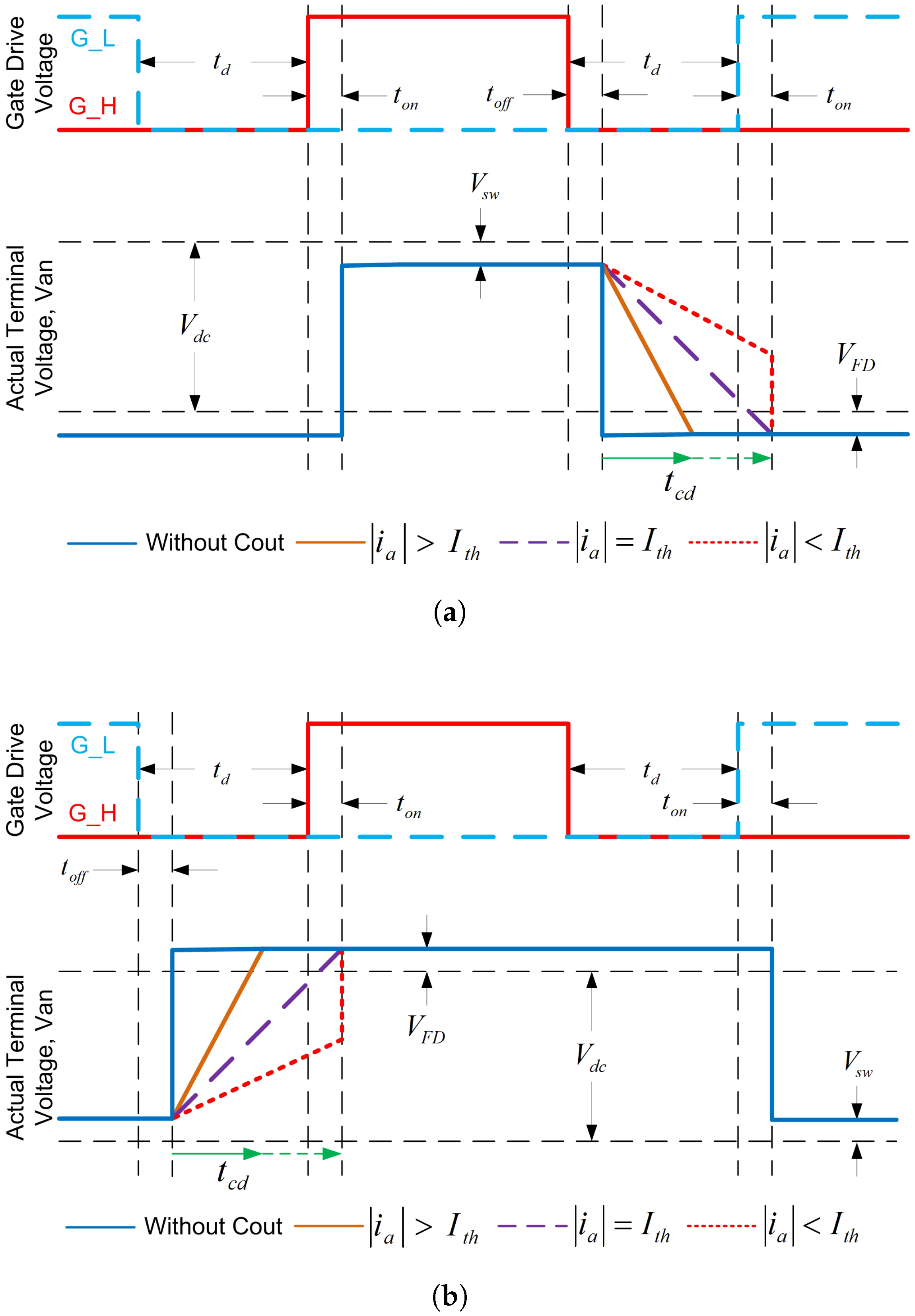

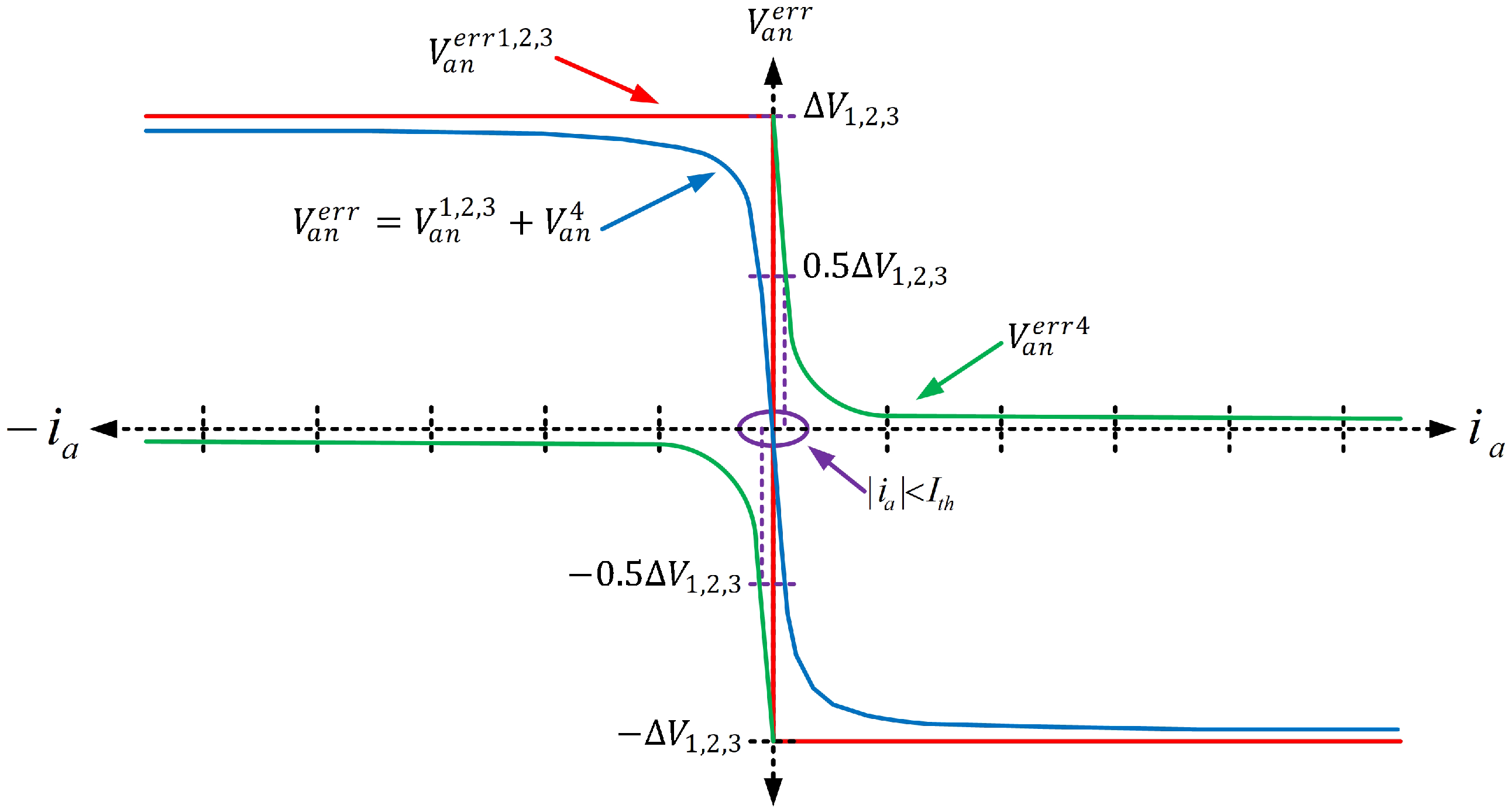

2.3. Effects of Parasitic Capacitance

- if ;

- if ;

- if ;

3. The Influence of Imperfections on the Output Voltage of the Inverter

3.1. RMS Value of the Fundamental Component of the Output Voltage

3.2. Harmonics Generated by the Inverter’s Imperfections

4. Experimental Results

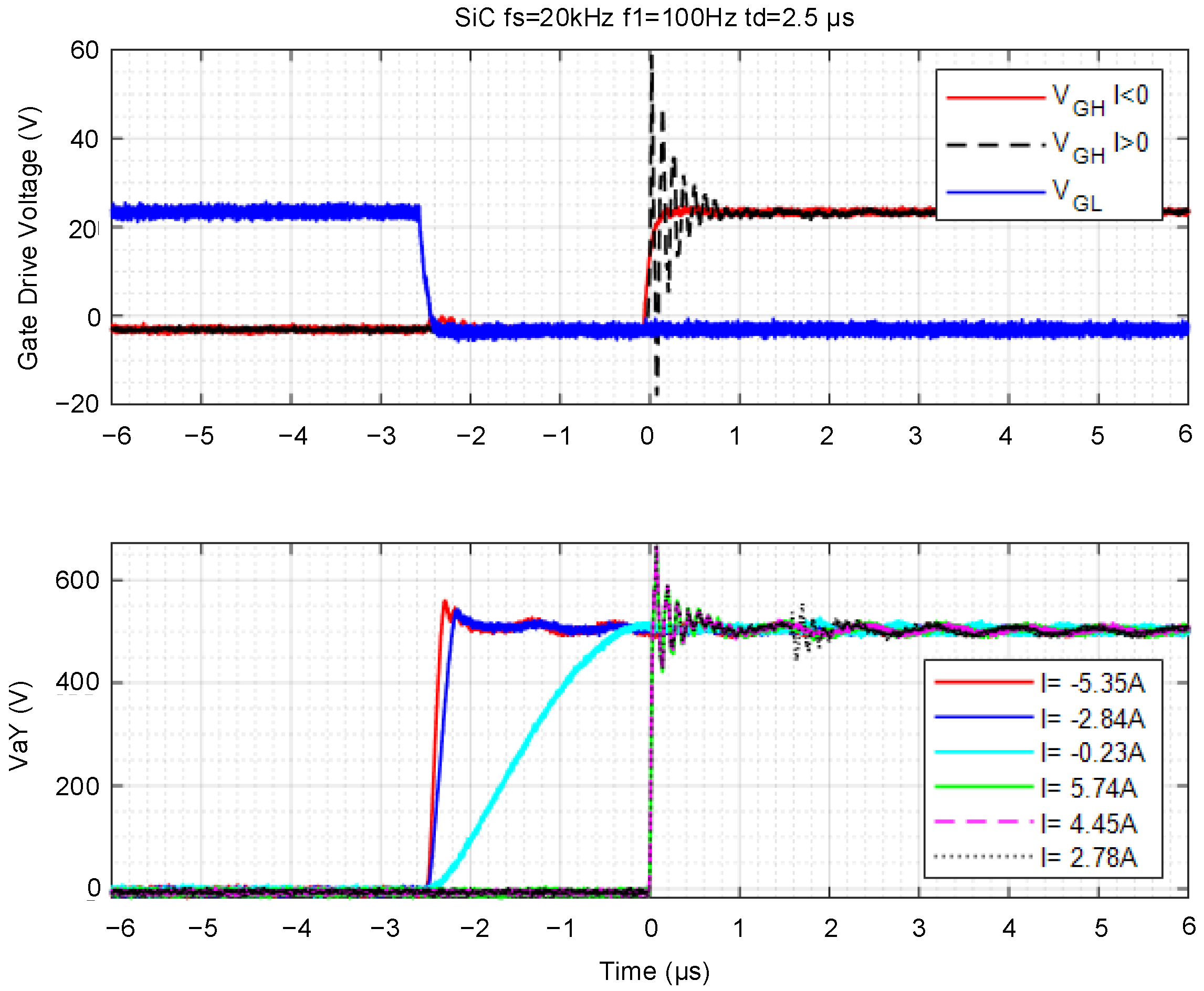

4.1. Analysis of Switching Events for the SiC-MOSFET Inverter

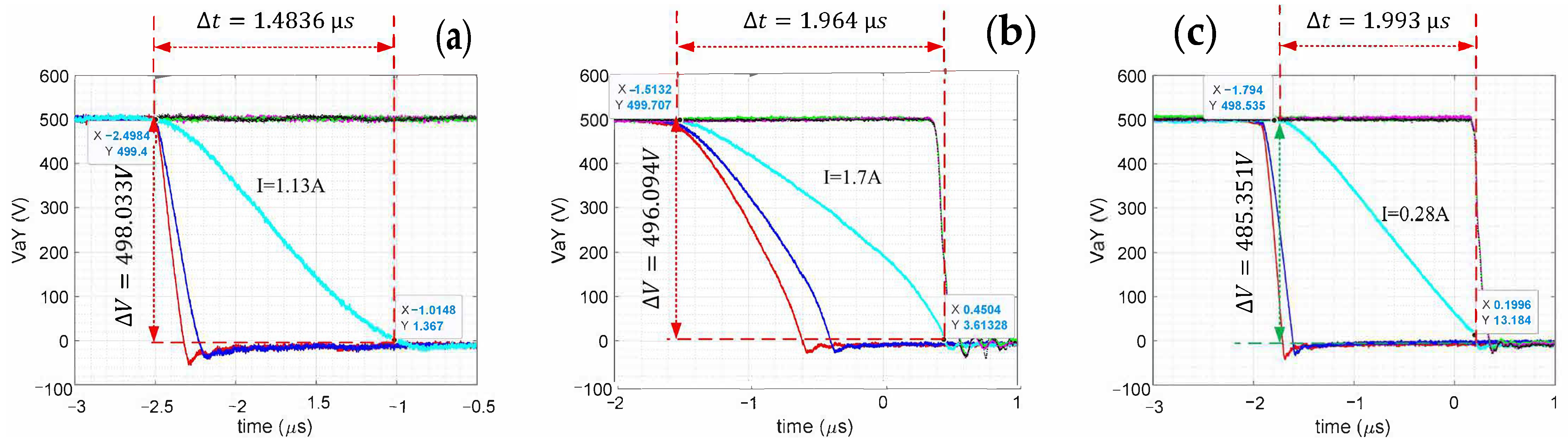

4.2. Measurement of the Value of Parasitic Capacitances

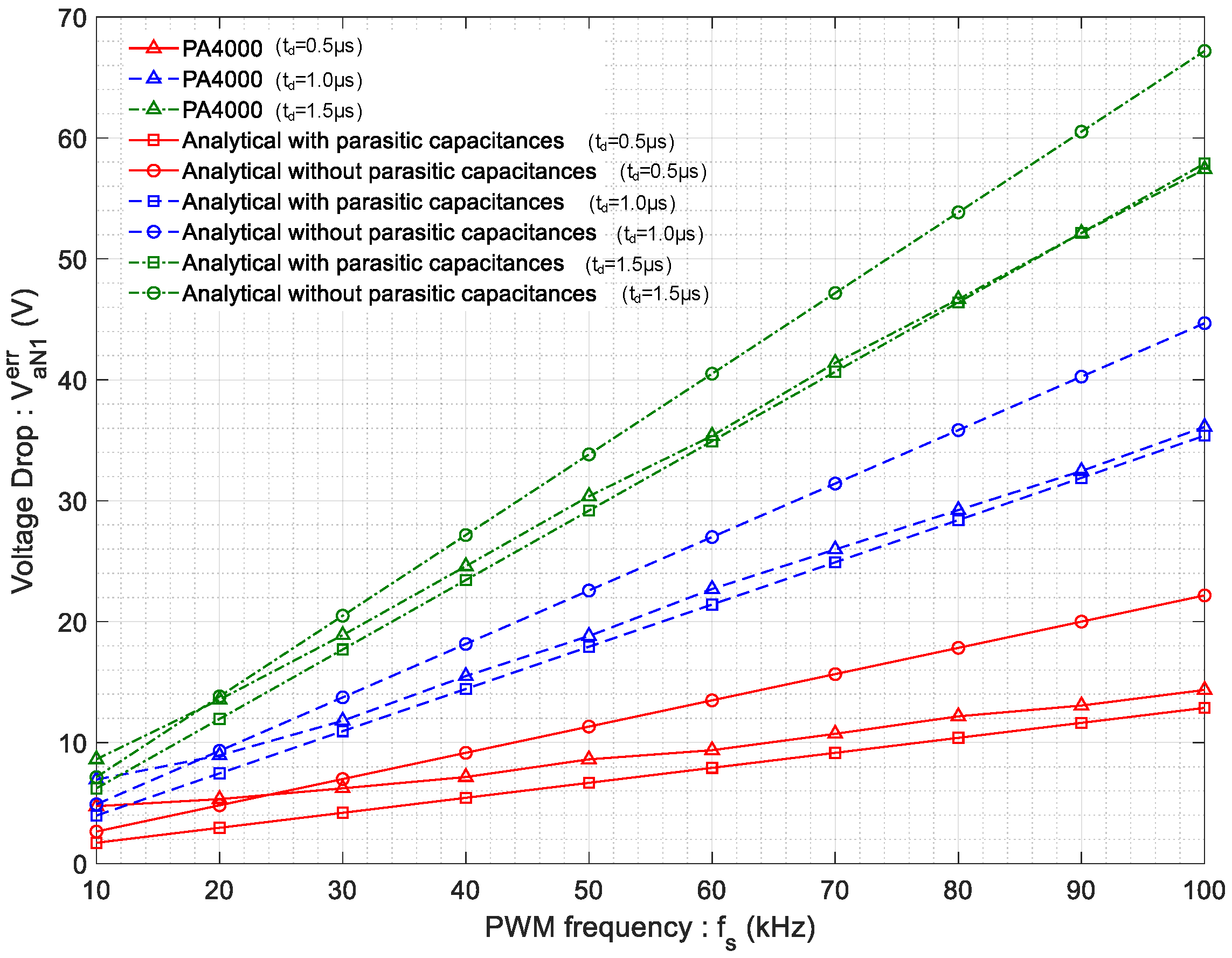

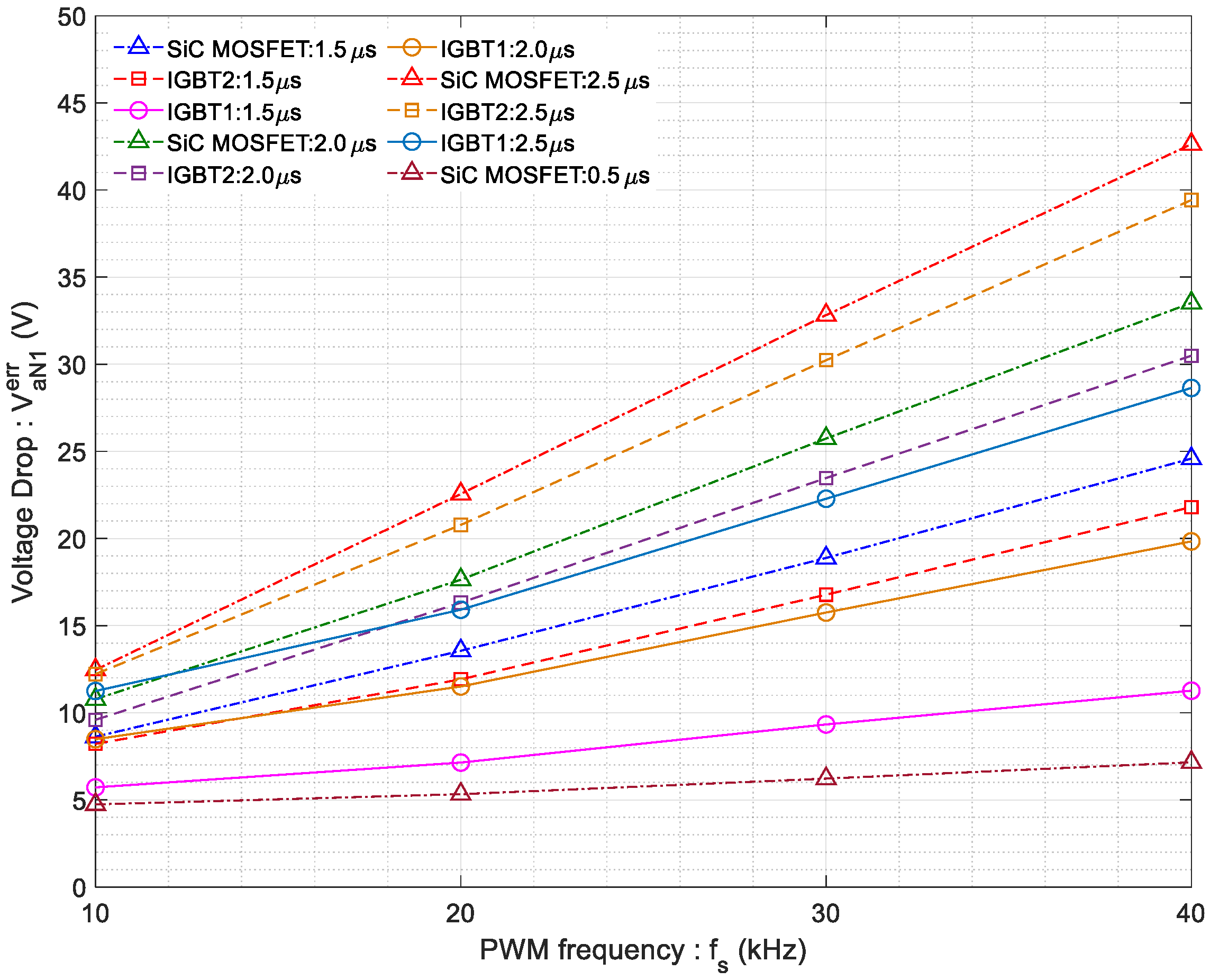

4.3. Comparison of the Performances of the 3 Inverters

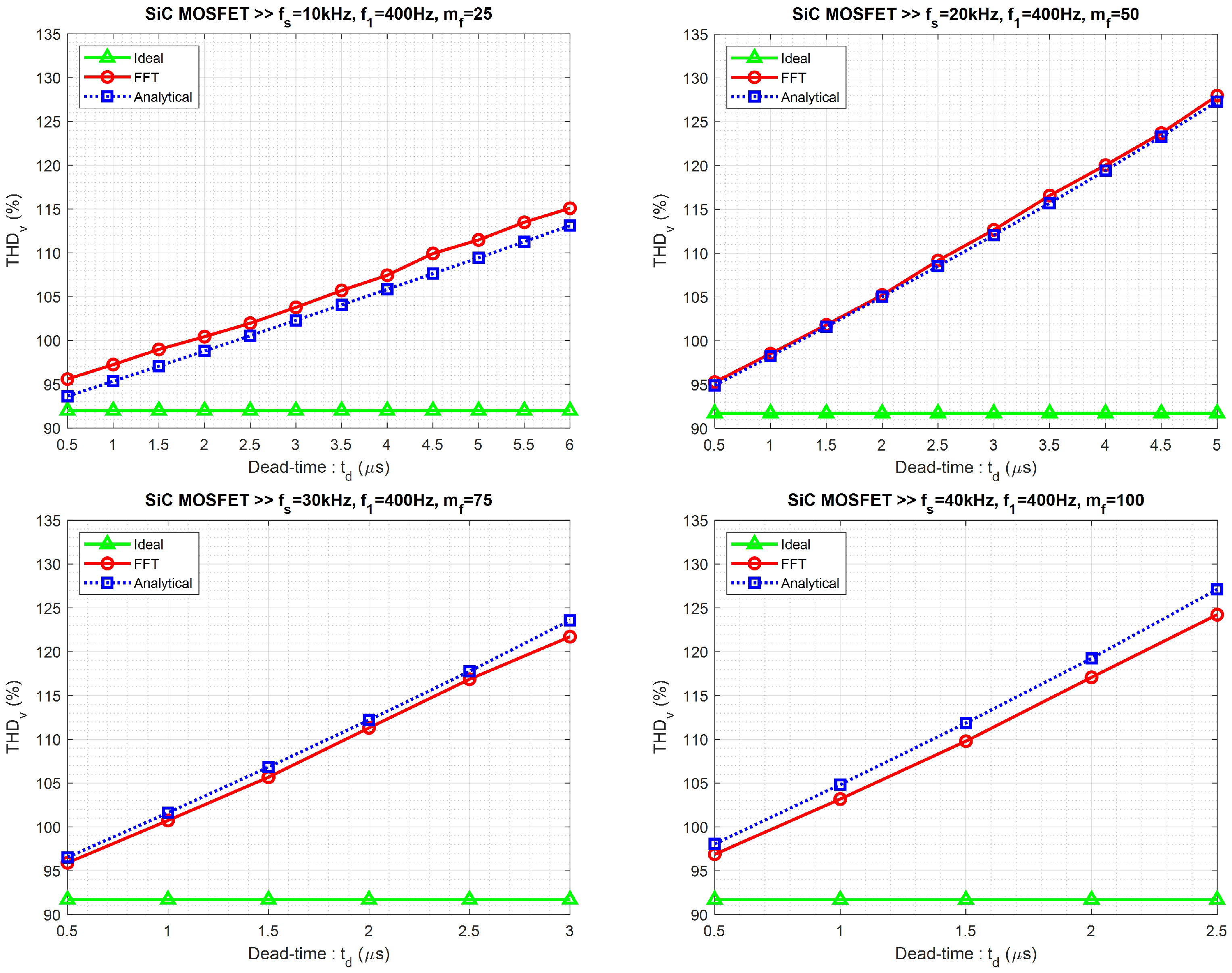

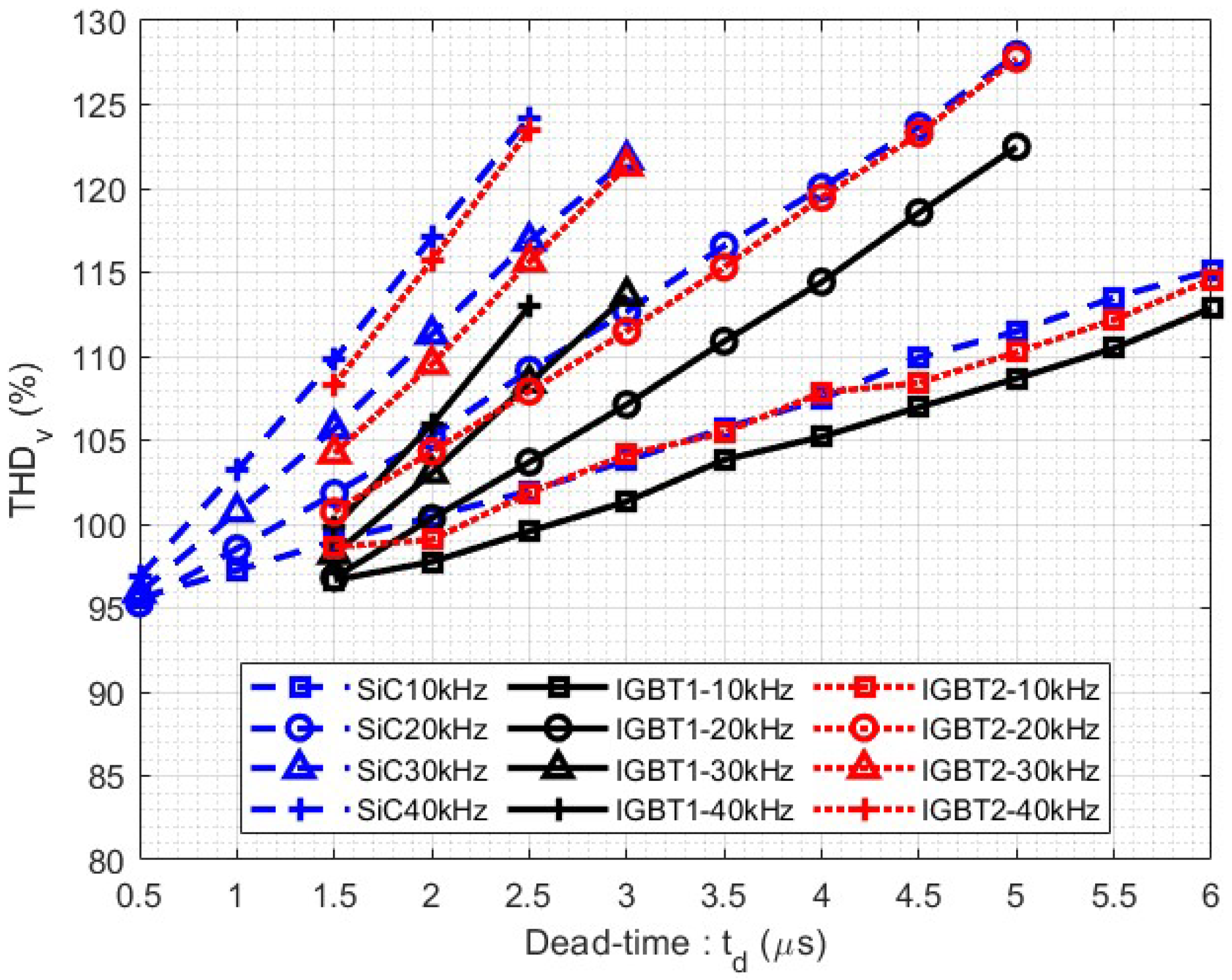

4.4. Measurement of the Total Harmonic Distortion of Voltage for the 3 Types of Inverters

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Akrami, M.; Jamshidpour, E.; Pierfederici, S.; Frick, V. Comparison of Flatness-based Control and Field-Oriented Control for PMSMs in Automotive Water Pump Application. In Proceedings of the 2023 IEEE International Conference on Environment and Electrical Engineering and 2023 IEEE Industrial and Commercial Power Systems Europe (EEEIC/I&CPS Europe), Madrid, Spain, 6–9 June 2023; pp. 1–6. [Google Scholar] [CrossRef]

- Haghgooei, P.; Corne, A.; Jamshidpour, E.; Takorabet, N.; Khaburi, D.A.; Nahid-Mobarakeh, B. Current Sensorless Control for a Wound Rotor Synchronous Machine Based on Flux Linkage Model. IEEE J. Emerg. Sel. Top. Power Electron. 2022, 10, 4576–4586. [Google Scholar] [CrossRef]

- Haghgooei, P.; Jamshidpour, E.; Corne, A.; Takorabet, N.; Khaburi, D.A.; Baghli, L.; Nahid-Mobarakeh, B. A Parameter-Free Method for Estimating the Stator Resistance of a Wound Rotor Synchronous Machine. World Electr. Veh. J. 2023, 14, 65. [Google Scholar] [CrossRef]

- Tawfiq, K.B.; Mansour, A.S.; Sergeant, P. Mathematical Design and Analysis of Three-Phase Inverters: Different Wide Bandgap Semiconductor Technologies and DC-Link Capacitor Selection. Mathematics 2023, 11, 2137. [Google Scholar] [CrossRef]

- Xu, Y.; Kersten, A.; Klacar, S.; Sedarsky, D. Maximizing Efficiency in Smart Adjustable DC Link Powertrains with IGBTs and SiC MOSFETs via Optimized DC-Link Voltage Control. Batteries 2023, 9, 302. [Google Scholar] [CrossRef]

- Lin, Z.; An, Q.; Xie, C. SiC-Based Inverter Fed High-Speed Permanent Magnet Synchronous Motor Drive. In Proceedings of the 5th Asia Conference on Power and Electrical Engineering (ACPEE), Chengdu, China, 7 June 2020; pp. 1300–1304. [Google Scholar]

- Allca-Pekarovic, A.; Kollmeyer, P.J.; Mahvelatishamsabadi, P. Comparison of IGBT and SiC Inverter Loss for 400V and 800V DC Bus Electric Vehicle Drivetrains. In Proceedings of the IEEE Energy Conversion Congress and Exposition (ECCE), Detroit, MI, USA, 11–15 October 2020; pp. 6338–6344. [Google Scholar]

- Perdikakis, W.; Scott, M.; Kitzmiller, C.; Yost, K.J. Comparison of Si and SiC EMI and Efficiency in a Two-level Aerospace Motor Drive Application. IEEE Trans. Transp. Electrif. 2020, 6, 1401–1411. [Google Scholar] [CrossRef]

- Kapino, G.; Franke, W. Loss Comparison for Different Technologies of Semiconductors for Electrical Drive Motor Application. In Proceedings of the IEEE 13th International Conference on Compatibility, Power Electronics and Power Engineering (CPE-POWERENG), Sonderborg, Denmark, 23–25 April 2019. [Google Scholar]

- Qi, F.; Wang, M.; Xu, L. Investigation and Review of Challenges in A High Temperature 30 kVA 3 phase inverter using SiC MOSFETs. IEEE Trans. Ind. Appl. 2018, 54, 2483–2491. [Google Scholar] [CrossRef]

- Shenoy, P.; Solis, O.; Zheng, L. Commercializing medium voltage VFD that utilizes high voltage SiC technology. In Proceedings of the IEEE International Workshop On Integrated Power Packaging (IWIPP), Delft, The Netherlands, 5–7 April 2017. [Google Scholar]

- Nawawi, A.; Tong, C.F.; Yin, S.; Sakanova, A. Design and Demonstration of High Power Density Inverter for Aircraft Applications. IEEE Trans. Ind. Appl. 2017, 53, 1168–1176. [Google Scholar] [CrossRef]

- Han, D.; Li, Y.; Sarlioglu, B. Analysis of SiC Based Power Electronic Inverters for High-Speed Machines. In Proceedings of the IEEE Applied Power Electronics Conference and Exposition (APEC), Charlotte, NC, USA, 15–19 March 2015; pp. 304–310. [Google Scholar]

- Poolphaka, P.; Jamshidpour, E.; Takorabet, N.; Lubin, T. Performance Comparison between IGBT and SiC Devices in Three-Phase Inverter for High-Speed Motor Drive Applications. In Proceedings of the 2022 25th International Conference on Electrical Machines and Systems (ICEMS), Chiang Mai, Thailand, 29 November–2 December 2022; pp. 1–6. [Google Scholar] [CrossRef]

- Umegami, H.; Harada, T.; Nakahara, K. Performance Comparison of Si IGBT and SiC MOSFET Power Module Driving IPMSM or IM under WLTC. World Electr. Veh. J. 2023, 14, 112. [Google Scholar] [CrossRef]

- Bedetti, N.; Calligaro, S.; Petrella, R. Self-Commissioning of Inverter Dead-Time Compensation by Multiple Linear Regression Based on a Physical Model. IEEE Trans. Ind. Appl. 2015, 51, 3954–3964. [Google Scholar] [CrossRef]

- Ding, X.; Du, M.; Duan, C.; Guo, H.; Xiong, R.; Xu, J.; Cheng, J.; Luk, P. Analytical and Experimental Evaluation of SiC-Inverter Nonlinearities for Traction Drives Used in Electric Vehicles. IEEE Trans. Veh. Technol. 2018, 67, 146–159. [Google Scholar] [CrossRef]

- Bedetti, N.; Calligaro, S.; Petrella, R. Accurate modeling, compensation and self-commissioning of inverter voltage distortion for high-performance motor drives. In Proceedings of the 2014 IEEE Applied Power Electronics Conference and Exposition-APEC 2014, Fort Worth, TX, USA, 16–20 March 2014; pp. 1550–1557. [Google Scholar]

- Dafang, W.; Peng, Z.; Yi, J.; Miaoran, W.; Gang, L.; Mingyu, W. Influences on Output Distortion in Voltage Source Inverter Caused by Power Devices’ Parasitic Capacitance. IEEE Trans. Power Electron. 2018, 33, 4261–4273. [Google Scholar]

- Holmes, D.G.; Lipo, T.A. Modulation of Three-Phase Voltage Source Inverters. In Pulse Width Modulation for Power Converters: Principles and Practice; IEEE: Piscataway, NJ, USA, 2003; pp. 215–258. [Google Scholar]

- Wu, C.M.; Lau, W.H.; Chung, H.S.H. Analytical Technique for Calculating the Output Harmonics of an H-Bridge Inverter with Dead Time. IEEE Trans. Circuits Syst. Fundam. Theory Appl. 1999, 46, 617–627. [Google Scholar] [CrossRef]

- Deng, H.; Helle, L.; Bo, Y.; Larsen, K.B. A general solution for theoretical harmonic components of carrier-based PWM schemes. In Proceedings of the APEC 2009, Washington, DC, USA, 15–19 February 2009; pp. 1698–1703. [Google Scholar]

- Kus, V.; Josefova, T. The Influence of the Dead Time Duration and Switching Frequency on the Input Current Distortion of Voltage-Source Active Rectifiers. In Proceedings of the International Conference on Applied Electronics (AE) 2015, Pilsen, Czech Republic, 8–9 September 2015; pp. 1–4. [Google Scholar]

- Baghli, L.; Jamshidpour, E. Implementing a 200 kHz PWM Field Oriented Control using RTLib and C program on a dSPACE MicroLabBox. In Proceedings of the 2022 2nd International Conference on Advanced Electrical Engineering (ICAEE), Constantine, Algeria, 29–31 October 2022; pp. 1–6. [Google Scholar] [CrossRef]

| Parameters | IGBT1 | IGBT2 | SiC MOSFET |

|---|---|---|---|

| (SEMiX251GD126HD) | (SKM100GB125DN) | (CCS050M12CM) | |

| or (V) | 1200 | 1200 | 1200 |

| or (A) at 25 °C | 242 | 100 | 87 |

| (A) at 25 °C | 207 | 95 | 102 |

| or (m) | 7 | 22.5 | 25 |

| (m) | 5 | 11.1 | 20 |

| (V) | 0.9 | 2.3 | 0 |

| (V) | 1.1 | 1 | 1.5 |

| (mJ) | 37 | 11 | 1.1 |

| (mJ) | 22 | 4 | 0.6 |

| (mJ) | 12 | 4 | - |

| (ns) | 295 | 75 | 51 |

| (ns) | 625 | 600 | 69 |

| () | 10 | 10 | 20 |

| Parameters | Value |

|---|---|

| DC bus voltage () | >540 V |

| Output current of the inverter () | 30 Arms |

| PWM frequency () | 10–100 kHz |

| Fundamental frequency () | 50–3000 Hz |

| Efficiency () | >90% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Poolphaka, P.; Jamshidpour, E.; Lubin, T.; Baghli, L.; Takorabet, N. Comparative Study of IGBT and SiC MOSFET Three-Phase Inverter: Impact of Parasitic Capacitance on the Output Voltage Distortion. Actuators 2023, 12, 355. https://doi.org/10.3390/act12090355

Poolphaka P, Jamshidpour E, Lubin T, Baghli L, Takorabet N. Comparative Study of IGBT and SiC MOSFET Three-Phase Inverter: Impact of Parasitic Capacitance on the Output Voltage Distortion. Actuators. 2023; 12(9):355. https://doi.org/10.3390/act12090355

Chicago/Turabian StylePoolphaka, Paisak, Ehsan Jamshidpour, Thierry Lubin, Lotfi Baghli, and Noureddine Takorabet. 2023. "Comparative Study of IGBT and SiC MOSFET Three-Phase Inverter: Impact of Parasitic Capacitance on the Output Voltage Distortion" Actuators 12, no. 9: 355. https://doi.org/10.3390/act12090355

APA StylePoolphaka, P., Jamshidpour, E., Lubin, T., Baghli, L., & Takorabet, N. (2023). Comparative Study of IGBT and SiC MOSFET Three-Phase Inverter: Impact of Parasitic Capacitance on the Output Voltage Distortion. Actuators, 12(9), 355. https://doi.org/10.3390/act12090355