A Novel High-Voltage-Cable Stripping Robot

Abstract

:1. Introduction

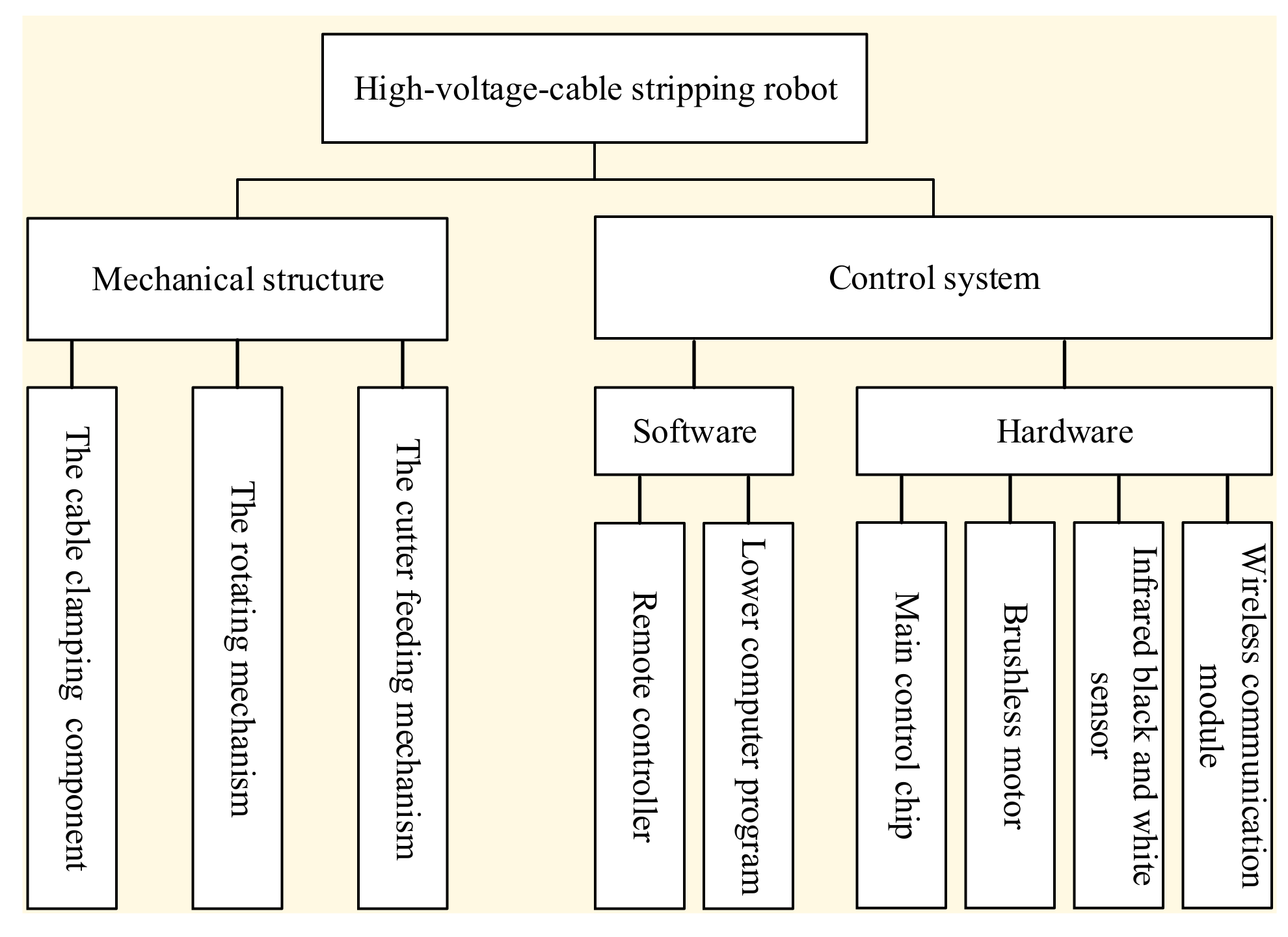

2. Introduction of the Novel Cable—Stripping Robot

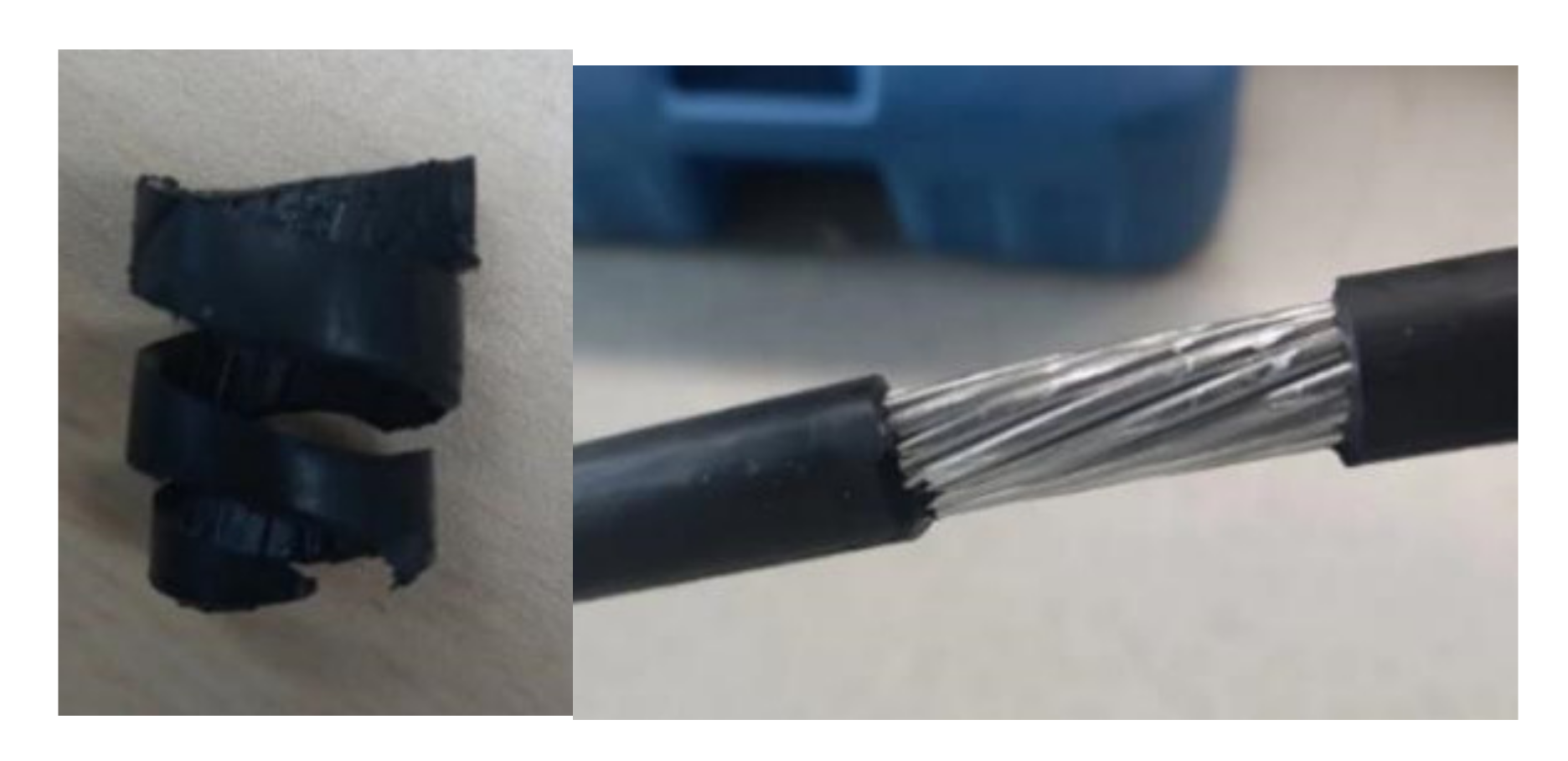

2.1. Operating Environment and Design Requirements

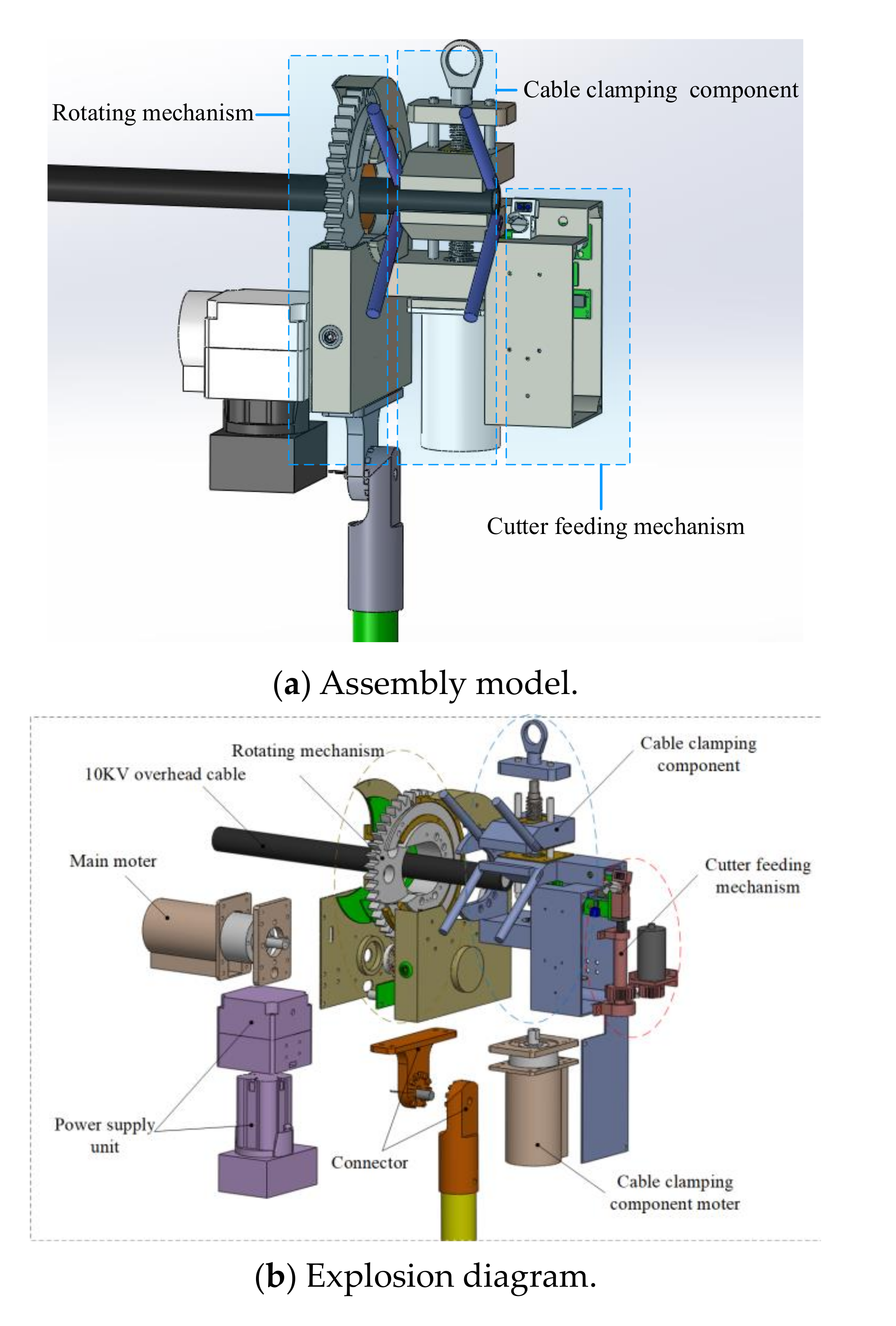

2.2. Description of the Robot Structure

2.2.1. Torque Calculation of Screw Motor

2.2.2. Torque Calculation of Screw Motor

2.2.3. Torque of the Rotating Mechanism Motor

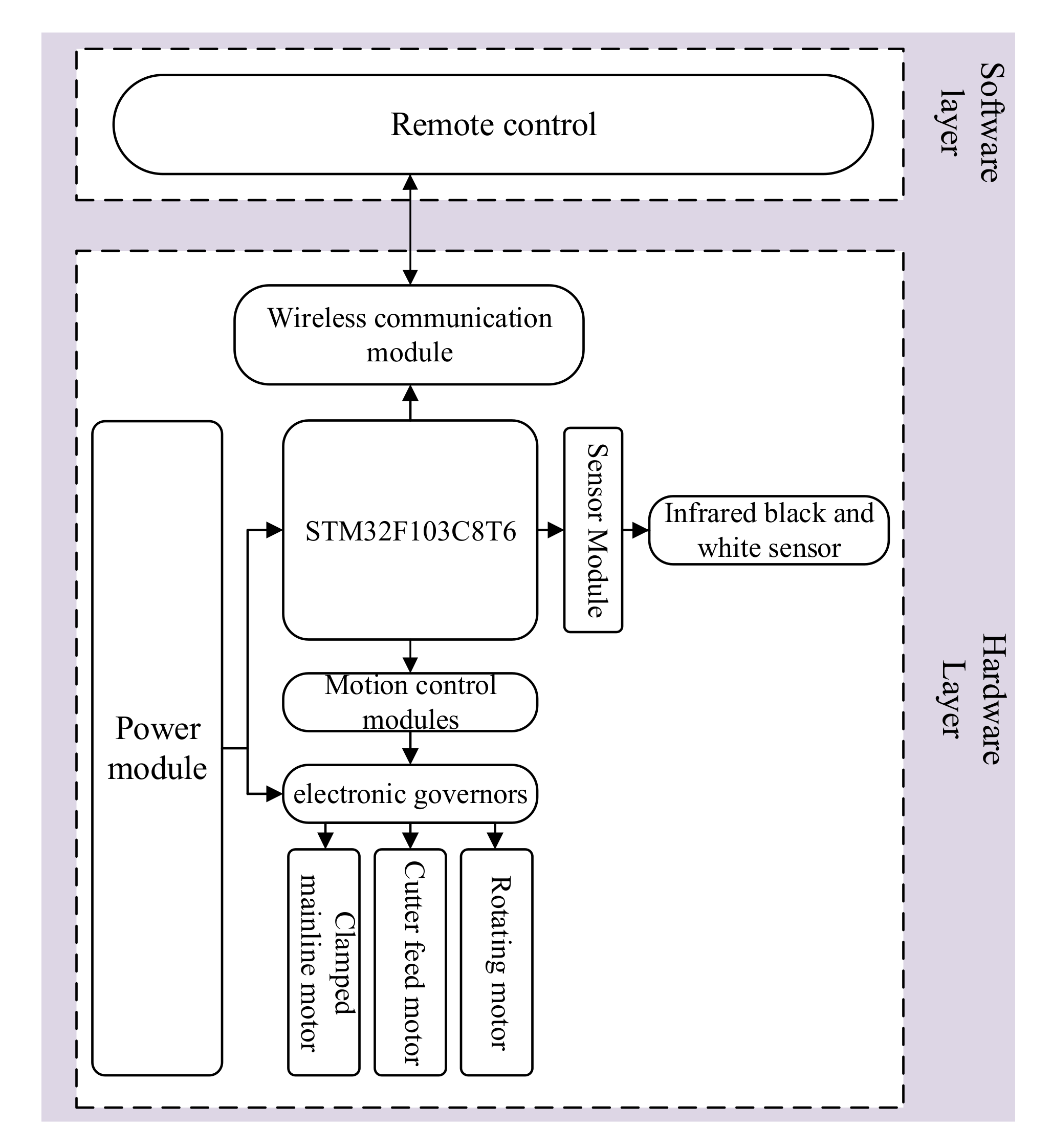

3. Controlling System of the Cable-Stripping Robot

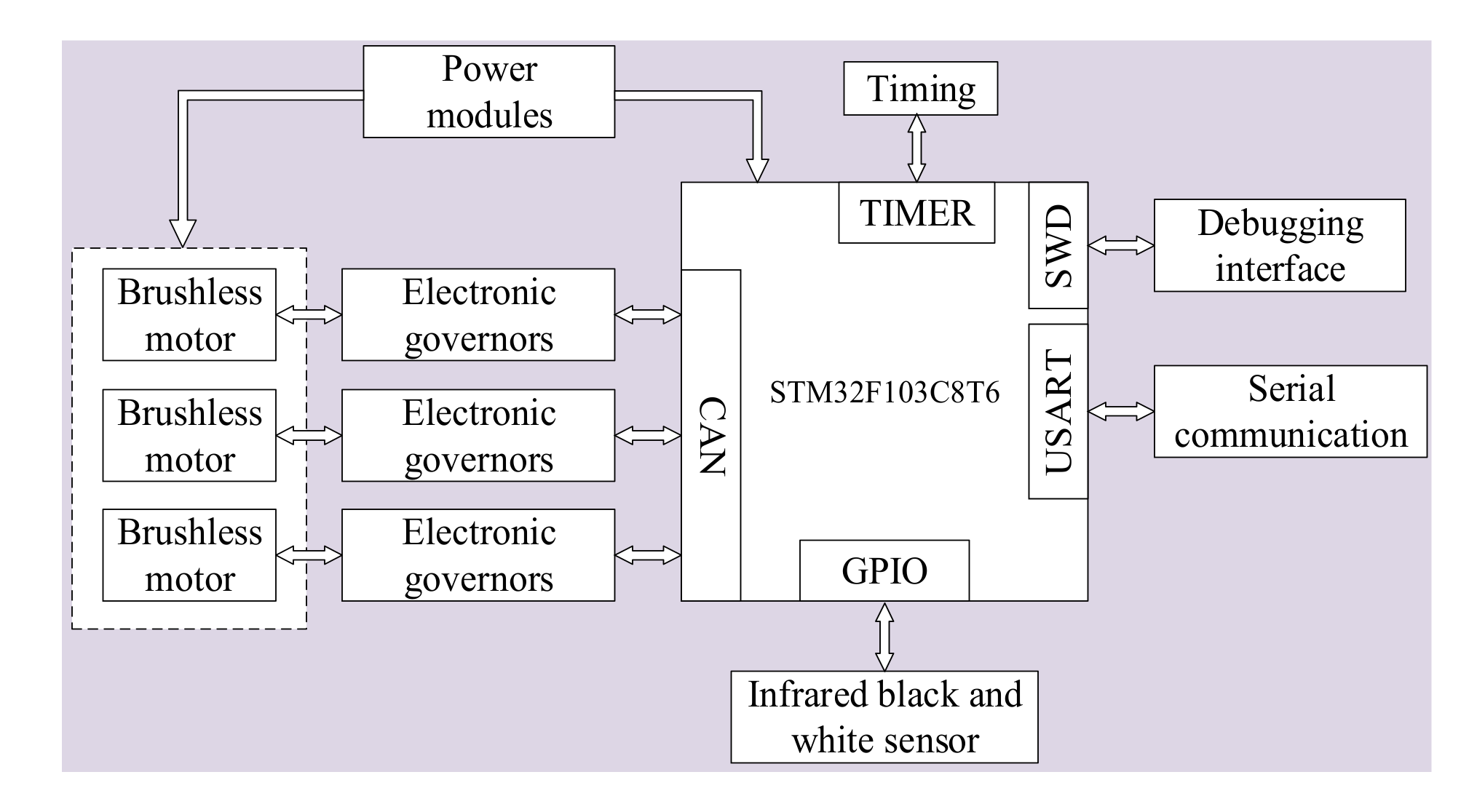

3.1. Hardware Design

3.1.1. Motors and Electronic Governors

3.1.2. Infrared Black and White Sensor

3.1.3. Wireless Communication Module

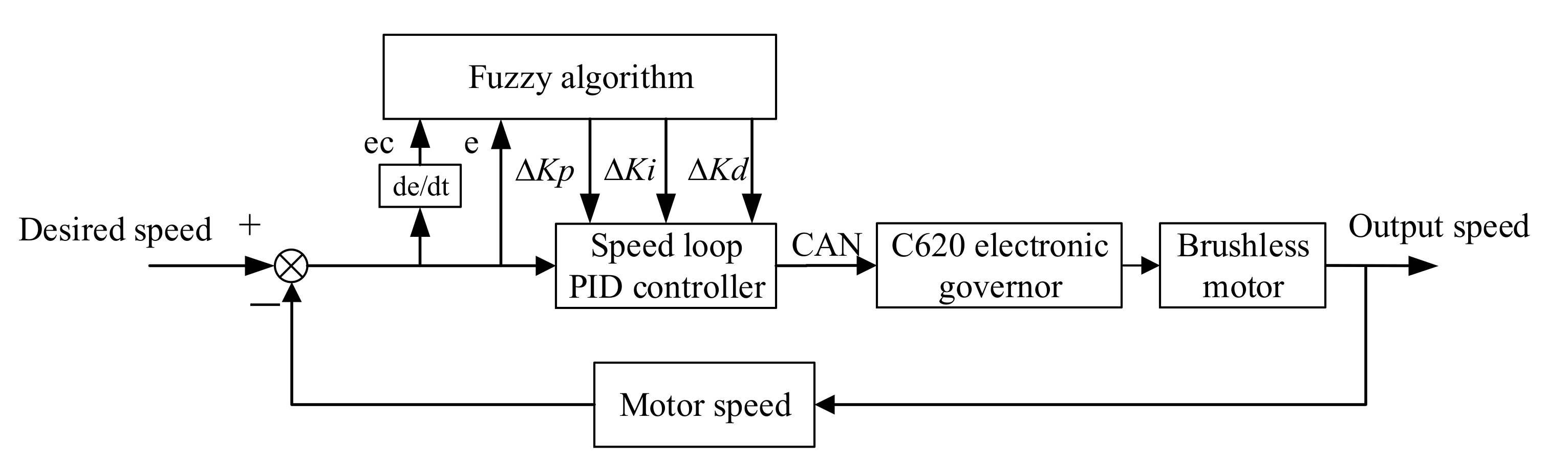

3.2. Control Algorithm of the Cable-Stripping Robot

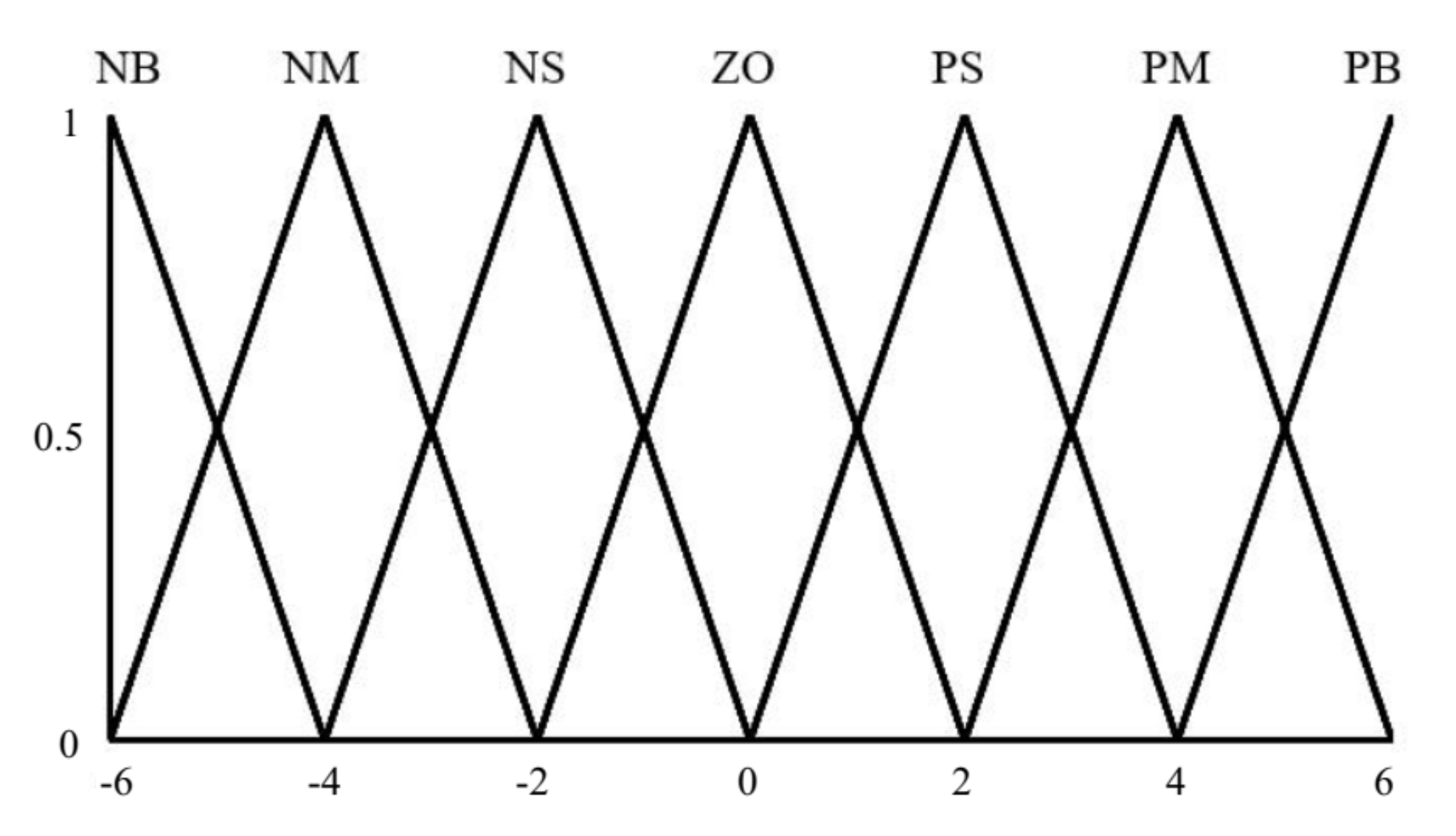

3.2.1. Fuzzy PID Strategy

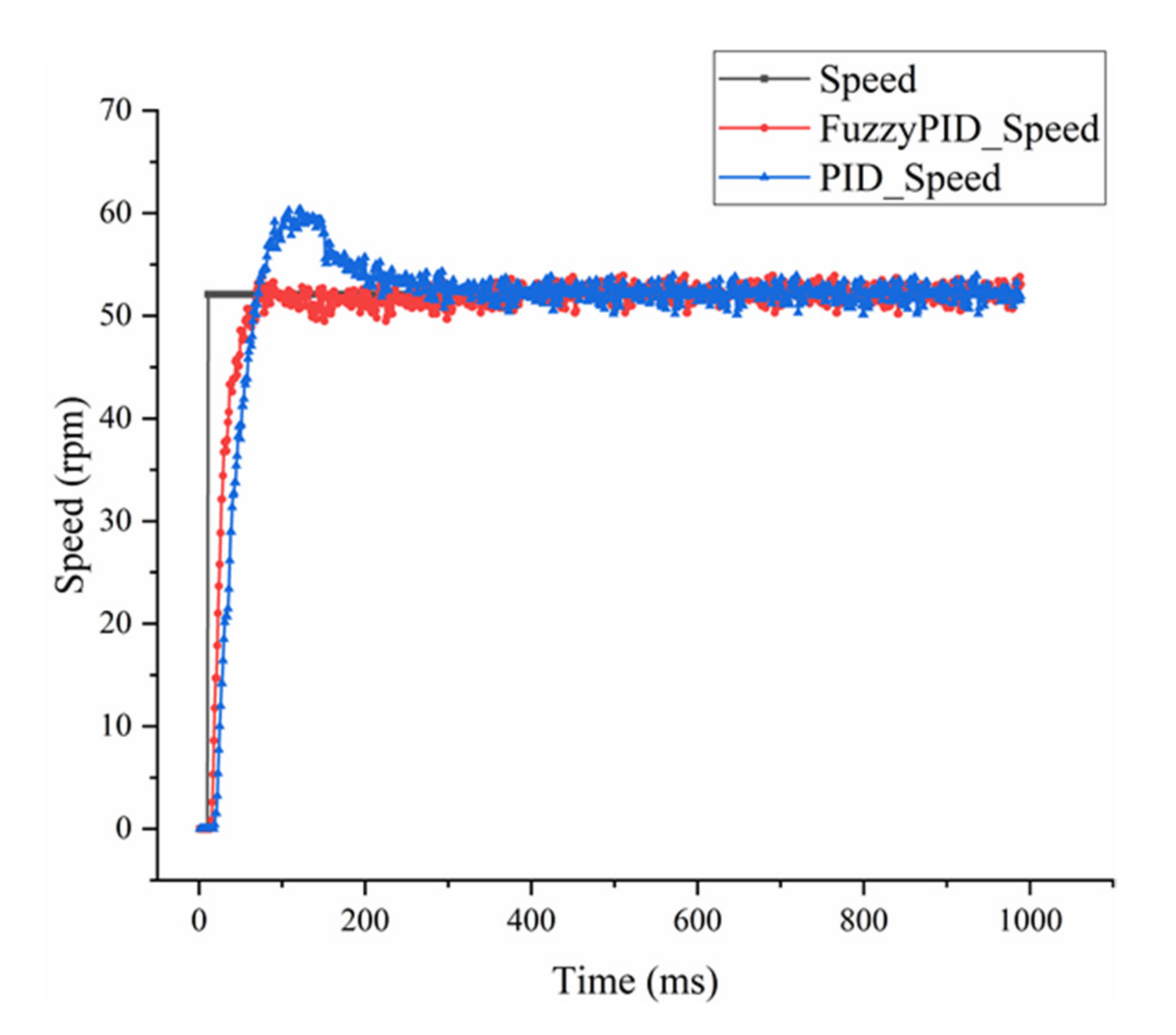

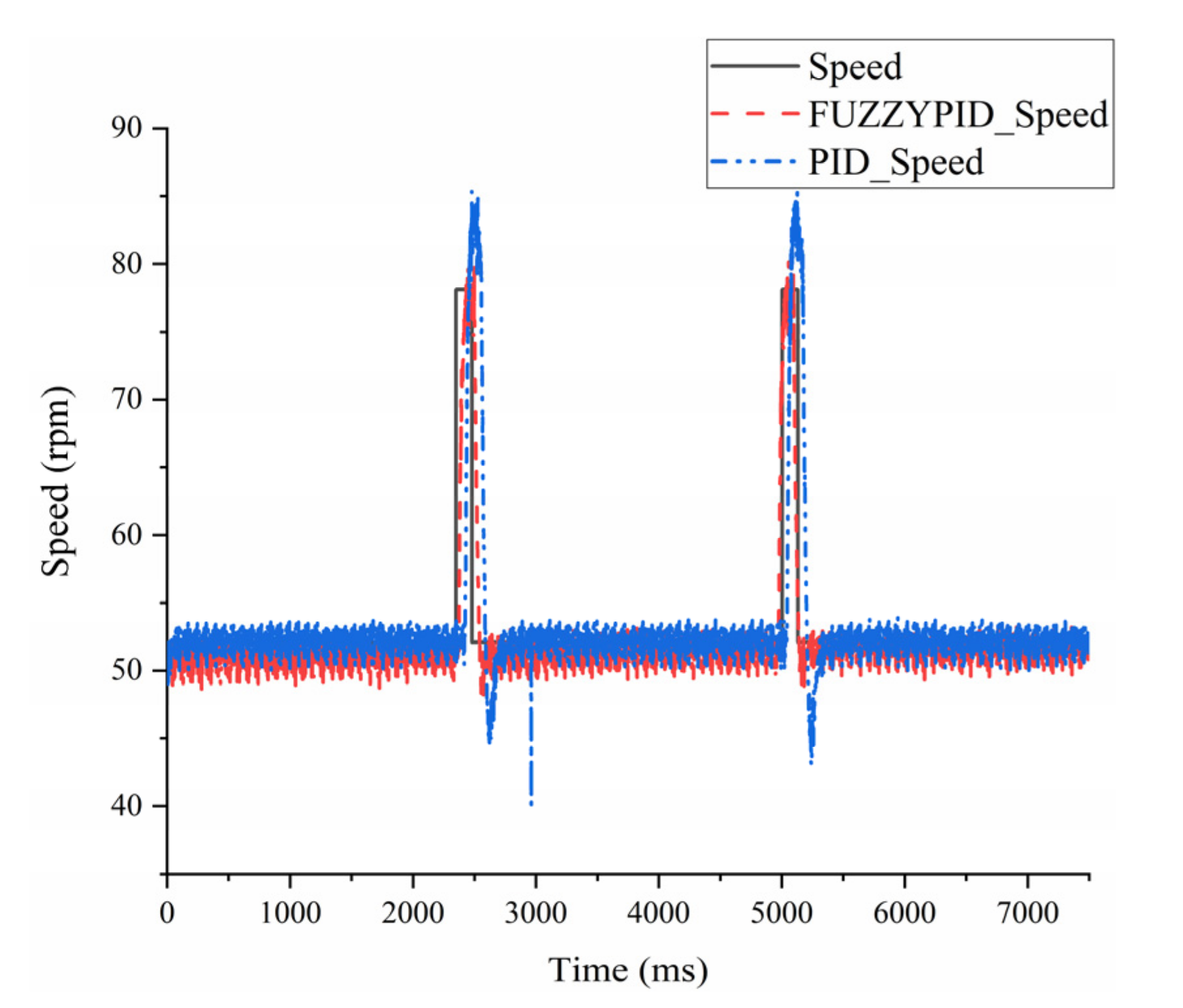

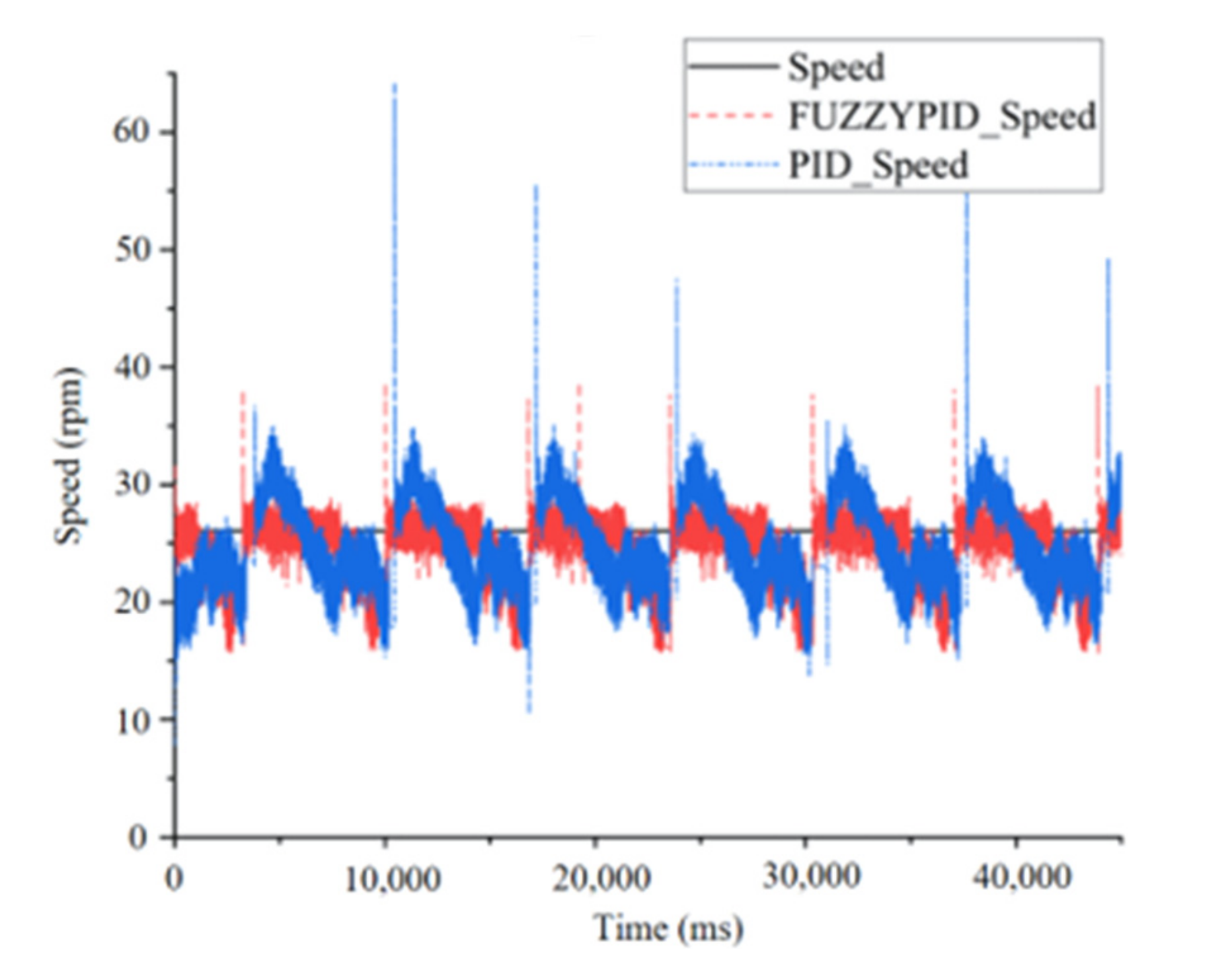

3.2.2. Fuzzy PID Controller and Its Experimental Validations

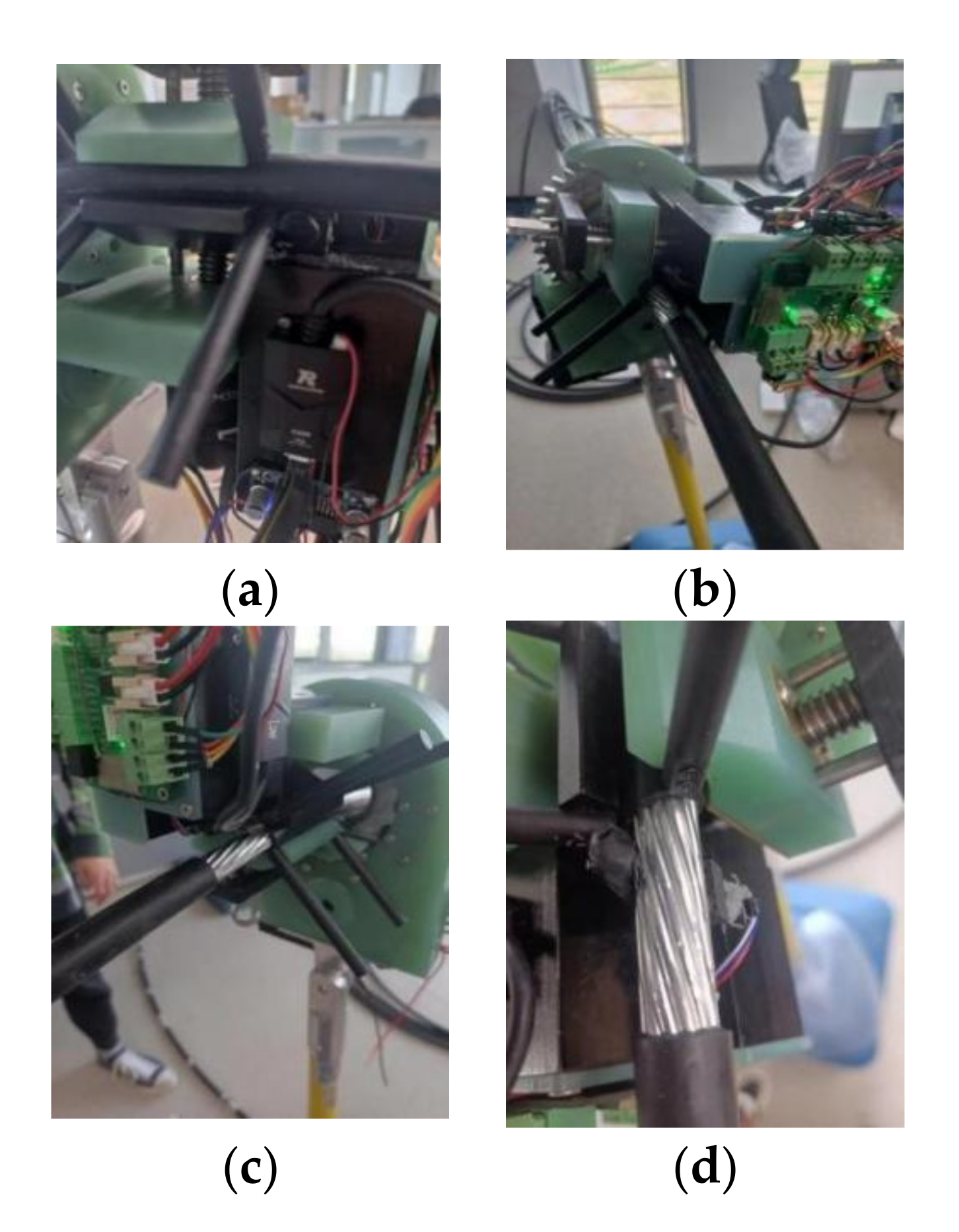

4. Prototype and Validations

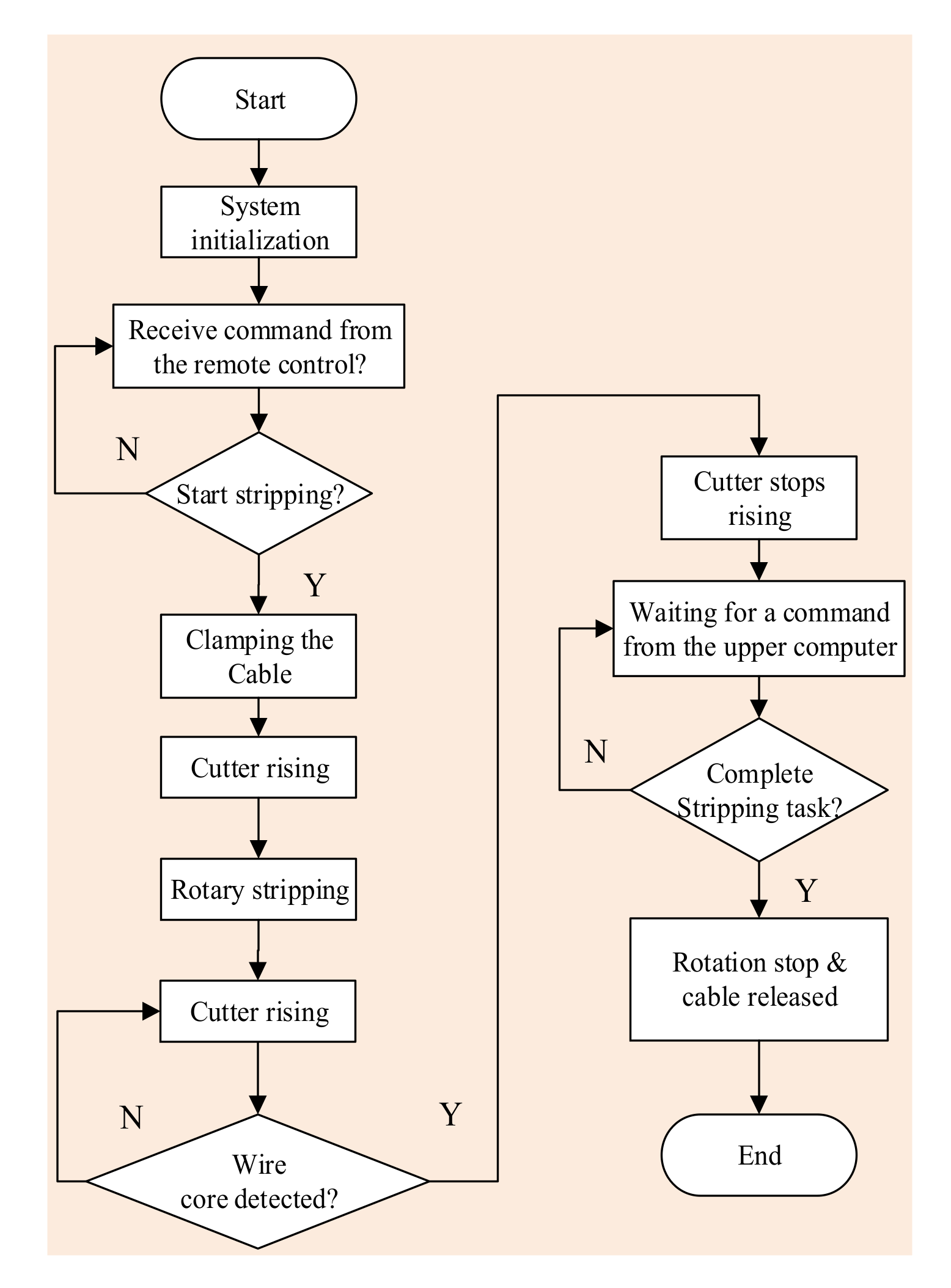

4.1. Prototype of the Robot and Its Workflow

4.2. Experiments and Discussions

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| F | The screw thrust |

| T | The screw torque |

| P | The screw lead |

| η | Transmission efficiency |

| Mr | Circumferential component torque |

| μ | The friction coefficient |

References

- Gao, X.; Sun, L.; Zhang, W. Design and Development of High Voltage Live Drainage Robot System. Mach. Des. Res. 2021, 37, 10–14. [Google Scholar] [CrossRef]

- Du, Y.; Liu, Y.; Shao, Q.; Sheng, G.; Jiang, X.; Luo, L. Single Line-to-Ground Faulted Line Detection of Distribution Systems with Resonant Grounding Based on Feature Fusion Framework. In Proceedings of the 2020 IEEE Power & Energy Society General Meeting (PESGM), Montreal, QC, Canada, 2–6 August 2020; p. 1. [Google Scholar] [CrossRef]

- Sun, J.; Yang, Q.; Xu, W.; He, W. A Distribution Line Fault Location Estimation Algorithm Based on Electromagnetic Time-Reversal Method Calculated in the Finite Difference Time Domain. IEEE Trans. Electromagn. Compat. 2022, 64, 865–873. [Google Scholar] [CrossRef]

- Takaoka, K.; Yokoyama, K.; Wakisako, H.; Yano, K.; Higashijima, K.; Murakami, S. Development of the fully-automatic live-line maintenance robot-Phase III. In Proceedings of the 2001 IEEE International Symposium on Assembly and Task Planning (ISATP2001). Assembly and Disassembly in the Twenty-first Century. (Cat. No.01TH8560), Fukuoka, Japan, 29 May 2001; pp. 423–428. [Google Scholar] [CrossRef]

- Yano, K.; Maruyama, Y.; Morita, K.; Nakashima, M. Development of the semi-automatic hot-line work robot system “Phase II”. In Proceedings of the ESMO’95—1995 IEEE 7th International Conference on Transmission and Distribution Construction, Op-eration and Live-Line Maintenance, Columbus, OH, USA, 29 October–3 November 1995; pp. 212–218. [Google Scholar] [CrossRef]

- Nakashima, M.; Yano, K.; Maruyama, Y.; Yakabe, H. The hot line work robot system “Phase II” and its human-robot in-terface “MOS”. Proceedings 1995 IEEE/RSJ International Conference on Intelligent Robots and Systems. Human Robot Interaction and Cooperative Robots, Pittsburgh, PA, USA, 5–9 August 1995; Volume 2, pp. 116–123. [Google Scholar] [CrossRef]

- Pouliot, N.; Montambault, S. LineScout Technology: From inspection to robotic maintenance on live transmission power lines. In Proceedings of the 2009 IEEE International Conference on Robotics and Automation, St. Louis, MO, USA, 25–28 March 1985; pp. 1034–1040. [Google Scholar]

- Penin, L.F.; Aracil, R.; Ferre, M.; Pinto, E.; Hernando, M.; Barrientos, A. Telerobotic system for live power lines maintenance: ROBTET. In Proceedings of the 1998 IEEE International Conference on Robotics and Automation (Cat. No.98CH36146), Leuven, Belgium, 20–20 May 1998; Volume 3, pp. 2110–2115. [Google Scholar]

- Zhao, Y.; Qi, H.; Xu, W.; Li, J.; Zhao, J. Research on Master-slave Controlling Remote Operation of Live Working Robots in Agricultural Distribution Network. In Proceedings of the 2018 IEEE 3rd Advanced Information Technology, Electronic and Automation Control Conference (IAEAC), Chongqing, China, 12–14 October 2018; pp. 1401–1405. [Google Scholar] [CrossRef]

- Han, W. An Automatic Stripping Device for Hot-line Connection of 10 kV Cables. J. Phys. Conf. Ser. 2021, 2005, 012211. [Google Scholar] [CrossRef]

- Lei, T.; Xie, Z.; Wang, K.; Zhong, L.; Chen, D. Design of high voltage live operation robot system. In Proceedings of the 2021 International Conference on Wireless Communications and Smart Grid (ICWCSG), Hangzhou, China, 13–15 August 2021; pp. 473–476. [Google Scholar]

- Zhang, J.; Hu, Y.; Xu, S.; Zhang, T.; Ren, S.; Wang, M. Design and analysis of terminal live installation tool for robot in distribution work. Procedia Comput. Sci. 2021, 183, 412–417. [Google Scholar] [CrossRef]

- Yan, Y.; Liu, L.; Zhou, Z.; Fan, Y. Development of Live Working Robot for Distribution Network. IOP Conf. Ser. Earth Environ. Sci. 2019, 237, 062026. [Google Scholar] [CrossRef]

- Seki, H.; Nakayama, S.; Uenishi, K.; Tsuji, T.; Hikizu, M.; Makino, Y.; Kakiuchi, A.; Kanda, Y. Development of assistive robotic arm for power line maintenance. Precis. Eng. 2020, 67, 69–76. [Google Scholar] [CrossRef]

- Feng, J.; Zhang, W. Autonomous Live-Line Maintenance Robot for a 10 kV Overhead Line. IEEE Access 2021, 9, 61819–61831. [Google Scholar] [CrossRef]

- Liming, Z.; Yulong, H.; Shanjun, X.; Tong, Z.; Junlong, G.; Mingrui, W. Mechanical design and finite element analysis of live working robot for 10kV distribution power systems. Procedia Comput. Sci. 2021, 183, 331–336. [Google Scholar] [CrossRef]

- Zhang, M.; Du, J. Design and development of smart socket based on STM32. J. Comput. Methods Sci. Eng. 2020, 20, 227–243. [Google Scholar] [CrossRef]

- Hu, Y.; Chen, C.; Wu, H.; Song, C. Study on structural optimization design and cascade PID control of maglev actuator for active vibration isolation system. J. Vib. Control 2016, 24, 1829–1847. [Google Scholar] [CrossRef]

- Li, J.; Zhang, L.; Huang, X.; Zhang, Q.; Wang, G. Cascade PID control algorithm for wind turbine blade mold temperature based on improved RBF neural network. Acta Energ. Sol. Sin. 2022, 43, 330–335. [Google Scholar] [CrossRef]

- Lyu, D.; Su, H.; Li, Y.; Zhang, Z.; Long, H.; Zhao, J. An Embedded Linear Model Three-Dimensional Fuzzy PID Control System for a Bionic AUV under Wave Disturbance. Math. Probl. Eng. 2022, 2022, 4126595. [Google Scholar] [CrossRef]

- Tang, X.; Wang, C.; Hu, Y.; Liu, Z.; Li, F. Adaptive Fuzzy PID Based on Granular Function for Proton Exchange Membrane Fuel Cell Oxygen Excess Ratio Control. Energies 2021, 14, 1140. [Google Scholar] [CrossRef]

- Zhang, L.; Zhang, L.; Yang, J.; Gao, M.; Li, Y. Application Research of Fuzzy PID Control Optimized by Genetic Algorithm in Medium and Low Speed Maglev Train Charger. IEEE Access 2021, 9, 152131–152139. [Google Scholar] [CrossRef]

- Jiang, W.; Liu, G.; Wang, T.; Gao, K. Variable universe fuzzy PID control based on adaptive contracting-expanding factors. Eng. Mech. 2021, 38, 23–32. [Google Scholar]

- Zhou, J.; Li, Z.; Li, X.; Wang, X.; Song, R. Human–Robot Cooperation Control Based on Trajectory Deformation Algorithm for a Lower Limb Rehabilitation Robot. IEEE/ASME Trans. Mechatron. 2021, 26, 3128–3138. [Google Scholar] [CrossRef]

- Fan, R.; Li, Y. An Adaptive Fuzzy Trajectory Tracking Control via Improved Cerebellar Model Articulation Controller for Electro-Hydraulic Shovel. IEEE/ASME Trans. Mechatron. 2021, 26, 2870–2880. [Google Scholar] [CrossRef]

- Wang, T.; Wang, H.; Hu, H.; Lu, X.; Zhao, S. An adaptive fuzzy PID controller for speed control of brushless direct current motor. SN Appl. Sci. 2022, 4, 71. [Google Scholar] [CrossRef]

| ec | ||||||||

|---|---|---|---|---|---|---|---|---|

| NB | NM | NS | ZO | PS | PM | PB | ||

| e | NB | PB/NB/PS | PB/NB/NS | PM/NM/NB | PM/NM/NB | PS/NS/NB | ZO/ZO/NM | ZO/ZO/PS |

| NM | PB/NB/PS | PBNB/NS | PM/NM/NB | PS/NS/NM | PS/NS/NM | ZO/ZO/NS | NS/ZO/ZO | |

| N S | PM/NB/ZO | PM/NM/NS | PM/NS/NM | PS/NS/NM | ZO/ZO/NS | NS/PS/NS | NS/PS/ZO | |

| ZO | PM/NM/ZO | PM/NM/NS | PS/NS/NS | ZO/ZO/NS | NS/PS/NS | NM/PM/NS | NM/PM/ZO | |

| P S | PS/NM/ZO | PS/NS/ZO | ZO/ZO/ZO | NS/PS/ZO | NS/PS/ZO | NM/PM/ZO | NM/PB/ZO | |

| PM | PS/ZO/PB | ZO/ZO/NS | NS/PS/NS | NM/PS/PS | NM/PM/PS | NM/PB/PS | NB/PB/PB | |

| P B | ZO/ZO/PB | ZO/ZO/PM | NM/PS/PM | NM/PM/PM | NM/PM/PS | NB/PB/PS | NB/PB/PB | |

| Type | Nominal Cross-Sectional Area (mm2) | Number of Aluminum Wires | Aluminum Wire Diameter (mm) | Insulation Layer Thickness (mm) |

|---|---|---|---|---|

| JKLYJ | 120 | 24 | 0.8 | 2.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhong, J.; Ai, W.; Wang, Z.; Hu, S.; Zhang, H. A Novel High-Voltage-Cable Stripping Robot. Actuators 2023, 12, 201. https://doi.org/10.3390/act12050201

Zhong J, Ai W, Wang Z, Hu S, Zhang H. A Novel High-Voltage-Cable Stripping Robot. Actuators. 2023; 12(5):201. https://doi.org/10.3390/act12050201

Chicago/Turabian StyleZhong, Jun, Wenxu Ai, Zhichao Wang, Shaoguang Hu, and Hongshuang Zhang. 2023. "A Novel High-Voltage-Cable Stripping Robot" Actuators 12, no. 5: 201. https://doi.org/10.3390/act12050201

APA StyleZhong, J., Ai, W., Wang, Z., Hu, S., & Zhang, H. (2023). A Novel High-Voltage-Cable Stripping Robot. Actuators, 12(5), 201. https://doi.org/10.3390/act12050201