A Study on the Design of Novel Slotless Motor Considering Winding Manufacture Process for a Collaborative Robot

Abstract

:1. Introduction

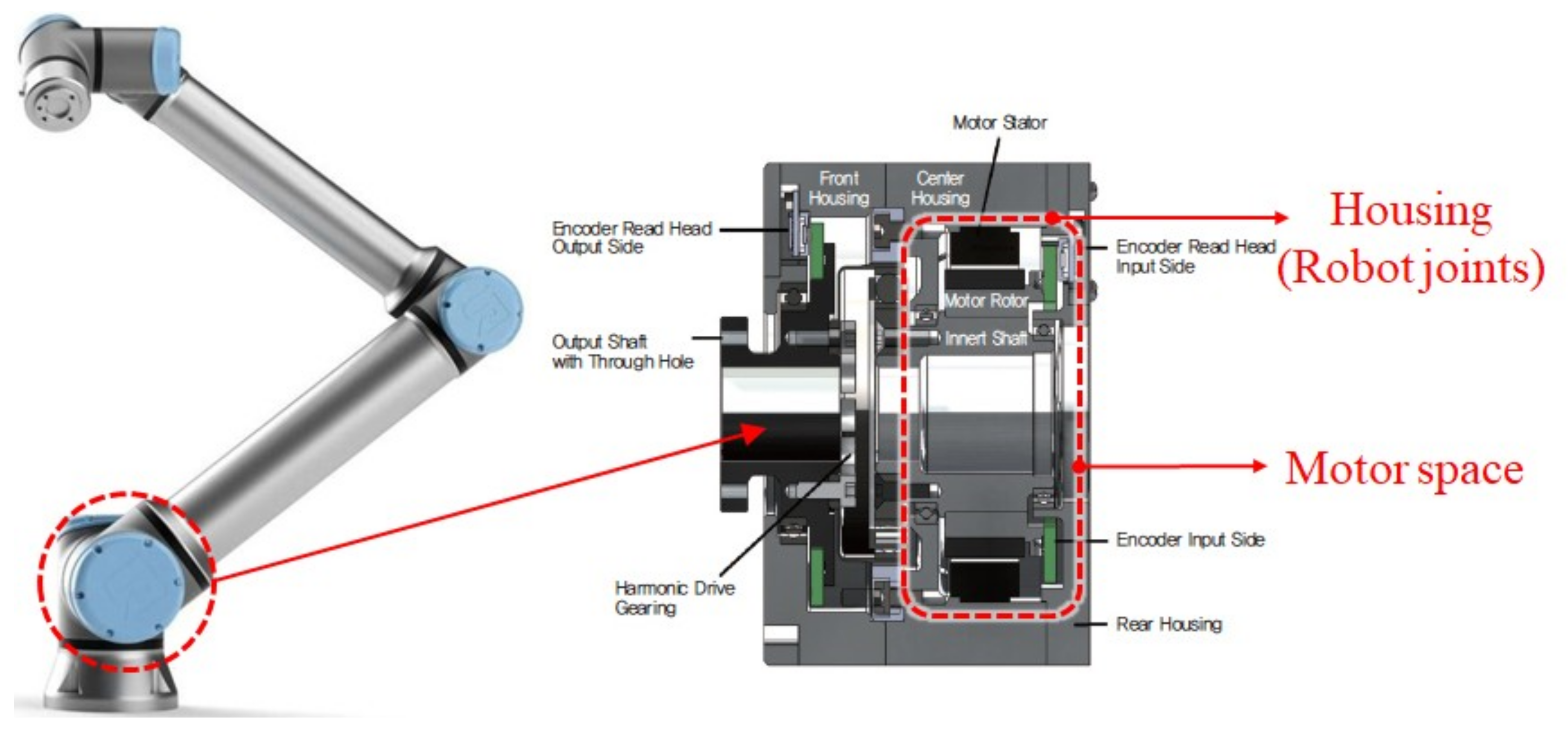

2. Specifications of Slotless Motor for the Collaborative Robot

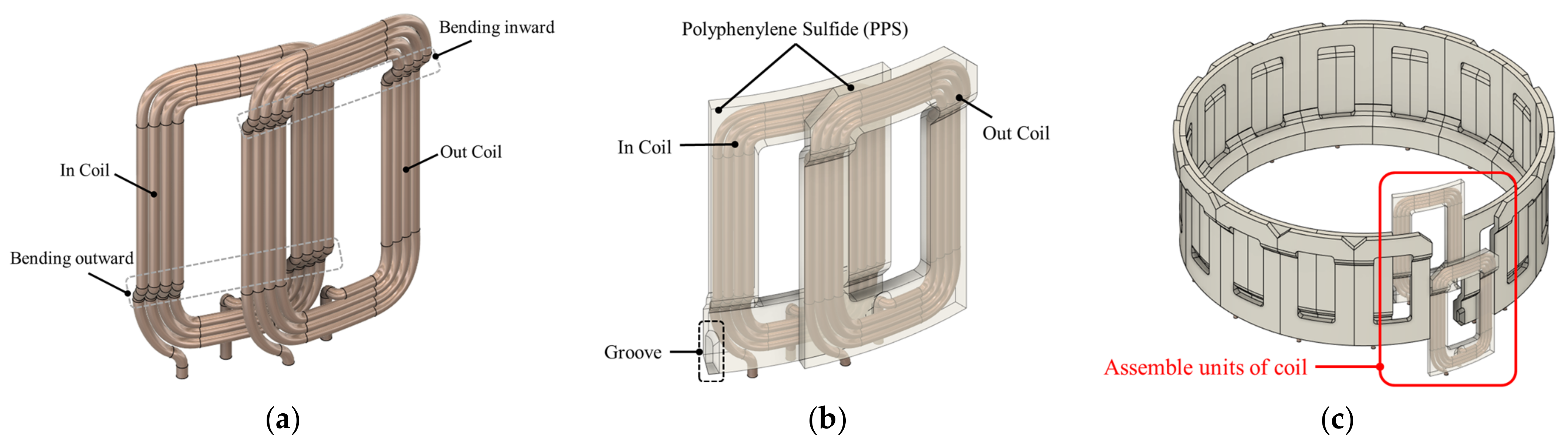

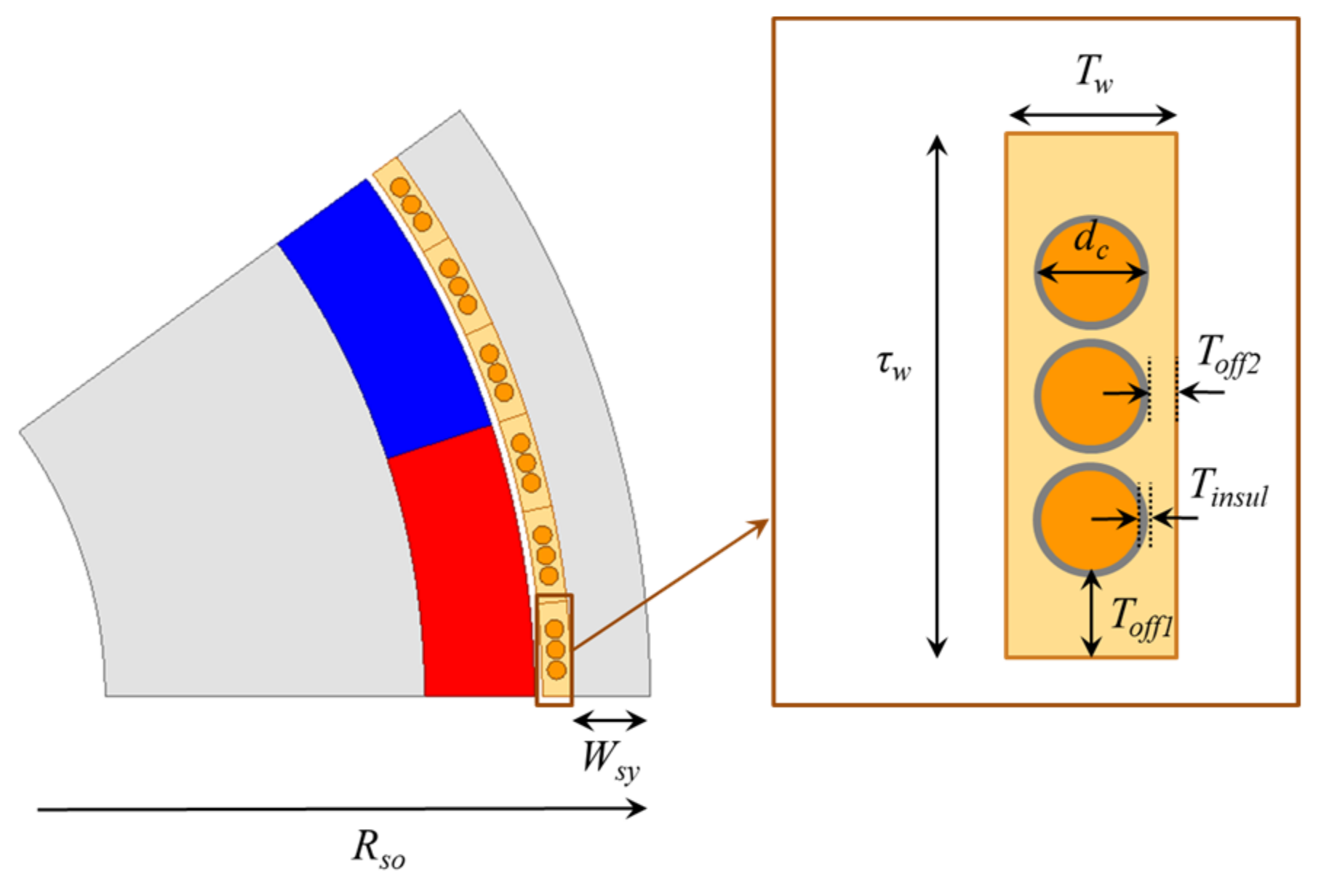

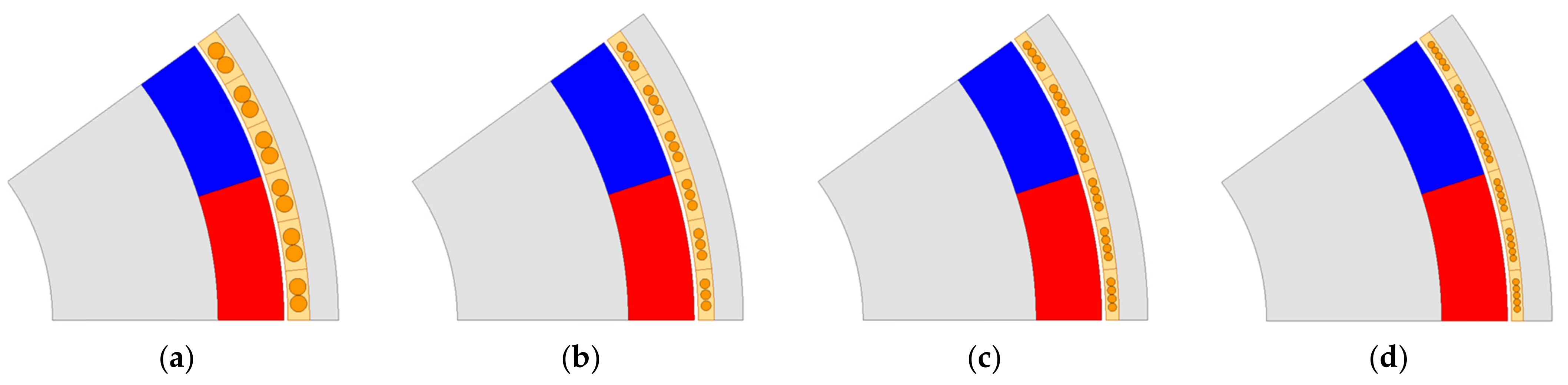

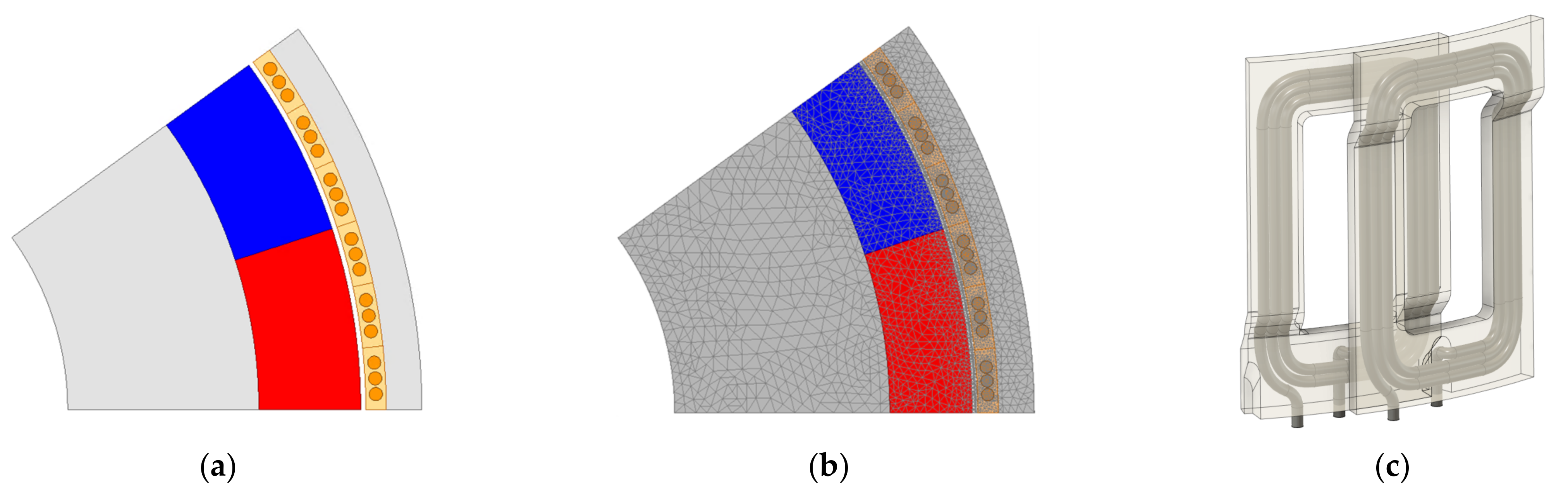

3. Structure and Manufacture Concept of the Novel Slotless Motor

4. Design of Slotless Motor Considering the Proposed Manufacture Process

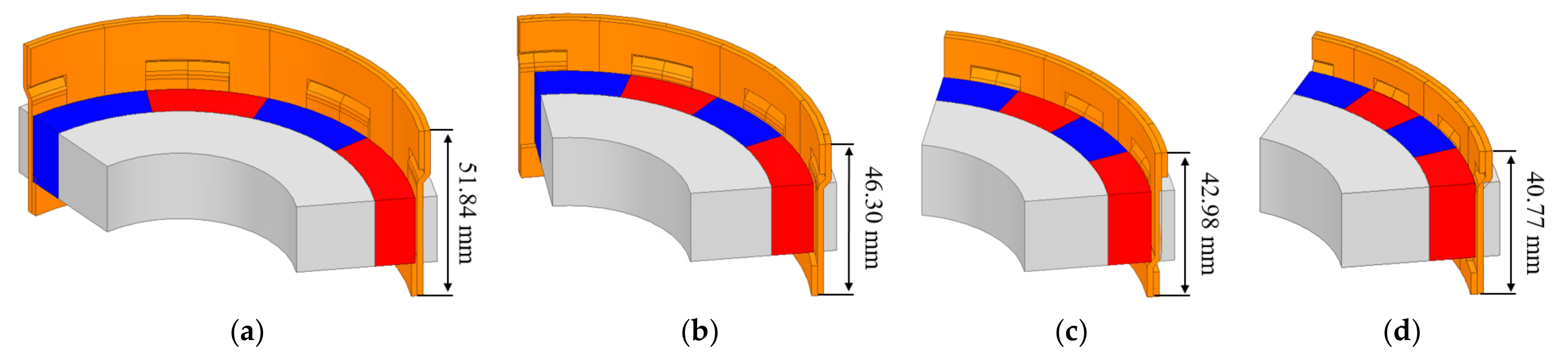

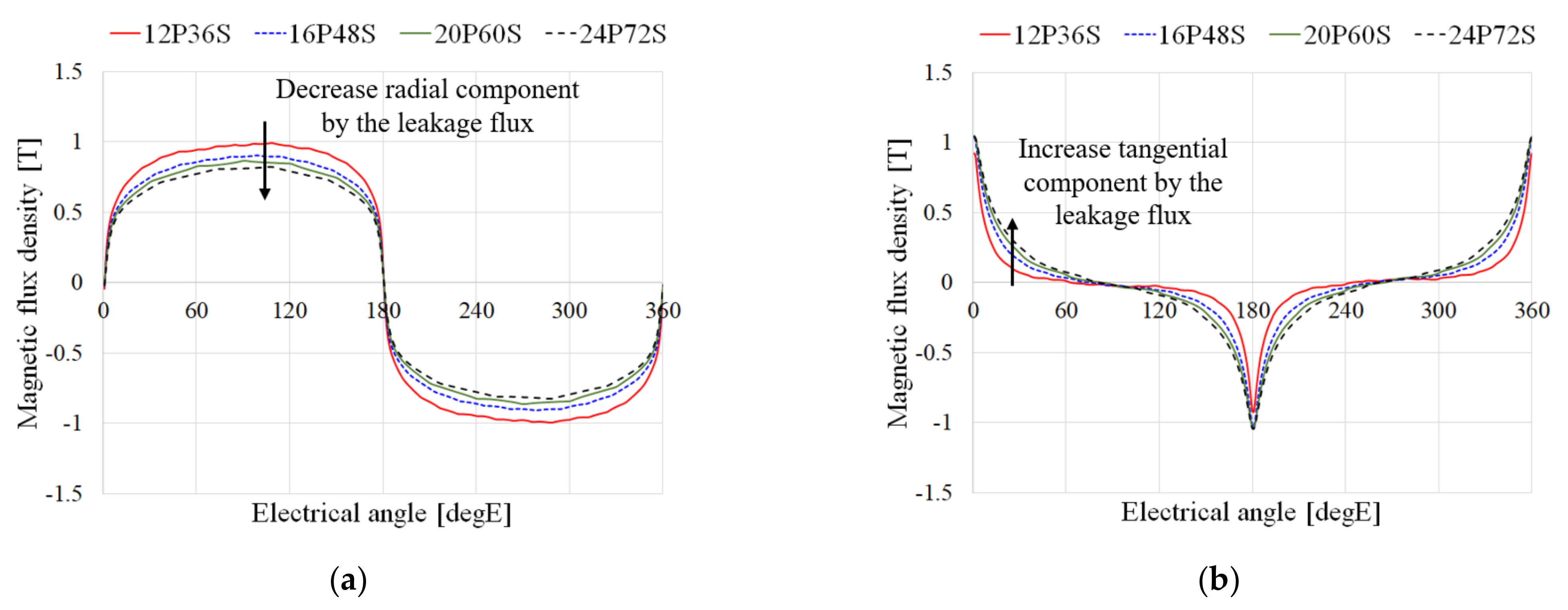

4.1. Pole Slot Combination

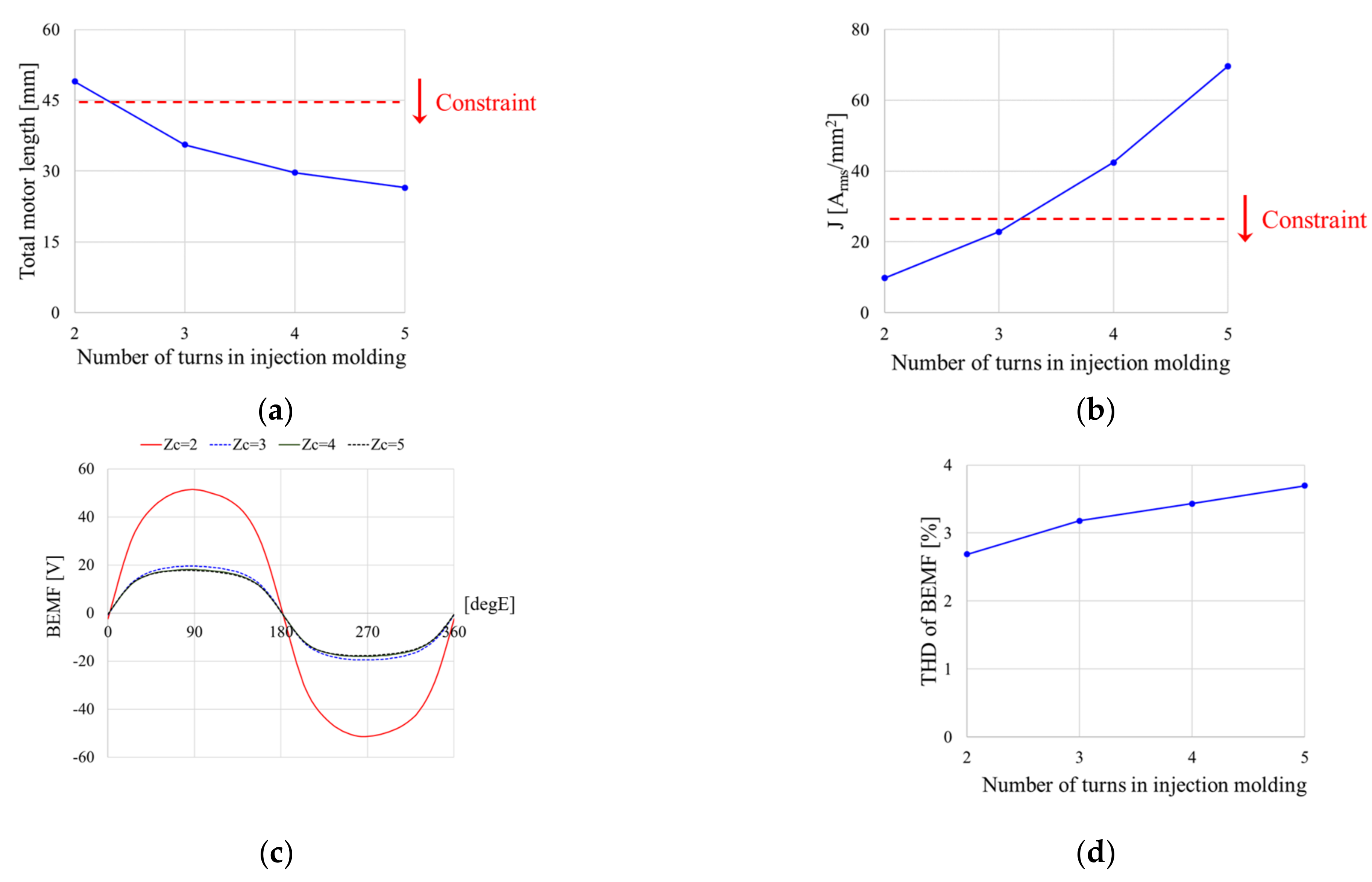

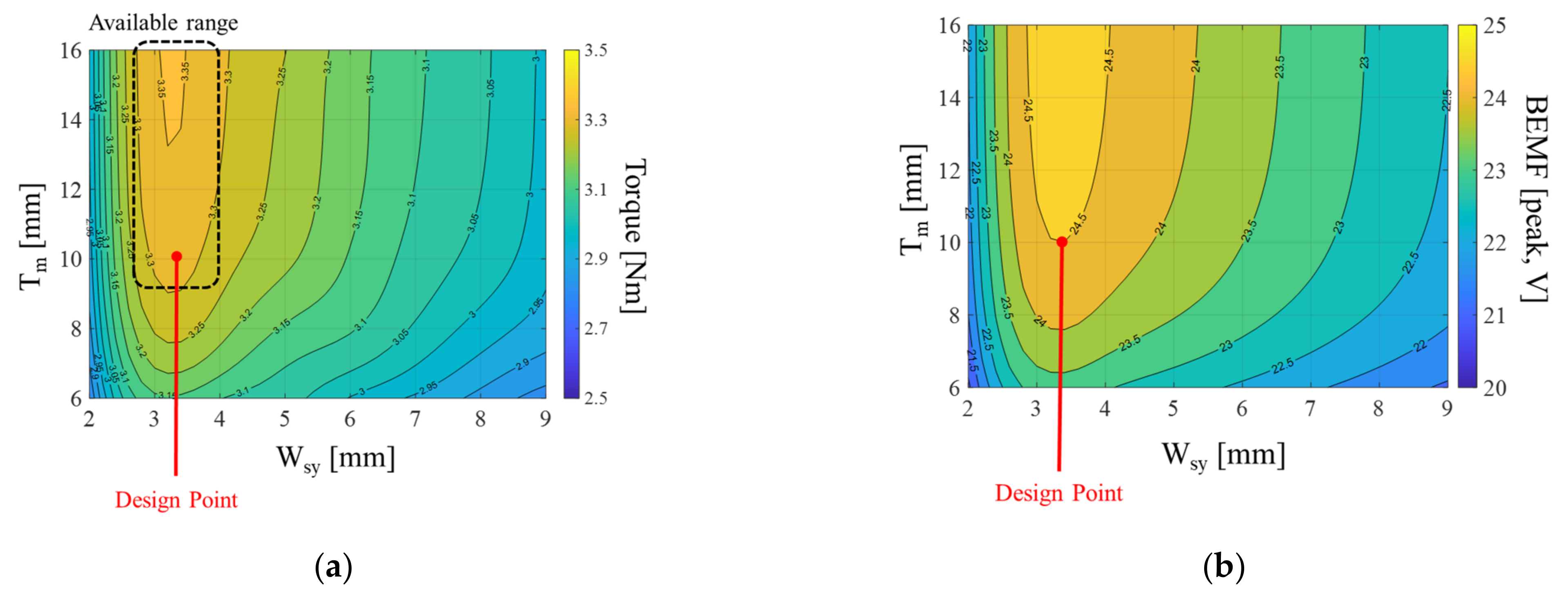

4.2. Design of Slotless Motor Considering Constraints of Winding Manufacture

4.3. Final Model of Slotless Motor

5. Manufacture and Experiment Verification

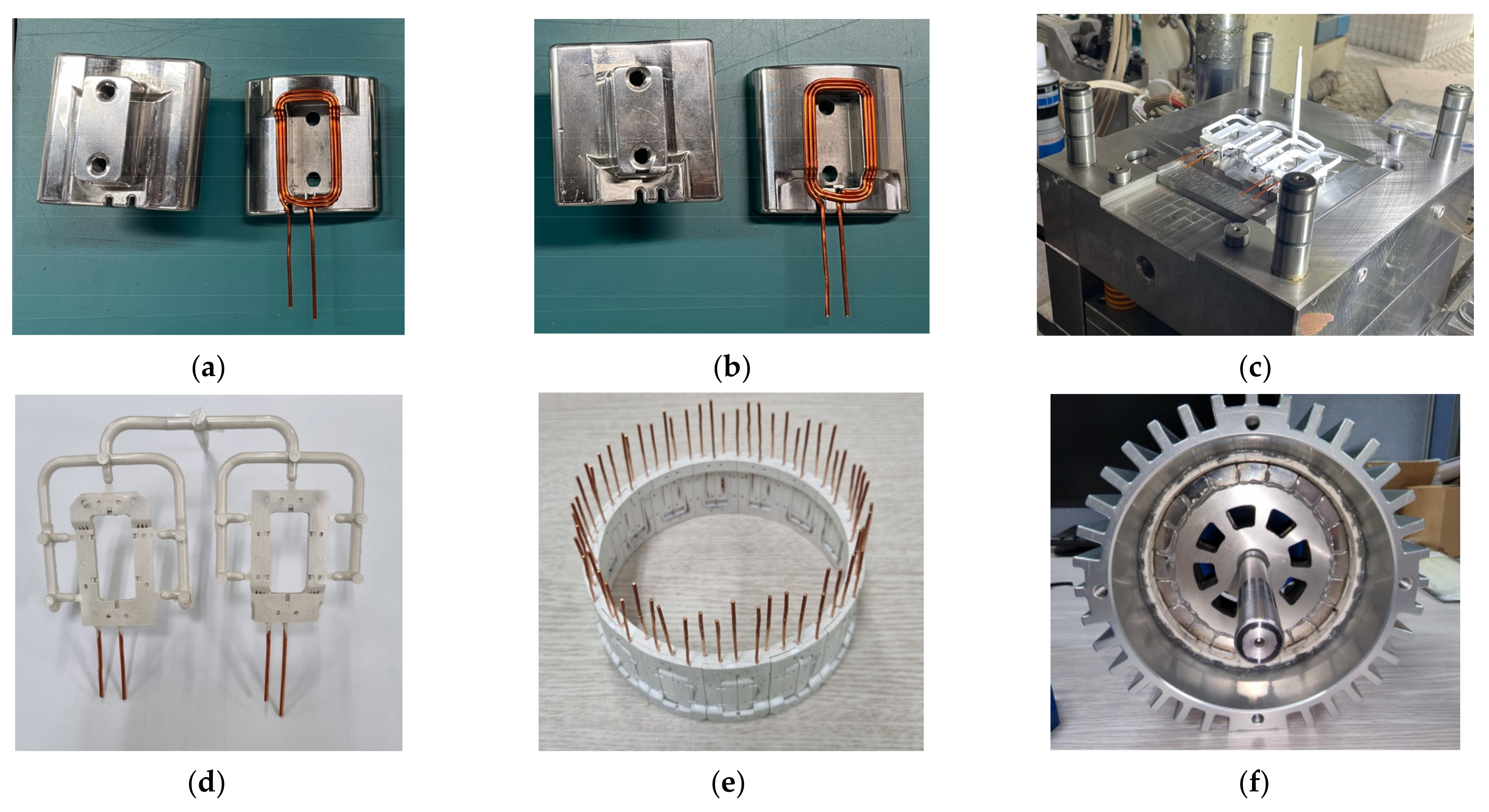

5.1. Manufacture of Slotless Motor

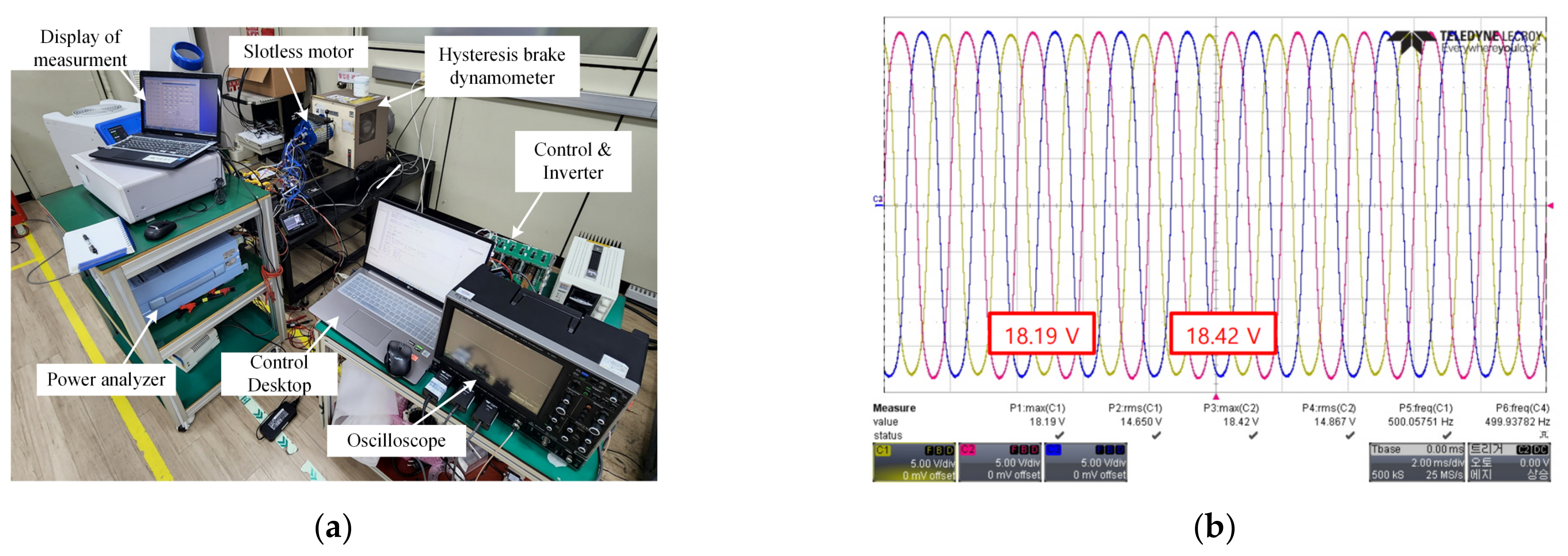

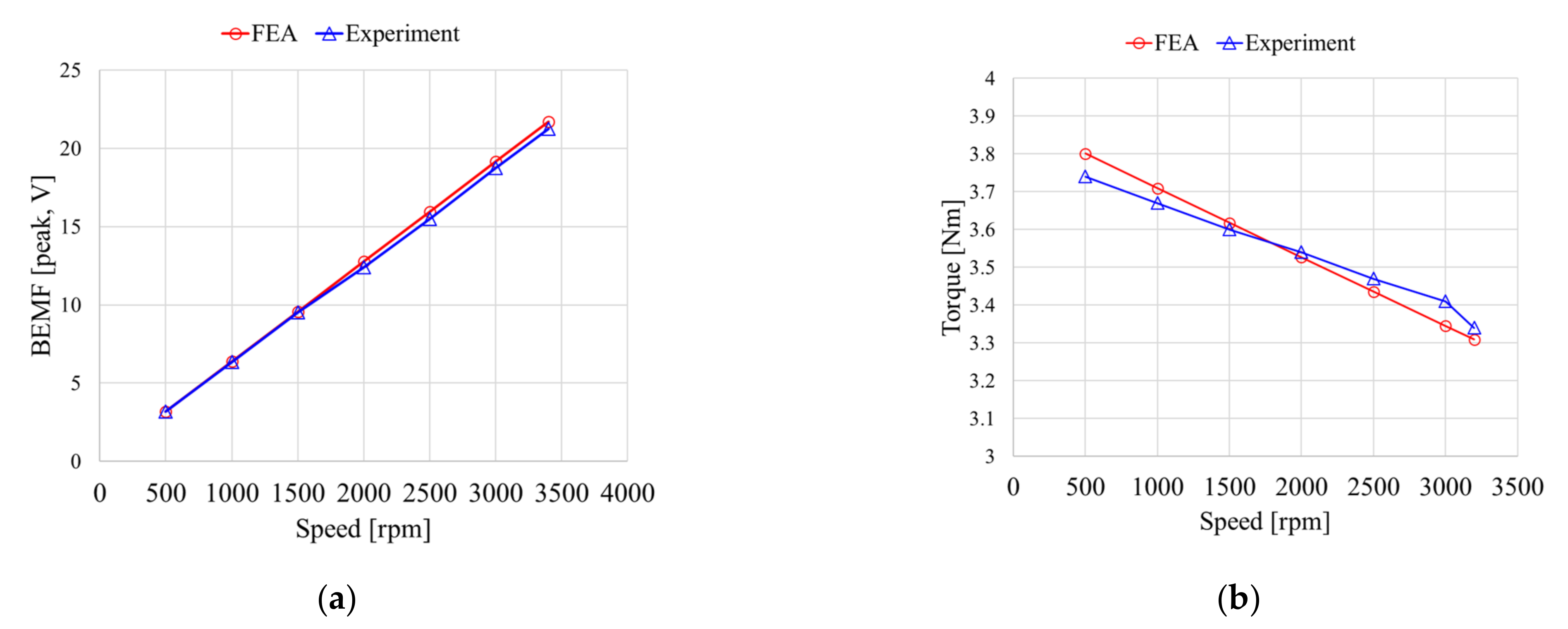

5.2. Experiment Verification

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Liu, B.; Fu, W.; Wang, W.; Gao, Z.; Li, R.; Peng, L.; Du, H.; Chen, X. Research on Cobot Action Decision-Making Method Based on Intuitionistic Fuzzy Set and Game Theory. IEEE Access 2022, 10, 103349–103363. [Google Scholar] [CrossRef]

- Van de Perre, G.; Hubert, T.; Verstraten, T.; Vanderborght, B. Investigating the Potential of Flexible Links for Increased Payload to Mass Ratios for Collaborative Robotics. IEEE Access 2023, 11, 15981–15995. [Google Scholar] [CrossRef]

- Hameed, A.; Ordys, A.; Możaryn, J.; Sibilska-Mroziewicz, A. Control System Design and Methods for Collaborative Robots: Review. Appl. Sci. 2023, 13, 675. [Google Scholar] [CrossRef]

- Hong, D.-K.; Hwang, W.; Lee, J.-Y.; Woo, B.-C. Design, Analysis, and Experimental Validation of a Permanent Magnet Synchronous Motor for Articulated Robot Applications. IEEE Trans. Magn. 2018, 54, 8201304. [Google Scholar] [CrossRef]

- Luu, P.T.; Lee, J.-Y.; Park, J.-H. Electromagnetic and Thermal Analysis of Permanent-Magnet Synchronous Motors for Cooperative Robot Applications. IEEE Trans. Magn. 2020, 56, 7512804. [Google Scholar] [CrossRef]

- Zhang, W.; Xu, Y.; Zhou, G. Research on a Novel Transverse Flux Permanent Magnet Motor with Hybrid Stator Core and Disk-Type Rotor for Industrial Robot Applications. IEEE Trans. Ind. Electron. 2021, 68, 11223–11233. [Google Scholar] [CrossRef]

- Zhao, W.; Wang, X.; Gerada, C.; Zhang, H.; Liu, C.; Wang, Y. Multi-Physics and Multi-Objective Optimization of a High Speed PMSM for High Performance Applications. IEEE Trans. Magn. 2018, 54, 8106405. [Google Scholar] [CrossRef]

- Zhang, C.; Zhou, G. Research on the identification of the moment of inertia of PMSM for industrial robots. In Proceedings of the Chinese Automation Congress (CAC), Shanghai, China, 6–8 November 2020. [Google Scholar]

- Shin, S.-C.; Choi, C.-H.; Youm, J.-H.; Lee, T.-K.; Won, C.-Y. Position control of PMSM using jerk-limited trajectory for torque ripple reduction in robot applications. In Proceedings of the IECON 2012—38th Annual Conference on IEEE Industrial Electronics Society, Montreal, QC, USA, 25–28 October 2012. [Google Scholar]

- Luu, P.T.; Lee, J.-Y.; Lee, J.-H.; Park, J.-W. Electromagnetic and Thermal Analysis of a Permanent Magnet Motor Considering the Effect of Articulated Robot Link. Energies 2020, 13, 3239. [Google Scholar] [CrossRef]

- Shin, D.-Y.; Jung, M.-J.; Lee, K.-B.; Kim, W.-H. A Study on the Improvement of Torque Density of an Axial Slot-Less Flux Permanent Magnet Synchronous Motor for Collaborative Robot. Energies 2022, 15, 3464. [Google Scholar] [CrossRef]

- Hwang, S.-W.; Chin, J.-W.; Lim, M.-S. Design Process and Verification of SPMSM for a Wearable Robot Considering Thermal Characteristics Through LPTN. IEEE/ASME Trans. Mechatron. 2021, 26, 1033–1042. [Google Scholar] [CrossRef]

- Yuan, T.; Wang, D.; Wang, X.; Wang, X.; Sun, Z. High-Precision Servo Control of Industrial Robot Driven by PMSM-DTC Utilizing Composite Active Vectors. IEEE Access 2019, 7, 7577–7587. [Google Scholar] [CrossRef]

- Kim, R.-E.; Seo, J.-M.; Rhyu, S.-H. Design of Permanent Magnet Motors with Distributed and Concentrated Windings for Robot Arms. In Proceedings of the IEEE International Conference on Electrical Machines and Systems, Jeju, Republic of Korea, 7–10 October 2018. [Google Scholar]

- Yu, H.-C.; Yu, B.-S.; Lin, C.-K. A dual notched design of radial-flux permanent magnet motors with low cogging torque and rare earth material. IEEE Trans. Magn. 2014, 50, 8203104. [Google Scholar] [CrossRef]

- Kim, J.-M.; Yoon, M.-H.; Hong, J.-P.; Kim, S.-I. Analysis of cogging torque caused by manufacturing tolerances of surface-mounted permanent magnet synchronous motor for electric power steering. IET Electr. Power Appl. 2016, 10, 691–696. [Google Scholar] [CrossRef]

- Yu, Y.; Pan, Y.; Chen, Q.; Zeng, D.; Hu, Y.; Goh, H.-H.; Niu, S.; Zhao, Z. Cogging Torque Minimization of Surface-Mounted Permanent Magnet Synchronous Motor Based on RSM and NSGA-II. Actuators 2022, 11, 3793. [Google Scholar] [CrossRef]

- Kim, K.-C.; Jeon, S.-H. Analysis on Correlation between Cogging Torque and Torque Ripple by Considering Magnetic Saturation. IEEE Trans. Magn. 2013, 49, 2417–2420. [Google Scholar] [CrossRef]

- Ren, W.; Xu, Q.; Li, Q.; Zhou, L. Reduction of Cogging Torque and Torque Ripple in Interior PM Machines with Asymmetrical V-Type Rotor Design. IEEE Trans. Magn. 2016, 52, 8104105. [Google Scholar] [CrossRef]

- Wang, D.; Wang, X.; Jung, S.-Y. Cogging Torque Minimization and Torque Ripple Suppression in Surface-Mounted Permanent Magnet Synchronous Machines Using Different Magnet Widths. IEEE Trans. Magn. 2013, 49, 2295–2298. [Google Scholar] [CrossRef]

- Wu, D.; Zhu, Z. Design Tradeoff between Cogging Torque and Torque Ripple in Fractional Slot Surface-Mounted Permanent Magnet Machines. In Proceedings of the IEEE International Magnetics Conference (INTERMAG), Beijing, China, 11–15 May 2015. [Google Scholar]

- Gao, J.; Wang, G.; Liu, X.; Zhang, W.; Huang, S.; Li, H. Cogging Torque Reduction by Elementary-Cogging-Unit Shift for Permanent Magnet Machines. IEEE Trans. Magn. 2017, 53, 8208705. [Google Scholar] [CrossRef]

- Zhu, X.; Hua, W.; Cheng, M.; Zhang, G. An Improved Configuration for Cogging Torque Reduction in Flux-Reversal Permanent Magnet Machines. In Proceedings of the IEEE Conference on Electromagnetic Field Computation (CEFC), Miami, FL, USA, 13–16 November 2016. [Google Scholar]

- Cheng, W.; Cao, G.; Deng, Z.; Xiao, L.; Li, M. Torque Comparison between Slotless and Slotted Ultra-High-Speed AFPM Motors Using Analytical Method. IEEE Trans. Magn. 2022, 58, 8101805. [Google Scholar] [CrossRef]

- Song, Z.; Liu, C.; Feng, K.; Zhao, H.; Yu, J. Field Prediction and Validation of a Slotless Segmented-Halbach Permanent Magnet Synchronous Machine for More Electric Aircraft. IEEE Trans. Transport. Electrific. 2020, 6, 1577–1591. [Google Scholar] [CrossRef]

- Lee, D.; Yoon, A.; Sirimanna, S.; Salon, S.; Haran, K.S. Impact of Manufacturing Tolerances on a Low-Reactance Slotless PM Synchronous Machine. IEEE Trans. Energy Convers. 2022, 35, 366–374. [Google Scholar] [CrossRef]

- Cheng, W.; Cao, G.; Deng, Z.; Xiao, L.; Li, M. Analytical Solution for Electromagnetic Torque of Ultrahigh Speed AFPM Motor with Slotless Stator Core and Toroidal Coils. IEEE Trans. Magn. 2021, 57, 8202505. [Google Scholar] [CrossRef]

- Lee, H.-Y.; Yoon, S.-Y.; Kwon, S.-O.; Shin, J.-Y.; Park, S.-H.; Lim, M.-S. A Study on a Slotless Brushless DC Motor with Toroidal Winding. Processes 2021, 9, 1881. [Google Scholar] [CrossRef]

- Si, J.; Zhang, T.; Hu, Y.; Gan, C.; Li, Y. An Axial-Flux Dual-Rotor Slotless Permanent Magnet Motor with Novel Equidirectional Toroidal Winding. IEEE Trans. Energy Convers. 2022, 37, 1752–1763. [Google Scholar] [CrossRef]

- Gallego, G.B.; Rossini, L.; Achtnich, T.; Araujo, D.M.; Perriard, Y. Efficiency Optimization of Slotless Magnetic-Bearing Machines. IEEE Trans. Ind. Appl. 2021, 57, 6833–6843. [Google Scholar] [CrossRef]

- Burnand, G.; Thabuis, A.; Araujo, D.M.; Perriard, Y. Novel Optimized Shape and Topology for Slotless Windings in BLDC Machines. IEEE Trans. Ind. Appl. 2020, 56, 1275–1283. [Google Scholar] [CrossRef]

- Song, Z.; Liu, C.; Liu, S.; Wang, W. Active Harmonic Suppression of Low-Reactance Multiphase Slotless Permanent Magnet Synchronous Machines. IEEE J. Emerg. Sel. Top. Power Electron. 2022, 10, 1777–1787. [Google Scholar] [CrossRef]

| Component | Value | Unit |

|---|---|---|

| Outer diameter of stator | 127 | mm |

| Total motor length including end turn of winding | ≤45 | mm |

| Airgap length | 0.5 | mm |

| Shaft diameter | 57.5 | mm |

| Component | Value | Unit |

|---|---|---|

| DC link voltage | 48 | Vdc |

| Rated power | 1.1 | kW |

| Rated speed | 3400 | rpm |

| Rated torque considering the margin | 3.3 | Nm |

| Rated current | 28.5 | Arms |

| Current density | ≤25 | Arms/mm2 |

| Component | 12P36S | 16P48S | 20P60S | 24P72S | Unit |

|---|---|---|---|---|---|

| Total series turn | 60 | - | |||

| Torque | 4.39 | 3.88 | 3.77 | 3.58 | Nm |

| End turn length | 32.84 | 27.3 | 23.98 | 21.77 | mm |

| Total motor length | 51.84 | 46.3 | 42.98 | 40.77 | mm |

| Component | Value | Unit |

|---|---|---|

| Number of pole/slot | 20/60 | - |

| Outer diameter of stator/rotor | 127/115 | mm |

| Length of airgap | 0.5 | mm |

| Thickness of injection molding | 2 | mm |

| Thickness of stator yoke | 3 | mm |

| Diameter of coil excluding insulator | 1.2 | mm |

| Number of turns in injection molding | 3 | - |

| Stack length | 19 | mm |

| Total motor length | 44.54 | mm |

| Torque | 3.33 | Nm |

| Cogging torque | 0 | Nm |

| Input current | 28.5 | Arms |

| Voltage | 24.64 | Vmax |

| Copper loss | 119.61 | W |

| Core loss | 17.79 | W |

| PM eddy loss | 0.0047 | W |

| Efficiency | 89.61 | % |

| Current density | 25 | Arms/mm2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kang, J.; Kim, J.; Ahn, J.; Yoon, I.; Kim, H.; Lee, J.; Jung, D. A Study on the Design of Novel Slotless Motor Considering Winding Manufacture Process for a Collaborative Robot. Actuators 2023, 12, 156. https://doi.org/10.3390/act12040156

Kang J, Kim J, Ahn J, Yoon I, Kim H, Lee J, Jung D. A Study on the Design of Novel Slotless Motor Considering Winding Manufacture Process for a Collaborative Robot. Actuators. 2023; 12(4):156. https://doi.org/10.3390/act12040156

Chicago/Turabian StyleKang, Junho, Jeongwon Kim, Jungho Ahn, Inyeol Yoon, Hyunwoo Kim, Ju Lee, and Donghoon Jung. 2023. "A Study on the Design of Novel Slotless Motor Considering Winding Manufacture Process for a Collaborative Robot" Actuators 12, no. 4: 156. https://doi.org/10.3390/act12040156

APA StyleKang, J., Kim, J., Ahn, J., Yoon, I., Kim, H., Lee, J., & Jung, D. (2023). A Study on the Design of Novel Slotless Motor Considering Winding Manufacture Process for a Collaborative Robot. Actuators, 12(4), 156. https://doi.org/10.3390/act12040156