Analysis and Validation of Sensitivity in Torque-Sensitive Actuators

Abstract

1. Introduction

2. Analytical Modeling

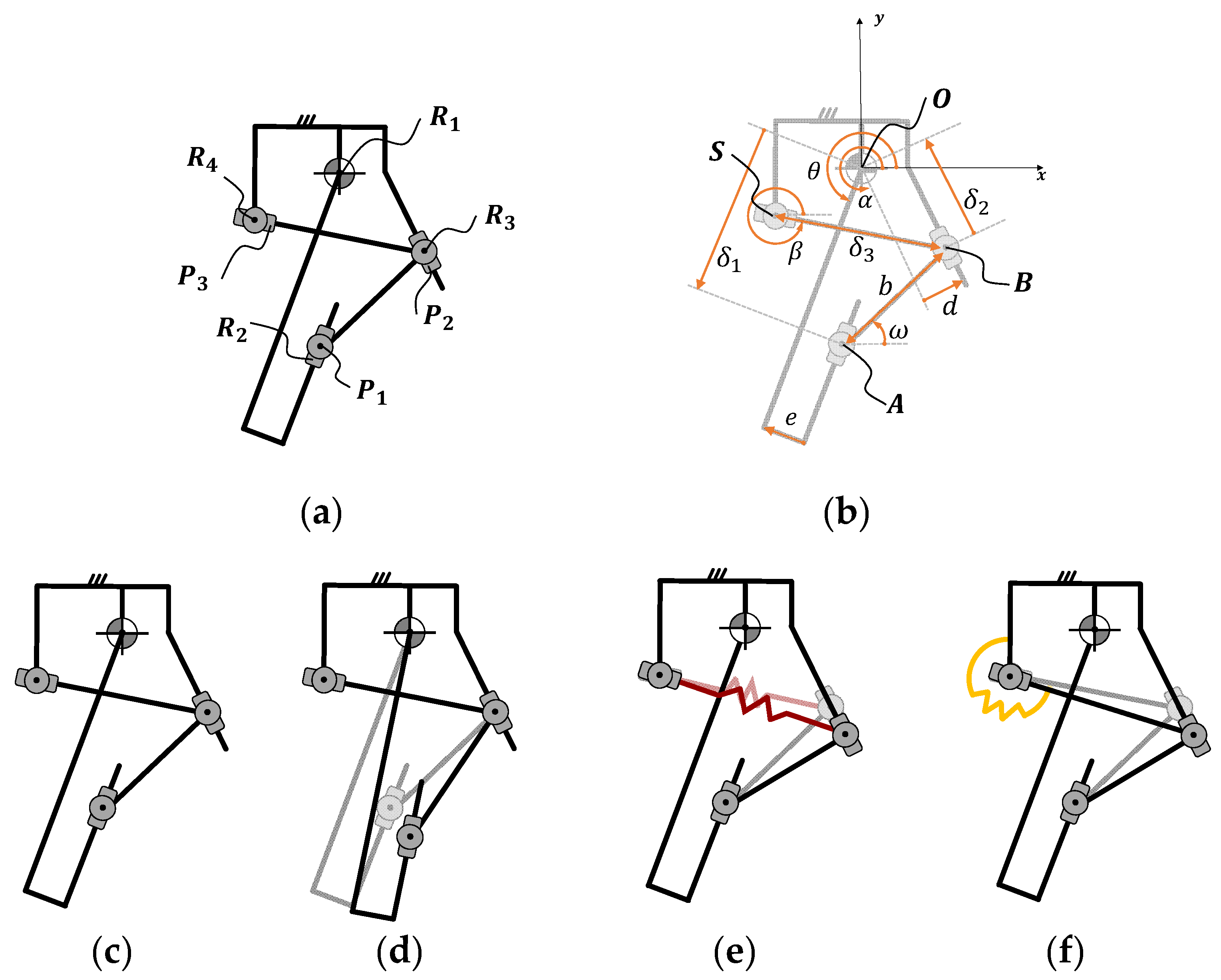

2.1. Kinematic Analysis

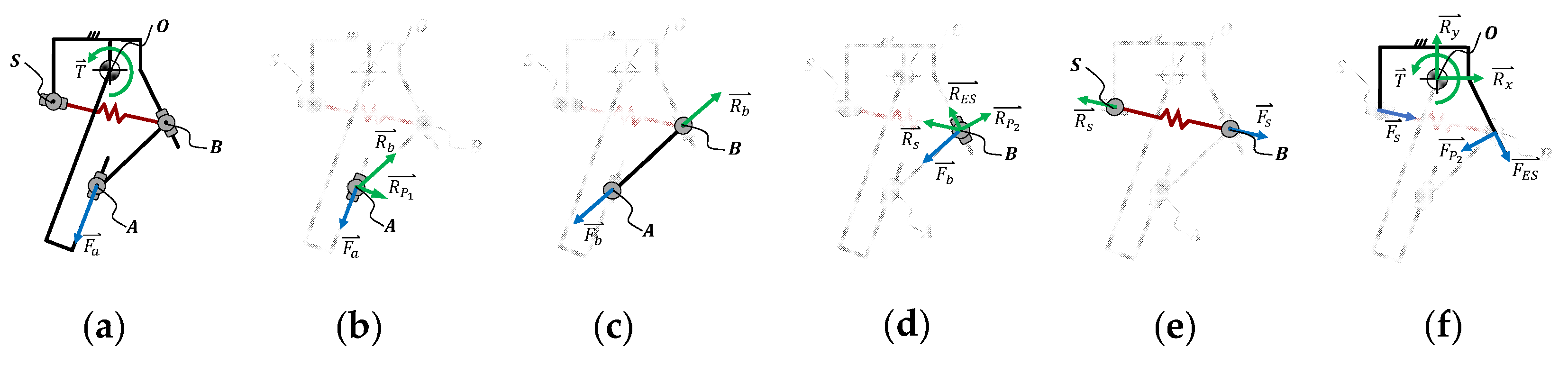

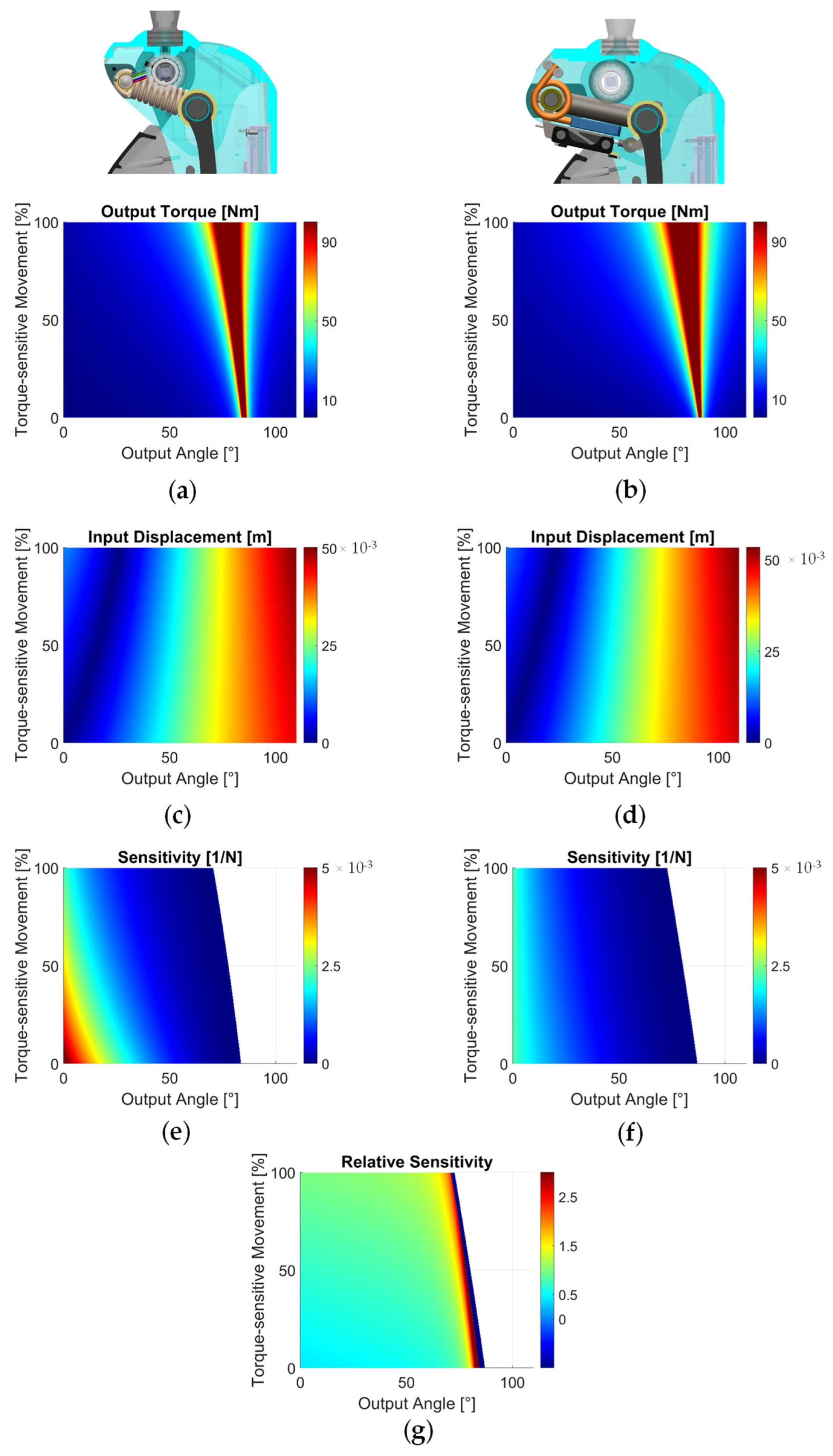

2.2. Free-Body Diagram and Torque Ratio

3. Formulation of Sensitivity

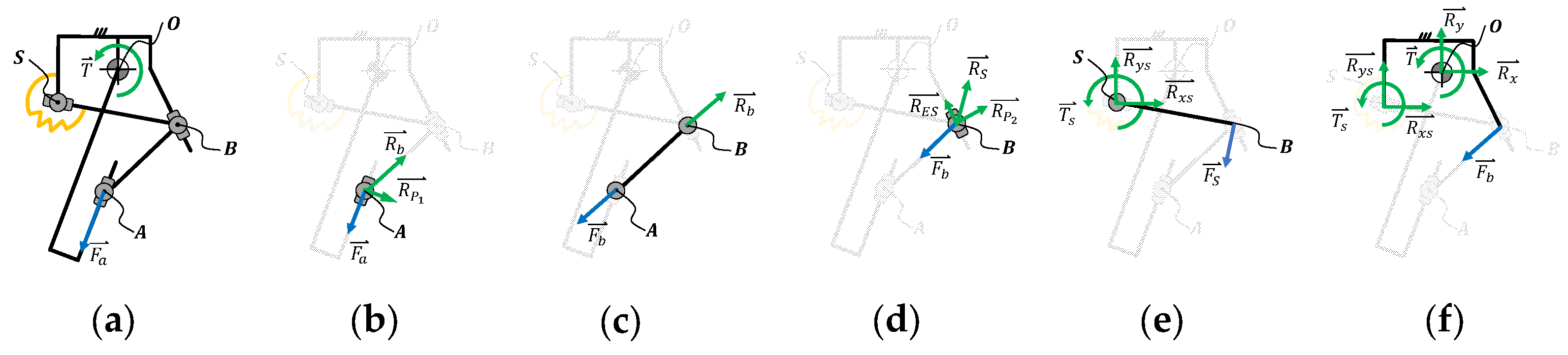

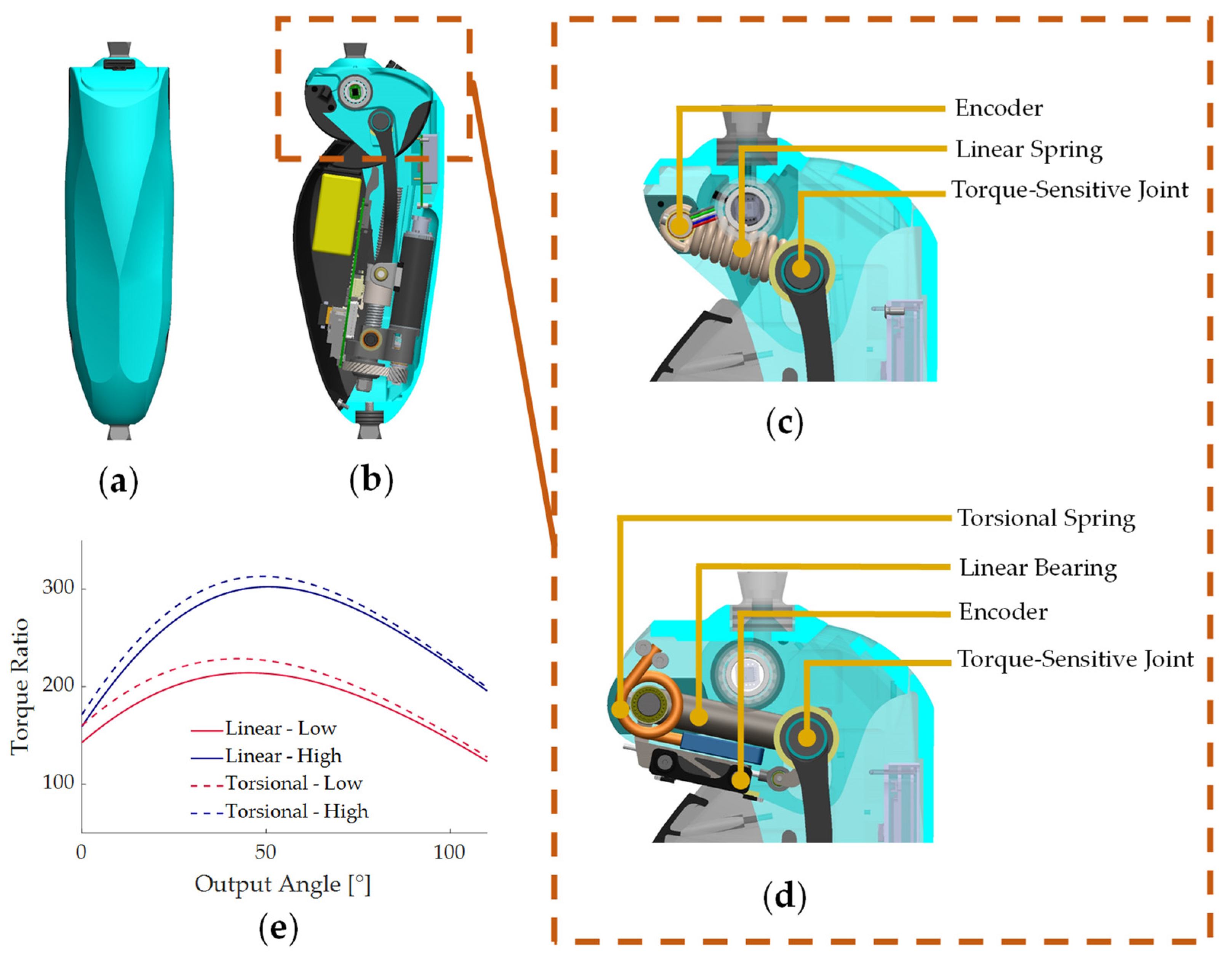

4. Mechatronic Implementation

5. Sensitivity Analysis

6. Experiments

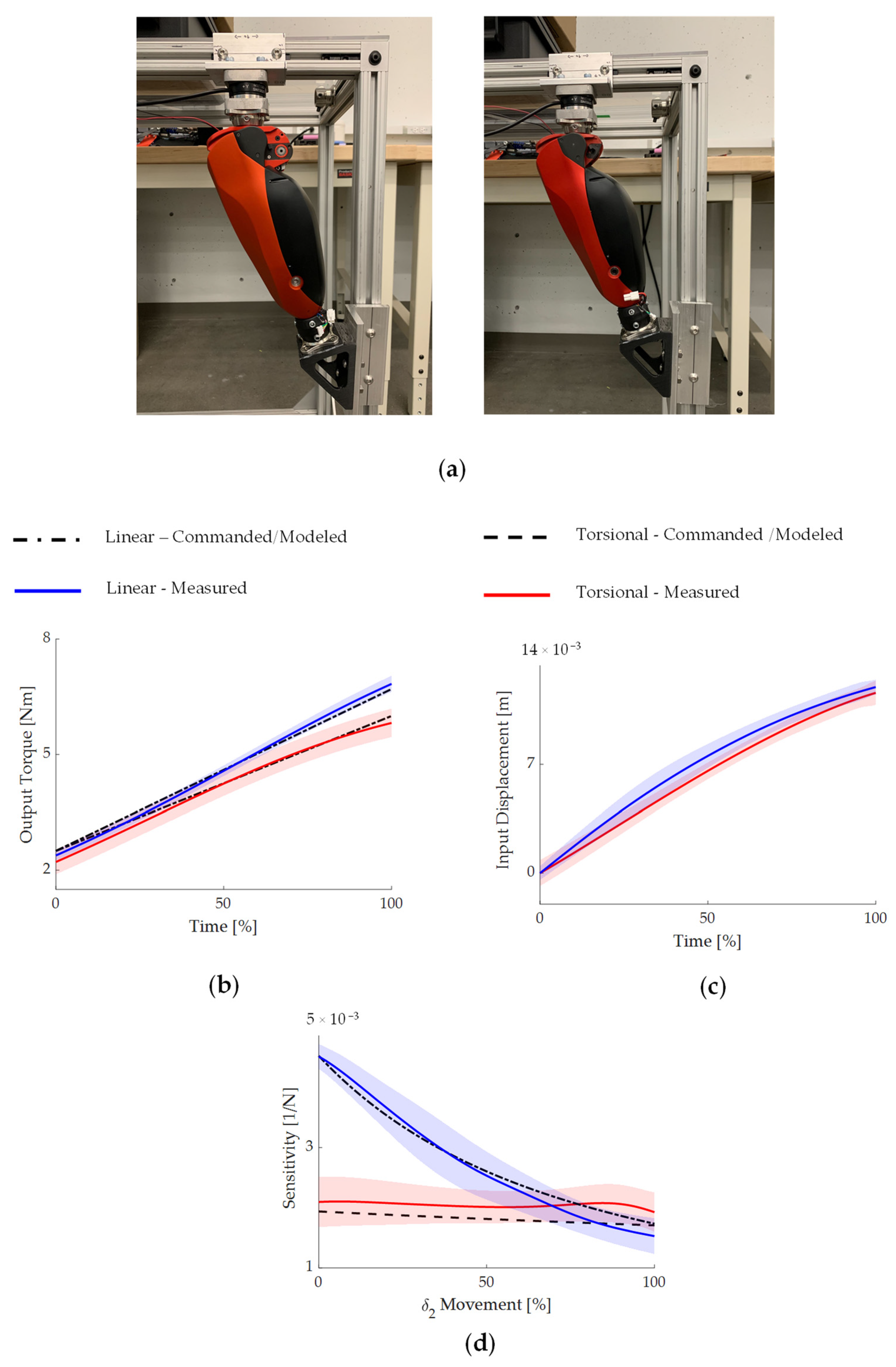

6.1. Joint Torque and Sensitivity Characterization

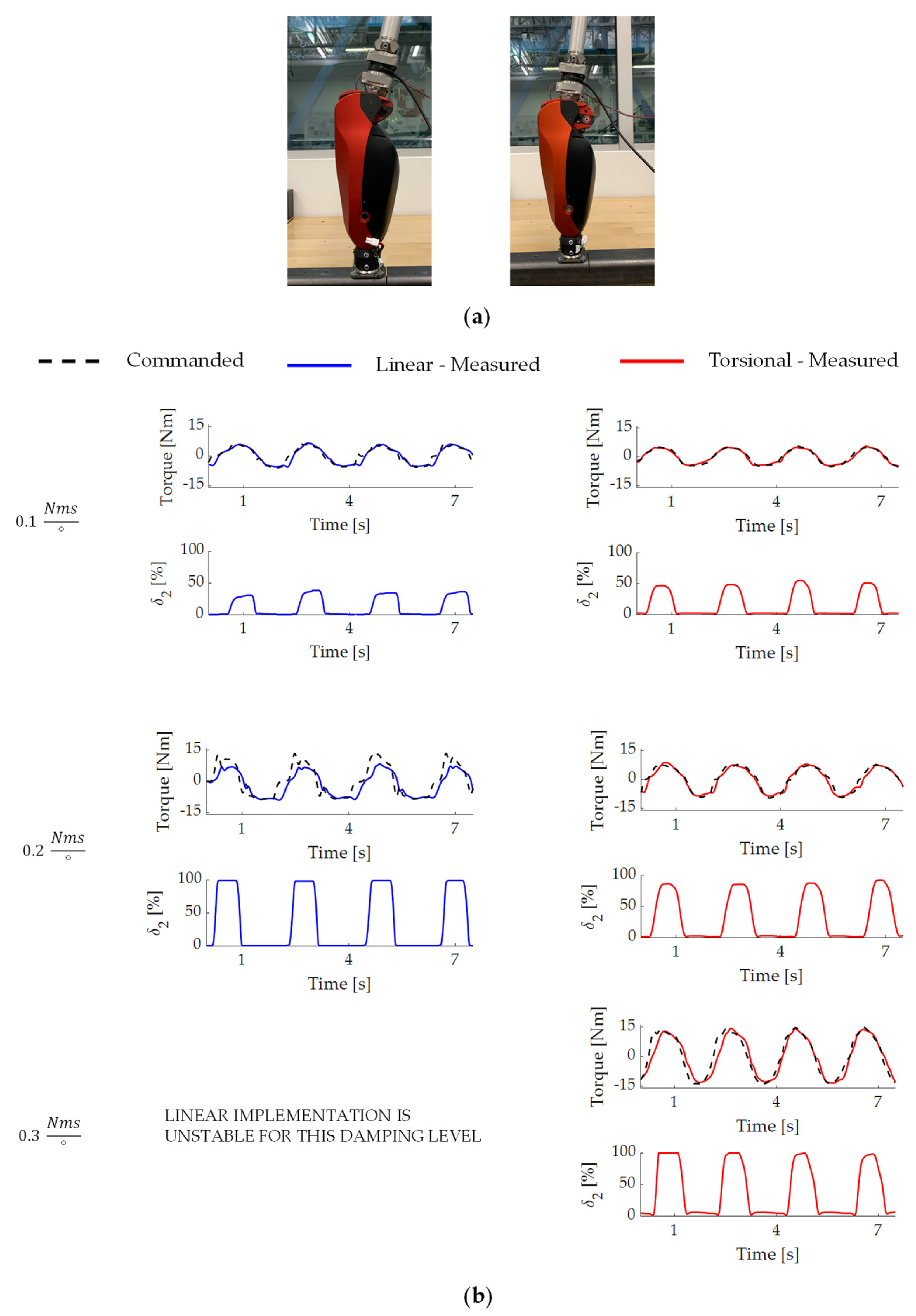

6.2. Damping Emulation

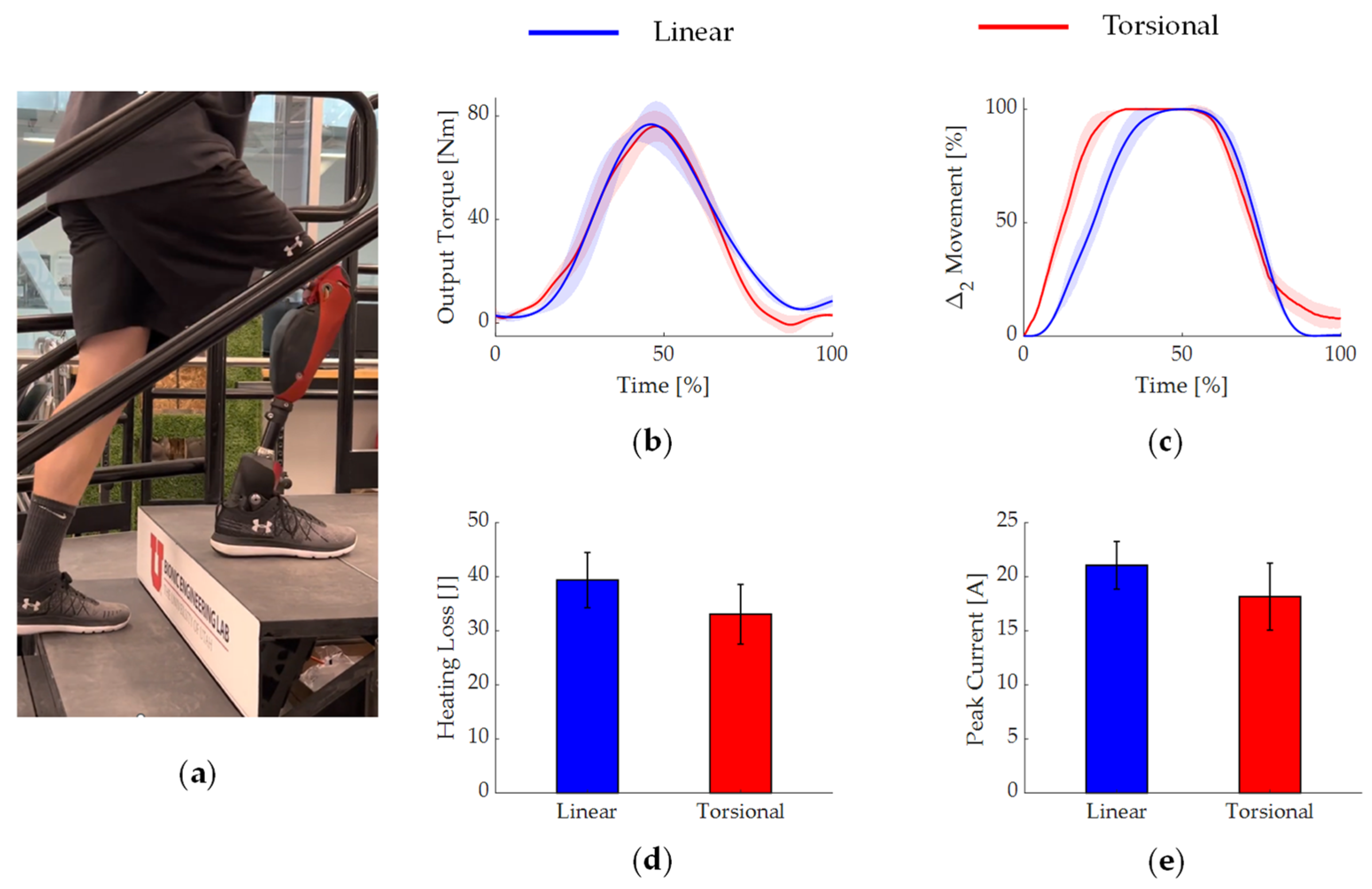

6.3. Stair Ascent with an above-Knee Amputee

7. Discussion

8. Conclusions

9. Patents

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Goldfarb, M.; Lawson, B.E.; Shultz, A.H. Realizing the Promise of Robotic Leg Prostheses. Sci. Transl. Med. 2013, 5, 210ps15. [Google Scholar] [CrossRef] [PubMed]

- Asano, Y.; Okada, K.; Inaba, M. Design principles of a human mimetic humanoid: Humanoid platform to study human intelligence and internal body system. Sci. Robot. 2017, 2, eaaq0899. [Google Scholar] [CrossRef] [PubMed]

- Fitzgerald, C. Developing baxter. In Proceedings of the IEEE Conference on Technologies for Practical Robot Applications, TePRA, Woburn, MA, USA, 22–23 April 2013. [Google Scholar] [CrossRef]

- Ficht, G.; Behnke, S. Bipedal Humanoid Hardware Design: A Technology Review. Curr. Robot. Rep. 2021, 2, 201–210. [Google Scholar] [CrossRef]

- Sawicki, G.S.; Beck, O.N.; Kang, I.; Young, A.J. The exoskeleton expansion: Improving walking and running economy. J. Neuroeng. Rehabil. 2020, 17, 25. [Google Scholar] [CrossRef] [PubMed]

- Lo, H.S.; Xie, S.Q. Exoskeleton robots for upper-limb rehabilitation: State of the art and future prospects. Med. Eng. Phys. 2012, 34, 261–268. [Google Scholar] [CrossRef] [PubMed]

- Farina, D.; Vujaklija, I.; Brånemark, R.; Bull, A.M.J.; Dietl, H.; Graimann, B.; Hargrove, L.J.; Hoffmann, K.-P.; Huang, H.; Ingvarsson, T.; et al. Toward higher-performance bionic limbs for wider clinical use. Nat. Biomed. Eng. 2021, 1–13. [Google Scholar] [CrossRef]

- Winter, D.A. Chapter 9: Kinesiological Electromyography. In Biomechanics and Motor Control of Human Movement, 4th ed.; Winter, D.A., Ed.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2005. [Google Scholar]

- Riener, R.; Rabuffetti, M.; Frigo, C. Stair ascent and descent at different inclinations. Gait Posture 2002, 15, 32–44. [Google Scholar] [CrossRef]

- Weir, R.F.; Ph, D. Design of Artificial Arms and Hands for Prosthetic Applications. Standard Handbook of Biomedical Engineering and Design. 2004. Available online: https://www.accessengineeringlibrary.com/content/book/9780071498395/chapter/chapter20 (accessed on 3 January 2023).

- Chen, F.C.; Appendino, S.; Battezzato, A.; Favetto, A.; Mousavi, M.; Pescarmona, F. Human Finger Kinematics and Dynamics. In Mechanisms and Machine Science; Springer: Berlin/Heidelberg, Germany, 2014; pp. 115–122. [Google Scholar] [CrossRef]

- Maxon Motor Maxon DC Motor and Maxon EC Motor Key Information. 2009. Available online: https://people.ece.ubc.ca/leos/pdf/datasheets/Maxon/MaxonSpecs.pdf (accessed on 31 October 2022).

- Pratt, G.; Williamson, M. Series elastic actuators. In Proceedings of the IEEE International Conference on Intelligent Robots and Systems, Pittsburgh, PA, USA, 5–9 August 1995. [Google Scholar] [CrossRef]

- Paine, N.; Mehling, J.S.; Holley, J.; Radford, N.A.; Johnson, G.; Fok, C.-L.; Sentis, L. Actuator Control for the NASA-JSC Valkyrie Humanoid Robot: A Decoupled Dynamics Approach for Torque Control of Series Elastic Robots. J. Field Robot. 2015, 32, 378–396. [Google Scholar] [CrossRef]

- Kashiri, N.; Baccelliere, L.; Muratore, L.; Laurenzi, A.; Ren, Z.; Hoffman, E.M.; Kamedula, M.; Rigano, G.F.; Malzahn, J.; Cordasco, S.; et al. CENTAURO: A Hybrid Locomotion and High Power Resilient Manipulation Platform. IEEE Robot. Autom. Lett. 2019, 4, 1595–1602. [Google Scholar] [CrossRef]

- Veneman, J.F.; Ekkelenkamp, R.; Kruidhof, R.; Van Der Helm, F.C.T.; Van Der Kooij, H. A Series Elastic- and Bowden-Cable-Based Actuation System for Use as Torque Actuator in Exoskeleton-Type Robots. Int. J. Robot. Res. 2006, 25, 261–281. [Google Scholar] [CrossRef]

- Zhang, T.; Tran, M.; Huang, H. Design and Experimental Verification of Hip Exoskeleton with Balance Capacities for Walking Assistance. IEEE/ASME Trans. Mechatron. 2018, 23, 274–285. [Google Scholar] [CrossRef]

- Ishmael, M.K.; Archangeli, D.; Lenzi, T. Powered hip exoskeleton improves walking economy in individuals with above-knee amputation. Nat. Med. 2021, 27, 1783–1788. [Google Scholar] [CrossRef] [PubMed]

- Ishmael, M.K.; Tran, M.; Lenzi, T. ExoProsthetics: Assisting Above-Knee Amputees with a Lightweight Powered Hip Exoskeleton. In Proceedings of the IEEE International Conference on Rehabilitation Robotics, Toronto, ON, Canada, 24–28 June 2019. [Google Scholar] [CrossRef]

- Sarkisian, S.V.; Ishmael, M.K.; Hunt, G.R.; Lenzi, T. Design, Development, and Validation of a Self-Aligning Mechanism for High-Torque Powered Knee Exoskeletons. IEEE Trans. Med. Robot. Bionics 2020, 2, 248–259. [Google Scholar] [CrossRef]

- Au, S.K.; Weber, J.; Herr, H. Powered Ankle—Foot Prosthesis Improves Walking Metabolic Economy. IEEE Trans. Robot. 2009, 25, 51–66. [Google Scholar] [CrossRef]

- Pfeifer, S.; Pagel, A.; Riener, R.; Vallery, H. Actuator With Angle-Dependent Elasticity for Biomimetic Transfemoral Prostheses. IEEE/ASME Trans. Mechatron. 2014, 20, 1384–1394. [Google Scholar] [CrossRef]

- Toxiri, S.; Calanca, A.; Ortiz, J.; Fiorini, P.; Caldwell, D.G. A Parallel-Elastic Actuator for a Torque-Controlled Back-Support Exoskeleton. IEEE Robot. Autom. Lett. 2017, 3, 492–499. [Google Scholar] [CrossRef]

- Hurst, J.; Rizzi, A.; Hobbelen, D. Series elastic actuation: Potential and pitfalls. International Conference on …, 2004. Available online: http://mime.oregonstate.edu/research/drl/publications/_documents/hurst_2004a.pdf (accessed on 3 January 2023).

- Wolf, S.; Grioli, G.; Eiberger, O.; Friedl, W.; Grebenstein, M.; Hoppner, H.; Burdet, E.; Caldwell, D.G.; Carloni, R.; Catalano, M.G.; et al. Variable Stiffness Actuators: Review on Design and Components. IEEE/ASME Trans. Mechatron. 2015, 21, 2418–2430. [Google Scholar] [CrossRef]

- Grioli, G.; Wolf, S.; Garabini, M.; Catalano, M.; Burdet, E.; Caldwell, D.; Carloni, R.; Friedl, W.; Grebenstein, M.; Laffranchi, M.; et al. Variable stiffness actuators: The user’s point of view. Int. J. Robot. Res. 2015, 34, 727–743. [Google Scholar] [CrossRef]

- Wang, X.; Zhang, Y.; Liang, W.; Chen, W.; Xiu, H.; Ren, L.; Wei, G.; Ren, L. Design, Control, and Validation of a Polycentric Hybrid Knee Prosthesis. IEEE Trans. Ind. Electron. 2022. [Google Scholar] [CrossRef]

- Gabert, L.; Hood, S.; Tran, M.; Cempini, M.; Lenzi, T. A Compact, Lightweight Robotic Ankle-Foot Prosthesis: Featuring a Powered Polycentric Design. IEEE Robot. Autom. Mag. 2020, 27, 87–102. [Google Scholar] [CrossRef]

- Li, Z.; Zhou, C.; Zhu, Q.; Xiong, R. Humanoid Balancing Behavior Featured by Underactuated Foot Motion. IEEE Trans. Robot. 2017, 33, 298–312. [Google Scholar] [CrossRef]

- Gabert, L.; Tran, M.; Lenzi, T. Design of an Underactuated Powered Ankle and Toe Prosthesis. In Proceedings of the Annual International Conference of the IEEE Engineering in Medicine and Biology Society, EMBS, virtual, 1–5 November 2021. [Google Scholar] [CrossRef]

- Aukes, D.M.; Heyneman, B.; Ulmen, J.; Stuart, H.; Cutkosky, M.R.; Kim, S.; Garcia, P.; Edsinger, A. Design and testing of a selectively compliant underactuated hand. Int. J. Robot. Res. 2014, 33, 721–735. [Google Scholar] [CrossRef]

- Leddy, M.T.; Dollar, A.M. The Yale MyoAdapt Hand: A Highly Functional and Adaptive Single Actuator Prosthesis. IEEE Trans. Med. Robot. Bionics 2022, 4, 807–820. [Google Scholar] [CrossRef]

- Rouse, E.J.; Mooney, L.M.; Herr, H.M. Clutchable series-elastic actuator: Implications for prosthetic knee design. Int. J. Robot. Res. 2014, 33, 1611–1625. [Google Scholar] [CrossRef]

- Zhang, T.; Huang, H. Design and Control of a Series Elastic Actuator With Clutch for Hip Exoskeleton for Precise Assistive Magnitude and Timing Control and Improved Mechanical Safety. IEEE/ASME Trans. Mechatron. 2019, 24, 2215–2226. [Google Scholar] [CrossRef]

- Lenzi, T.; Lipsey, J.; Sensinger, J.W. The RIC Arm—A Small Anthropomorphic Transhumeral Prosthesis. IEEE/ASME Trans. Mechatron. 2016, 21, 2660–2671. [Google Scholar] [CrossRef]

- Guercini, L.; Tessari, F.; Driessen, J.; Buccelli, S.; Pace, A.; De Giuseppe, S.; Traverso, S.; De Michieli, L.; Laffranchi, M. An Over-Actuated Bionic Knee Prosthesis: Modeling, Design and Preliminary Experimental Characterization. In Proceedings of the IEEE International Conference on Robotics and Automation, Philadelphia, PA, USA, 23–27 May 2022; pp. 5467–5473. [Google Scholar] [CrossRef]

- Martinez-Villalpando, E.C.; Herr, H. Agonist-antagonist active knee prosthesis: A preliminary study in level-ground walking. J. Rehabil. Res. Dev. 2009, 46. [Google Scholar] [CrossRef]

- Verstraten, T.; Furnémont, R.; López-García, P.; Rodriguez-Cianca, D.; Vanderborght, B.; Lefeber, D. Kinematically redundant actuators, a solution for conflicting torque–speed requirements. Int. J. Robot. Res. 2019, 38, 612–629. [Google Scholar] [CrossRef]

- Flynn, L.; Geeroms, J.; Jimenez-Fabian, R.; Vanderborght, B.; Vitiello, N.; Lefeber, D. Ankle–knee prosthesis with active ankle and energy transfer: Development of the CYBERLEGs Alpha-Prosthesis. Robot. Auton. Syst. 2015, 73, 4–15. [Google Scholar] [CrossRef]

- Machida, H. Technology of a Traction Drive CVT-Past, Present and Future. Tribol. Interface Eng. Ser. 2005, 48, 3–13. [Google Scholar] [CrossRef]

- Lenzi, T.; Cempini, M.; Hargrove, L.J.; Kuiken, T.A. Actively variable transmission for robotic knee prostheses. In Proceedings of the 2017 IEEE International Conference on Robotics and Automation (ICRA), Singapore, 29 May–3 June 2017; pp. 6665–6671. [Google Scholar] [CrossRef]

- Tran, M.; Gabert, L.; Cempini, M.; Lenzi, T. A Lightweight, Efficient Fully Powered Knee Prosthesis With Actively Variable Transmission. IEEE Robot. Autom. Lett. 2019, 4, 1186–1193. [Google Scholar] [CrossRef]

- Belter, J.T.; Dollar, A.M. A Passively Adaptive Rotary-to-Linear Continuously Variable Transmission. IEEE Trans. Robot. 2014, 30, 1148–1160. [Google Scholar] [CrossRef]

- Ingvast, J.; Wikander, J.; Ridderström, C. The PVT, an Elastic Conservative Transmission. Int. J. Robot. Res. 2006, 25, 1013–1032. [Google Scholar] [CrossRef]

- Phlernjai, M.; Takayama, T.; Omata, T. Passively switched cable-driven transmission for high-speed/high-force robot finger. Adv. Robot. 2016, 30, 1559–1570. [Google Scholar] [CrossRef]

- Takaki, T.; Omata, T. Load-Sensitive Continuously Variable Transmission for Robot Hands. J. Robot. Soc. Jpn. 2005, 23, 238–244. [Google Scholar] [CrossRef]

- O’Brien, K.W.; Xu, P.A.; Levine, D.J.; Aubin, C.A.; Yang, H.-J.; Xiao, M.F.; Wiesner, L.W.; Shepherd, R.F. Elastomeric passive transmission for autonomous force-velocity adaptation applied to 3D-printed prosthetics. Sci. Robot. 2018, 3, eaau5543. [Google Scholar] [CrossRef]

- Tran, M.; Gabert, L.; Hood, S.; Lenzi, T. A Lightweight Robotic Leg Prosthesis Replicating the Biomechanics of the Knee, Ankle, and Toe Joint. Sci. Robot. 2022, 7, eabo3996. [Google Scholar] [CrossRef]

- Lawson, B.E.; Mitchell, J.; Truex, D.; Shultz, A.; Ledoux, E.; Goldfarb, M. A Robotic Leg Prosthesis: Design, Control, and Implementation. IEEE Robot. Autom. Mag. 2014, 21, 70–81. [Google Scholar] [CrossRef]

- Azocar, A.F.; Mooney, L.M.; Duval, J.-F.; Simon, A.M.; Hargrove, L.J.; Rouse, E.J. Design and clinical implementation of an open-source bionic leg. Nat. Biomed. Eng. 2020, 4, 941–953. [Google Scholar] [CrossRef]

- Eslami, M. Theory of Sensitivity in Dynamic Systems; Springer: Berlin/Heidelberg, Germany, 1994. [Google Scholar] [CrossRef]

- Au, S.K.; Herr, H.M. Powered ankle-foot prosthesis. IEEE Robot. Autom. Mag. 2008, 15, 52–59. [Google Scholar] [CrossRef]

- Hood, S.; Gabert, L.; Lenzi, T. Powered Knee and Ankle Prosthesis With Adaptive Control Enables Climbing Stairs With Different Stair Heights, Cadences, and Gait Patterns. IEEE Trans. Robot. 2022, 38, 1430–1441. [Google Scholar] [CrossRef] [PubMed]

| Symbol | Value |

|---|---|

| 22 mm | |

| 35 mm | |

| 150 N | |

| K | 35 N/mm |

| −5 mm | |

| −22 mm | |

| b | 107 mm |

| e | 35 mm |

| d | −16 mm |

| 275° | |

| Lead | 2 mm |

| Gear ratio | 2.5 |

| Symbol | Value |

|---|---|

| 22 mm | |

| 35 mm | |

| 5 Nm | |

| 1.1 Nm/° | |

| −10 mm | |

| −33 mm | |

| b | 107 mm |

| e | 35 mm |

| d | −19 mm |

| 272° | |

| Lead | 2 mm |

| Gear ratio | 2.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tran, M.; Gabert, L.; Lenzi, T. Analysis and Validation of Sensitivity in Torque-Sensitive Actuators. Actuators 2023, 12, 80. https://doi.org/10.3390/act12020080

Tran M, Gabert L, Lenzi T. Analysis and Validation of Sensitivity in Torque-Sensitive Actuators. Actuators. 2023; 12(2):80. https://doi.org/10.3390/act12020080

Chicago/Turabian StyleTran, Minh, Lukas Gabert, and Tommaso Lenzi. 2023. "Analysis and Validation of Sensitivity in Torque-Sensitive Actuators" Actuators 12, no. 2: 80. https://doi.org/10.3390/act12020080

APA StyleTran, M., Gabert, L., & Lenzi, T. (2023). Analysis and Validation of Sensitivity in Torque-Sensitive Actuators. Actuators, 12(2), 80. https://doi.org/10.3390/act12020080