Abstract

In this paper, we propose and demonstrate a haptic device with liquid-pouch motors that can simulate a handshake. Because handshakes involve contact of the palms or soft skin, handshake simulation requires the haptic device to provide pressure onto specific areas of the palm with soft contact. This can be achieved with thermally driven liquid-pouch motors, which inflate and deflate when a low-boiling-point liquid, here Novec™ 7000, evaporates and condenses, respectively. Due to the simplicity of the soft actuator system, this haptic glove is lightweight and conformable. To design the haptic glove, we experimentally investigated the contact region and strength in handshakes, which led to an optimal number, size and position for the liquid-pouch motors. Sensory experiments with human subjects verified that the designed haptic glove successfully simulated handshakes.

1. Introduction

The skin is our largest organ and covers our whole body, and we particularly rely on tactile information obtained from the hands [1]. As shown in the cortical homunculus, a large area of the brain is used to process information from the hands [2]. Such information is used in the characterization and manipulation of touched objects and to interact and communicate with others.

Social touching, such as handshakes, stroking and hugs, is known to have positive effects on us in many aspects, such as physical and emotional, attachment, attitude and behavior and emotional transference [3]. In addition, social touch increases intimacy in interpersonal relationships because it can leave the impression that the other person is “more familiar” or “happy to see you” [4]. Devices that reproduce stroking or hugging motions have been demonstrated [5,6]. In this study, we focused on handshakes. Because tactile communication takes place only at the hands in a handshake, we considered replication of handshakes with a rather simple system, specifically, haptic gloves.

Haptic gloves have been developed as wearable devices to present tactile sensations to users’ hands [7], which can enrich the user experience in extended-reality technology and human–computer interactions [8,9]. Haptic gloves stimulate skin or tactile receptors inside the skin either physically or electrically. For physical-type haptic gloves, they need to be compact and light enough to be worn by the users, while generating a sufficiently large force and displacement with the actuators of the gloves. Soft actuators are considered to contribute to such glove applications. A haptic glove using soft doughnut-shaped actuators was proposed to provide tactile feedback to the fingers [10]. A soft actuator that is composed of an anisotropically fiber-reinforced material and an elastomer matrix is attached to the back of the finger to provide force sensation to the user [11]. The haptic glove with this actuator can generate large feedback without interfering with the user’s motion on the palm side. Pulse width modulation (PWM) of a small soft actuator embedded inside the glove was reported to efficiently provide tactile feedback [12]. Soft actuators can easily work with other actuators due to their lightweight. A pneumatic balloon actuator is used for force sensation in addition to an electromagnetic actuator that generates vibration to provide a greater sense of touch [13]. Thus, glove-type devices that present tactile sensations are expected. However, because the actuators are close to human skin, high voltage and temperature must be avoided and, in addition, soft or compliant actuators are preferable.

As soft and compliant actuators, pneumatic actuators have been studied. Pneumatic actuators are promising soft actuators [14,15]. Air is the working fluid, and it has lightweight and large compliance. The drawbacks of pneumatic actuators are that the air needs to be supplied externally using tubes and valves, which are typically bulky, from a control system.

Gas–liquid phase change actuators have been studied as compact soft actuators [16,17,18,19,20,21,22]. A low-boiling-point liquid, such as Novec ™ 7000 with a boiling point of 34 °C, is encapsulated inside a deformable pouch. When the pouch is heated, the encapsulated liquid vaporizes, and the pouch volume drastically increases. Centimeter-sized pouch motors were reported to produce a force of 50 N [21]. The pouch can be miniaturized down to the millimeter scale [23]. These liquid-pouch motors require only a heat source in order to be actuated. An external heat source, such as a hair dryer, does not require any additional components to control the pouch. Direct heating of the pouch by designing a resistive heater on or in the vicinity of the pouch is favored due to its high efficiency and ease of control [24]. When metal particles are included in the encapsulated liquid, it can be heated by irradiation using an infrared laser, which can control the pouch motor externally with high efficiency [25,26,27].

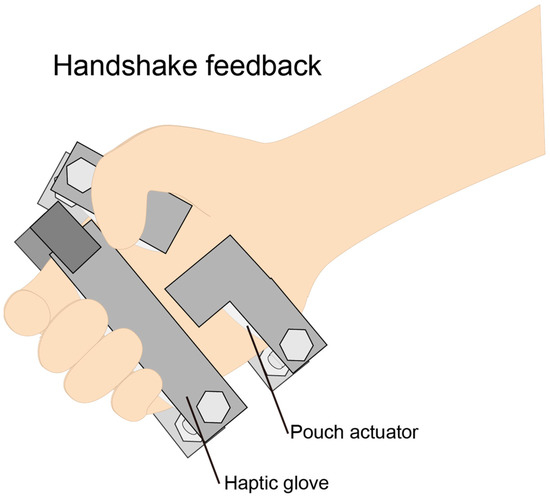

In this paper, we propose and demonstrate a haptic device with liquid-pouch motors containing Novec ™ 7000 to simulate a handshake. Figure 1 shows the concept figure of the haptic glove that simulates a handshake. Because handshakes involve contact of the palms or soft skin, the simulation of a handshake requires the haptic device to provide pressure onto specific areas of the palm with soft contact. This can be achieved with liquid-pouch motors. In addition, warm liquid-pouch motors, which are slightly warmer than the boiling point of Novec ™ 7000, may contribute by simulating the warmness of another person’s hand. External heating with a hair dryer was used to actuate the liquid-pouch motors. We experimentally investigated the contact region and strength during handshakes, which were used to determine the number, size and position of the liquid-pouch motors. A questionnaire-based survey was conducted to validate the concept. This work was approved by the Research Ethics Committee of the Faculty of Science and Technology, Keio University (2021-89).

Figure 1.

The haptic glove that simulates a handshake. The pouch actuators provide pressure onto the palm and the back of the hand to replicate the tactile perception in a handshake.

2. Design of Pouch Gloves

2.1. Pouch Actuator

The pouch actuator consists of a hydrofluoroether fluid (Novec ™ 7000, 3M Company, St. Paul, MN, USA) with a boiling point of 34 °C enclosed in a 75 µm-thick nylon polyethylene sheet (Nylon Poly New L Type, Fukusuke Kogyo, Niihama, Japan). To fabricate the product, we first cut two polyethylene sheets with scissors and heat-sealed three sides using a heat sealer (Ishizaki Electric Works, Tokyo, Japan). The width of the seal was 2.5 mm. We then injected a fixed amount of Novec ™ 7000 with a micro syringe and heat-sealed the remaining side to form a pouch. Because polyethylene does not expand or contract, the area to which force is applied can be controlled by the area of the pouch when enough Novec ™ 7000 is sealed within it.

The pouch actuator is used as a bistable thermal actuator; when heated to a temperature above the boiling point of Novec ™ 7000, the actuator expands due to the gas–liquid phase change of Novec ™ 7000. The pouch actuator is positioned on the palm of the user’s hand with a haptic glove and when the actuator is heated, it expands and provides pressure on the palm. The temperature of the pouch actuator during expansion is slightly higher than 34 °C. Because the average surface temperature of the human body is about 33 °C, the inflated pouch roughly replicates the warmth of another person’s hand. The response time of the pouch is 3~5 s after heating, and there is no problem with handshake feedback.

The size of the pouch actuator needs to be determined. To avoid disturbing the opening and closing of the wearer’s hand, the length of the horizontal side of the pouch was set to be 20.0 mm. The length of the vertical side was from 20.0 to 50.0 mm. Based on the results of our preliminary experiments, when the amount of Novec ™ 7000 sealed in the pouch was 0.30 mL, the liquid phase of Novec ™ 7000 remained in the pouch even when the pouch was maximally inflated.

2.2. Overall Design of Haptic Glove

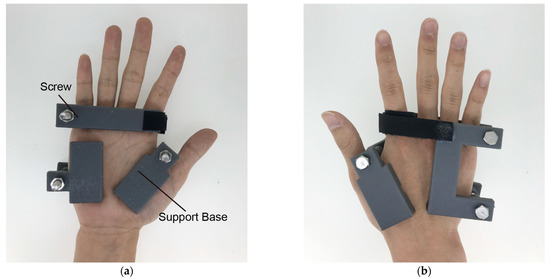

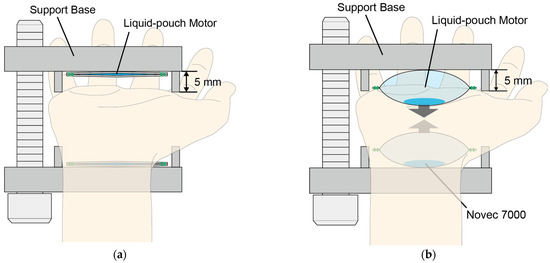

Figure 2 shows a photograph of the proposed device. As shown in Figure 3, the device is composed of a pouch actuator, a support base, and an adjustment screw. The pouch expands upon heating to provide a tactile pressure sensation to the palm.

Figure 2.

Photograph of proposed haptic glove: (a) palm side and (b) back side of the hand.

Figure 3.

Mechanism of applying pressure onto palm with pouch actuators: (a) before heating and (b) after heating.

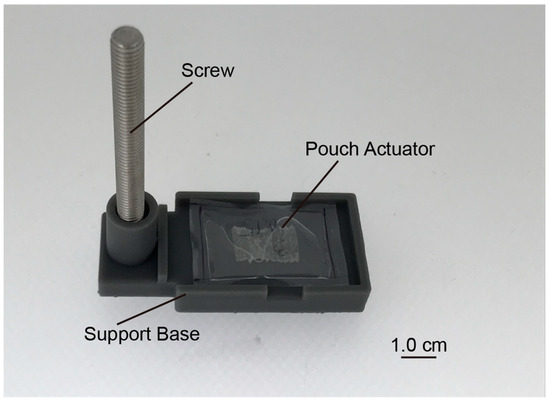

The support base has two plates with pockets inside for placing the pouch actuators, as shown in Figure 4. We designed the gap between the plates to be controlled with screws. We fabricated the plates with gray resin (UV-curable acrylic resin) using a 3D printer (Form3, Formlabs, Medford, OR, USA). The tensile strength and Young’s modulus of the gray resin are 65 MPa and 2.8 GPa, respectively. The weight of this material is approximately 15 g, which is sufficiently light to avoid interference with hand movement. The resin does not deform when the pouch actuator expands and can hold the actuator in place. A video of the haptic glove can be found in Supplementary Materials.

Figure 4.

Support base manufactured using 3D printing.

2.3. Detailed Design of Haptic Glove: Areas That Apply Pressure

To replicate a handshake, a suitable pressure needs to be applied to appropriate areas with the right timing. These design parameters were deduced from experiments. First, we examined the contact points and strength distribution in a handshake and selected the position and shape of the pouch on the palm and the back of the hand, as described in Section 2.2. In this experiment, we visualized the contact points between the palm and the back of the hand during a handshake to determine the positions of the pouch actuators. We applied green ink to the palm and fingers of the participants’ right hand (Figure 5a). Each participant was asked to shake hands with the other participants. As shown in Figure 5b, after the ink dried, we scanned the palm with a scanner (MFC-L9570CDW, Brother Industries, Nagoya, Japan). We drew the silhouette of the hand on a transparent plastic sheet and placed the hand on it for consistency in the analyses. Five participants, including three males and two females aged 20–25 years, performed two trials each with different partners, which resulted in a total of twenty trials. The images were processed to quantify the contact area.

Figure 5.

Contact areas during the handshake, as deduced experimentally: (a) green ink that was applied to the palm and fingers of each participant’s right hand; (b,c) green ink was transferred to another participant’s hand during a handshake.

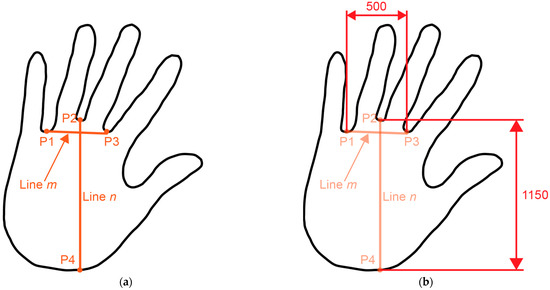

In the analysis, the hands were normalized as follows (Figure 6). First, point P1 was defined as the interdigital space between the little finger and ring finger, point P2 as the interdigital space between the ring finger and middle finger, and point P3 as the interdigital space between the middle finger and index finger. A straight-line connecting point P1 and point P3 was defined as line m. The hand angle was adjusted so that line m was horizontal. A line perpendicular to line m was drawn from point P2 and this line was defined as line n. The intersection of line n and the contour of the lower bottom of the hand was defined as point P4. To match the aspect ratio to the reference hand, we affine-transformed the entire hand so that line m was 500 mm and line n was 1150 mm in length.

Figure 6.

Normalization of palm: (a) Points P1–P4 and lines m and n defined on palm of hand. The angle was adjusted so that line m was horizontal. (b) Normalization was conducted such that the lengths of lines m and n were 500 mm and 1500 mm, respectively.

Next, we converted the image from 24-bit RGB to 8-bit grayscale using the NTSC-weighted average method and applied the green filter in Adobe Photoshop CC 2020. Black-and-white binarization was performed using a gray value of 120 as the threshold. A mesh (approximately 6.25 mm × 6.25 mm, 300 dpi) was set up for each hand, and if more than 50% of each mesh was black, the area corresponding to the mesh was considered to be in contact during the handshake and was labeled as 1. The results of all 20 trials were averaged. This trial was performed for the back of the hand as well.

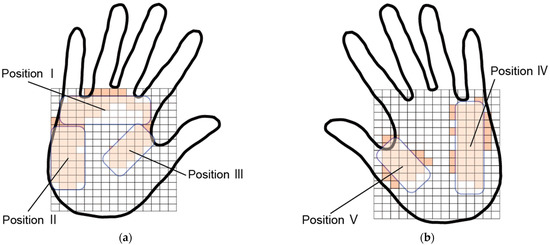

Figure 7 shows the regions where the computed average value was greater than 0.5 among the 20 trials. On the palm of the hand, the three areas of contact during the handshake were referred to as positions I, II and III. On the back of the hand, we found two contact areas, positions IV and V. The liquid-pouch motors, which are positioned in the pocket of the support base, need to cover these areas. The pockets were designed to have a size of 5.0 × 2.0 cm for position I, 4.0 × 2.0 cm for position II and 4.0 × 2.0 cm for position III. On the back of the hand, position IV was 6.0 cm × 2.0 cm and position V was 4.0 cm × 2.0 cm.

Figure 7.

Deduced contact areas during handshake: (a) Palm of the hand. (b) Back of the hand.

2.4. Detailed Design of Haptic Glove: Distribution of Contact Strength

Next, we experimentally obtained the distribution of the pressure applied to the palm during a handshake, which was needed to determine the requirements of the pouch actuator.

A pressure-sensitive sheet (Prescale, Fujifilm, Tokyo, Japan) was used to obtain the pressure distribution during handshakes. The pressure-sensitive sheet consists of two sheets with a chromophore layer and a developer layer. When sufficient pressure is applied, the microcapsules containing dye in the chromophore layer disintegrate and the dye that leaks from the microcapsules is absorbed by the developer layer and turns red. The range of measurable pressure depends on the size and strength of the microcapsules. The intensity of the color in a particular region represents the pressure.

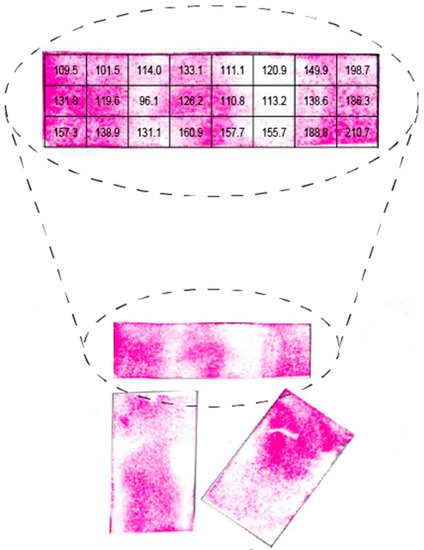

The following experiment was performed twice on 5 participants (3 males and 2 females between the ages of 20 and 25) for a total of 20 trials. The pressure-sensitive sheets were set in positions I, II and III of each participant’s hand and he/she shook hands with another participant. After the handshake, the sheets were collected and scanned (MFC-L9570CDW scanner, Brother Industries, Nagoya, Japan). The color distribution of the sheets was converted to a grayscale image using the green filter correction in Adobe Photoshop CC 2020. Positions I, II and III were divided into grids of 3 × 8, 3 × 6 and 3 × 6 squares, respectively (each measuring approximately 6.25 mm × 6.25 mm, 300 dpi). As shown in Figure 8, the average gray value for each grid cell was obtained.

Figure 8.

Pressure-sensitive sheets used to deduce the pressure distribution during a handshake. The quantified color intensity represents the pressure distribution in the grid at position I.

Based on these results, the size and position of the pouch actuator were determined to match the pressure distribution for the actuator as close as possible to that for the handshake. The pouch actuators were set on the support base at positions I, II and III. The pressure-sensitive sheets were attached on top of the pouch actuator or the pocket of the haptic glove. The actuators were then heated with an air-dryer to expand and then apply pressure onto the sheets. The pressure-sensitive sheets were scanned as before. Image processing and evaluation were the same as those described above. This method was performed five times for each actuator, and the average gray value for each grid cell was obtained for each actuator.

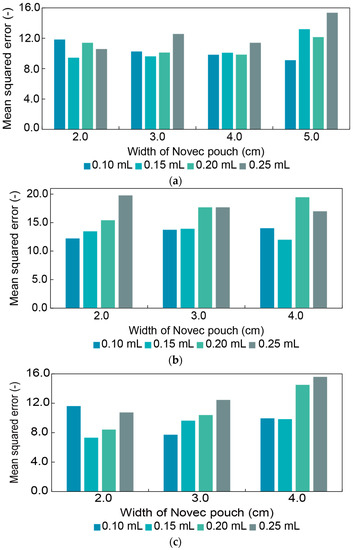

The pressure applied by the participants and that by the pouch actuators were compared with respect to the magnitude and distribution. The difference was evaluated based on the least-squares error with respect to the position. Figure 9 shows the least-squares error for each actuator at positions I, II and III. Based on the results, the pouch actuators were selected for each position as shown in Table 1. In positions IV and V on the back of the hand, the actuator was often in contact with the tips of the fingers of the other person’s hand and the amount of force applied to that position could not be uniquely determined due to individual differences in grip force. Therefore, we decided to install an actuator equivalent to position I for position IV and position III for position V.

Figure 9.

Differences in the pressure distribution between handshakes and pouch actuators at (a) position I, (b) position II and (c) position III.

Table 1.

Pouches selected for each position.

2.5. Detailed Design of the Haptic Glove: Number of Pouch Actuators

The experimental results suggested that three positions (I, II and III) need to be pressed by the appropriately designed pouch actuators to replicate a handshake. However, we surmised that applying pressure to either one or two of these three areas may be sufficient to replicate a handshake. For this preliminary study, a support base measuring 7 cm × 7 cm and covering the entire palm was fabricated. Using this support base, the arrangement of the pouch actuators was experimentally evaluated.

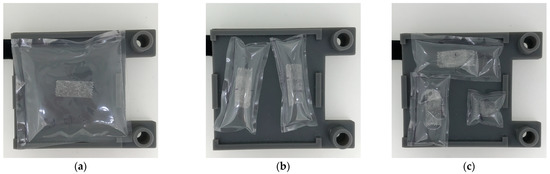

The experiments with one pouch, two pouches and three pouches are referred to here as experiments A, B and C, respectively. The arrangement of pouches for each experiment is shown in Figure 10. In experiment A, a 7 cm × 7 cm pouch with 0.30 mL of Novec ™ 7000 was used (see Figure 10a). Two pouches measuring 5 cm × 2 cm with 0.30 mL of Novec ™ 7000 and measuring 4 cm × 2 cm with 0.30 mL of Novec ™ 7000 were arranged as shown in Figure 10b for experiment B. A maximum of 0.30 mL was encapsulated inside each pouch. We chose the arrangement to cause the largest areas to be covered by the two pouches. For experiment C, three pouches were set to cover positions I, II and III.

Figure 10.

Three types of tested haptic gloves: (a) 1 liquid-pouch motor, (b) 2 motors and (c) 3 motors.

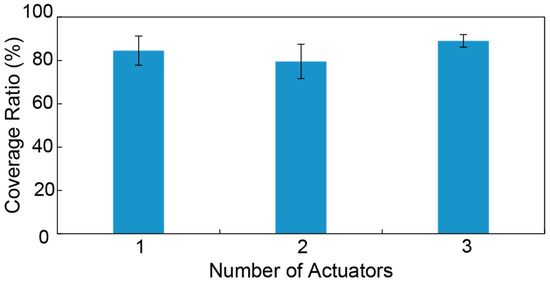

First, the pouch actuators were set onto the support base with a pressure-sensitive sheet measuring 7 cm × 7 cm attached to the top. The haptic glove was then set on the hand of a participant and was subsequently heated with a hair dryer. We scanned the pressure-sensitive sheet, normalized the image, binarized it to black and white and rendered it as described in Section 2.4. We conducted this procedure five times for each experiment and deduced the average values for each grid cell. Grid cells with values above 0.5 were considered as the contact points. The results were compared to the results of the handshakes obtained as described in Section 2.4. When a grid cell had the same results, its value was given as 1, otherwise as 0. The sum of these numbers divided by the total number of grid cells was used as the coverage rate to assess the replicability.

Figure 11 shows the results. It was found that experiment C with three actuators exhibited the highest coverage with the lowest standard deviation, though no significant differences were found. We decided to use the haptic glove with three actuators for subsequent experiments to investigate the number of actuators driven out of the three results in the perception of a handshake. Figure 2 shows a photograph of a haptic glove with three liquid-pouch motors.

Figure 11.

Comparison of coverage for each experiment.

3. Experiments with Proposed Haptic Glove

3.1. Experimental Protocol

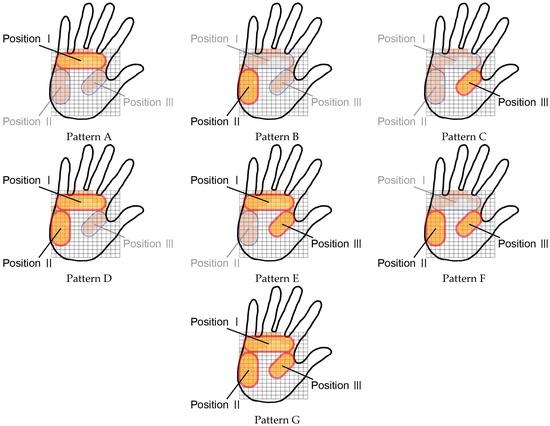

The developed haptic glove (see Figure 2) can vary the positions of the three sets of pouch actuator supports independently. This design allowed the device to apply pressure at contact points almost identical to those in a handshake. Seven types of devices were prepared, as shown in Table 2 and Figure 12. The areas where no actuators were present had only a support base, and the pocket was empty. The positions of the actuators on the back of the hand were the same for the seven devices.

Table 2.

The seven experimental patterns.

Figure 12.

The seven experimental glove patterns.

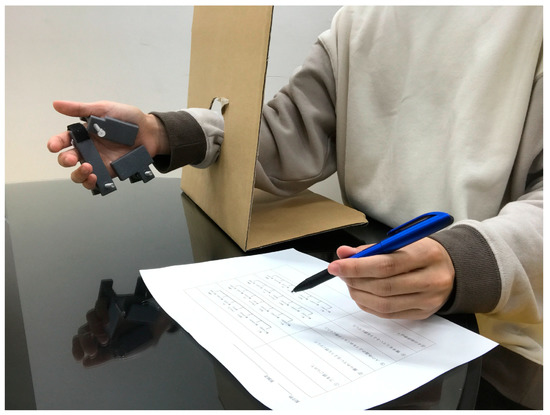

A total of 8 participants, 5 males and 3 females aged 20–25 years, participated in the experiment. Figure 13 shows the experiment. The experimental procedure was as follows:

Figure 13.

A photograph of the experiment.

- (1)

- The gloves were heated with a hair dryer (1200 W, Panasonic, Osaka, Japan) for 30 s to ensure that the bag actuators would properly inflate. The temperature of the pouch at that time was appropriate at a translation of 33 °C.

- (2)

- The participant sat on a chair and wore the haptic glove on their right hand.

- (3)

- The participant placed their hand with the device at a predetermined position. A fence prevented participants from seeing their hand.

- (4)

- The gloved hand was heated with a hair dryer from a position about 20 cm away. The actuators were heated over the haptic glove; each actuator was heated for 3 s, and they were actuated sequentially in a clockwise direction for a total of 30 s. Under this condition, none of the 10 participants perceived excessive heat from the dryer. The participants were asked to keep their eyes closed.

- (5)

- The participants were asked to move their hands for 5 s to simulate a handshake. Subsequently, the participants answered survey questions for 30 s. The questions are summarized in Table 3. In addition to the question concerning whether they felt the sensation of a handshake, three additional questions were prepared in this study. The first was whether they felt the force from the actuator. The second was whether they felt warmth from the heated actuator. The third was whether they felt the sensation of being grasped. The participants were asked to respond using a 7-point scale (from 1: Could not feel at all to 7: Feeling was strong). Because the surface temperature of the palm of the hand was about 33 °C, the pouch actuator did not shrink for about 30 s after the heating stopped.

Table 3. Questions for the sensory evaluation.

Table 3. Questions for the sensory evaluation. - (6)

- Steps (1)–(5) were repeated for all glove patterns. Before the next pattern, the tactile glove was removed from the hand and the actuator was allowed to cool down for 1 min. The pouch actuators returned to their original state before the next experiment.

3.2. Experimental Results

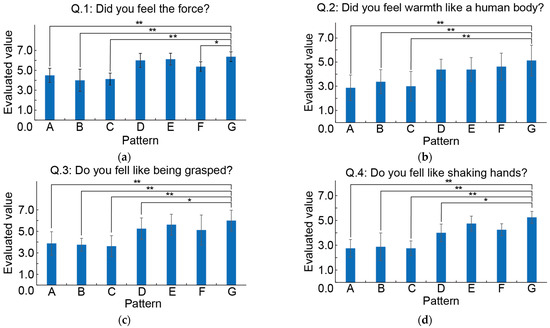

Figure 14 reports the means and standard errors of all the evaluated values for each experiment, as well as the significant differences (* 0.01 < p < 0.05, ** p < 0.01).

Figure 14.

Answers of the participants for questionnaires: (a) question 1, (b) 2, (c) 3 and (d) 4. * 0.01 < p < 0.05, ** p < 0.01.

As shown in Figure 14a, glove patterns D, E, F and G with multiple pouch actuators were evaluated higher than patterns A, B and C with a single pouch actuator. Therefore, multiple pouch actuators produced more force than one actuator. Pattern G with three actuators showed a significant difference from A, B, C and F. No significant difference was found among patterns D, E and G. This implies that the actuator in position I plays a crucial role in transferring the force onto the palm. It has been reported that there are many Merkel plates in this position and that they sense delicate skin deformation and are involved in the perception of edges and textures [28]. The other positions, II and III, are known to be less sensitive to force and skin deformation because they have thicker skin and superior deep sensation compared to position I.

Figure 14b shows how the participants perceived the warmth from the actuators. The evaluation value was about 3 for patterns A, B and C with one actuator; 4 for D, E and F with two actuators; and 5 for G with three actuators. We consider that this may originate from the contact areas of the actuators and the palm, which increases with the number of actuators. It is known that there are about 15 cold points and 4 warm points/cm2 on the palm of the hand, and both cold and warm points are sensitive to temperatures in the range of 15 to 40 °C. The temperature of the actuators is slightly higher than that of the human body and the warm points perceive the warmth.

Figure 14c,d show whether the participants perceived hand holding and handshaking, respectively. The trend was found to be similar: the pattern with a low evaluation for Q3 also had a low evaluation score for Q4. In particular, patterns A, B and C with one actuator had low ratings, and a significant difference from pattern G was obtained. This indicates that sensation from multiple areas is necessary for the participants to perceive the “holding” feeling. The similarity between the results for Q3 and Q4 suggests that the feeling of holding a hand is necessary to feel a handshake. A significant difference was found between patterns D and G in both Q3 and Q4, while patterns E and F did not exhibit a significant difference from G, which implies that the pressure in position III is crucial for perceiving the holding feeling. Position III, the base of the thumb, is in contact with the base of the index finger of the other hand in a handshake. In the experiments with the pressure-sensitive test (see Figure 8), a relatively large force was applied to position III during the handshake.

Based on these results, we consider that the haptic glove with three actuators in positions I, II and III is the best. Handshakes were successfully replicated with a score greater than 5.

3.3. Discussion

Although the proposed haptic glove successfully simulated handshakes with a rating greater than 5, the slow response time of the pouch actuators may make the glove unusable for some applications. For example, in the reproduction of the sense of reality using a combination of vision and touch in a virtual reality environment, tactile reproduction must be timed to the timing of the image and the time delay between tactile and visual stimuli should be less than 1 s [29,30]. The proposed tactile glove uses the heat from a hair dryer to drive the liquid-pouch motors, which takes about 3 s. Some solutions have been already reported, such as direct heating of the pouch with a resistive heater on or in the vicinity of the pouch [24] and infrared-laser irradiation of the pouch actuators with metal particles in the encapsulated liquid [25,26,27].

In this work, we did not investigate the design of the rigid parts, which are used to efficiently transfer the force from the pouch actuators to the hand. The rigid parts with bone shapes may lead to better replication of a handshake. The rigid parts that are made from soft but harder than the soft actuators can make the whole glove soft and compliant.

4. Conclusions

In this study, we fabricated a prototype haptic glove with gas–liquid phase-change actuators or liquid-pouch motors and successfully demonstrated simulated handshakes. The liquid-pouch motors are light and soft and do not require external devices, such as pneumatic valves or batteries, which improves the convenience of their use. The design requirements for the glove, namely, the position, number and force output of the pouch actuators, were experimentally determined. Perception experiments validated the effectiveness of the proposed haptic glove in simulating a handshake, which was scored by the participants as more than five out of seven points. This prototype has revealed that it provides the feedback of a handshake sensation. It is expected that further effects can be expected in the future by improving the heating method and the material of the support.

Supplementary Materials

The following supporting information can be downloaded at: https://www.mdpi.com/article/10.3390/act12020051/s1, Video S1: Simulated handshake.

Author Contributions

Conceptualization, S.Y. and N.M.; methodology, S.Y. and N.M.; software, S.Y.; validation, S.Y., T.H., H.I. and N.M.; formal analysis, S.Y.; investigation, T.H., H.I. and N.M.; resources, N.M.; data curation, S.Y. and N.M.; writing—original draft preparation, S.Y.; writing—review and editing, N.M.; visualization, S.Y. and N.M.; supervision, T.H., H.I. and N.M.; project administration, N.M.; funding acquisition, N.M. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by JSPS KAKENHI Grant Number 20H02121 and JST CREST Grant Number JPMJCR19A2, Japan.

Data Availability Statement

The data presented in this study are openly available in FigShare at https://doi.org/10.6084/m9.figshare.21769196. Accessed on 22 December 2022.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Graham, W.; Thomas, C.; Sriram, S.; Stephen, A.B. Perception of ultrasonic haptic feedback on the hand: Localisation and apparent motion. In CHI ‘14: Proceedings of the SIGCHI Conference on Human Factors in Computing Systems, Toronto, ON, Canada, 26 April–1 May 2014; Association for Computing Machinery: New York, NY, USA, 2014; pp. 1133–1142. [Google Scholar]

- Wilder, P.; Edwin, B. Somatic motor and sensory representation in the cerebral cortex of man as studied by electrical stimulation. Brain 1937, 60, 389–443. [Google Scholar]

- Greg, L.S.; Susan, L.D.; Murray, R.B.; Todd, C.D. Exploring the handshake in employment interviews. J. Appl. Psychol. 2008, 93, 1139–1146. [Google Scholar]

- Chaplin, W.F.; Phillips, J.B.; Brown, J.D.; Clanton, N.R.; Stein, J.L. Handshaking, gender, personality, and first impressions. J. Pers. Soc. Psychol. 2000, 79, 110–117. [Google Scholar] [PubMed]

- Nunez, C.M.; Huerta, B.N.; Okamura, A.M.; Culbertson, H. Investigating Social Haptic Illusions for Tactile Stroking (SHIFTS). In Proceedings of the 2020 IEEE Haptics Symposium (HAPTICS), Crystal City, VA, USA, 28–31 March 2020; Volume 1, pp. 629–636. [Google Scholar]

- Takahashi, N.; Okazaki, R.; Okabe, H.; Yoshikawa, H.; Aou, K.; Yamakawa, S.; Yokoyama, M.; Kajimoto, H. Sense-roid: Emotional haptic communication with yourself. In Proceedings of the Virtual Reality International Conference (VRIC 2011), Laval, France, 6–8 April 2011; Volume 1, pp. 6–8. [Google Scholar]

- Mourad, B.; Grigore, B.; Grigore, P.; Rares, B. The Rutgers Master II—New Design ForceFeedback Glove. IEEE/ASME Trans. Mechatron. 2002, 7, 256–263. [Google Scholar]

- Kitazaki, M.; Hamada, T.; Yoshiho, K.; Kondo, R.; Amemiya, T.; Hirota, K.; Ikei, Y. Virtual walking sensation by prerecorded oscillating optic flow and synchronous foot vibration. IEEE Comput. Graph. Appl. 2018, 38, 44–56. [Google Scholar] [CrossRef]

- Hirose, M.; Hirota, K.; Ogi, T.; Yano, H.; Kakehi, N.; Saito, M.; Nakashige, M. HapticGEAR: The development of a wearable force display system for immersive projection displays. In Proceedings of the IEEE Virtual Reality 2001, Yokohama, Japan, 13–17 March 2001; pp. 123–129. [Google Scholar]

- Talhan, A.; Kim, H.; Jeon, S. Tactile Ring: Multi-Mode Finger-Worn Soft Actuator for Rich Haptic Feedback. IEEE Access 2020, 8, 957–966. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, D.; Zhang, Y.; Liu, J.; Wen, L.; Xu, W.; Zhang, Y. A three-fingered force feedback glove using fiber-reinforced soft bending actuators. IEEE Trans. Ind. Electron. 2020, 67, 7681–7690. [Google Scholar]

- Uddin, M.W.; Zhang, X.; Wang, D. A pneumatic-driven haptic glove with force and tactile feedback. Front. Bioeng. Biotechnol. 2017, 304–311. [Google Scholar] [CrossRef]

- Premarathna, C.P.; Chathuranga, D.S.; Lalitharatne, T.D. Fabrication of a soft tactile display based on pneumatic balloon actuators and voice coils: Evaluation of force and vibration sensations. In Proceedings of the SII 2017—2017 IEEE/SICE International Symposium on System Integration, Taipei, Taiwan, 11–14 December 2017; pp. 763–768. [Google Scholar]

- Rognon, C.; Koehler, M.; Duriez, C.; Floreano, D.; Okamura, A.M. Soft Haptic Device to Render the Sensation of Flying Like a Drone. IEEE Robot. Autom. Lett. 2019, 4, 2524–2531. [Google Scholar] [CrossRef]

- Delazio, A.; Nakagaki, K.; Lehman, J.F.; Klatzky, R.L.; Sample, A.P.; Hudson, S.E. Force jacket: Pneumatically-actuated jacket for embodied haptic experiences. In Proceedings of the Conference on Human Factors in Computing Systems, Montreal, QC, Canada, 21–26 April 2018. [Google Scholar]

- Bardaweel, H.K.; Anderson, M.J.; Weiss, L.W.; Richards, R.F.; Richards, C.D. Characterization and modeling of the dynamic behavior of a liquid-vapor phase change actuator. Sens. Actuators A Phys. 2009, 149, 284–291. [Google Scholar] [CrossRef]

- Henning, A.K. Liquid and gas-liquid phase behavior in thermopneumatically actuated microvalves. Microfluid. Devices Syst. 1998, 3515, 53. [Google Scholar]

- Akagi, T.; Dohta, S.; Fujimoto, S.; Tsuji, Y.; Fujiwara, Y. Development of flexible thin actuator driven by low boiling point liquid. Dep. Intell. Mech. Eng. 2015, 3, 55–59. [Google Scholar] [CrossRef]

- Tsuji, Y.; Dohta, S.; Akagi, T.; Fujiwara, Y. Analysis of flexible thin actuator using gas-liquid phase-change of low boiling point liquid. In Proceedings of the 3rd International Conference on Intelligent Technologies and Engineering Systems (ICITES2014), Kaohsiung, Taiwan, 19–21 December 2014; 2016; Volume 345, pp. 67–73. [Google Scholar]

- Nakahara, K.; Narumi, K.; Niiyama, R.; Kawahara, Y. Electric phasechange actuator with inkjet printed flexible circuit for printable and integrated robot prototyping. In Proceedings of the IEEE International Conference on Robotics and Automation, Singapore, 29 May–3 June 2017; pp. 1856–1863. [Google Scholar]

- Narumi, K.; Sato, H.; Nakahara, K.; Seong, A.Y.; Morinaga, K.; Kakehi, Y.; Niiyama, R.; Kawahara, Y. Liquid pouch motors: Printable planar actuators driven by liquid-to-gas phase change for shape-changing interfaces. IEEE Robot. Autom. Lett. 2020, 5, 3915–3922. [Google Scholar]

- Sanchez, V.; Payne, J.C.; Preston, J.D.; Alvarez, T.J.; Weaver, C.J.; Atalay, T.A.; Boyvat, M.; Daniel, M.; Vogt, M.D.; Wood, J.R.; et al. Smart thermally actuating textiles. Adv. Mater. Technol. 2020, 5, 200038. [Google Scholar] [CrossRef]

- Hirai, S.; Nagatomo, T.; Hiraki, T.; Ishizuka, H.; Kawahara, Y.; Miki, N. Micro Elastic Pouch Motors: Elastically Deformable and Miniaturized Soft Actuators Using Liquid-to-Gas Phase Change. IEEE Robot. Autom. Lett. 2021, 6, 5373–5380. [Google Scholar] [CrossRef]

- Bell, L.E. Cooling, heating, generating power, and recovering waste heat with thermoelectric systems. Science 2008, 321, 1457–1461. [Google Scholar] [CrossRef]

- Altmüller, R.; Schwödiauer, R.; Kaltseis, R.; Bauer, S.; Graz, I.M. Large area expansion of a soft dielectric membrane triggered by a liquid gaseous phase change. Appl. Phys. A Mater. Sci. Process. 2011, 105, 1–3. [Google Scholar]

- Usui, T.; Ishizuka, H.; Hiraki, T.; Kawahara, Y.; Ikeda, S.; Oshiro, O. Miniaturized Liquid Pouch Motors Using Flexible Liquid Metal Heater. In Proceedings of the 33rd International Microprocesses and Nanotechnology Conference (MNC 2020), Online, 9–12 November 2020; Volume 3922, pp. 1–2. [Google Scholar]

- Meder, F.; Naselli, G.A.; Sadeghi, A.; Mazzolai, B. Remotely Light-Powered Soft Fluidic Actuators Based on Plasmonic-Driven Phase Transitions in Elastic Constraint. Adv. Mater. 2019, 31, 1905671. [Google Scholar]

- Kobayashi, K.; Maeno, T. Relationship between the Structure of Finger Tissue and the Location of Tactile Receptors. JSME Int. J. Ser. C Mech. Syst. Mach. Elem. Manuf. 1998, 41, 94–100. [Google Scholar]

- Kameyama, S.; Ishibashi, Y. Perception of synchronization errors in haptic and visual communications. In Proceedings of the Multimedia Systems and Applications IX, Boston, MA, USA, 2–3 October 2006; pp. 67–74. [Google Scholar]

- Silva, M.J.; Orozco, M.; Cha, J.; Saddik, E.A.; Petriu, M.E. Human perception of haptic-to-video and haptic-to-audio skew in multimedia applications. ACM Trans. Multimed. Comput. Commun. Appl. 2013, 9, 1–16. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).