1. Introduction

With the rise in the industrialization level and the continuous improvement of mechanical automation, ball screws are more and more widely used in industrial production. As a kind of high-precision, high-speed and high-load-transmission device, ball screws are widely used in machinery, manufacturing, aviation, rail transit, and other fields [

1]. With an increase in the running time of the ball screw, various fault-related problems often occur. The fault signal of the ball screw usually presents nonlinear and non-stationary characteristics and is characterized by periodic impact characteristics. The faults generated in actual production often cause very serious consequences. The working environment is usually harsh, and the fault signal characteristics are often covered by background noise and mechanical rotation signals, which are not easy to extract. Therefore, it is necessary to develop a fault diagnosis method when working under strong background noise interference conditions [

2,

3].

With the development of signal-processing technology, research on the fault diagnosis of rotating machinery has achieved certain results. Shi et al. [

4] proposed a bearing fault diagnosis algorithm based on wavelet multi-scale analysis and XGBoost fusion feature selection to address the problem that the rolling bearing fault signal is susceptible to the pollution of the surrounding noise environment and the difficulty of feature extraction and selection in the acquisition process. The collected sound signal is denoised by five-layer wavelet decomposition and reconstruction to filter out the doped noise signal. Wu et al. [

5] proposed a method of combining wavelet denoising analysis and FastICA independent component analysis, based on negative entropy, to deal with the noisy vibration signals of rolling bearings. First, the original signal is processed by wavelet denoising, then the processed signal is combined with the original signal to form the input matrix of FastICA for FastICA denoising. However, this classical noise reduction algorithm has the problem that the wavelet basis is difficult to select, and the FastICA algorithm is generally used for bearing signal noise reduction when in actual operation. Cai et al. [

6] proposed a bearing fault feature extraction method based on singular value decomposition (SVD) and variational mode decomposition (VMD) to address the problem that the impact signal contains a great deal of noise and it is difficult to extract the fault’s characteristic frequency when the bearing is weak. The results of simulation analysis and two different bearing tests show that the proposed method can effectively suppress noise and obtain signals that reflect the actual fault information. Empirical mode decomposition (EMD) is an adaptive time-frequency analysis method proposed by Huang et al. [

7], but it has the defect of mode mixing. In order to solve this defect, TORRES et al. [

8] proposed the CEEMDAN algorithm. Wang Zhijian et al. [

9] proposed using an evaluative health index (EHI), which combines the proportional weighting method of three evaluation indexes of monotonicity, trend, and prognosis and integrates multiple sources of degradation information. Aiming to address the problem that the fault signal of wind turbine bearings is weak, difficult to extract, and difficult to identify, Liu et al. [

10] proposed a fault diagnosis method for use with wind turbine bearings, based on adaptive noise complete ensemble empirical mode decomposition (CEEMDAN) and a grey wolf optimization kernel extreme learning machine (GWO-KELM). Yan et al. [

11] combined the synchrosqueezed generalized S-transform of variational mode decomposition and the Teager–Kaiser energy operator and used the Teager–Kaiser energy operator to enhance the extracted attenuation gradient and effectively highlight the oil and gas area. Tang Guiji et al. [

12] proposed a rolling bearing fault diagnosis method based on multivariate variational mode decomposition (MVMD) and a 1.5-dimensional spectrum. First, the 1.5-dimensional spectrum of the envelope signal is calculated, and the fault feature information extracted from the spectrum is then analyzed to diagnose the fault type. The fault diagnosis experiment of a rolling bearing proves that this method can effectively extract feature information on a weak bearing fault and achieve an accurate diagnosis of a bearing fault feature.

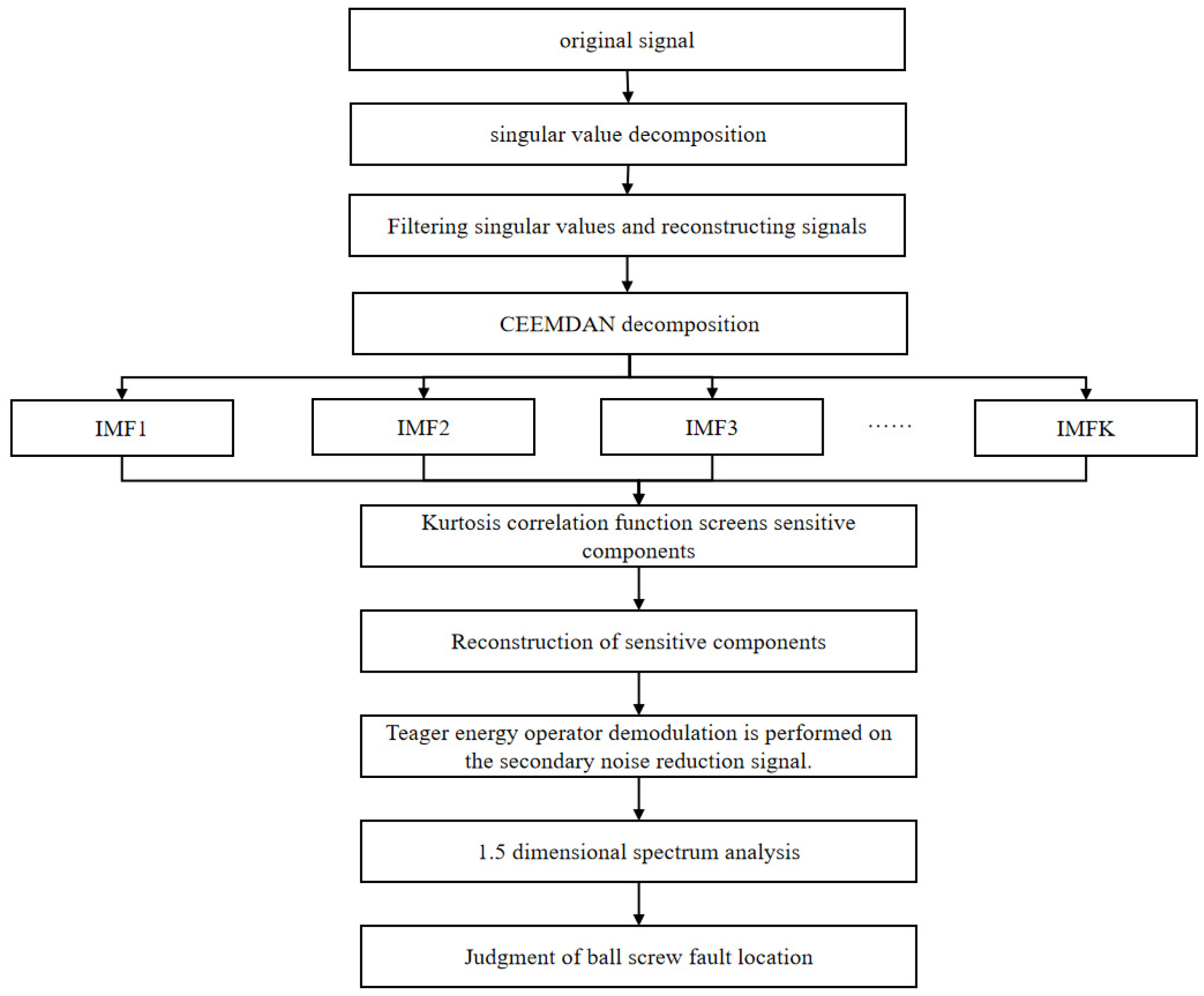

In order to make full use of the advantages of SVD, CEEMDAN, and the 1.5D spectrum in terms of noise reduction and feature extraction, this paper proposes combining the three for the fault diagnosis of a ball screw in an environment with strong background noise and uses a singular value decomposition noise reduction method to extract the initial vibration signal of the ball screw. Then, the initial noise-reduced signal is decomposed via CEEMDAN, the kurtosis correlation of the IMF component is calculated to filter the component, and the signal is reconstructed to complete the noise reduction. Finally, the fault frequency is extracted by demodulating the signal’s Teager energy operator and analyzing the 1.5D spectrum. Simulation and experimentation show that the proposed method can effectively extract fault feature information on the ball screw.

3. Fault Diagnosis Process

In this paper, an SVD-CEEMDAN-1.5DTES method is proposed to extract the fault signal characteristics of a ball screw under conditions of strong background noise interference and carry out a fault diagnosis [

19]. The steps are as follows.

Step 1: For singular value decomposition of the original one-dimensional signal data, select and decompose several groups of singular values, compare and analyze the size of the singular values, and retain the larger singular values. The smaller singular values are set to zero, the signal is reconstructed, and the signal after noise reduction is restored.

Step 2: CEEMDAN decomposition is performed on the signal of the initial noise reduction to obtain several IMF component components. Because the kurtosis is particularly sensitive to the pulse impact signal, it is very effective for early ball screw fault detection. The expression is shown as Equation (12). The correlation between each IMF component and the original signal can be quantified by the correlation coefficient. The expression is shown as Equation (13). The sensitive components, which contain more fault information, are screened according to the kurtosis correlation function index, and the signal is reconstructed to complete the second noise reduction.

Here, is the mean, and σ is the standard deviation. ρXY is the correlation coefficient between each component and the original signal, E is the expectation, and D is the variance. The kurtosis value of the original signal is taken as X and the kurtosis value of the IMF component is taken as Y, which is substituted into Equation (13) to obtain the size of the correlation coefficient.

Step 3: Teager energy operator demodulation is performed on the denoised signal, after which, 1.5D spectrum analysis is performed. The fault frequency extracted from the spectrum is compared with the fault frequency obtained from the theoretical calculation, and the fault location of the ball screw is determined.

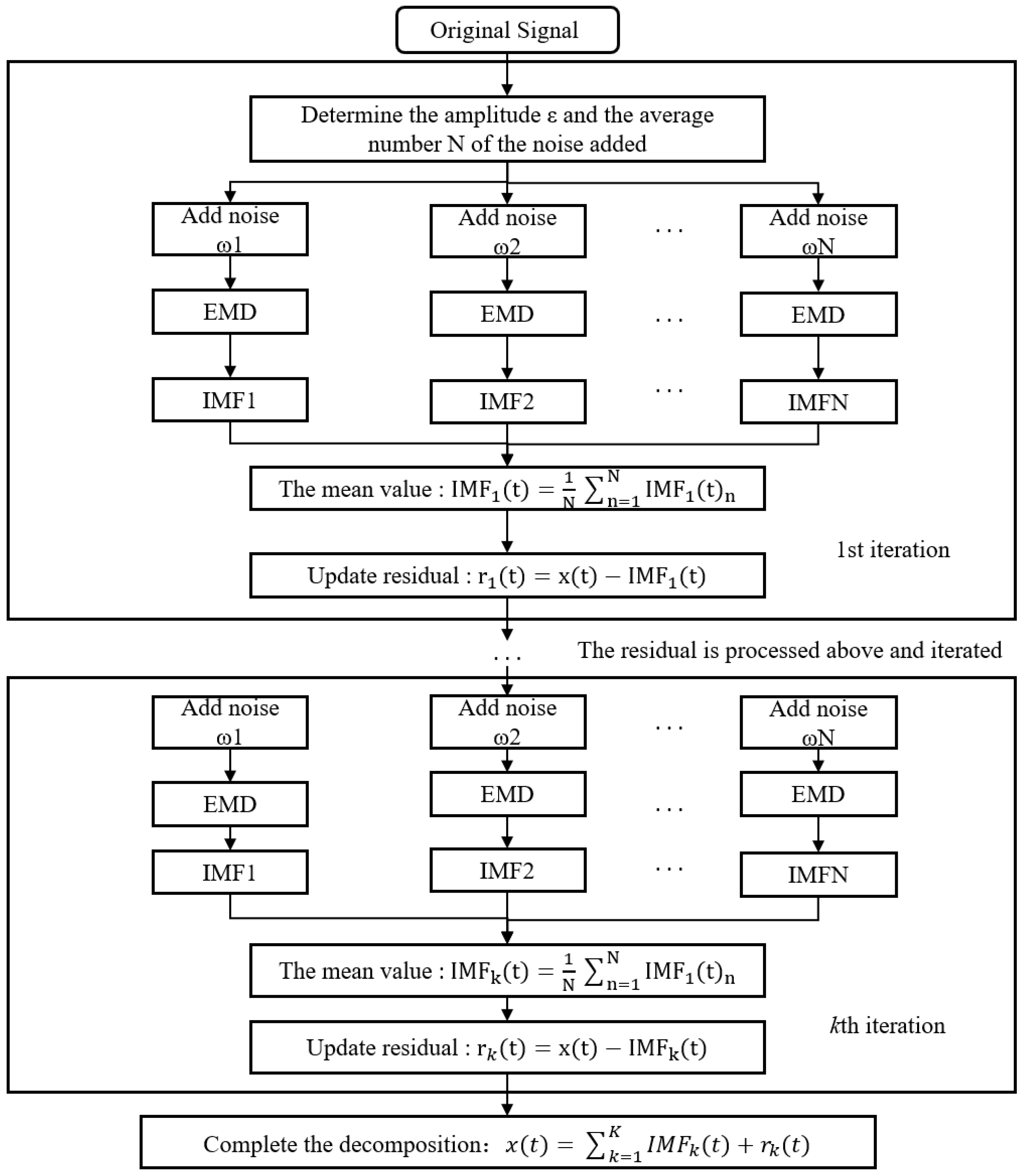

The specific steps of CEEMDAN decomposition are shown in

Figure 2.

5. Measured Signal Analysis

The ball screw model GD4010 was selected for the test, and the process parameters are shown in

Table 1.

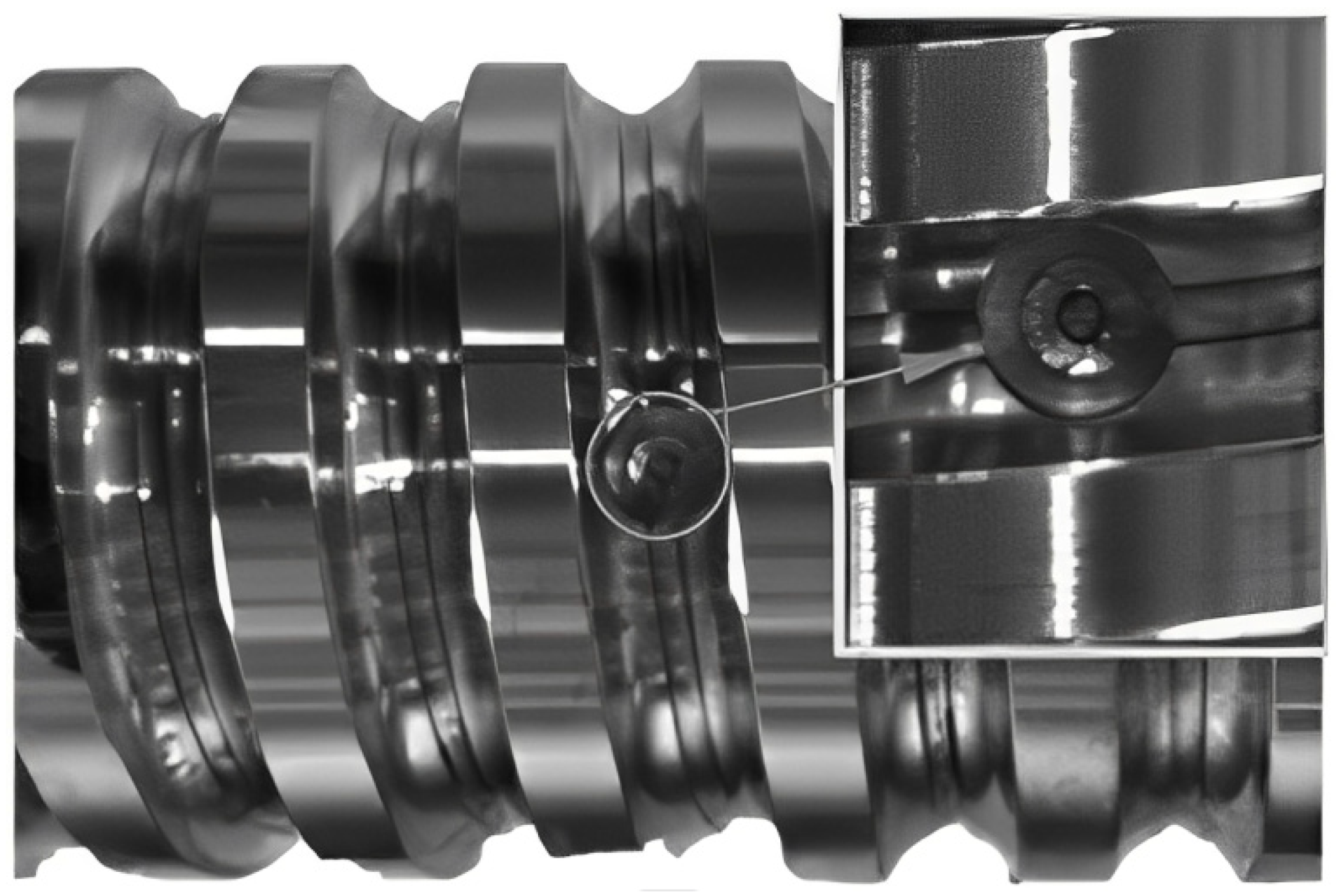

The fatigue pitting failure fault signal of a ball screw pair was analyzed and tested. Because the ball screw pair will undergo induction quenching heat treatment on the surface before leaving the factory, the hardness and wear resistance will be greatly improved. Therefore, it often takes some time to run in a new ball screw pair to the point of obvious pitting failure characteristics. In order to save testing time, EDM technology was used to create pits on the surface of the screw raceway to simulate the pitting failure state of the screw, as shown in

Figure 9.

The frequency of the driving motor is f

r; if the pitting defect occurs in the nut raceway, the corresponding fault characteristic frequency is f

o; if the pitting defect appears in the screw raceway, the fault characteristic frequency is f

i [

20], and the expression is as follows:

where n is the motor speed, d

b is the ball diameter, d

0 is the nominal diameter of the screw, α is the contact angle of the ball with the nut and the screw, and ω

s is the derivative of the angular displacement generated by the screw rotation. Where

, rm is the vertical distance from the ball center to the screw center.

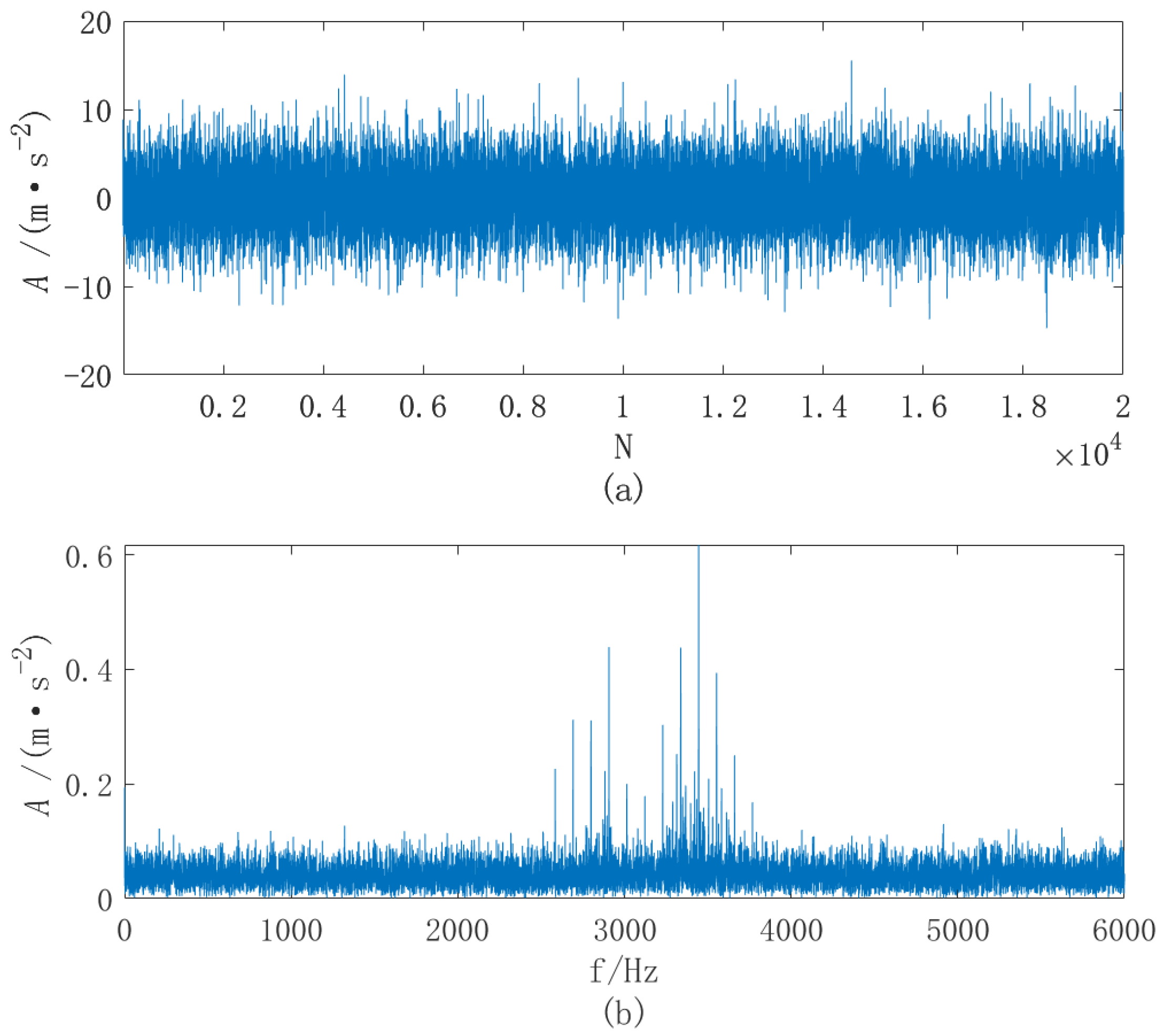

In order to verify the anti-noise performance of the method, Gaussian white noise with a signal-to-noise ratio of 14 dB was added to the original signal. The time-domain and frequency-domain diagrams of the denoised signal are shown in

Figure 10 and

Figure 11.

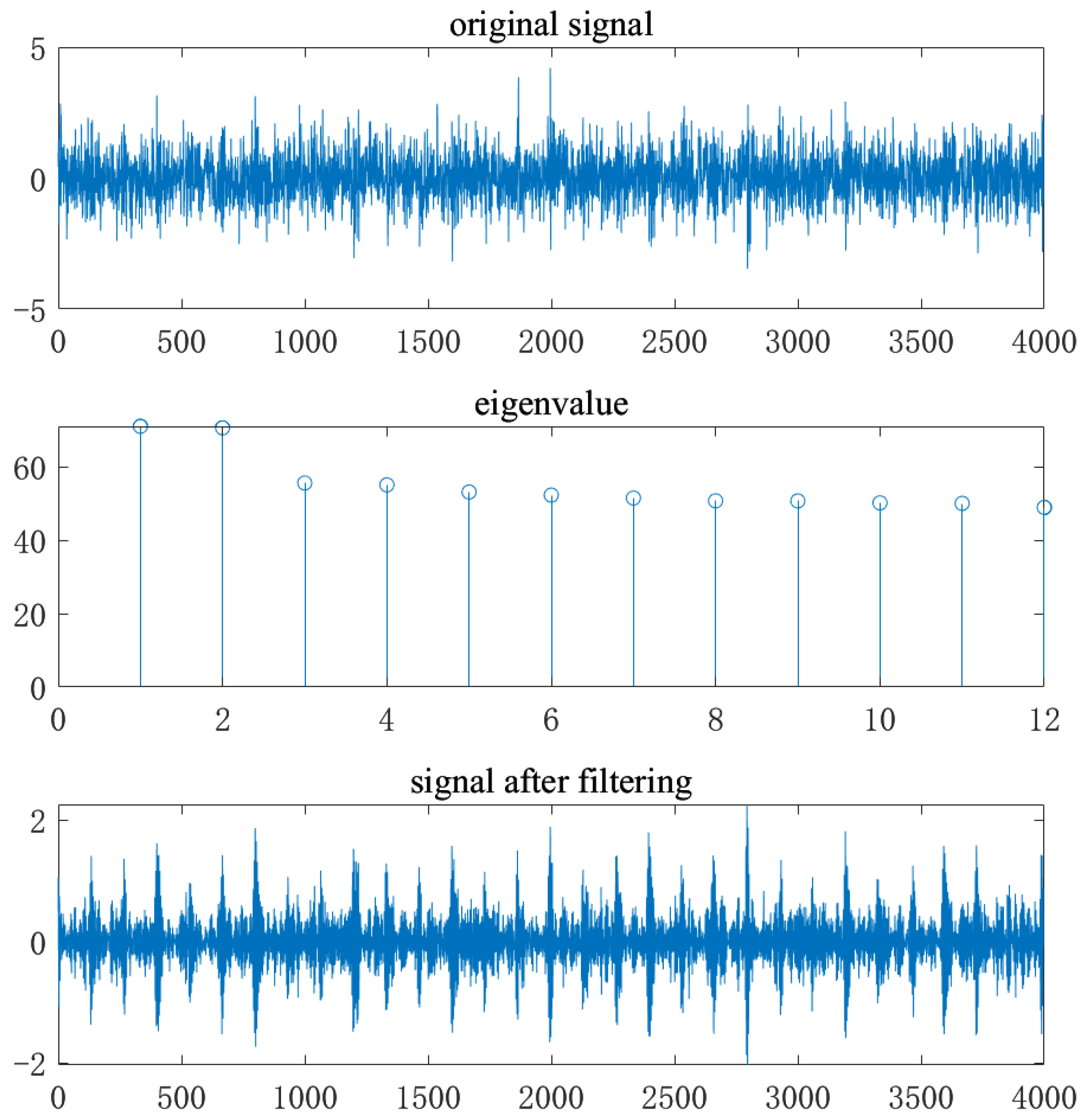

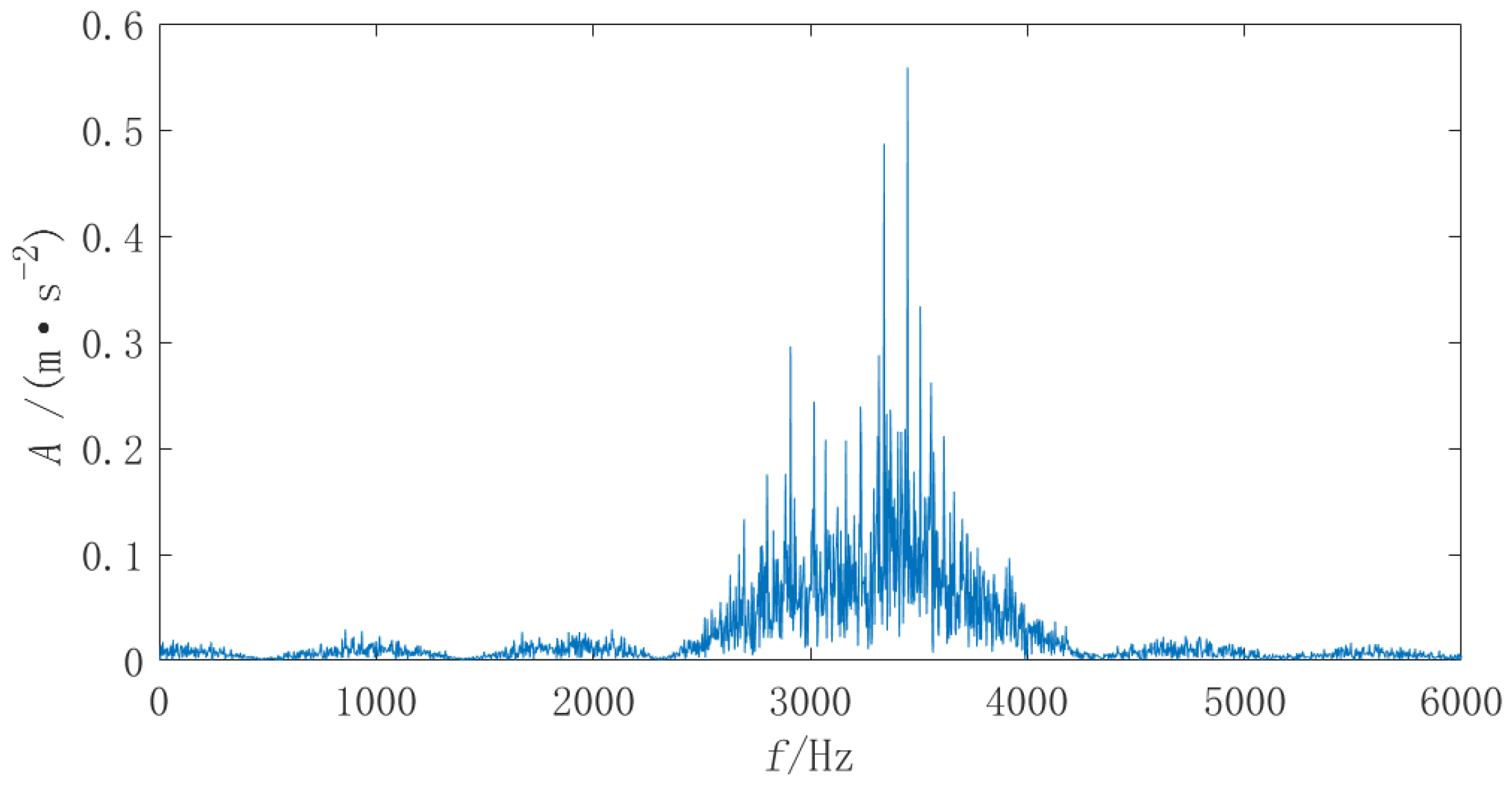

It can be seen from (a) in

Figure 10 that there was a great deal of random noise interference, the signal was messy, and the impact characteristics have been completely annihilated. The fault characteristic frequency in frequency domain (b) in

Figure 10 has migrated, and the fault characteristic frequency of the screw raceway could not be observed due to the influence of strong background noise. Therefore, it was necessary to denoise the signal. The wavelet packet was used to pre-denoise the ball screw raceway fault signal of the ball screw. Singular value decomposition of the signal was carried out, and a total of 12 singular values were decomposed. The singular values were filtered and then reconstructed. Each singular value that was calculated is shown in

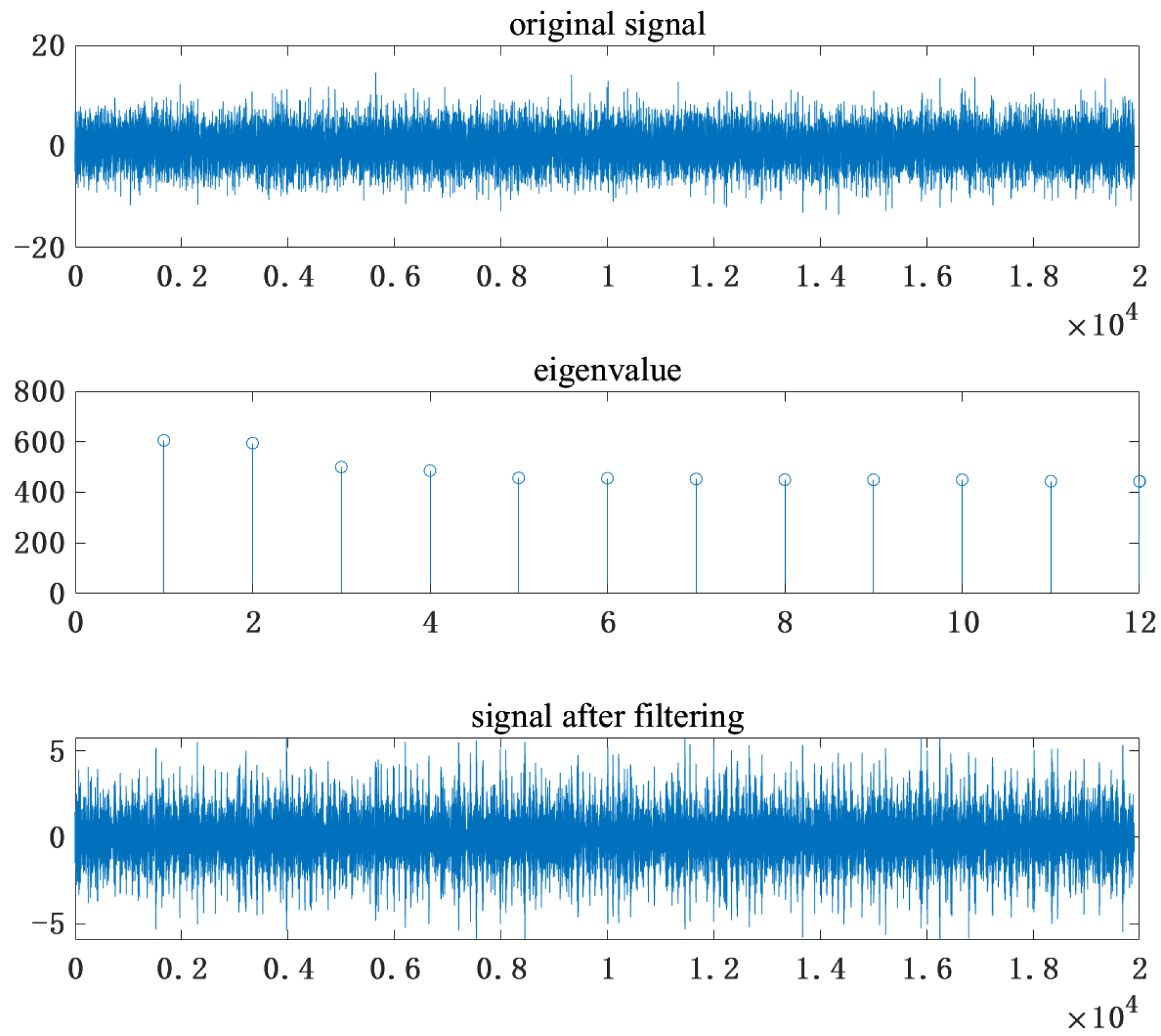

Figure 11. It can clearly be seen that the fault features were mainly concentrated in the first and second singular values. Therefore, the signal corresponding to the two singular values was reconstructed, which effectively removed other parts with less fault information and achieved a certain noise-reduction effect.

By comparing the original signal and the signal after filtering in

Figure 11, it can be seen that a small part of the noise was removed after singular value decomposition; the impact characteristics were still not obvious, and the noise interference was very large. Comparing

Figure 10 and

Figure 12, it can be seen that the noise on both sides has been well suppressed, and the signal-to-noise ratio has been improved. However, the fault frequency cannot be identified from the spectrogram. Thus, the fault frequency of the screw cannot be extracted by relying solely on singular value decomposition noise reduction. Therefore, it is necessary to perform CEEMDAN decomposition on the initial noise reduction signal and then filter the sensitive components and reconstruct them for secondary noise reduction. A total of 13 IMF components were generated during the decomposition process, and only the first seven components are shown in

Figure 13. The time-domain waveform of the first seven IMF components of CEEMDAN decomposition is shown in

Figure 13.

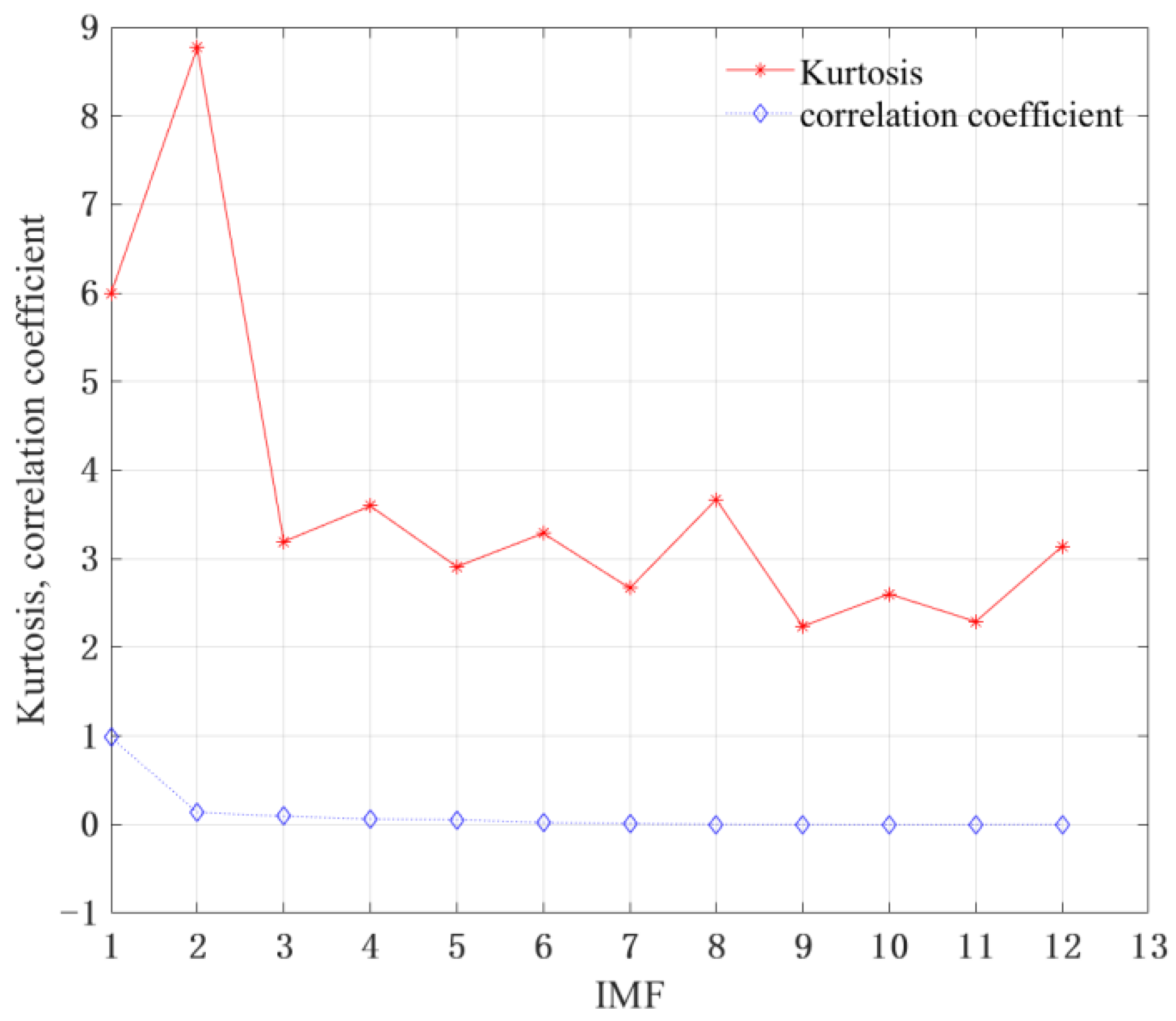

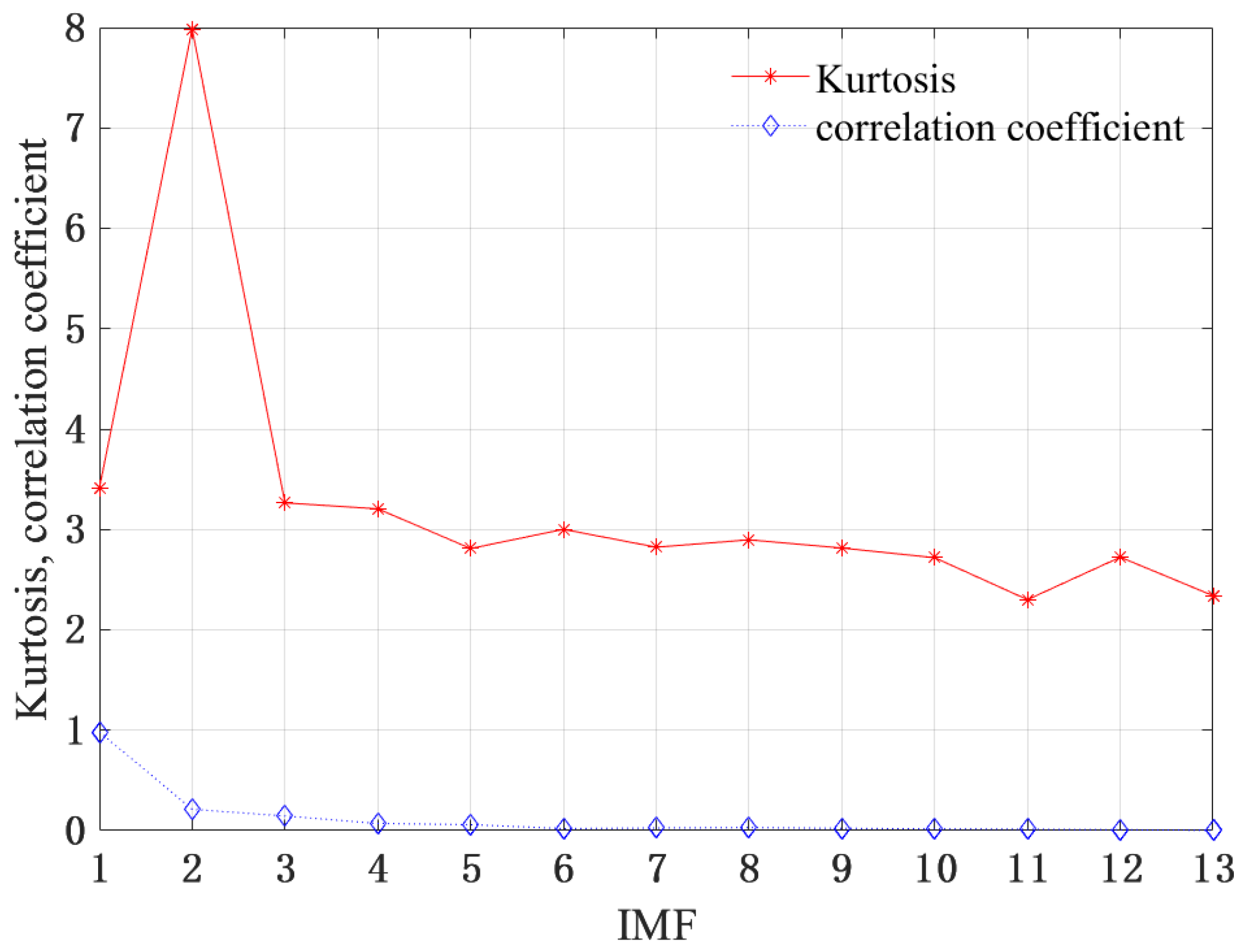

The sensitive components were screened, based on the set kurtosis−correlation coefficient criterion. It can be seen from

Figure 14 that the correlation coefficient shows a downward trend as a whole, indicating that the first three components contain more fault information. The first and second components of kurtosis value are the largest, and the impact characteristics are obvious. Considered comprehensively, the vibration signals of the first three components were reconstructed to complete the secondary noise reduction processing.

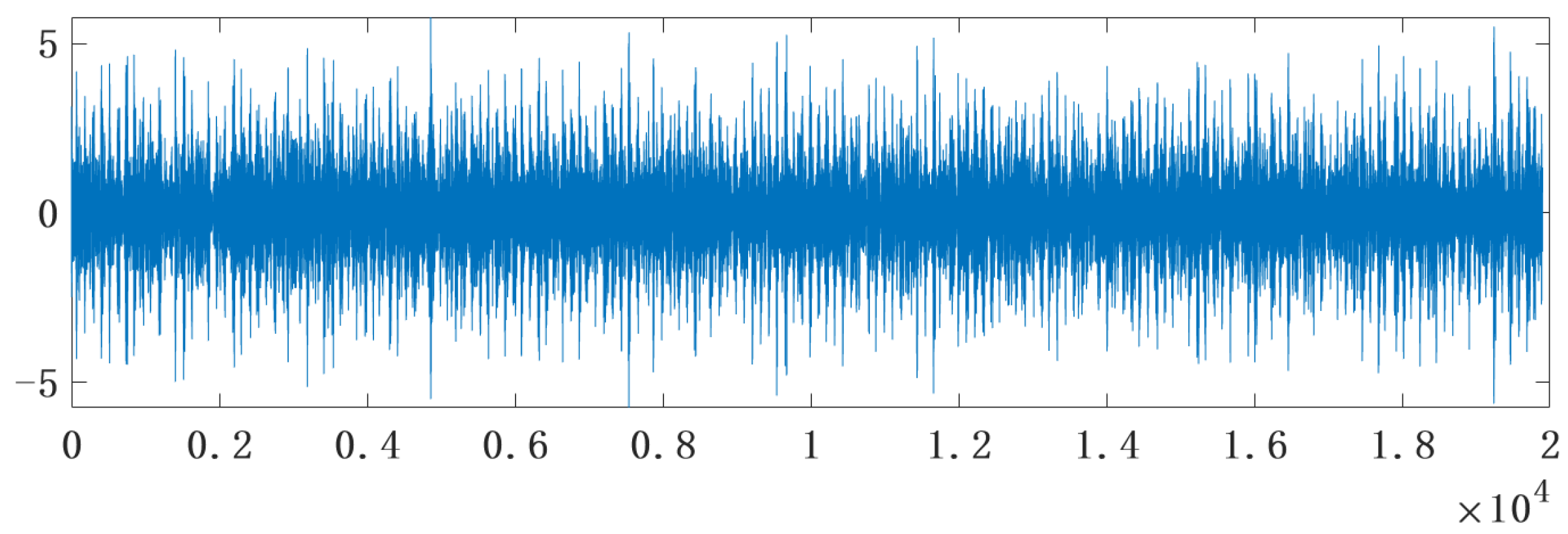

The first two IMF components after CEEMDAN decomposition were reconstructed; the reconstructed signal vibration image is shown in

Figure 15. This is the final vibration signal image, which was extracted after two noise reductions.

In order to verify the effectiveness and accuracy of the method proposed in this chapter, the original signal was directly analyzed using 1.5DTES without noise reduction. Singular value decomposition, CEEMDAN and Teager energy spectrum analysis were used to compare with the proposed method. The results are as follows.

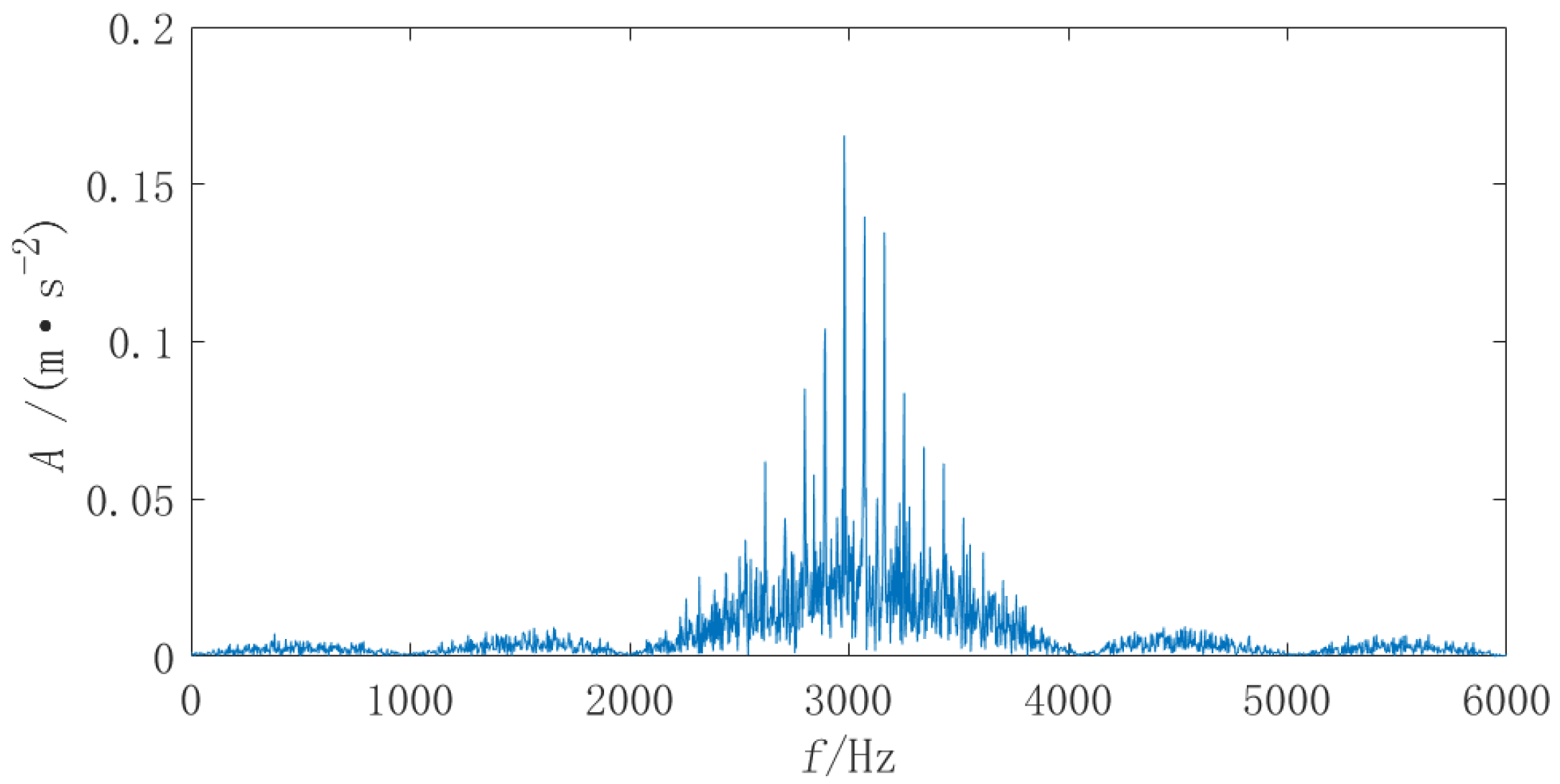

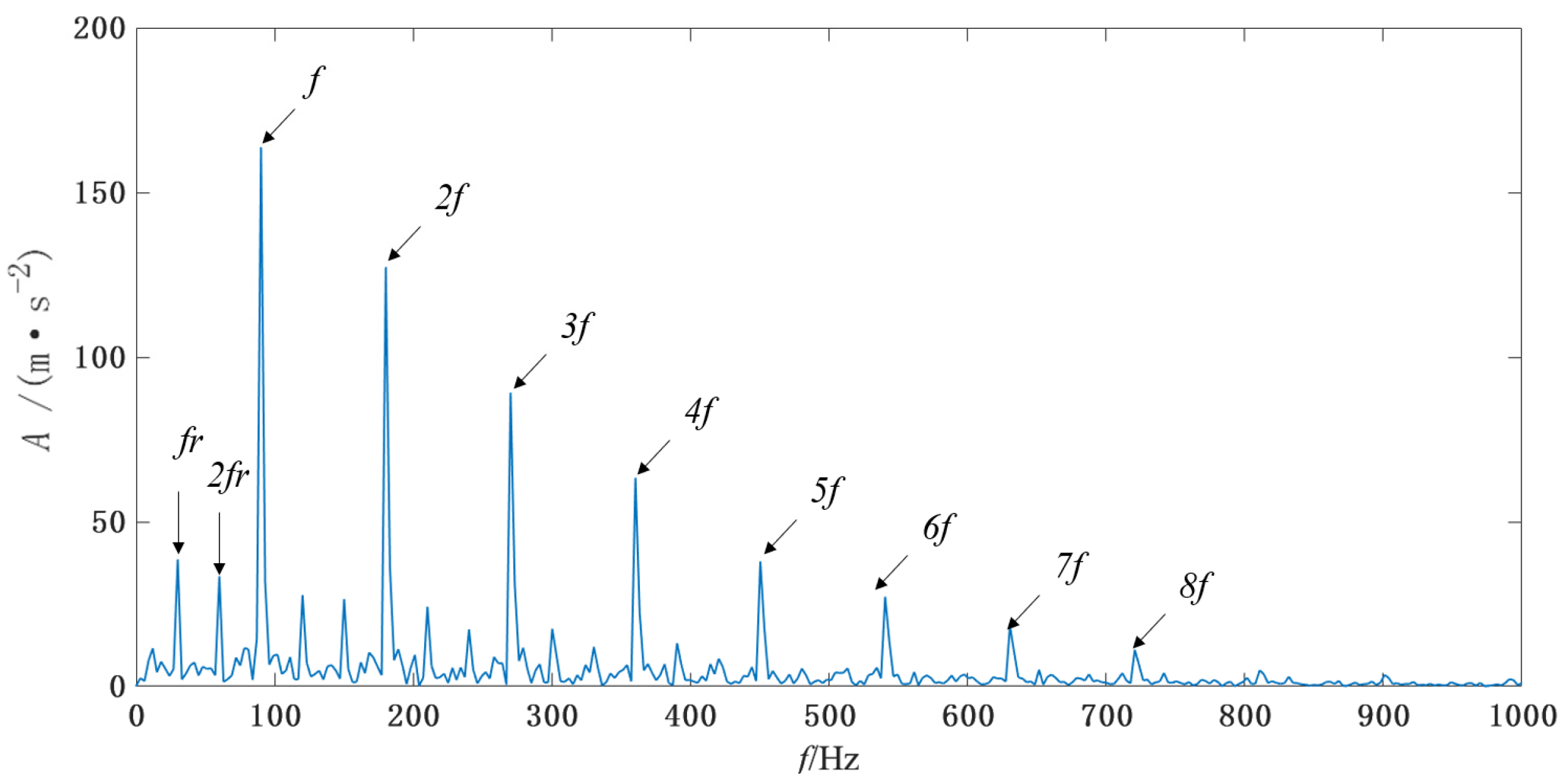

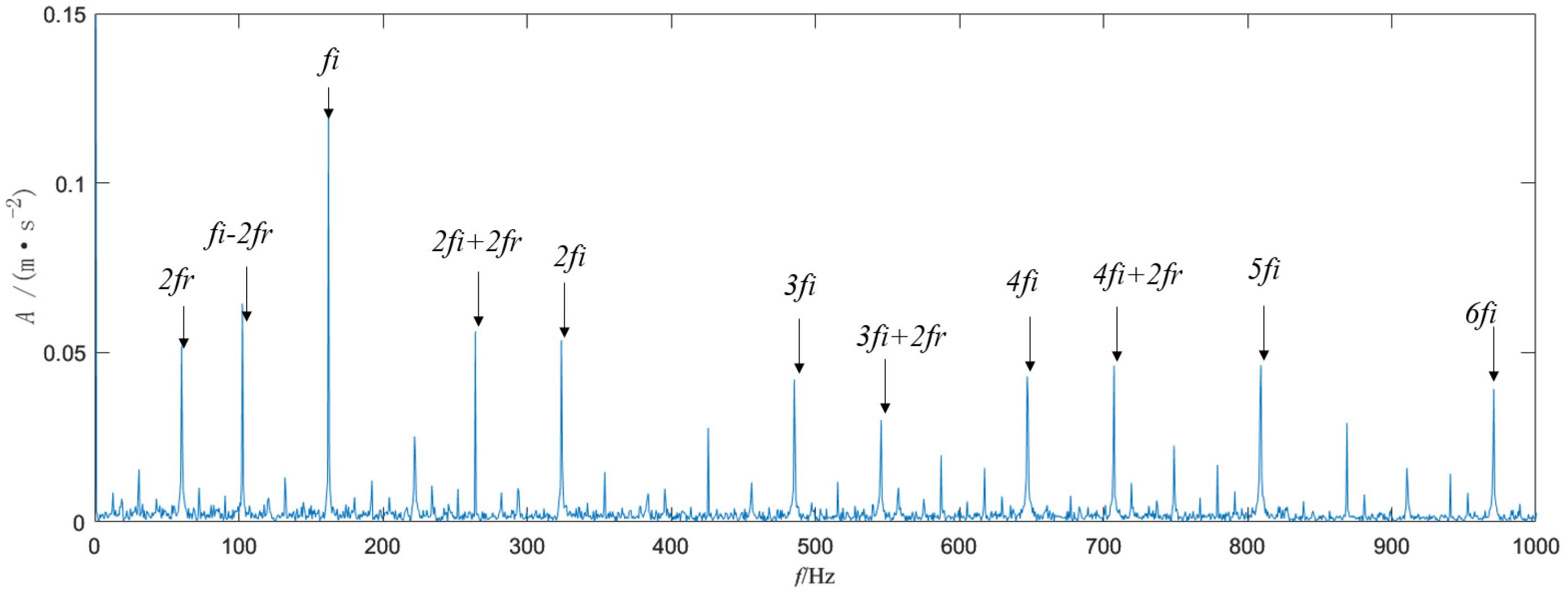

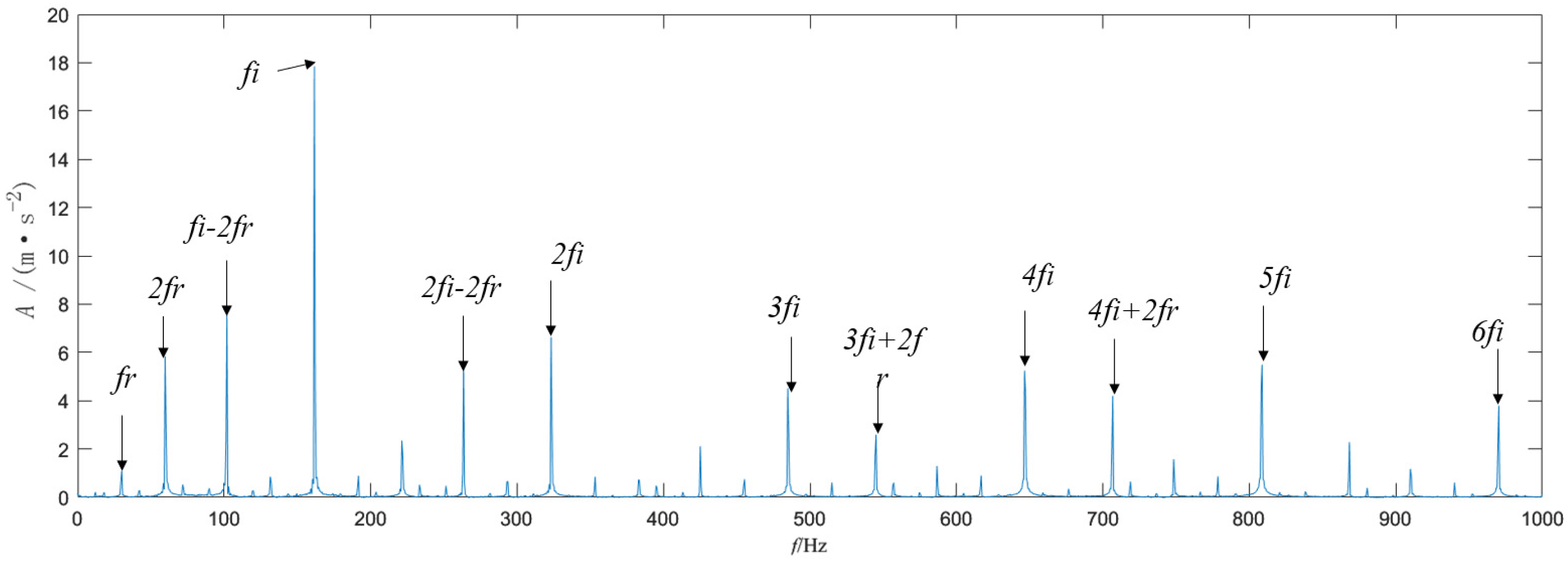

In

Figure 16, the fault signal of the ball screw is analyzed using 1.5DTES, which can only identify double the failure frequency. The noise interference is great, and the extraction effect is poor. From

Figure 17 and

Figure 18, it can be concluded that the Teager energy spectrum and 1.5DTES can extract the 2-times rotation frequency, the fault characteristic frequency, and the 2 to 6-times frequency, and the sideband of the rotation frequency modulation can be clearly observed. It has been comprehensively determined that there is a fault in the screw raceway of the ball screw. Comparing

Figure 17 and

Figure 18, it is clear that the rotation frequency and twice rotation frequency can be extracted from

Figure 18, while only a twice the rotation frequency can be identified in

Figure 17. In addition, by combining the Teager energy operator with the 1.5D spectrum, the noise component is significantly lower, the spectral line is more prominent, and the overall effect is better. This shows that the 1.5D spectrum has a good inhibitory effect on noise. The frequency value extracted from

Figure 18 is 161.6 Hz, and the theoretical fault frequency is 161.74 Hz. These values are very close; Therefore, it is possible to prove that the extraction is very accurate. This also verifies that the method used in this chapter can accurately extract the frequency of the screw raceway fault signal.

Wavelet denoising and singular value denoising have certain effects on ball screw fault diagnosis. The wavelet denoising method is widely used in the field of signal processing. It can effectively remove the noise and interference from the signal and retain the important information of the signal. In the fault diagnosis of ball screws, wavelet denoising can remove the noise and interference in the vibration signal, improve the signal-to-noise ratio of the signal, and is conducive to the accurate diagnosis of ball screw faults. Singular value denoising is employed to decompose the signal into different parts by singular value decomposition and to remove the noise and interference contained therein. In ball screw fault diagnosis, singular value denoising can decompose the vibration signal, extract the principal component of the signal, and avoid the influence of noise and interference on the fault diagnosis. Therefore, a wavelet regression network (WRN) was used to denoise the original signal for the first time, and the results are compared with the results of this method.

Ren Liang et al. [

21] used the singular spectrum decomposition algorithm to decompose the fault signal and reconstructed the decomposed signal according to the time domain cross-correlation criterion. Subsequently, the whale optimization algorithm (WOA) was used to optimize the parameters of VMD, and the reconstructed signal was decomposed by the parameter-optimized VMD. Working according to the kurtosis index, the fault characteristic signal was extracted from the decomposed intrinsic mode function. In order to verify the superiority of the proposed method, Ren Liang’s method was used to analyze the measured fault signal with 14 dB of Gaussian white noise, and the results were compared with the proposed method. The results of the above two methods are shown in

Table 2.