Study on Characteristics of an AC Sliding Discharge Plasma Actuator Operating at Different Pressures

Abstract

1. Introduction

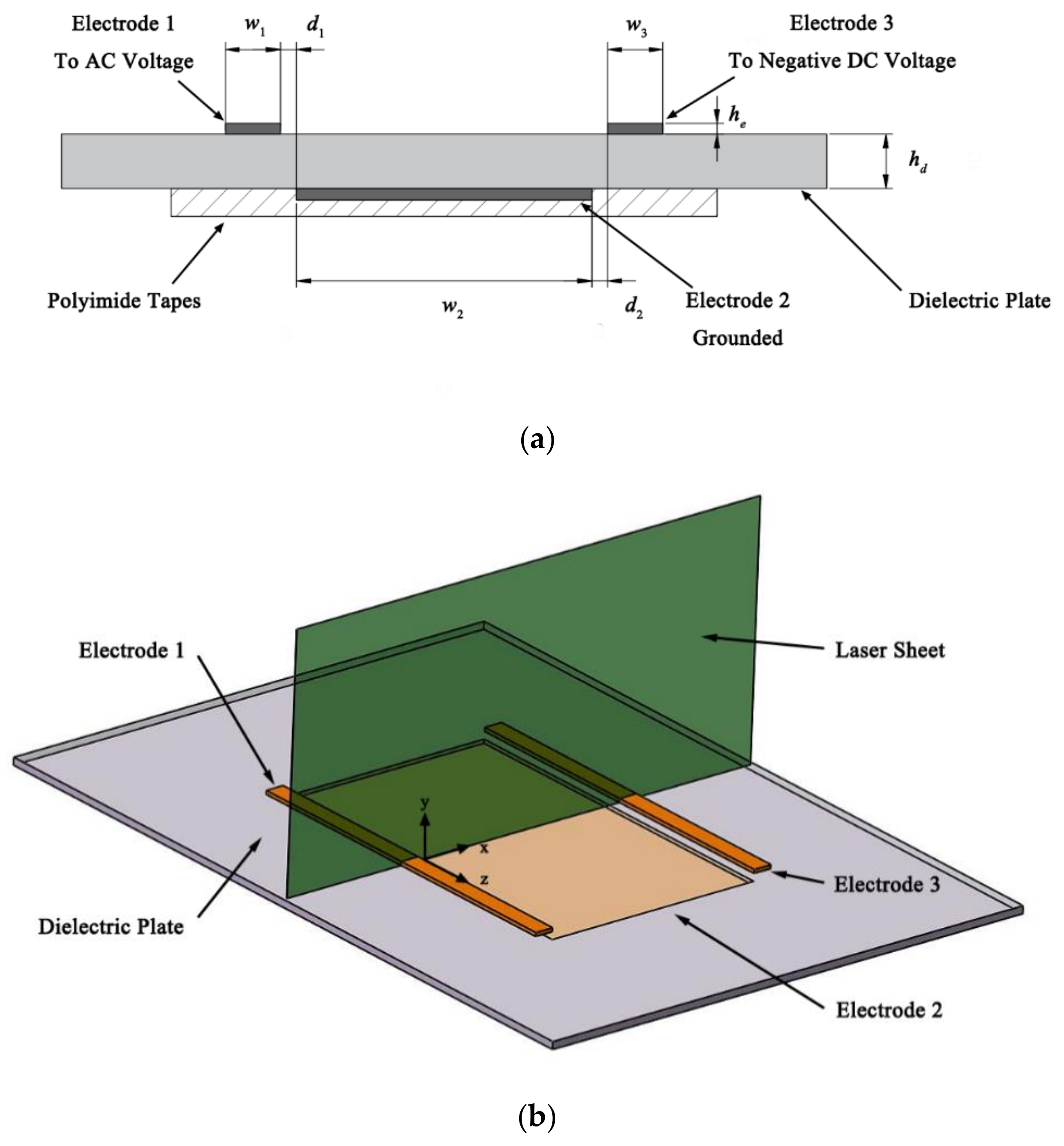

2. Experimental Setup

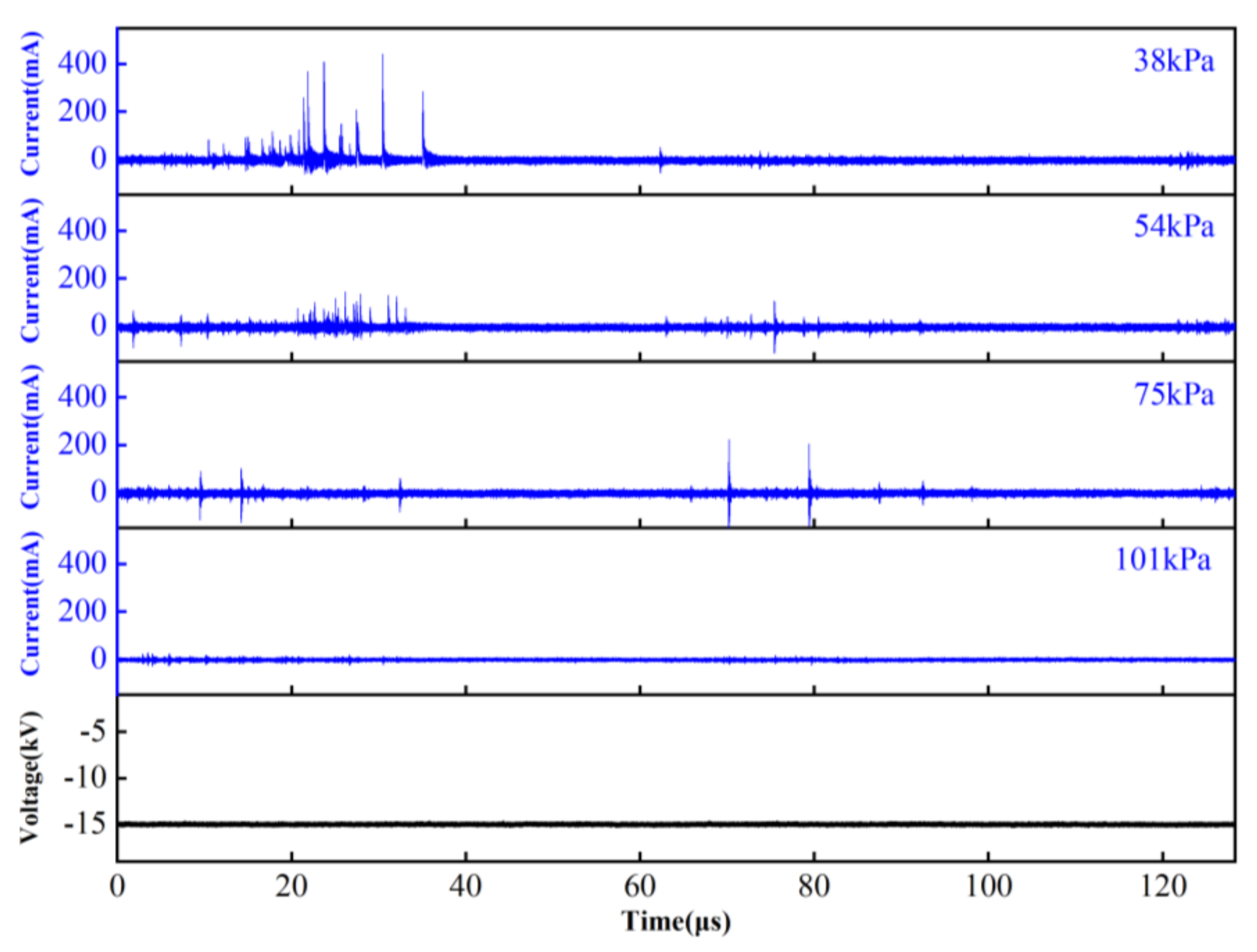

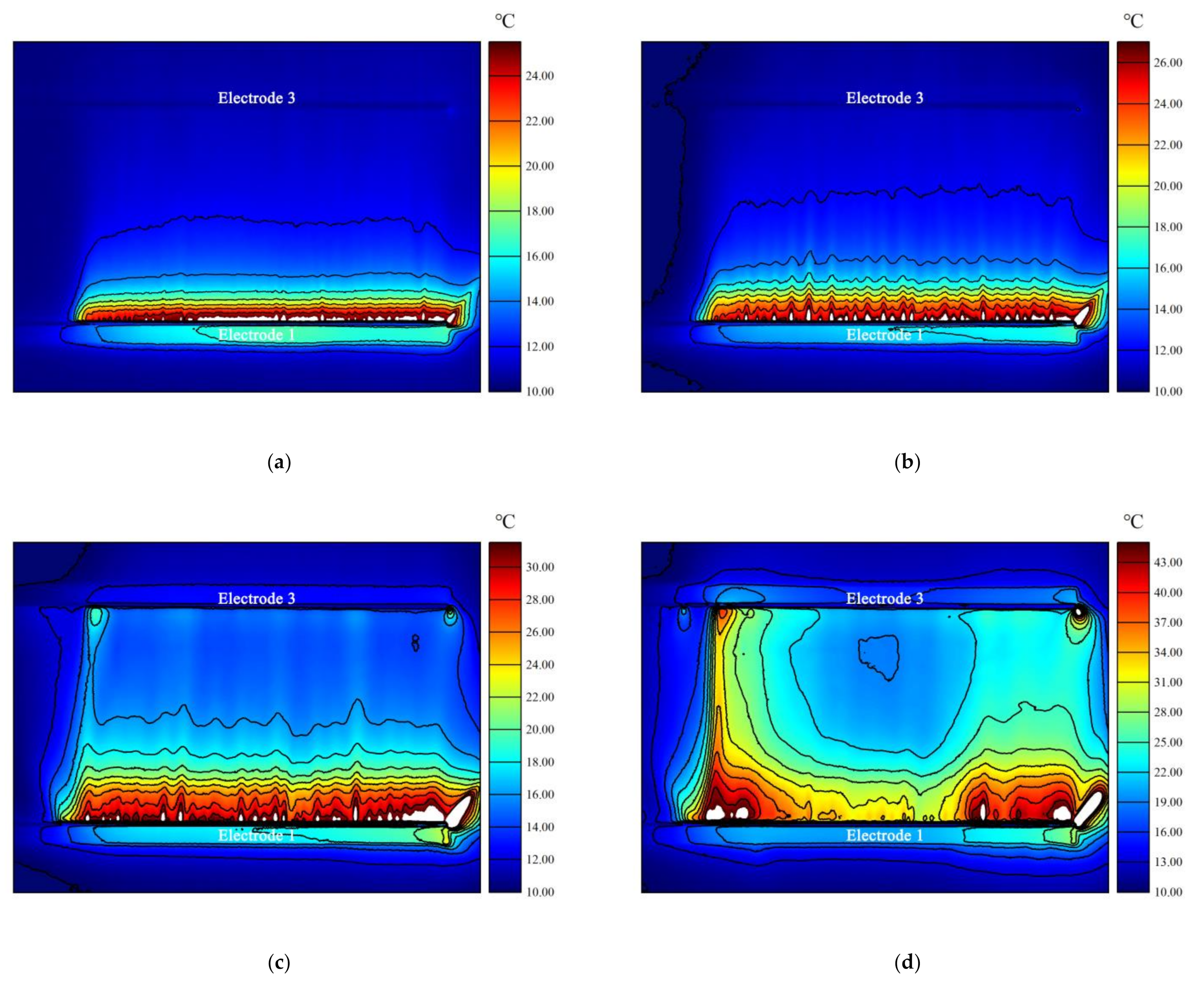

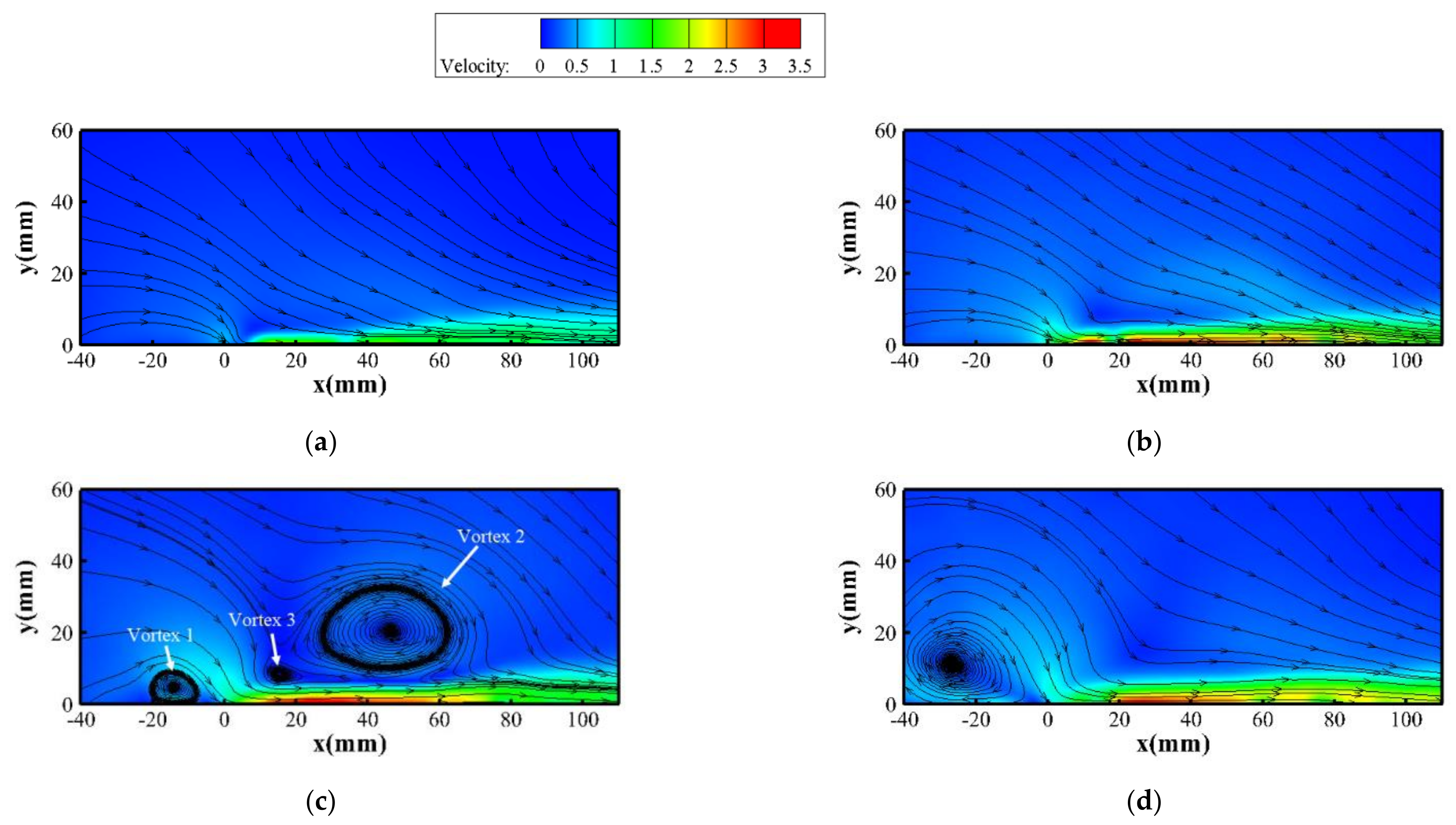

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Roth, J.; Sherman, D.; Wilkinson, S. Boundary layer flow control with a one atmosphere uniform glow discharge surface plasma. In Proceedings of the 36th AIAA Aerospace Sciences Meeting and Exhibit, Reno, NV, USA, 12–15 January 1998; p. 328. [Google Scholar] [CrossRef]

- Corke, T.C.; Post, M.L.; Orlov, D.M. Single dielectric barrier discharge plasma enhanced aerodynamics: Physics, modeling and applications. Exp. Fluids 2009, 46, 1–26. [Google Scholar] [CrossRef]

- Benard, N.; Moreau, E. Electrical and mechanical characteristics of surface AC dielectric barrier discharge plasma actuators applied to airflow control. Exp. Fluids 2014, 55, 1–43. [Google Scholar] [CrossRef]

- Kotsonis, M. Diagnostics for characterisation of plasma actuators. Meas. Sci. Technol. 2015, 26, 092001. [Google Scholar] [CrossRef]

- Benard, N.; Moreau, E. Role of the electric waveform supplying a dielectric barrier discharge plasma actuator. Appl. Phys. Lett. 2012, 100, 193503. [Google Scholar] [CrossRef]

- Abe, T.; Takizawa, Y.; Sato, S.; Kimura, N. Experimental study for momentum transfer in a dielectric barrier discharge plasma actuator. AIAA J. 2008, 46, 2248–2256. [Google Scholar] [CrossRef]

- Soni, J.; Roy, S. Low pressure characterization of dielectric barrier discharge actuators. Appl. Phys. Lett. 2013, 102, 112908. [Google Scholar] [CrossRef]

- Debien, A.; Benard, N.; Moreau, E. Streamer inhibition for improving force and electric wind produced by DBD actuators. J. Phys. D: Appl. Phys. 2012, 45, 215201. [Google Scholar] [CrossRef]

- Procházka, P. Vortex Structures Generated by Plasma DBD Actuator; Scholars’ Press: Chisinau, Republic of Moldova, 2019. [Google Scholar]

- Wu, Y.; Li, Y.; Jia, M.; Song, H.; Liang, H. Effect of pressure on the emission characteristics of surface dielectric barrier discharge plasma. Sensors Actuators A Phys. 2013, 203, 1–5. [Google Scholar] [CrossRef]

- Geuns, R.; Goekce, S.; Plyushchev, G.; Leyland, P.; Pimentel, R. Understanding SDBD actuators: An experimental study on plasma characteristics. In Proceedings of the 45th AIAA Plasmadynamics and Lasers Conference, Atlanta, GA, USA, 16–20 June 2014. [Google Scholar]

- Joussot, R.; Boucinha, V.; Weber-Rozenbaum, R.; Rabat, H.; Leroy-Chesneau, A.; Hong, D. Thermal Characterization of a DBD Plasma Actuator: Dielectric Temperature Measurements Using Infrared Thermography. In Proceedings of the 40th Fluid Dynamics Conference and Exhibit, Chicago, IL, USA, 28 June–1 July 2010; p. 5102. [Google Scholar] [CrossRef]

- Durscher, R.; Stanfield, S.; Roy, S. Characterization and manipulation of the “saturation” effect by changing the surface temperature of a dielectric barrier discharge actuator. Appl. Phys. Lett. 2012, 101, 252902. [Google Scholar] [CrossRef]

- Meng, X.; Hu, H.; Li, C.; Abbasi, A.A.; Cai, J.; Hu, H. Mechanism study of coupled aerodynamic and thermal effects using plasma actuation for anti-icing. Phys. Fluids 2019, 31, 037103. [Google Scholar] [CrossRef]

- Tian, Y.; Zhang, Z.; Cai, J.; Yang, L.; Kang, L. Experimental study of an anti-icing method over an airfoil based on pulsed dielectric barrier discharge plasma. Chin. J. Aeronaut. 2018, 31, 1449–1460. [Google Scholar] [CrossRef]

- Mao, Z.; Asai, Y.; Yamanoi, A.; Seki, Y.; Wiranata, A.; Minaminosono, A. Fluidic rolling robot using voltage-driven oscillating liquid. Smart Mater. Struct. 2022, 31, 105006. [Google Scholar] [CrossRef]

- Mao, Z.-B.; Asai, Y.; Wiranata, A.; Kong, D.-Q.; Man, J. Eccentric actuator driven by stacked electrohydrodynamic pumps. J. Zhejiang Univ. A 2022, 23, 329–334. [Google Scholar] [CrossRef]

- Lilley, A.J.; Roy, S.; Michels, L. Performance recovery of plasma actuators in wet conditions. J. Phys. D Appl. Phys. 2022, 55, 155201. [Google Scholar] [CrossRef]

- Bychkov, V.; Kuz’min, G.; Minaev, I.; Rukhadze, A.; Timofeev, I. Sliding discharge application in aerodynamics. In Proceedings of the 41st Aerospace Sciences Meeting and Exhibit, Reno, NV, USA, 6–9 January 2003; p. 530. [Google Scholar]

- Louste, C.; Artana, G.; Moreau, E.; Touchard, G. Sliding discharge in air at atmospheric pressure: Electrical properties. J. Electrost. 2005, 63, 615–620. [Google Scholar] [CrossRef]

- Moreau, E.; Sosa, R.; Artana, G. Electric wind produced by surface plasma actuators: A new dielectric barrier discharge based on a three-electrode geometry. J. Phys. D Appl. Phys. 2008, 41, 115204. [Google Scholar] [CrossRef]

- Moreau, E.; Louste, C.; Touchard, G. Electric wind induced by sliding discharge in air at atmospheric pressure. J. Electrost. 2008, 66, 107–114. [Google Scholar] [CrossRef]

- Song, H.; Li, Y.; Zhang, Q.; Jia, M.; Wu, Y. Experimental Investigation on the Characteristics of Sliding Discharge Plasma Aerodynamic Actuation. Plasma Sci. Technol. 2011, 13, 608–611. [Google Scholar] [CrossRef]

- Znamenskaya, I.; Glazyrin, F.; Koroteeva, E. PIV investigation of low-pressure pulse discharge flow. In Proceedings of the 10th Pacific Symposium on Flow Visualization and Image Processing (PSFVIP-10), Naples, Italy, 15–18 June 2015; University of Naples Federico II: Naples, Italy, 2015; p. 153-1. [Google Scholar]

- Sosa, R.; Arnaud, E.; Mémin, E.; Artana, G. Study of the flow induced by a sliding discharge. IEEE Trans. Dielectr. Electr. Insul. 2009, 16, 305–311. [Google Scholar] [CrossRef]

- Debien, A.; Benard, N.; Moreau, E. Electric wind produced by sliding discharges. In Proceedings of the 2nd ISNPEDADM New Electrical Technologies for Environment, Nouméa, France, 15–16 January 2011. [Google Scholar]

- Dong, H.; Li, Z.; Geng, X.; Shi, Z.; Sun, Q. Study of the airflow induced by a sliding discharge plasma actuator. Mod. Phys. Lett. B 2019, 33, 1950011. [Google Scholar] [CrossRef]

- Zheng, B.; Ke, X.; Ge, C.; Zhu, Y.; Wu, Y.; Liu, F.; Luo, S. Electrical and Flow Characteristics of a Double-Side Sliding Pulsed Discharge Plasma Actuator. AIAA J. 2020, 58, 733–746. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, Q.; Geng, X.; Li, Z.; Shi, Z.; Sun, Z.; Cheng, K. Study on Characteristics of an AC Sliding Discharge Plasma Actuator Operating at Different Pressures. Actuators 2023, 12, 34. https://doi.org/10.3390/act12010034

Sun Q, Geng X, Li Z, Shi Z, Sun Z, Cheng K. Study on Characteristics of an AC Sliding Discharge Plasma Actuator Operating at Different Pressures. Actuators. 2023; 12(1):34. https://doi.org/10.3390/act12010034

Chicago/Turabian StyleSun, Qijie, Xi Geng, Zheng Li, Zhiwei Shi, Zhikun Sun, and Keming Cheng. 2023. "Study on Characteristics of an AC Sliding Discharge Plasma Actuator Operating at Different Pressures" Actuators 12, no. 1: 34. https://doi.org/10.3390/act12010034

APA StyleSun, Q., Geng, X., Li, Z., Shi, Z., Sun, Z., & Cheng, K. (2023). Study on Characteristics of an AC Sliding Discharge Plasma Actuator Operating at Different Pressures. Actuators, 12(1), 34. https://doi.org/10.3390/act12010034