Eight-DOF Dynamic Modeling of EMA Mechanical Transmission and Spalling Fault Characteristic Analysis

Abstract

:1. Introduction

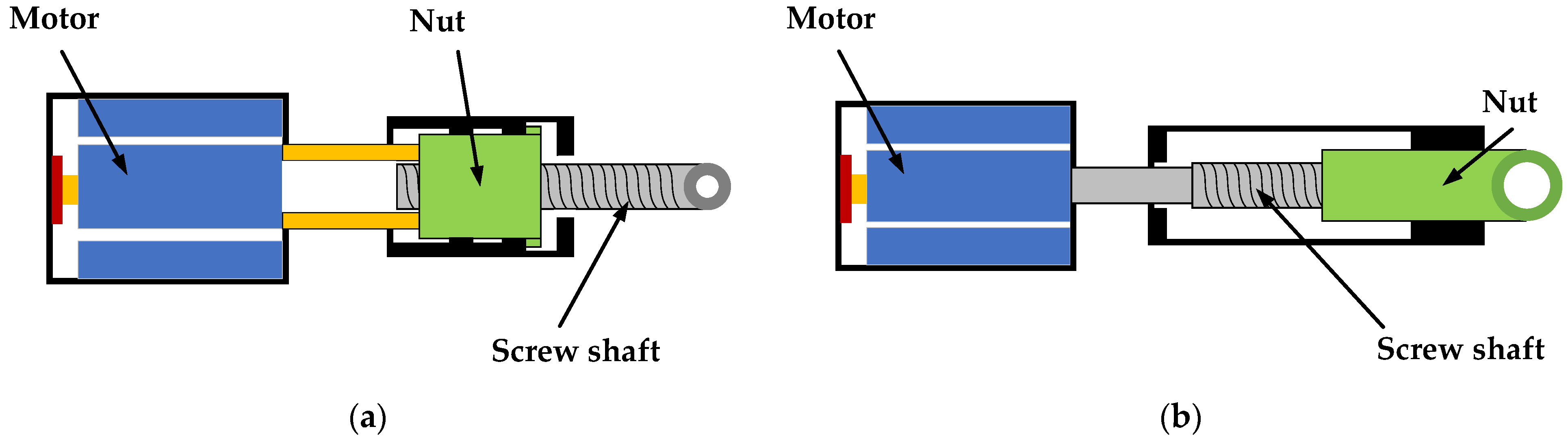

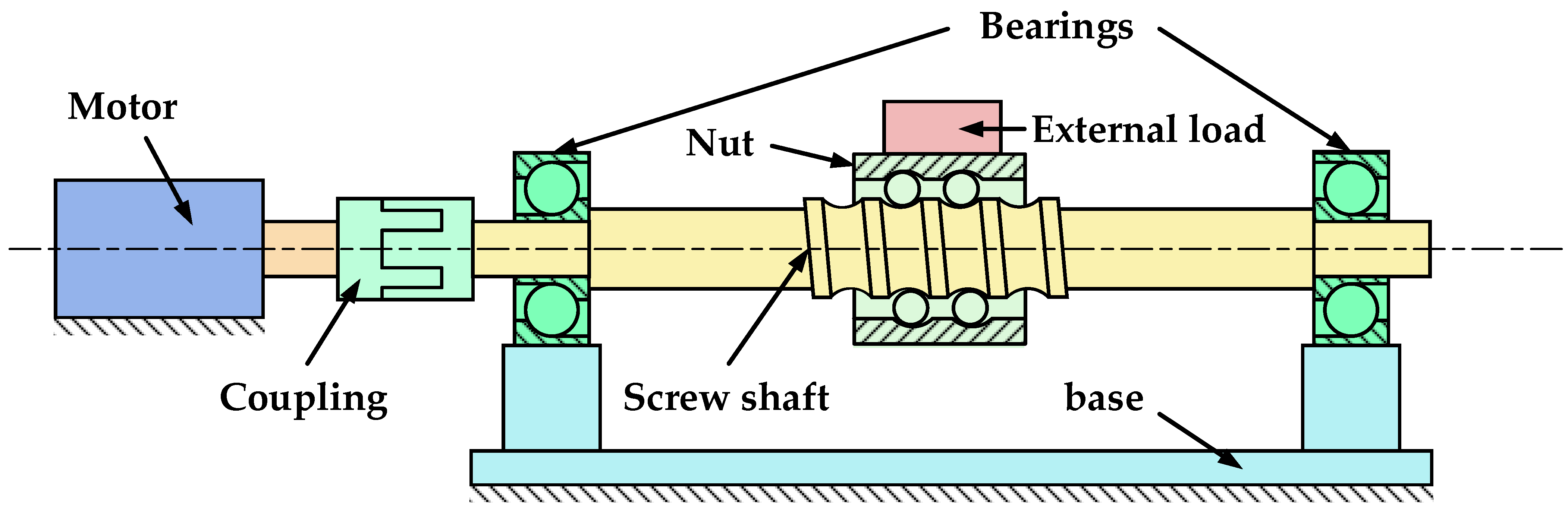

2. Dynamic Modeling under Normal Condition

2.1. Equations of Motion

- (1)

- All the balls are closely distributed in the nut of the ball-screw pair;

- (2)

- The direction of the preload applied on the nut is collinear with the axis of the nut;

- (3)

- Both the nut raceway and the screw shaft raceway are rigid bodies;

- (4)

- Each ball in the nut rotates at the same speed around the screw shaft when not in contact with the spalling fault;

- (5)

- The damping constants of the ball-screw pair are equal in all three directions;

- (6)

- The influences of the machining and assembly errors are not considered;

- (7)

- The profiles and materials of all balls are exactly the same, and the materials of the nut raceway and the screw shaft raceway are also the same;

- (8)

- Gravity is applied in the radial direction of the system;

- (9)

- Backlash is not considered;

- (10)

- As the total mass of the balls inside the nut is negligible, the inertial loads of the balls are not considered;

- (11)

- The motion of each ball inside the nut occurs by pure rolling only; and

- (12)

- The influence of friction is not considered in the models.

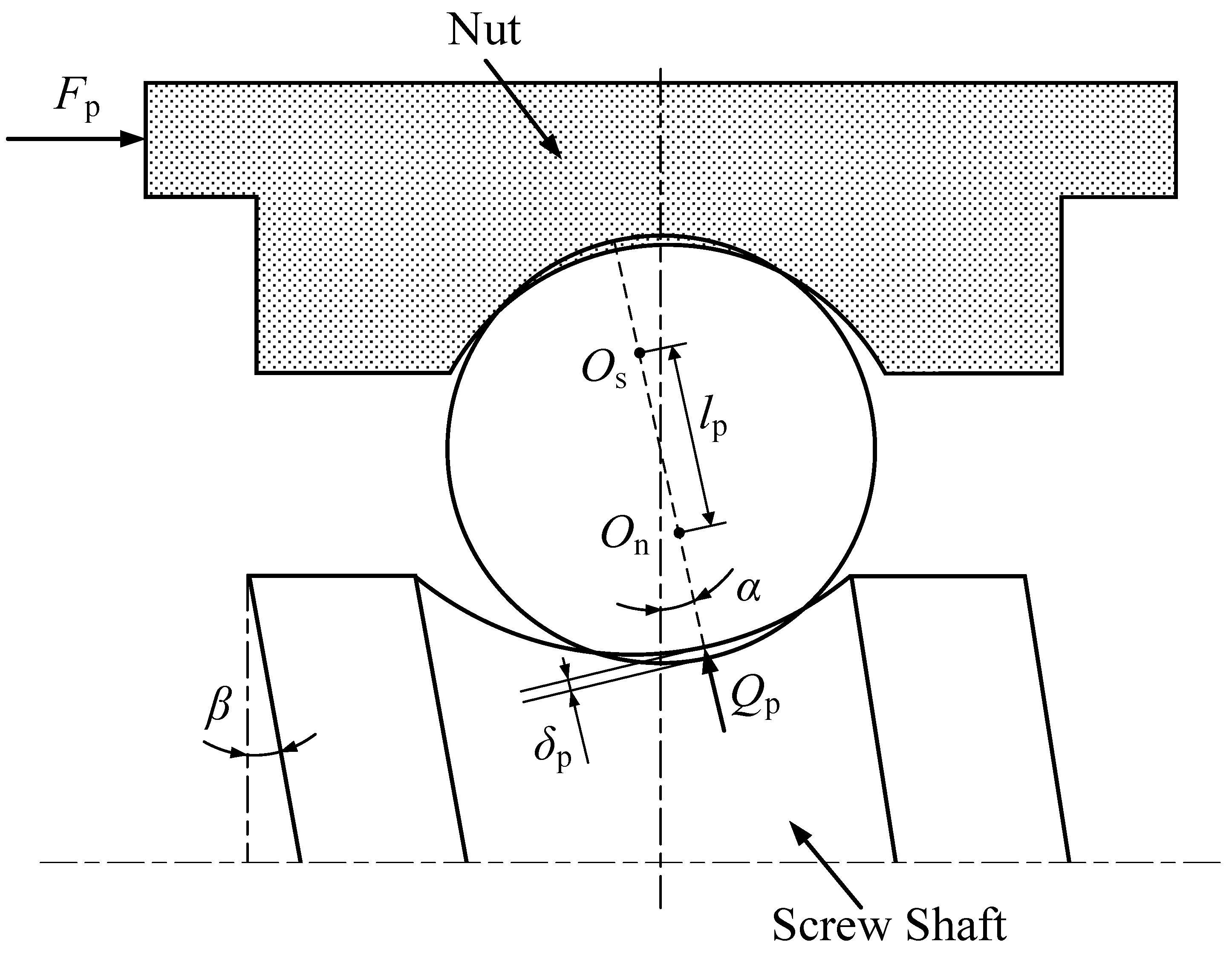

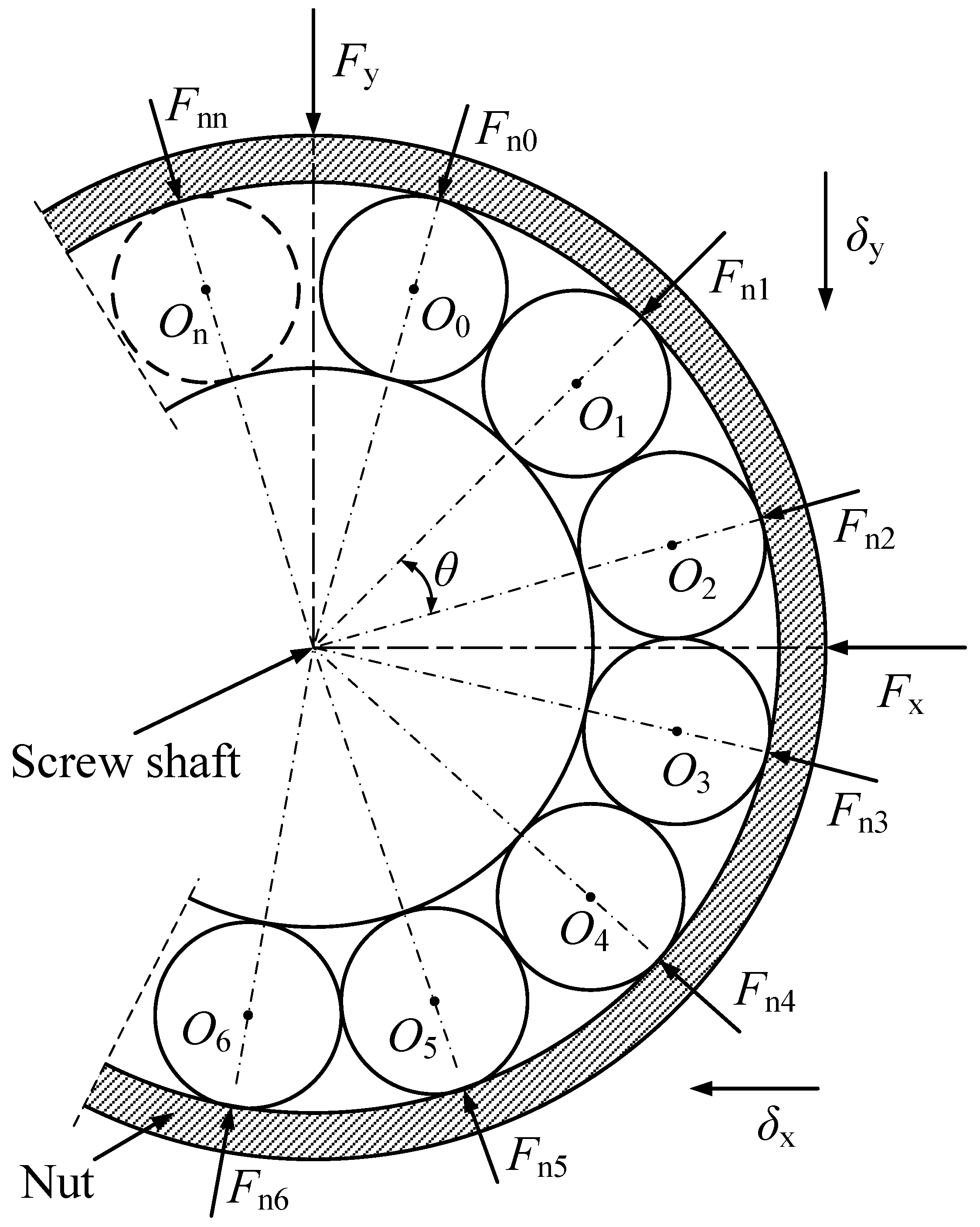

2.2. Solution of the Total Elastic Restoring Force of Balls

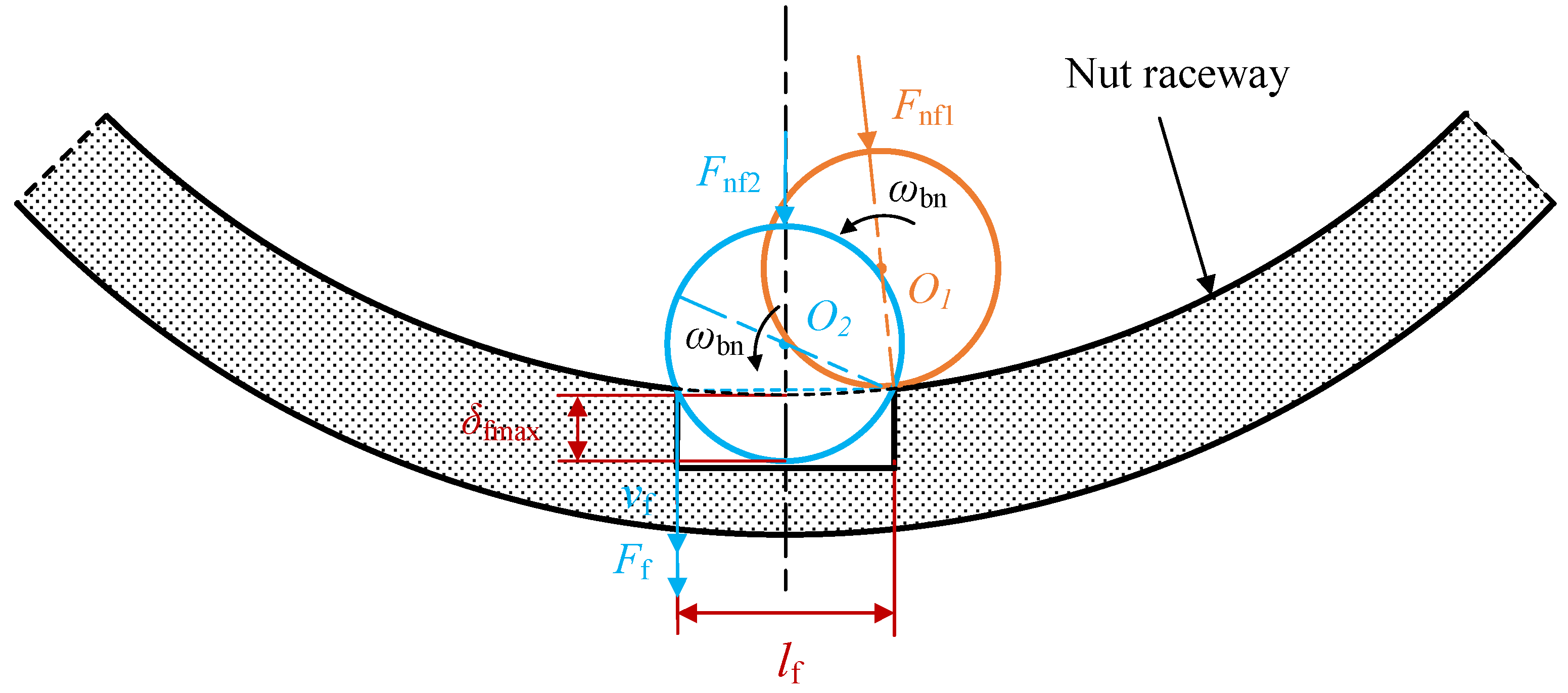

3. Dynamic Modeling under Faulty Conditions

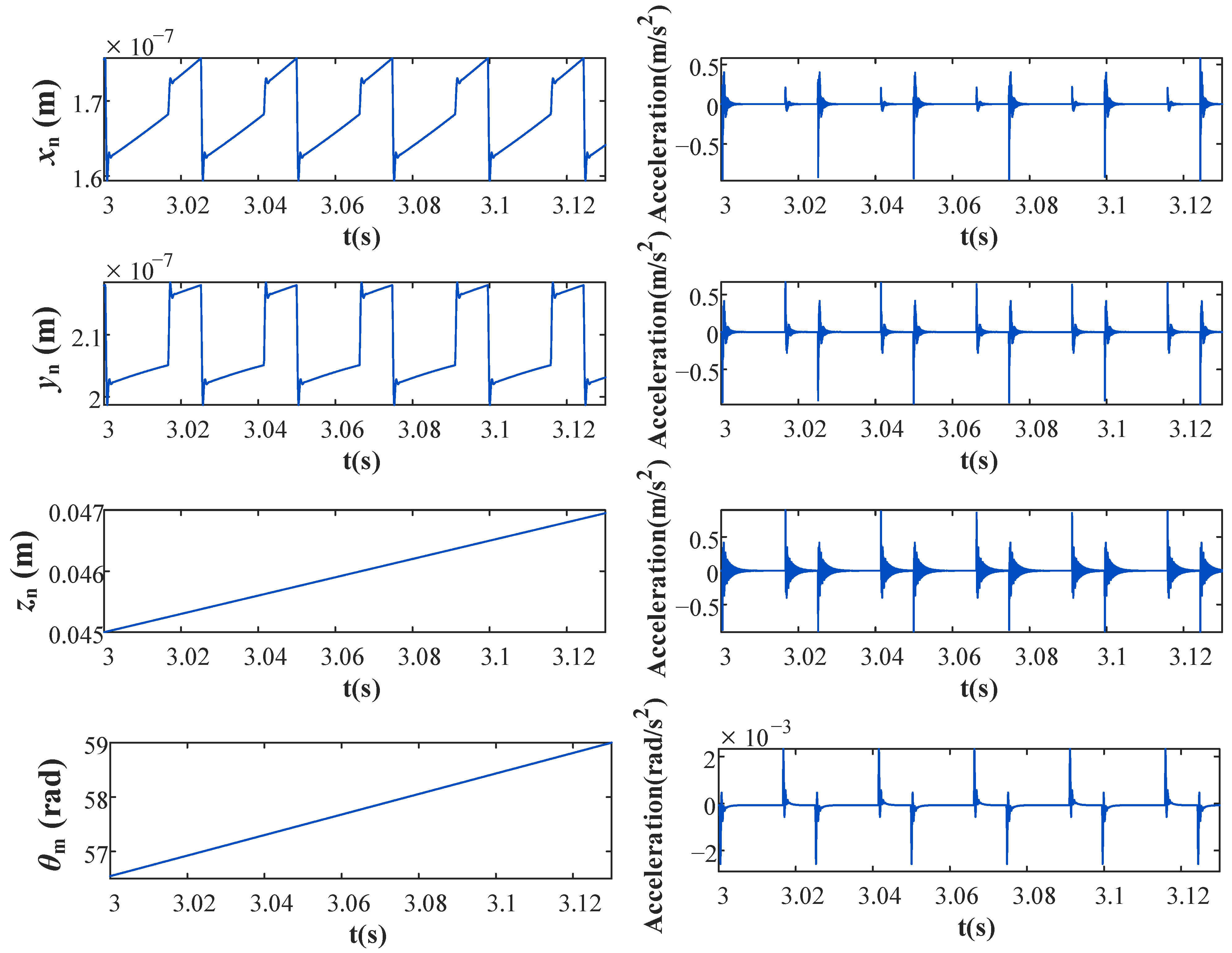

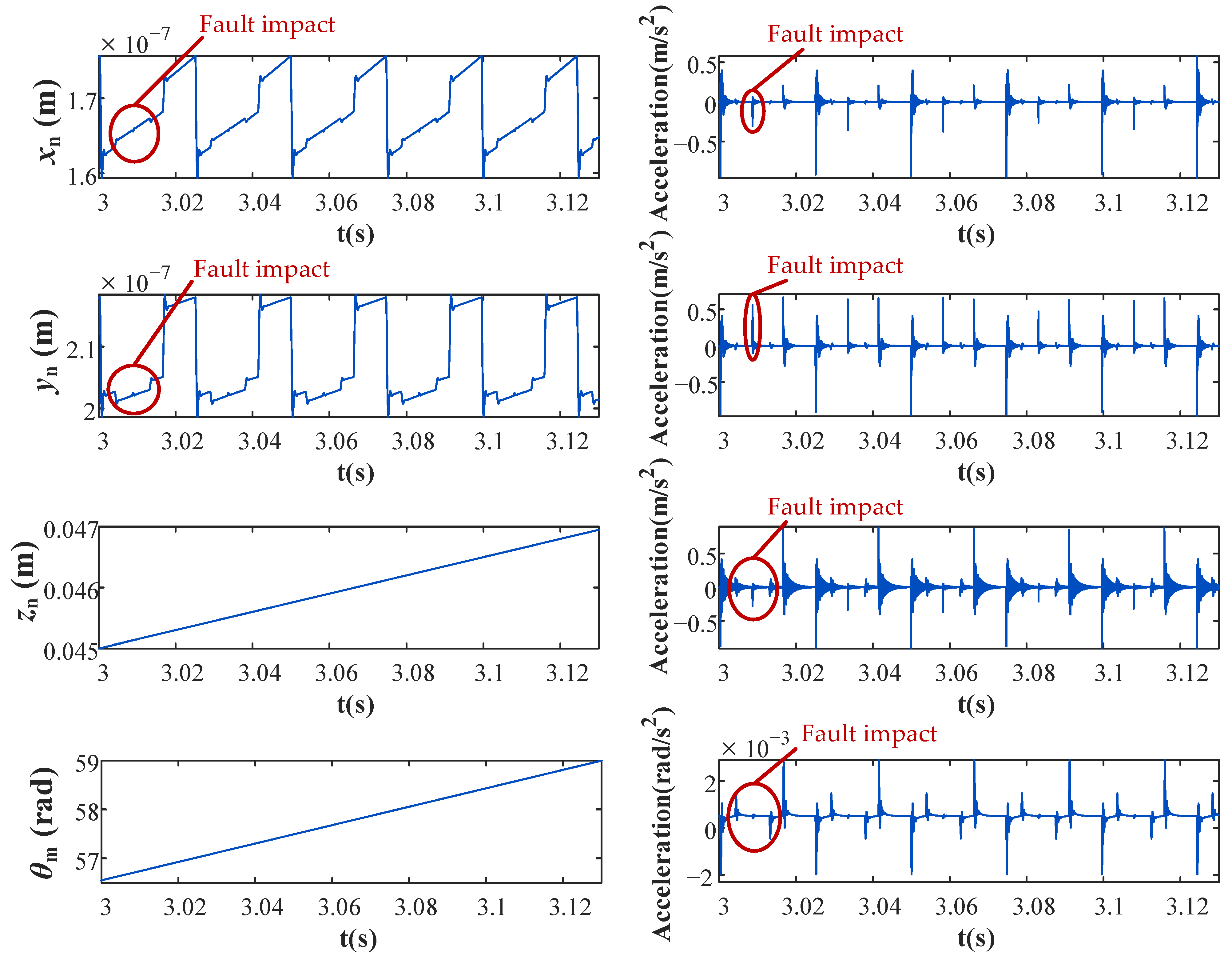

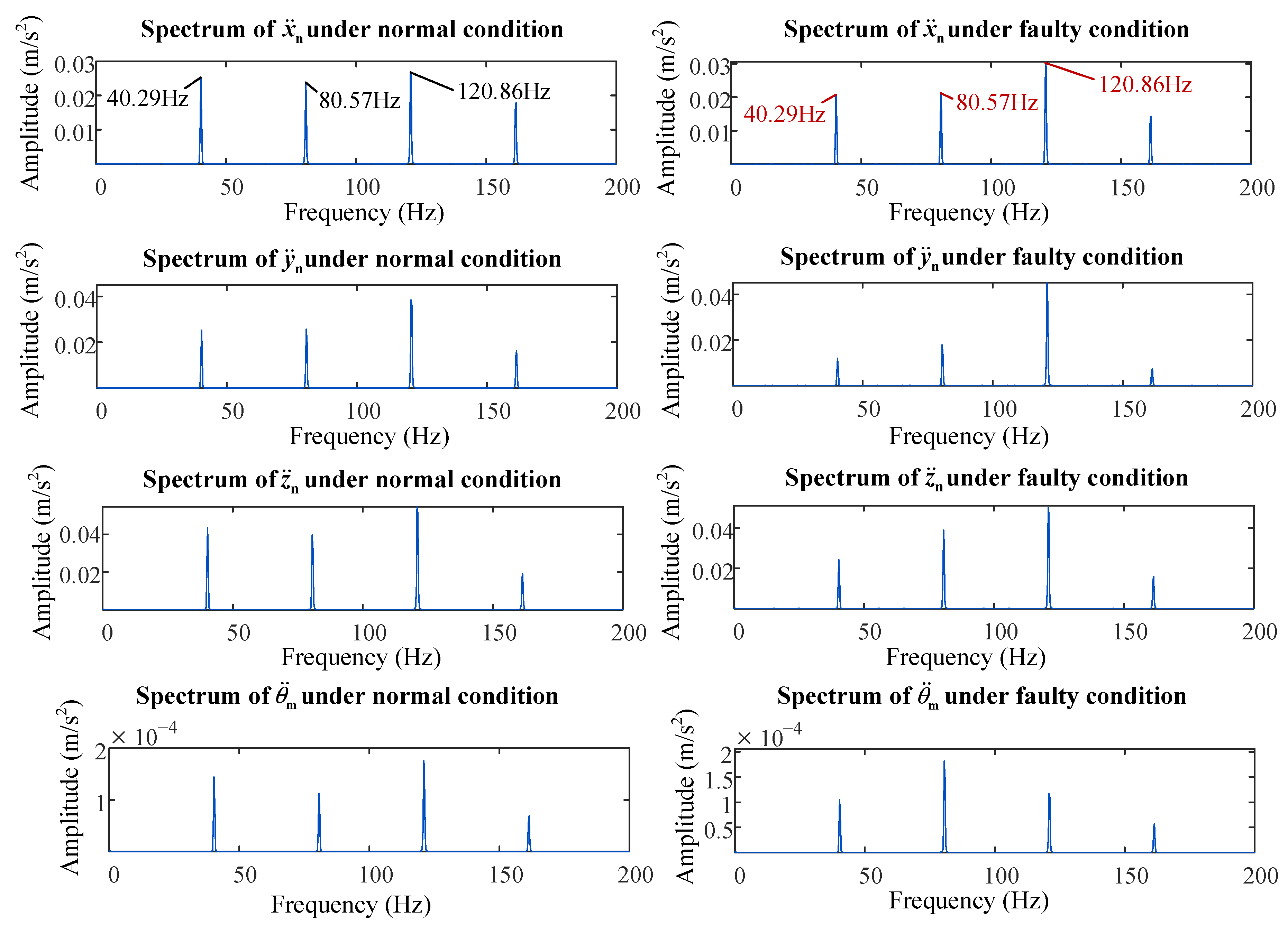

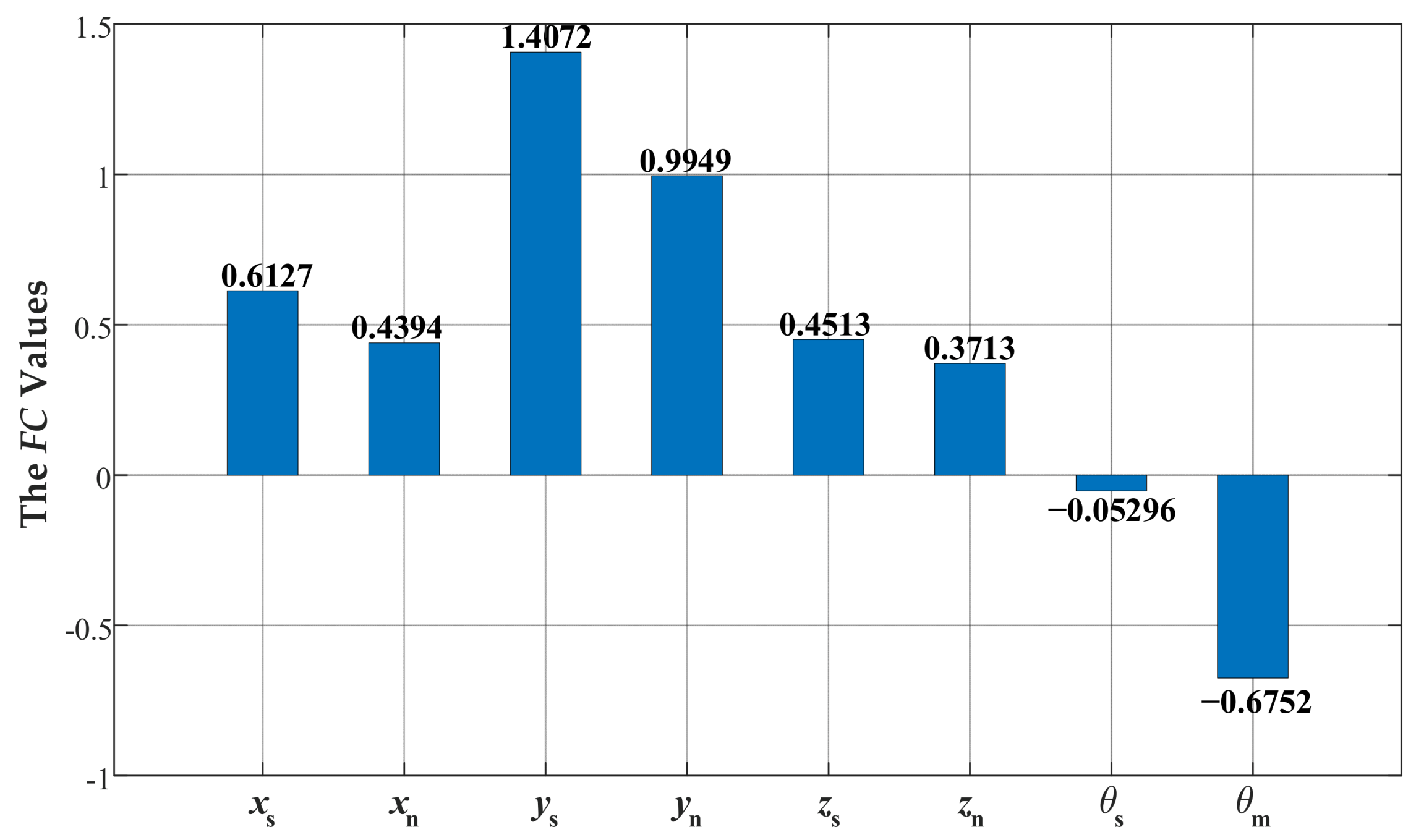

4. Simulation Results and Fault Characteristic Analysis

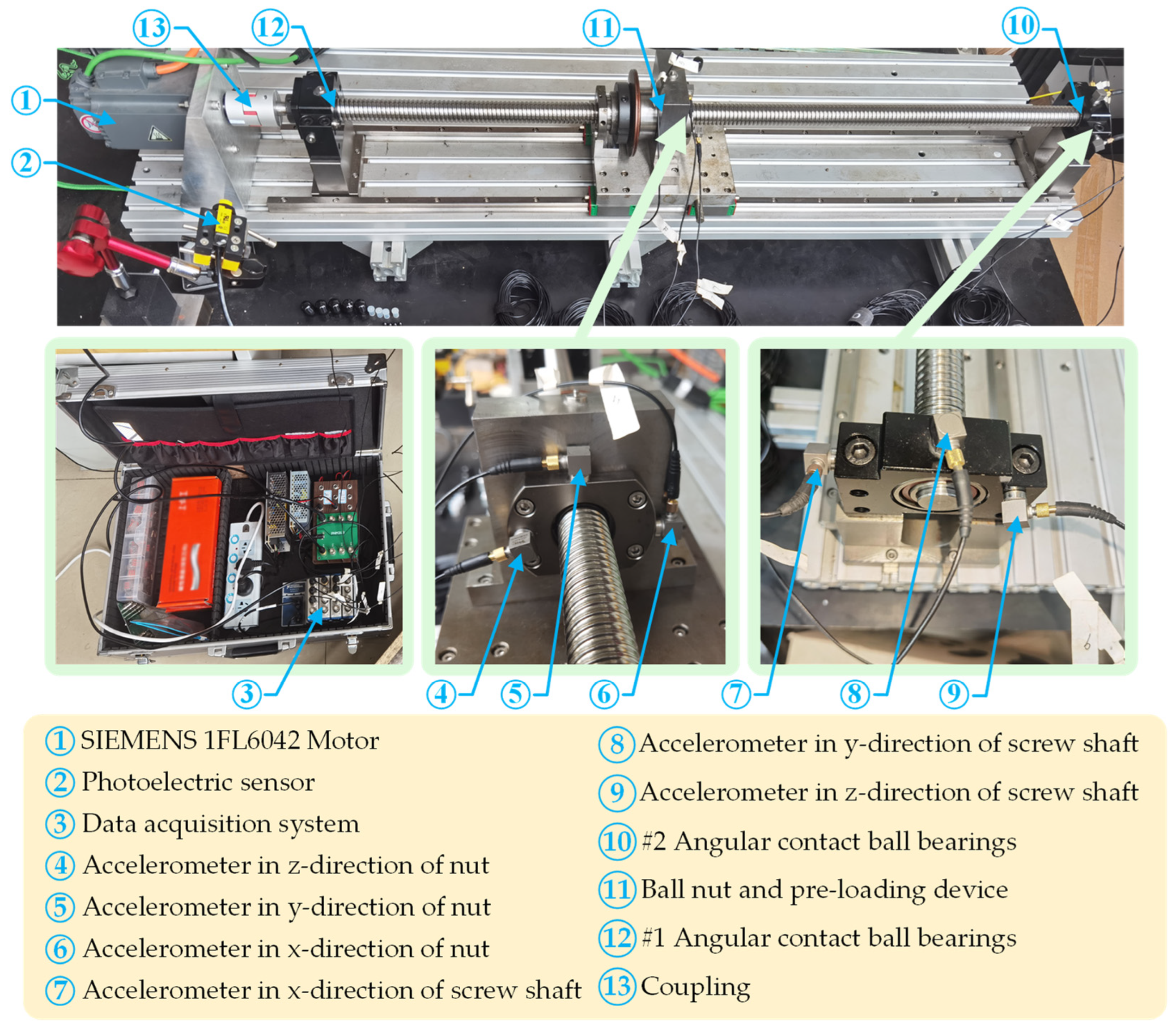

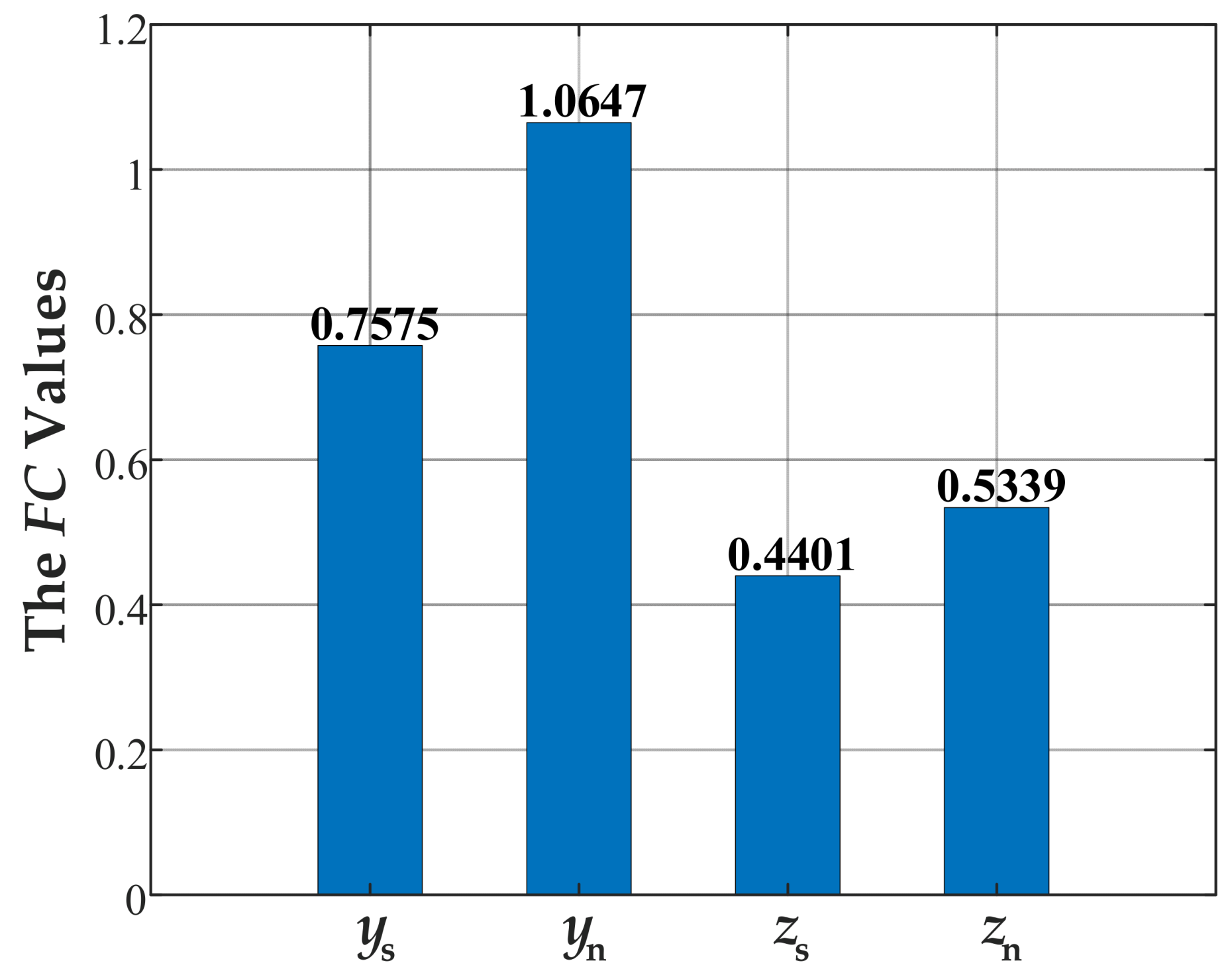

5. Experimental Verification

6. Discussion

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Mazzoleni, M.; Di Rito, G.; Previdi, F. Electro-Mechanical Actuators for the More Electric Aircraft, 1st ed.; Springer: Cham, Switzerland, 2021; Volume 2021. [Google Scholar]

- Yin, Z.; Hu, N.; Chen, J.; Yang, Y.; Shen, G. A review of fault diagnosis, prognosis and health management for aircraft electromechanical actuators. IET Electr. Power Appl. 2022; early view. [Google Scholar]

- Balaban, E.; Bansal, P.; Stoelting, P.; Saxena, A.; Goebel, K.F.; Curran, S. A diagnostic approach for electro-mechanical actuators in aerospace systems. In Proceedings of the 2009 IEEE Aerospace Conference, Big Sky, MT, USA, 7–14 March 2009; pp. 1–13. [Google Scholar]

- Ismail, M.A.A.; Balaban, E.; Spangenberg, H. Fault detection and classification for flight control electromechanical actuators. In Proceedings of the 2016 IEEE Aerospace Conference, Big Sky, MT, USA, 5–12 March 2016; pp. 1–10. [Google Scholar]

- Balaban, E.; Saxena, A.; Narasimhan, S.; Roychoudhury, I.; Goebel, K. Experimental validation of a prognostic health management system for electro-mechanical actuators. In Infotech@aerospace; American Institute of Aeronautics and Astronautics: St. Louis, MO, USA, 2011. [Google Scholar]

- Balaban, E.; Saxena, A.; Narasimhan, S.; Roychoudhury, I.; Goebel, K.; Koopmans, M. Airborne Electro-Mechanical Actuator Test Stand for Development of Prognostic Health Management Systems. In Proceedings of the Annual Conference of the Prognostics and Health Management Society, Portland, OR, USA, 10–16 October 2010. [Google Scholar]

- Balaban, E.; Saxena, A.; Goebel, K.; Byington, C.; Watson, M.; Bharadwaj, S.; Smith, M.; Amin, S. Experimental data collection and modeling for nominal and fault conditions on electro-mechanical actuators. In Proceedings of the Annual Conference of the Prognostics and Health Management Society, San Diego, CA, USA, 27 September–1 October 2009; pp. 1–15. [Google Scholar]

- Bodden, D.S.; Clements, N.S.; Schley, B.; Jenney, G. Seeded failure testing and analysis of an electro-mechanical actuator. In Proceedings of the 2007 IEEE Aerospace Conference, Big Sky, MT, USA, 3–10 March 2007; pp. 1–8. [Google Scholar]

- Wang, C.; Tao, L.; Ding, Y.; Lu, C.; Ma, J. An adversarial model for electromechanical actuator fault diagnosis under nonideal data conditions. Neural Comput. Appl. 2022, 34, 5883–5904. [Google Scholar] [CrossRef]

- Hussain, Y.M.; Burrow, S.; Henson, L.; Keogh, P. A high fidelity model based approach to identify dynamic friction in electromechanical actuator ballscrews using motor current. Int. J. Progn. Health Manag. 2020, 9. [Google Scholar] [CrossRef]

- Mazzoleni, M.; Maccarana, Y.; Previdi, F. A comparison of data-driven fault detection methods with application to aerospace electro-mechanical actuators. IFAC-PapersOnLine 2017, 50, 12797–12802. [Google Scholar] [CrossRef]

- Chirico, A.J.; Kolodziej, J.R. A data-driven methodology for fault detection in electromechanical actuators. J. Dyn. Syst. Meas. Control 2014, 136, 041025. [Google Scholar] [CrossRef]

- Yang, T.; Cao, X.; Yang, J. Fault detection and isolation of the electro-mechanical actuator based on bit. IOP Conf. Ser. Mater. Sci. Eng. 2020, 790, 012163. [Google Scholar] [CrossRef]

- Ismail, M.A.A.; Balaban, E.; Windelberg, J. Spall fault quantification method for flight control electromechanical actuator. Actuators 2022, 11, 29. [Google Scholar] [CrossRef]

- Hospital, F.; Budinger, M.; Reysset, A.; Maré, J.-C. Preliminary design of aerospace linear actuator housings. Aircr. Eng. Aerosp. Technol. 2015, 87, 224–237. [Google Scholar] [CrossRef]

- Liu, C.; Zhao, C.; Wen, B. Dynamics analysis on the mdof model of ball screw feed system considering the assembly error of guide rails. Mech. Syst. Signal Process. 2022, 178, 109290. [Google Scholar] [CrossRef]

- Xu, M.; Cai, B.; Li, C.; Zhang, H.; Liu, Z.; He, D.; Zhang, Y. Dynamic characteristics and reliability analysis of ball screw feed system on a lathe. Mech. Mach. Theory 2020, 150, 103890. [Google Scholar] [CrossRef]

- Liu, J.; Ou, Y. Dynamic axial contact stiffness analysis of position preloaded ball screw mechanism. Adv. Mech. Eng. 2019, 11, 1687814018819289. [Google Scholar] [CrossRef]

- Gu, J.; Zhang, Y. Dynamic analysis of a ball screw feed system with time-varying and piecewise-nonlinear stiffness. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2019, 233, 6503–6518. [Google Scholar] [CrossRef]

- Guo, C.; Chen, L.; Ding, J. A novel dynamics model of ball-screw feed drives based on theoretical derivations and deep learning. Mech. Mach. Theory 2019, 141, 196–212. [Google Scholar] [CrossRef]

- Bertolino, A.C.; Sorli, M.; Jacazio, G.; Mauro, S. Lumped parameters modelling of the emas’ ball screw drive with special consideration to ball/grooves interactions to support model-based health monitoring. Mech. Mach. Theory 2019, 137, 188–210. [Google Scholar] [CrossRef]

- Bertolino, A.C.; Mauro, S.; Jacazio, G.; Sorli, M. Multibody dynamic model of a double nut preloaded ball screw mechanism with lubrication. In Proceedings of the ASME 2020 International Mechanical Engineering Congress and Exposition, Virtual Online, 16–19 November 2020. [Google Scholar]

- Vicente, D.; Hecker, R.; Villegas, F.; Flores, G. Modeling and vibration mode analysis of a ball screw drive. Int. J. Adv. Manuf. Technol. 2012, 58, 257–265. [Google Scholar] [CrossRef]

- Feng, G.-H.; Pan, Y.-L. Investigation of ball screw preload variation based on dynamic modeling of a preload adjustable feed-drive system and spectrum analysis of ball-nuts sensed vibration signals. Int. J. Mach. Tools Manuf. 2012, 52, 85–96. [Google Scholar] [CrossRef]

- Hu, N.; Hu, L.; Cheng, Z. Mechanical Vibration; National University of Defense Technology Press: Changsha, China, 2017; p. 335. [Google Scholar]

- Chen, J.S.; Huang, Y.K.; Cheng, C.C. Mechanical model and contouring analysis of high-speed ball-screw drive systems with compliance effect. Int. J. Adv. Manuf. Technol. 2004, 24, 241–250. [Google Scholar] [CrossRef]

- Vashisht, R.K.; Peng, Q. Online chatter detection for milling operations using lstm neural networks assisted by motor current signals of ball screw drives. J. Manuf. Sci. Eng. 2021, 143, 011008. [Google Scholar] [CrossRef]

- Xu, M.; Zhang, H.; Liu, Z.; Li, C.; Zhang, Y.; Mu, Y.; Hou, C. A time-dependent dynamic model for ball passage vibration analysis of recirculation ball screw mechanism. Mech. Syst. Signal Process. 2021, 157, 107632. [Google Scholar] [CrossRef]

- Varanis, M.V.M.; Mereles, A.G.; Silva, A.L.; Balthazar, J.M.; Tusset, A.M.; Oliveira, C. Modeling and experimental validation of two adjacent portal frame structures subjected to vibro-impact. Lat. Am. J. Solids Struct. 2019, 16, e179. [Google Scholar] [CrossRef] [Green Version]

- Liu, Z.; Xu, M.; Zhang, H.; Miao, H.; Li, Z.; Li, C.; Zhang, Y. Nonlinear dynamic analysis of ball screw feed system considering assembly error under harmonic excitation. Mech. Syst. Signal Process. 2021, 157, 107717. [Google Scholar] [CrossRef]

- Zhang, Y. Research on Contact Mechanics Vibration Model and Feature Extraction Method of Ball Screw. Master’s Thesis, Southeast University, Nanjing, China, 2013. [Google Scholar]

- Inman, D.J. Single-degree-of-freedom systems. In Vibration with Control; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2006; pp. 1–38. [Google Scholar]

- Ni, Z. Vibration Mechanics; Xi’an Jiaotong University Press: Xi’an, China, 1989; p. 521. [Google Scholar]

| Parameter | Value |

|---|---|

| Ball diameter, db (m) | 0.003175 |

| Diameter of the screw shaft pitch circle, ds (m) | 0.025 |

| Lead angle, β (rad) | 0.063576 |

| Contact angle, α (rad) | 0.25π |

| Number of turns of the nut raceway, Ns | 4.8 |

| Mass of the nut, mn (kg) | 0.6605 |

| Mass of the screw shaft, ms (kg) | 3.4285 |

| Axial preload, Fp (N) | 25 |

| Width of nut spalling fault, lf (m) | 0.001 |

| Screw shaft rotating speed (rpm) | 180 |

| Spectrum | Amplitude Increase Rate (%) | ||

|---|---|---|---|

| fb | 2fb | 3fb | |

| ys | 46.9832 | −11.2515 | 111.486 |

| zs | 59.3389 | −15.1929 | 88.1544 |

| yn | 10.7598 | −58.4076 | 58.8222 |

| zn | 22.3039 | −40.7564 | 71.6203 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yin, Z.; Yang, Y.; Shen, G.; Chen, L.; Hu, N. Eight-DOF Dynamic Modeling of EMA Mechanical Transmission and Spalling Fault Characteristic Analysis. Actuators 2022, 11, 226. https://doi.org/10.3390/act11080226

Yin Z, Yang Y, Shen G, Chen L, Hu N. Eight-DOF Dynamic Modeling of EMA Mechanical Transmission and Spalling Fault Characteristic Analysis. Actuators. 2022; 11(8):226. https://doi.org/10.3390/act11080226

Chicago/Turabian StyleYin, Zhengyang, Yi Yang, Guoji Shen, Ling Chen, and Niaoqing Hu. 2022. "Eight-DOF Dynamic Modeling of EMA Mechanical Transmission and Spalling Fault Characteristic Analysis" Actuators 11, no. 8: 226. https://doi.org/10.3390/act11080226

APA StyleYin, Z., Yang, Y., Shen, G., Chen, L., & Hu, N. (2022). Eight-DOF Dynamic Modeling of EMA Mechanical Transmission and Spalling Fault Characteristic Analysis. Actuators, 11(8), 226. https://doi.org/10.3390/act11080226