Achieving Full Forward Flow of Valveless Piezoelectric Micropump Used for Micro Analysis System

Abstract

:1. Introduction

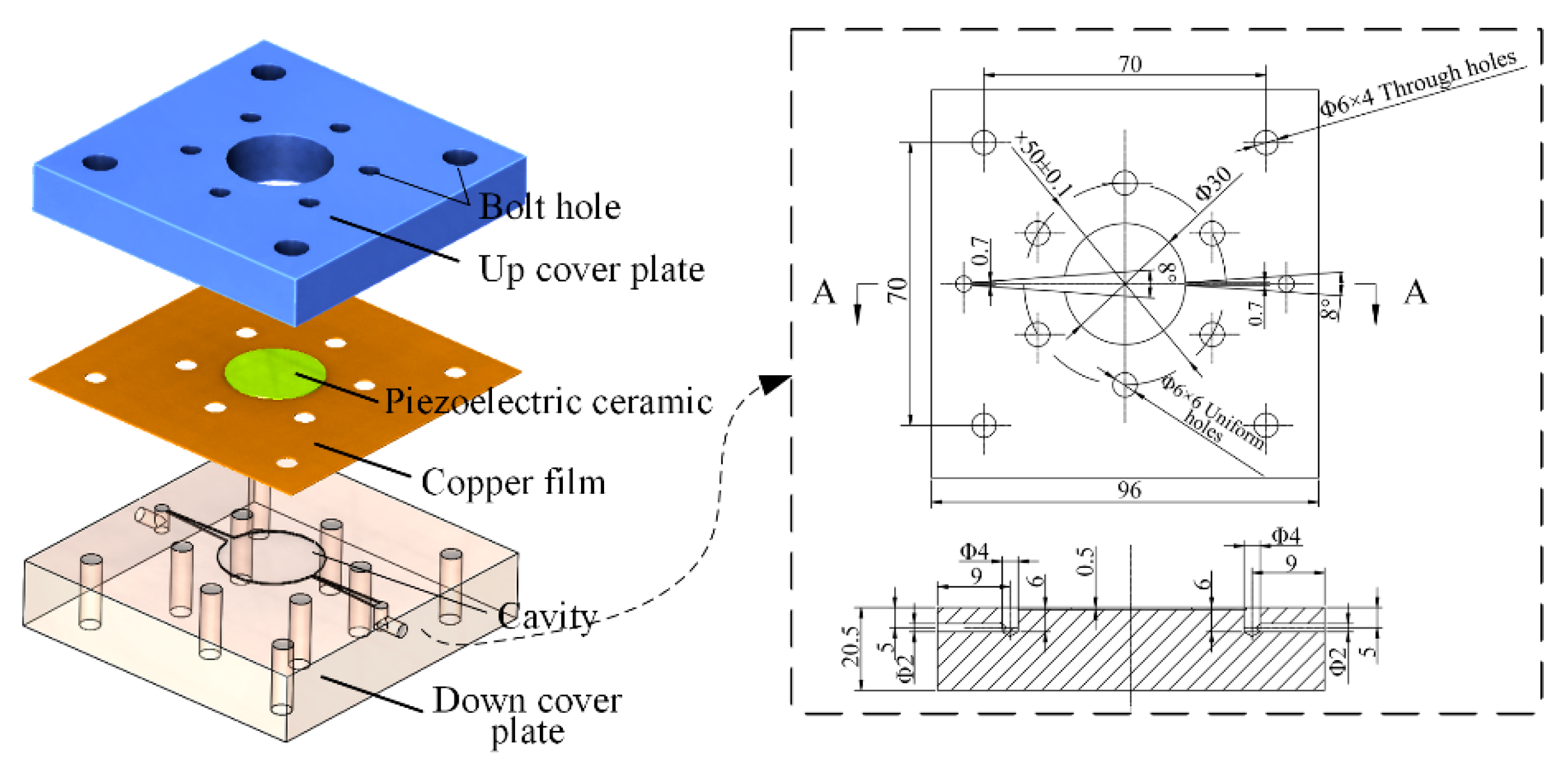

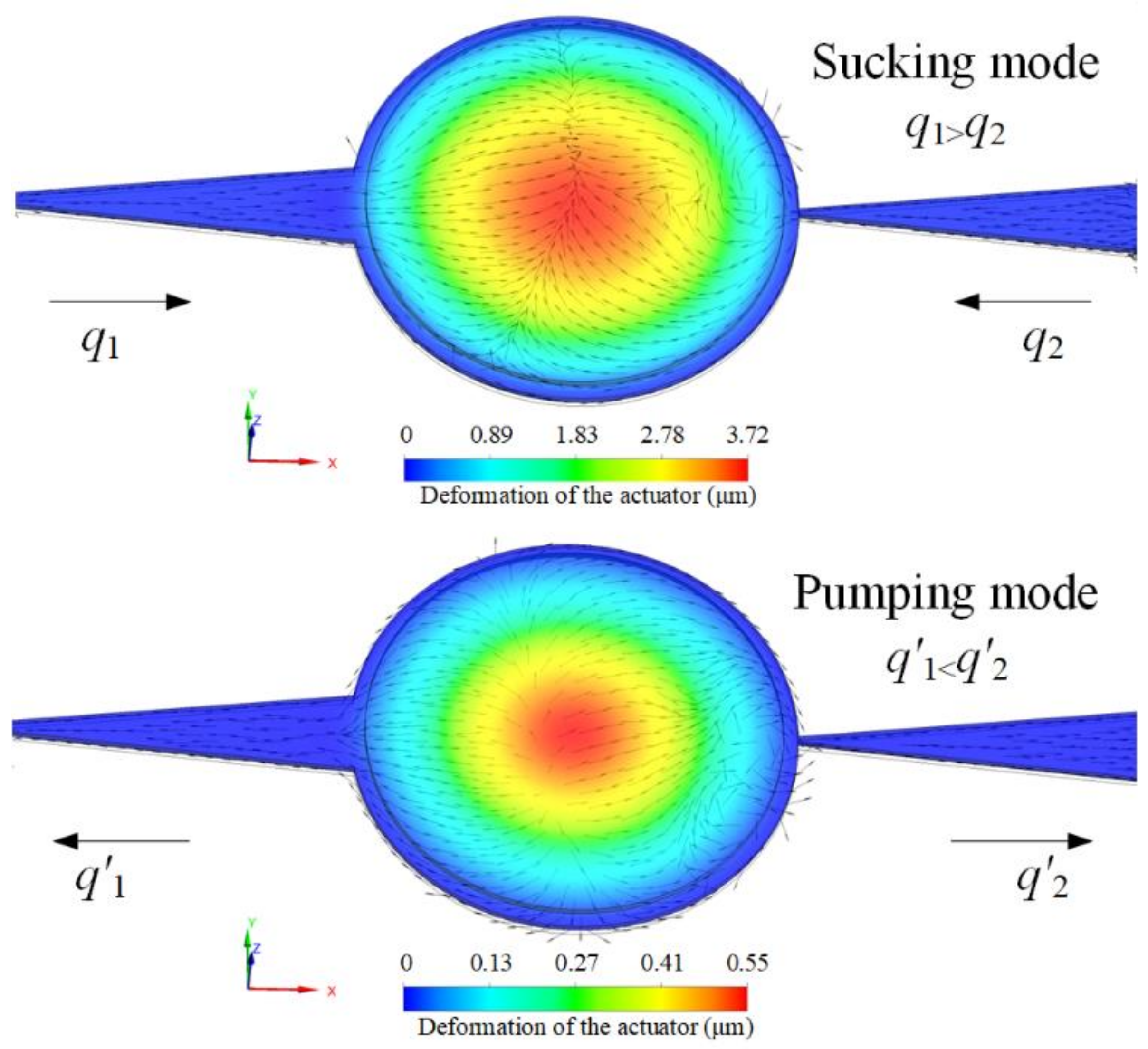

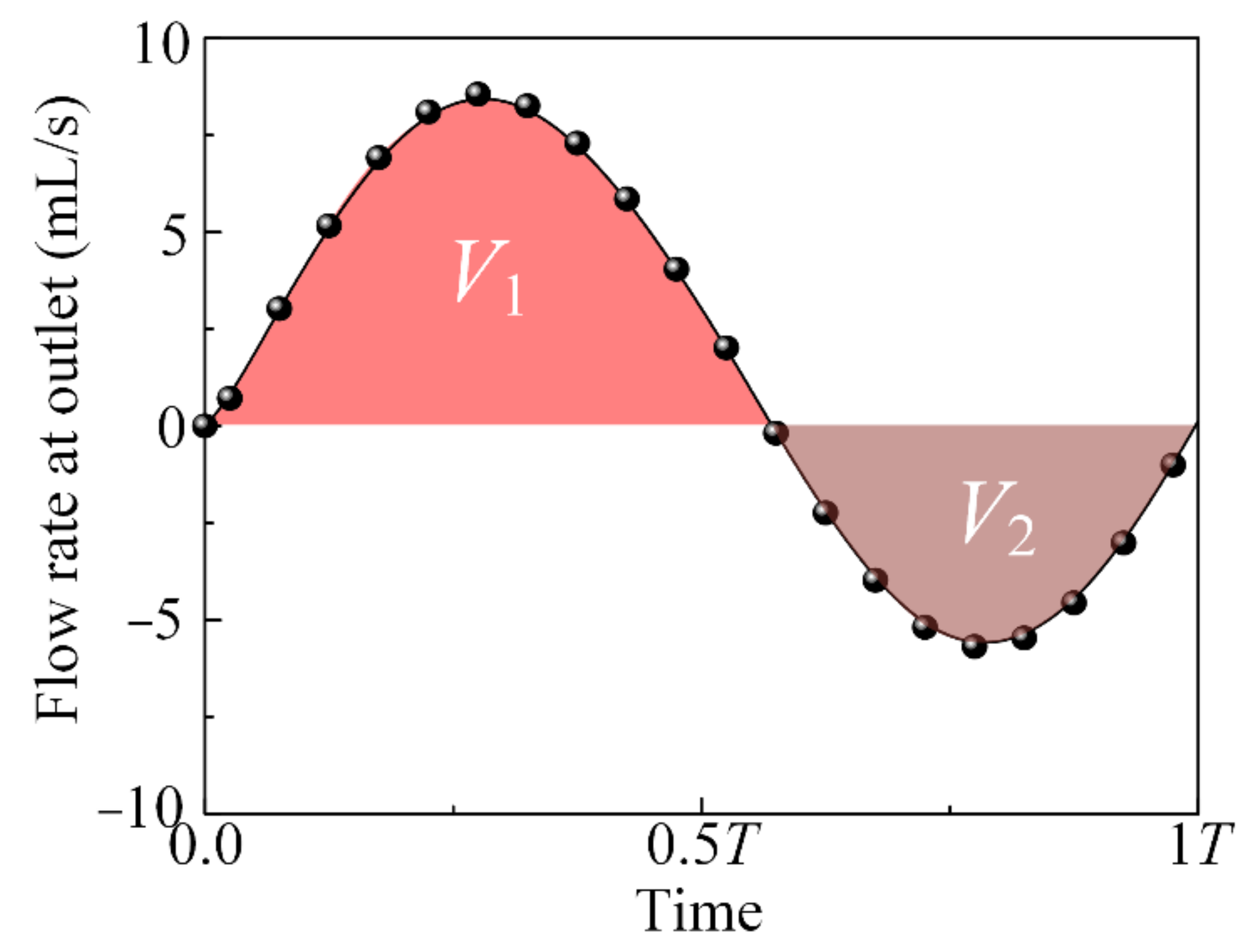

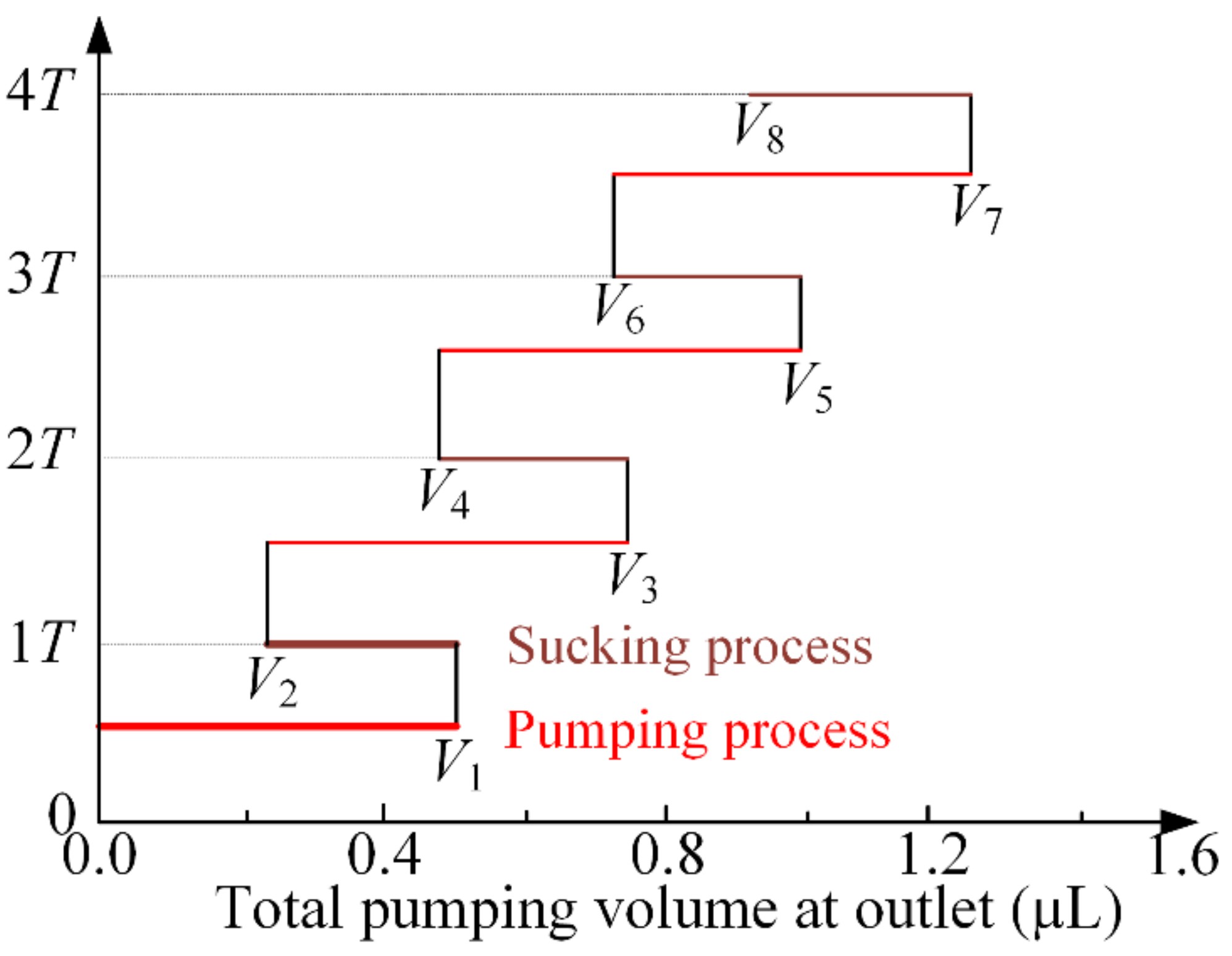

2. Structure of Micropump

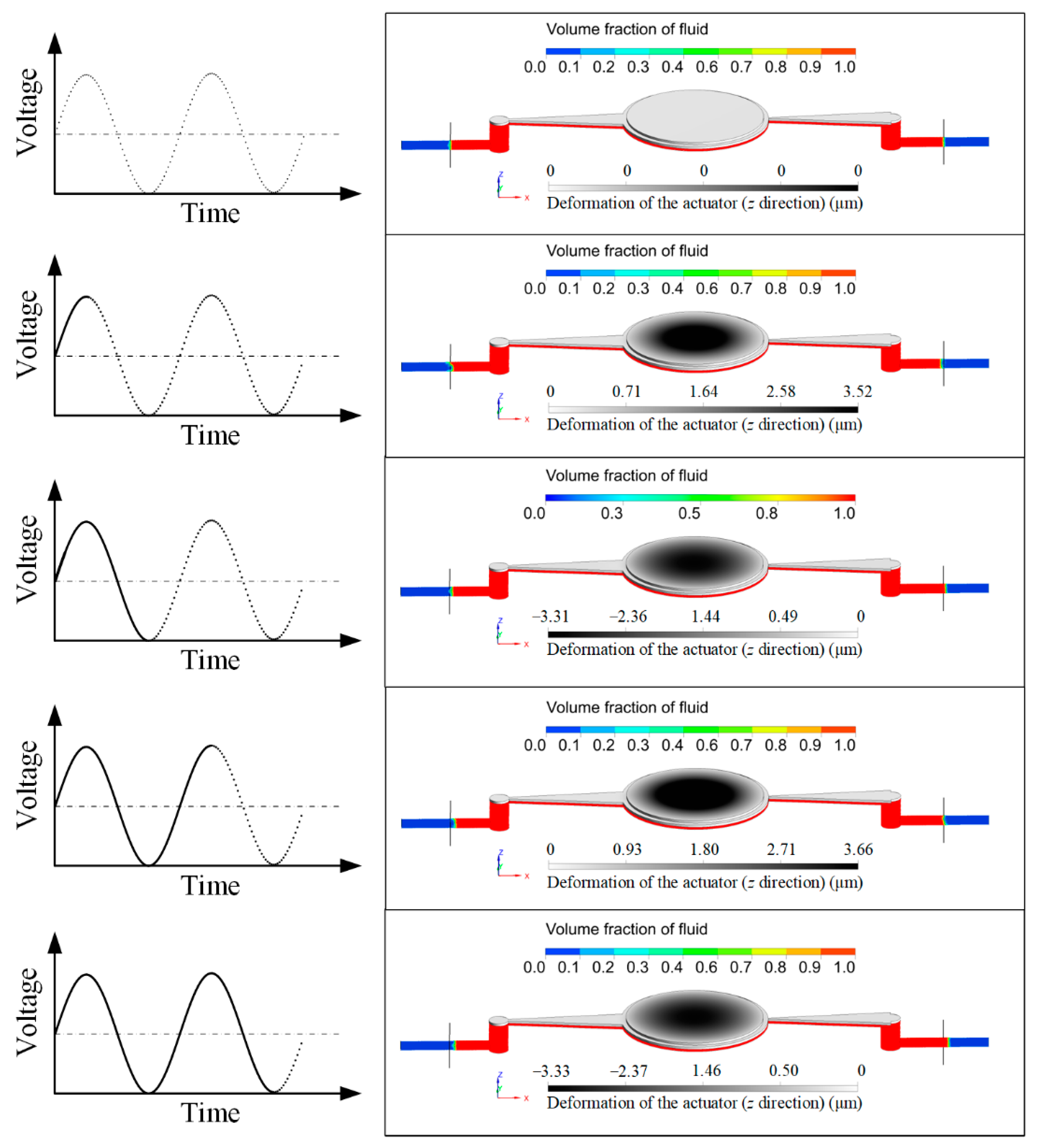

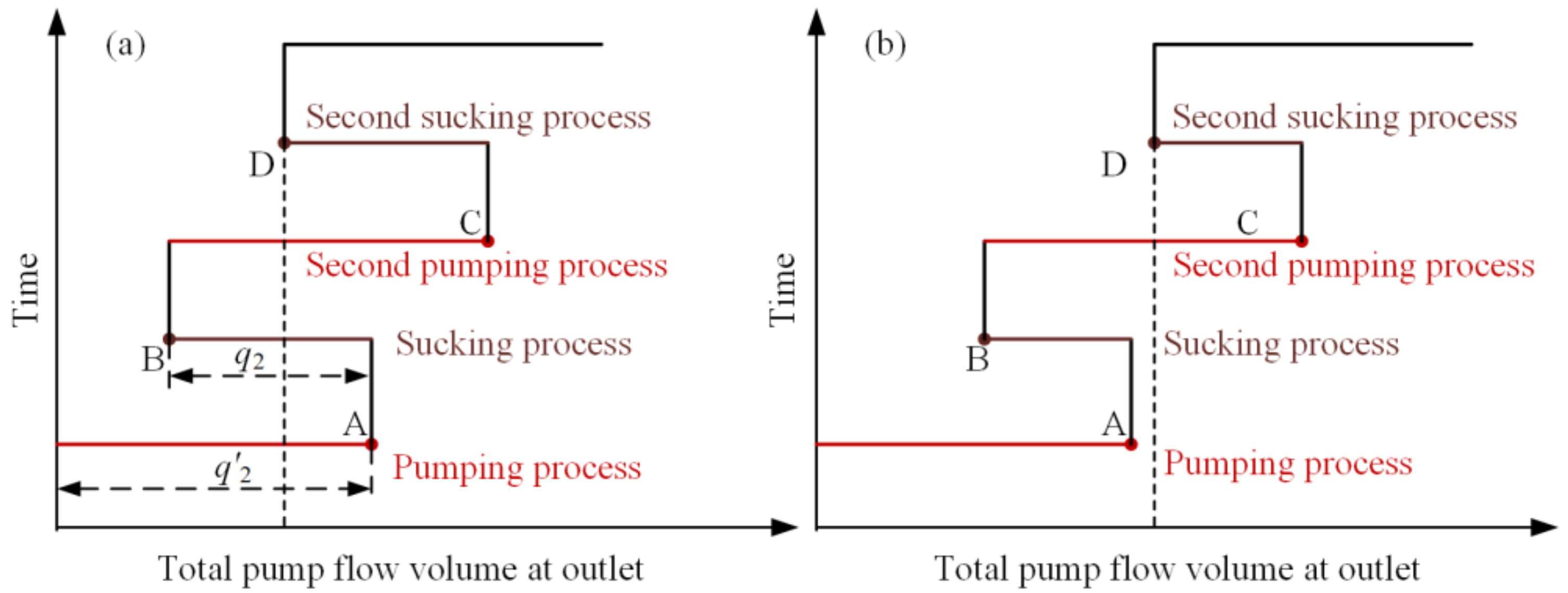

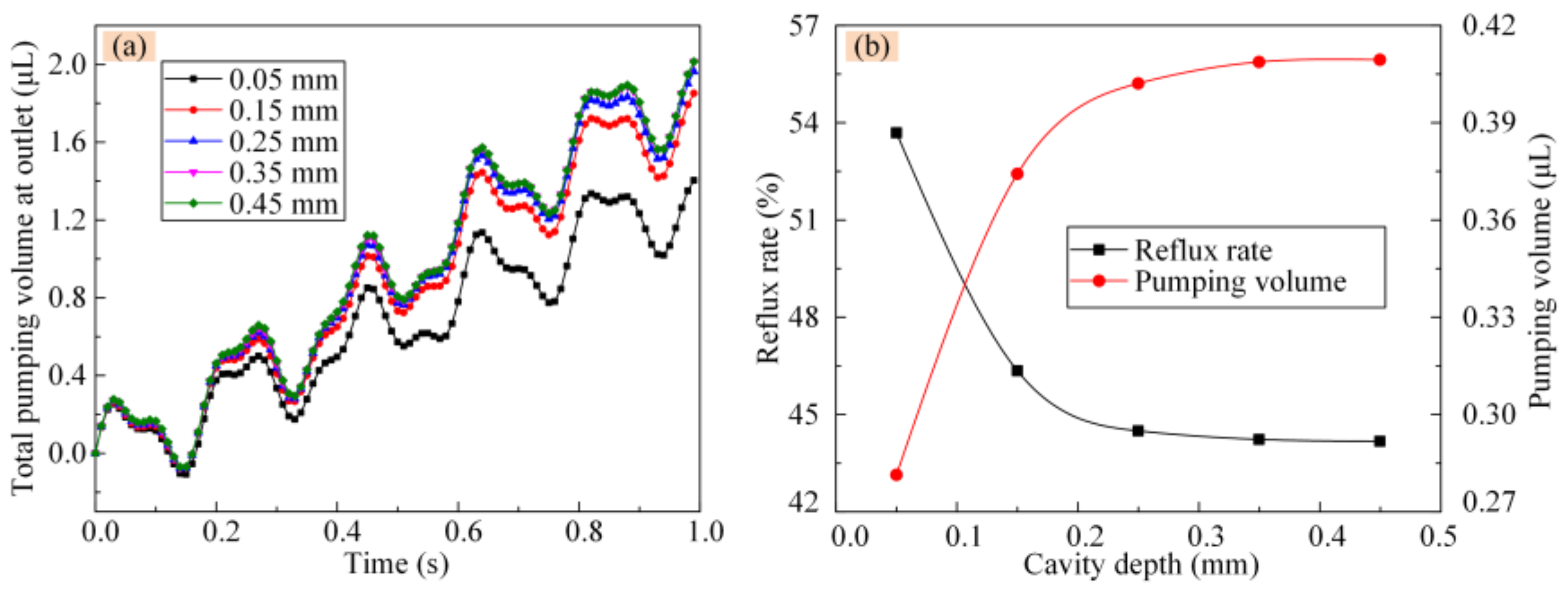

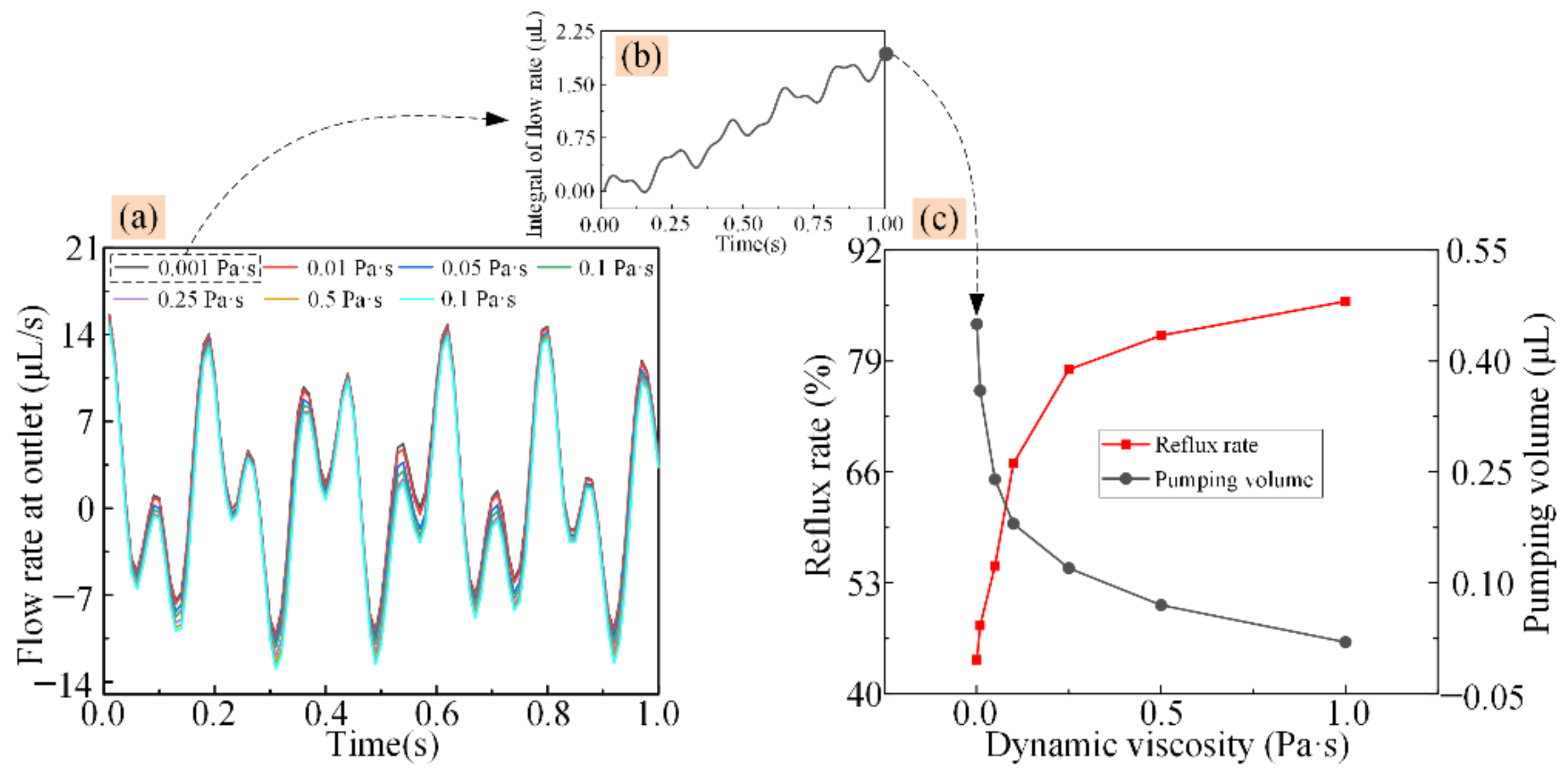

3. Simulation Procedure and Results

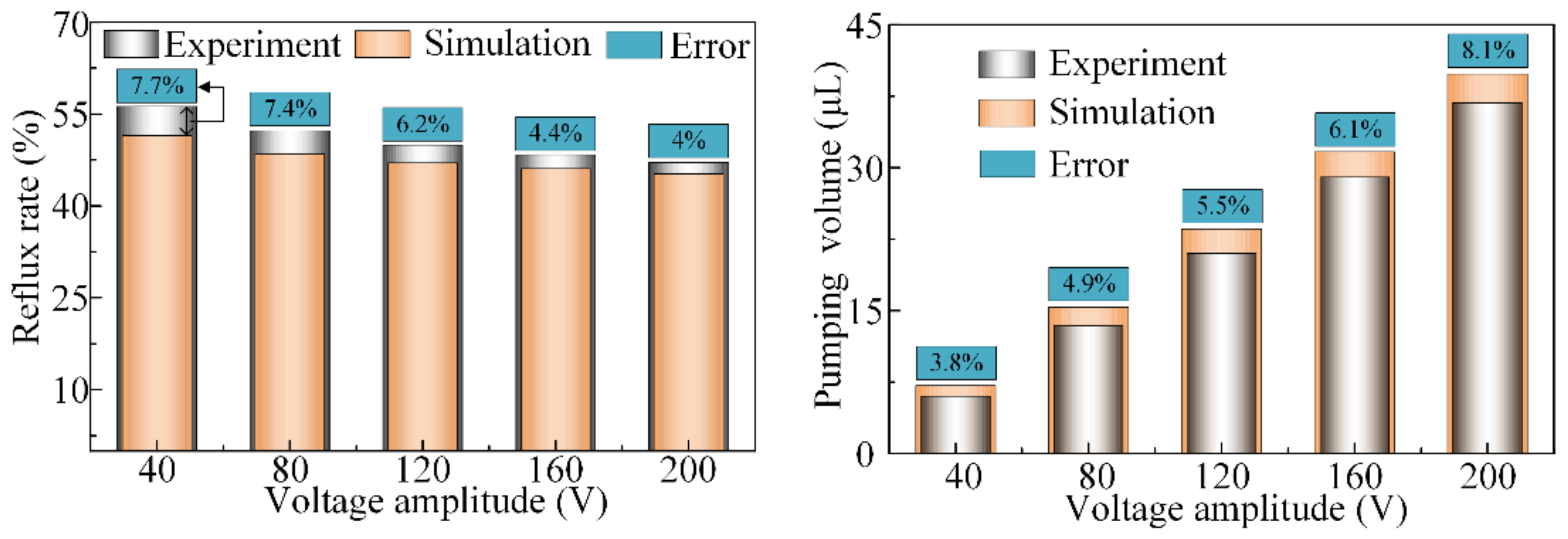

4. Pump Characteristics

5. Experiments

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Wen, C.Y.; Yeh, S.J.; Leong, K.P.; Kuo, W.S.; Lin, H. Application of a Valveless Impedance Pump in a Liquid Cooling System. IEEE Trans. Compon. Pack. Manuf. Technol. 2013, 3, 783–791. [Google Scholar] [CrossRef] [Green Version]

- Gidde, R.R.; Pawar, P.M.; Ronge, B.P.; Dhamgaye, V.P. Design optimization of an electromagnetic actuation based valveless micropump for drug delivery application. Microsyst. Technol. 2019, 25, 509–519. [Google Scholar]

- Veeresha, R.K.; Muralidhara; Rao, R.; Tauro, A.M. Investigation on the Performance of Valveless Pump for Microdelivery of the Fluid, Fabricated Using Tool-Based Micromachining Setup. J. Adv. Manuf. Syst. 2017, 16, 145–156. [Google Scholar] [CrossRef]

- Yan, Q.; Yin, Y.; Sun, W.; Fu, J. Advances in Valveless Piezoelectric Pumps. Appl. Sci. 2021, 11, 7016. [Google Scholar] [CrossRef]

- Pan, Q.; Li, Y.; Wang, X.; Jiang, H.; Wang, Q.; Huang, Z.; Zhang, Y. Design and investigation on a piezoelectric screw pump with high flowrate. Smart Mater. Struct. 2021, 30, 085019. [Google Scholar] [CrossRef]

- Pan, Q.; Jiang, H.; Zhang, Y.; Li, R.; Huang, B.; Huang, Q. Development of a novel valve-based piezoelectric ultrasonic pump using a Langevin vibrator. Smart Mater. Struct. 2022, 31, 065026. [Google Scholar] [CrossRef]

- Ashraf, M.W.; Tayyaba, S.; Nisar, A.; Afzulpurkar, N. Fabrication and analysis of hollow microneedles and polymeric piezoelectric valveless micropump for transdermal drug-delivery system. IET Commun. 2012, 6, 3248–3256. [Google Scholar] [CrossRef]

- Cui, Q.; Liu, C.; Zha, X.F. Study on a piezoelectric micropump for the controlled drug delivery system. Microfluid. Nanofluid. 2007, 3, 377–390. [Google Scholar] [CrossRef]

- Su, G.; Pidaparti, R.M. Drug Particle Delivery Investigation Through a Valveless Micropump. J. Microelectromech. Syst. 2010, 19, 1390–1399. [Google Scholar] [CrossRef]

- Dinh, T.X.; Dau, V.T.; Sugiyama, S.; Pham, P.H. Fluidic device with pumping and sensing functions for precise flow control. Sens. Actuators B Chem. 2010, 150, 819–824. [Google Scholar] [CrossRef]

- Azarbadegan, A.; Eames, I.; Sharma, S.; Cass, A. Computational study of parallel valveless micropumps. Sens. Actuators B Chem. 2011, 158, 432–440. [Google Scholar] [CrossRef]

- Huang, J.; Zhang, J.; Wang, S.; Liu, W. Analysis of the Flow Rate Characteristics of Valveless Piezoelectric Pump with Fractal-like Y-shape Branching Tubes. Chin. J. Mech. Eng. 2014, 27, 628–634. [Google Scholar] [CrossRef]

- Yueh, W.; Wan, Z.; Xiao, H.; Yalamanchili, S.; Joshi, Y.; Mukhopadhyay, S. Active Fluidic Cooling on Energy Constrained System-on-Chip Systems. IEEE Trans. Compon. Packag. Manuf. Technol. 2017, 7, 1813–1822. [Google Scholar] [CrossRef]

- Zhang, T.; Wang, Q.M. Performance evaluation of a valveless micropump driven by a ring-type piezoelectric actuator. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2006, 53, 463–473. [Google Scholar] [CrossRef]

- Ma, H.K.; Hsu, Y.L.; Luo, W.F. Development of a Bi-cell Proton Exchange Membrane Fuel Cell with Optimized Groove-designed Piezoelectric Actuator. Fuel Cells 2017, 17, 752–761. [Google Scholar] [CrossRef]

- Hu, B.S.; Yu, H.L. Optimal Design and Simulation of a Microsuction Cup Integrated with a Valveless Piezoelectric Pump for Robotics. Shock Vib. 2018, 2018, 7987502. [Google Scholar] [CrossRef]

- Yang, S.; He, X.H.; Yuan, S.Q.; Zhang, X.T.; Zhu, J.W.; Yan, J. A bidirectional valveless piezoelectric micropump with double chambers based on Coanda effect. J. Braz. Soc. Mech. Sci. Eng. 2016, 38, 345–353. [Google Scholar] [CrossRef]

- Zhang, Z.H.; Kan, J.W.; Wang, S.Y.; Wang, H.Y.; Wen, J.M.; Ma, Z.H. Flow rate self-sensing of a pump with double piezoelectric actuators. Mech. Syst. Signal. Proc. 2013, 41, 639–648. [Google Scholar] [CrossRef]

- Wang, A.B.; Hsieh, M.C. Unveiling the missing transport mechanism inside the valveless micropump. Lab Chip 2012, 12, 3024–3027. [Google Scholar] [CrossRef]

- Fu, G.; Zhou, W.; Li, X. Remotely tunable microfluidic platform driven by nanomaterial-mediated on-demand photothermal pumping. Lab Chip 2020, 20, 2218–2227. [Google Scholar] [CrossRef] [PubMed]

- Shoji, E. Fabrication of a diaphragm micropump system utilizing the ionomer-based polymer actuator. Sens. Actuators B Chem. 2016, 237, 660–665. [Google Scholar] [CrossRef]

- Graf, N.J.; Bowser, M.T. A soft-polymer piezoelectric bimorph cantilever-actuated peristaltic micropump. Lab Chip 2008, 8, 1664–1670. [Google Scholar] [CrossRef] [Green Version]

- Peng, T.J.; Guo, Q.Q.; Yang, J.; Xiao, J.F.; Wang, H.; Lou, Y.; Liang, X. A high-flow, self-filling piezoelectric pump driven by hybrid connected multiple chambers with umbrella-shaped valves. Sens. Actuators B Chem. 2019, 301, 6. [Google Scholar] [CrossRef]

- Sotoudegan, M.S.; Mohd, O.; Ligler, F.S.; Walker, G.M. Paper-based passive pumps to generate controllable whole blood flow through microfluidic devices. Lab Chip 2019, 19, 3787–3795. [Google Scholar] [CrossRef] [PubMed]

- Park, J.; Park, J.K. Integrated microfluidic pumps and valves operated by finger actuation. Lab Chip 2019, 19, 2973–2977. [Google Scholar] [CrossRef]

- Andersson, H.; van der Wijngaart, W.; Nilsson, P.; Enoksson, P.; Stemme, G. A valve-less diffuser micropump for microfluidic analytical systems. Sens. Actuators B Chem. 2001, 72, 259–265. [Google Scholar] [CrossRef]

- Ma, H.K.; Chen, R.H.; Hsu, Y.H. Development of a piezoelectric-driven miniature pump for biomedical applications. Sens. Actuators A Phys. 2015, 234, 23–33. [Google Scholar] [CrossRef]

- Rosenfeld, T.; Bercovici, M. Dynamic control of capillary flow in porous media by electroosmotic pumping. Lab Chip 2019, 19, 328–334. [Google Scholar] [CrossRef]

- Lin, Y.; Gao, Y.; Wu, M.R.; Zhou, R.; Chung, D.Y.; Caraveo, G.; Xu, J. Acoustofluidic stick-and-play micropump built on foil for single-cell trapping. Lab Chip 2019, 19, 3045–3053. [Google Scholar] [CrossRef]

- Wang, X.L.; Zhao, D.; Phan, D.T.T.; Liu, J.Q.; Chen, X.; Yang, B.; Hughes, C.C.W.; Zhang, W.J.; Lee, A.P. A hydrostatic pressure-driven passive micropump enhanced with siphon-based autofill function. Lab Chip 2018, 18, 2167–2177. [Google Scholar] [CrossRef]

- He, L.P.; Zhao, D.; Li, W.; Xu, Q.W.; Cheng, G.M. Performance analysis of valveless piezoelectric pump with dome composite structures. Rev. Sci. Instrum. 2019, 90, 10. [Google Scholar] [CrossRef] [PubMed]

- Seo, J.; Wang, C.; Chang, S.; Park, J.; Kim, W. A hydrogel-driven microfluidic suction pump with a high flow rate. Lab Chip 2019, 19, 1790–1796. [Google Scholar] [CrossRef] [PubMed]

- Aggarwal, S.; Paul, B.E.; DasGupta, A.; Chatterjee, D. Experimental characterization of piezoelectrically actuated micromachined silicon valveless micropump. Microfluid. Nanofluid. 2017, 21, 2. [Google Scholar] [CrossRef]

- Guevara-Pantoja, P.E.; Jimenez-Valdes, R.J.; Garcia-Cordero, J.L.; Caballero-Robledo, G.A. Pressure-actuated monolithic acrylic microfluidic valves and pumps. Lab Chip 2018, 18, 662–669. [Google Scholar] [CrossRef] [PubMed]

- Olsson, A.; Stemme, G.; Stemme, E. Numerical and experimental studies of flat-walled diffuser elements for valve-less micropumps. Sens. Actuators A Phys. 2000, 84, 165–175. [Google Scholar] [CrossRef]

| Parameters | Values | Parameters | Values |

|---|---|---|---|

| Voltage Amplitude | 200 V | Inlet Length | 20 mm |

| Fluid Viscosity | 0.001 Pa·s | Outlet Length | 20 mm |

| Inlet Angle | 6° | Depth of the Cavity | 0.25 mm |

| Outlet Angle | 6° |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, K.; Zhou, X.; Zheng, H.; Liu, B.; Chen, S.; Chen, W.; Liu, J. Achieving Full Forward Flow of Valveless Piezoelectric Micropump Used for Micro Analysis System. Actuators 2022, 11, 218. https://doi.org/10.3390/act11080218

Li K, Zhou X, Zheng H, Liu B, Chen S, Chen W, Liu J. Achieving Full Forward Flow of Valveless Piezoelectric Micropump Used for Micro Analysis System. Actuators. 2022; 11(8):218. https://doi.org/10.3390/act11080218

Chicago/Turabian StyleLi, Kai, Xianxin Zhou, Haoyuan Zheng, Biao Liu, Shuo Chen, Weishan Chen, and Junkao Liu. 2022. "Achieving Full Forward Flow of Valveless Piezoelectric Micropump Used for Micro Analysis System" Actuators 11, no. 8: 218. https://doi.org/10.3390/act11080218

APA StyleLi, K., Zhou, X., Zheng, H., Liu, B., Chen, S., Chen, W., & Liu, J. (2022). Achieving Full Forward Flow of Valveless Piezoelectric Micropump Used for Micro Analysis System. Actuators, 11(8), 218. https://doi.org/10.3390/act11080218