An Inertial Impact Piezoelectric Actuator Designed by the Asymmetric Friction Principle and Achieved by Laser Texturing of the Driving Feet

Abstract

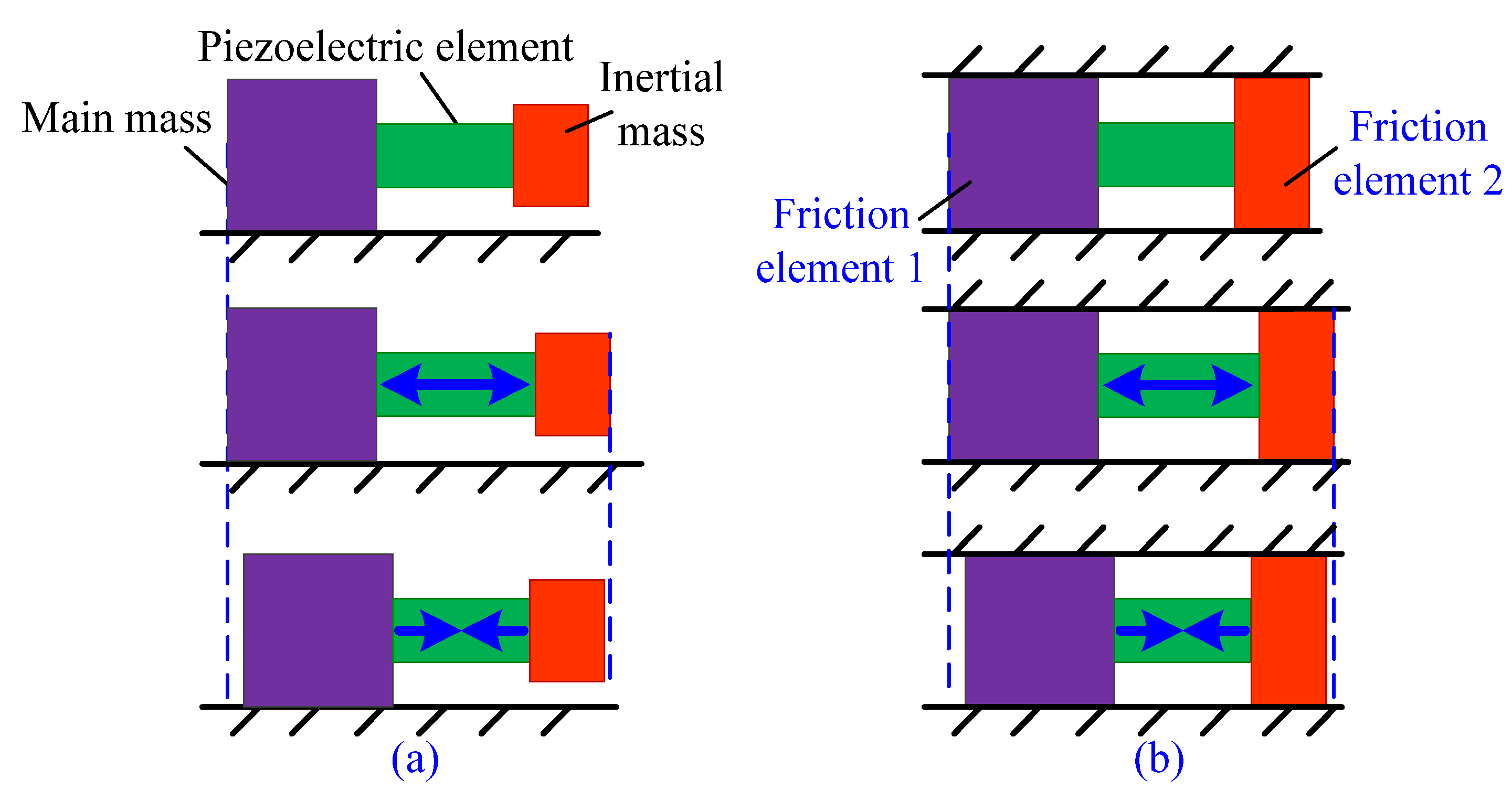

:1. Introduction

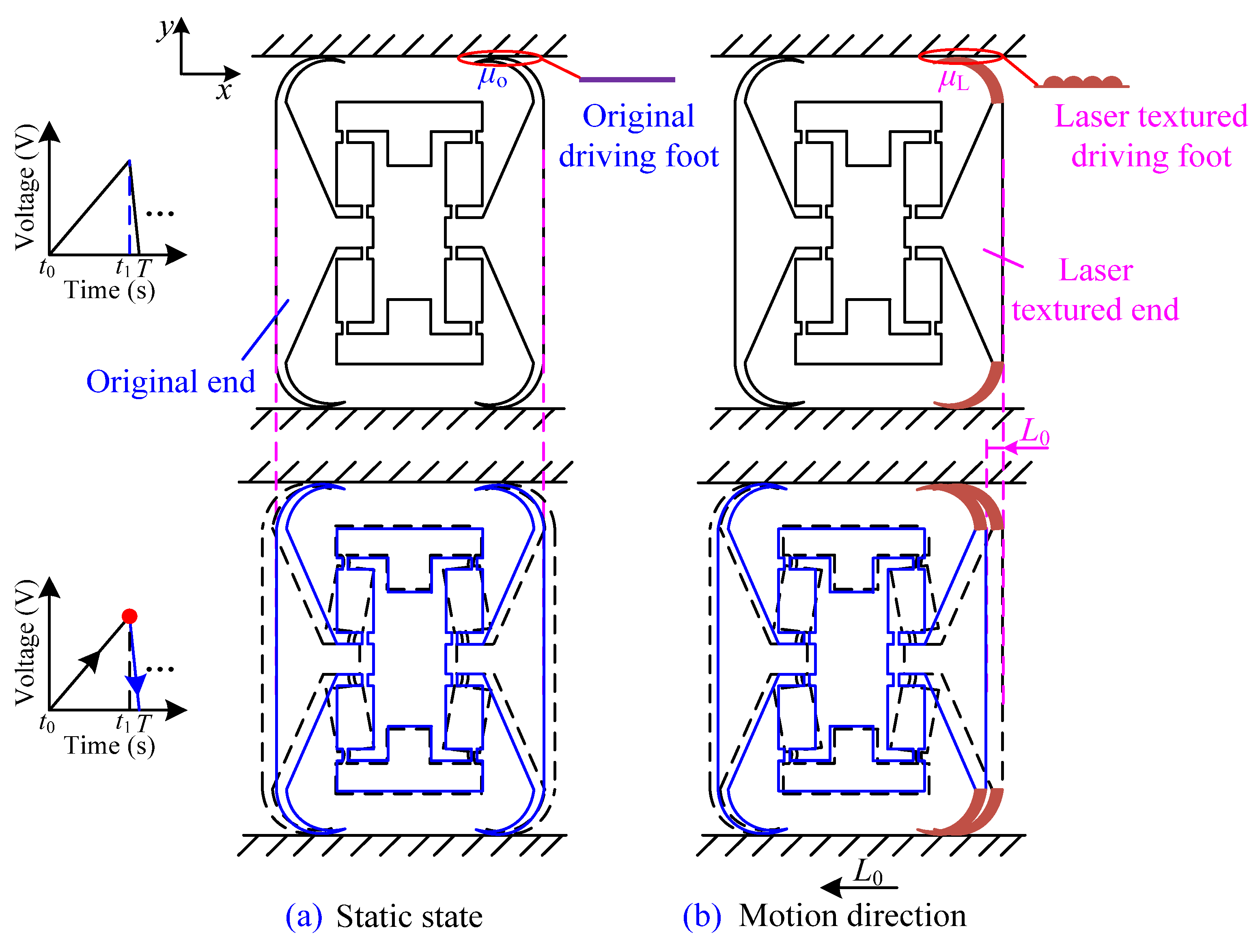

2. Structure of the Developed Actuator

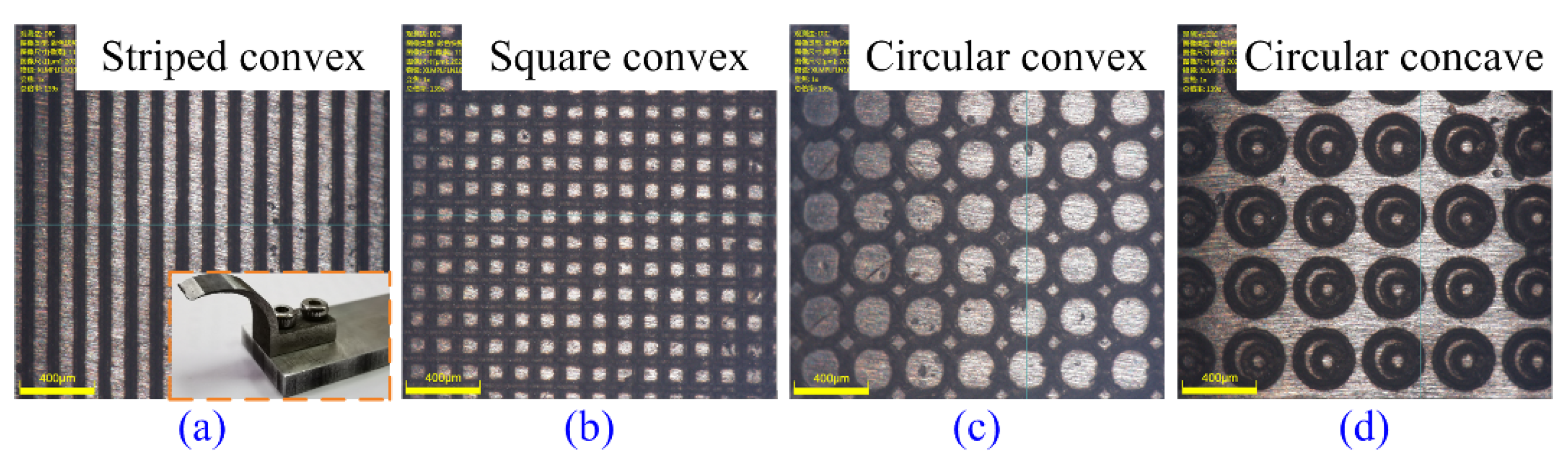

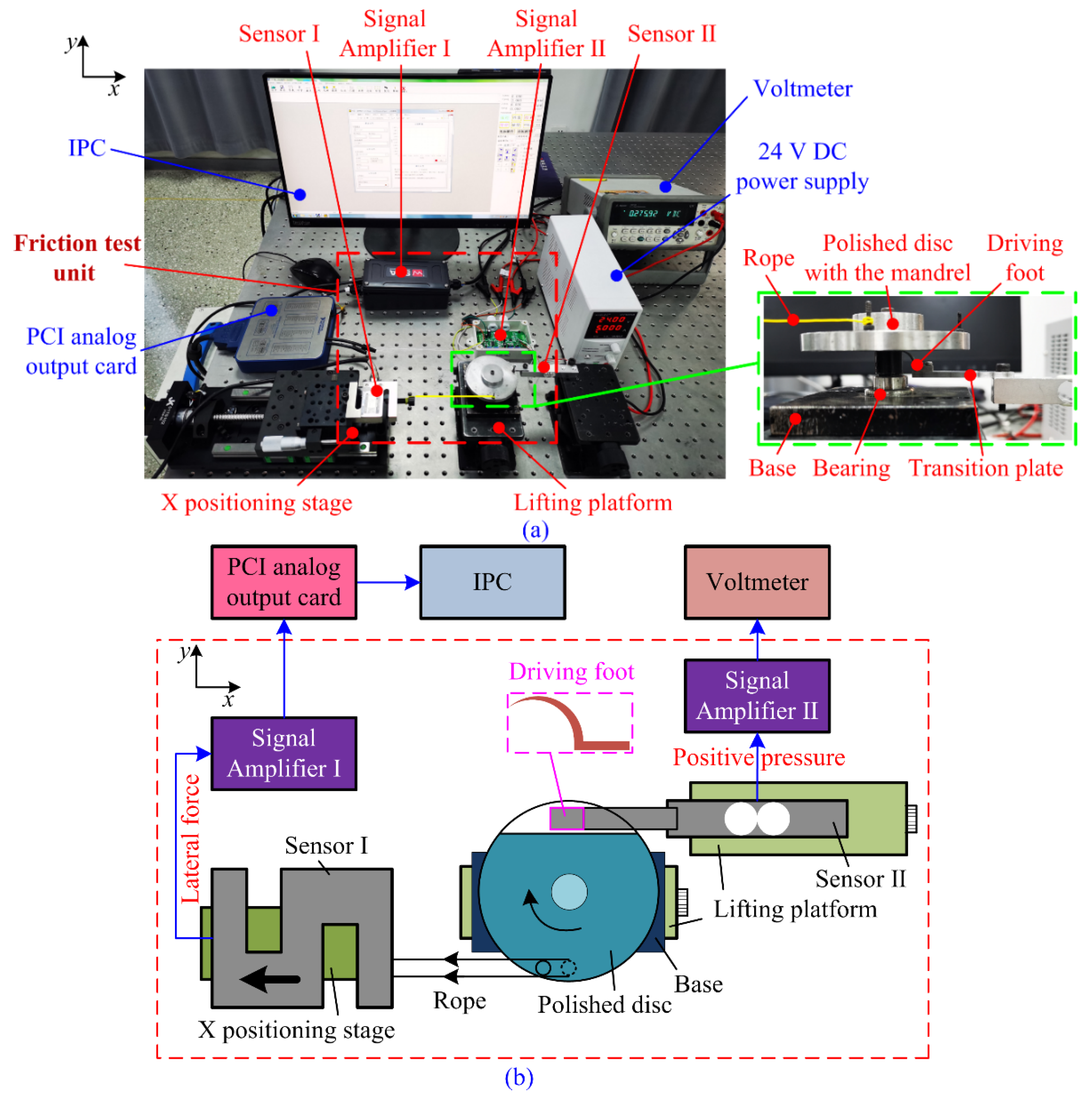

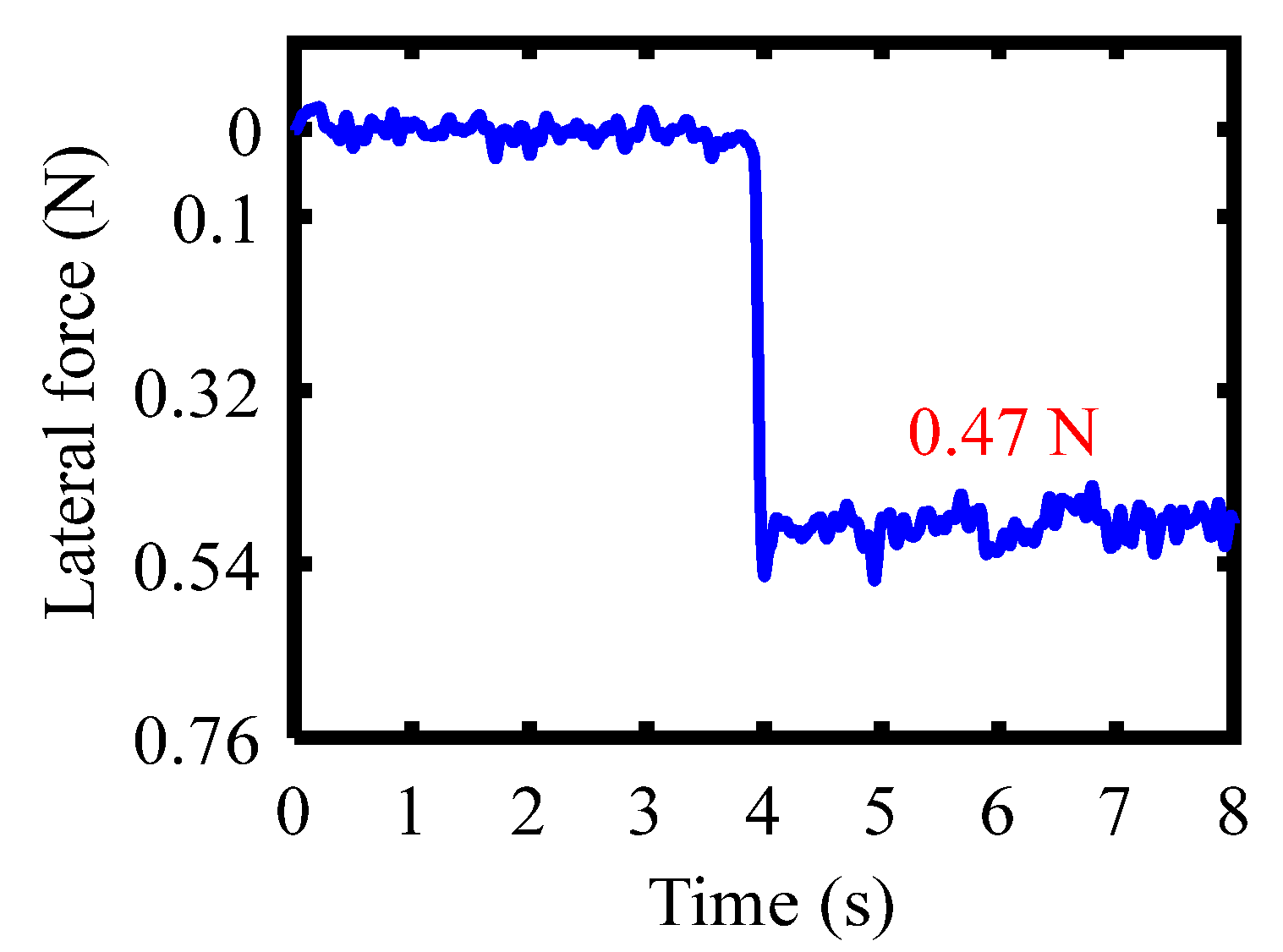

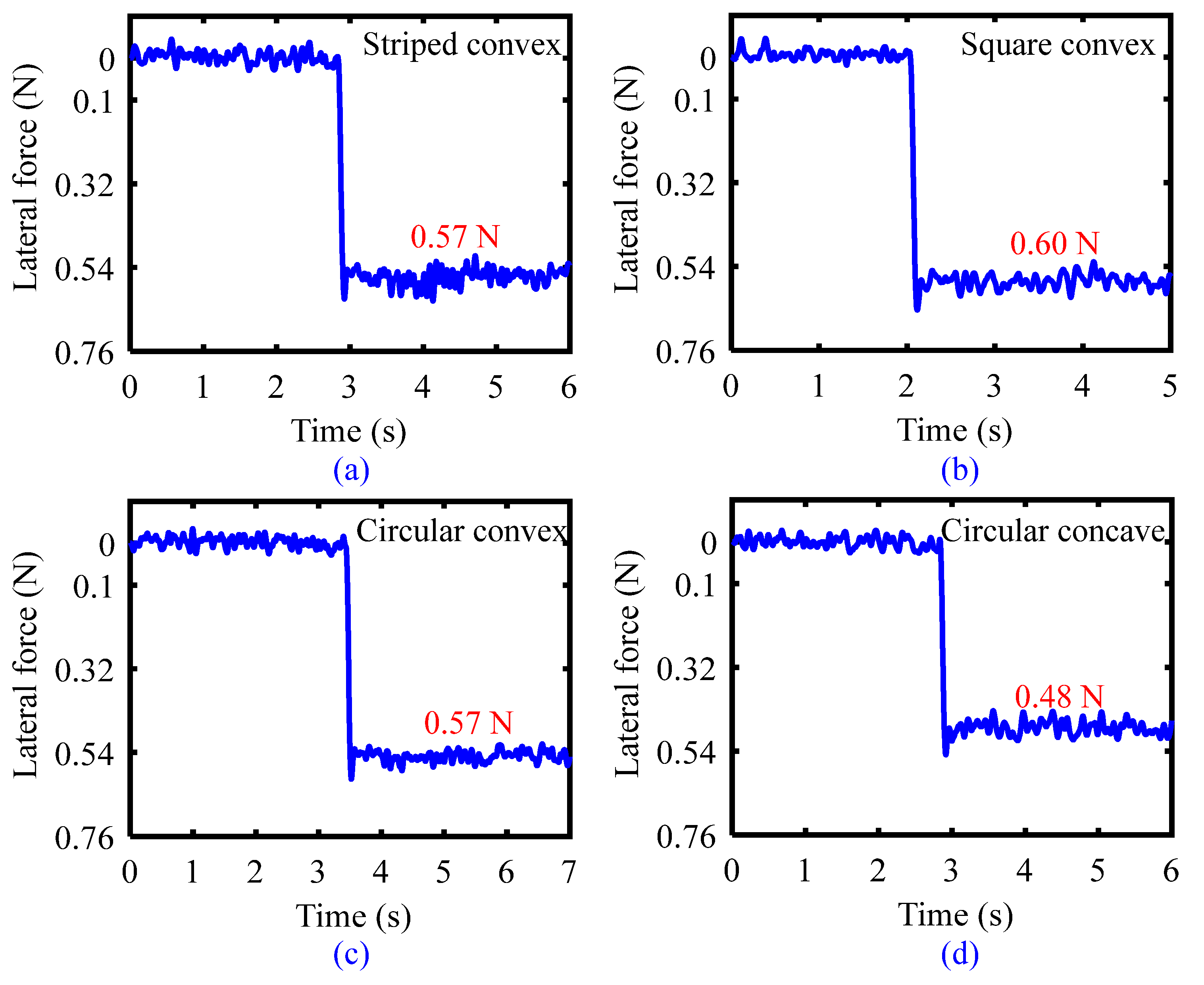

3. Selection of Microstructures for Laser Texturing of the Driving Foot

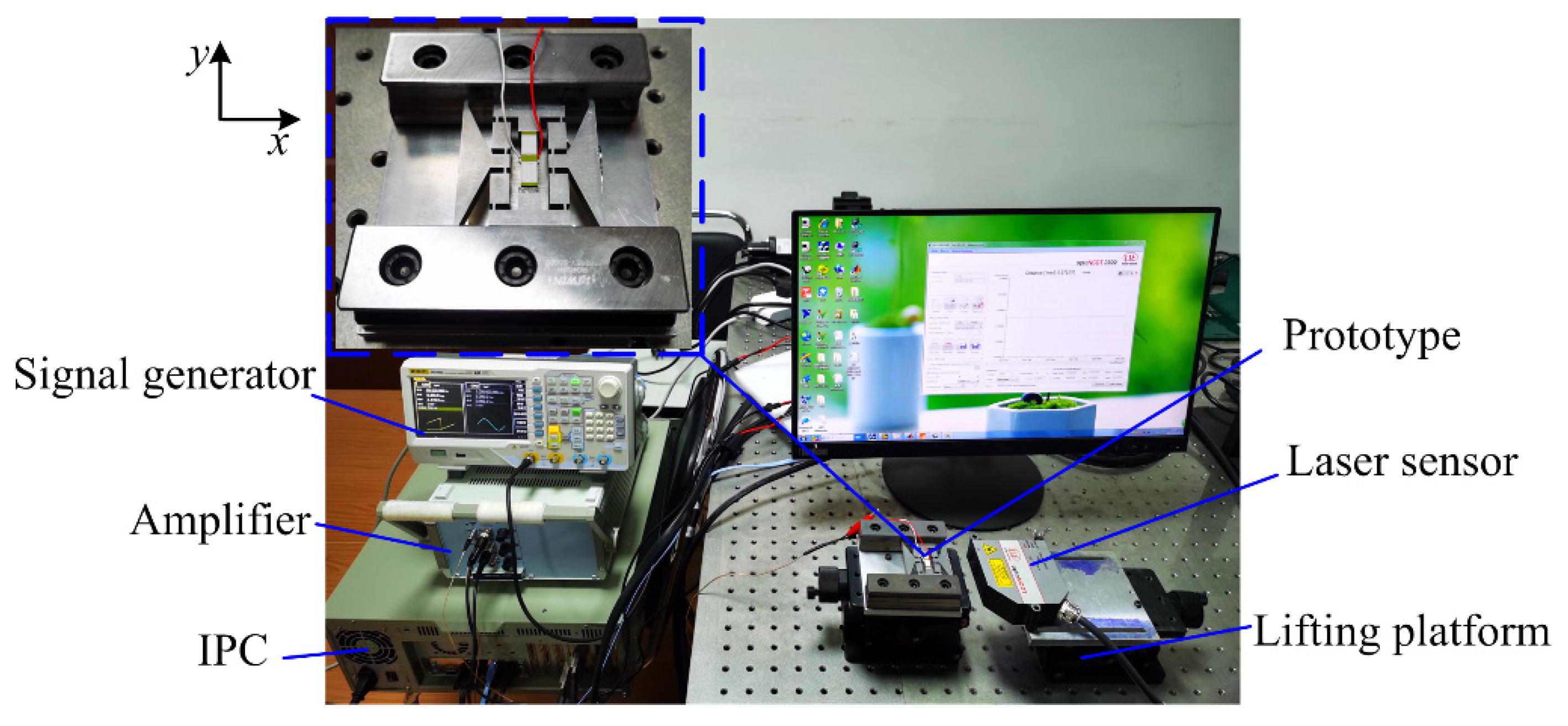

4. Experiments and Output Characteristics of the Actuator

4.1. Output Characteristics with Various Working Gaps

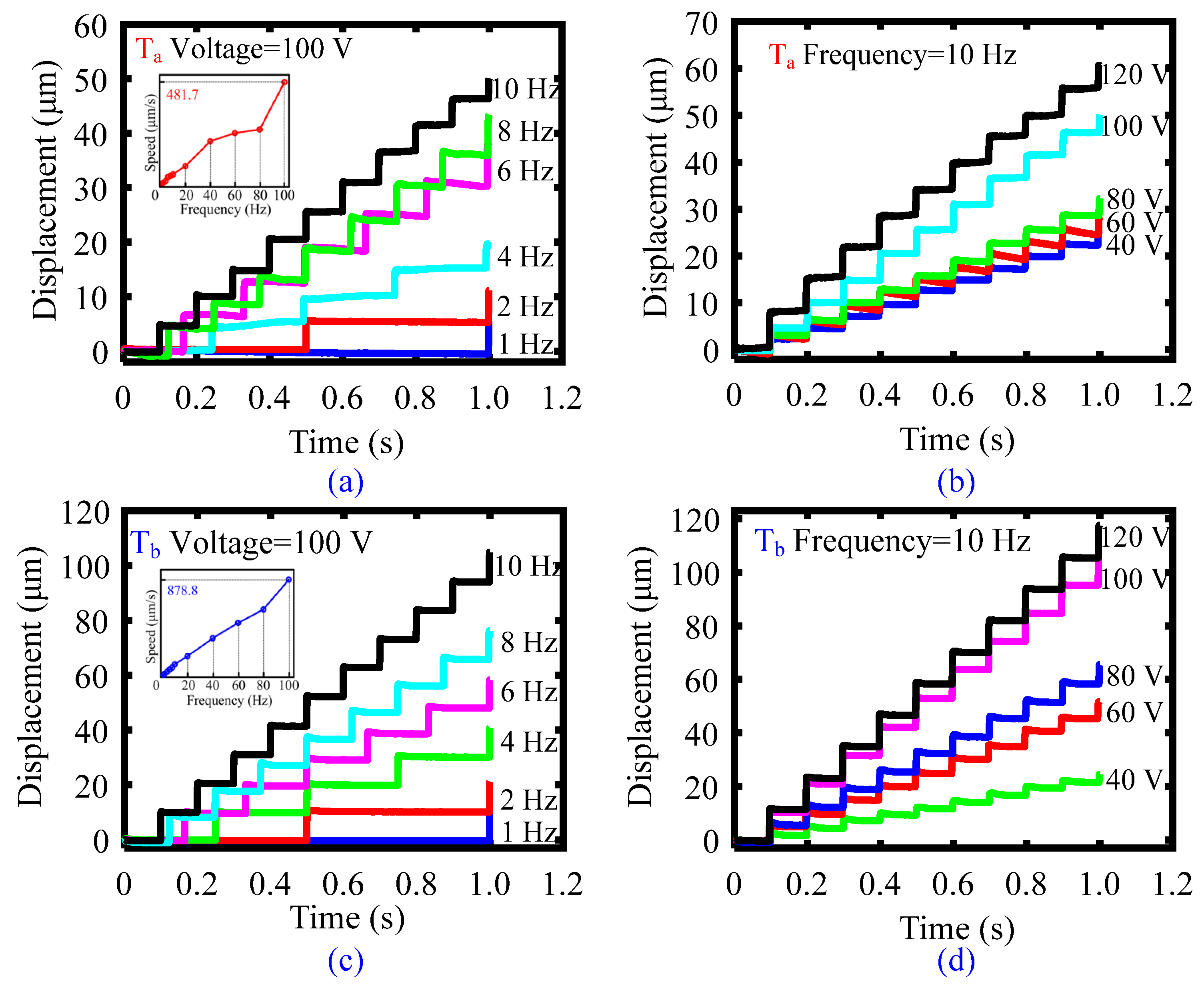

4.2. Output Characteristics with Various Driving Voltages and Frequencies

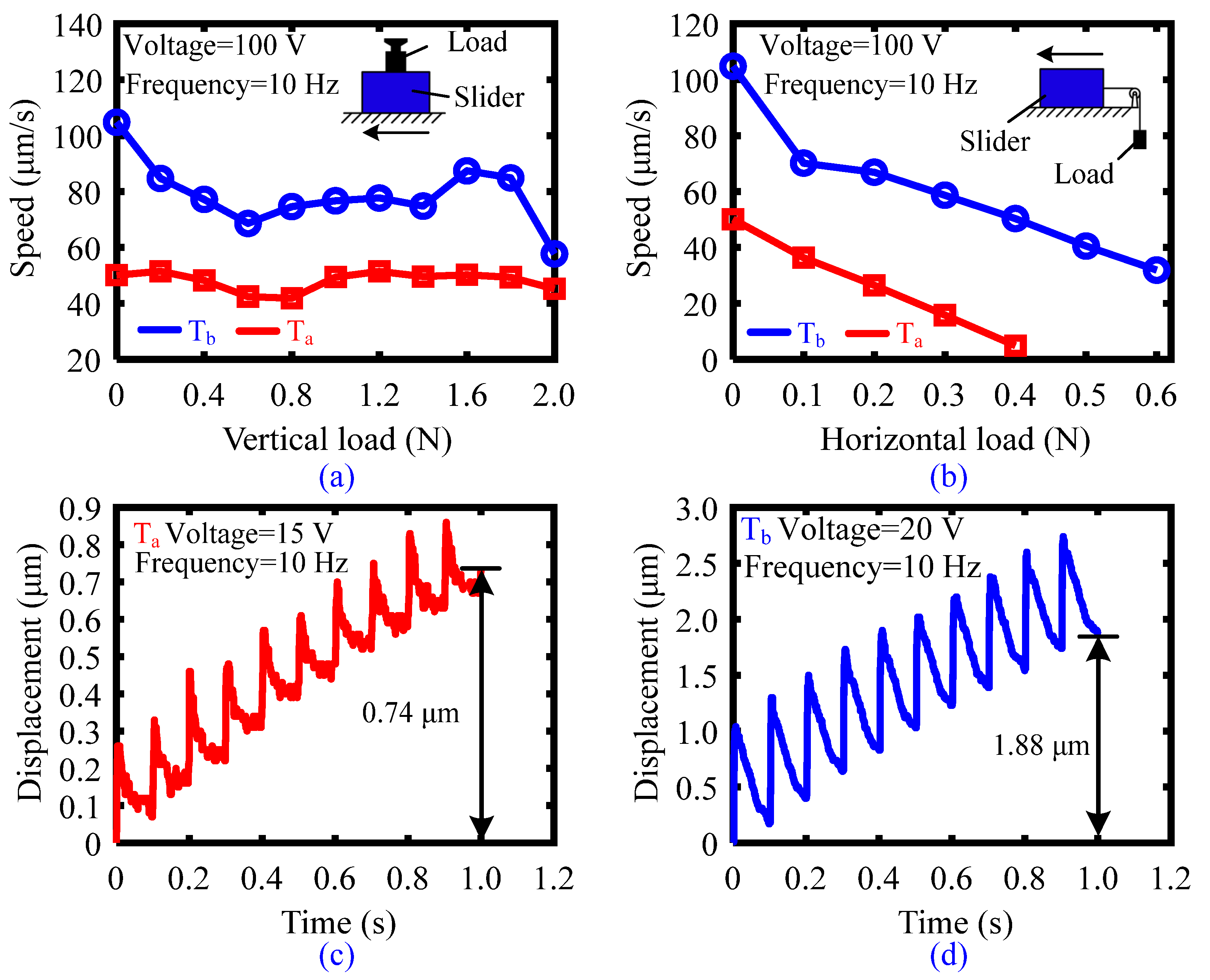

4.3. Loading Capacity and Resolution

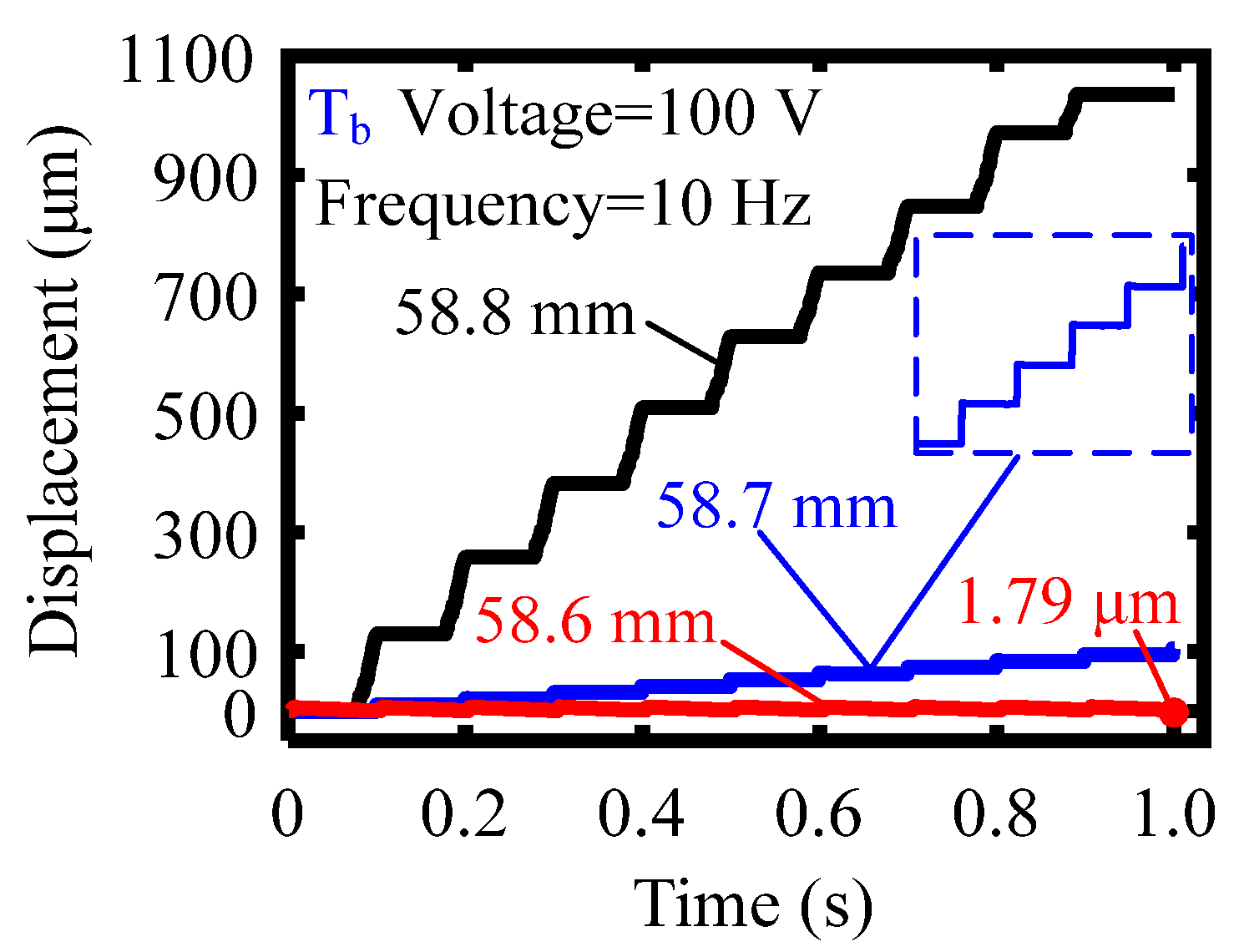

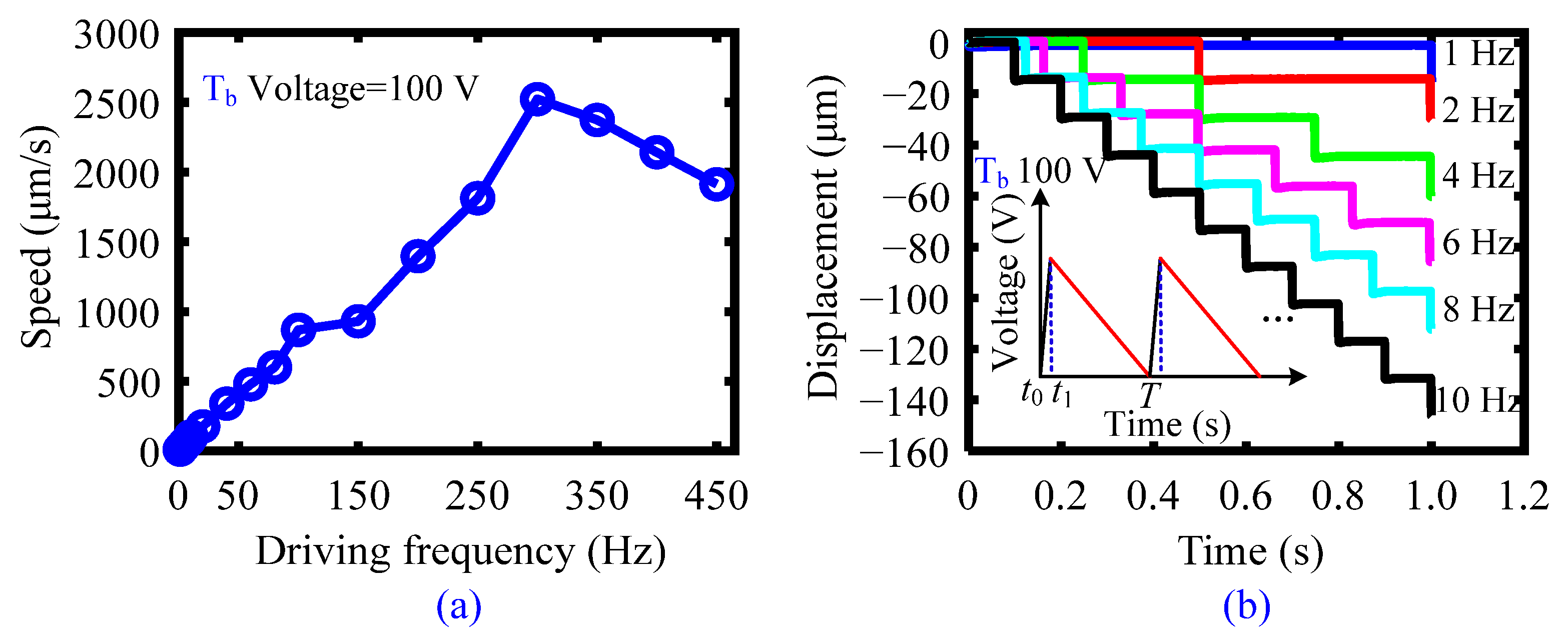

4.4. Output Characteristics of the Actuator with the Tb Microstructure

4.5. Comparison and Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Elahi, H.; Eugeni, M.; Gaudenzi, P.; Qayyum, F.; Swati, R.F.; Khan, H.M. Response of piezoelectric materials on thermomechanical shockingand electrical shocking for aerospace applications. Microsyst. Technol. 2018, 24, 3791–3798. [Google Scholar] [CrossRef]

- Li, M.; Yuan, J.; Guan, D.; Chen, W. Application of piezoelectric fiber composite actuator to aircraft wing for aerodynamic performance improvement. Sci. China Technol. Sci. 2011, 54, 395–402. [Google Scholar] [CrossRef]

- Qing, X.; Li, W.; Wang, Y.; Sun, H. Piezoelectric Transducer-Based Structural Health Monitoring for Aircraft Applications. Sensors 2019, 19, 545. [Google Scholar] [CrossRef] [PubMed]

- Holmström, S.T.S.; Baran, U.; Urey, H. Laser Scanners A Review. J. Microelectromechanical Syst. 2014, 23, 259–274. [Google Scholar] [CrossRef]

- Koh, K.H.; Kobayashi, T.; Hsiao, F.L.; Lee, C. Characterization of piezoelectric PZT beam actuators for driving 2D scanningmicromirrors. Sens. Actuators A Phys. 2010, 162, 336–347. [Google Scholar] [CrossRef]

- Wang, Z. Piezopotential gated nanowire devices Piezotronics and piezo-phototronics. Nano Today 2010, 5, 540–552. [Google Scholar] [CrossRef]

- Chorsi, M.T.; Curry, E.J.; Chorsi, H.T.; Das, R.; Baroody, J.; Purohit, P.K.; Ilies, H.; Nguyen, T.D. Piezoelectric Biomaterials for Sensors and Actuators. Adv. Mater. 2019, 31, 1802084. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yuan, H.; Lei, T.; Qin, Y.; He, J.H.; Yang, R. Design and application of piezoelectric biomaterials. J. Phys. D Appl. Phys. 2019, 52, 194002. [Google Scholar] [CrossRef] [Green Version]

- Zheng, Q.; Shi, B.; Li, Z.; Wang, Z. Recent Progress on Piezoelectric and Triboelectric Energy Harvesters in Biomedical Systems. Adv. Mater. 2017, 4, 1700029. [Google Scholar] [CrossRef]

- Ji, F.; Li, T.; Yu, S.; Wu, Z.; Zhang, L. Propulsion Gait Analysis and Fluidic Trapping of Swinging Flexible Nanomotors. ACS Nano 2021, 15, 5118–5128. [Google Scholar] [CrossRef]

- Li, T.; Zhang, A.; Shao, G.; Wei, M.; Guo, B.; Zhang, G.; Li, L.; Wang, W. Janus Microdimer Surface Walkers Propelled by Oscillating Magnetic Fields. Adv. Funct. Mater. 2018, 28, 1706066. [Google Scholar] [CrossRef]

- Wang, H.; Yu, S.; Liao, J.; Qing, X.; Sun, D.; Ji, F.; Song, W.; Wang, L.; Li, T. A Robot Platform for Highly Efficient Pollutant Purification. Front. Bioeng. Biotechnol. 2022, 10, 903219. [Google Scholar] [CrossRef] [PubMed]

- Guan, C.; Jiao, Z. A piezoelectric direct-drive servo valve with a novel multi-body contacting spool-driving mechanism: Design, modelling and experiment. P. I. Mech. Eng. C-J. Mec. 2014, 228, 169–185. [Google Scholar] [CrossRef]

- Mohith, S.; Upadhya, A.R.; Navin, K.P.; Kulkarni, S.M.; Rao, M. Recent trends in piezoelectric actuators for precision motion and their applications: A review. Smart Mater. Struct. 2021, 30, 013002. [Google Scholar] [CrossRef]

- Wang, L.; Chen, W.; Liu, J.; Deng, J.; Liu, Y. A review of recent studies on non-resonant piezoelectric actuators. Mech. Syst. Signal Process. 2019, 133, 106254. [Google Scholar] [CrossRef]

- Gao, Y.; Wen, J.; Ma, J.; Zhang, Y.; Wang, R.; Hu, Y.; Li, J. A self-adapting linear inchworm piezoelectric actuator based on a permanent magnets clamping structure. Mech. Syst. Signal Process. 2019, 132, 429–440. [Google Scholar] [CrossRef]

- Li, J.; Zhao, H.; Shao, M.; Zhou, X.; Huang, H.; Fan, Z. Design and experiment performances of an inchworm type rotary actuator. Rev. Sci. Instrum. 2014, 85, 085004. [Google Scholar] [CrossRef]

- Shao, S.; Song, S.; Shao, Y.; Xu, M. Long-range piezoelectric actuator with large load capacity using inchworm and stick-slip driving principles. Precis. Eng. 2022, 75, 167–179. [Google Scholar] [CrossRef]

- Deng, J.; Liu, Y.; Chen, W.; Yu, H. A XY Transporting and Nanopositioning Piezoelectric Robot Operated by Leg Rowing Mechanism. IEEE-ASME Trans. Mechatron. 2019, 24, 207–217. [Google Scholar] [CrossRef]

- Liu, R.; Wen, Z.; Cao, T.; Lu, C.; Wang, B.; Wu, D.; Li, X. A precision positioning rotary stage driven by multilayer piezoelectric stacks. Precis. Eng. 2022, 76, 226–236. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, L.; Gu, Z.; Quan, Q.; Deng, J. Development of a Two-Dimensional Linear Piezoelectric Stepping Platform Using Longitudinal-Bending Hybrid Actuators. IEEE Trans. Ind. Electron. 2019, 66, 3030–3040. [Google Scholar] [CrossRef]

- Delibas, B.; Koc, B. L1B2 Piezo Motor Using D33 Effect. In Proceedings of the ACTUATOR 2018: 16th International Conference on New Actuators, Bremen, Germany, 25–27 June 2018; pp. 1–4. [Google Scholar]

- Feng, Y.; Chang, X.; Liu, H.; Hu, Y.; Li, T.; Li, L. Multi-response biocompatible Janus micromotor for ultrasonic imaging contrast enhancement. Appl. Mater. Today 2021, 23, 101026. [Google Scholar] [CrossRef]

- Tian, X.; Liu, Y.; Deng, J.; Wang, L.; Chen, W. A review on piezoelectric ultrasonic motors for the past decade: Classification, operating principle, performance, and future work perspectives. Sens. Actuators A Phys. 2020, 306, 111971. [Google Scholar] [CrossRef]

- Tang, J.; Wei, J.; Wang, Y.; Xu, Z.; Huang, H. A Novel Rotation-Structure Based Stick-Slip Piezoelectric Actuator with High Consistency in Forward and Reverse Motions. Actuators 2021, 10, 189. [Google Scholar] [CrossRef]

- Yang, X.; Tang, J.; Guo, W.; Huang, H.; Fan, H.; Liu, J.; Li, T. Design and Analysis of a Stepping Piezoelectric Actuator Free of Backward Motion. Actuators 2021, 10, 200. [Google Scholar] [CrossRef]

- Nguyen, X.H.; Mau, T.H.; Meyer, I.; Dang, B.L.; Pham, H.P. Improvements of Piezo-Actuated Stick–Slip Micro-Drives: Modeling and Driving Waveform. Coatings 2018, 8, 62. [Google Scholar] [CrossRef] [Green Version]

- Shao, Y.; Shao, S.; Xu, M.; Song, S.; Tian, Z. An inertial piezoelectric actuator with miniaturized structure and improved load capacity. Smart Mater. Struct. 2019, 28, 055023. [Google Scholar] [CrossRef]

- Zhang, E.; Hu, Y.; Bao, H.; Li, J.; Ma, J.; Wen, J. A linear inertial piezoelectric actuator using a single bimorph vibrator. Smart Mater. Struct. 2019, 28, 115020. [Google Scholar] [CrossRef]

- Hunstig, M. Piezoelectric Inertia Motors—A Critical Review of History, Concepts, Design, Applications, and Perspectives. Actuators 2017, 6, 7. [Google Scholar] [CrossRef] [Green Version]

- Higuchi, T.; Watanabe, M.; Kudou, K. Precise positioner utilizing rapid deformations of a piezoelectric element. J. Jpn. Soc. Precis. Eng. 1988, 54, 2107–2112. [Google Scholar] [CrossRef] [Green Version]

- Okamoto, Y.; Yoshida, R.; Sueyoshi, H. The development of a smooth impact drive mechanism (SIDM) using a piezoelectric element. Konica Minolta Technol. Rep. 2004, 1, 23–26. [Google Scholar]

- Hu, Y.; Wang, R.; Wen, J. A Low-Frequency Structure-Control-Type Inertial Actuator Using Miniaturized Bimorph Piezoelectric Vibrators. IEEE Trans. Ind. Electron. 2019, 66, 6179–6188. [Google Scholar] [CrossRef]

- Zhang, Z.M.; An, Q.; Li, J.W.; Zhang, W.J. Piezoelectric friction–inertia actuator-a critical review and future perspective. Int. J. Adv. Manuf. Technol. 2012, 62, 669–685. [Google Scholar] [CrossRef]

- Cao, Y.; Xu, Z.; You, L.; Wu, Y.; Huang, H. An inertial piezoelectric actuator with small structure but large loading capacity. Rev. Sci. Instrum. 2021, 92, 085004. [Google Scholar] [CrossRef] [PubMed]

- Hu, Y.; Lin, S.; Ma, J.; Zhang, Y.; Li, J.; Wen, J. Piezoelectric inertial rotary actuator operating in two-step motion mode for eliminating backward motion. Appl. Phys. Lett. 2020, 117, 031902. [Google Scholar] [CrossRef]

- Xu, Z.; Yang, Z.; Wang, K.; Li, X.; Dong, J.; Huang, H. A bionic inertial piezoelectric actuator with improved frequency bandwidth. Mech. Syst. Signal Process. 2021, 156, 107620. [Google Scholar] [CrossRef]

- Sun, W.; Xu, Z.; Wang, K.; Li, X.; Tang, J.; Yang, Z.; Huang, H. An impact inertial piezoelectric actuator designed by means of the asymmetric friction. IEEE Trans. Ind. Electron. 2022, 1. [Google Scholar] [CrossRef]

- Bushnell, D.M. Drag Reduction in Nature. Annu. Rev. Fluid Mech. 1991, 23, 65–79. [Google Scholar] [CrossRef]

- Ren, L. Progress in the bionic study on anti-adhesion and resistance reduction of terrain machines. Sci. China Ser. E Technol. Sci. 2009, 52, 273–284. [Google Scholar] [CrossRef]

- Ren, L.; Liang, Y. Biological couplings: Classification and characteristic rules. Sci. China Ser. E Technol. Sci. 2009, 52, 2791–2800. [Google Scholar] [CrossRef]

- Shen, D.; Wen, J.; Ma, J.; Hu, Y.; Wang, R.; Li, J. A novel linear inertial piezoelectric actuator based on asymmetric clamping materials. Sens. Actuators A Phys. 2020, 303, 111746. [Google Scholar] [CrossRef]

- Wang, R.; Hu, Y.; Shen, D.; Ma, J.; Wen, J. Design and Experimental Performance of a Novel Piezoelectric Inertial Actuator for Magnetorheological Fluid Control Using Permanent Magnet. IEEE Access 2019, 7, 43573–43580. [Google Scholar] [CrossRef]

| Parameter | Meaning | Value |

|---|---|---|

| r1 | Radius of circle O1 | 7.5 mm |

| r2 | Radius of circle O2 | 7 mm |

| t | Thickness of the driving foot | 1.6 mm |

| x1 | Distance between points O1 and O | 14.5 mm |

| x2 | Distance between points O2 and O | 13.4 mm |

| Reference | [29] | [33] | [42] | [43] | [37] | [38] | This Work (Tb) |

|---|---|---|---|---|---|---|---|

| Frequency bandwidth (Hz) | 45 | 35 | 13 | 11 | 275 | 390 | 300 |

| Maximum speed (mm/s) | / | 0.44 | 0.2 | 0.03 | 1.218 | 7.311 | 2.523 |

| Resolution (nm) | 600 | 30 | 2000 | 20 | 214 | 221 | 188/Ta-74 |

| Horizontal load (N) | / | / | / | / | 0.6 | 1.4 | 0.6 |

| Vertical load (N) | 4.25 | 0.06 | 0.9 | 8 | 17 | 20 | 2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, W.; Liu, Y.; Li, X.; Xu, Z.; Yang, Z.; Huang, H. An Inertial Impact Piezoelectric Actuator Designed by the Asymmetric Friction Principle and Achieved by Laser Texturing of the Driving Feet. Actuators 2022, 11, 211. https://doi.org/10.3390/act11080211

Sun W, Liu Y, Li X, Xu Z, Yang Z, Huang H. An Inertial Impact Piezoelectric Actuator Designed by the Asymmetric Friction Principle and Achieved by Laser Texturing of the Driving Feet. Actuators. 2022; 11(8):211. https://doi.org/10.3390/act11080211

Chicago/Turabian StyleSun, Wuxiang, Yanwei Liu, Xuan Li, Zhi Xu, Zhaojun Yang, and Hu Huang. 2022. "An Inertial Impact Piezoelectric Actuator Designed by the Asymmetric Friction Principle and Achieved by Laser Texturing of the Driving Feet" Actuators 11, no. 8: 211. https://doi.org/10.3390/act11080211

APA StyleSun, W., Liu, Y., Li, X., Xu, Z., Yang, Z., & Huang, H. (2022). An Inertial Impact Piezoelectric Actuator Designed by the Asymmetric Friction Principle and Achieved by Laser Texturing of the Driving Feet. Actuators, 11(8), 211. https://doi.org/10.3390/act11080211