A Paper-Based Cantilever Beam Mini Actuator Using Hygro-Thermal Response

Abstract

:1. Introduction

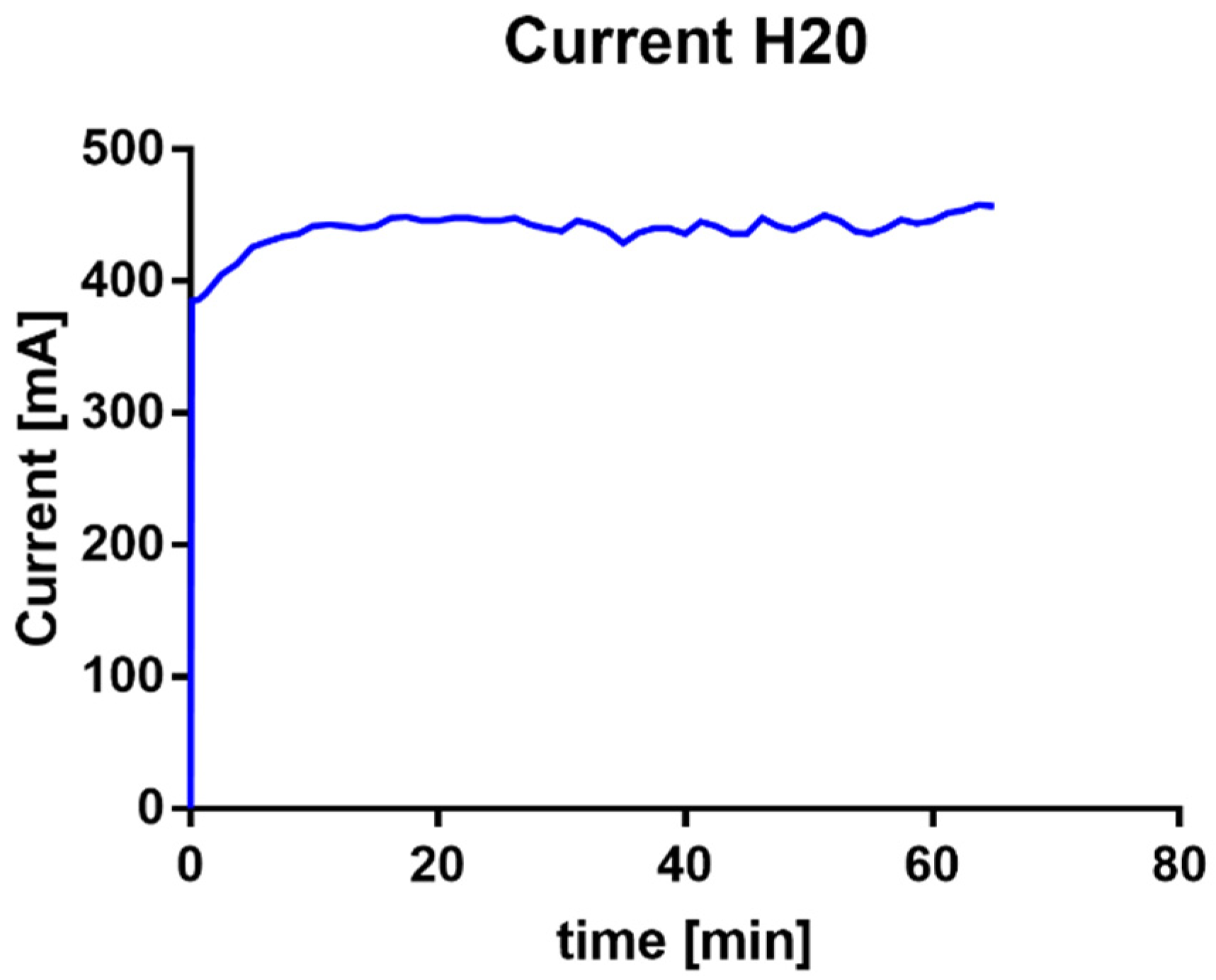

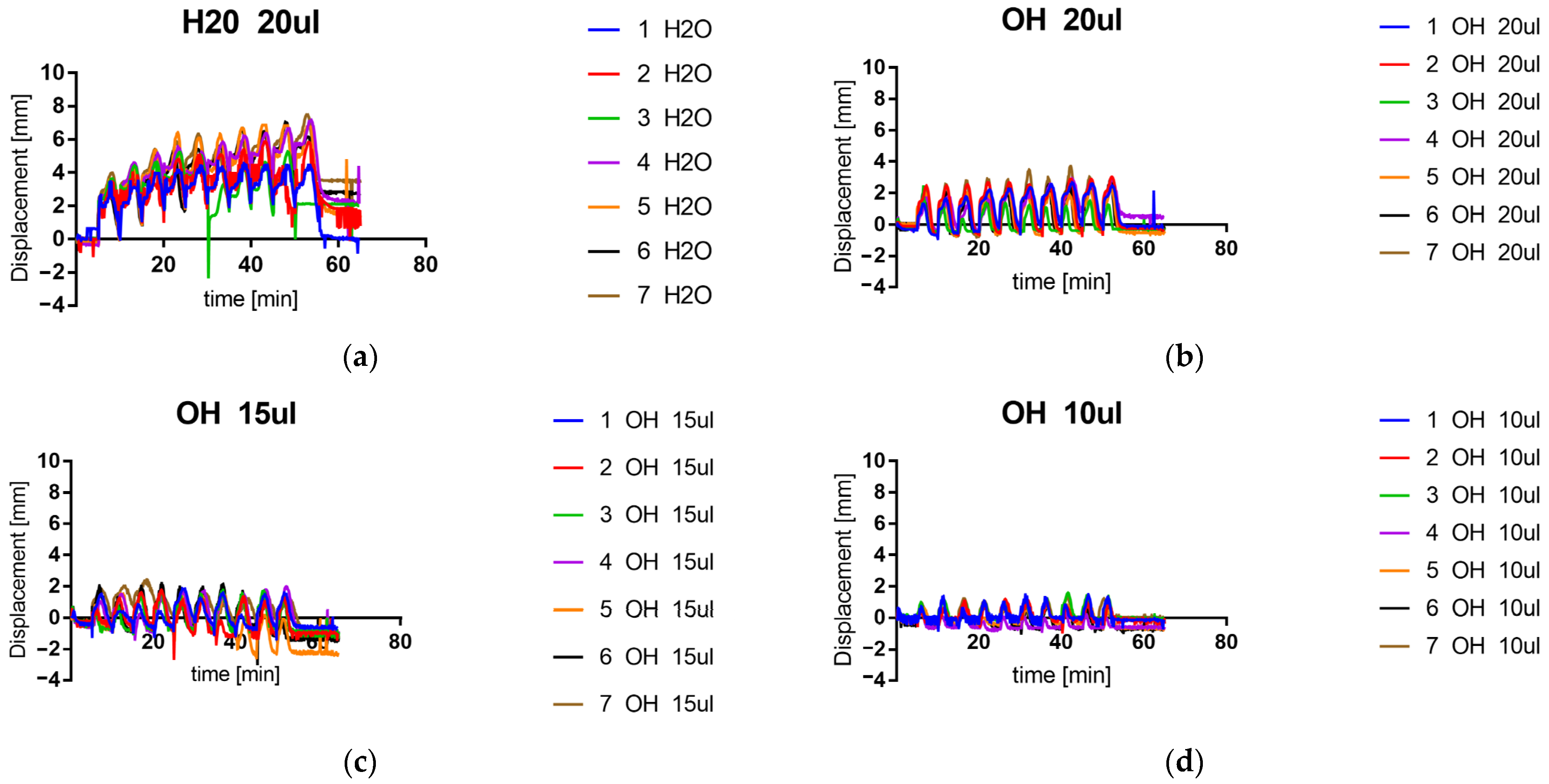

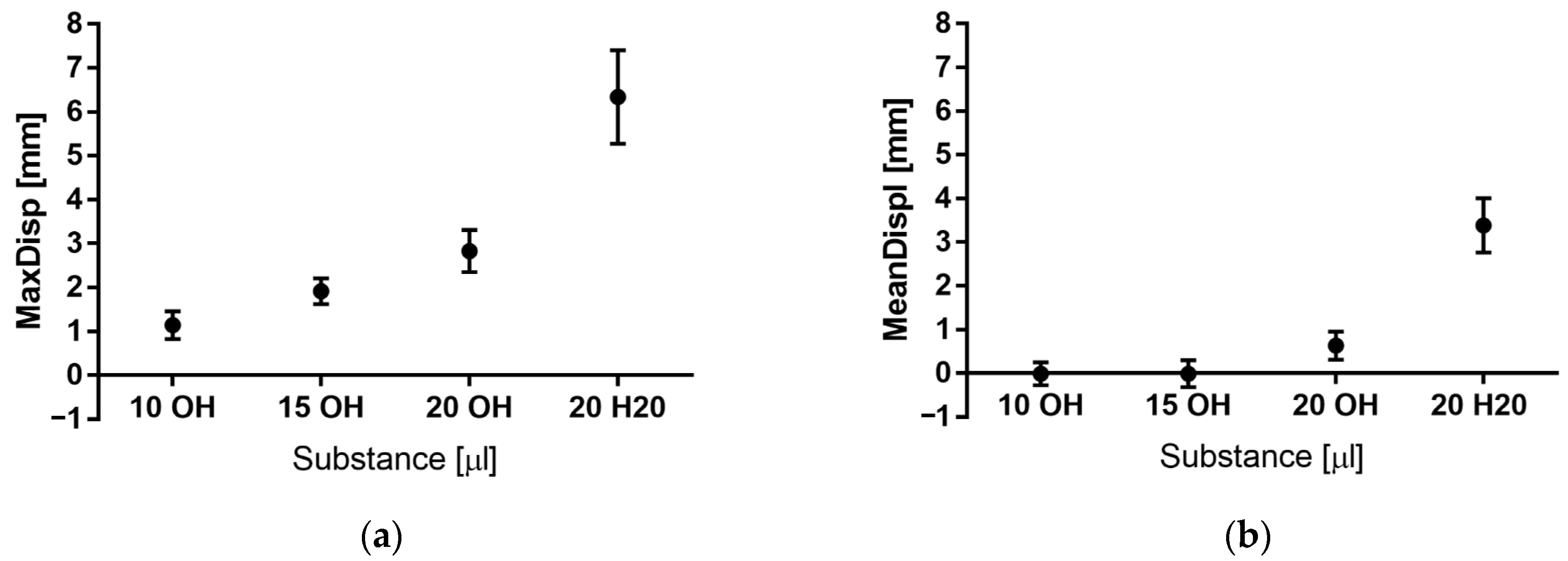

2. Materials and Methods

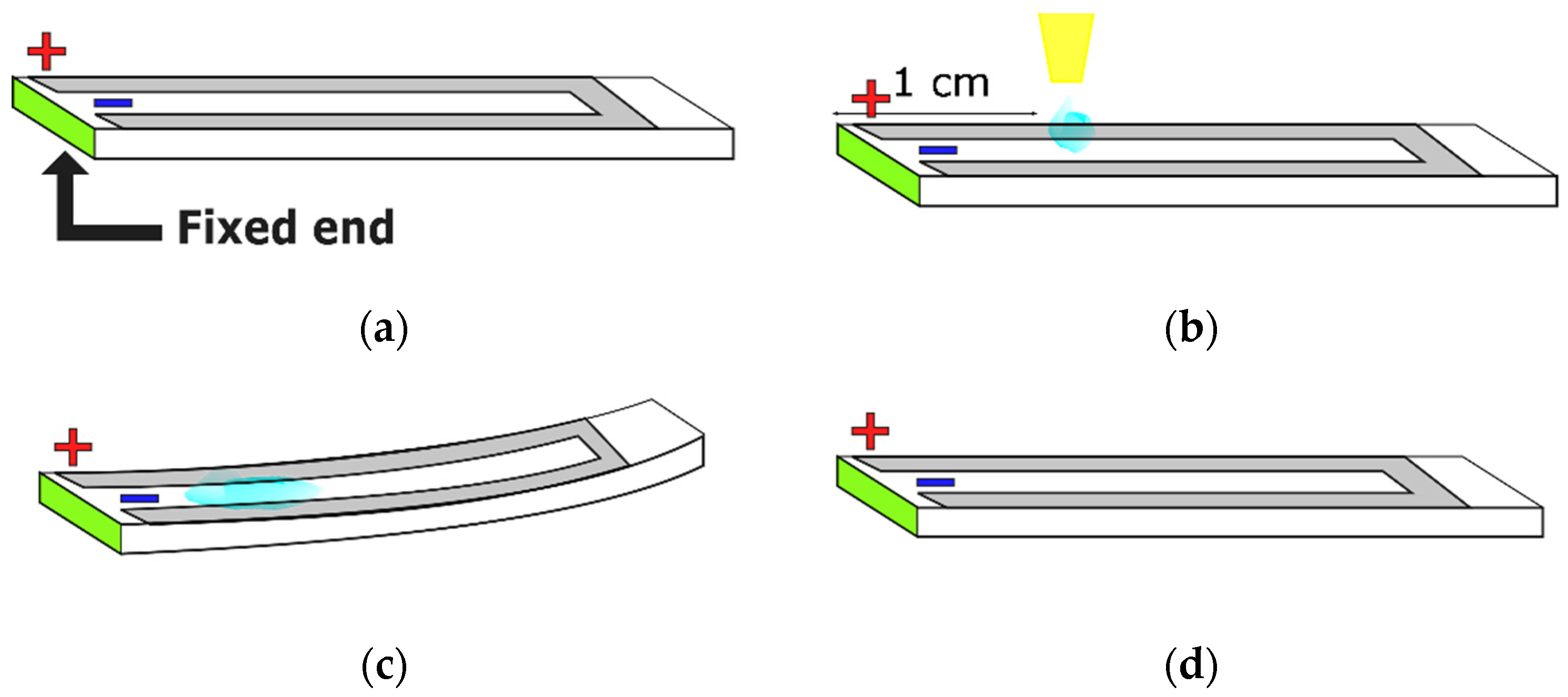

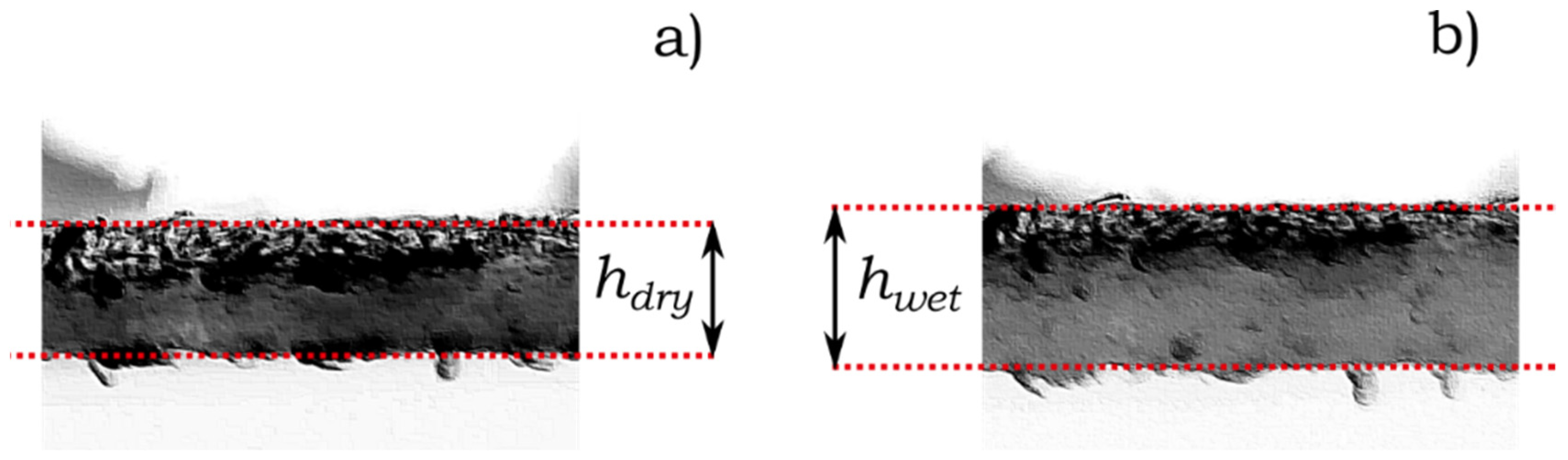

2.1. Mini Actuator Working Principle

2.2. Experimental Set Up

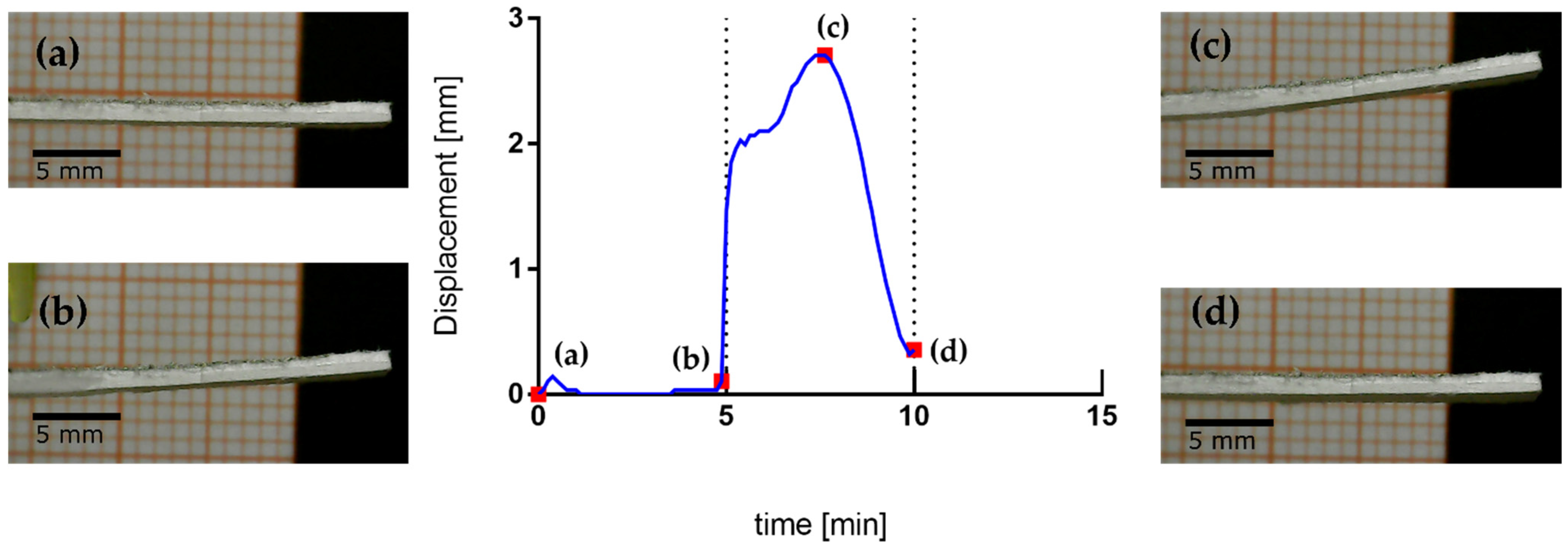

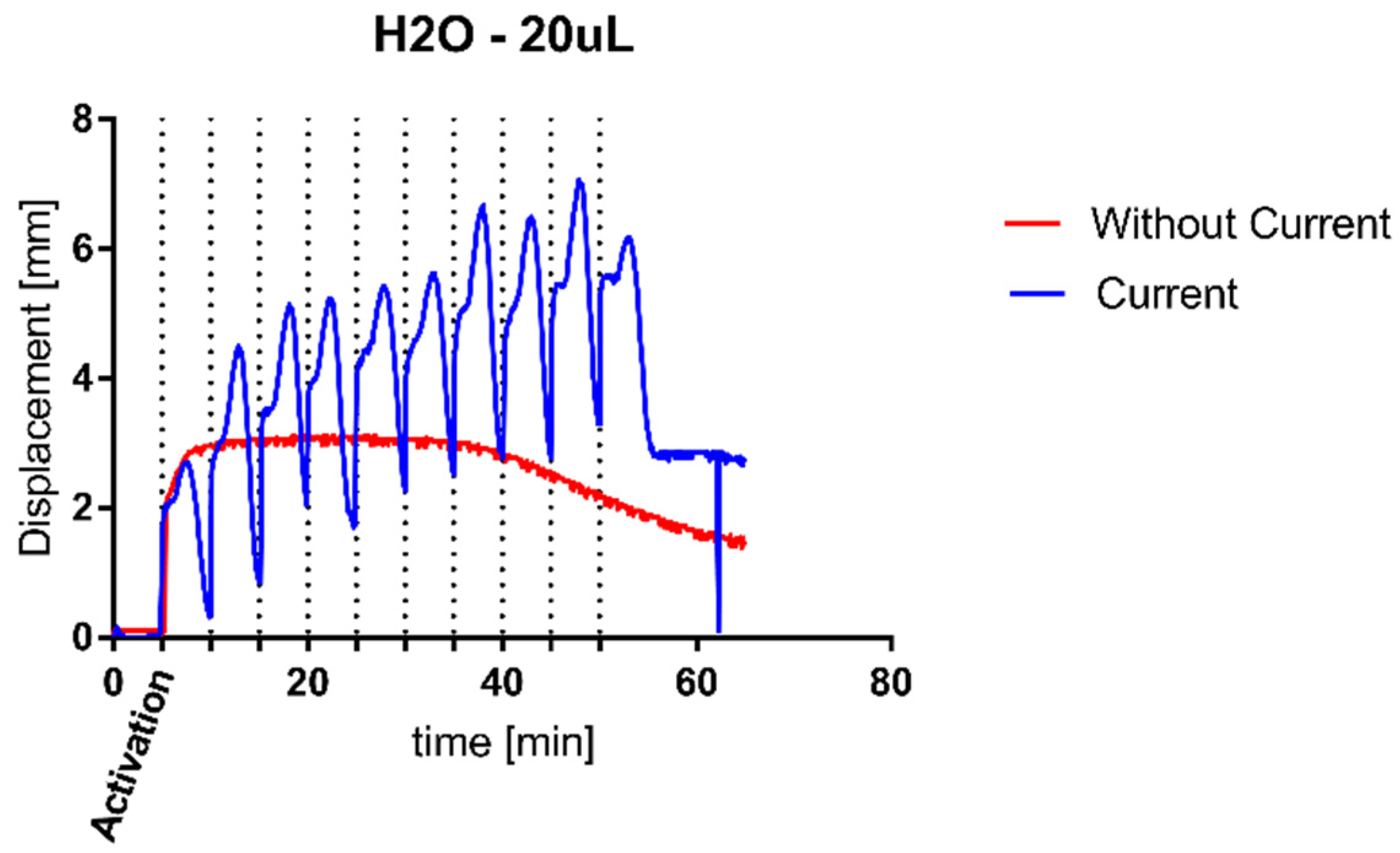

2.3. Tuning Response of the Mini Actuator

3. Results and Discussions

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Oguntosin, V.; Abdulkareem, A. Design of a pneumatic soft actuator controlled via eye tracking and detection. Heliyon 2020, 6, e04388. [Google Scholar] [CrossRef]

- Venkiteswaran, V.K.; Tan, D.K.; Misra, S. Tandem actuation of legged locomotion and grasping manipulation in soft robots using magnetic fields. Extreme Mech. Lett. 2020, 41, 101023. [Google Scholar] [CrossRef]

- Tang, D.; Zhang, C.; Sun, H.; Dai, H.; Xie, J.; Fu, J.; Zhao, P. Origami-inspired magnetic-driven soft actuators with programmable designs and multiple applications. Nano Energy 2021, 89, 106424. [Google Scholar] [CrossRef]

- Fu, C.; Xia, Z.; Hurren, C.; Nilghaz, A.; Wang, X. Textiles in soft robots: Current progress and future trends. Biosens. Bioelectron. 2022, 196, 113690. [Google Scholar] [CrossRef]

- Kirkman, S.; Rothemund, P.; Acome, E.; Keplinger, C. Electromechanics of planar HASEL actuators. Extreme Mech. Lett. 2021, 48, 101408. [Google Scholar] [CrossRef]

- Zhao, G.; Yang, J.; Wang, Y.; Zhao, H.; Wang, Z. Preparation and electromechanical properties of the chitosan gel polymer actuator based on heat treating. Sens. Actuators A Phys. 2018, 279, 481–492. [Google Scholar] [CrossRef]

- Migliorini, L.; Santaniello, T.; Rondinini, S.; Saettone, P.; Comes Franchini, M.; Lenardi, C.; Milani, P. Bioplastic electromechanical actuators based on biodegradable poly(3-hydroxybutyrate) and cluster-assembled gold electrodes. Sens. Actuators B Chem. 2019, 286, 230–236. [Google Scholar] [CrossRef]

- Qi, X.; Li, X.; Jo, H.; Sideeq Bhat, K.; Kim, S.; An, J.; Kang, J.; Lim, S. Mulberry paper-based graphene strain sensor for wearable electronics with high mechanical strength. Sens. Actuators Phys. 2020, 301, 111697. [Google Scholar] [CrossRef]

- Jia, G.; Zheng, A.; Wang, X.; Zhang, L.; Li, L.; Li, C.; Zhang, Y.; Cao, L. Flexible, biocompatible and highly conductive MXene-graphene oxide film for smart actuator and humidity sensor. Sens. Actuators B Chem. 2021, 346, 130507. [Google Scholar] [CrossRef]

- Wang, W.; Liu, D.; Liu, Y.; Leng, J.; Bhattacharyya, D. Electrical actuation properties of reduced graphene oxide paper/epoxy-based shape memory composites. Compos. Sci. Technol. 2015, 106, 20–24. [Google Scholar] [CrossRef]

- Smith, S.; Korvink, J.G.; Mager, D.; Land, K. The potential of paper-based diagnostics to meet the ASSURED criteria. RSC Adv. 2018, 8, 34012–34034. [Google Scholar] [CrossRef] [Green Version]

- Zhang, L.; Kong, Q.; Li, L.; Wang, Y.; Ge, S.; Yu, J. Direct-readout photoelectrochemical lab-on-paper biosensing platform based on coupled electricity generating system and paper supercapacitors. Talanta 2021, 222, 121517. [Google Scholar] [CrossRef] [PubMed]

- Kong, Q.; Cui, K.; Zhang, L.; Wang, Y.; Sun, J.; Ge, S.; Zhang, Y.; Yu, J. “on-Off-On” Photoelectrochemical/Visual Lab-on-Paper Sensing via Signal Amplification of CdS Quantum Dots@Leaf-Shape ZnO and Quenching of Au-Modified Prism-Anchored Octahedral CeO2 Nanoparticles. Anal. Chem. 2018, 90, 11297–11304. [Google Scholar] [CrossRef] [PubMed]

- Ozer, T.; McMahon, C.; Henry, C.S. Advances in Paper-Based Analytical Devices. Annu. Rev. Anal. Chem. 2020, 13, 85–109. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lim, W.Y.; Goh, B.T.; Khor, S.M. Microfluidic paper-based analytical devices for potential use in quantitative and direct detection of disease biomarkers in clinical analysis. J. Chromatogr. B Analyt. Technol. Biomed. Life. Sci. 2017, 1060, 424–442. [Google Scholar] [CrossRef] [PubMed]

- Mahato, K.; Srivastava, A.; Chandra, P. Paper based diagnostics for personalized health care: Emerging technologies and commercial aspects. Biosens. Bioelectron. 2017, 96, 246–259. [Google Scholar] [CrossRef] [PubMed]

- Tai, H.; Duan, Z.; Wang, Y.; Wang, S.; Jiang, Y. Paper-Based Sensors for Gas, Humidity, and Strain Detections: A Review. ACS Appl. Mater. Interfaces 2020, 12, 31037–31053. [Google Scholar] [CrossRef] [PubMed]

- Long, Y.; He, P.; Xu, R.; Hayasaka, T.; Shao, Z.; Zhong, J.; Lin, L. Molybdenum-carbide-graphene composites for paper-based strain and acoustic pressure sensors. Carbon 2020, 157, 594–601. [Google Scholar] [CrossRef]

- Lee, D.; Kim, D. Paper-Based, Hand-Painted Strain Sensor Based on ITO Nanoparticle Channels for Human Motion Monitoring. IEEE Access 2019, 7, 77200–77207. [Google Scholar] [CrossRef]

- Huang, Y.; Wang, Z.; Zhou, H.; Guo, X.; Zhang, Y.; Wang, Y.; Liu, P.; Liu, C.; Ma, Y.; Zhang, Y. Highly sensitive pressure sensor based on structurally modified tissue paper for human physiological activity monitoring. J. Appl. Polym. Sci. 2020, 137, 48973. [Google Scholar] [CrossRef]

- Liu, H.; Qing, H.; Li, Z.; Han, Y.L.; Lin, M.; Yang, H.; Li, A.; Lu, T.J.; Li, F.; Xu, F. Paper: A promising material for human-friendly functional wearable electronics. Mater. Sci. Eng. R Rep. 2017, 112, 1–22. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, H.; Zhao, W.; Zhang, M.; Qin, H.; Xie, Y. Flexible, Stretchable Sensors for Wearable Health Monitoring: Sensing Mechanisms, Materials, Fabrication Strategies and Features. Sensors 2018, 18, 645. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wang, X.; Liu, Z.; Zhang, T. Flexible Sensing Electronics for Wearable/Attachable Health Monitoring. Small 2017, 13, 1602790. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Shang, S.; Mo, S.; Wang, P.; Yin, B.; Wei, J. Soft actuators built from cellulose paper: A review on actuation, material, fabrication, and applications. J. Sci. Adv. Mater. Devices 2021, 6, 321–337. [Google Scholar] [CrossRef]

- Li, Y.; Stapleton, S.E.; Reese, S.; Simon, J.W. Anisotropic elastic-plastic deformation of paper: Out-of-plane model. Int. J. Solids Struct. 2018, 130–131, 172–182. [Google Scholar] [CrossRef]

- Kanaparthi, S.; Sekhar, V.R.; Badhulika, S. Flexible, eco-friendly and highly sensitive paper antenna based electromechanical sensor for wireless human motion detection and structural health monitoring. Extreme Mech. Lett. 2016, 9, 324–330. [Google Scholar] [CrossRef]

- Kim, J. Chapter 7—Nanocellulose-based paper actuators. In Nanocellulose Based Composites for Electronics; Thomas, S., Pottathara, Y.B., Eds.; Elsevier: Amsterdam, The Netherlands, 2021; pp. 163–183. [Google Scholar] [CrossRef]

- Khan, A.; Abas, Z.; Kim, H.; Kim, J. Recent Progress on Cellulose-Based Electro-Active Paper, Its Hybrid Nanocomposites and Applications. Sensors 2016, 16, 1172. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Fan, Q.; Miao, J.; Tian, M.; Zhao, H.; Zhu, S.; Liu, X.; Ma, Y.; Qu, L. Low-voltage Driven Flexible Double-layer Electrothermal Actuator for Smart Human-machine Interactions. Sens. Actuators Phys. 2020, 315, 112352. [Google Scholar] [CrossRef]

- Shin, S.; So, H. Time-dependent motion of 3D-printed soft thermal actuators for switch application in electric circuits. Addit. Manuf. 2021, 39, 101893. [Google Scholar] [CrossRef]

- Ha, J.; Kim, H.Y. Capillarity in Soft Porous Solids. Annu. Rev. Fluid Mech. 2020, 52, 263–284. [Google Scholar] [CrossRef] [Green Version]

- Brandberg, A.; Motamedian, H.R.; Kulachenko, A.; Hirn, U. The role of the fiber and the bond in the hygroexpansion and curl of thin freely dried paper sheets. Int. J. Solids Struct. 2020, 193–194, 302–313. [Google Scholar] [CrossRef]

- Kumar, A.; Heidari-Bafroui, H.; Charbaji, A.; Rahmani, N.; Anagnostopoulos, C.; Faghri, M. Numerical and Experimental Modeling of Paper-Based Actuators. Chem. Proc. 2021, 5, 15. [Google Scholar] [CrossRef]

- Weng, M.; Tang, Z.; Zhu, J. Multi-responsive soft paper-based actuators with programmable shape-deformations. Sens. Actuators Phys. 2021, 331, 113016. [Google Scholar] [CrossRef]

- Hamedi, M.M.; Campbell, V.E.; Rothemund, P.; Güder, F.; Christodouleas, D.C.; Bloch, J.; Whitesides, G.M. Electrically Activated Paper Actuators. Adv. Funct. Mater. 2016, 26, 2446–2453. [Google Scholar] [CrossRef]

- Zhou, L.; Nie, B.; Ren, S.; Żur, K.K.; Kim, J. On the hygro-thermo-electro-mechanical coupling effect on static and dynamic responses of piezoelectric beams. Compos. Struct. 2021, 259, 113248. [Google Scholar] [CrossRef]

- Lee, M.; Kim, S.; Kim, H.Y.; Mahadevan, L. Bending and buckling of wet paper. Phys. Fluids 2016, 28, 042101. [Google Scholar] [CrossRef]

- Douezan, S.; Wyart, M.; Brochard-Wyart, F.; Cuvelier, D. Curling instability induced by swelling. Soft Matter. 2011, 7, 1506–1511. [Google Scholar] [CrossRef]

- Reyssat, E.; Mahadevan, L. How wet paper curls. Europhys. Lett. 2011, 93, 54001. [Google Scholar] [CrossRef] [Green Version]

- Cueva-Perez, I.; Perez-Cruz, A.; Stiharu, I.; Dominguez-Gonzalez, A.; Trejo-Hernandez, M.; Osornio-Rios, R.A. A parametric study on the nonlinear dynamic response of paper-based mechanical systems due to liquid transport. Int. J. Non-Linear Mech. 2020, 118, 103280. [Google Scholar] [CrossRef]

- Perez-Cruz, A.; Stiharu, I.; Dominguez-Gonzalez, A. Nonlinear imbibition influence on the hygro-mechanical bending response of paper due to its interaction with water. Int. J. Non-Linear Mech. 2017, 97, 89–95. [Google Scholar] [CrossRef]

- Ansari, M.Z.; Cho, C. A conduction–convection model for self-heating in piezoresistive microcantilever biosensors. Sens. Actuators A Phys. 2012, 175, 19–27. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ireta-Muñoz, L.A.; Cueva-Perez, I.; Saucedo-Dorantes, J.J.; Pérez-Cruz, A. A Paper-Based Cantilever Beam Mini Actuator Using Hygro-Thermal Response. Actuators 2022, 11, 94. https://doi.org/10.3390/act11030094

Ireta-Muñoz LA, Cueva-Perez I, Saucedo-Dorantes JJ, Pérez-Cruz A. A Paper-Based Cantilever Beam Mini Actuator Using Hygro-Thermal Response. Actuators. 2022; 11(3):94. https://doi.org/10.3390/act11030094

Chicago/Turabian StyleIreta-Muñoz, Laura Alejandra, Isaias Cueva-Perez, Juan Jose Saucedo-Dorantes, and Angel Pérez-Cruz. 2022. "A Paper-Based Cantilever Beam Mini Actuator Using Hygro-Thermal Response" Actuators 11, no. 3: 94. https://doi.org/10.3390/act11030094

APA StyleIreta-Muñoz, L. A., Cueva-Perez, I., Saucedo-Dorantes, J. J., & Pérez-Cruz, A. (2022). A Paper-Based Cantilever Beam Mini Actuator Using Hygro-Thermal Response. Actuators, 11(3), 94. https://doi.org/10.3390/act11030094