Study on Properties of Potassium Sodium Niobate Coating Prepared by High Efficiency Supersonic Plasma Spraying

Abstract

:1. Introduction

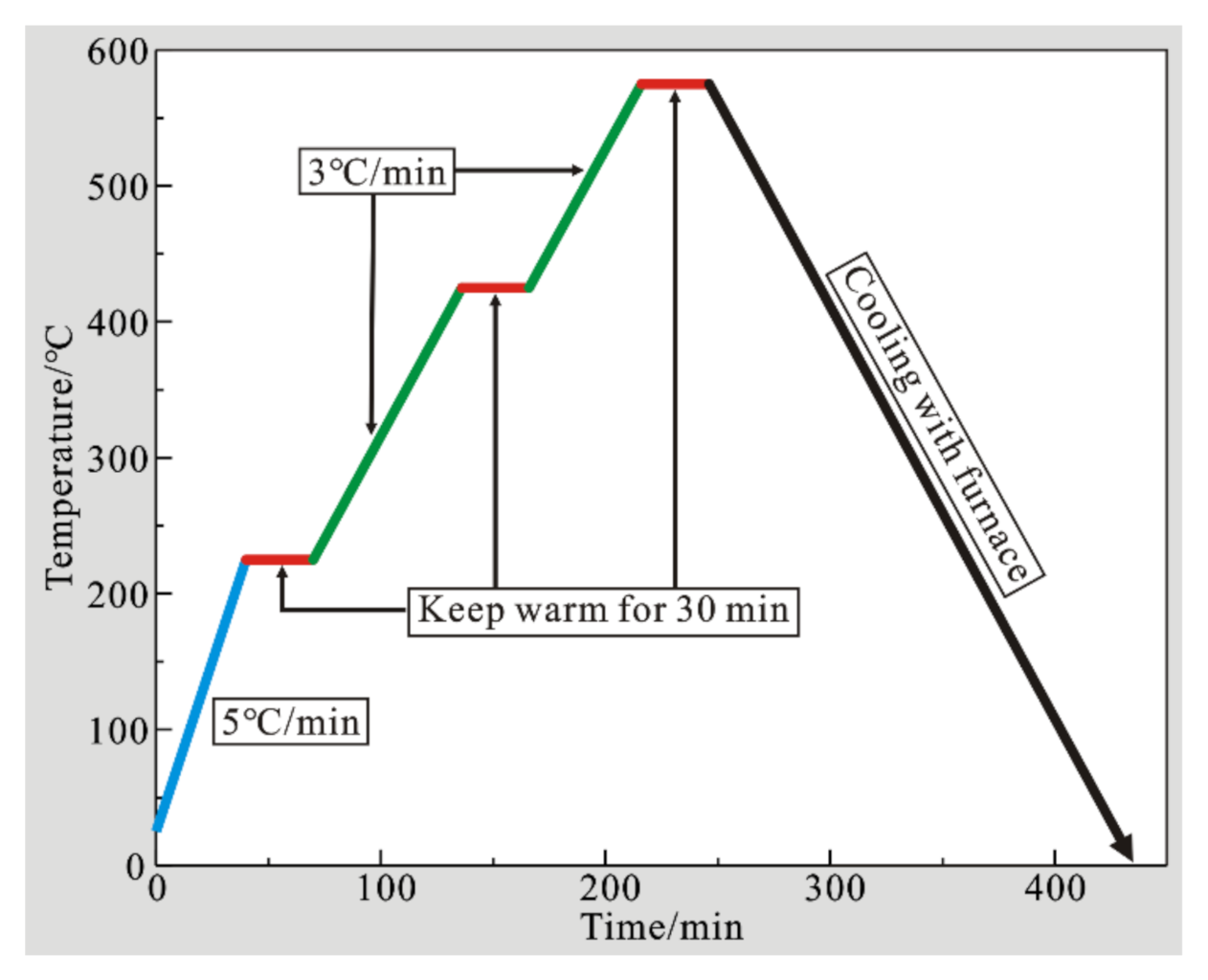

2. Materials and Methods

3. Result and Discussion

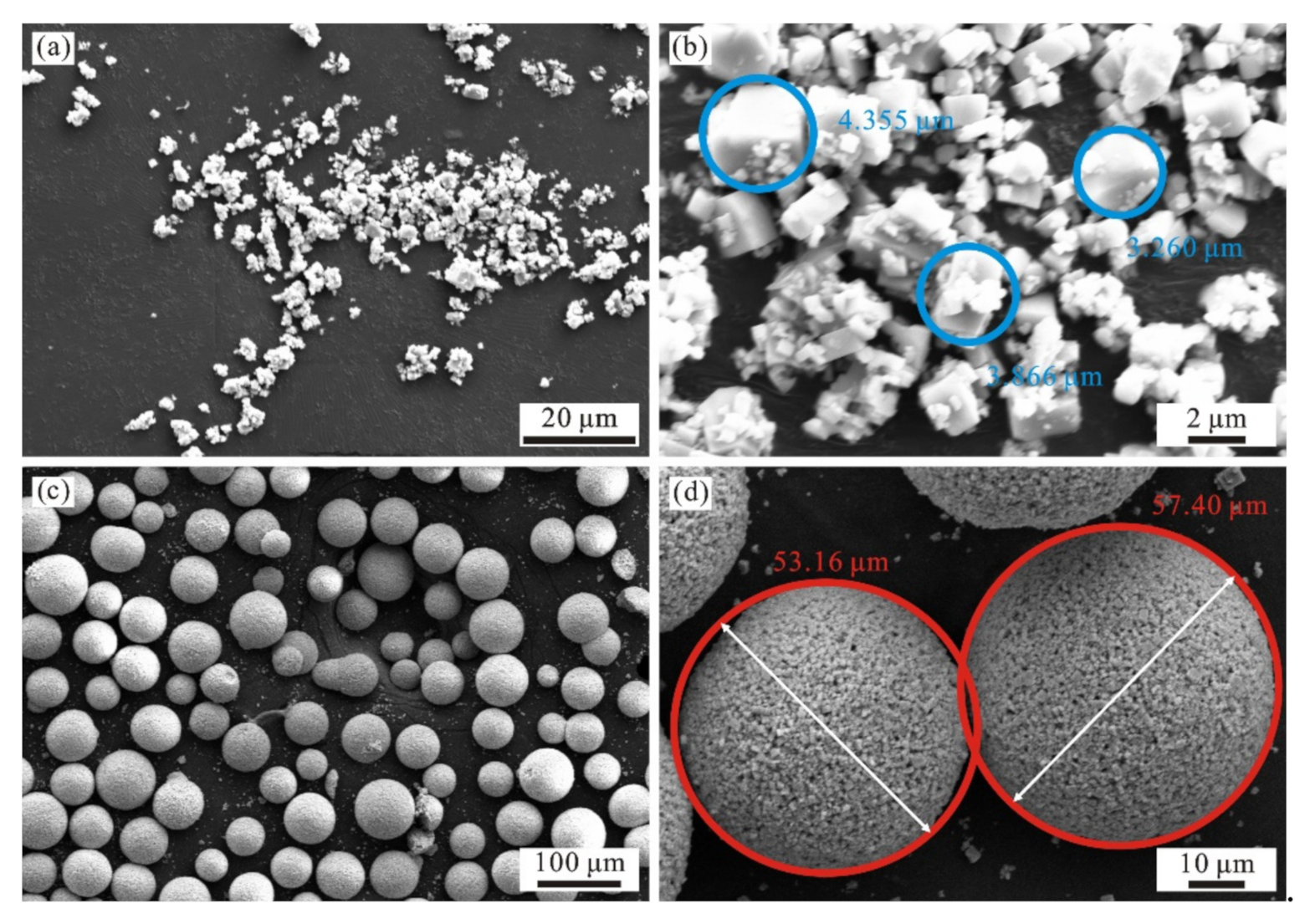

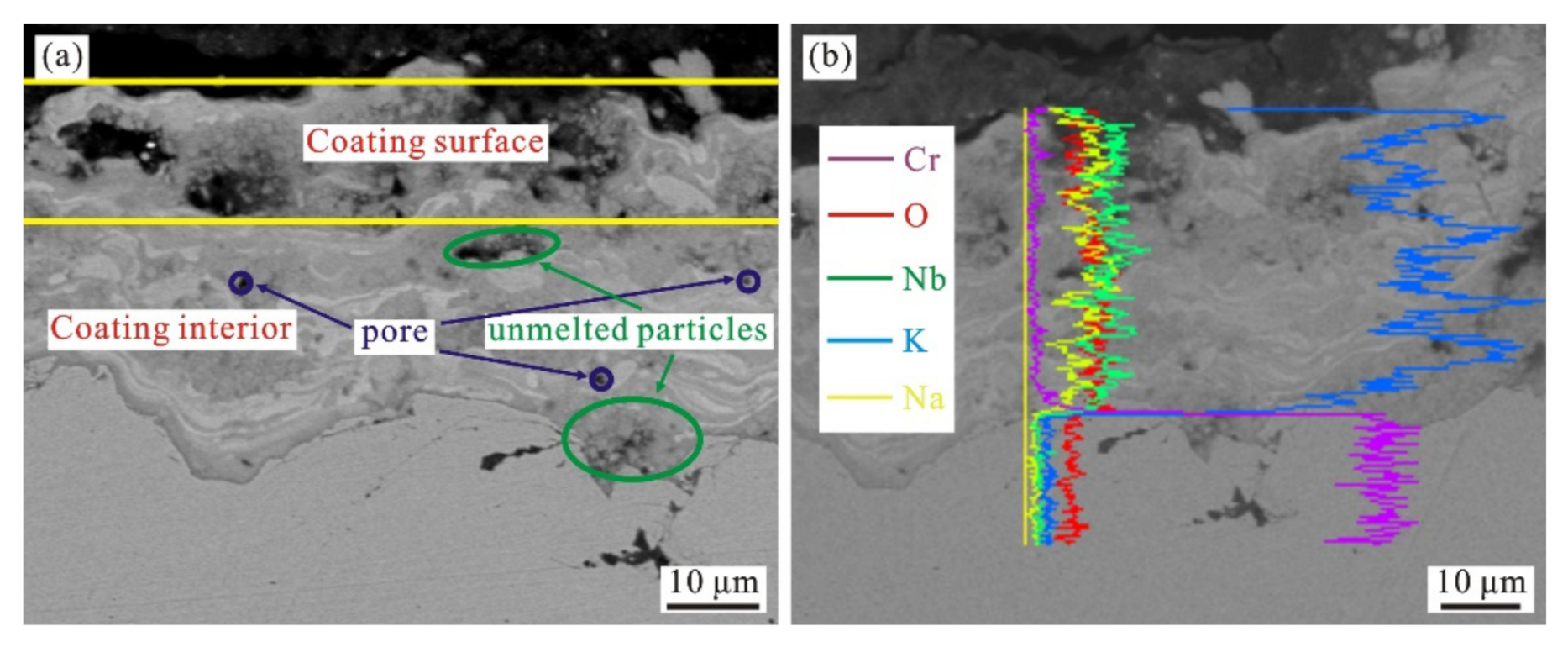

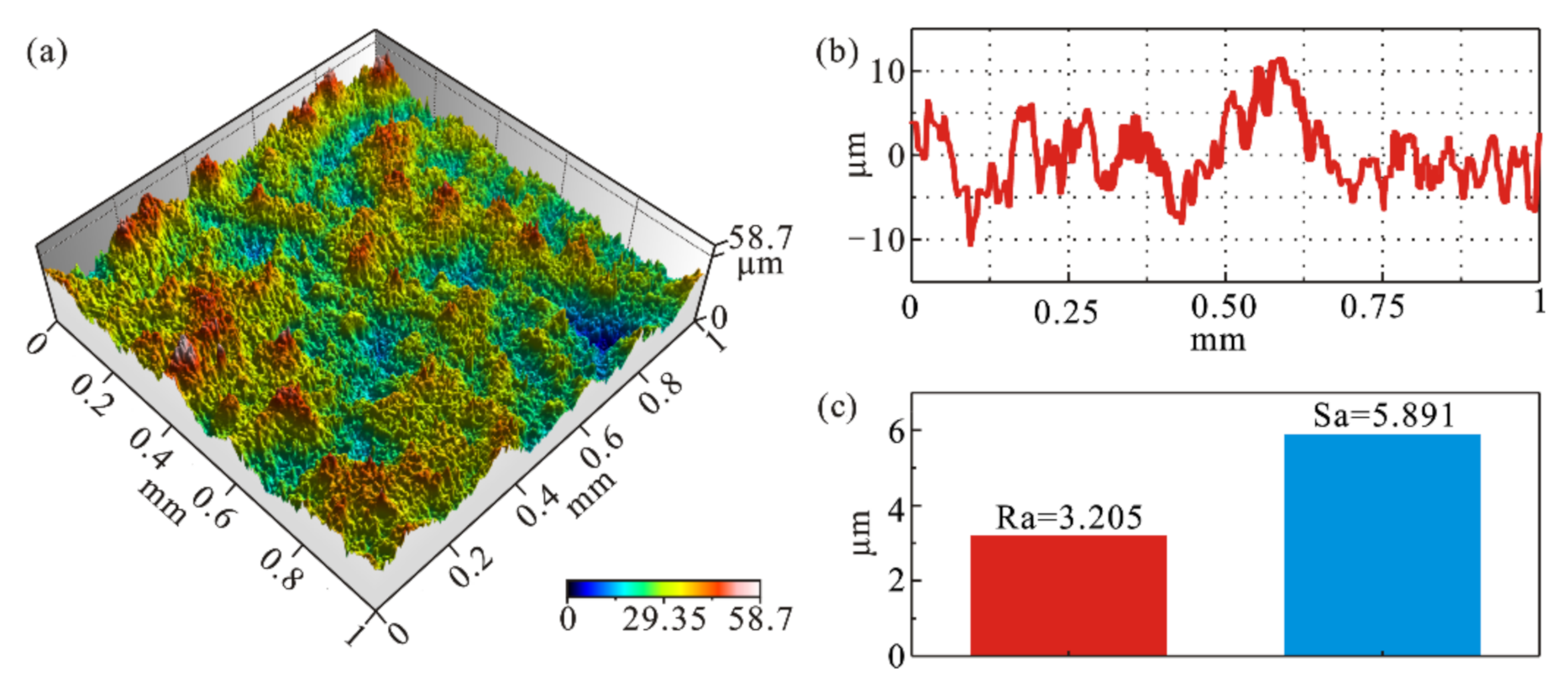

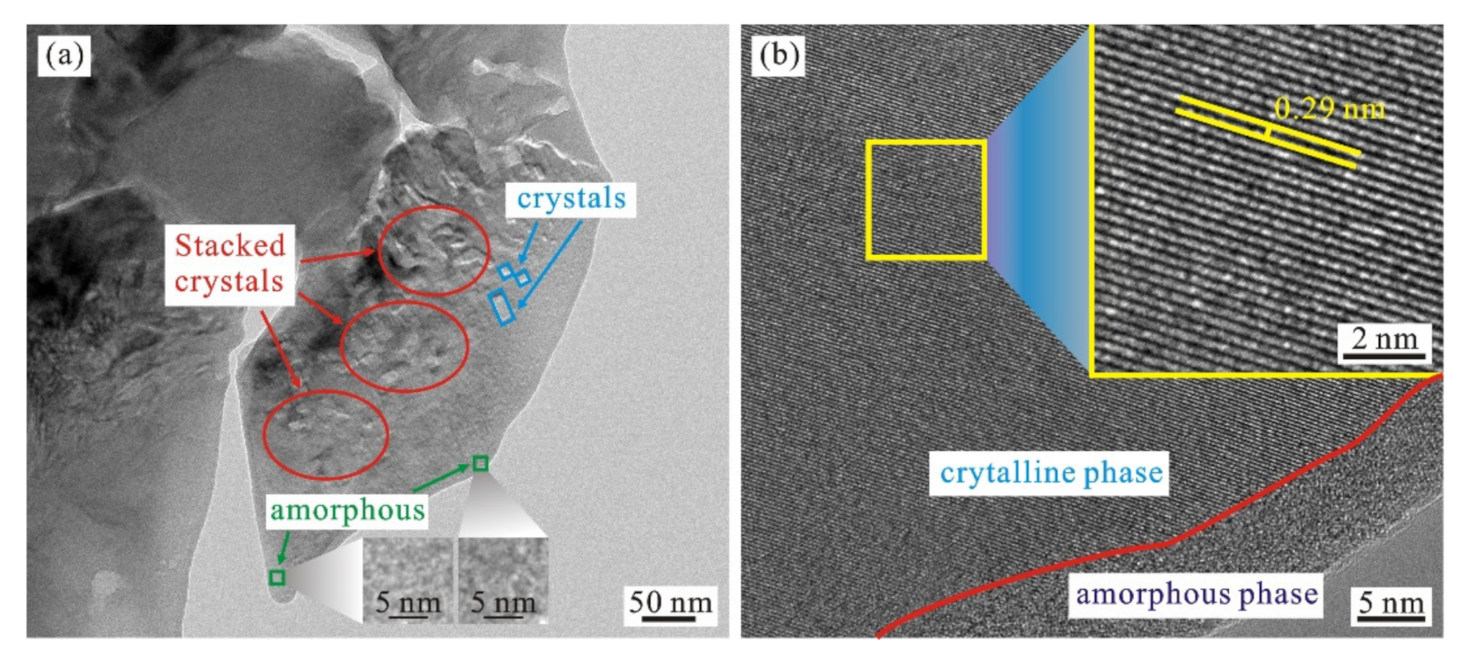

3.1. Microstructures

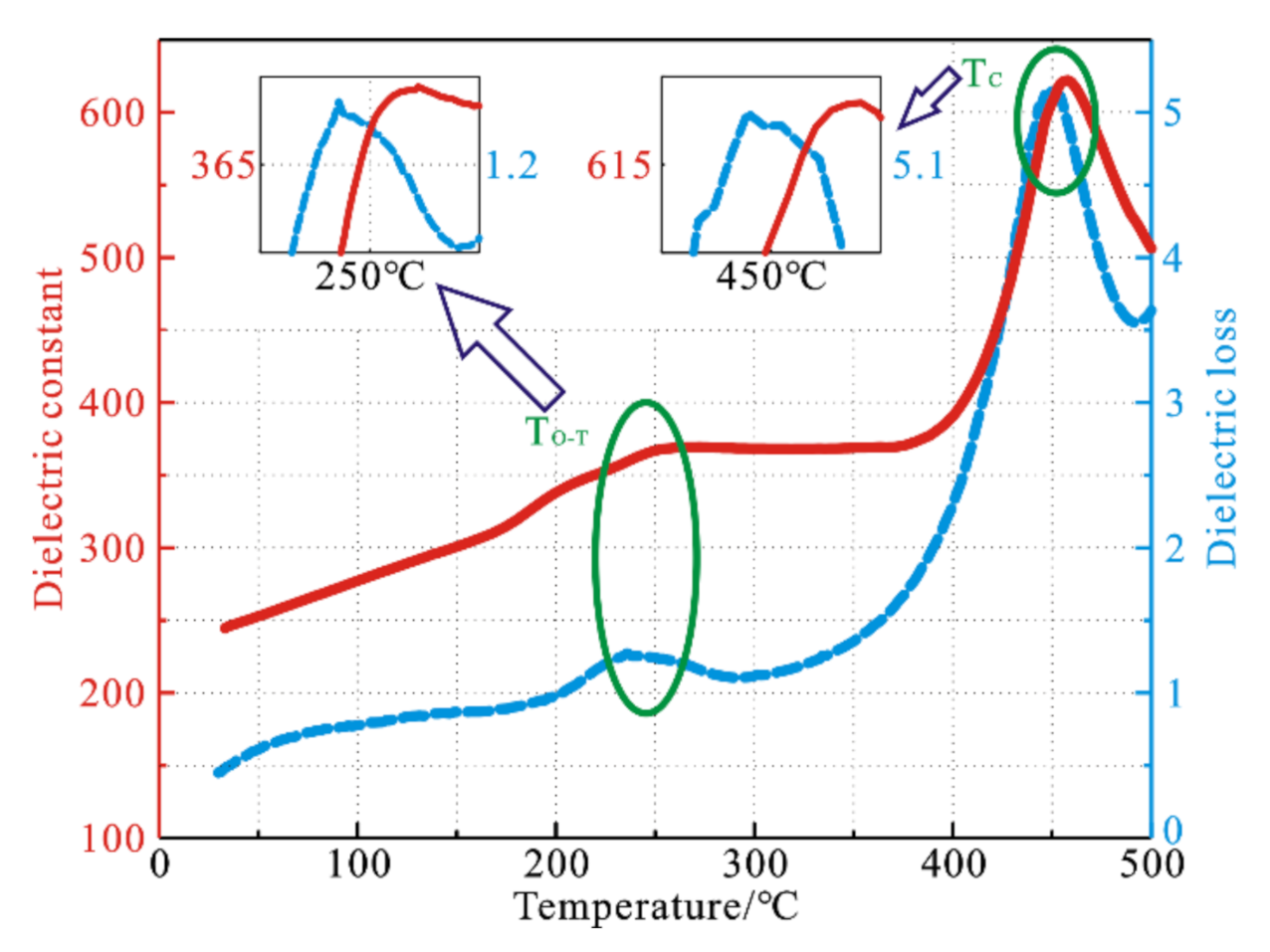

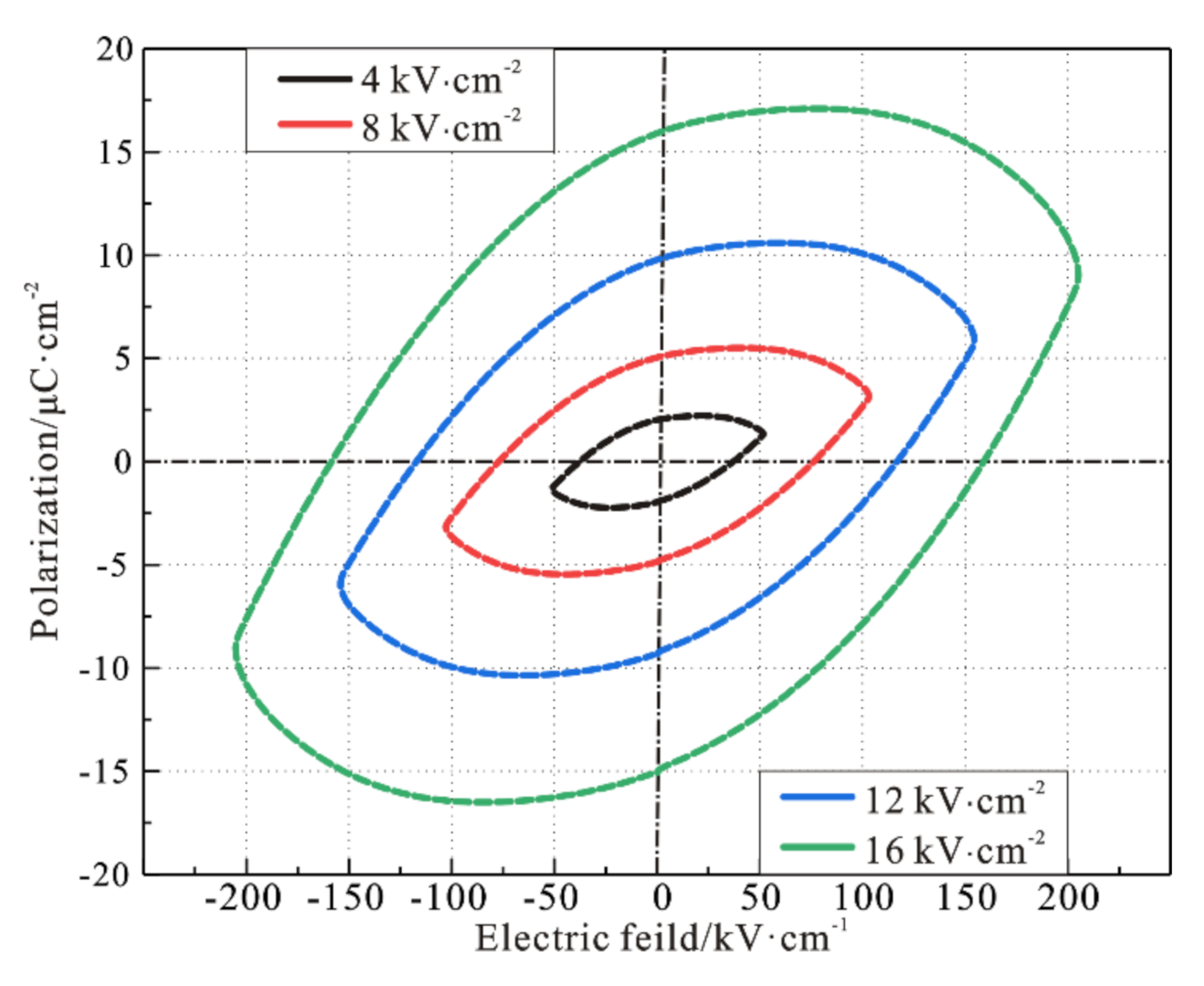

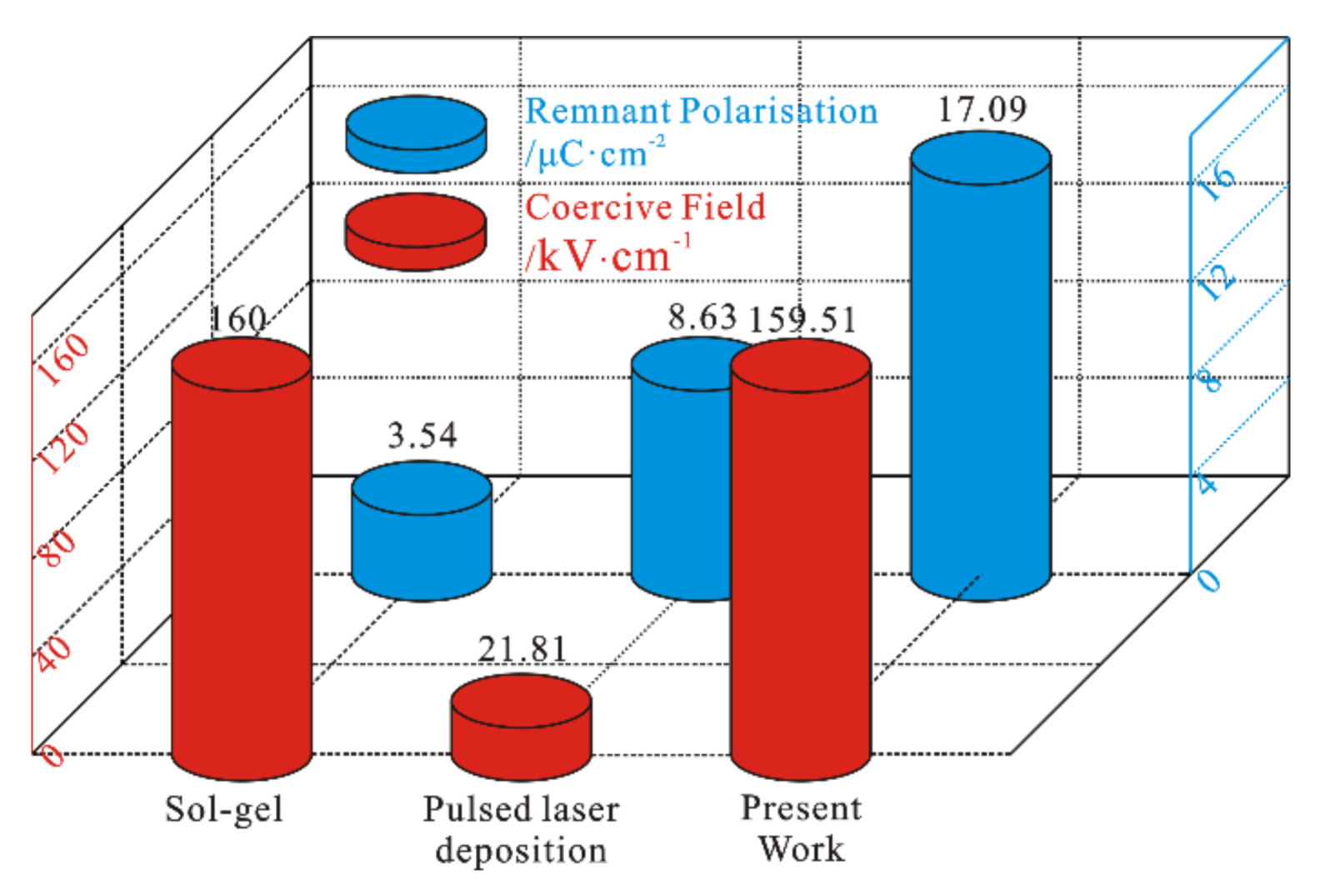

3.2. Electrical Property

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Lee, T.; Lee, J. Setting time and compressive strength prediction model of concrete by nondestructive ultrasonic pulse velocity testing at early age. Constr. Build. Mater. 2020, 252, 119027. [Google Scholar] [CrossRef]

- Abramovich, H. The Vibration Correlation Technique—A reliable nondestructive method to predict buckling loads of thin walled structures. Thin-Walled Struct. 2020, 159, 107308. [Google Scholar] [CrossRef]

- Huang, Q.D.; Gardoni, P.; Hurlebaus, S. A probabilistic damage detection approach using vibration-based nondestructive testing. Struct. Saf. 2012, 38, 11–21. [Google Scholar] [CrossRef]

- Xu, C.G.; Song, W.T.; Pan, Q.X.; Li, H.X.; Liu, S. Nondestructive testing residual stress using ultrasonic critical refracted longitudinal wave. Phys. Proced. 2015, 70, 594–598. [Google Scholar] [CrossRef] [Green Version]

- Zhou, Z.Y.; Zheng, Q.Y.; Ding, C.; Yan, J.Y.; Piao, Z.Y. Effect of surface burnishing process with different strain paths on the copper microstructure. J. Manuf. Process. 2021, 71, 653–668. [Google Scholar]

- Zhou, Z.Y.; Zheng, Q.Y.; Ding, C.; Yan, J.Y.; Peng, G.J.; Piao, Z.Y. Research on the promotion mechanism of surface burnishing process by two-dimensional ultrasonic vibration. J. Mater. Res. Technol. 2021, 13, 1068–1082. [Google Scholar]

- Li, X.W.; Yu, Q.Y.; Chen, X.; Zhang, Q.X. Microstructures and electrochemical behaviors of casting magnesium alloys with enhanced compression strengths and decomposition rates. J. Magnes. Alloy 2021. [Google Scholar] [CrossRef]

- Li, X.W.; Liang, J.S.; Shi, T.; Yang, D.N.; Chen, X.C.; Zhang, C.W.; Liu, Z.H.; Liu, D.Z.; Zhang, Q.X. Tribological behaviors of vacuum hot-pressed ceramic composites with enhanced cyclic oxidation and corrosion resistance. Ceram. Int. 2020, 46, 12911–12920. [Google Scholar] [CrossRef]

- Hayden, B.E.; Yakovlev, S. Structural, dielectric and ferroelectric properties of (Bi,Na)TiO3-BaTiO3 system studied by high throughput screening. Thin Solid Film. 2016, 603, 108–114. [Google Scholar] [CrossRef] [Green Version]

- Clabel, J.L.H.; Awan, I.T.; Rivera, V.A.G.; Nogueira, I.C.; Pereira-da-Silva, M.; Li, M.S.; Ferreira, S.O.; Marega, E. Growth process and grain boundary defects in Er doped BaTiO3 processed by EB-PVD: A study by XRD, FTIR, SEM and AFM. Appl. Surf. Sci. 2019, 493, 982–993. [Google Scholar] [CrossRef]

- Reis, D.M.D.; Rzepka, S.; Hiller, K. Reliability testing of integrated low-temperature PVD PZT films. Microelectron. Reliab. 2018, 88, 835–839. [Google Scholar] [CrossRef]

- Xie, L.Y.; Huang, X.Y.; Yang, K.; Li, S.T.; Jiang, P.K. “Grafting to” route to PVDF-HFP-GMA/BaTiO3 nanocomposites with high dielectric constant and high thermal conductivity for energy storage and thermal management applications. J. Mater. Chem. 2014, 2, 5244–5251. [Google Scholar] [CrossRef]

- Ohno, T.; Fukumitsu, K.; Honda, T.; Sakamoto, A.; Tanaka, S.; Hirai, S.; Matsuda, T.; Sakamoto, N.; Suzuki, H. Piezoelectric properties of a near strain-free lead zirconate titanate thin films deposited on a Si substrate. Mater. Lett. 2019, 239, 71–74. [Google Scholar] [CrossRef]

- Li, X.M.; Wu, X.Q.; Ren, W.; Shi, P.; Ye, Z.G. Preparation and characterization of sodium potassium niobate-silver niobate lead-free films by chemical solution deposition. Ceram. Int. 2015, 41, 228–233. [Google Scholar] [CrossRef]

- Raeder, T.M.; Bakken, K.; Glaum, J.; Einarsrud, M.A.; Grande, T. Enhanced in-plane ferroelectricity in BaTiO3 thin films fabricated by aqueous chemical solution deposition. AIP Adv. 2018, 8, 105228. [Google Scholar] [CrossRef] [Green Version]

- Uchida, H.; Oi, T.; Noguchi, K.; Moki, S.; Kim, J.W.; Shima, H.; Nishida, K.; Kiguchi, T.; Akama, A.; Konno, T.J.; et al. Orientation control of barium titanate films using metal oxide nanosheet layer. Jpn. J. Appl. Phys. 2016, 55, 10TA15. [Google Scholar] [CrossRef]

- Bruncková, H.; Medvecký, Ľ.; Hvizdoš, P. Effect of substrate on microstructure and mechanical properties of sol–gel prepared (K, Na)NbO3 thin films. Mater. Sci. Eng. 2013, 178, 254–262. [Google Scholar] [CrossRef]

- Tachafine, A.; Fasquelle, D.; Desfeux, R.; Ferri, A.; Da Costa, A.; Carru, J.C.; Outzourhit, A. Doping effect on nanoscopic and macroscopic electrical properties of Barium Zirconate Titanate thin films. Spectrosc Lett. 2021, 54, 507–519. [Google Scholar] [CrossRef]

- Kawamura, G.; Ohara, K.; Tan, W.K.; Goto, T.; Nakamura, Y.; Inoue, M.; Muto, H.; Yamaguchi, K.; Boccaccini, A.R.; Matsuda, A. Multiferroic nanocomposite fabrication via liquid phase using anodic alumina template. Sci. Technol. Adv. Mat. 2018, 19, 535–542. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Liu, Y.M.; Lam, K.H.; Shung, K.K.; Li, J.Y. Enhanced piezoelectric performance of composite sol–gel thick films evaluated using piezoresponse force microscopy. J. Appl. Phys. 2014, 13, 187205. [Google Scholar] [CrossRef] [Green Version]

- Guo, K.; Mirshekarloo, M.S.; Lin, M.; Yao, K.; Chen, S.T.; Tay, F.E.H. Microstructure and piezoelectric properties of thermal sprayed Bi0.5(Na0.70K0.20Li0.10)0.5TiO3 ceramic coatings. Ceram. Int. 2019, 45, 3570–3573. [Google Scholar] [CrossRef]

- Xing, Z.G.; Wang, H.D.; Zhu, L.N.; Zhou, X.Y.; Huang, Y.F. Properties of the BaTiO3 coating prepared by supersonic plasma spraying. J. Alloy Compd. 2014, 582, 246–252. [Google Scholar] [CrossRef]

- Wang, Y.W.; Sun, X.W.; Wang, L.; Yang, Y.; Ren, X.X.; Ma, Y.D.; Cui, Y.H.; Sun, W.W.; Wang, X.Y.; Dong, Y.C. Microstructure and properties of CrB2-Cr3C2 composite coatings prepared by plasma spraying. Surf. Coat. Technol. 2021, 425, 127693. [Google Scholar] [CrossRef]

- Yang, J.J.; Jia, J.H.; Li, X.; Lu, C.; Feng, X.C. Synergistic lubrication of Ag and Ag2MoO4 nanoparticles anchored in plasma-sprayed YSZ coatings: Remarkably-durable lubricating performance at 800 °C. Tribol. Int. 2021, 153, 106670. [Google Scholar] [CrossRef]

- Chen, S.Y.; Wang, H.D.; Xu, B.S.; Kang, J.J. Investigation on the bonding behavior of the interface within the supersonic plasma sprayed coating system based on the fractal theory. Acta Phys. Sin. 2014, 63, 156801. [Google Scholar] [CrossRef]

- Haessler, W.; Thielsch, R.; Mattern, N. Structure and Electrical Properties of PZT Thick Films Produced by Plasma Spraying. Mater. Lett. 1995, 24, 387–391. [Google Scholar] [CrossRef]

- Zhang, J.; Zhang, Y.S.; Yan, Z.M.; Wang, A.J.; Jiang, P.; Zhong, M. Fabrication and performance of PNN-PZT piezoelectric ceramics obtained by low-temperature sintering. Sci. Eng. Compos. Mater. 2020, 27, 359–365. [Google Scholar] [CrossRef]

- Bian, K.; Gu, Q.L.; Zhu, K.J.; Zhu, R.Q.; Wang, J.; Liu, J.S.; Qiu, J.H. Improved sintering activity and piezoelectric properties of PZT ceramics from hydrothermally synthesized powders with Pb excess. J. Mater. Sci. Mater. Electron. 2016, 27, 8573–8579. [Google Scholar] [CrossRef]

- Wang, J.; Xing, Z.G.; Lv, Z.L.; Ding, K.N.; Wang, H.D. First-principle study of the properties in BaTiO3 and the electronic structure of H2O adsorption on BaTiO3. Int. J. Quantum Chem. 2021, 121, e26576. [Google Scholar] [CrossRef]

- Tenne, D.A.; Turner, P.; Schmidt, J.D.; Biegalski, M.; Li, Y.L.; Chen, L.Q.; Soukiassian, A.; Trolier-McKinstry, S.; Schlom, D.G.; Xi, X.X.; et al. Ferroelectricity in ultrathin BaTiO3 films: Probing the size effect by ultraviolet Raman spectroscopy. Phys. Rev. Lett. 2009, 103, 177601. [Google Scholar] [CrossRef] [Green Version]

- Pop-Ghe, P.; Wolff, N.; Rubab, A.; Kienle, L.; Quandt, E. Tailoring growth modes by excess alkali addition in magnetron sputtered potassium sodium niobate thin films. Mater Today Commun. 2022, 27, 102221. [Google Scholar] [CrossRef]

- Sharma, S.; Gupta, R.; Kumar, A.; Gupta, V.; Tomar, M. Investigation of optical non-linearity of lead-free ferroelectric potassium sodium niobate (K0.35Na0.65NbO3) thin films via two-wave mixing phenomenon. Opt. Laser Technol. 2021, 141, 107148. [Google Scholar] [CrossRef]

- Burns, S.R.; Dolgos, M.R. Sizing up (K1-xNax)NbO3 films: A review of synthesis routes, properties & applications. New J. Chem. 2021, 45, 7408–7436. [Google Scholar]

- Akmal, M.H.M.; Warikh, A.R.M. Electrical behaviour of yttrium-doped potassium sodium niobate thin film for piezoelectric energy harvester applications. J. Aust. Ceram. Soc. 2021, 57, 589–596. [Google Scholar] [CrossRef]

- Chen, S.T.; Tan, C.K.I.; Yao, K. Potassium–sodium niobate-based lead-free piezoelectric ceramic coatings by thermal spray process. J. Am. Ceram. Soc. 2016, 99, 3293–3299. [Google Scholar] [CrossRef]

- Chen, S.T.; Tan, C.K.I.; Tan, S.Y.; Guo, S.F.; Zhang, L.; Yao, K. Potassium sodium niobate (KNN)-based lead-free piezoelectric ceramic coatings on steel structure by thermal spray method. J. Am. Ceram. Soc. 2018, 101, 5524–5533. [Google Scholar] [CrossRef]

- Guo, S.F.; Zhang, L.; Chen, S.T.; Tan, C.K.I.; Yao, K. Ultrasonic transducers from thermal sprayed lead-free piezoelectric ceramic coatings for in-situ structural monitoring for pipelines. Smart Mater. Struct. 2019, 28, 075031. [Google Scholar] [CrossRef]

- Li, G.L.; Gu, L.S.; Wang, H.D.; Xing, Z.G.; Zhu, L.N. Microstructures and Dielectric Properties of PZT Coatings Prepared by Supersonic Plasma Spraying. J. Therm. Spray Technol. 2014, 23, 525–529. [Google Scholar] [CrossRef]

- Yan, X.; Ren, W.; Wu, X.Q.; Shi, P.; Yao, X. Lead-free(K,Na)NbO3 ferroelectric thin films: Preparation, structure and electrical properties. J. Alloy Compd. 2010, 508, 129–132. [Google Scholar] [CrossRef]

- Sharma, S.; Kumar, A.; Gupta, V.; Tomar, M. Dielectric and ferroelectric studies of KNN thin film grown by pulsed laser deposition technique. Vacuum 2019, 160, 233–237. [Google Scholar] [CrossRef]

| Spraying Voltage/V | Spraying Current/A | Spraying Distance/mm | Powder Feeding Rate/ g·min−1 | Ar Gas Flow/ L·min−1 | H2 Gas Flow/ L·min−1 |

|---|---|---|---|---|---|

| 400 | 120 | 100 | 25 | 120 | 10 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, L.; Li, X.; He, D.; Guo, W.; Huang, Y.; He, G.; Xing, Z.; Wang, H. Study on Properties of Potassium Sodium Niobate Coating Prepared by High Efficiency Supersonic Plasma Spraying. Actuators 2022, 11, 28. https://doi.org/10.3390/act11020028

Zhou L, Li X, He D, Guo W, Huang Y, He G, Xing Z, Wang H. Study on Properties of Potassium Sodium Niobate Coating Prepared by High Efficiency Supersonic Plasma Spraying. Actuators. 2022; 11(2):28. https://doi.org/10.3390/act11020028

Chicago/Turabian StyleZhou, Longlong, Xuewu Li, Dongyu He, Weiling Guo, Yanfei Huang, Gengchao He, Zhiguo Xing, and Haidou Wang. 2022. "Study on Properties of Potassium Sodium Niobate Coating Prepared by High Efficiency Supersonic Plasma Spraying" Actuators 11, no. 2: 28. https://doi.org/10.3390/act11020028

APA StyleZhou, L., Li, X., He, D., Guo, W., Huang, Y., He, G., Xing, Z., & Wang, H. (2022). Study on Properties of Potassium Sodium Niobate Coating Prepared by High Efficiency Supersonic Plasma Spraying. Actuators, 11(2), 28. https://doi.org/10.3390/act11020028