Study on Multidegree-of-Freedom Ultrasonic Motor Using Vibration Mode Rotation of Metal Spherical Stator

Abstract

1. Introduction

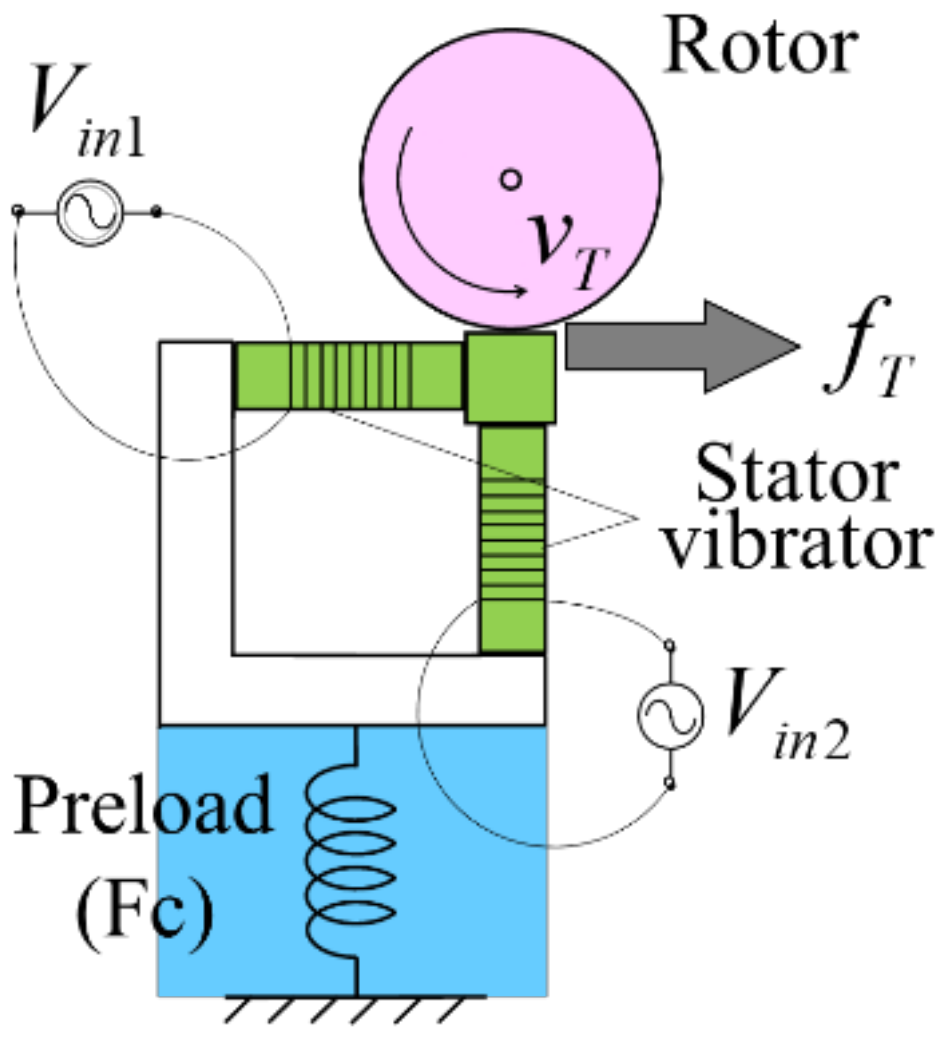

2. Operating Principle

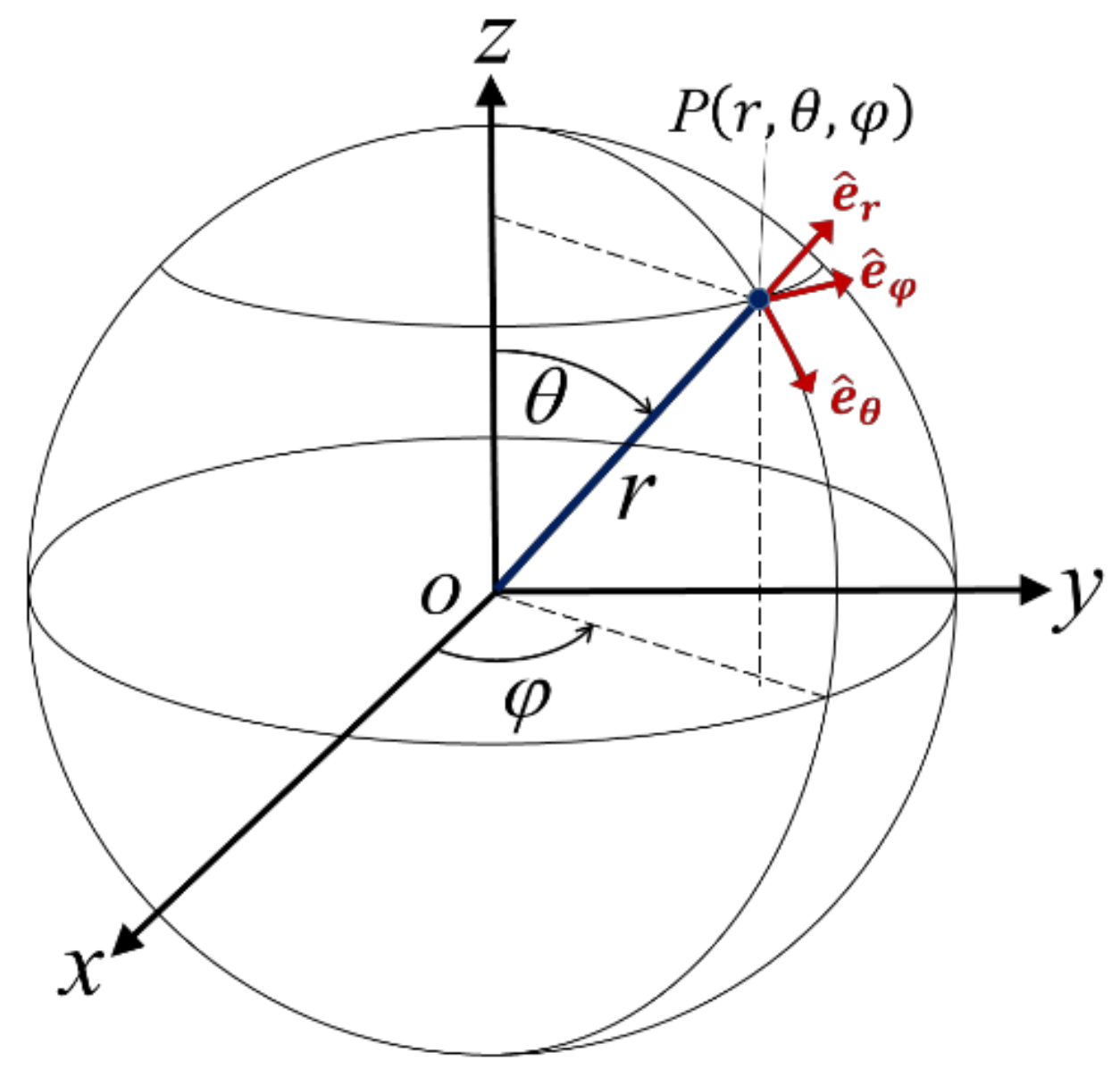

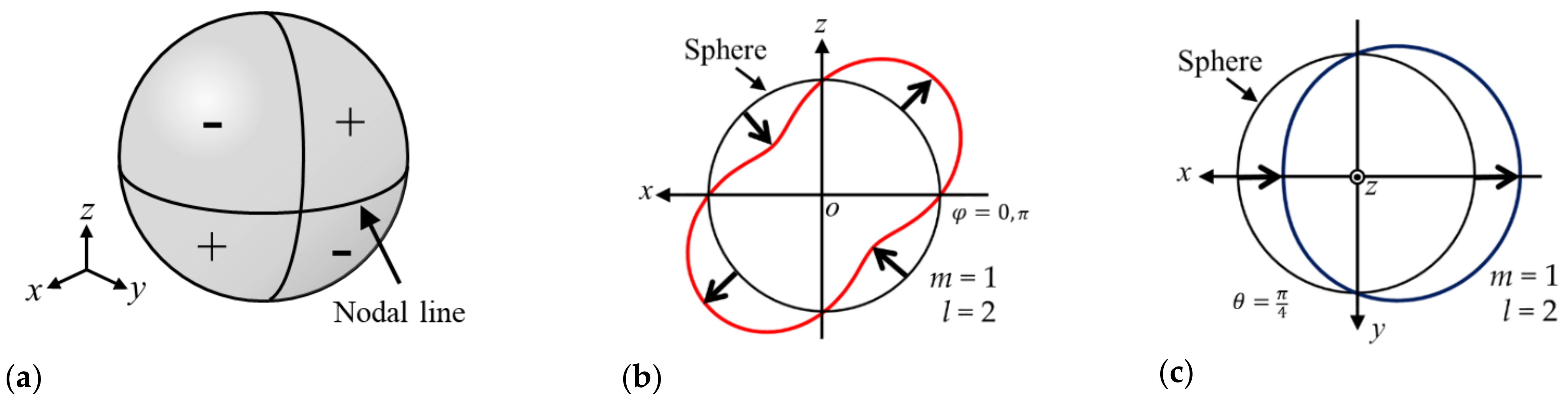

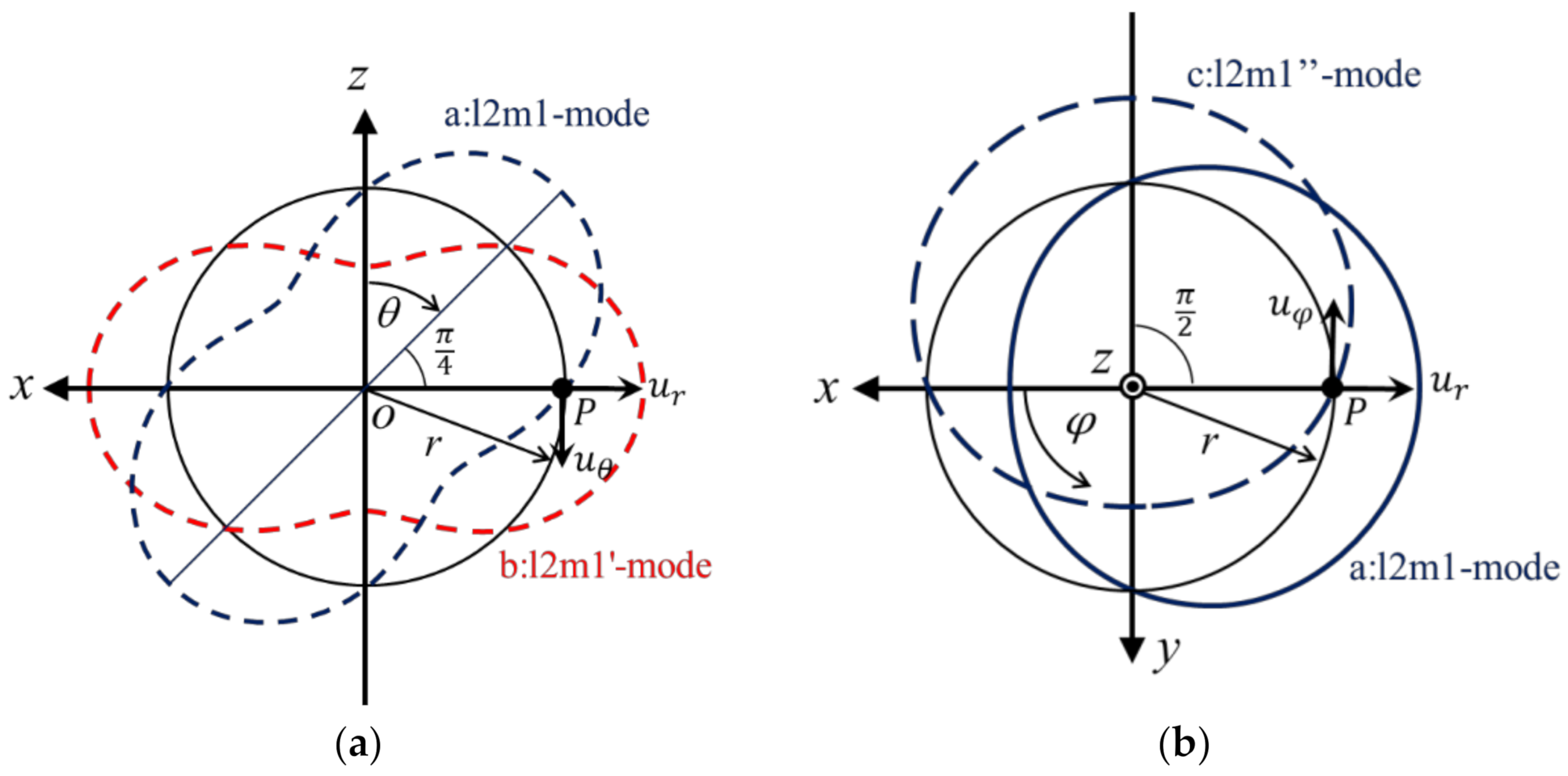

2.1. Natural Vibration Mode of a Sphere

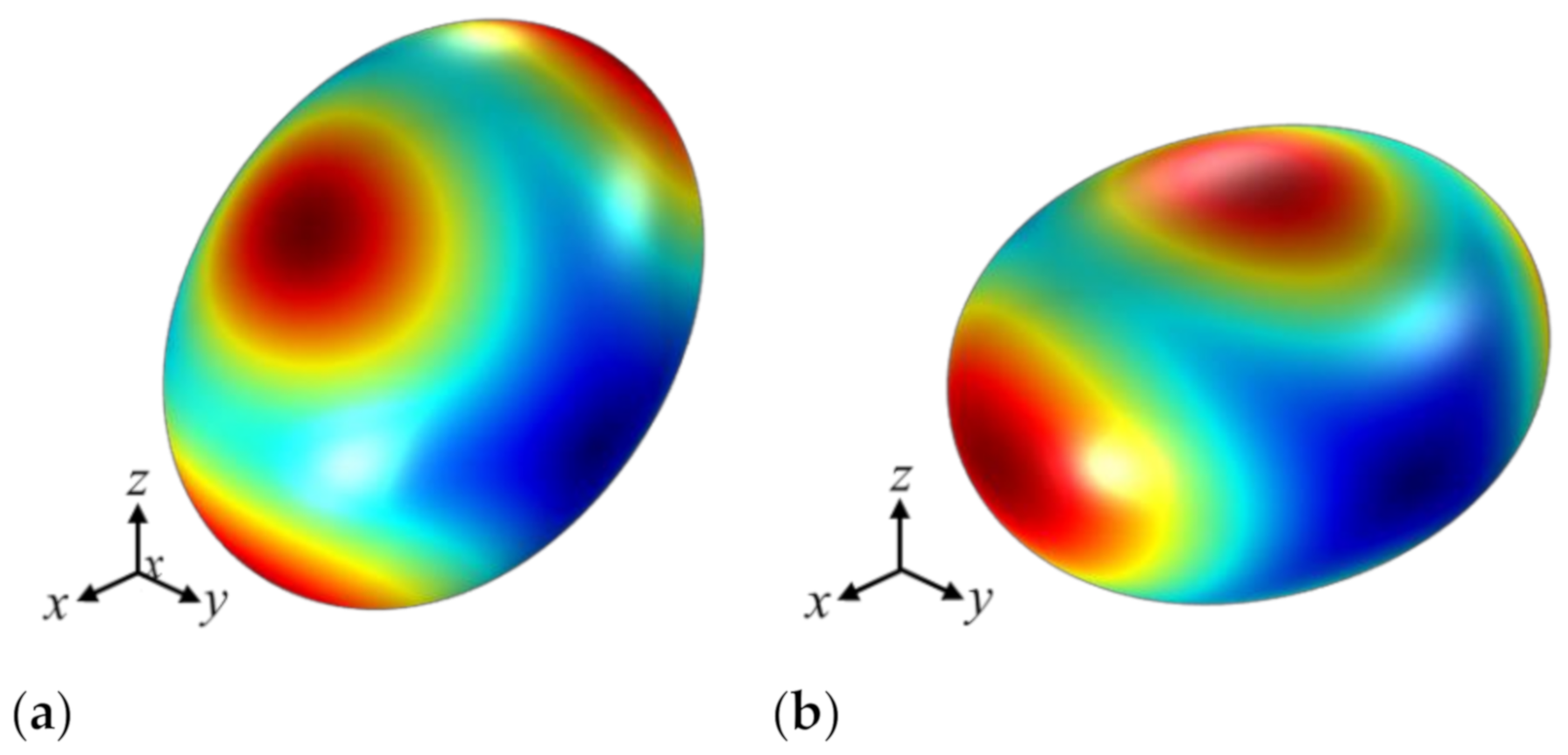

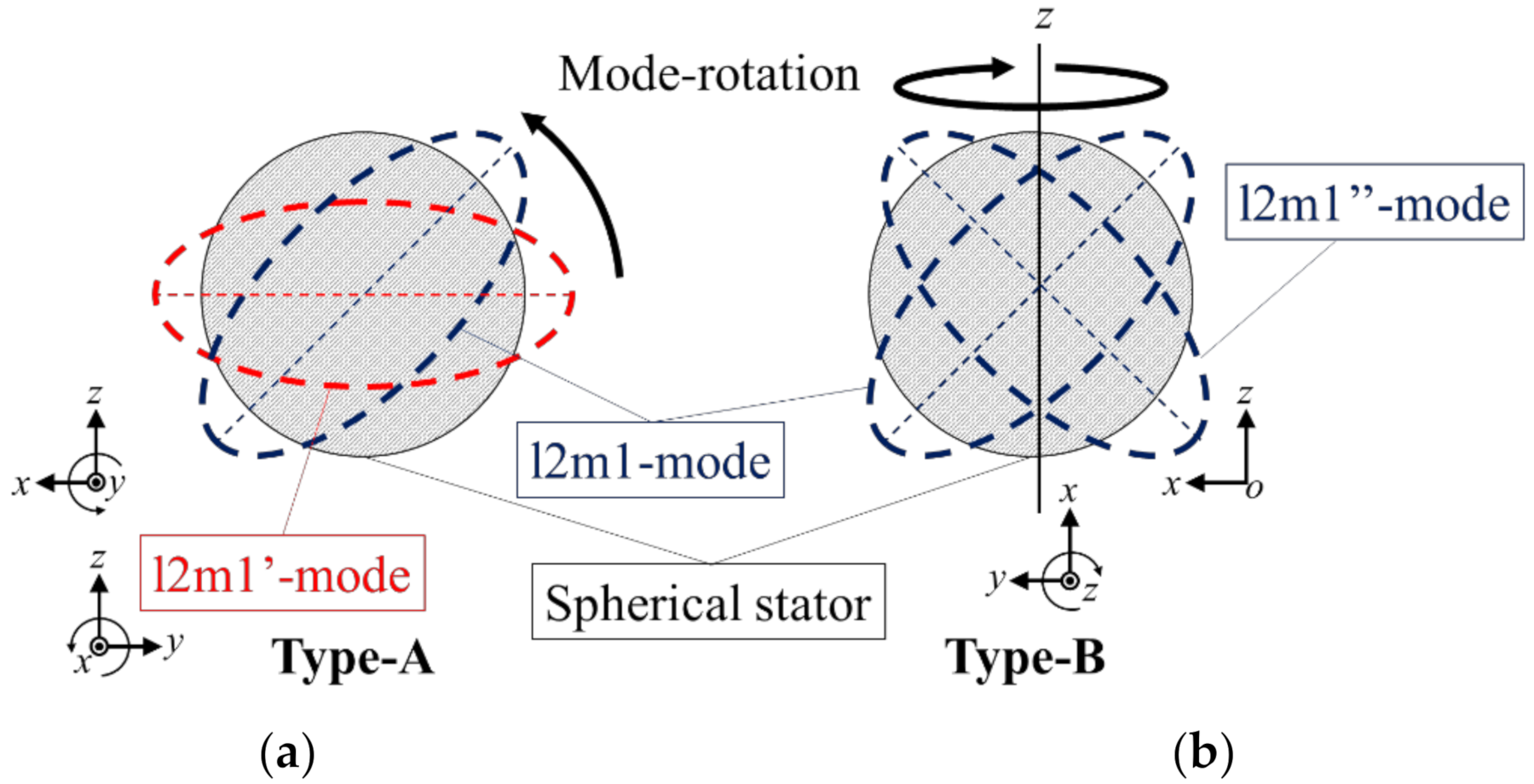

2.2. Vibration Mode Rotation

3. Vibration Analysis

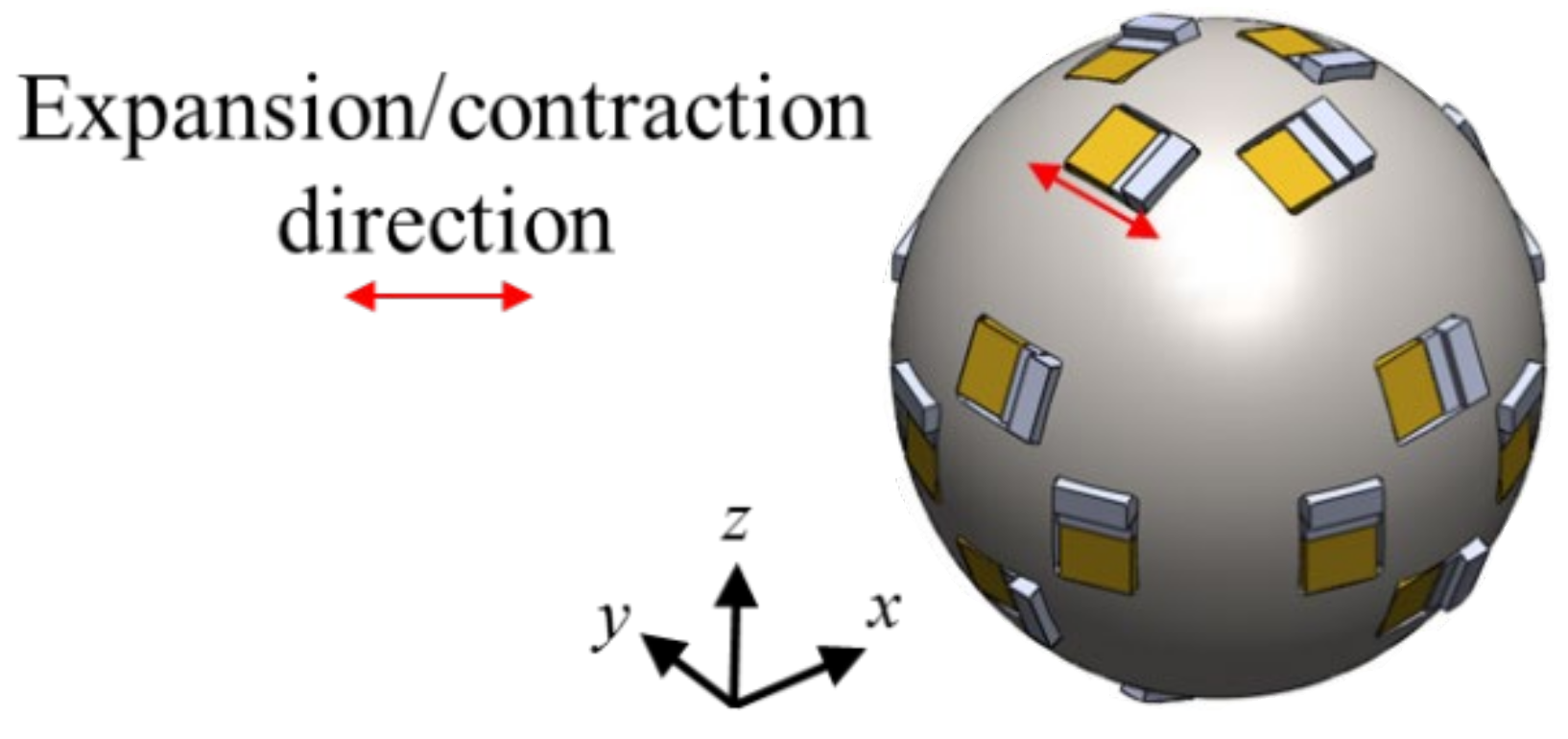

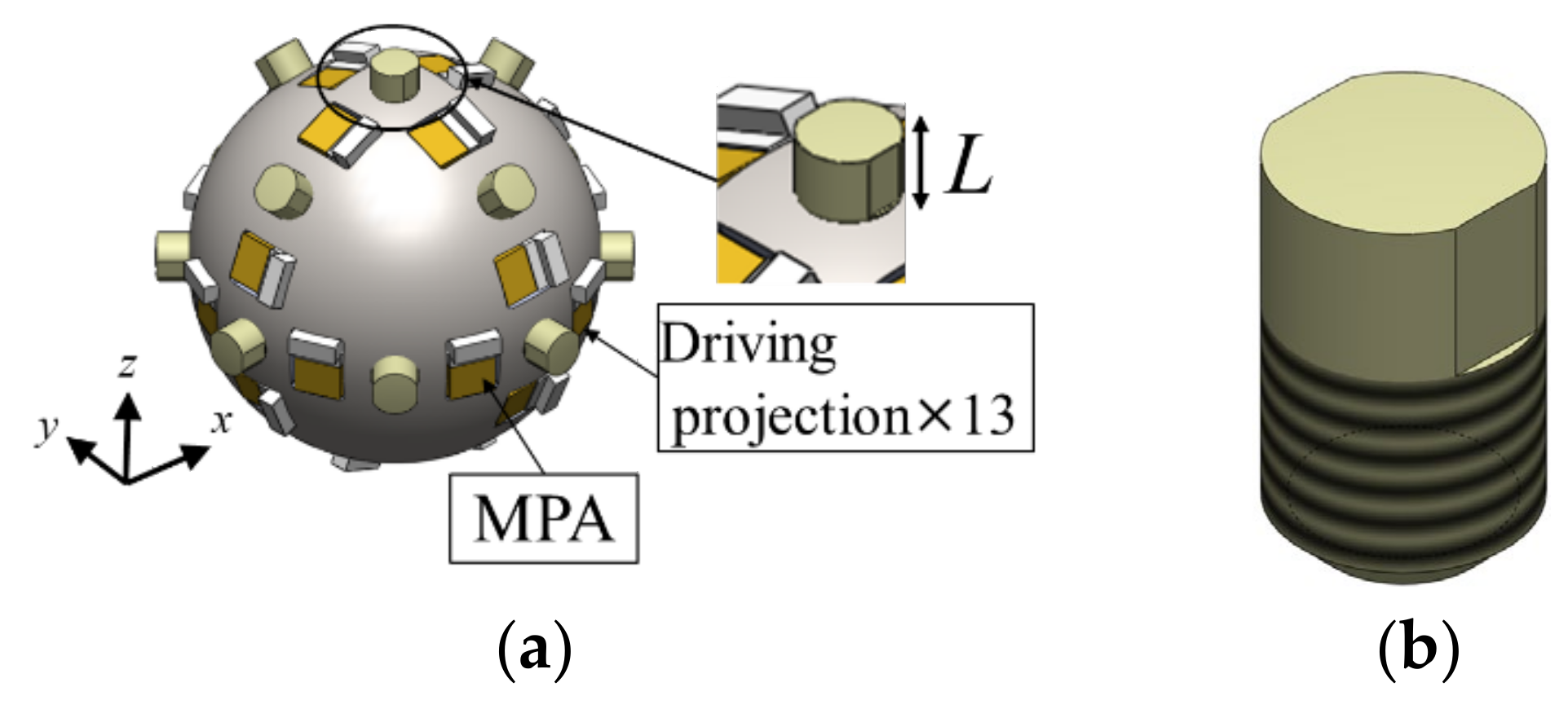

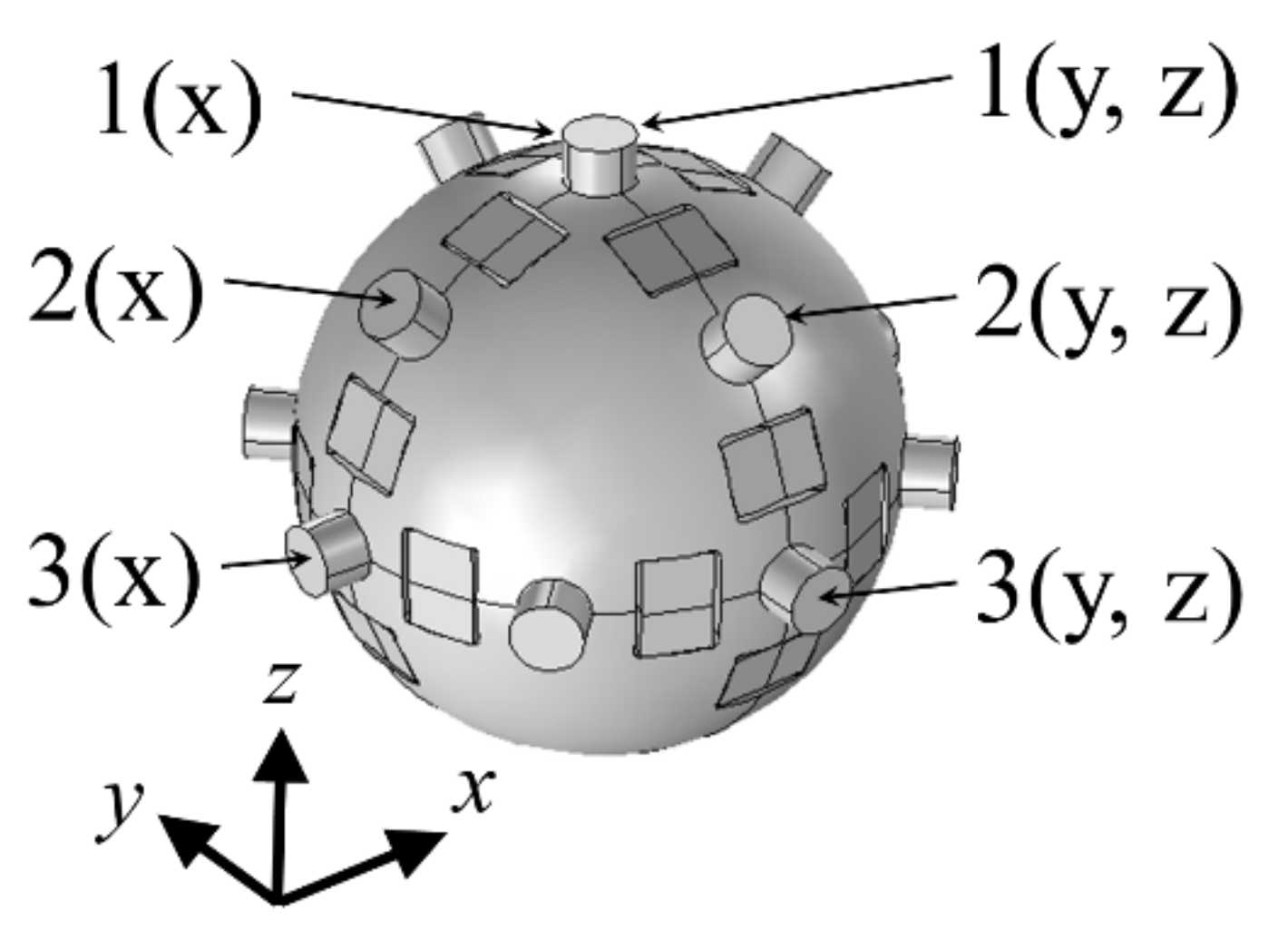

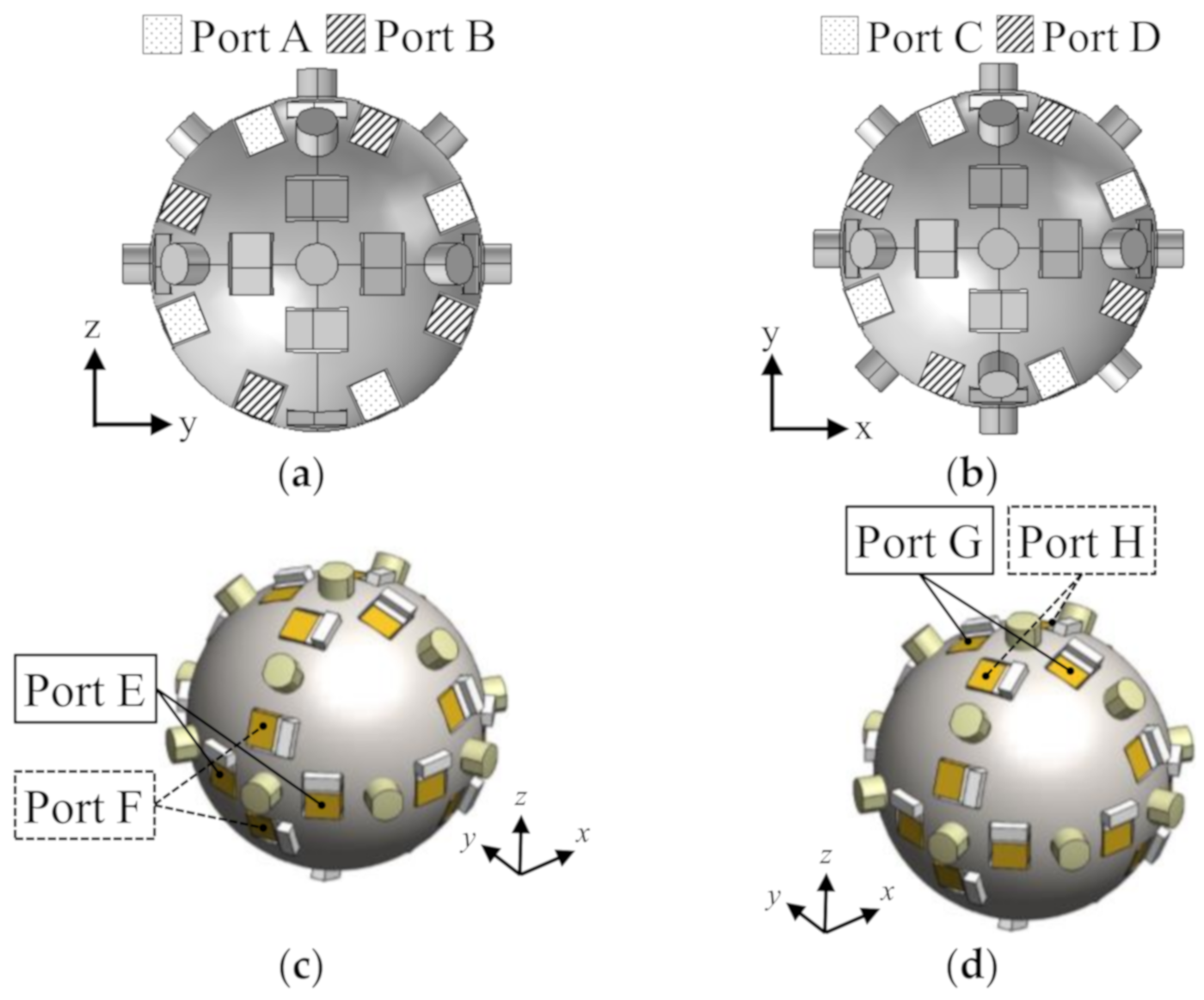

3.1. Stator Construction

3.2. Effect of Driving Projection

4. Thrust Generation Analysis

5. Performance Evaluation of MDOF-USM Using Spherical Stator

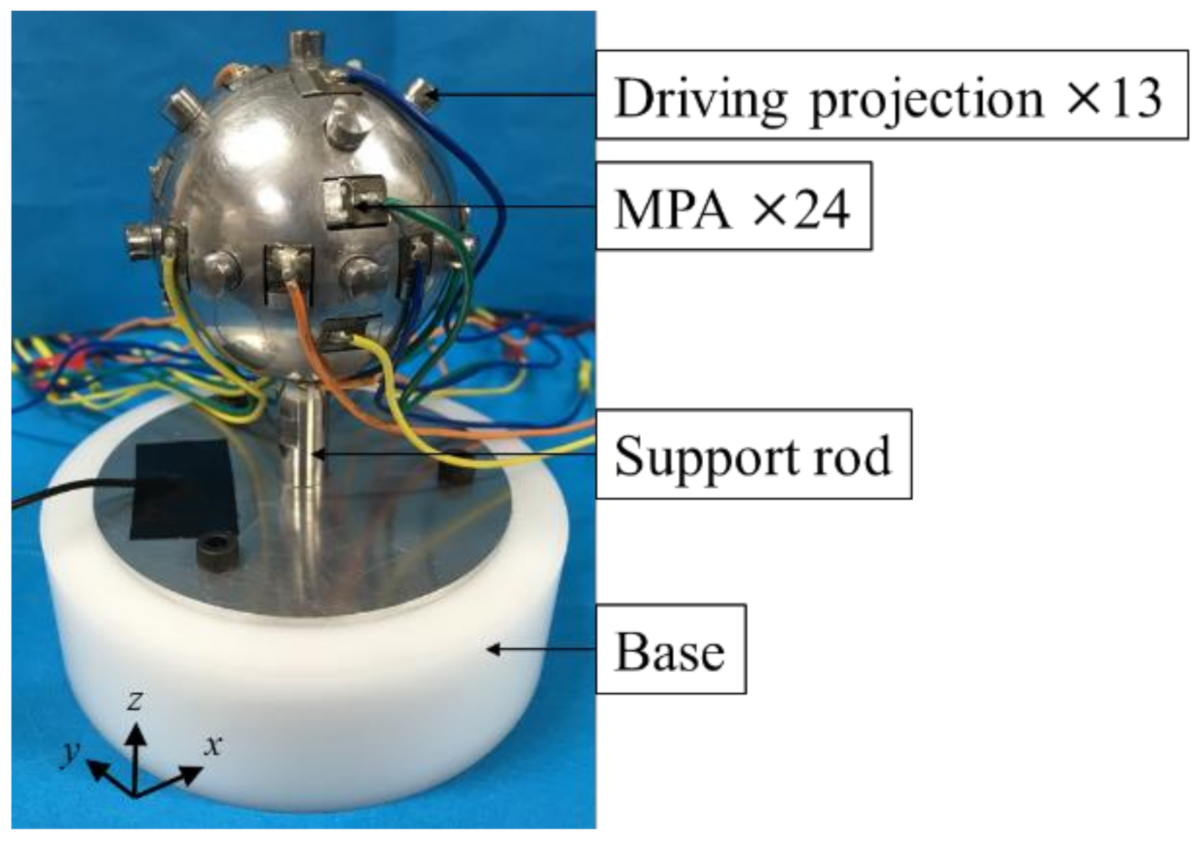

5.1. Construction of Prototype Spherical Stator

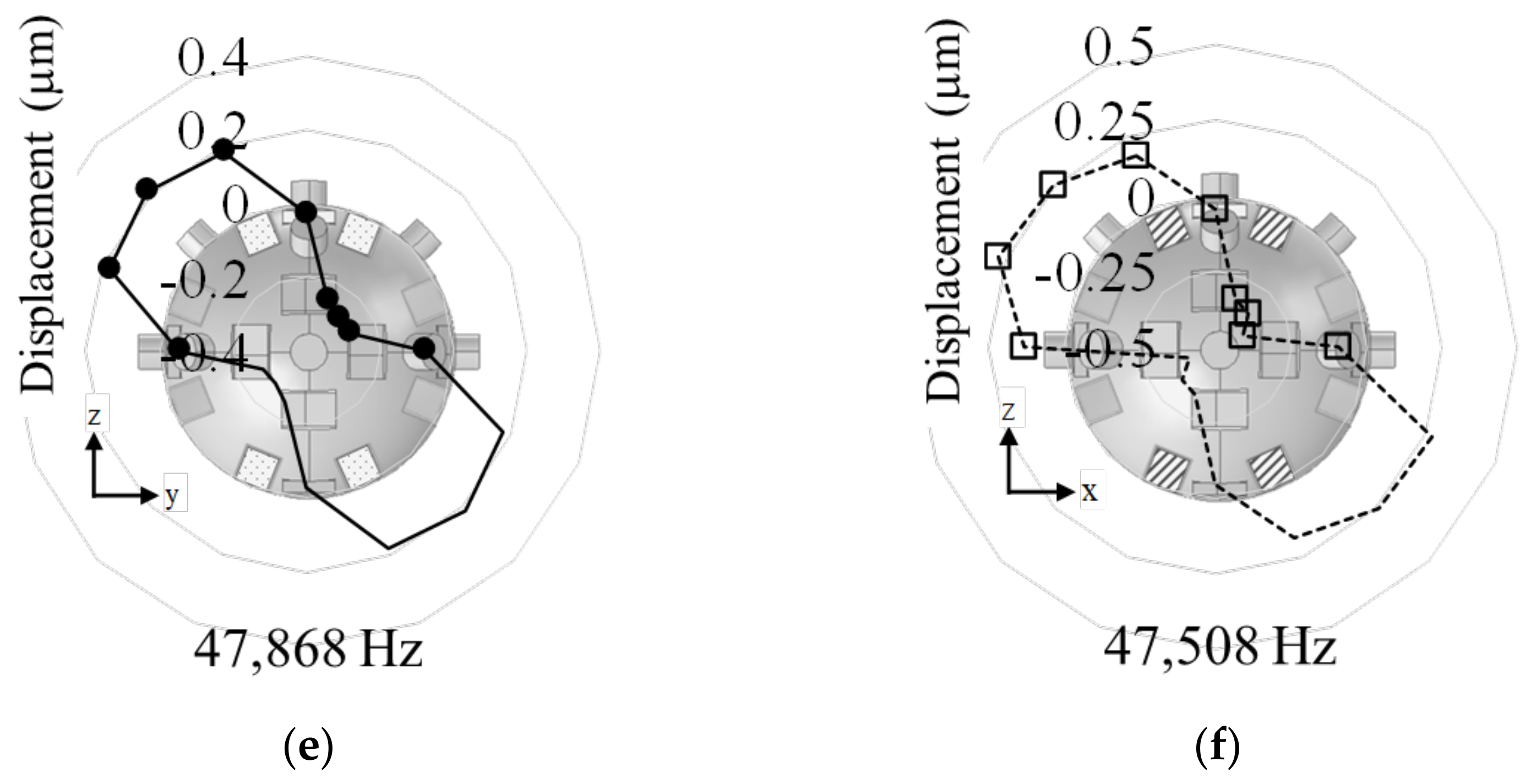

5.2. Displacement Measurement

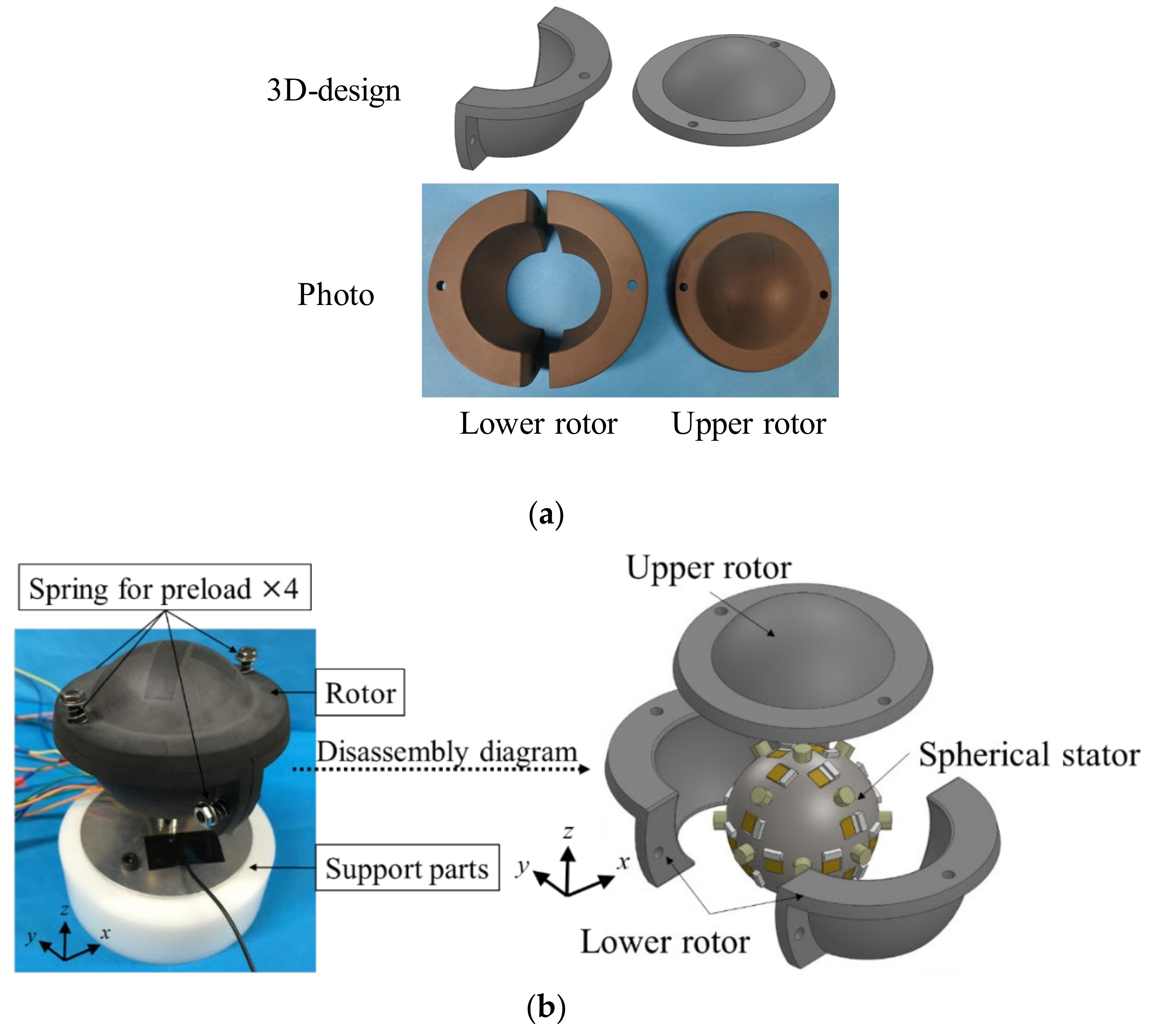

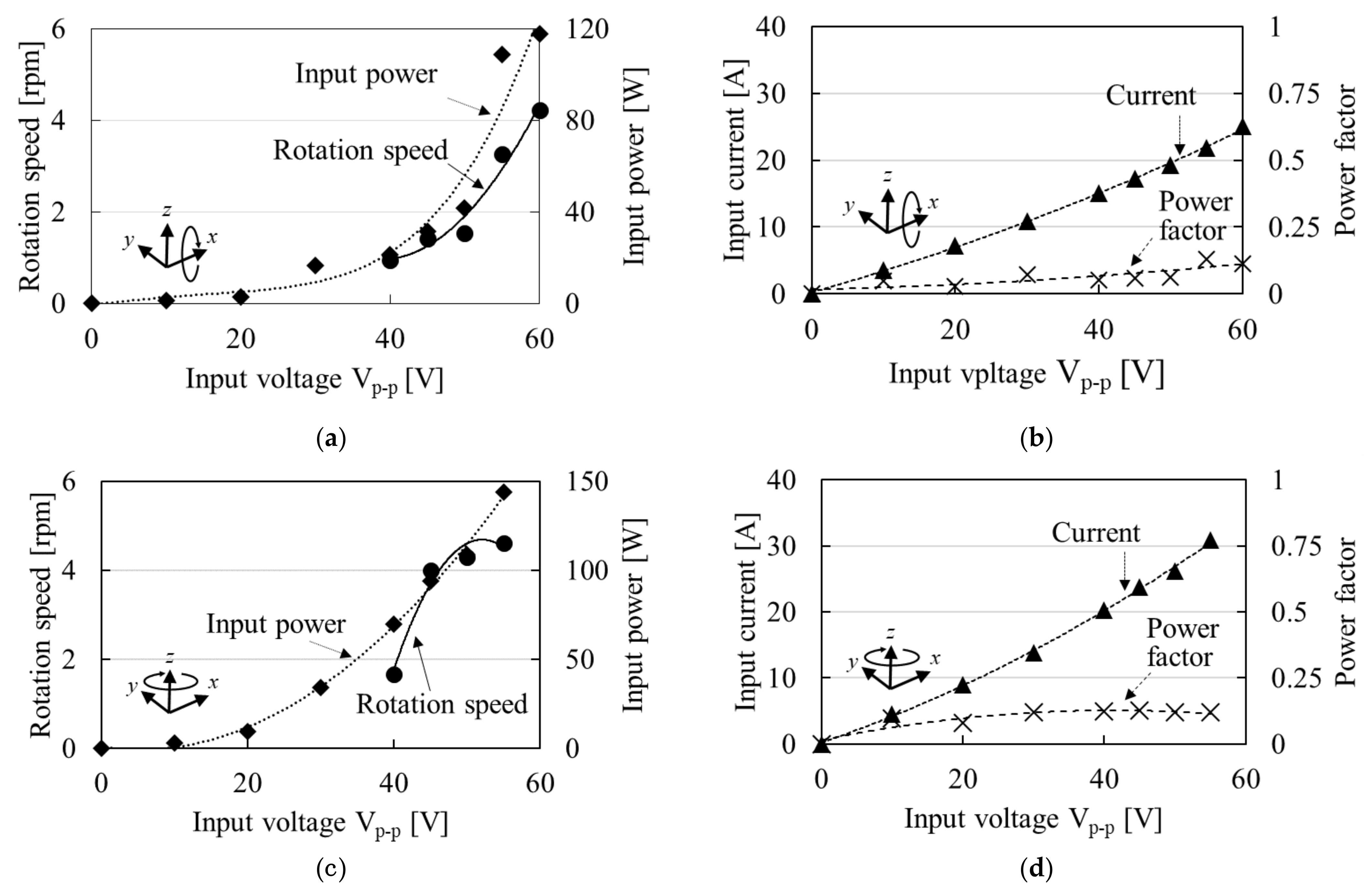

5.3. Characteristic of MDOF-USM Using Spherical Stator

6. Summary and Conclusions

- The spherical stator extended for 3-DOF rotation was designed. Twenty-four MPAs were embedded on the stator to excite three sets of combinations of l2m1-mode and its orthogonal mode.

- The surface of the stator could not be used for thrust output by friction force directly because the surface was not smooth with obstacles such as MPAs, their fixture, and their wiring. Hence, projections were arranged as driving parts on the spherical stator to output thrust force. The shape of the driving projection was designed by FEA, and its suitable dimension was clarified.

- By analyzing the electromechanical equivalent circuit of an ultrasonic actuator on ECS, the contribution of each driving projection to each axis rotation was calculated in the case of two types of vibration mode rotation, Type-A and Type-B.

- The spherical stator was fabricated, and the l2m1-modes and its orthogonal modes excited from each electrical port were confirmed. From the measurement results of the vibration displacement, the vibration mode rotations of Type-A and Type-B were suitable for x(y)-axis rotation and z-axis rotation, respectively.

- The MDOF-USM using the metal spherical stator was made. The rotor formed from three parts was devised for enfolding the stator and applying a preload from plural directions. The rotations around three axes were confirmed. However, the measured maximum rotation speed was low, and output torque was too small to measure, although input power was too much.

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

Appendix A

- Next, the terminals of the normal component and tangential component on the equivalent circuit in Figure A1 were short-circuited to consider only stator without any load.

- The simulated elliptical displacement shown in Figure 8 was reproduced by the instantaneous value of charges at P and Q on the equivalent circuit. Circuit constants and voltage sources were adjusted by trial-and-error until the reproduced displacement was similar to the simulated one. The magnitude and the oblateness of the elliptical displacement were reproduced by the magnitudes of input voltages of Vin1 and Vin2, and the tilt angle of the elliptical displacement was reproduced by the phase difference of both input voltages. In addition, the values of equivalent circuit elements were assumed so that the stator had high output mechanical impedance.

- The terminal of the tangential component on the circuit was opened for generating the maximum thrust, but the normal component circuit was terminated by serially connected elements DN, 1/KN about the rotor. Because the stator had high output mechanical impedance, the preload FC can be set freely, and the influence on the stator by the preload and the load was supposed to be negligibly small.

- Finally, the transient analysis of the equivalent circuit was carried out on ECS, and then the mean value of the generated maximum thrust in steady-state (fT) was calculated.

| Symbol | Mean | Value |

| Vin1 | Applied voltage | 4~850 VP-P |

| Vin2 | Applied voltage | 3~530 VP-P |

| theta | Phase between Vin1 and Vin2 | −90° or 90° |

| Fc | Preload | 30 V |

| A | Force factor | 5.75 N/V |

| Cd | Capacitance of vibrator | 0.75 μF |

| Dm | Damping coefficient of vibrator | 150 N·s/m |

| Mo | Mass of vibrator | 8 × 10−3 kg |

| Km | Stiffness of vibrator | 93 × 106 N/m |

| DP | Damping coefficient of preload element | 1.0 × 103 N·s/m |

| MP | Mass of preload element | 0.2 kg |

| KP | Spring constant of preload element | 0.169 N/m |

| KN | Normal spring constant of contact surface | 1.23 × 109 N/m |

| DN | Normal damping coefficient of contact surface | 100 N·s/m |

| MT | Equivalent mass of rotor | 0.49 kg |

| KT | Tangential spring constant of contact surface | 1.23 × 1010 N/m |

| Dloss | Loss of rotor | ∞ |

| μ | Frictional coefficient | 1 |

| f | Driving frequency | 23.5 kHz |

References

- Yano, T.; Kaneko, K. Basic Consideration of Actuators with Multi DOF Having an Identical Center of Rotation. J. Robot. Mechatron. 1995, 7, 458–466. [Google Scholar] [CrossRef]

- Wang, J.; Mitchell, K.; Jewell, G.W.; Howe, D. Multi-degree-of-freedom spherical permanent magnet motors. In Proceedings of the IEEE International Conference on Robotics and Automation (ICRA 2001), Seoul, Korea, 21–26 May 2001; pp. 1798–1805. [Google Scholar]

- Kaneko, K.; Yamada, I.; Itao, K. A Spherical DC Servo Motor with Three Degree of Freedom. J. Dyn. Syst. Meas. Control 1989, 111, 398–402. [Google Scholar] [CrossRef]

- Yano, T. Development of a Synchronous Motor with Three Degrees of Freedom, Theory and Practice of Robots and Manipulators. In Proceedings of the ROMANSY 10: The Tenth CISM-IFToMM Symposium, Gdansk, Poland, 12–15 September 1994. [Google Scholar]

- Kumagai, M. Development and control of a three dof spherical induction motor. In Proceedings of the IEEE International Conference on Robotics and Automation (ICRA), Karlsruhe, Germany, 6–10 May 2013. [Google Scholar]

- Yano, T. Basic characteristics of a hexahedron-octahedron based spherical stepping motor. In Proceedings of the SPEEDAM 2010, Pisa, Italy, 14–16 June 2010. [Google Scholar]

- Li, Z.; Chen, Q.; Guo, P.; Wang, Q. Vibration mode analysis of multi-degree-of-freedom permanent magnet synchronous motor. J. Vibroeng. 2018, 20, 2966–2977. [Google Scholar] [CrossRef]

- Maeda, S.; Hirata, K.; Niguchi, N. Characteristics Verification of an Independently Controllable Electromagnetic Spherical Motor. Sensors 2014, 14, 10072–10080. [Google Scholar] [CrossRef] [PubMed]

- Nishiura, Y.; Hirata, K.; Sakaidani, Y. 3-DOF Outer Rotor Electromagnetic Spherical Actuator. Int. J. Autom. Technol. 2016, 10, 591–598. [Google Scholar] [CrossRef]

- Takemura, K.; Maeno, T. Design and Control of an Ultrasonic Motor Capable of Generating Multi-DOF Motion. IEEE/ASME Trans. Mechatron. 2001, 6, 499–506. [Google Scholar] [CrossRef]

- Nishiguchi, S.; Ogawa, K.; Yoshikawa, Y.; Chikaraishi, T.; Hirata, O.; Ishiguro, H. Theatrical approach: Designing human-like behaviour in humanoid robots. Robot. Auton. Syst. 2017, 89, 158–166. [Google Scholar] [CrossRef]

- Reingold, E.M. Eye tracking research and technology: Towards objective measurement of data quality. Vis. Cogn. 2014, 22, 635–652. [Google Scholar] [CrossRef]

- Oohashi, T.; Toyama, S. Development of spherical ultrasonic motor for space. Appl. Mech. Mater. 2014, 555, 26–31. [Google Scholar] [CrossRef]

- Nishizawa, U.; Oohashi, T.; Toyama, S. Evaluation of spherical ultrasonic motor for space in low temperature condition. J. Vibroeng. 2017, 19, 5170–5181. [Google Scholar] [CrossRef]

- Abe, T.; Moriya, T.; Irie, T.; Sato, M.; Takeuchi, S. Experimental study of the Π-shaped coiled stator ultrasound motor. Jpn. J. Appl. Phys. 2014, 53, 07KE15. [Google Scholar] [CrossRef]

- Toyama, S.; Sugitani, S.; Zhang, G.; Miyatani, Y.; Nakamura, K. Multi Degree of Freedom Spherical Ultrasonic Motor. In Proceedings of the 1995 IEEE International Conference on Robotics and Automation, Nagoya, Japan, 21–27 May 1995. [Google Scholar]

- Amano, T.; Ishii, T.; Nakamura, K.; Ueha, S. An ultrasonic actuator with multi-degree of freedom using bending and longitudinal vibrations of a single stator. In Proceedings of the 1998 IEEE Ultrasonics Symp, Sendai, Japan, 5–8 October 1998. [Google Scholar]

- Takemura, K.; Kojima, N.; Maeno, T. Development of a Bar-Shaped Ultrasonic Motor for Three-Degrees of Freedom Motion. In Proceedings of the 4th International Conference on Motion and Vibration Control, Zurich, Switzerland, 25–28 August 1998. [Google Scholar]

- Yun, C.-H.; Niwano, S.; Friend, J.R.; Nakamura, K.; Ueha, S. Support Mechanism for the Ball Rotor in the Three-Degree-of-Freedom Ultrasonic Motor. Jpn. J. Appl. Phys. 2003, 42, 3000–3001. [Google Scholar] [CrossRef]

- Aoyagi, M.; Nakajima, T.; Tomikawa, Y.; Takano, T. Examination of Disk-Type Multidegree-of-Freedom Ultrasonic Motor. Jpn. J. Appl. Phys. 2004, 43, 2884–2890. [Google Scholar] [CrossRef]

- Lu, B.; Aoyagi, M.; Takano, T.; Tamura, H. Examination of Sandwich-Type Multidegree-of-Freedom Spherical Ultrasonic Motor. Jpn. J. Appl. Phys. 2010, 49, 07HE24. [Google Scholar] [CrossRef]

- Khoo, T.F.; Dang, D.H.; Friend, J.; Oetomo, D.; Yeo, L. Triple Degree-of-Freedom Piezoelectric Ultrasonic Micromotor via Flexural-Axial. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2009, 56, 1716–1724. [Google Scholar] [CrossRef]

- Watson, B.; Friend, J.; Yeo, L. Piezoelectric ultrasonic resonant motor with stator diameter less than 250 μm: The Proteus motor. J. Micromech. Microeng. 2009, 19, 022001. [Google Scholar] [CrossRef]

- Aoyagi, M.; Beeby, S.P.; White, N.M. A novel multi-degree-of-freedom thick-film ultrasonic motor. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2002, 49, 151–158. [Google Scholar] [CrossRef]

- Goda, Y.; Koyama, D.; Nakamura, K. Design of Multi-Degree-of-Freedom Ultrasonic Micromotors. Jpn. J. Appl. Phys. 2009, 48, 07GM06. [Google Scholar] [CrossRef]

- Lu, B.; Aoyagi, M.; Tamura, H.; Takano, T. Development of a Novel Rotor-Embedded-Type Multidegree-of-Freedom Spherical Ultrasonic Motor. J. Robot. Mechatron. 2012, 24, 876–883. [Google Scholar] [CrossRef]

- Mizuno, A.; Oikawa, K.; Aoyagi, M.; Tamura, H.; Takano, T. Examination of High-Torque Sandwich-Type Spherical Ultrasonic Motor Using with High-Power Multimode Annular Vibrating Stator. Actuators 2018, 7, 8. [Google Scholar] [CrossRef]

- Nakajima, S.; Kajiwara, H.; Aoyagi, M.; Tamura, H.; Takano, T. Study on spherical stator for multidegree-of-freedom ultrasonic motor. Jpn. J. Appl. Phys. 2016, 55, 07KE18. [Google Scholar] [CrossRef]

- Huang, Z.; Shi, S.; Chen, W.; Wang, L.; Wu, L.; Liu, Y. Development of a novel spherical stator multi-DOF ultrasonic motor using in-plane non-axisymmetric mode. Mech. Syst. Signal Process. 2020, 140, 106658. [Google Scholar] [CrossRef]

- Sakai, S.; Aoyagi, M. Dynamic characteristic analysis of nonresonance-type ultrasonic actuator using electronic circuit simulator. Jpn. J. Appl. Phys. 2015, 54, 07KE14. [Google Scholar] [CrossRef][Green Version]

- Williams, E.G. Fourier Acoustics: Sound Radiation and Nearfield Acoustical Holography; Academic Press: San Diego, CA, USA, 1999; pp. 183–193. [Google Scholar]

- Love, A.E.H. A Treatise on the Mathematical Theory of Elasticity, 2nd ed.; Cambridge University Press: Cambridge, UK, 1944; pp. 236–246. [Google Scholar]

- Tomikawa, Y.; Ogasawara, T.; Takano, T. Ultrasonic motors—Constructions/characteristics/applications. Ferroelectrics 1989, 91, 163–178. [Google Scholar] [CrossRef]

| Density | Mechanical Quality Factor | Coupling Factor | Piezoelectric Strain Constant | Young’s Modulus | Relative Permittivity | Dielectric Dissipation Factor |

|---|---|---|---|---|---|---|

| Qm | K33 | d33 | Y33 | ε33/ε0 | ||

| kg/m3 | - | - | 10−12 m/V | 1010 N/m2 | - | % |

| 7600 | 2000 | 0.69 | 315 | 6.5 | 1460 | 0.4 |

| Mode Rotation Type | Axis of Rotation | Contribution of Driving Projection (%) | ||

|---|---|---|---|---|

| 1(x), 1(y, z) | 2(x), 2(y, z) | 3(x), 3(y, z) | ||

| Type-A | x, y | 100 | 98.1 | 83.7 |

| z | 0 | 88.6 | 100 | |

| Type-B | x, y | 0 | 100 | 68.2 |

| z | 33.8 | 100 | 0 | |

| Mode Rotation Type | Rotation Axis | Drive Port | Influence of Support Rod |

|---|---|---|---|

| Type-A | x | A, B | Large, Uneven |

| z | C, D | Small, Even | |

| Type-B | x | E, F | Large, Uneven |

| z | G, H | Not small, Even |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mizuno, A.; Kajiwara, H.; Tamura, H.; Aoyagi, M. Study on Multidegree-of-Freedom Ultrasonic Motor Using Vibration Mode Rotation of Metal Spherical Stator. Actuators 2022, 11, 27. https://doi.org/10.3390/act11010027

Mizuno A, Kajiwara H, Tamura H, Aoyagi M. Study on Multidegree-of-Freedom Ultrasonic Motor Using Vibration Mode Rotation of Metal Spherical Stator. Actuators. 2022; 11(1):27. https://doi.org/10.3390/act11010027

Chicago/Turabian StyleMizuno, Ai, Hidekazu Kajiwara, Hideki Tamura, and Manabu Aoyagi. 2022. "Study on Multidegree-of-Freedom Ultrasonic Motor Using Vibration Mode Rotation of Metal Spherical Stator" Actuators 11, no. 1: 27. https://doi.org/10.3390/act11010027

APA StyleMizuno, A., Kajiwara, H., Tamura, H., & Aoyagi, M. (2022). Study on Multidegree-of-Freedom Ultrasonic Motor Using Vibration Mode Rotation of Metal Spherical Stator. Actuators, 11(1), 27. https://doi.org/10.3390/act11010027