Model-Based Systems Engineering Approach for the First-Stage Separation System of Launch Vehicle

Abstract

1. Introduction

2. Research Progress

3. The First-Stage Separation System Design Based on MBSE

3.1. The First-Stage Separation System

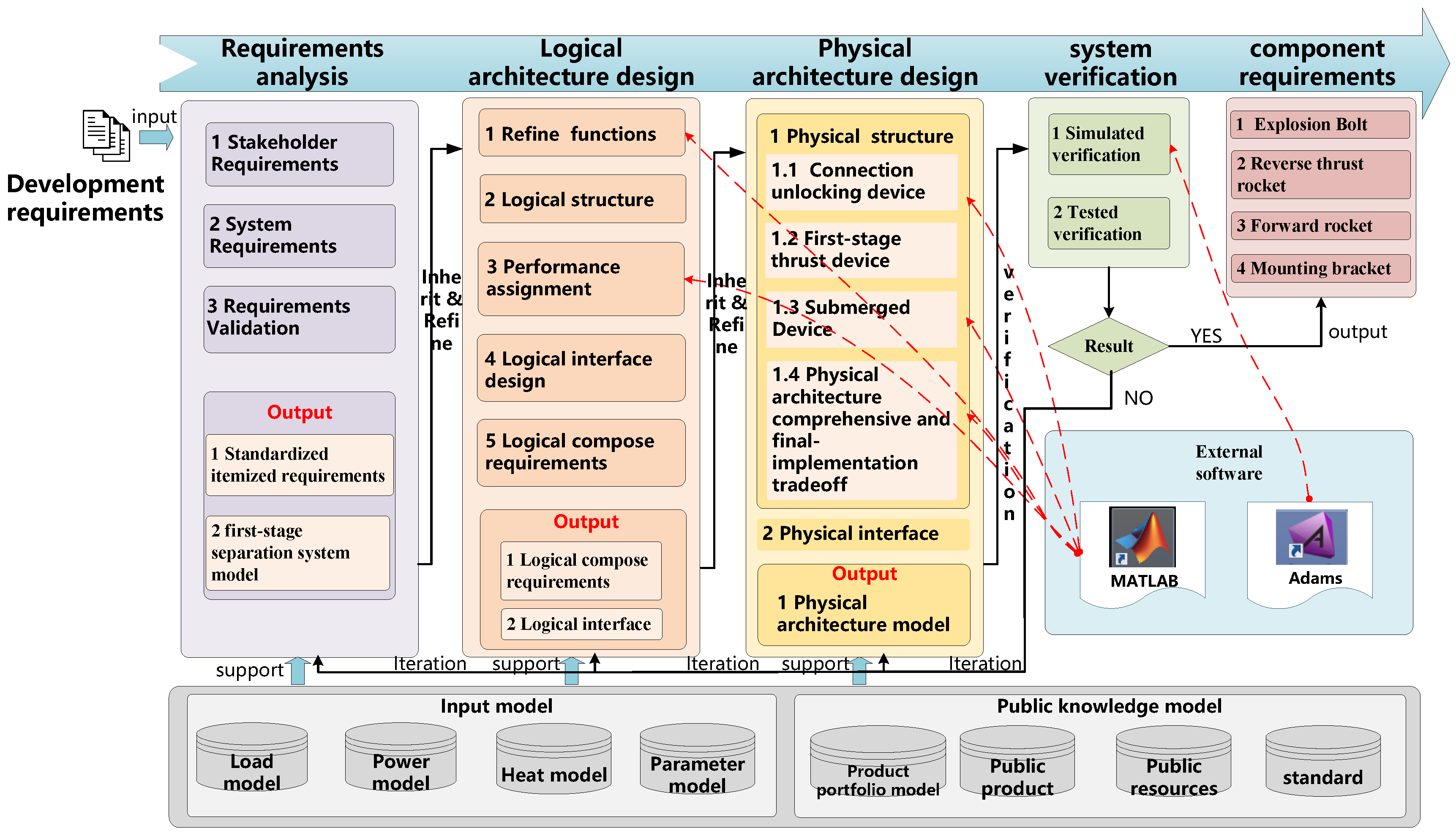

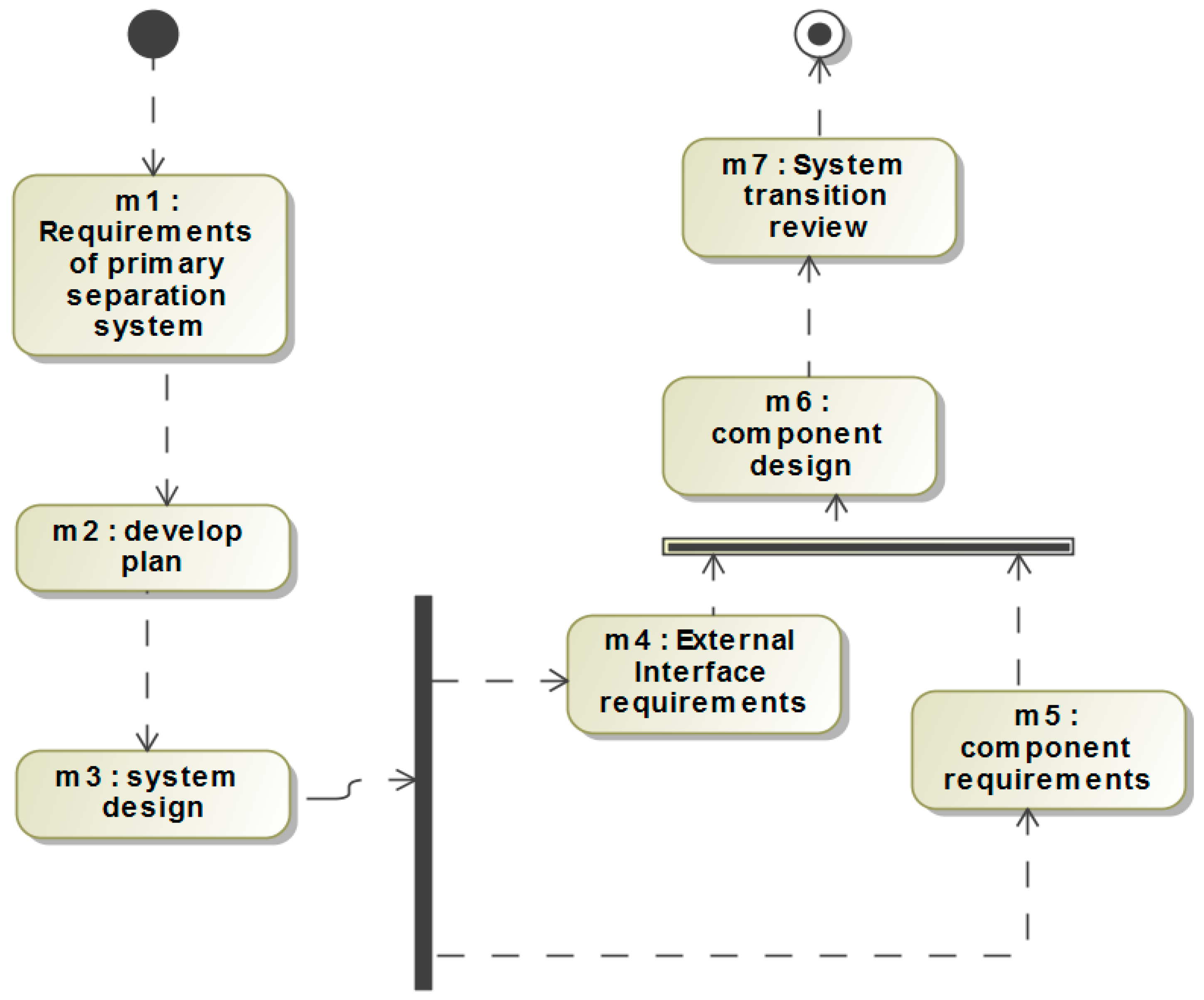

3.2. Modeling Framework of the Separation System Adopting MBSE Approach

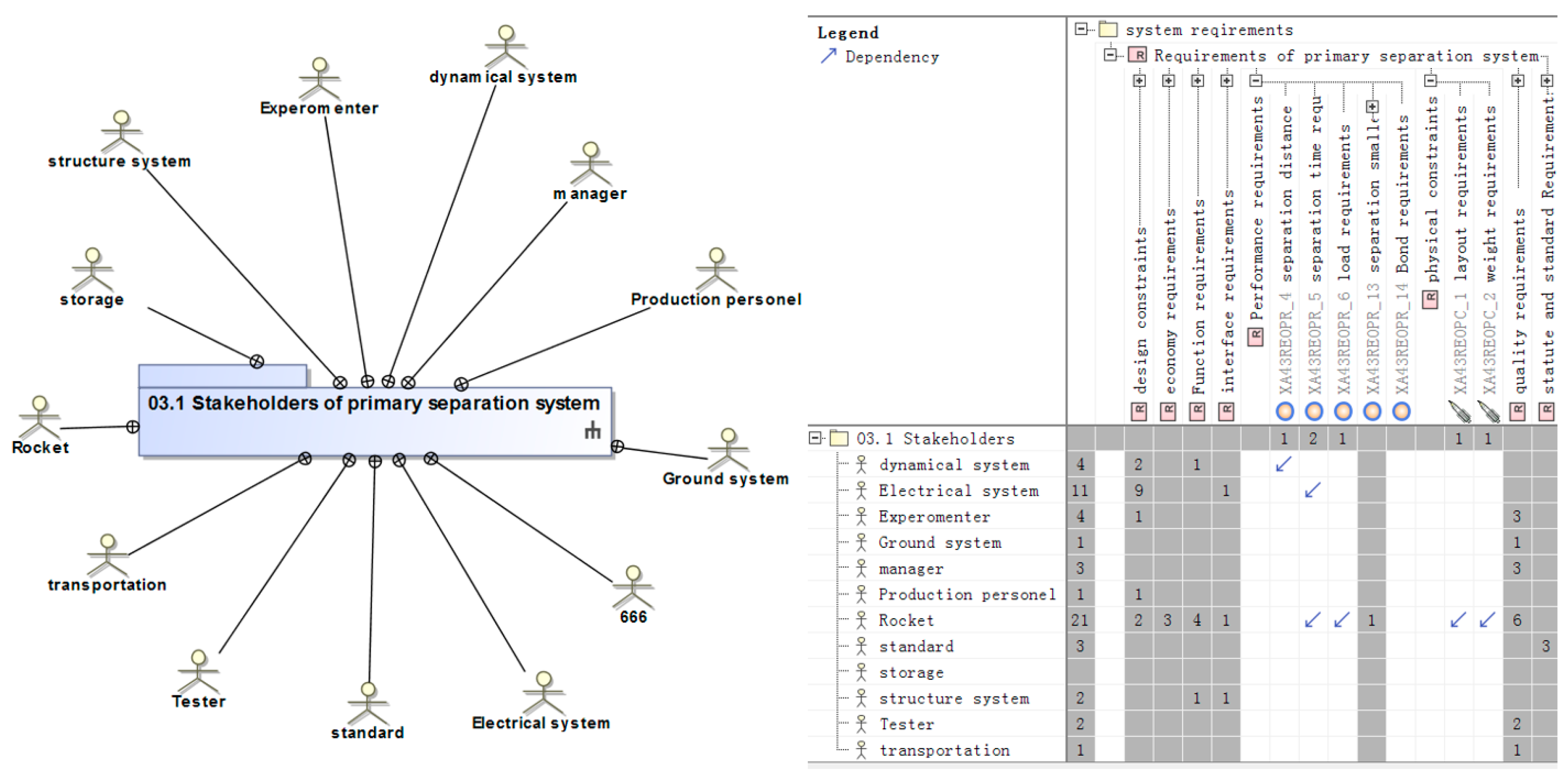

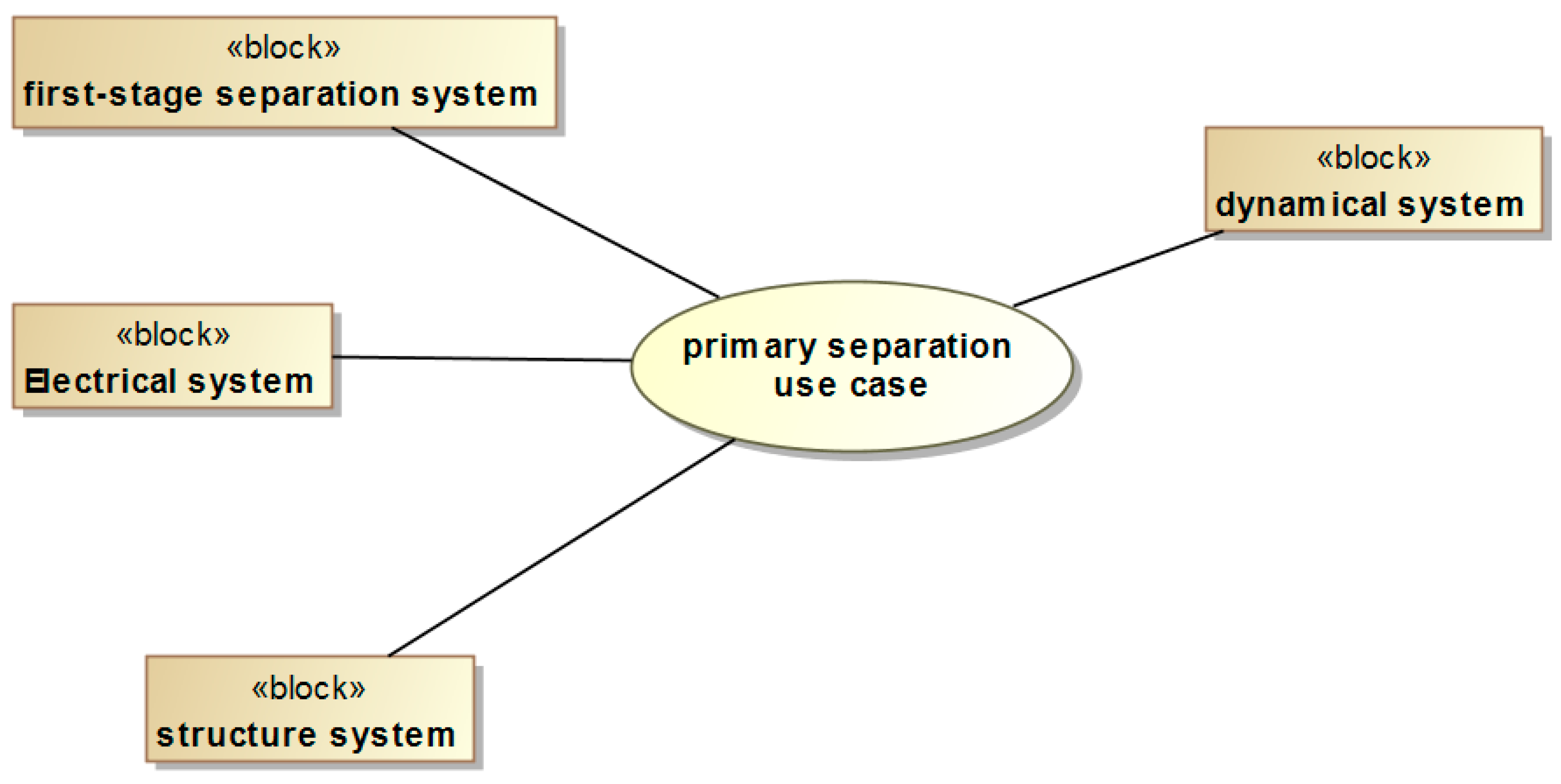

3.3. Requirements Analysis of the First-Stage Separation System

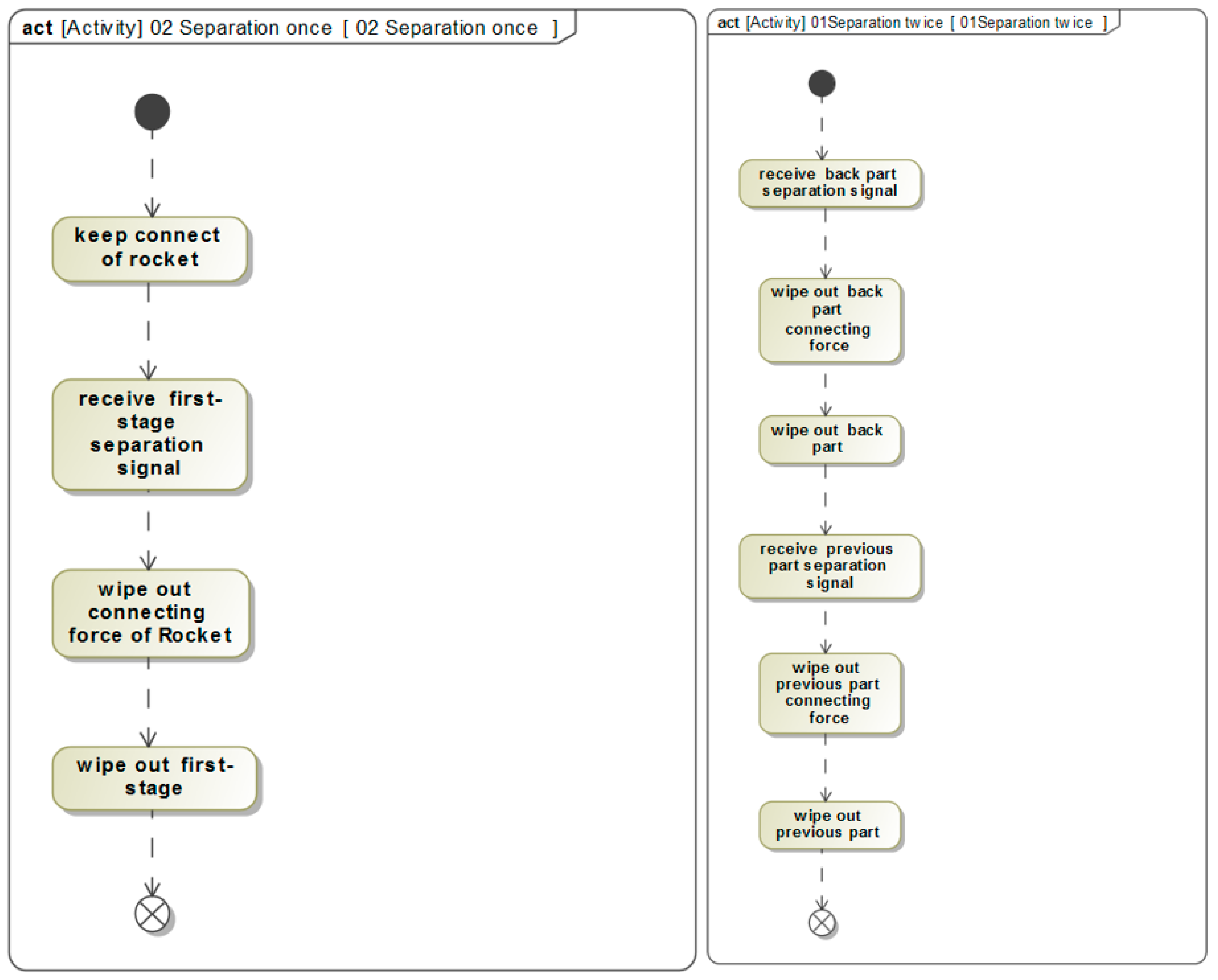

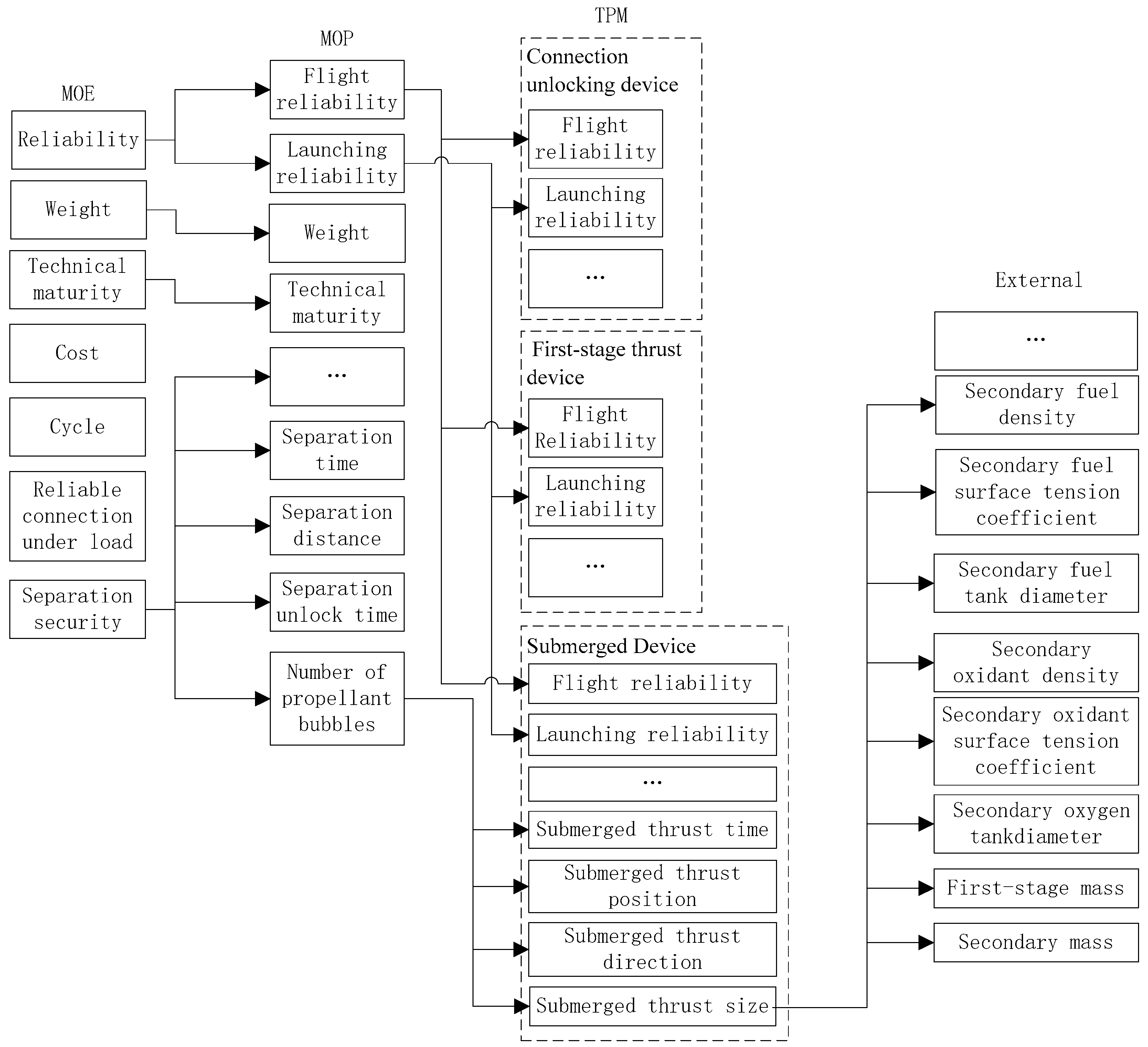

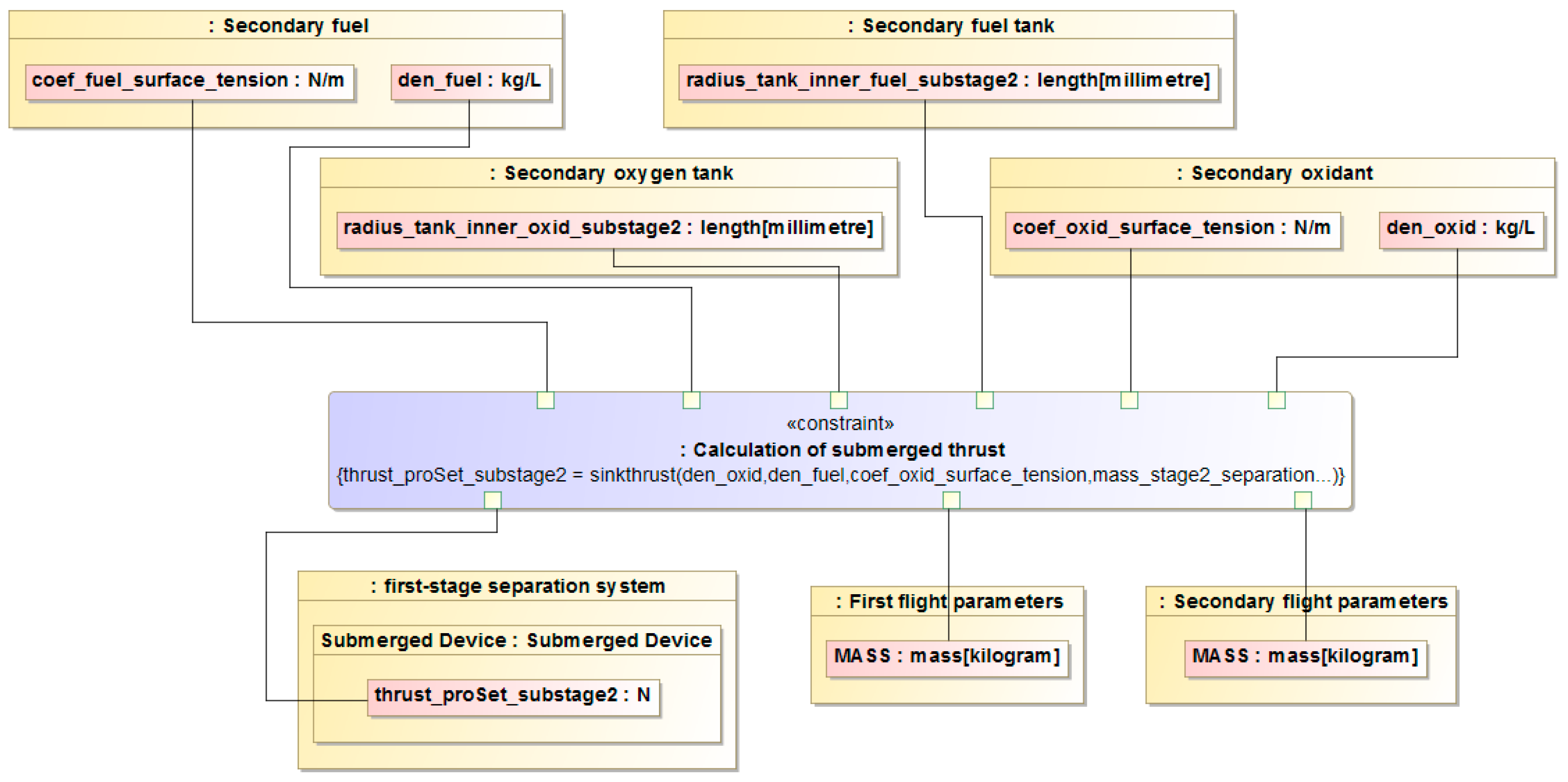

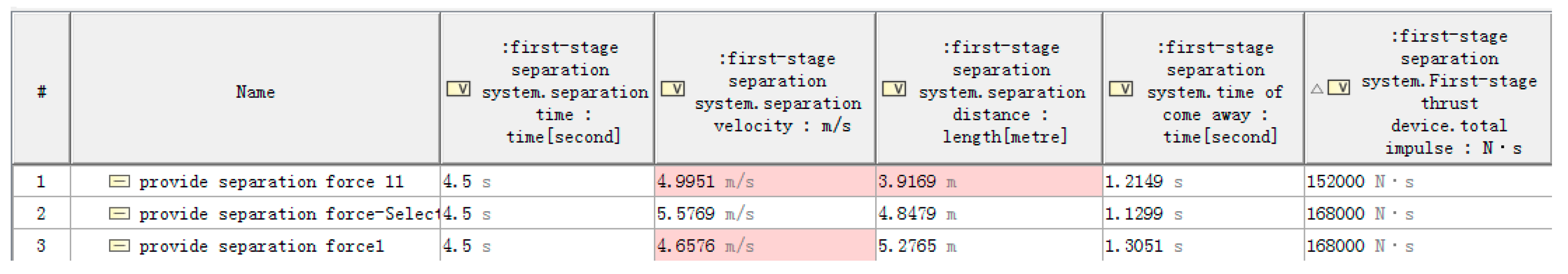

3.4. Logic Architecture Design of the Separation System for Key Parameters

- The connection device needs to provide a connection force greater than 940,286 N.

- The first thrust device needs to provide a total axial impulse greater than 168,000 N/s.

- The device, to ensure propellant sinking to the bottom, should provide an axial thrust force greater than 293 N.

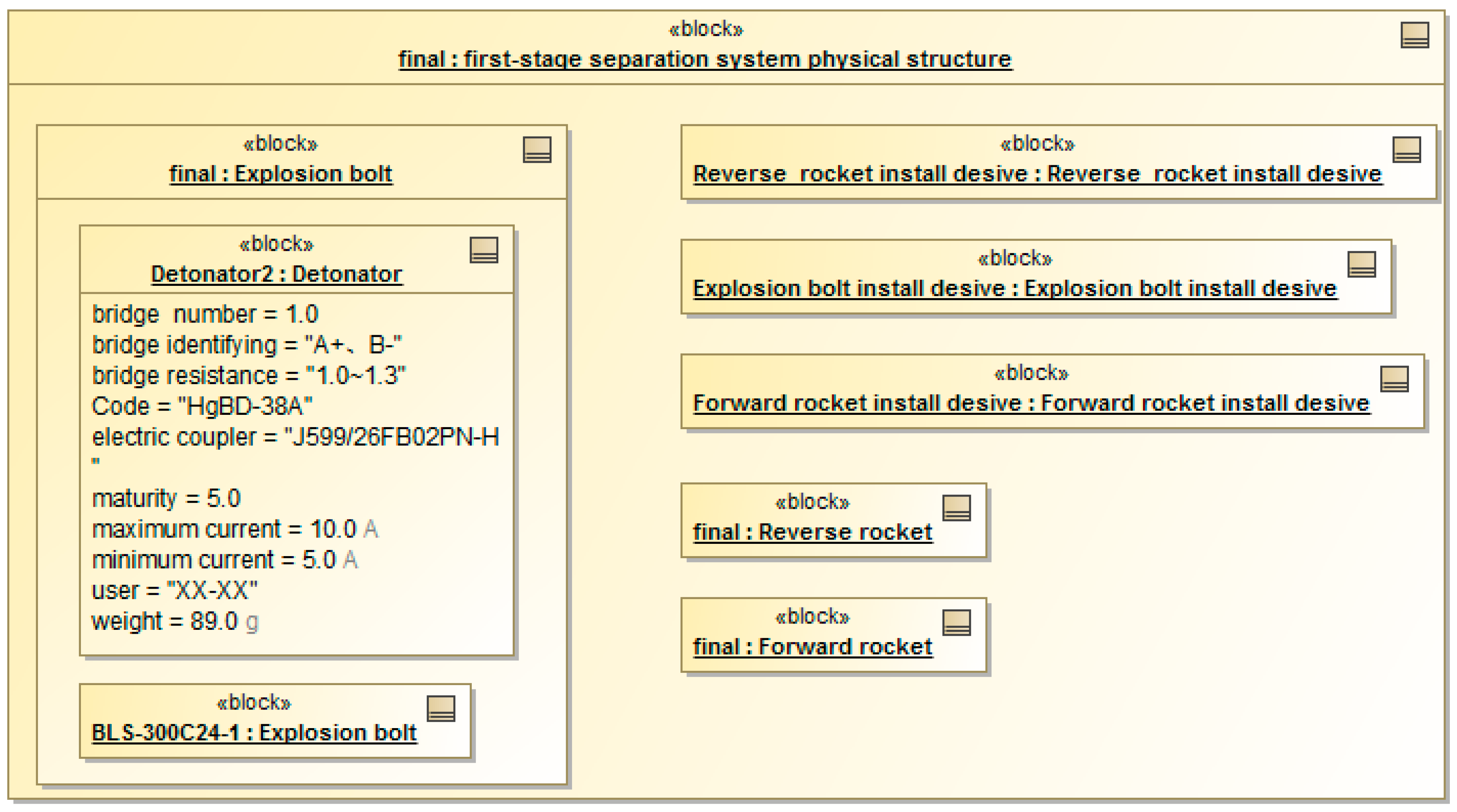

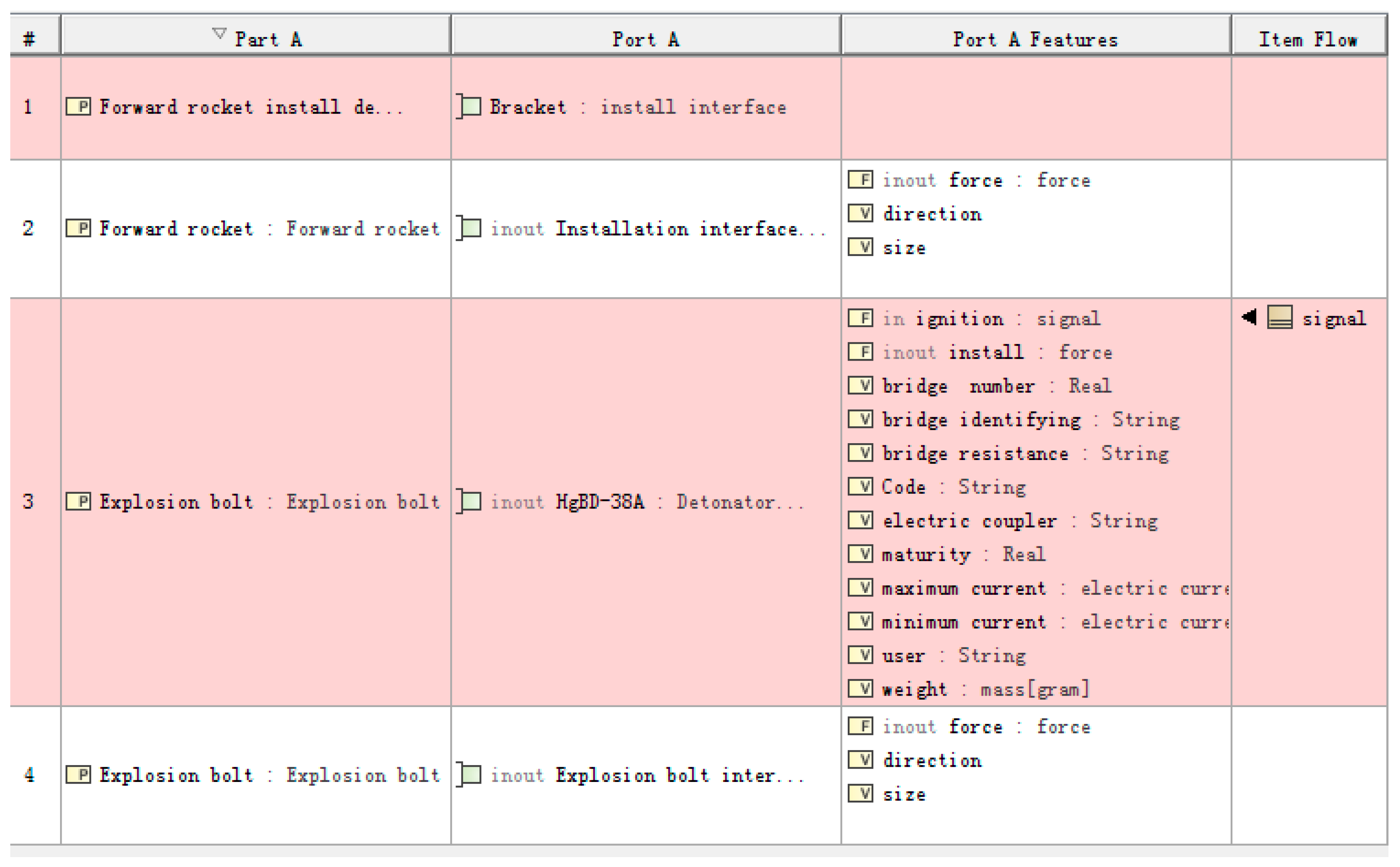

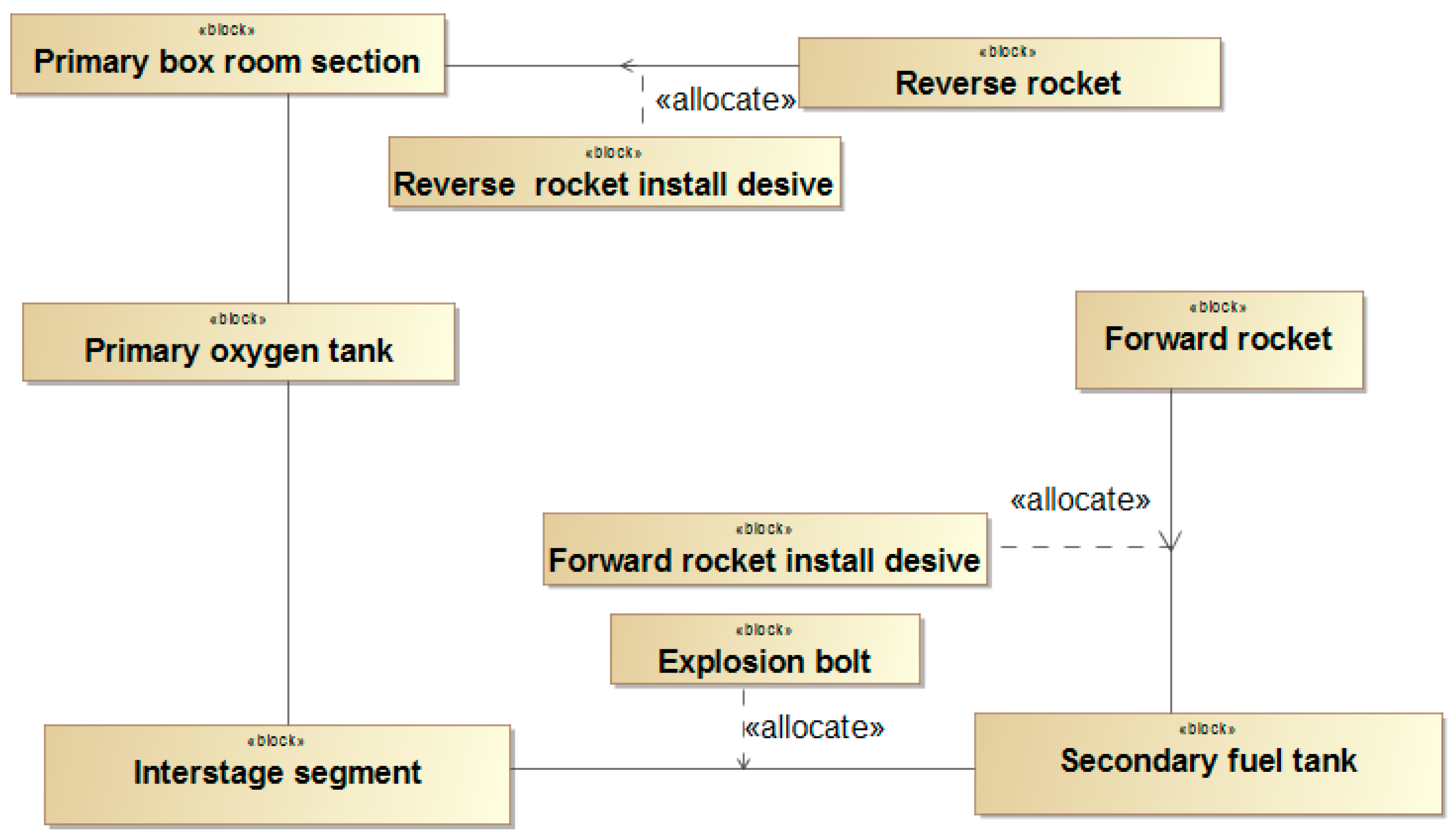

3.5. Physical Architecture Design of the First-Stage Separation System Based on Model Selection Analysis

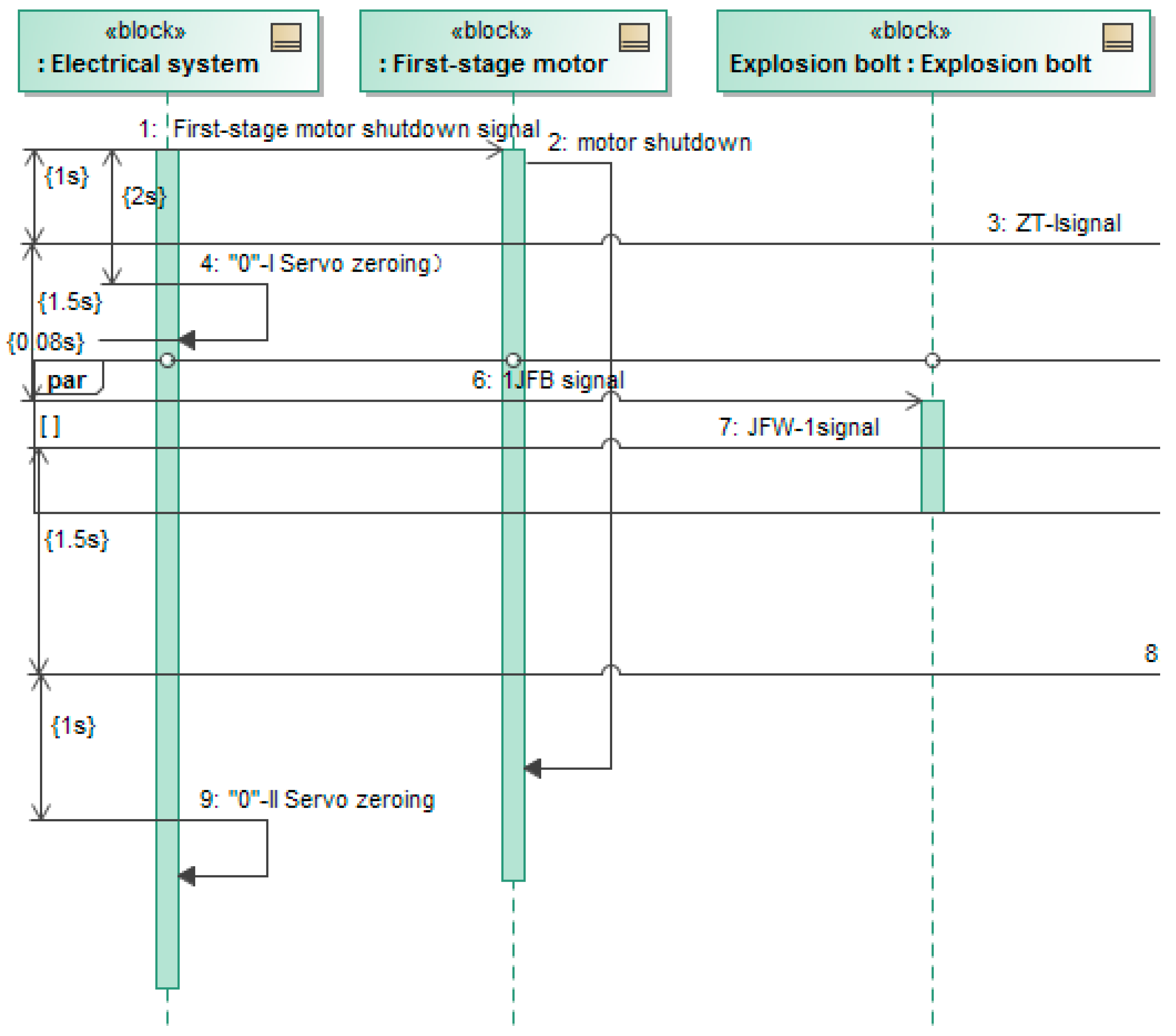

3.6. Validation and Verification of the First-Stage Separation System Based on the Object-Oriented Method

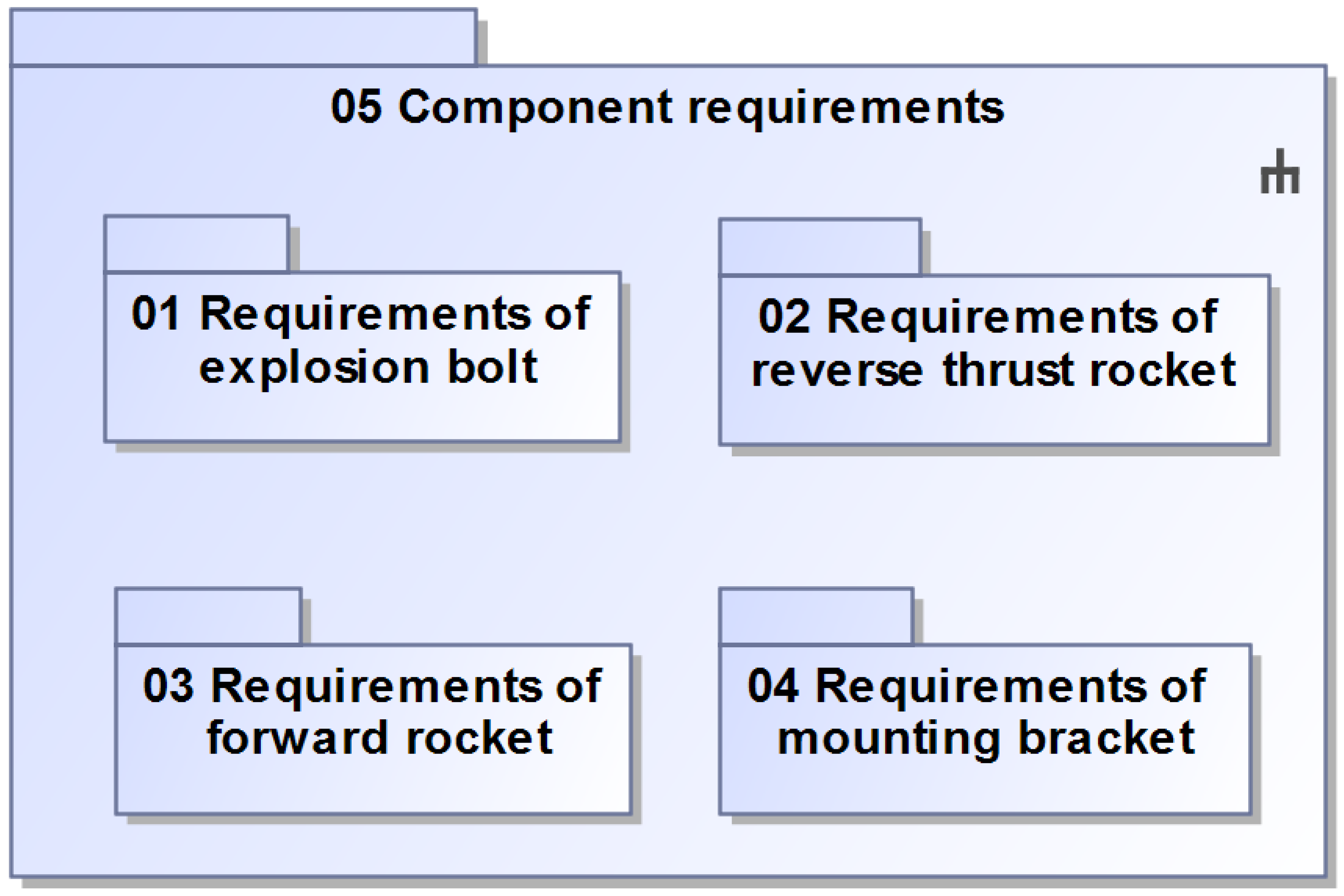

3.7. Component Requirements for the First-Stage Separation System

4. The Application Advantages of Using System Model in Engineering Activity

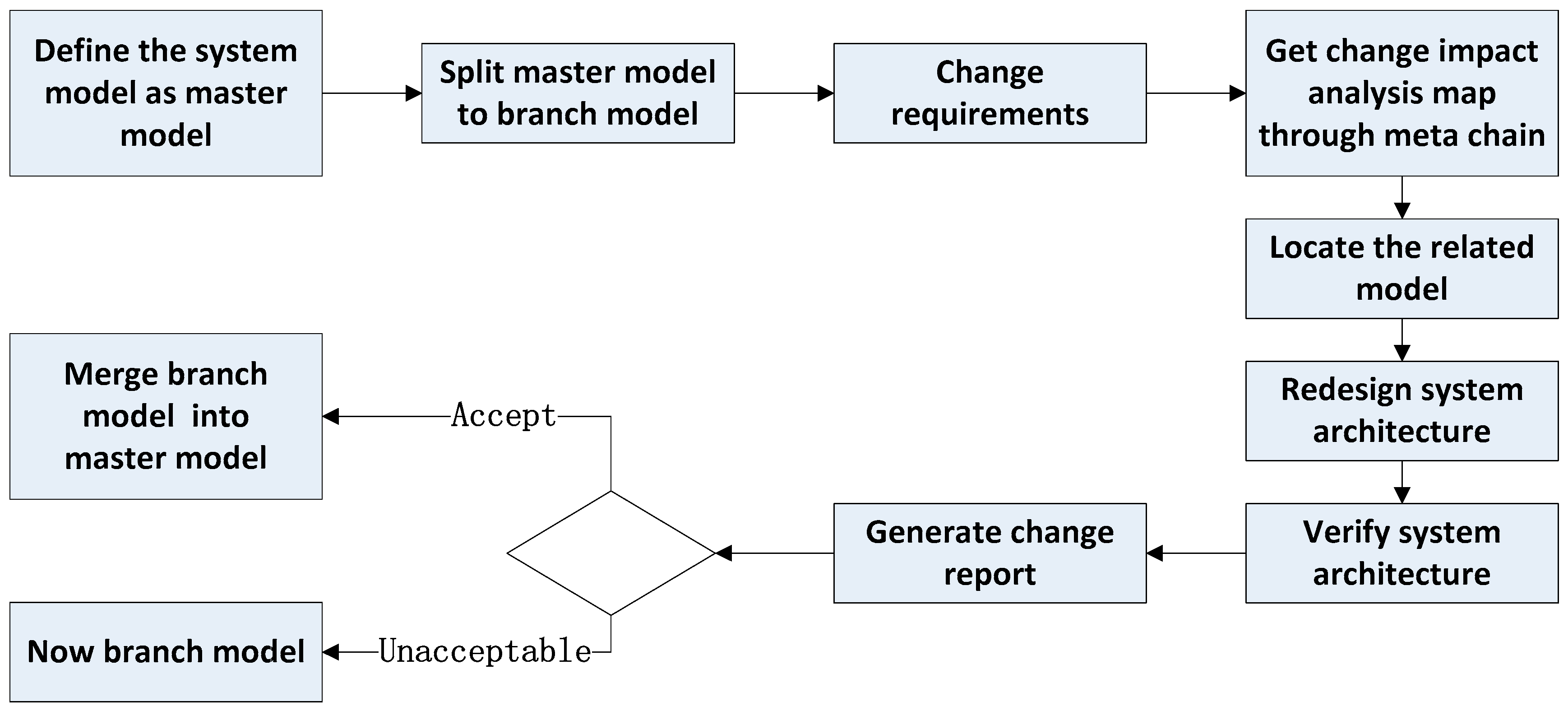

4.1. Requirement Changes Analysis Using the System Model

4.2. Multi-Views Based on Authority Model

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Redmon, J.; Shirley, M.; Kinard, P. A Large-Scale Design Integration Approach Developed in Conjunction with the Ares Launch Vehicle Program. In Proceedings of the 50th AIAA Aerospace Sciences Meeting including the New Horizons Forum and Aerospace Exposition, Nashville, TN, USA, 9–12 January 2012; p. 881. [Google Scholar]

- Henderson, K.; Salado, A. Value and benefits of model-based systems engineering (MBSE): Evidence from the literature. Syst. Eng. 2021, 24, 51–66. [Google Scholar] [CrossRef]

- Wade, J.; Verma, D.; McDermott, T.; Boehm, B. The SERC 5-year technical plan: Designing the future of Systems Engineering Research. In Proceedings of the Ninth International Conference on Complex Systems Design & Management, Paris, France, 18–19 December 2018; Volume 1, p. 241. [Google Scholar]

- Mann, C.J.H. A practical guide to SysML: The systems modeling language. Kybernetes 2009, 38, 989–994. [Google Scholar] [CrossRef]

- Huldt, T.; Stenius, I. State-of-practice survey of model-based systems engineering. Syst. Eng. 2019, 22, 134–145. [Google Scholar] [CrossRef]

- Kaslow, D.; Ayres, B.; Cahill, P.T.; Hart, L. A model-based systems engineering approach for technical measurement with application to a CubeSat. In Proceedings of the 2018 IEEE Aerospace Conference, Big Sky, MT, USA, 3–10 March 2018; pp. 1–10. [Google Scholar]

- Kaslow, D.; Anderson, L.; Asundi, S.; Ayres, B.; Iwata, C.; Shiotani, B.; Thompson, R. Developing a cubesat model-based system engineering (mbse) reference model-interim status. In Proceedings of the 2015 IEEE Aerospace Conference, Big Sky, MT, USA, 7–14 March 2015; pp. 1–16. [Google Scholar]

- Kaslow, D.; Ayres, B.; Cahill, P.T.; Hart, L.; Yntema, R. Developing a CubeSat Model-Based Systems Engineering (MBSE) Reference Model—Interim Status #3. In Proceedings of the IEEE Aerospace Conference, Big Sky, MT, USA, 4–11 March 2017. [Google Scholar]

- Kaslow, D.; Ayres, B.; Cahill, P.T.; Hart, L.; Levi, A.G.; Croney, C. Developing an mbse cubesat reference model–interim status# 4. In Proceedings of the 2018 AIAA SPACE and Astronautics Forum and Exposition, Orlando, FL, USA, 17–19 September 2018; p. 5328. [Google Scholar]

- Kaslow, D.; Madni, A.M. Validation and Verification of MBSE-Compliant CubeSat Reference Model; Disciplinary Convergence in Systems Engineering Research; Springer: Cham, Switzerland, 2018; pp. 381–393. [Google Scholar]

- Kaslow, D.; Cahill, P.T.; Ayres, B. Development and application of the CubeSat system reference model. In Proceedings of the 2020 IEEE Aerospace Conference, Big Sky, MT, USA, 7–14 March 2020; pp. 1–15. [Google Scholar]

- De Saqui-Sannes, P.; Vingerhoeds, R.A.; Garion, C.; Thirioux, X. A taxonomy of MBSE approaches by languages, tools and methods. IEEE Access 2022, 10, 120936–120950. [Google Scholar] [CrossRef]

- Holladay, J.B.; Knizhnik, J.; Weiland, K.J.; Stein, A.; Sanders, T.; Schwindt, P. MBSE Infusion and Modernization Initiative (MIAMI):“Hot” benefits for real NASA applications. In Proceedings of the 2019 IEEE Aerospace Conference, Big Sky, MT, USA, 2–9 March 2019; pp. 1–14. [Google Scholar]

- Estefan, J.A. Survey of model-based systems engineering (MBSE) methodologies. Incose MBSE Focus Group 2007, 25, 1–12. [Google Scholar]

- Pagnanelli, C.A.G.; Carson, R.S.; Palmer, J.R.; Crow, M.E.; Sheeley, B.J. 4.5. 3 Model-Based Systems Engineering in an Integrated Environment. In Proceedings of the INCOSE International Symposium, Rome, Italy, 9–12 July 2012; Volume 22, pp. 633–649. [Google Scholar]

- Roques, P. MBSE with the ARCADIA Method and the Capella Tool. In Proceedings of the 8th European Congress on Embedded Real Time Software and Systems (ERTS 2016), Toulouse, France, 27–29 January 2016. [Google Scholar]

- Forte, S.; Göbel, J.C.; Dickopf, T. System of systems lifecycle engineering approach integrating smart product and service ecosystems. Proc. Des. Soc. 2021, 1, 2911–2920. [Google Scholar] [CrossRef]

- Parrott, E.; Trase, K.; Green, R.; Varga, D.; Powell, J. NASA GRC MBSE Implementation Status; GSFC MBSE Workshop: Washington, DC, USA, 17 February 2016; No. GRC-E-DAA-TN29928. [Google Scholar]

- Hause, M.C.; Day, R.L. Frenemies: Opm and SysML together in an MBSE model. In Proceedings of the INCOSE International Symposium, Orlando, FL, USA, 20–25 July 2019; Volume 29, pp. 691–706. [Google Scholar]

- Schindel, W.D. Realizing the Promise of Digital Engineering: Planning, Implementing, and Evolving the Ecosystem. In Proceedings of the INCOSE International Symposium, Detroit, MI, USA, 25–30 June 2022; Volume 32, pp. 1114–1130. [Google Scholar]

- Chang, S.; Wang, Y. Civil aircraft IVHM system analysis using model based system engineering. In Proceedings of the 2017 Second International Conference on Reliability Systems Engineering (ICRSE), Beijing, China, 10–12 July 2017; pp. 1–5. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, W.; Liu, Z.; Liu, X.; Jin, Y.; Wang, Q.; Hong, R. Model-Based Systems Engineering Approach for the First-Stage Separation System of Launch Vehicle. Actuators 2022, 11, 366. https://doi.org/10.3390/act11120366

Zhang W, Liu Z, Liu X, Jin Y, Wang Q, Hong R. Model-Based Systems Engineering Approach for the First-Stage Separation System of Launch Vehicle. Actuators. 2022; 11(12):366. https://doi.org/10.3390/act11120366

Chicago/Turabian StyleZhang, Wenfeng, Zhendong Liu, Xiong Liu, Yili Jin, Qixiao Wang, and Rong Hong. 2022. "Model-Based Systems Engineering Approach for the First-Stage Separation System of Launch Vehicle" Actuators 11, no. 12: 366. https://doi.org/10.3390/act11120366

APA StyleZhang, W., Liu, Z., Liu, X., Jin, Y., Wang, Q., & Hong, R. (2022). Model-Based Systems Engineering Approach for the First-Stage Separation System of Launch Vehicle. Actuators, 11(12), 366. https://doi.org/10.3390/act11120366