Mechanical Properties and Microstructural Behavior of Uniaxial Tensile-Loaded Anisotropic Magnetorheological Elastomer

Abstract

1. Introduction

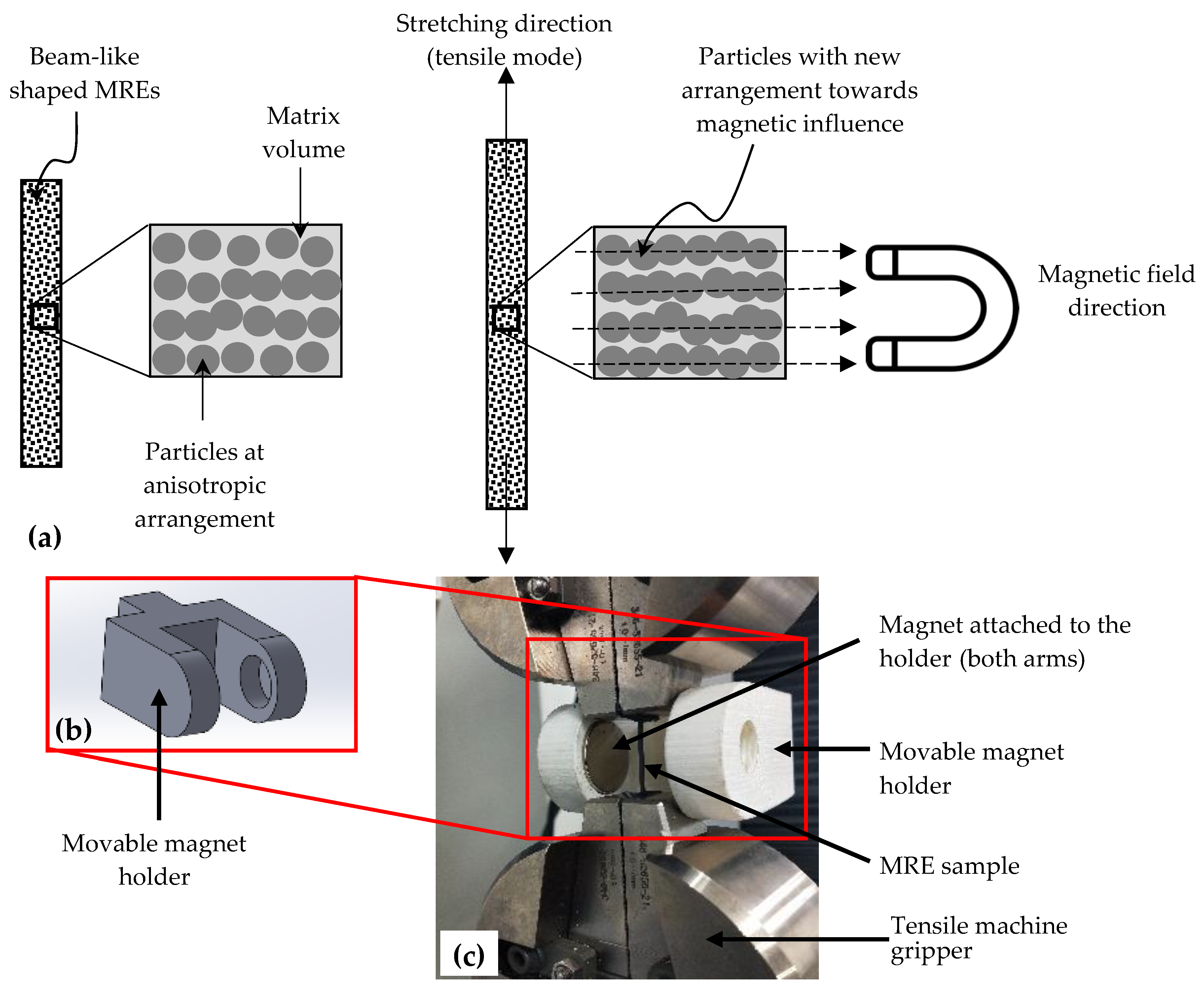

2. Materials and Methods

2.1. Sample Preparation

2.2. Testing Method—Uniaxial Tension Testing

2.3. Morphology Analysis

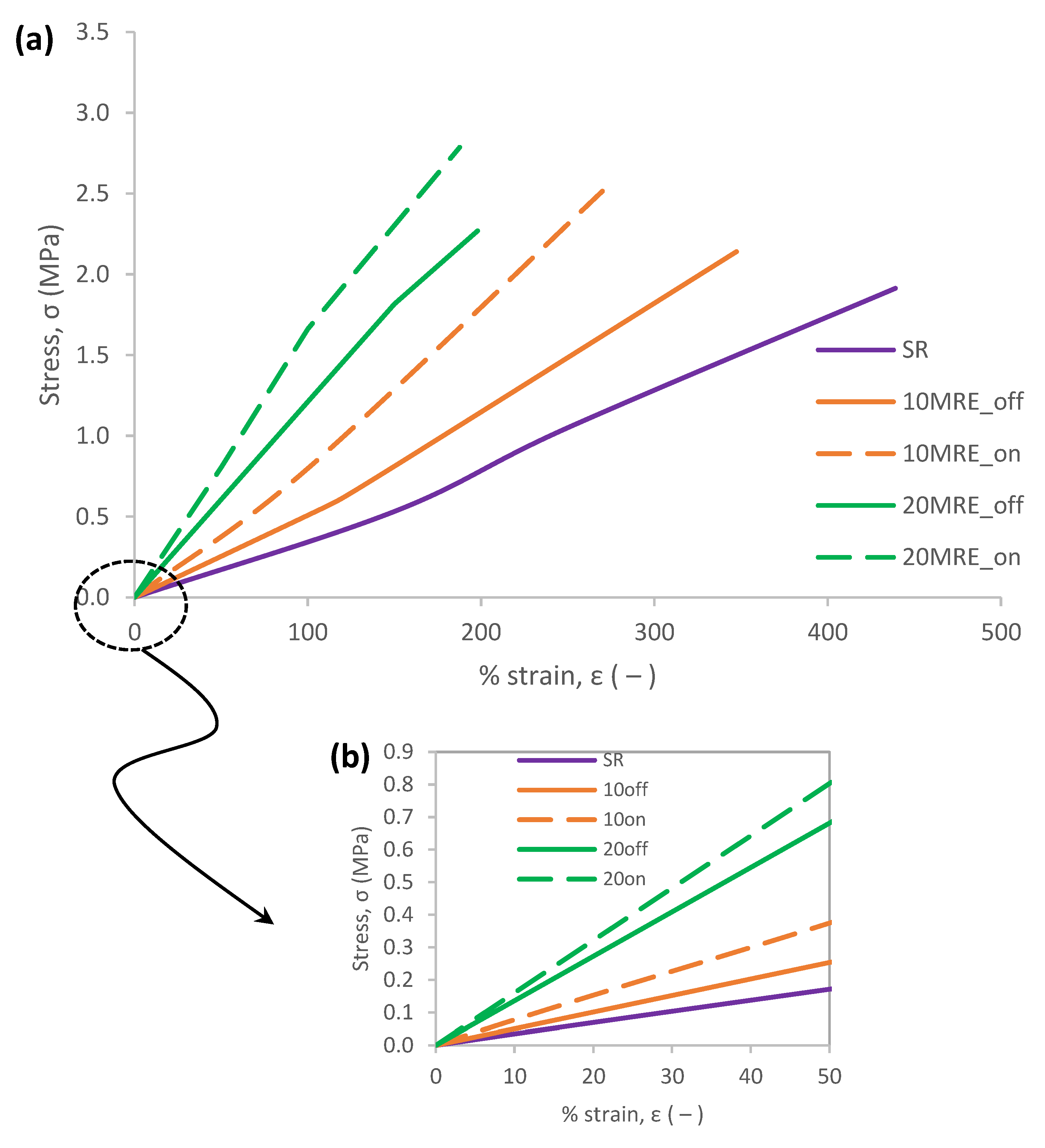

3. Results

3.1. CIP Concentrations and Magnetic Field Influence

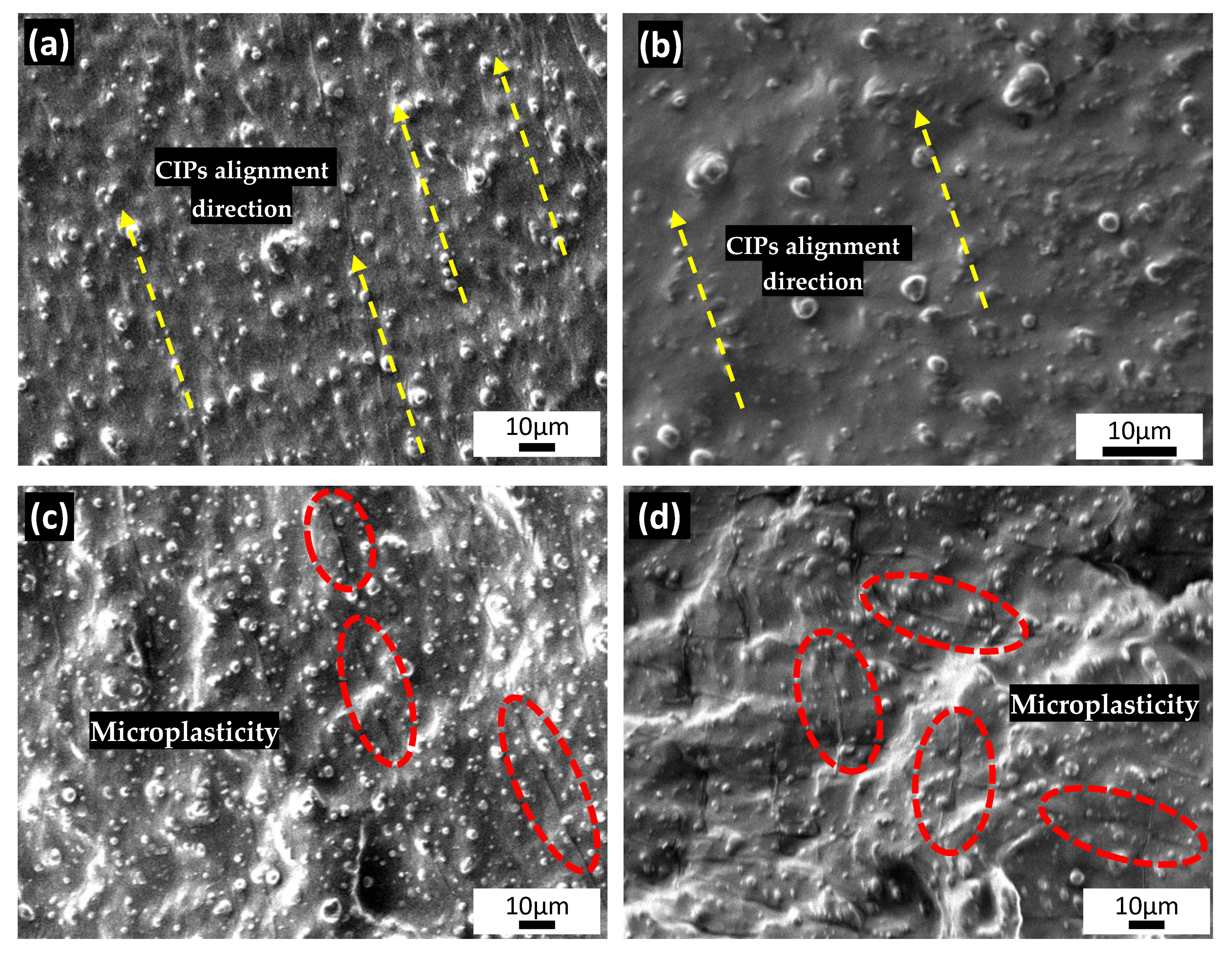

3.2. Morphological Analysis

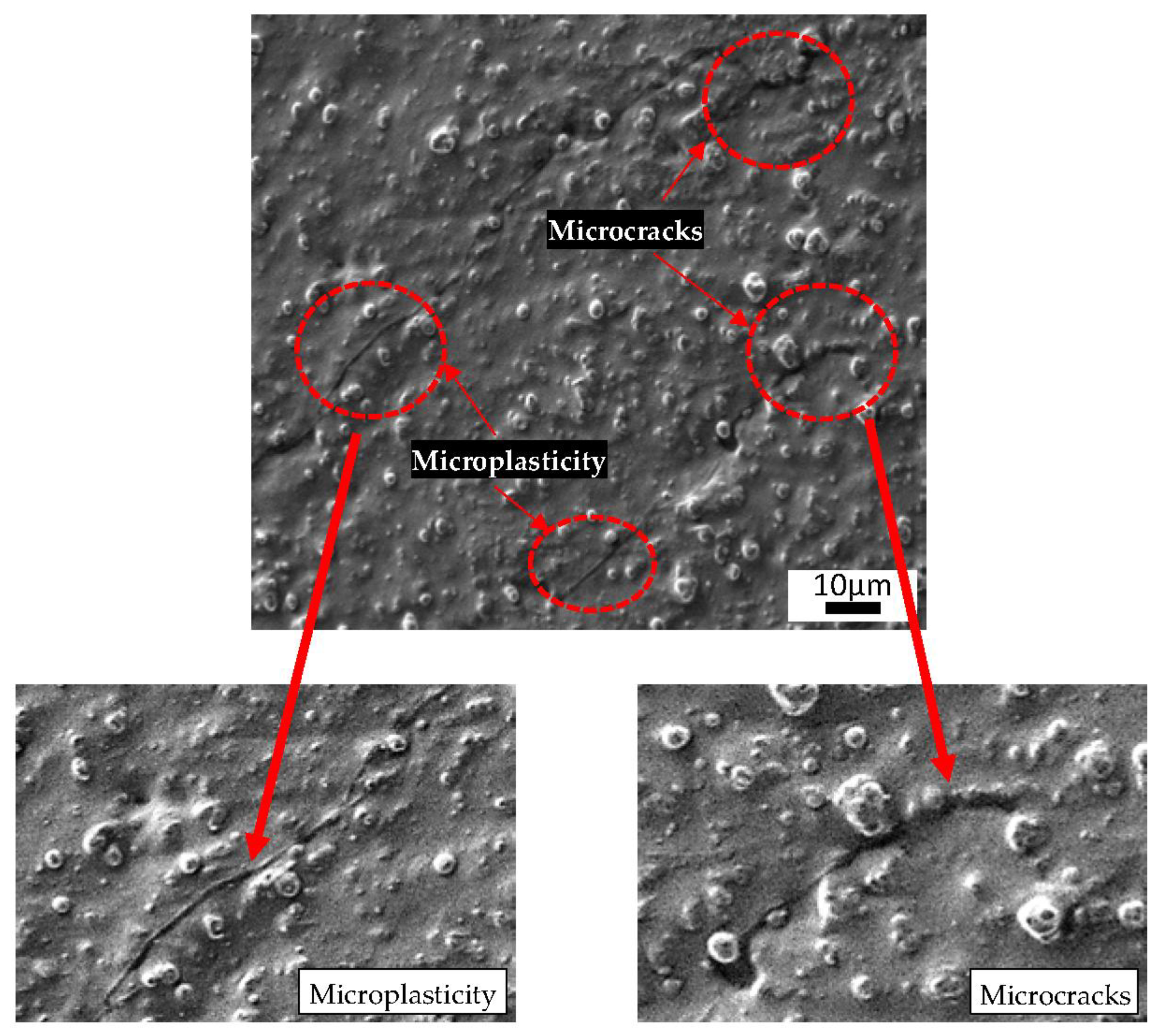

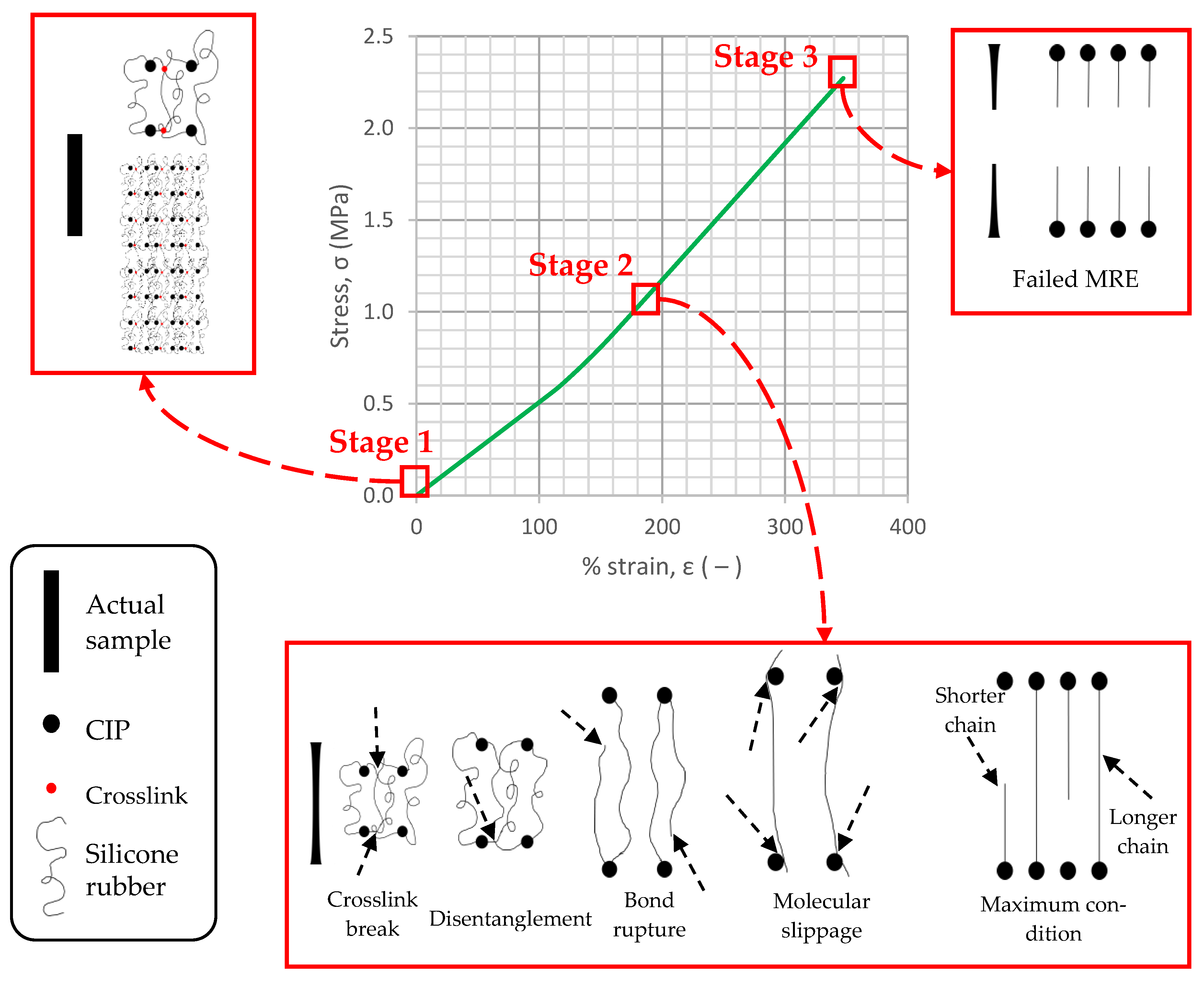

3.3. Failure Mechanism under Tension

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ubaidillah; Sutrisno, J.; Purwanto, A.; Mazlan, S.A. Recent Progress on Magnetorheological Solids: Materials, Fabrication, Testing, and Applications. Adv. Eng. Mater. 2015, 17, 563–597. [Google Scholar] [CrossRef]

- Sandesh, B.; Sriharsha, H.; Rao Sathish, U.; Nikhil, G. Investigation of Tensile Properties of RTV Silicone Based Isotropic Magnetorheological Elastomers. MATEC Web. Conf. 2018, 144, 02015. [Google Scholar] [CrossRef][Green Version]

- Faizal Johari, M.A.; Mazlan, S.A.; Ubaidillah; Harjana; Abdul Aziz, S.A.; Nordin, N.A.; Johari, N.; Nazmi, N. An Overview of Durability Evaluations of Elastomer-Based Magnetorheological Materials. IEEE Access 2020, 8, 134536–134552. [Google Scholar] [CrossRef]

- Abd Rashid, R.Z.; Johari, N.; Mazlan, S.A.; Abdul Aziz, S.A.; Nordin, N.A.; Nazmi, N.; Aqida, S.N.; Johari, M.A.F. Effects of Silica on Mechanical and Rheological Properties of EPDM-Based Magnetorheological Elastomers. Smart Mater. Struct. 2021, 30, 105033. [Google Scholar] [CrossRef]

- Johari, M.A.F.; Mazlan, S.A.; Nasef, M.M.; Ubaidillah, U.; Nordin, N.A.; Aziz, S.A.A.; Johari, N.; Nazmi, N. Microstructural Behavior of Magnetorheological Elastomer Undergoing Durability Evaluation by Stress Relaxation. Sci. Rep. 2021, 11, 10936. [Google Scholar] [CrossRef]

- Aziz, S.A.A.; Mazlan, S.A.; Ismail, N.I.N.; Ubaidillah, U.; Choi, S.B.; Khairi, M.H.A.; Yunus, N.A. Effects of Multiwall Carbon Nanotubes on Viscoelastic Properties of Magnetorheological Elastomers. Smart Mater. Struct. 2016, 25, 077001. [Google Scholar] [CrossRef]

- Khairi, M.H.A.; Fatah, A.Y.A.; Mazlan, S.A.; Ubaidillah, U.; Nordin, N.A.; Ismail, N.I.N.; Choi, S.B.; Aziz, S.A.A. Enhancement of Particle Alignment Using Silicone Oil Plasticizer and Its Effects on the Field-Dependent Properties of Magnetorheological Elastomers. Int. J. Mol. Sci. 2019, 20, 4085. [Google Scholar] [CrossRef]

- Burhannuddin, N.L.; Nordin, N.A.; Mazlan, S.A.; Abdul Aziz, S.A.; Choi, S.B.; Kuwano, N.; Nazmi, N.; Johari, N. Effects of Corrosion Rate of the Magnetic Particles on the Field-Dependent Material Characteristics of Silicone Based Magnetorheological Elastomers. Smart Mater. Struct. 2020, 29, 087003. [Google Scholar] [CrossRef]

- Zhang, G.; Zhang, J.; Guo, X.; Zhang, M.; Liu, M.; Qiao, Y.; Zhai, P. Effects of Graphene Oxide on Microstructure and Mechanical Properties of Isotropic Polydimethylsiloxane-Based Magnetorheological Elastomers. Rheol. Acta 2022, 61, 215–228. [Google Scholar] [CrossRef]

- Kumar, V.; Lee, D.J. Iron Particle and Anisotropic Effects on Mechanical Properties of Magneto-Sensitive Elastomers. J. Magn. Magn. Mater. 2017, 441, 105–112. [Google Scholar] [CrossRef]

- Schubert, G.; Harrison, P. Large-Strain Behaviour of Magneto-Rheological Elastomers Tested under Uniaxial Compression and Tension, and Pure Shear Deformations. Polym. Test. 2015, 42, 122–134. [Google Scholar] [CrossRef]

- Norouzi, M.; Gilani, M.; Alehashem, S.M.S.; Vatandoost, H. Dynamic Characterization and Modeling of Isotropic Magnetorheological Elastomers under Tensile-Compressive Loadings. IEEE Trans. Magn. 2017, 53, 2900412. [Google Scholar] [CrossRef]

- Soria-hern, C.G.; Palacios-pineda, L.M.; Elias-Zuniga, A.; Perales-Martínez, I.A.; Martínez-Romero, O. Investigation of the Effect of Carbonyl Iron Micro-Particles on the Mechanical and Rheological Properties of Isotropic and Anisotropic MREs: Constitutive Magneto-Mechanical Material Model. Polymers 2019, 11, 1705. [Google Scholar] [CrossRef] [PubMed]

- Gorman, D.; Murphy, N.; Ekins, R.; Jerrams, S. The Evaluation and Implementation of Magnetic Fields for Large Strain Uniaxial and Biaxial Cyclic Testing of Magnetorheological Elastomers. Polym. Test. 2016, 51, 74–81. [Google Scholar] [CrossRef]

- Kumar, V.; Alam, M.N.; Park, S.S. Soft Composites Filled with Iron Oxide and Graphite Nanoplatelets under Static and Cyclic Strain for Different Industrial Applications. Polymers 2022, 14, 2393. [Google Scholar] [CrossRef]

- Qiao, Y.; Zhang, J.; Zhang, M.; Liu, L.; Zhai, P. A Magneto-Hyperelastic Model for Silicone Rubber-Based Isotropic Magnetorheological Elastomer under Quasi-Static Compressive Loading. Polymers 2020, 12, 2435. [Google Scholar] [CrossRef]

- Vatandoost, H.; Sedaghati, R.; Rakheja, S.; Hemmatian, M. Effect of Pre-Strain on Compression Mode Properties of Magnetorheological Elastomers. Polym. Test. 2021, 93, 106888. [Google Scholar] [CrossRef]

- Johari, M.A.F.; Mazlan, S.A.; Nordin, N.A.; Ubaidillah, U.; Aziz, S.A.A.; Nazmi, N.; Johari, N.; Choi, S.B. The Effect of Microparticles on the Storage Modulus and Durability Behavior of Magnetorheological Elastomer. Micromachines 2021, 12, 948. [Google Scholar] [CrossRef]

- Gao, P.; Liu, H.; Xiang, C.; Yan, P.; Mahmoud, T. A New Magnetorheological Elastomer Torsional Vibration Absorber: Structural Design and Performance Test. Mech. Sci. 2021, 12, 321–332. [Google Scholar] [CrossRef]

- Akif, M.; Fakhree, M.; Nordin, N.A.; Nazmi, N.; Mazlan, S.A.; Aishah, S.; Aziz, A.; Ubaidillah, U.; Ahmad, F.; Choi, S. Field-Dependent Rheological Properties of Magnetorheological Elastomer with Fountain-Like Particle Chain Alignment. Micromachines 2022, 13, 492. [Google Scholar]

- Khairi, M.H.A.; Mazlan, S.A.; Ubaidillah; Nordin, N.A.; Aziz, S.A.A.; Nazmi, N. Effect of Mould Orientation on the Field-Dependent Properties of Mr Elastomers under Shear Deformation. Polymers 2021, 13, 3273. [Google Scholar] [CrossRef] [PubMed]

- El-Atab, N.; Mishra, R.B.; Al-Modaf, F.; Joharji, L.; Alsharif, A.A.; Alamoudi, H.; Diaz, M.; Qaiser, N.; Hussain, M.M. Soft Actuators for Soft Robotic Applications: A Review. Adv. Intell. Syst. 2020, 2, 128. [Google Scholar] [CrossRef]

- Diani, J.; Fayolle, B.; Gilormini, P. A Review on the Mullins Effect. Eur. Polym. J. 2009, 45, 601–612. [Google Scholar] [CrossRef]

- Wei, C.; Wang, J.; He, Y.; Li, J.; Beaugnon, E. Solidification of Immiscible Alloys under High Magnetic Field: A Review. Metals 2021, 11, 525. [Google Scholar] [CrossRef]

- Milyutin, V.A.; Gervasyeva, I.V. Thermally Activated Transformations in Alloys with Different Type of Magnetic Ordering under High Magnetic Field. J. Magn. Magn. Mater. 2019, 492, 165654. [Google Scholar] [CrossRef]

- Xiang, Z.; Zhang, L.; Xin, Y.; An, B.; Niu, R.; Mardani, M.; Siegrist, T.; Lu, J.; Goddard, R.E.; Man, T.; et al. Ultrafine Microstructure and Hardness in Fe-Cr-Co Alloy Induced by Spinodal Decomposition under Magnetic Field. Mater. Des. 2021, 199, 109383. [Google Scholar] [CrossRef]

- Han, K.; Zhou, X. Effect of High Magnetic Field on the Processing of Pearlitic Steels. Mater. Manuf. Process. 2017, 32, 1317–1324. [Google Scholar] [CrossRef]

- Zuo, X.; Zhang, L.; Wang, E. Influence of External Static Magnetic Fields on Properties of Metallic Functional Materials. Crystals 2017, 7, 374. [Google Scholar] [CrossRef]

- Boczkowska, A.; Awietj, S. Microstructure and Properties of Magnetorheological Elastomers. In Advanced Elastomers—Technology, Properties and Applications; InTech: Rijeka, Croatia, 2012. [Google Scholar]

- Lai, N.T.; Ismail, H.; Abdullah, M.K.; Shuib, R.K. Optimization of Pre-Structuring Parameters in Fabrication of Magnetorheological Elastomer. Arch. Civ. Mech. Eng. 2019, 19, 557–568. [Google Scholar] [CrossRef]

- Boczkowska, A.; Awietjan, S.F.; Wejrzanowski, T.; Kurzydłowski, K.J. Image Analysis of the Microstructure of Magnetorheological Elastomers. J. Mater. Sci. 2009, 44, 3135–3140. [Google Scholar] [CrossRef]

- Chen, L.; Gong, X.L.; Li, W.H. Microstructures and Viscoelastic Properties of Anisotropic Magnetorheological Elastomers. Smart Mater. Struct. 2007, 16, 2645. [Google Scholar] [CrossRef]

- Damiani, R.; Sun, L.Z. Microstructural Characterization and Effective Viscoelastic Behavior of Magnetorheological Elastomers with Varying Acetone Contents. Int. J. Damage Mech. 2017, 26, 104–118. [Google Scholar] [CrossRef]

- Liao, G.; Gong, X.L.; Xuan, S. Influence of Shear Deformation on the Normal Force of Magnetorheological Elastomer. Mater. Lett. 2013, 106, 270–272. [Google Scholar] [CrossRef]

- Johari, M.A.F.; Mazlan, S.A.; Ubaidillah; Nordin, N.A.; Aziz, S.A.A.; Johari, N.; Nazmi, N.; Homma, K. Shear Band Formation in Magnetorheological Elastomer under Stress Relaxation. Smart Mater. Struct. 2021, 30, 045015. [Google Scholar] [CrossRef]

- Guan, X.; Dong, X.; Ou, J. Magnetostrictive Effect of Magnetorheological Elastomer. J. Magn. Magn. Mater. 2008, 320, 158–163. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mohd Shahar, S.F.; Mazlan, S.A.; Johari, N.; Johari, M.A.F.; Abdul Aziz, S.A.; Ahmad Khairi, M.H.; Nordin, N.A.; Mohd Hapipi, N. Mechanical Properties and Microstructural Behavior of Uniaxial Tensile-Loaded Anisotropic Magnetorheological Elastomer. Actuators 2022, 11, 306. https://doi.org/10.3390/act11110306

Mohd Shahar SF, Mazlan SA, Johari N, Johari MAF, Abdul Aziz SA, Ahmad Khairi MH, Nordin NA, Mohd Hapipi N. Mechanical Properties and Microstructural Behavior of Uniaxial Tensile-Loaded Anisotropic Magnetorheological Elastomer. Actuators. 2022; 11(11):306. https://doi.org/10.3390/act11110306

Chicago/Turabian StyleMohd Shahar, Siti Fatimah, Saiful Amri Mazlan, Norhasnidawani Johari, Mohd Aidy Faizal Johari, Siti Aishah Abdul Aziz, Muntaz Hana Ahmad Khairi, Nur Azmah Nordin, and Norhiwani Mohd Hapipi. 2022. "Mechanical Properties and Microstructural Behavior of Uniaxial Tensile-Loaded Anisotropic Magnetorheological Elastomer" Actuators 11, no. 11: 306. https://doi.org/10.3390/act11110306

APA StyleMohd Shahar, S. F., Mazlan, S. A., Johari, N., Johari, M. A. F., Abdul Aziz, S. A., Ahmad Khairi, M. H., Nordin, N. A., & Mohd Hapipi, N. (2022). Mechanical Properties and Microstructural Behavior of Uniaxial Tensile-Loaded Anisotropic Magnetorheological Elastomer. Actuators, 11(11), 306. https://doi.org/10.3390/act11110306