Experimental Evaluation on Haptic Feedback Accuracy by Using Two Self-Made Haptic Devices and One Additional Interface in Robotic Teleoperation

Abstract

1. Introduction

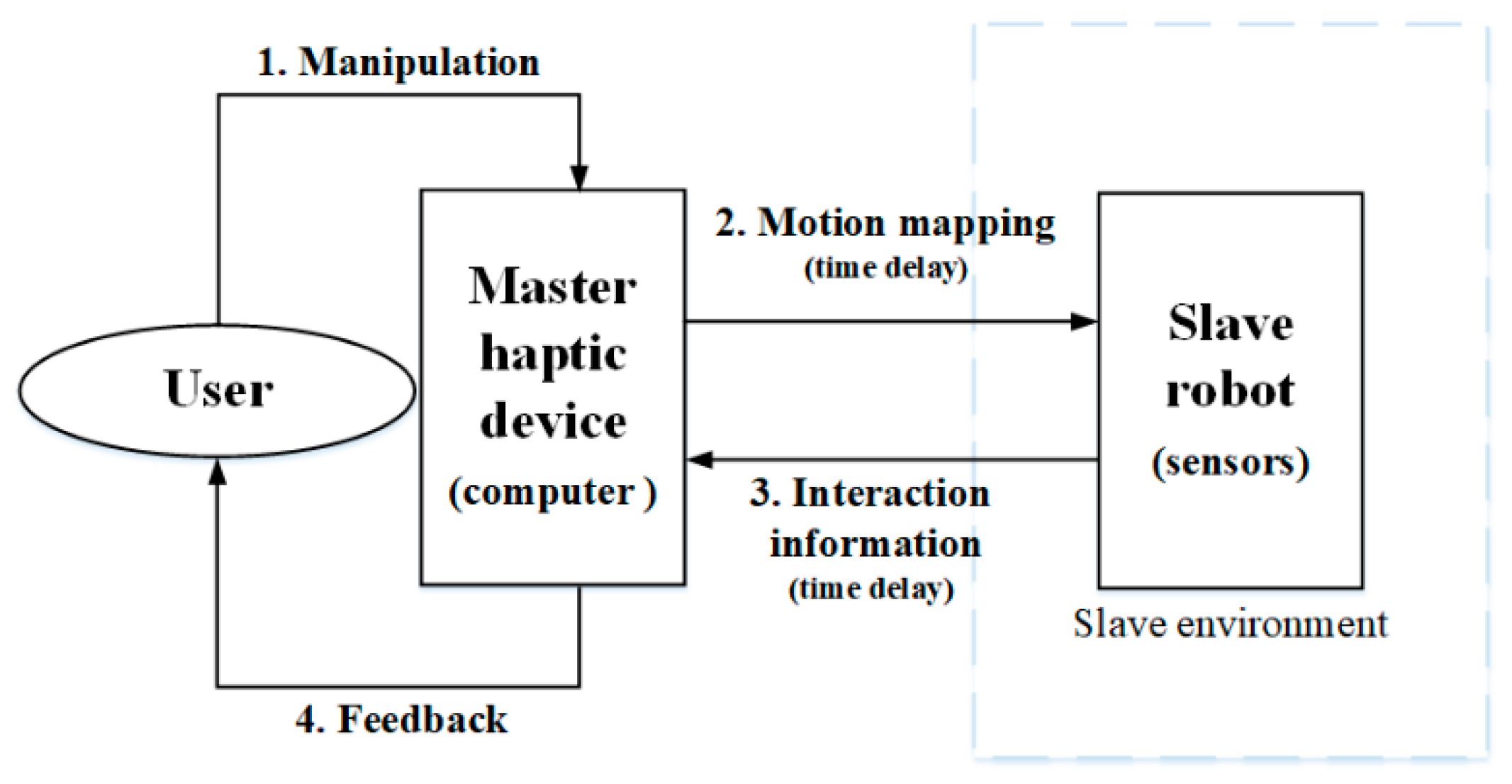

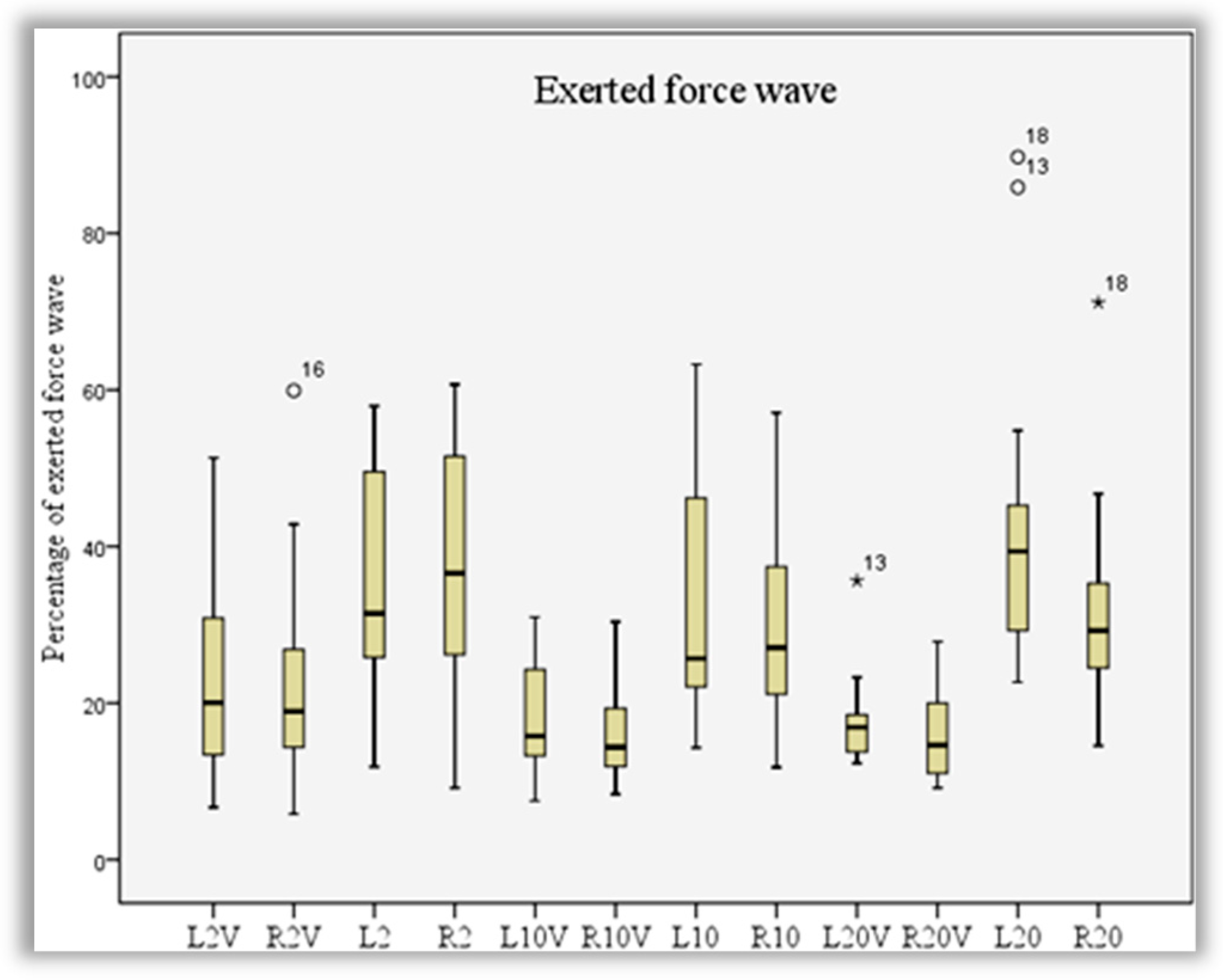

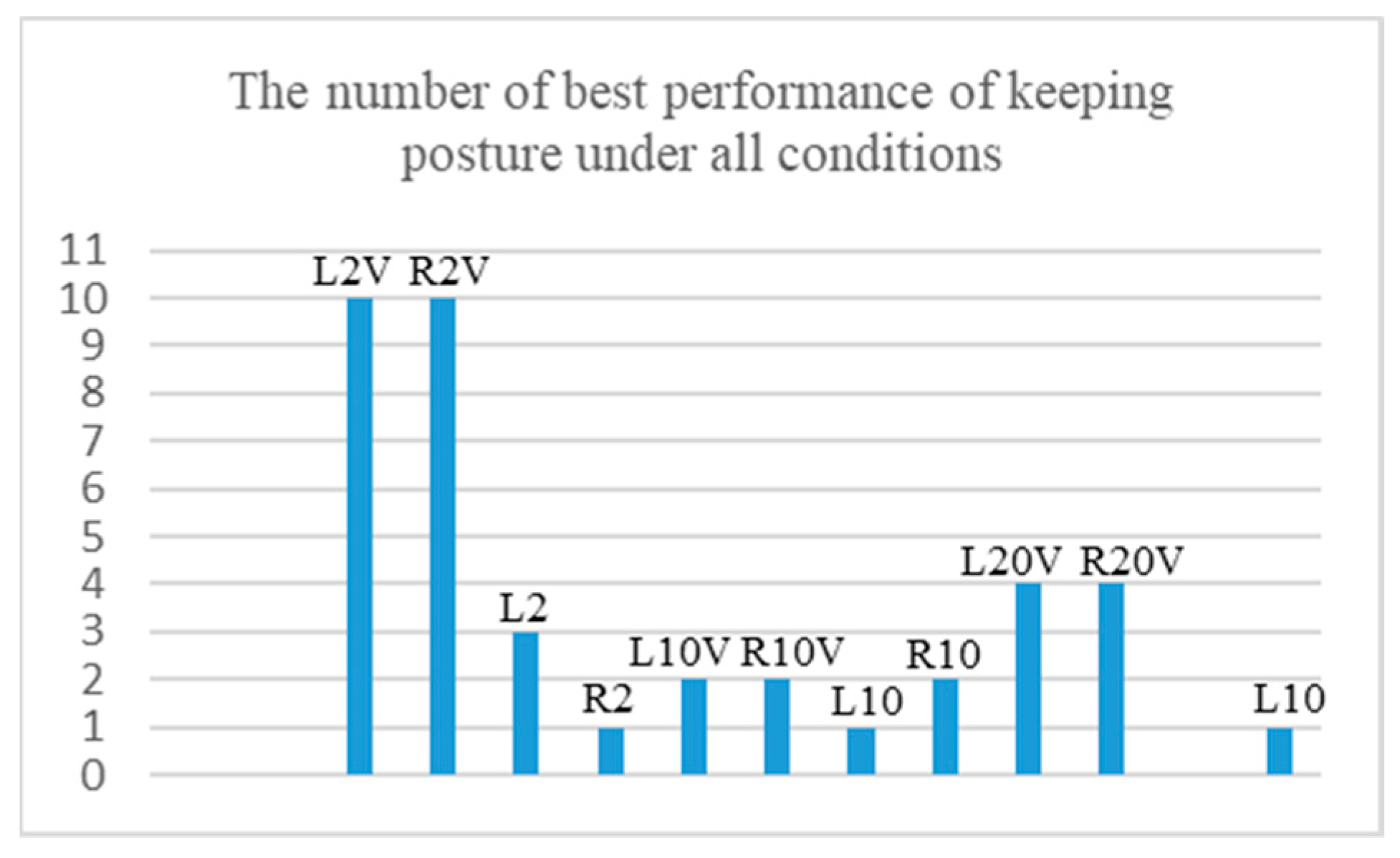

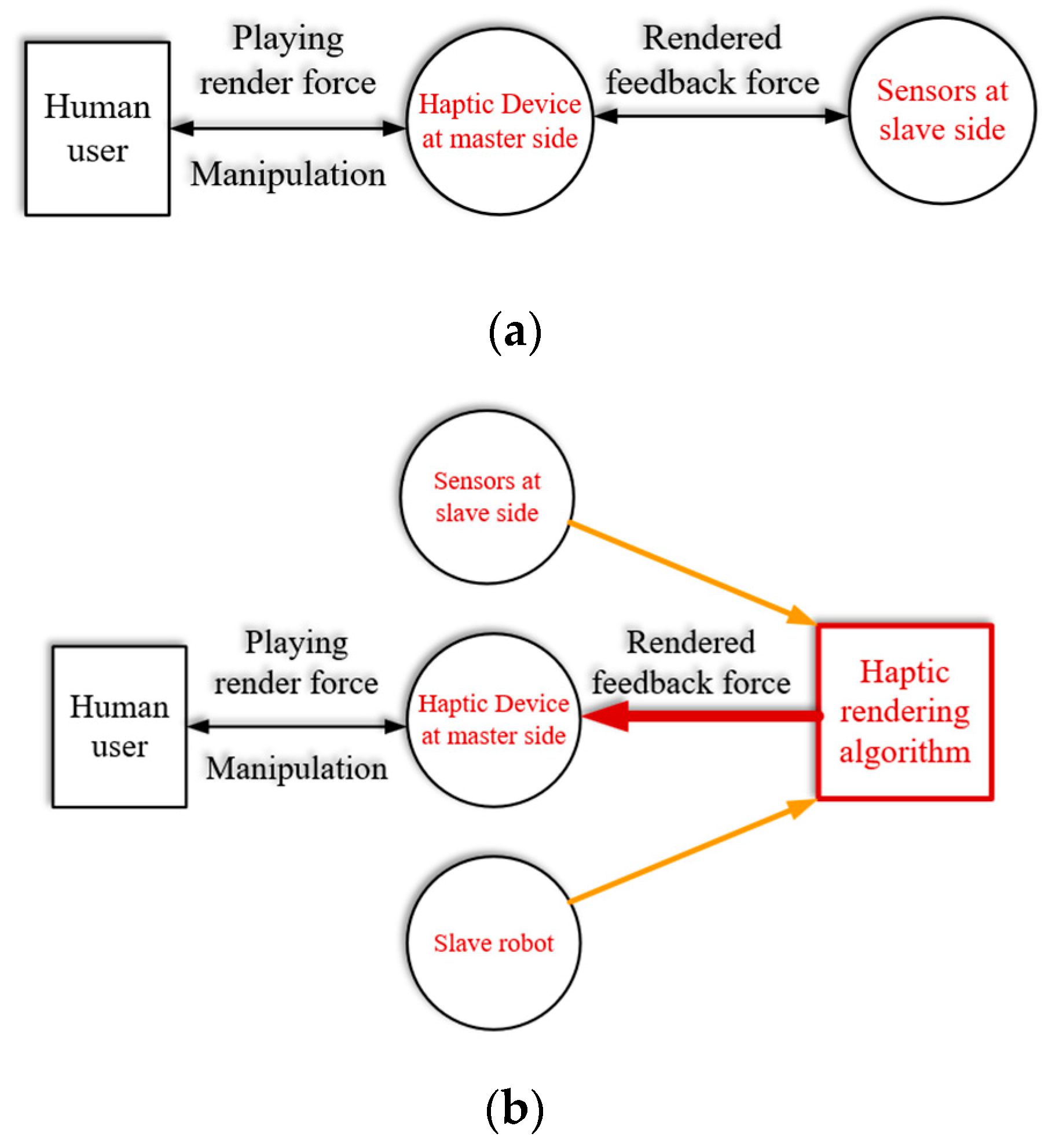

2. Principle of Experimental Evaluation on Haptic Feedback Accuracy in Teleoperation

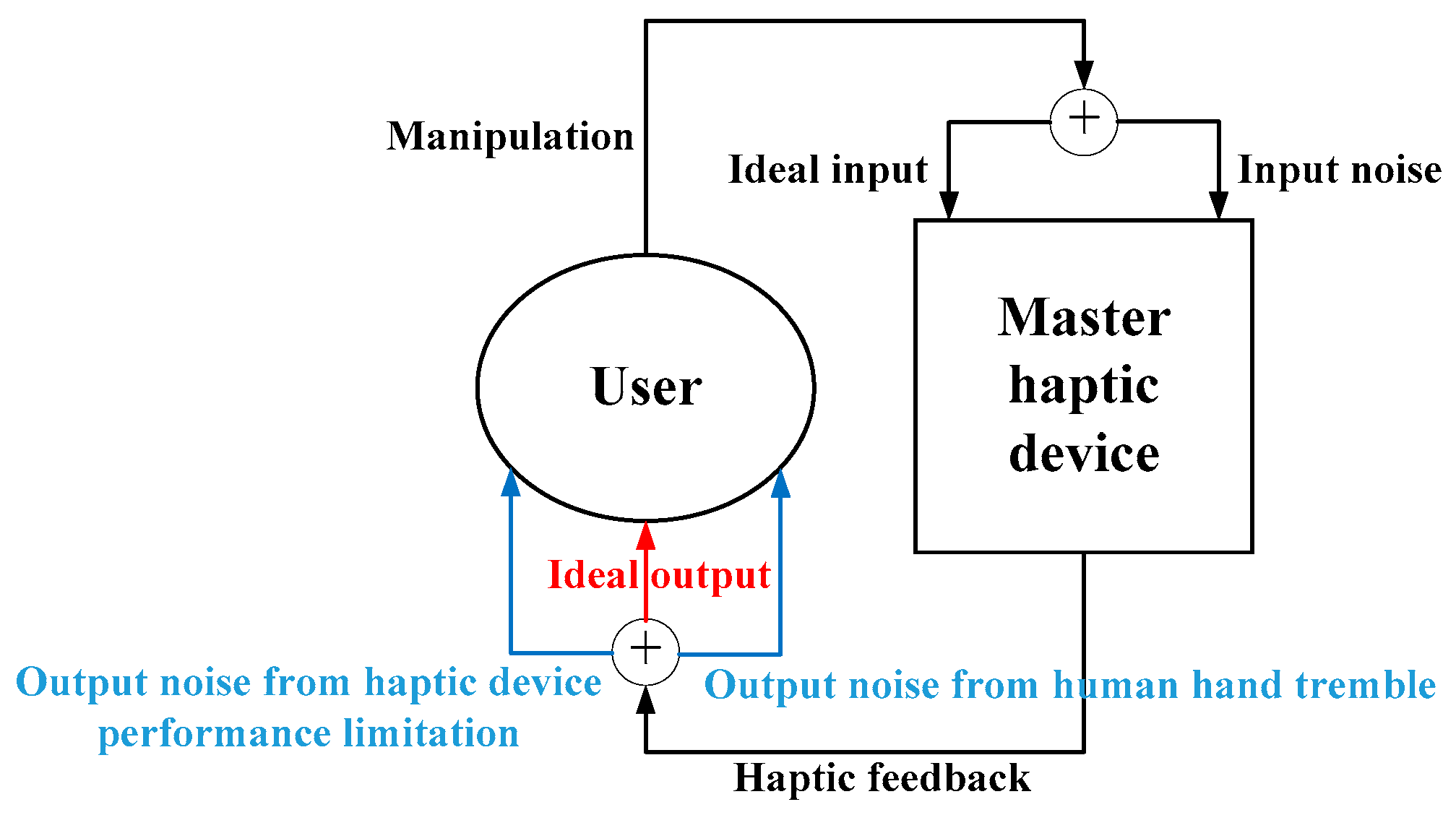

2.1. Interaction between Human Hand and Haptic Device at the Master Side in Teleoperation

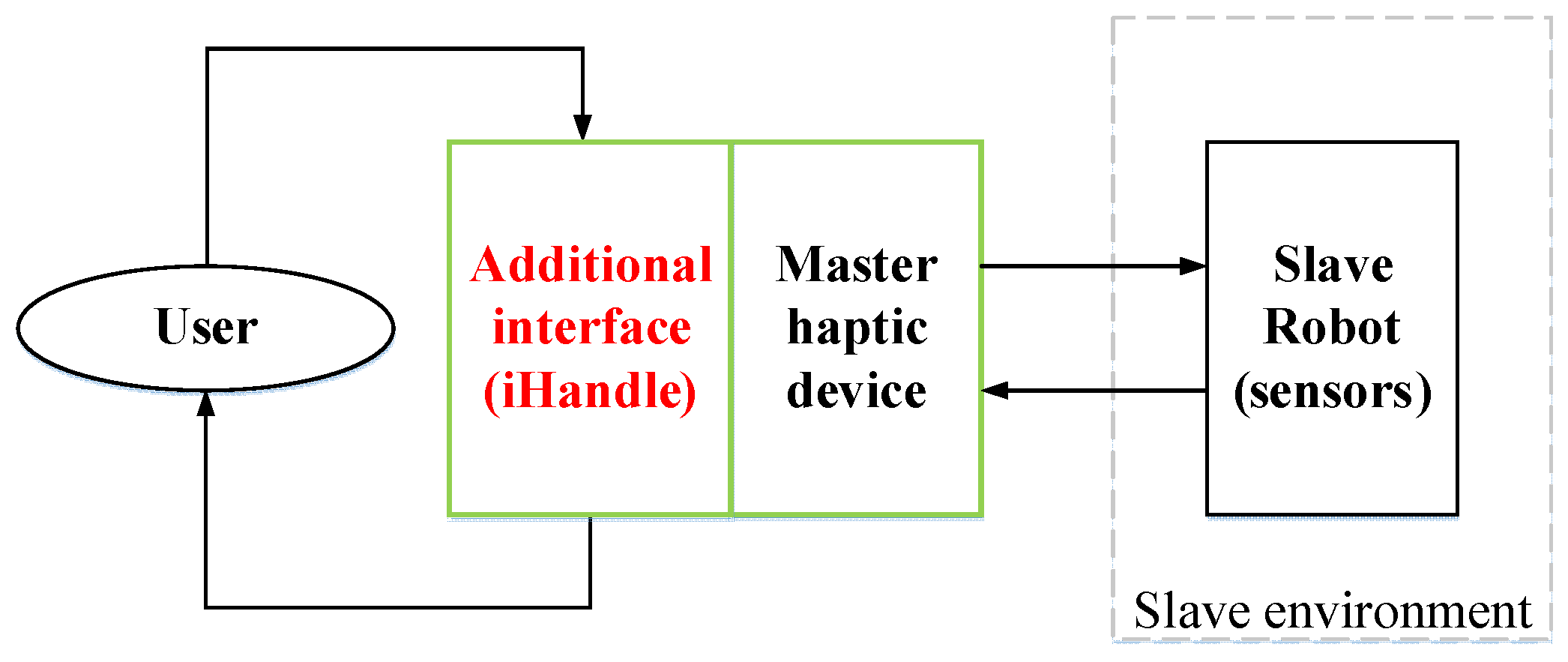

2.2. iHandle: An Additional Interface between Human Hand and Haptic Device

3. Identification of Input Noise

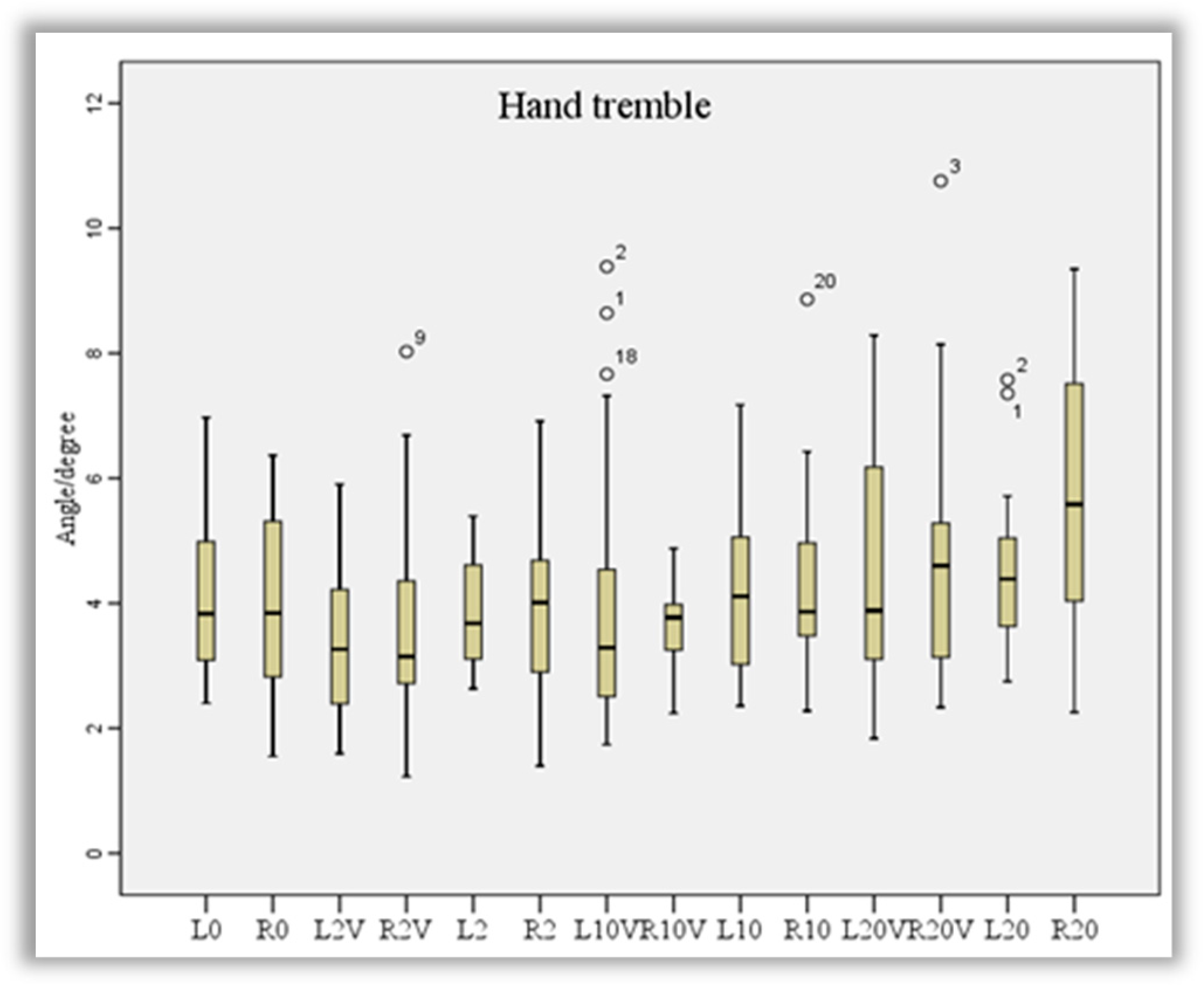

3.1. Experiment Design by Using the iHandle

3.2. Experimental Process

3.3. Analysis of Experiment Results

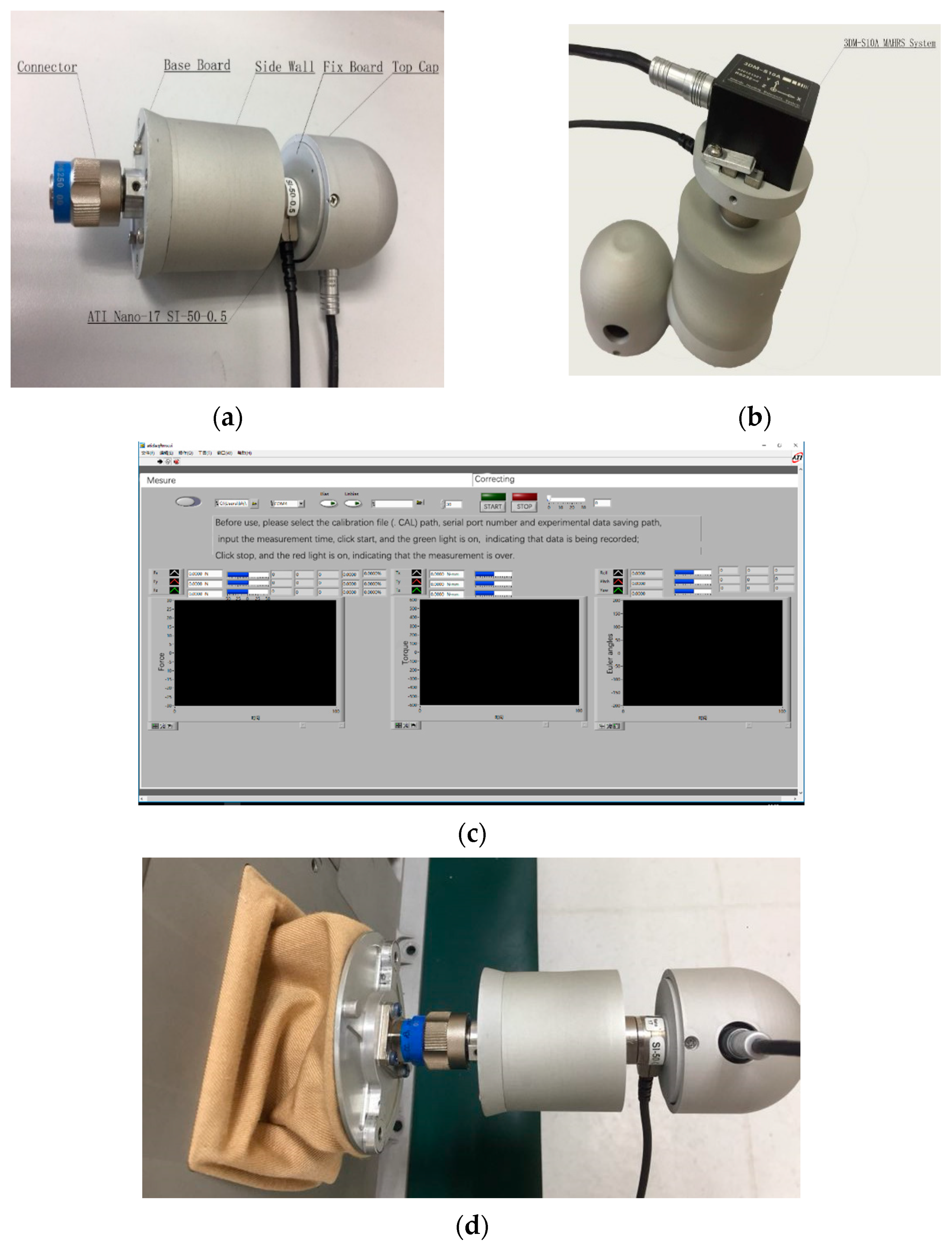

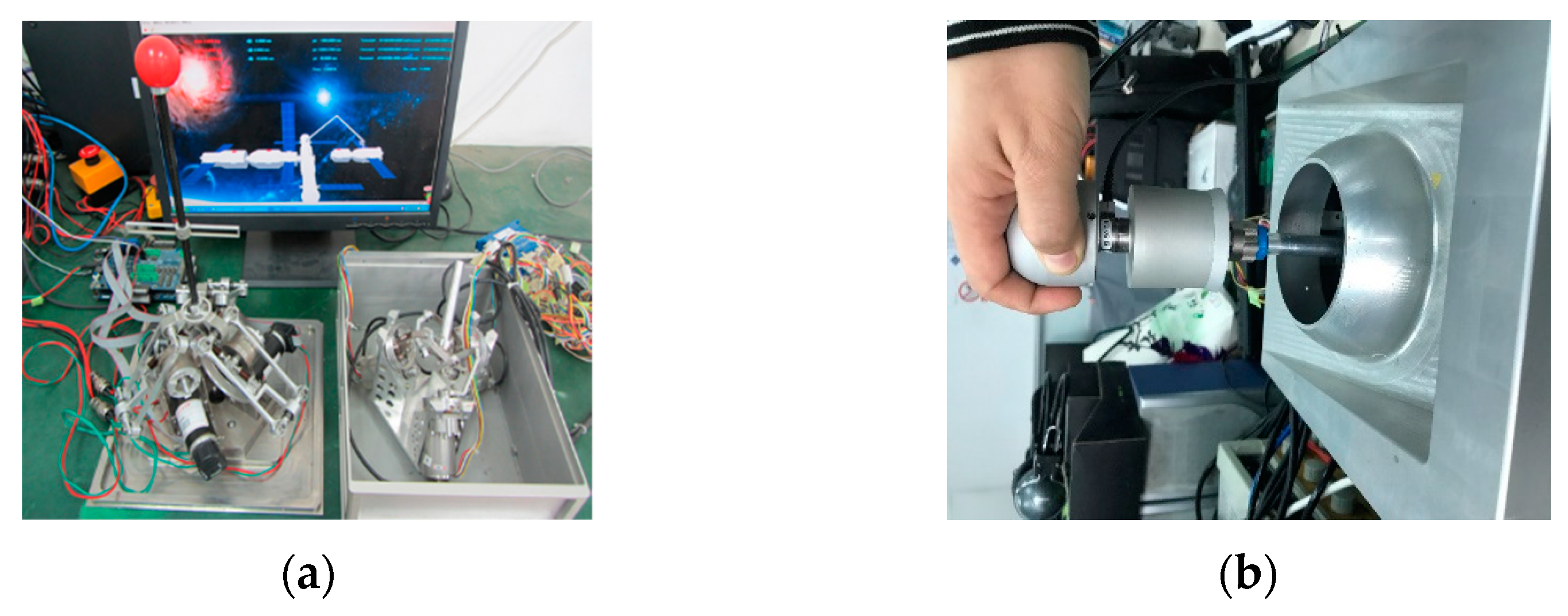

4. Identification of Output Noise: Measurement of Haptic Devices iGrasp-T and iGrasp-R Developed for Robotic Teleoperation

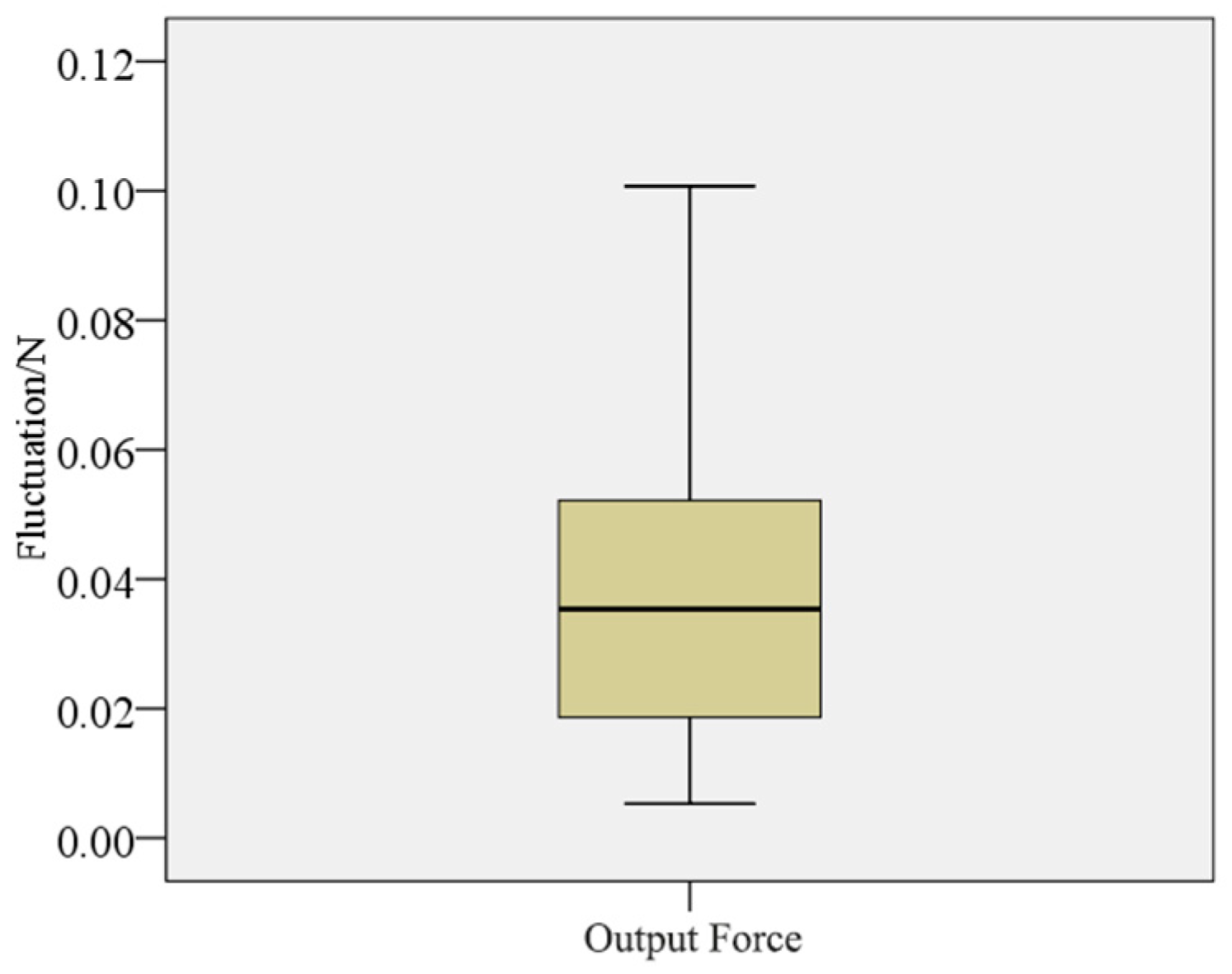

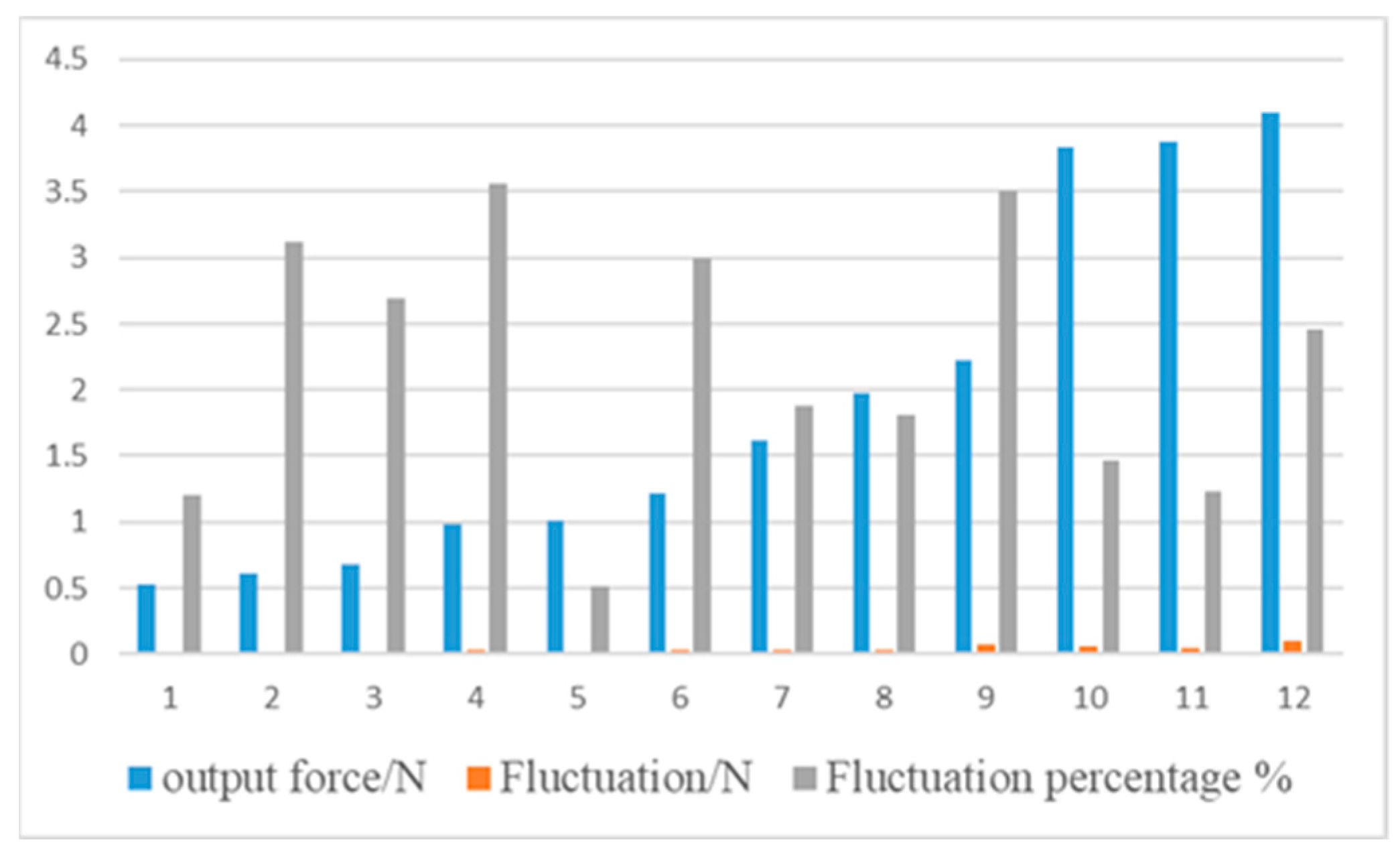

4.1. Measurement of Output Force Fluctuation without Human Hand Tremble by Using iGrasp-R and iGrasp-T

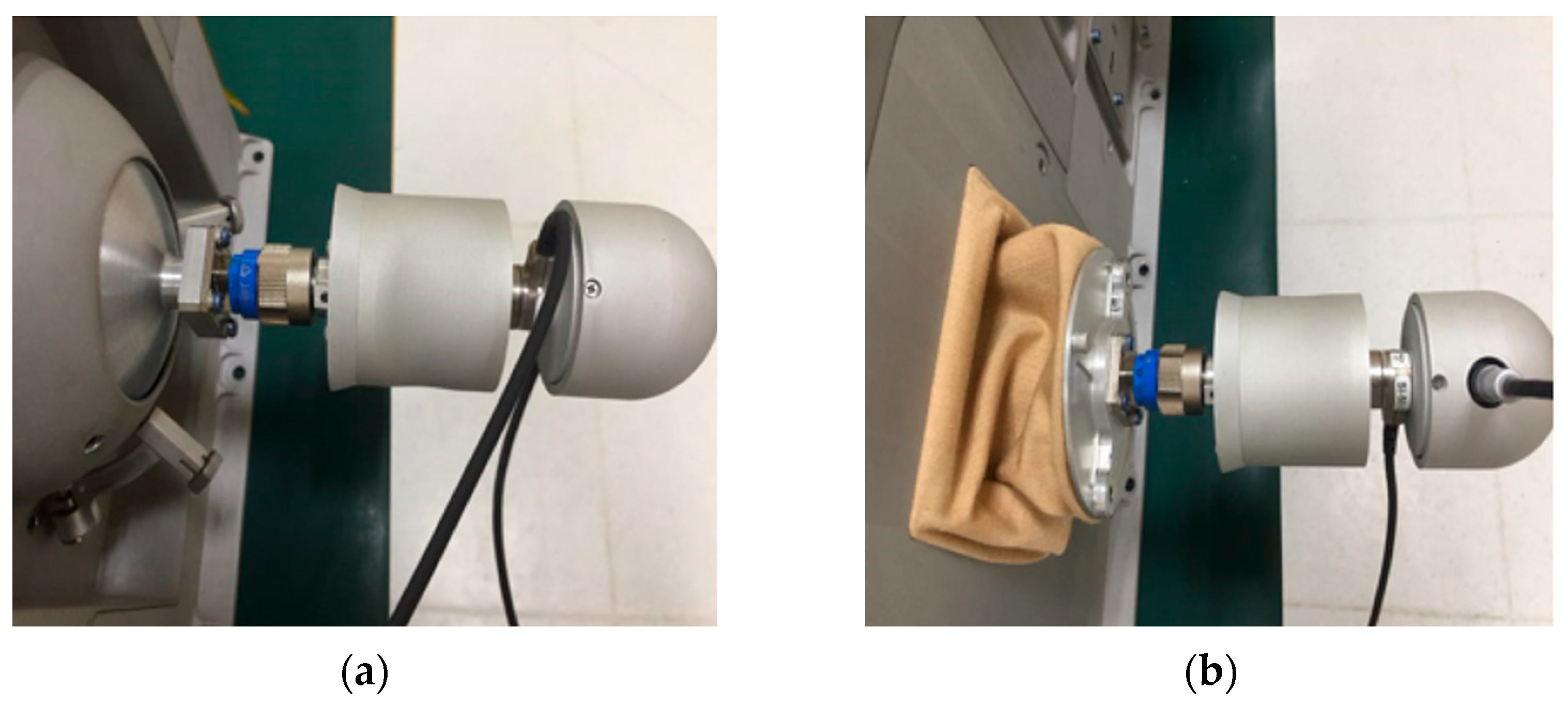

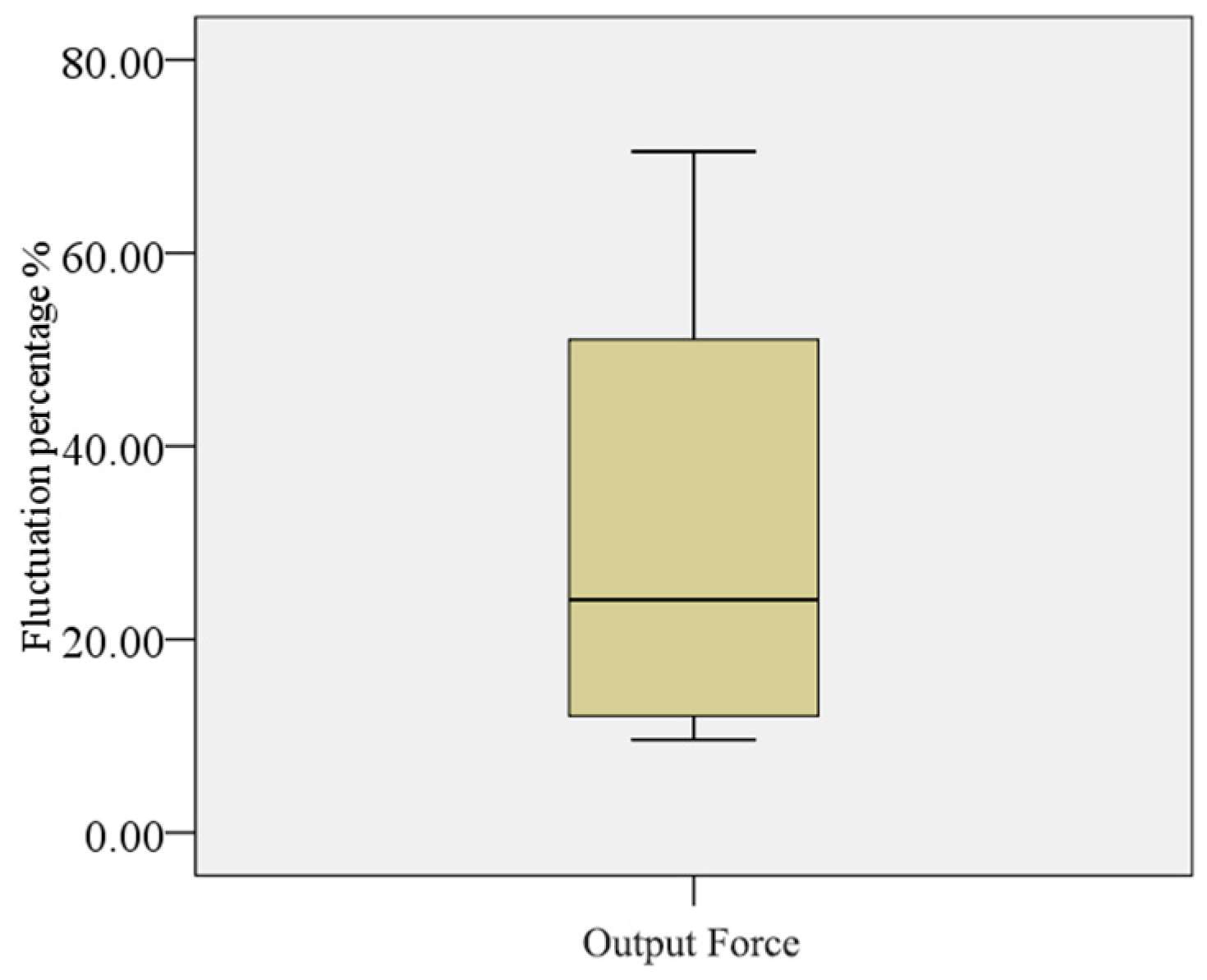

4.2. Measurement of Output Force Fluctuation under Human Manipulation by Using iGrasp-R

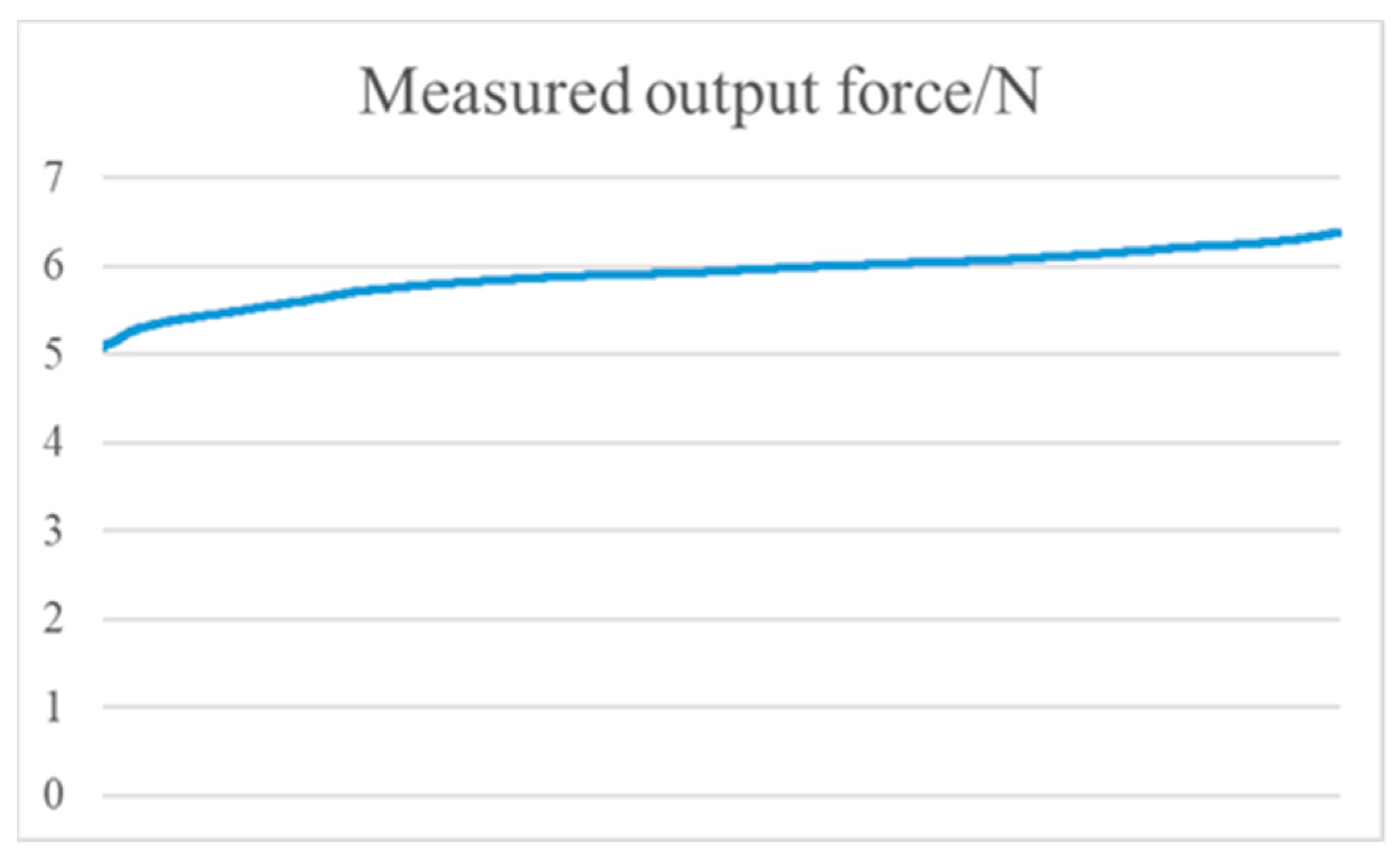

4.3. Measurement of Output Force Accuracy by Using iGrasp-T

5. Evaluation and Suggestion for Haptic Display Accuracy in Teleoperation

5.1. Haptic Rendering Discipline to Eliminate the Influence of Human Hand Tremble

5.2. iGrasp and iHandle Combined as One Haptic Device to Output High Accuracy Force/Torque

6. Conclusions and Future Work

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Sheridan, T.B. Space teleoperation through time delay: Review and prognosis. Autom. IEEE Trans. 1993, 9, 592–606. [Google Scholar] [CrossRef]

- Sheridan, T.B. Telerobotics, Automation, and Human Supervisory Control; MIT Press: Cambridge, MA, USA, 1992. [Google Scholar]

- Hogan, N. Impedance control: An approach to manipulation. ASME J. Dyn. Syst. Meas. Control 1984, 107, 481–490. [Google Scholar]

- Elhajj, I.; Xi, N.; Fung, W.K.; Liu, Y.H.; Li, W.J.; Kaga, T.; Fukuda, T. Haptic information in Internet-based teleoperation. Mechatron. IEEE/ASME Trans. 2001, 6, 295–304. [Google Scholar] [CrossRef]

- Kim, W.S.; Hannaford, B.; Fejczy, A.K. Force-reflection and shared compliant control in operating telemanipulators with time delay. IEEE Trans. Robot. Autom. 2016, 8, 176–185. [Google Scholar] [CrossRef]

- Kim, C.Y.; Kang, B.H.; Lee, M.C.; Yoon, S.M. Design of Master Console Haptic Handle for Robot Assisted Laparoscopy. Stud. Comput. Intell. 2013, 466, 333–340. [Google Scholar]

- Meli, L.; Pacchierotti, C.; Prattichizzo, D. Experimental evaluation of magnified haptic feedback for robot-assisted needle insertion and palpation. Int. J. Med. Robot. 2017, 13, 1809. [Google Scholar] [CrossRef] [PubMed]

- Lee, D.; Kim, U.; Choi, H.R. Development of multi-axial force sensing system for haptic feedback enabled minimally invasive robotic surgery. In Proceedings of the 2014 IEEE/RSJ International Conference on Intelligent Robots and Systems, Chicago, IL, USA, 14–18 September 2014; pp. 4309–4314. [Google Scholar]

- Franken, M.; Satramigioli, S.; Misra, S.; Secchi, C.; Macchelli, A. Bilateral Telemanipulation with Time Delays: A Two-Layer Approach Combining Passivity and Transparency. IEEE Trans. Robot. 2011, 27, 741–756. [Google Scholar] [CrossRef]

- Chan, L.; Naghdy, F.; Stirling, D. Application of Adaptive Controllers in Teleoperation Systems: A Survey. IEEE Trans. Hum.-Mach. Syst. 2014, 44, 337–352. [Google Scholar]

- Slifkin, A.B.; Newell, K.M. Noise, information transmission, and force variability. J. Exp. Psychol. Hum. Percept. Perform. 1999, 25, 837–851. [Google Scholar] [CrossRef] [PubMed]

- Christou, E.A.; Grossman, M.; Carlton, L.G. Modeling variability of force during isometric contractions of the quadriceps femoris. J. Mot. Behav. 2002, 34, 67–81. [Google Scholar] [CrossRef] [PubMed]

- Baweja, H.S.; Patel, B.K.; Martinkewiz, J.D.; Vu, J.; Christou, E.A. Removal of visual feedback alters muscle activity and reduces force variability during constant isometric contractions. Exp. Brain Res. 2009, 197, 35–47. [Google Scholar] [CrossRef] [PubMed]

- Pacchierotti, C.; Tirmizi, A.; Bianchini, G.; Prattichizzo, D. Enhancing the Performance of Passive Teleoperation Systems via Cutaneous Feedback. IEEE Trans. Haptics 2015, 8, 397–409. [Google Scholar] [CrossRef] [PubMed]

- Sakaguchi, M.; Furusho, J.; Takesue, N. Passive Force Display Using ER Brakes and its Control Experiments. In Proceedings of the IEEE Virtual Reality 2001, IEEE Computer Society, Yokohama, Japan, 13–17 March 2001; pp. 7–12. [Google Scholar]

- Senkal, D.; Gurocak, H. Haptic joystick with hybrid actuator using air muscles and spherical MR-brake. Mechatronics 2011, 21, 951–960. [Google Scholar] [CrossRef]

- Lee, C.D.; Lawrence, D.A.; Pao, L.Y. Isotropic force control for haptic interfaces. Control Eng. Pract. 2004, 12, 1423–1436. [Google Scholar] [CrossRef]

- Hung, V.M.; Na, U.J. Tele-operation of a 6-DOF serial robot using a new 6-DOF haptic interface. In Proceedings of the 2010 IEEE International Symposium on Haptic Audio Visual Environments and Games, Phoenix, AZ, USA, 16–17 October 2010. [Google Scholar]

- Ueberle, M.; Mock, N.; Buss, M. VISHARD10, a novel hyper-redundant haptic interface. In International Conference on Haptic Interfaces for Virtual Environment and Teleoperator Systems; IEEE Computer Society: Washington, DC, USA, 2004. [Google Scholar]

- He, X.; Chen, Y. Six-Degree-of-Freedom Haptic Rendering in Virtual Teleoperation. IEEE Trans. Instrum. Meas. 2008, 57, 1866–1875. [Google Scholar]

- Ryu, J.H.; Kim, J.H.; Seo, C.H.; Lim, Y.A.; Kim, J.P. A Survey of Haptic Control Technology. Trans. Korean Soc. Mech. Eng. A 2009, 33, 283–295. [Google Scholar] [CrossRef][Green Version]

- Salisbury, K.; Conti, F.; Barbagli, F. Haptic rendering: Introductory concepts. IEEE Comput. Graph. Appl. 2004, 24, 24–32. [Google Scholar] [CrossRef] [PubMed]

- Ruffaldi, E.; Morris, D.; Edmunds, T.; Barbagli, F.; Pai, D.K. Standardized Evaluation of Haptic Rendering Systems//Symposium on Haptic Interfaces for Virtual Environment and Teleoperator Systems; IEEE Computer Society: Washington, DC, USA, 2006. [Google Scholar]

- Wang, D.; Xiao, J.; Zhang, Y. Evaluation of Haptic Rendering Methods//Haptic Rendering for Simulation of Fine Manipulation; Springer: Berlin/Heidelberg, Germany, 2014. [Google Scholar]

- Raphael, H.; Luca, M.D.; Harders, M. User-based evaluation of data-driven haptic rendering. ACM Trans. Appl. Percept. 2010, 8, 1–23. [Google Scholar]

- Liu, G.Y.; Chen, Y.; Xie, Z.; Geng, X. GA\SQP optimization for the dimensional synthesis of a delta mechanism based haptic device design. Robot. Comput.-Integr. Manuf. 2018, 51, 73–84. [Google Scholar] [CrossRef]

| Step No. | L (Left Hand) | R (Right Hand) | Force (N) | V for Exerting Force (Visual Cue from Computer Screen) | Label |

|---|---|---|---|---|---|

| 1 | √ | 0 | L0 | ||

| 2 | √ | 0 | R0 | ||

| 3 | √ | 2 | √ | L2V | |

| 4 | √ | 2 | √ | R2V | |

| 5 | √ | 2 | L2 | ||

| 6 | √ | 2 | R2 | ||

| 7 | √ | 10 | √ | L10V | |

| 8 | √ | 10 | √ | R10V | |

| 9 | √ | 10 | L10 | ||

| 10 | √ | 10 | R10 | ||

| 11 | √ | 20 | √ | L20V | |

| 12 | √ | 20 | √ | R20V | |

| 13 | √ | 20 | L20 | ||

| 14 | √ | 20 | R20 |

| No. | MeanDiff | SEM | q Value | Prob | Alpha | Sig | LCL | UCL |

|---|---|---|---|---|---|---|---|---|

| R and L | 0.33782 | 0.33093 | 1.44368 | 0.32747 | 0.05 | 0 | −0.3832 | 1.05885 |

| No. | MeanDiff | SEM | q Value | Prob | Alpha | Sig | LCL | UCL |

|---|---|---|---|---|---|---|---|---|

| V and NV | 14.79673 | 2.40063 | 8.71676 | 0.000106 | 0.05 | 1 | 9.44779 | 20.14568 |

| No. | MeanDiff | SEM | q Value | Prob | Alpha | Sig | LCL | UCL |

|---|---|---|---|---|---|---|---|---|

| R and L | −1.3957 | 5.24047 | 0.37665 | 0.7954 | 0.05 | 0 | −13.0722 | 10.2808 |

| Maximum Value along z Axis (N) | Minimum Value along z Axis (N) | Maximum Value Perpendicular to z Axis (N) | Maximum Error along z Axis (N) | Maximum Error Percentage along z Axis |

|---|---|---|---|---|

| 6.32 | 5.08 | 0.66 | 0.92 | 16% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, G.-Y.; Wang, Y.; Huang, C.; Guan, C.; Ma, D.-T.; Wei, Z.; Qiu, X. Experimental Evaluation on Haptic Feedback Accuracy by Using Two Self-Made Haptic Devices and One Additional Interface in Robotic Teleoperation. Actuators 2022, 11, 24. https://doi.org/10.3390/act11010024

Liu G-Y, Wang Y, Huang C, Guan C, Ma D-T, Wei Z, Qiu X. Experimental Evaluation on Haptic Feedback Accuracy by Using Two Self-Made Haptic Devices and One Additional Interface in Robotic Teleoperation. Actuators. 2022; 11(1):24. https://doi.org/10.3390/act11010024

Chicago/Turabian StyleLiu, Guan-Yang, Yi Wang, Chao Huang, Chen Guan, Dong-Tao Ma, Zhiming Wei, and Xinan Qiu. 2022. "Experimental Evaluation on Haptic Feedback Accuracy by Using Two Self-Made Haptic Devices and One Additional Interface in Robotic Teleoperation" Actuators 11, no. 1: 24. https://doi.org/10.3390/act11010024

APA StyleLiu, G.-Y., Wang, Y., Huang, C., Guan, C., Ma, D.-T., Wei, Z., & Qiu, X. (2022). Experimental Evaluation on Haptic Feedback Accuracy by Using Two Self-Made Haptic Devices and One Additional Interface in Robotic Teleoperation. Actuators, 11(1), 24. https://doi.org/10.3390/act11010024