1. Introduction

Hybrid mechatronic systems, which include interacting continuous and discrete dynamics, are widely used in modern industrial systems, such as automobile, chemical plant, and aerospace engineering [

1,

2]. As their complexities increase, higher demand on safety and reliability requires more accurate fault diagnosis and failure prognosis which could provide effective means for system maintenance. Consequently, it is important to detect and isolate system faults as soon as possible and then considerable economic losses can be avoided [

3,

4,

5]. Since recent years, many valuable works have been reported in the hybrid system fault diagnosis and prognosis fields [

6,

7,

8,

9,

10]. Among these works, discrete event system model-based methods (e.g., Petri net and automaton) are widely investigated. The timed Petri net model is used for mode tracking and fault diagnosis of hybrid systems [

6]. This model can only depict the temporal discrete event degradation of the hybrid system because the continuous dynamics is neglected. The main problem of this method is that domain-specific knowledge is required to build the fault–symptom table. In addition, training data obtained from reliability testing are needed to compute the individual faults prior probability distributions. The hybrid automaton model is utilized for fault diagnosis of hybrid systems based on structured residuals [

7]. The hybrid automaton model consists of finite state automaton and continuous state-space model. The continuous state-space model is used to derive structured residuals for fault detection. The structured residuals can generate the fault signatures for fault isolation. However, for complex hybrid systems with many modes, this method needs to derive a large number of state-space models. Therefore, it is difficult to design fault diagnosis algorithms and real-time implementation under this situation. Fortunately, hybrid bond graph (HBG), which is a graphical tool only, utilizes a set of unified equations (i.e., global analytical redundancy relations (GARR)) for fault diagnosis where information of all modes and physical component faults are incorporated [

10]. According to GARRs, the fault signature matrix (FSM) and mode change signature matrix (MCSM) can be established, based on which the isolation of unexpected mode change and component fault can be carried out.

In some cases, the estimations of fault parameters are needed to evaluate the fault severity (e.g., fault severity is required for fault tolerant control) and at the same time refine the set of fault candidates (SFC) if some faults in SFC are non-isolable. The Kalman filter (KF) is a popular method for fault parameter estimation of linear systems with Gaussian noise where the fault parameter is treated as a special state. It generates recursive estimations of state vectors by optimally weighting information from the system dynamic model and current measurements [

11]. However, KF is geared toward linear systems [

12]. To deal with nonlinear systems, extended Kalman filter (EKF) is developed, and this method linearizes the nonlinear systems using the Jacobian matrix, which may reduce the estimation accuracy [

13]. To ameliorate the filter performance, some more efficient methods, e.g., unscented Kalman filter (UKF) and cubature Kalman filter (CKF), are proposed. The advantage of these methods over EKF lies in that the calculation of Jacobian matrix is not required (e.g., UKF directly propagates the nonlinear function through unscented transformation and CKF uses cubature points to approximate the variance and mean). As a result, UKF and CKF can achieve more accurate filtering performance for strongly nonlinear systems [

14,

15]. However, UKF may lead to uncertain solution because it requires the weight of the central sampling point to be positive [

16]. Likewise, the covariance matrix of CKF cannot be decomposed if its positive definiteness is not ensured, which may obstruct the algorithm implementation. To solve the above problem, the square root cubature Kalman filter (SRCKF) which utilizes the square root of the covariance matrix is proposed to guarantee the non-negative definiteness of the covariance matrix [

15]. Nevertheless, it is not a trivial task to properly set the filter noise covariances for SRCKF.

The health monitoring not only needs to diagnose the fault, but also needs to prevent the failure by predicting the remaining useful life (RUL). Roughly speaking, RUL prediction (or prognosis) methods are mainly composed of model-based approaches and data-driven approaches [

17,

18,

19,

20,

21]. A model-based sequential prognosis method is developed for an electric scooter in the presence if intermittent fault [

17]. However, it is challenging to obtain the accurate mathematical model of the degradation process which makes the application of model-based prognosis methods difficult. Therefore, many literatures investigate data-driven approaches which rely on the quality and quantity of history data as alternatives. Yang et al. propose an intelligent RUL prediction method based on a double convolutional neural network model architecture [

19]. Both the above model-based and data-driven methods use deterministic degradation models where the randomness of the degradation process is not considered [

10,

17,

18,

19]. To overcome this shortcoming, the Wiener process, which incorporates stochastic nature in degradation models, is proved to be a suitable tool [

20]. In [

21], Wiener process with linear drift is utilized for the preventive maintenance of microelectromechanical systems. However, most degradation processes are nonlinear where the standard Wiener process may not be a promising solution.

To cope with the aforementioned difficulties, this article proposes a new prognosis method based on improved Wiener process for the hybrid mechatronic system. The main contributions of this article are threefold:

(1) An adaptive square root cubature Kalman filter (ASRCKF) which can adaptively estimate the unknown noise distributions is proposed to accurately estimate the fault parameter.

(2) An improved Wiener process with nonlinear term is developed to capture the degradation of incipient fault.

(3) A prognosis method using fast krill herd (FKH) algorithm is proposed where the FKH is developed to estimate the degradation model coefficients based on the identified fault data from fault estimation module.

The remainder of this article is organized as follows.

Section 2 models the hybrid mechatronic system based on the diagnostic hybrid bond graph (DHBG) theory. In

Section 3, the ASRCKF-based fault estimation is introduced.

Section 4 presents the RUL prediction based on improved Wiener process whose coefficients are estimated by FKH.

Section 5 analyzes the simulation results. Finally, the concluding remarks are given in

Section 6.

2. FDI Based on DHBG Model

Due to the capability in modeling systems with multi-energetic domains, bond graph (BG) theory, which is based on energy conservation law, is a reasonable choice for fault diagnosis and isolation (FDI) of complex mechatronic systems [

4]. In BG methodology, different types of multiport elements are utilized to model the physical components and their behaviors in a variety of energy domains. Generic BG elements consist of source elements (

and

), dissipative element (

R), storage elements (

C and

I), two junctions (0 junction and 1 junction), and two transducers (

and

) [

17]. The half arrow bond is used to connect these generic BG elements. For each bond, there are two power variables (effort

e and flow

f) which can describe the energy exchange between different elements. In addition, there is a perpendicular stroke at one end of a bond to represent the cause and effect relation between power variables. In summary, the BG modeling uses the generic BG elements and bonds with causalities to describe the behaviors of physical system. In

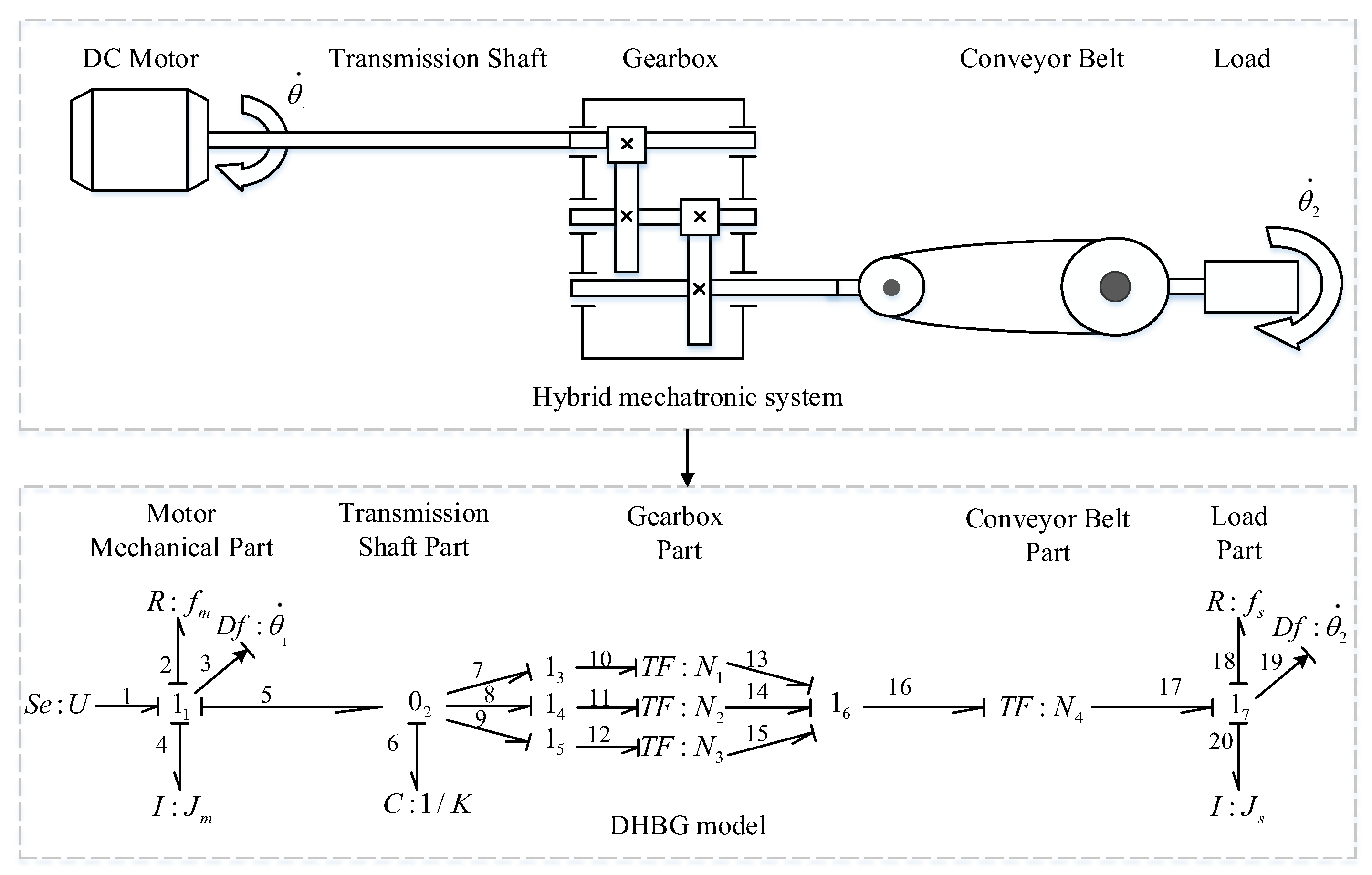

Figure 1, the hybrid mechatronic system which includes continuous and discrete states consists of several subsystems. Thus, it is preferred to use HBG to model the hybrid mechatronic system in a compact manner. The basic BG method is applied to the modeling of continuous systems, while the HBG extends the capability of basic BG to model hybrid systems with the aid of controlled junctions, by which the dynamic characteristic of discrete states characterized by modes can be described. For the purpose of FDI, the sequential causality assignment procedure for hybrid system diagnosis is developed to achieve DHBG, where the sensor causalities are inverted and controlled junctions are put in preferred causalities [

10]. After that, the GARR can be obtained from DHBG.

The DHBG model of the hybrid mechatronic system is shown in

Figure 1. The system can be divided into five parts: DC motor, transmission shaft, gearbox, conveyor belt, and load. The model input

:

U is an effort source, representing the input torque. The representation of

:

U follows the convention of BG modeling where the physical parameter of an element (i.e.,

U for effort source) is attached to the symbol of the element (i.e.,

for effort source) by a colon. This representation applies to all generic BG elements except junction elements. The DC motor mechanical part is composed of the rotor inertia

I:

and mechanical friction

R:

. The stiffness

K of the transmission shaft is represented by the capacitive element

C. The gearbox is modeled by three

elements with gear ratios

,

and

. Likewise, the transformer element

is used to model the conveyor belt with transmission ratio

. The load is characterized by rotational inertia

I:

and mechanical friction

R:

. The angular velocities of motor and load are measured by two flow sensors

:

and

:

.

Analytical redundancy relation (ARR) is a dynamic constraint only containing the known information (i.e., sensor measurements, inputs and physical parameters) of the system. According to the real-time numerical evaluation of ARR (i.e., residual), the fault can be detected if the observed residual exceeds the corresponding threshold. In the DHBG model, the structure and dynamic characteristics of the system are different under diverse modes, and the basic ARR is unable to describe the constraints under different modes in an unified manner. In order to efficiently utilize the residuals generated from DHBG models, the concept of the GARR is introduced. The main distinction between GARR and basic ARR is that GARR carries mode information. The general form of GARR can be represented as follows [

22]:

where

represents the

jth GARR,

a is the mode,

denotes the physical parameter,

U is the system input, and

and

represent the sensor measurements. In

Figure 1,

,

, and

are controlled junctions and the corresponding mode is

, where

,

, and

(indicates that at any instant only one gear ratio is in operation). In DHBG, the junctions attached with sensors of inverted causality are used to derive the GARR equations. In the causality inversion method, the causality of sensor is inverted and the output of the sensor-attached junction is zero (e.g.,

for junction

). Thus, the necessary condition of deriving an ARR (i.e., the junction output variable must be measured by a sensor) can be relaxed. In this way, the ARR can be established using the constitutive relation of the sensor-attached junction [

17]. For junction

connected to the sensor with inverted causality, the constitutive relation can be obtained as follows:

To derive the GARR from junction

, the unknown variables in (

2) should be eliminated by covering the causal paths. Thus, the unknown variables in (

2) can be expressed as

where

is the gear ratio which is in operation.

Substituting (

3) into (

2) leads to

as follows:

For junction

with sensor of inverted causality, the constitutive relation can be formulated as

In the similar way, the unknown variables in (

5) can be solved as

Substituting (

6) into (

5) results in

as follows:

when the fault or the unknown mode change occurs, the corresponding GARR will exceed the threshold. Therefore, a binary coherent vector CV

is defined to represent the consistency of GARRs. The decision rule of

is defined as follows:

In the developed prognosis method, the first step is to detect and isolate the unexpected mode change by comparing the CV with the MCSM. The MCSM is shown in

Table 1, where

represents the detectability. If the unexpected mode change is detected, all possible modes are put in the GARRs. The mode that makes the GARRs consistent is the actual mode. If no unexpected mode change is detected, the nonzero CV is caused by the parameter fault, and the SFC can be obtained by comparing the CV with the FSM in

Table 2. Take an example of the actuator fault in

U, CV

, which cannot be caused by the unexpected mode change, is detected upon the fault occurrence. After comparing the CV with FSM, the SFC

is obtained. To refine the SFC, the ASRCKF-based fault estimation is enabled, where the possible fault parameters in SFC are treated as special states in the state-space model derived from GARRs. Based on the fault estimation results, the fault data representing the fault parameter degradation can be obtained, by which the coefficients of improved Wiener process-based degradation model can be estimated by the FKH algorithm. Once the degradation model is obtained, the prognosis can be implemented using the predefined failure threshold. The framework of the developed prognosis method is illustrated in

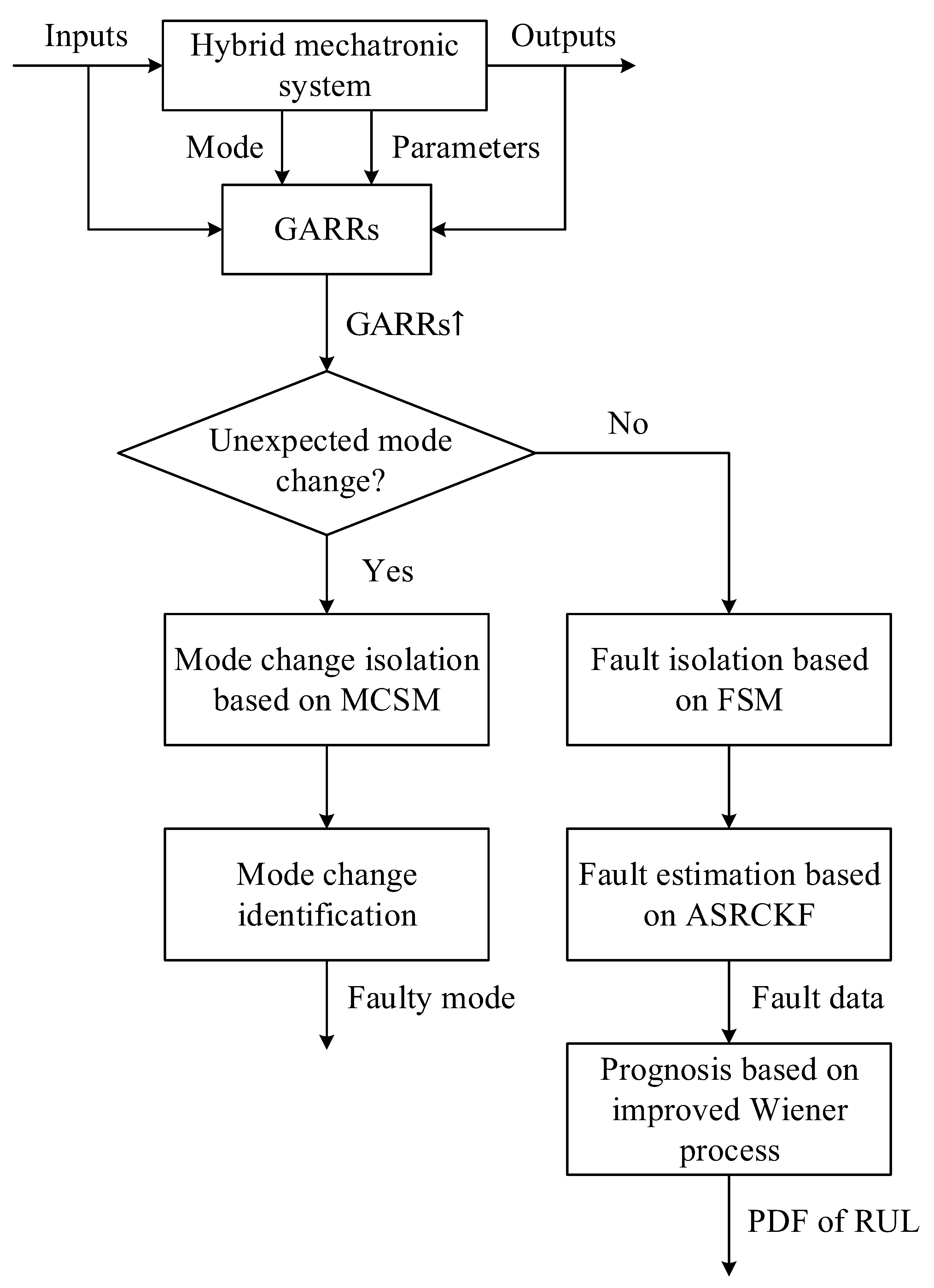

Figure 2.

3. Fault Estimation Based on ASRCKF

With the SFC, the next step is to identify the true fault. In this work, the CKF is employed for fault parameter estimation. Compared with the EKF, CKF which uses cubature points to approximate the variance and mean can achieve better filtering performance for some highly nonlinear systems. To avoid the situation that the covariance matrix of CKF cannot be decomposed, the SRCKF is proposed. However, both CKF and SRCKF require the prior statistical characteristics of noises which are usually unavailable in real applications. Motivated by this observation, ASRCKF is proposed to adaptively update the unknown covariance matrix of process noise and measurement noise.

To implement the ASRCKF for the joint estimation of state and fault parameters, the system state

requires to be augmented as

, where

represents the vector which contains all fault parameters in the SFC (e.g.,

U,

, and

if CV

). Consequently, the nonlinear discrete stochastic model can be derived as

Before introducing the ASRCKF, it is necessary to describe the cubature point selection strategy. According to the third-degree spherical-radial rule, the cubature points are defined as

where

n is the state dimension of the system and

is the

ith element in the operator space

In summary, the ASRCKF can be described as follows.

(1) Initialize state

and covariance matrix

and factorize the covariance matrix

(2) Calculate the cubature points of state vector and cubature points of prediction values of state vector

(3) Calculate the predicted state vector and the square root factor of the predicted error

where

denotes a general triangularization algorithm (e.g., the QR decomposition),

and

is calculated as

(4) Calculate the cubature points of predicted state vector and cubature points of prediction values of measurement vector

(5) Calculate the predicted measurement vector and square root factor of the innovation covariance matrix

where

and

is expressed as

(6) Calculate the cross-covariance matrix and Kalman gain matrix

where

is expressed as

(7) Update the state estimation and calculate the square root factor of the error covariance matrix

(8) Calculate the residual sequence and update the process noise covariance matrix and measurement noise covariance matrix

where

.

In the update stage of noise covariance matrixes, the output velocity residual sequence is used to adaptively estimate and .

To summarize, the different steps of the ASRCKF algorithm implementation are given in Algorithm 1.

| Algorithm 1: Pseudocode of ASRCKF. |

1. Initialize state vector and covariance matrix ,

For each time step:

2. Calculate the cubature points of state vector and cubature points of prediction values of state vector

3. Calculate the predicted state vector and square root factor of predicted error covariance

4. Calculate the cubature points of predicted state vector and cubature points of prediction values of measurement vector

5. Calculate the predicted measurement vector and the square root factor of innovation co-variance matrix

6. Calculate the cross-covariance matrix and Kalman gain matrix

7. Update the state estimation and calculate square root factor of error covariance matrix

8. Calculate the residual sequence and update the process noise covariance matrix and me-asurement noise covariance matrix

|

5. Simulation Results

To verify the effectiveness of the proposed prognosis method, simulations are carried out in MATLAB R2017a for the hybrid mechatronic system. There are two fault scenarios where the first one is a mode fault injected at 7 s and the second one is an incipient actuator fault introduced at 7 s. The nominal parameter values of the hybrid mechatronic system is shown in

Table 3.

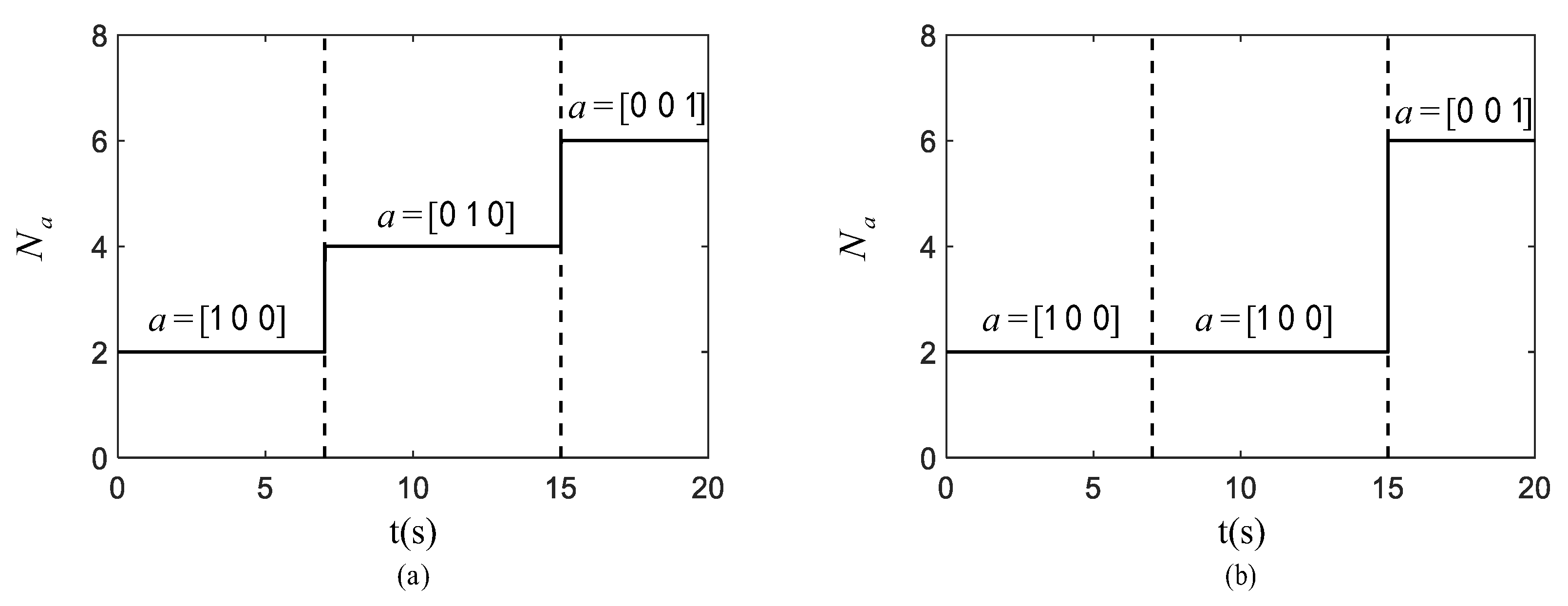

In the first fault scenario, the desired

in operation and the actual

in operation are shown in

Figure 3, where the state of mode changes at 7 s and 15 s. The mode fault is set as

between 7 s and 15 s, where the actual

is 2 (while the desired

is 4).

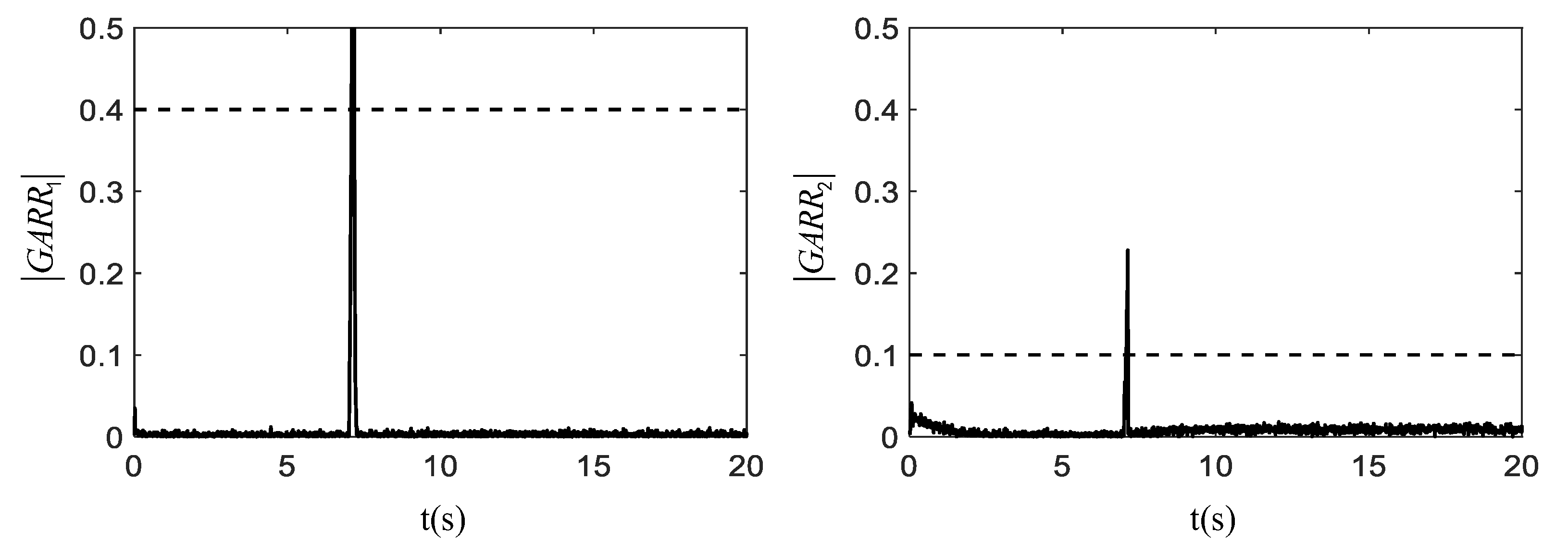

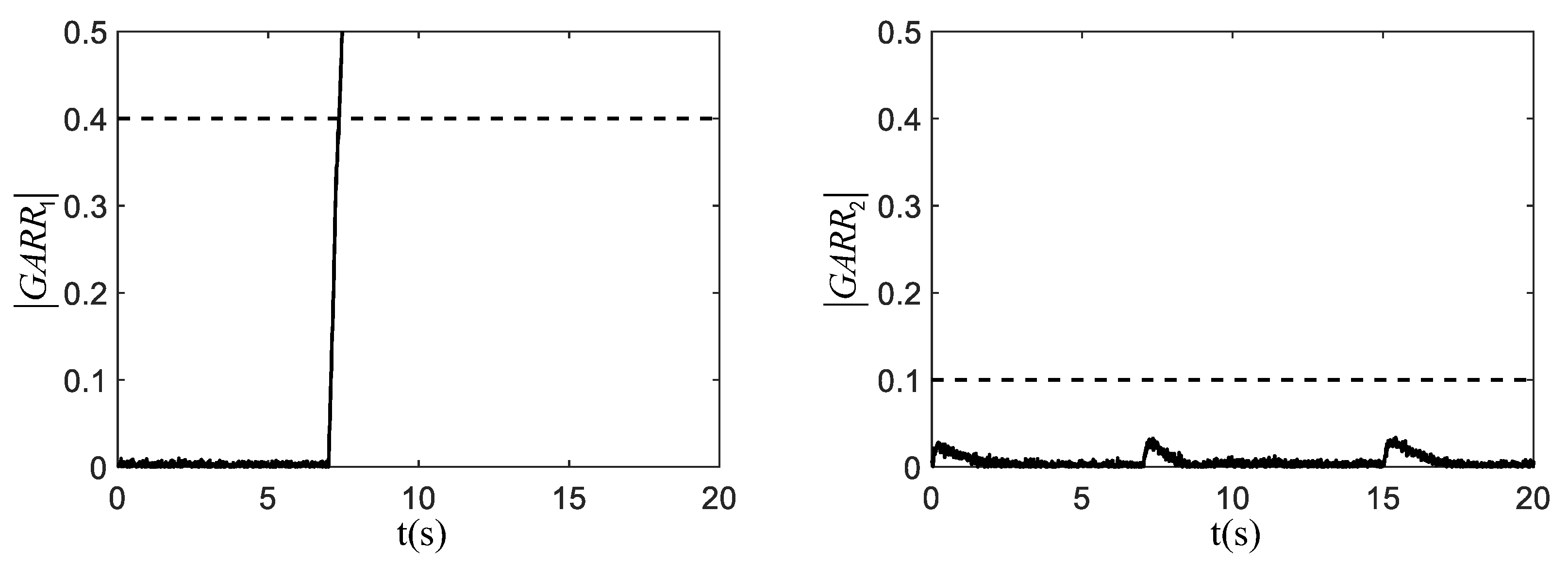

Figure 4 illustrates the residual responses where all residuals exceed the thresholds (i.e.,

and

) at 7 s. After that, the condition monitoring system is enabled to check whether the inconsistency is due to a mode fault by comparing the CV =

with the MCSM. Thus,

and

are two possible fault modes that may lead to the inconsistency. However, substituting

into GARRs cannot make GARRs consistent. Therefore, the possible fault mode is

, and the GARRs will return within the threshold after

a is set as

.

In the second fault scenario, the normal torque of the actuator is 1 Nm and an incipient fault of the actuator is injected at 7 s. The degradation law of incipient fault is defined as

, where

is 7 s and

is the Brownian motion which represents the randomness of degradation process.

Figure 5 shows the responses of residuals by which the CV is

after fault occurrence. As the nonzero CV has no matching in the MCSM, the possibility of mode fault is ruled out and SFC is obtained as

by comparing CV with the FSM. To refine the SFC, the fault estimation module is activated by using the ASRCKF. Estimation results of

and

by ASRCKF are shown in

Figure 6. According to estimation results,

and

are excluded from the SFC because their estimated values are close to the nominal ones.

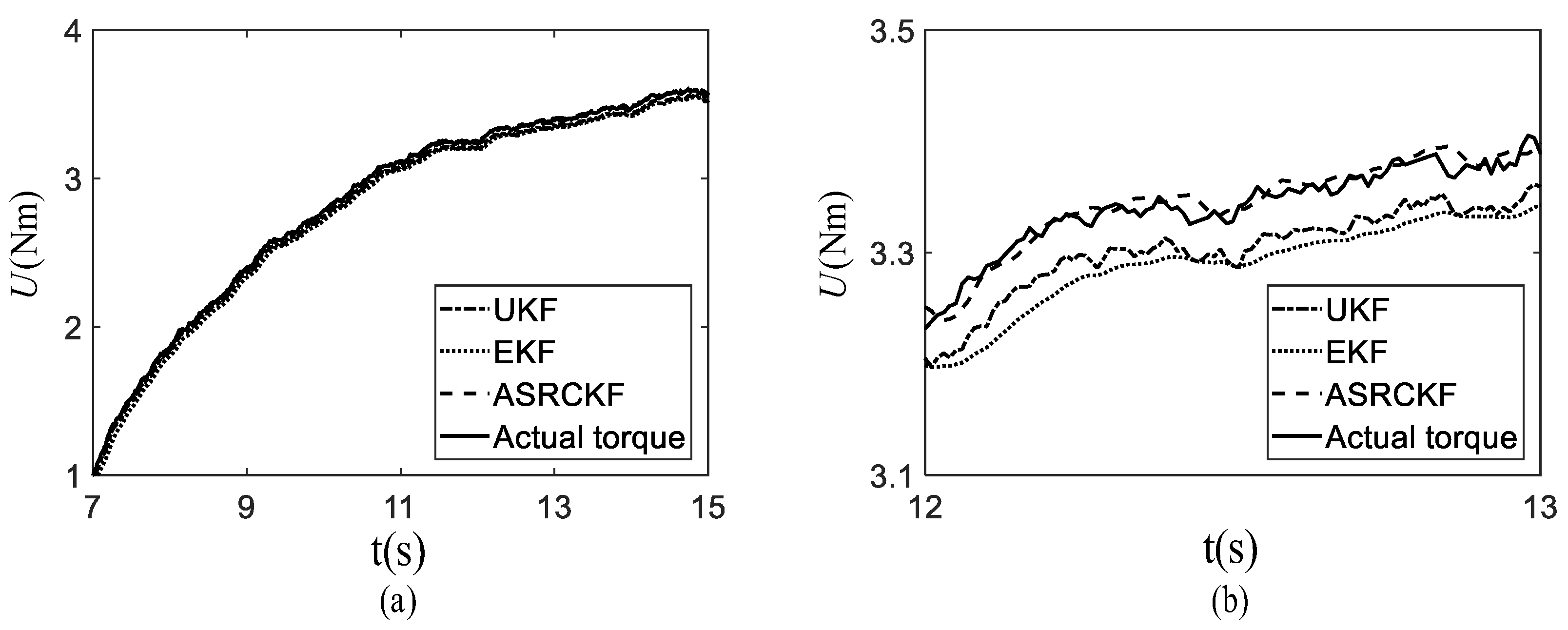

Figure 7a illustrates the estimated

U where the estimated value significantly deviates from the nominal one. As a result, the true fault is

U. To verify the superiority of ASRCKF, the EKF and UKF are also adopted to estimate

U for comparison. Initial parameters for all filters are set as

= diag(0.01,0.01,0.01,0.01,0.01,0.01,0.01),

= diag(0.1,0.1,0.1,0.1,0.1,0.1,0.1) and

= diag(0.01,0.01).

In addition to the estimation result of

U, the partial magnification of estimation results between 12 s and 13 s is illustrated in

Figure 7b. To make the comparison quantitatively, the estimation performance of three methods is given in

Table 4, where ASRCKF is superior to other two algorithms due to the employment of the square root factor and the adaptive estimation of noise covariance matrixes.

After fault estimation, the estimation of the degradation model (i.e., the improved Wiener process) coefficients can be implemented using the estimated fault data of

U. The estimate of

using the least square method is shown in

Figure 8a. It is observed that

increases as

increases, and

reaches the minimum value when

is equal to 2. Thus, the optimal value of

is 2. In

Figure 8b,c, the estimation results of

and

are obtained by the FKH. Initial parameters for KH and FKH are set as

,

,

,

,

,

, and

. Both KH and FKH run 10 times based on the same estimated fault data of

U, and the comparison of estimation results is given in

Table 5. It can be observed from the table that KH and FKH could achieve similar estimation results. However, compared with KH, it is found that FKH is more efficient in terms of the convergence speed.

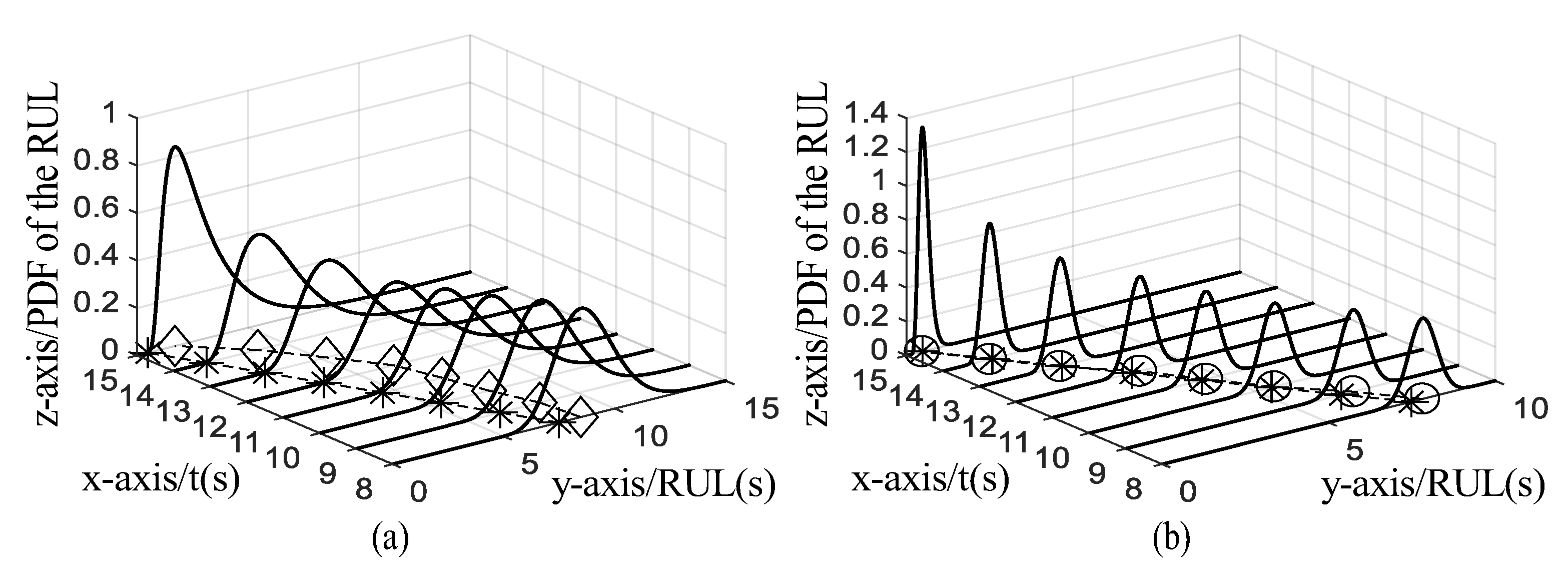

After the degradation model coefficients are obtained, RUL prediction can be carried out. The failure threshold of

U is 4 Nm. Based on the estimated degradation model coefficients and (

34), the PDF of RUL can be obtained. In

Figure 9a, the

x-axis,

y-axis, and

z-axis represent the time index, RUL, and the PDF of RUL. At each chosen instant, there is a curve (denoted by a solid line) covering different RULs. It is observed that actual RULs fall outside the coverage of the PDFs of RULs predicted by the standard Wiener process. The unsuccessful RUL prediction is due to the limited fitting capability of the standard Wiener process (i.e., only applicable to linear degradation process). In

Figure 9b, the axes are set the same as in

Figure 9a. It is found that the actual RULs are enveloped by the PDFs of RULs obtained by the improved Wiener process which is not the case for the standard Wiener process. For intuitive comparison, the top views of

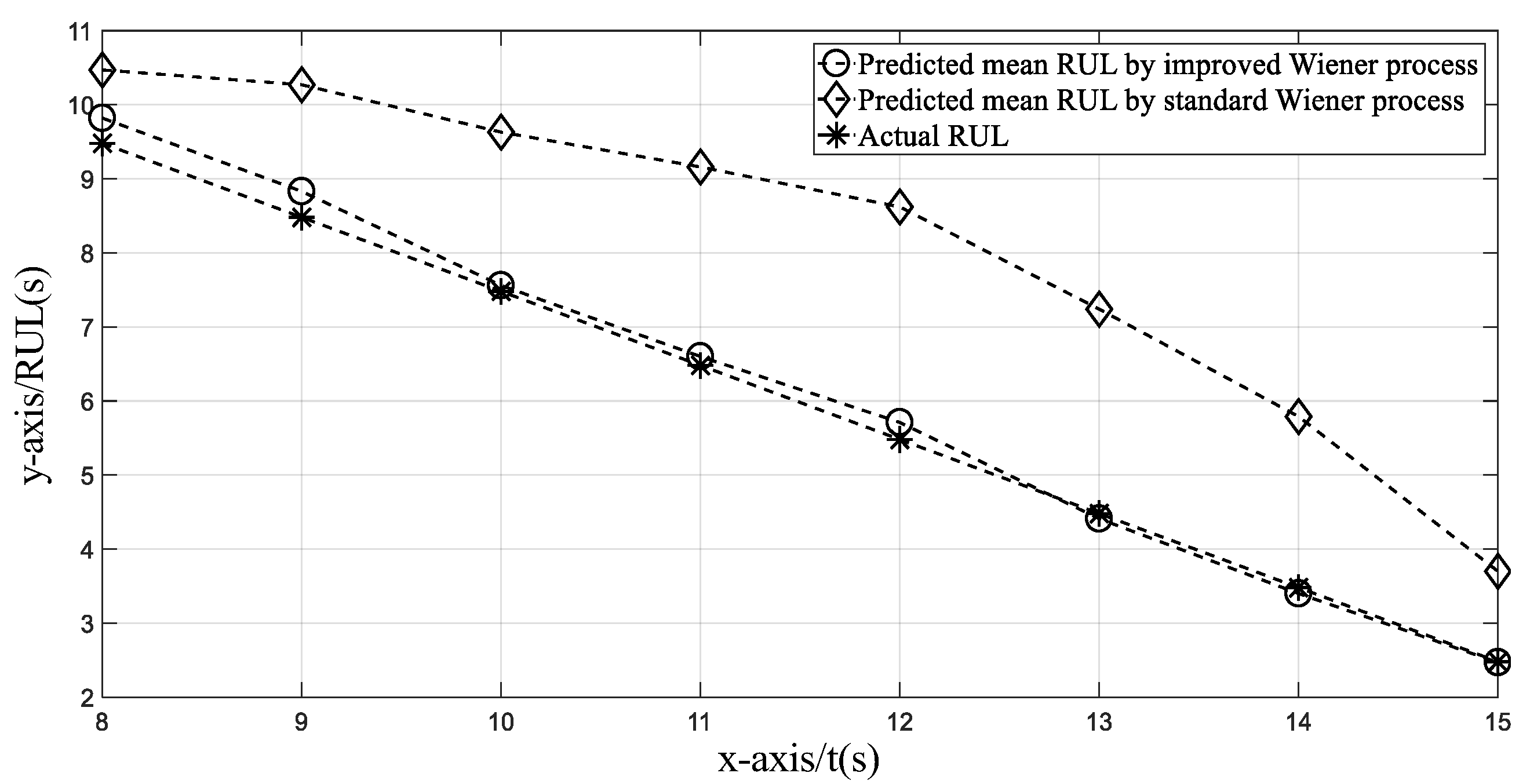

Figure 9a,b are combined to form

Figure 10 where

x-axis and

y-axis still represent the time index and RUL. In

Figure 10, the predicted mean RUL by standard Wiener process cannot track the actual RUL since only linear term is used. By contrast, the predicted mean RUL by improved Wiener process shows consistency with the corresponding actual RUL. Consequently, the proposed prognosis method using improved Wiener process performs better than the one using standard Wiener process.

6. Conclusions

In this article, a computational intelligence-based prognosis method is developed for the hybrid mechatronic system. Specifically, three main works are presented as follows (according to different sections): (1) GARRs derived by the DHBG are utilized to obtain MCSM and FSM, based on which both the unexpected mode changes and SFC can be isolated; (2) a novel filtering algorithm called ASRCKF is proposed for parameter estimation in the presence of unknown noise distributions. The ASRCKF functions better than other filtering methods (such as EKF and UKF); (3) the improved Wiener process incorporating nonlinear term is developed to capture the degradation of incipient fault, where the nonlinearity and randomness of degradation process are both taken into account. In addition, to ensure the accuracy of estimate, the FKH is proposed to estimate the degradation model coefficients efficiently.

In the future, there are three works that need to be addressed. First, only incipient fault is considered in this work. However, intermittent fault, abrupt fault, mode fault, or their combination may occur in the hybrid mechatronic system. Consequently, more sophisticated algorithms are required to handle this complicated fault situation. Second, the system is open-loop and no fault compensation is considered in this work. Thus, the fault-tolerant controller will be designed along with the effect of modeling and parametric uncertainties in the future work. Lastly, only simulation results are analyzed. Experiments will be carried out in modern industrial mechatronic systems to show practice significance of the proposed method.