1. Introduction

Shape memory alloys (SMA) are smart materials that undergo a phase transformation between two solid phases, martensite and austenite [

1]. Heating/cooling of an SMA element beyond the transformation temperature yields large and reversible strains that can be employed in actuator mechanisms.

The martensitic and reverse martensitic phase transformations are diffusionless first-order phase transformations between a high-temperature austenite phase and a low-temperature martensite phase. SMA exhibit strong nonlinear thermo-mechanical behaviors associated with abrupt changes in their lattice structure. The crystallographic symmetry of the austenite is higher than that of the martensite, leading to a variety of symmetry-related degenerate states in the martensite phase called variants [

2]. Local domains within the martensite phase that are oriented at different variants are termed twins and the interface between them is termed twin boundary.

When unloaded austenite is cooled below the transition temperature, different parts of the crystal transform to different variants and form a (self accommodated) twinned microstructure, such that the overall macroscopic shape of the crystal remains approximately the same [

3]. When subjected to a load at this low temperature, the mixture of variants is converted to variants more favorably oriented with respect to the load (detwinned martensite). For example, under tension, the variant with the longest unit cell parameter lying along the tensile axis will be favorable. The overall process of switching the martensitic variants is called twinning reorientation, and the process of reorienting the martensite phase towards the preferred variant is typically referred to as detwinning [

2]. These processes involve an overall significant strain change of several percentages. Since the different variants are energetically equivalent, no driving force exists to return to the mixture of variants upon unloading; thus, the deformation is apparently plastic. Heating above the transformation temperature under little or no load converts it back to the higher symmetry austenite phase, thereby recovering the strains [

2]. This process of returning to the original shape is called the shape memory effect. Specific conditioning of the SMA may result in favorable martensitic variants that are oriented in a specific direction, inducing a strain change even at the absence of external loads, typically referred to as the two-way shape memory effect.

SMA-based actuators provide a unique combination of large stresses and strains that result in work-per-volume larger by more than two orders of magnitude than all other actuators that are based on active materials [

4]. This advantage has gained SMA actuators significant interest in many medical, automobile, aerospace, wind energy, and industrial applications [

5,

6,

7,

8,

9,

10,

11,

12,

13,

14,

15,

16]. However, conventional SMA actuators suffer from two major drawbacks: slow actuation time and low energy efficiency [

10].

The response time of low-driving-force (slow-rate) SMA actuators, in which thermo-mechanical equilibrium is achieved throughout the transformation, is typically restricted by the rate of heat transfer rather than the rate of phase transformation in the SMA element. In fact, SMA wires can be heated very fast using Joule (resistance) heating. This can result in a high driving-force for the transformation allowing for high-rate uni-directional actuation.

Some progress has also been made in the field of active cooling of SMA actuators. It has been shown that various active cooling methods can improve the convective heat transfer coefficient up to eight folds compared with natural convection [

17] and five-fold improvement of cyclic actuation [

18]. However, the obtainable cooling times remain several orders of magnitudes larger than the heating time scales for single-shot actuation discussed in this paper. Recently, there is a growing interest in such high-rate actuators for single-shot applications, such as release/deployment mechanisms [

9,

19,

20,

21,

22,

23,

24], and high-strain-rate mechanical testing of materials [

25,

26], as well as high-frequency and energy efficient actuation in micro-scale systems [

27,

28,

29,

30,

31,

32].

In studies involving high-rate SMA actuation, heating pulses with duration as short as 1 μs [

33,

34,

35] were generated and tuned by discharging a capacitor onto SMA wires. The resulting mechanical response occurred in the microsecond time scale, dramatically reducing the response time of the actuator. In addition, pulsed heating of SMA wires was shown to be significantly advantageous over slow-rate SMA actuators in terms of energy efficiency and travel-per-length [

24,

36]. Applications of interest for heat-pulse activation of SMA wires typically require a small number of actuation activations. Repeatability and functional fatigue performances required for such applications are discussed in

Section 6.3 and are totally different than fatigue life performances required by slow-rate and low-stress cyclic applications, e.g., as described in Ref. [

37].

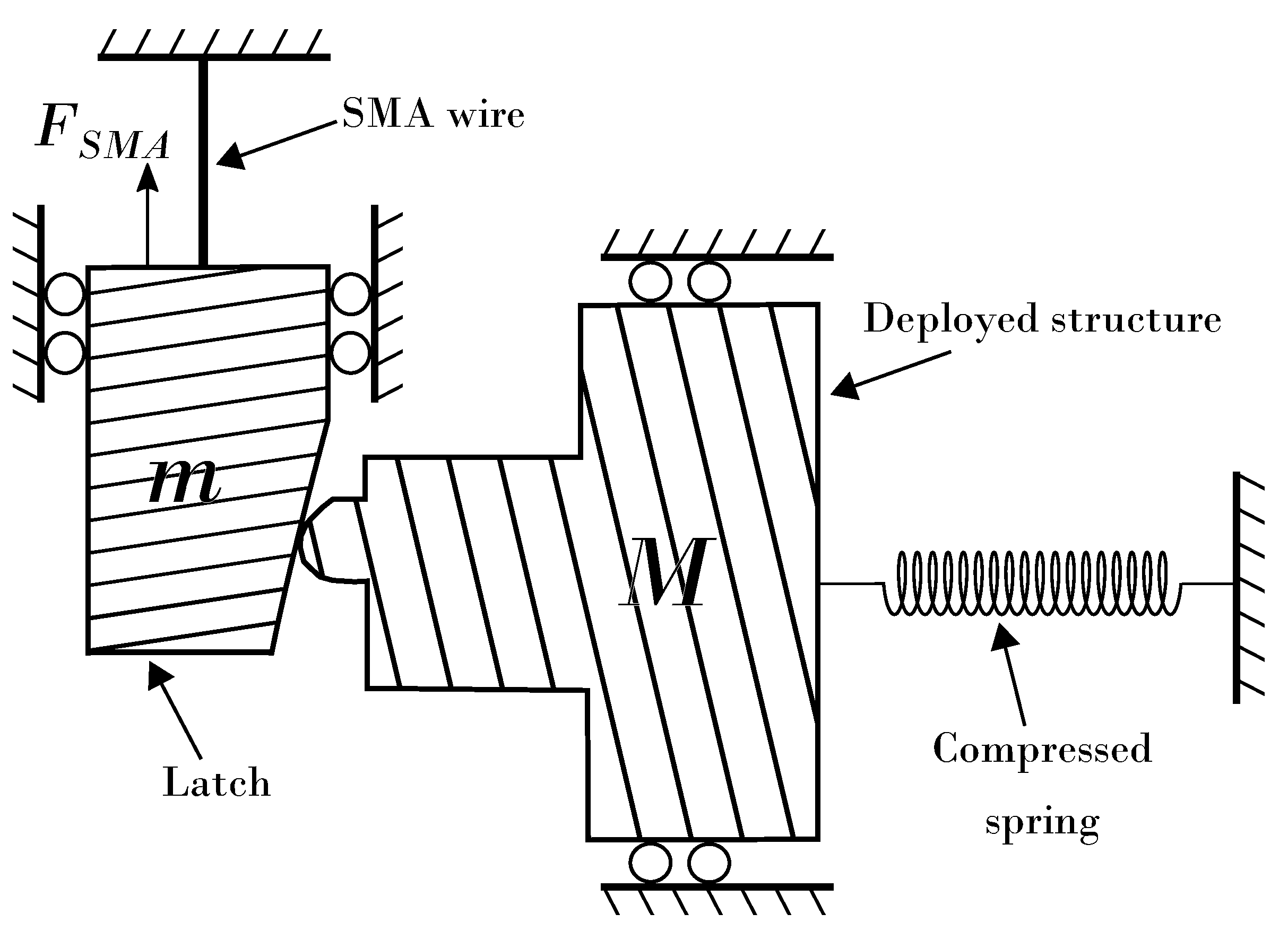

Clever design of mechanical mechanisms activated by the SMA actuator can utilize the fast and powerful actuation capabilities for reducing the required output work and total actuation duration. An example for such application has been demonstrated in Ref. [

24], which implemented a release mechanism consisting of a latch that locks/unlocks a deployed device; see

Figure 1. The SMA actuator rapidly pulled the latch faster than the motion of the deployed device. As a result, the contact between the latch and the deployed device was disconnected, and the friction forces between them decreased to approximately zero, effectively decreasing the required work. This mechanical design concept, combined with the improved energy efficiency that characterizes high-rate SMA actuators, reduced the required input energy by an order of magnitude compared to a slower-rate SMA-based release mechanism [

24].

Table 1 reviews previous studies of the thermo-mechanical response of SMA wires under electric pulse heating. The mechanical boundary conditions (third column) to which the SMA wire is subjected indicate the purpose of the study and potential related applications (as demonstrated in the following paragraphs).

Volkov et al. [

35] studied SMA wires that were completely free of mechanical loads and constrains. In this configuration, the wire does not act as an actuator, but the experimental results enable studying the response of the phase transformation, an open and interesting topic in materials science. They found that the phase transformation begins within ∼1 μs after the wire temperature reaches the transformation temperature.

Vollach et al. (2017) [

38,

39] studied the kinetics and thermodynamics of the phase transformation under conditions at which the response is restricted neither by heat transfer nor by mechanical inertia. To apply these conditions, they clamped the wire at both ends. In this configuration, the wire does not perform external work because there are no moving parts, but the mechanical constrains result in a significant internal stress. This configuration is relevant for applications in which the actuator is required to break a safety pin.

Dana et al. [

34] studied the kinetics of the reverse martensitic transformation by using time-resolved X-ray diffraction at synchrotron radiation to measure the in-situ microscopic phase content in a thin layer near the wire surface. Their mechanical boundary conditions were similar to those in Refs. [

38,

39]. The simultaneous measurement of the microscopic phase content and macroscopic stress provided evidence on the spatial evolution of transformation in high-quality polycrystalline NiTi wires. In particular, they found that the microscopic response occurred within approximately 5 μs of the heating pulse on the wire surface and that the bulk of the wire followed suit after approximately 20 μs. These results provide insight to the mechanisms by which the phase transformation propagates (e.g., by the evolution of macroscopic phase fronts).

References [

9,

21,

24,

33,

35,

36] applied mechanical conditions that are relevant for actuators, clamping the SMA wire at one end, while the other drives a mechanical part or an object (e.g., a hanging mass), generating work. The hanged mass may be allowed to move freely [

33,

40], subjected to a friction force due to contact with a deployed mechanical part [

19,

24], or connected to a spring [

36]. Refs. [

9,

21] studied a combination of a spring and friction.

The paper is organized as follows. In

Section 2, we provide general design guidelines for obtaining high energy efficiency, short actuation times, and large travel-per-wire-length. In

Section 3, we present guidelines for selecting the source of the electric pulse and its parameters (see the two right columns in

Table 1). In

Section 4, we present typical experimental results and their main features, discussing differences and similarities between the clamp-free and the clamp-clamp configuration. In

Section 5, we briefly survey previous results about the kinetics and thermodynamics of the phase transformation in view of its practical implications. In

Section 6, we present new experimental results regarding energy efficiency, total actuation time, and discuss repeatability and fatigue. In

Section 7 and

Section 8, we construct and solve detailed simulations of actuator response that can serve as accurate design tools.

Section 7 and

Section 8 focus on the clamp-free actuator configuration, in which the actuated mass can move freely, but show how the developed simulations can be expanded to consider cases in which the motion of the mass is subjected to external forces, such as friction or a restoring spring. Finally, in

Section 9, we conduct a discussion of the different aspects of SMA actuation considered above, and in

Section 10, we summarize and present our main conclusions.

3. Selecting and Designing the Source of the Electric Pulse

The length,

, and cross section area,

A, of the SMA wire determine its electric resistance via

where

, is the electric resistivity of the SMA, which is a material property. Note that

of the martensite and austenite phases differ by several percentages. For simplicity, this difference is ignored in this section. To obtain high electrical efficiency, it is desired that

will be much greater than the parasitic resistance

of the electric system, e.g., due to the resistance of the electric wires that connect the SMA wire to the power source. In cases where the value calculated by Equation (

7) is too small, one may replace a single thick SMA wire with several thin wires that are mechanically connected in parallel (to provide the same force) but electrically connected in series (to provide a greater resistance, see, e.g., Ref. [

24]).

Assuming that the electrical efficiency is close to one, the electric power,

P, scales as

where

is the voltage, and

is the overall resistance. Thus, for a given required value of

(see discussion in the previous section), there is a trade-off between the desires to have a low voltage and a short electric pulse duration, which are related through the discharged capacitance,

C (see detailed discussion in

Section 8).

Two types of power sources may be considered (cf.

Table 1). For voltages under approximately 125 V, a DC power source can be used, as demonstrated in Ref. [

36]. In this case,

represents the electric pulse duration, which is determined by an electronic switching device. For higher voltages, the power source has to be based on a single or a set of capacitors that are charged before the onset of actuation. Then, upon triggering, the capacitors are rapidly discharged onto the SMA wire. Assuming a complete discharge, the input energy for heating is given by

where

C is the overall capacitance, and

is the charged voltage. During the electric pulse, both the voltage and the current decay exponentially with a characteristic time equal to

Equations (

9) and (

10) indicate the aforementioned trade-off. A large capacitance is desired in order to use a lower voltage, but a small capacitance is desired in order to have a short pulse duration. In this regard, two voltage ranges may be considered. For a voltage lower than approximately 450 V, inexpensive electrolytic capacitors and a solid-state switching device can be used, as demonstrated in Ref. [

24]. For higher voltages (typically above 1 kV), ceramic capacitors and a spark-gap switching device should be used, as demonstrated in Refs. [

33,

35,

40]. These components are more expensive and the high voltage applies safety considerations.

Another important consideration of

comes from the electromagnetic skin effect. According to this effect, the penetration depth of an electric pulse is given by [

42]

where

is the magnetic permeability, approximately equal to that of free space (

) in NiTi [

40]. To allow for a uniform heating of the SMA cross-section, the penetration depth should be much larger than the wire radius, i.e.,

. Substituting Equation (

11) into this requirement, we obtain a condition for the minimal desirable value of

, for a given wire radius,

Here, again, the use of several SMA wires electrically connected in a series to manipulate the resistance for a given wire radius may be of value. A substitution of material properties of NiTi into Equation (

11) indicates that, for

values on the order of 1 μs, the penetration depth is larger than 1 mm, which is much larger than the diameters of any of the wires used in the experiments described in this paper.

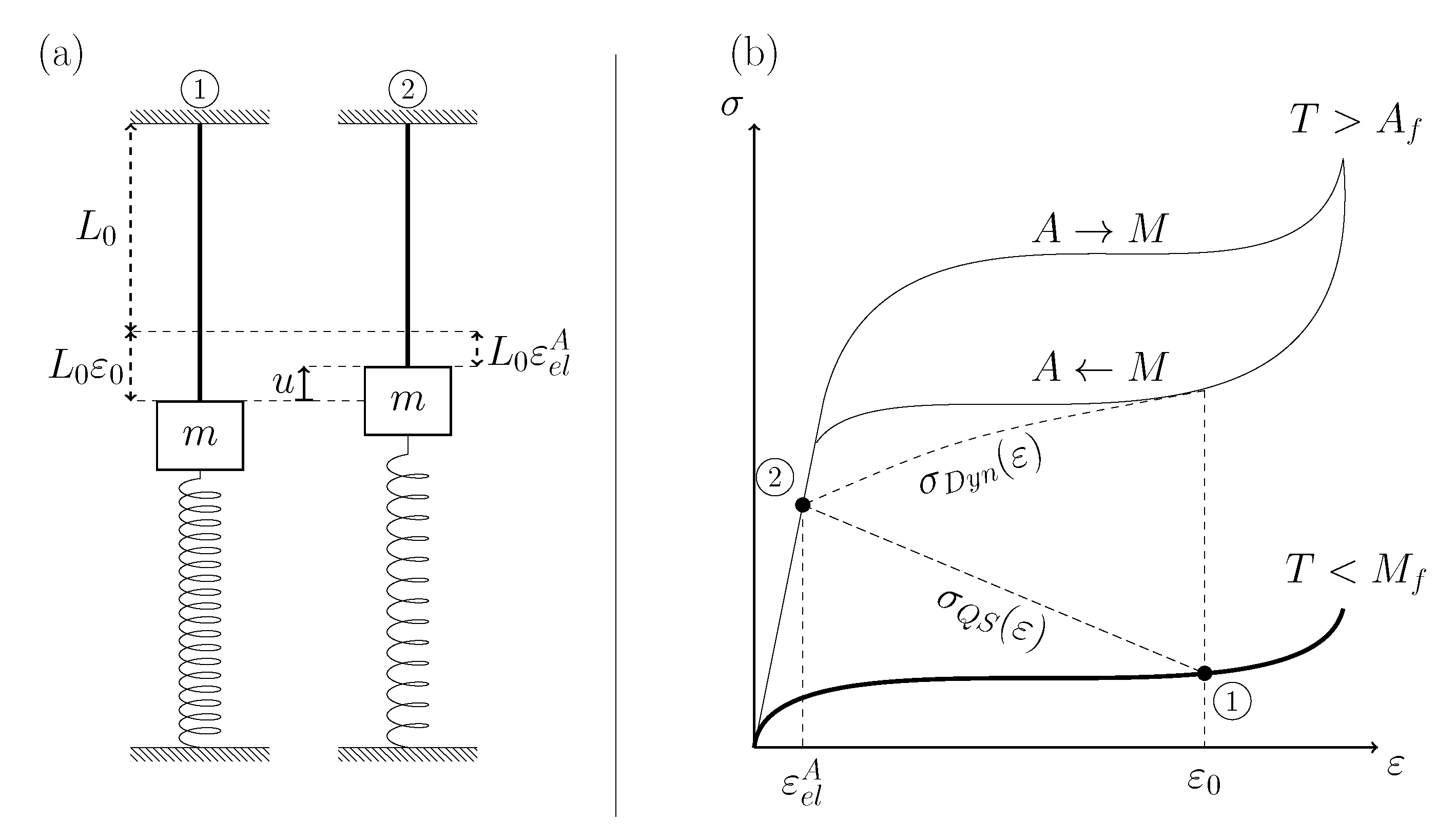

5. Kinetics and Thermodynamics of the Phase Transformation

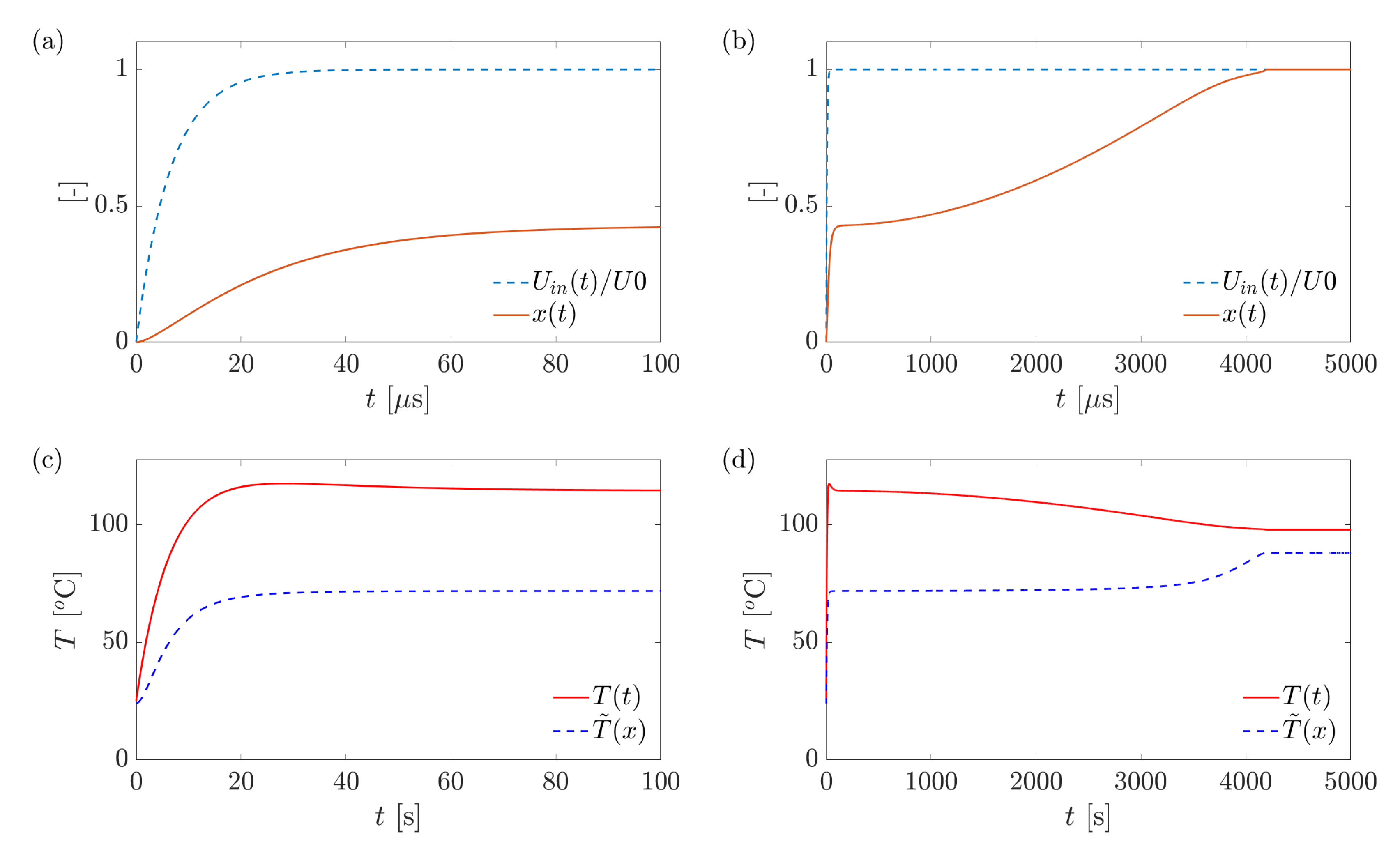

Herein, we will demonstrate that, in the clamp-free configuration, the conditions to which the SMA wire is subjected during the first 1000 μs (determined by the mechanical natural frequency of the actuator) are very similar to those of a wire that is clamped at both ends. The next section surveys typical results of this type of experiments. In particular, experiments in which the wire is clamped at both ends have been used for studying the kinetic law for the phase transformation and the equilibrium stress (as a function of temperature) [

38,

39]. The latter can be used for evaluating the average stress level at

μs in a clamp-free configuration. A schematic illustration of the mechanical set up of the clamp-clamp experimental configuration is depicted in

Figure 3b.

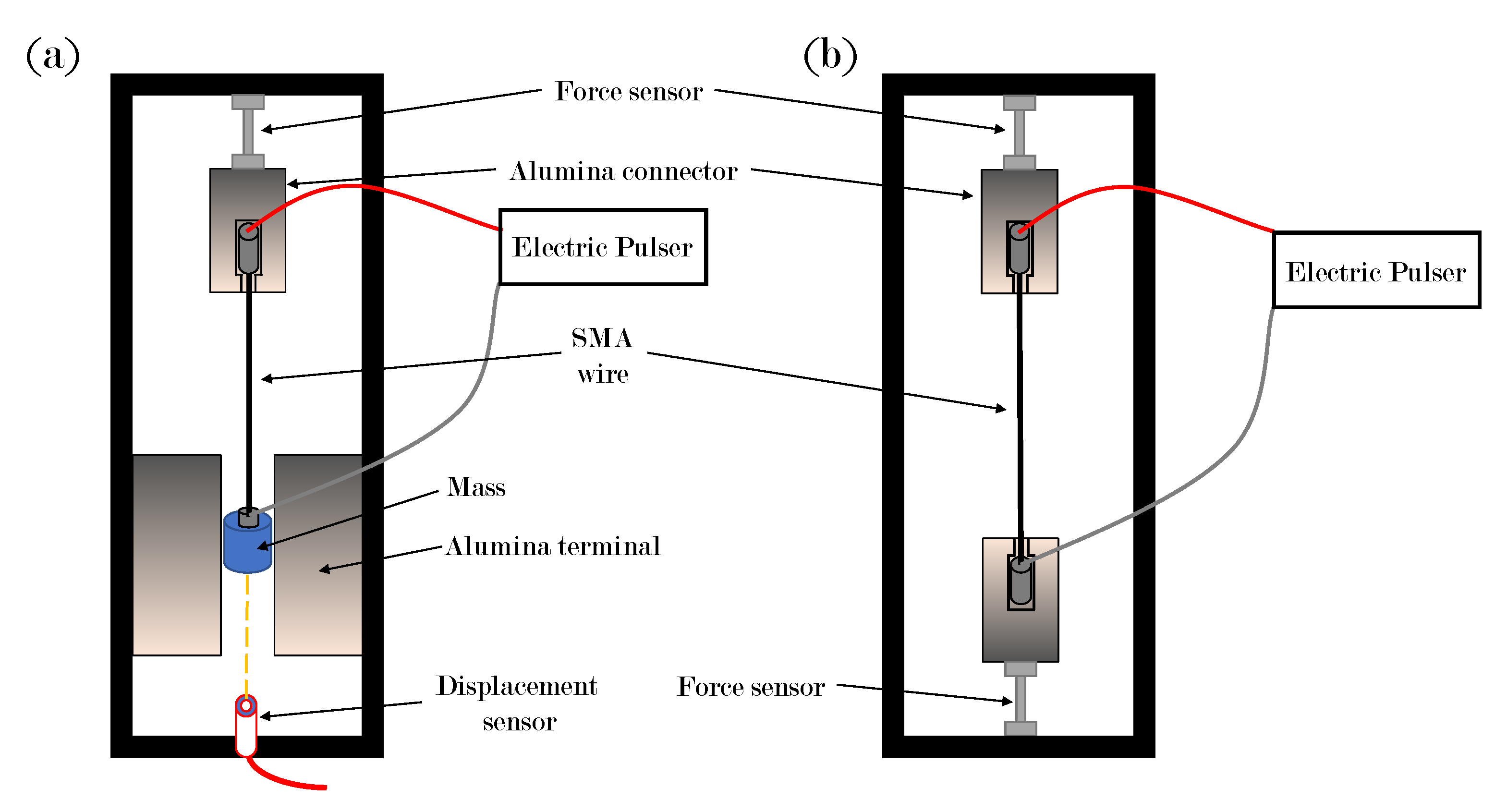

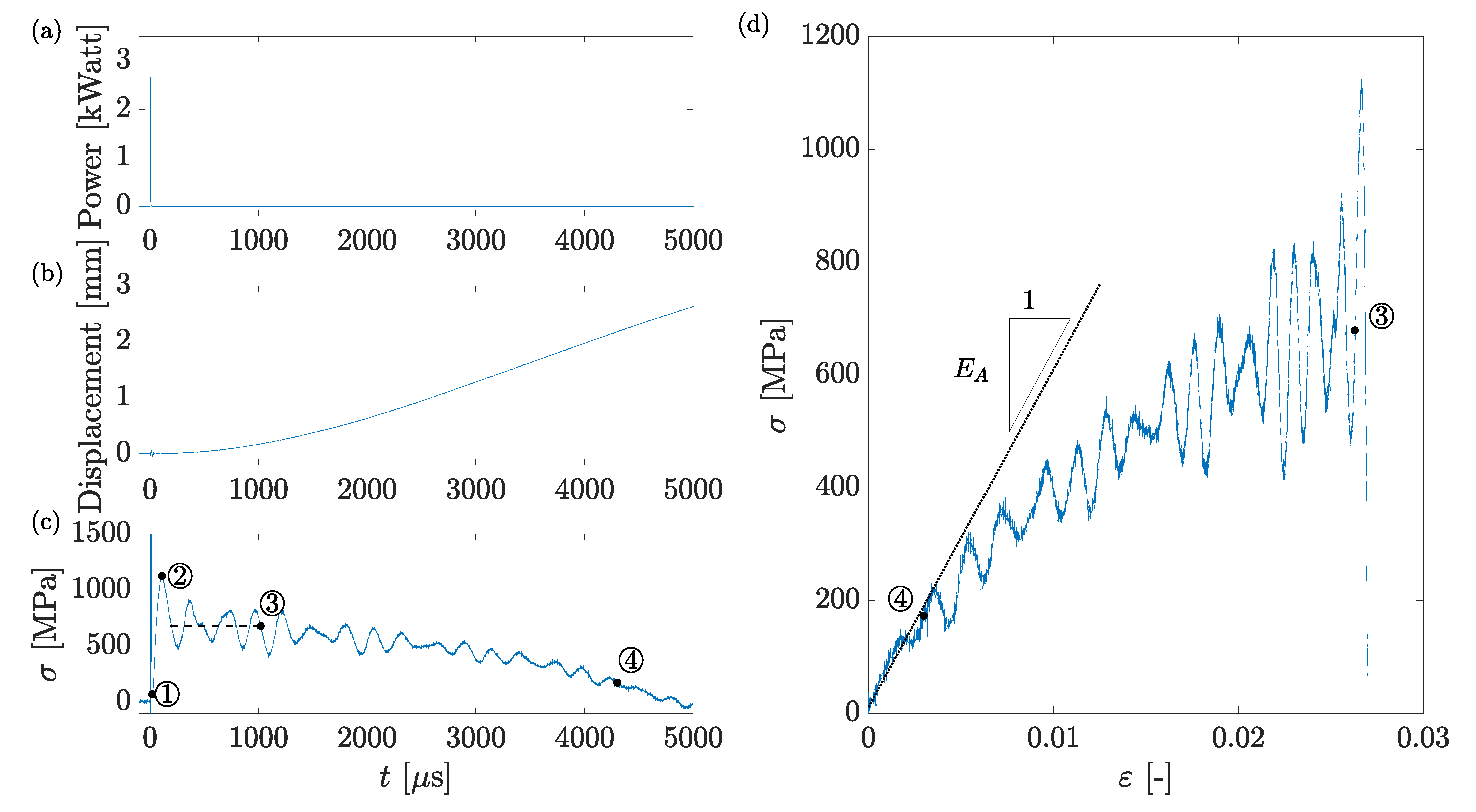

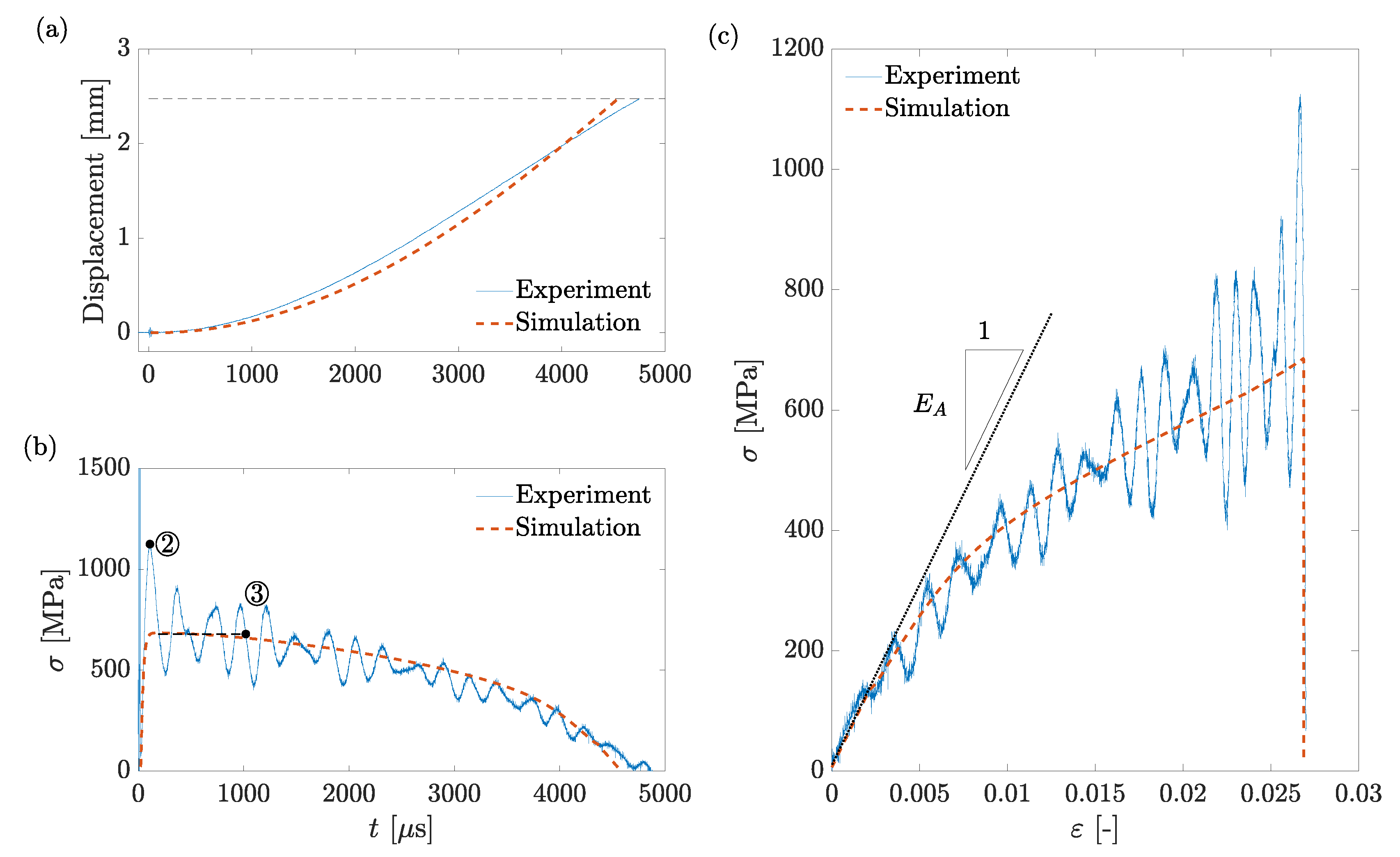

The kinetics and thermodynamics of the high-rate phase transformation under an abrupt heat pulse have been studied using the clamp-clamp mechanical configuration in which the wire was clamped at both ends [

34,

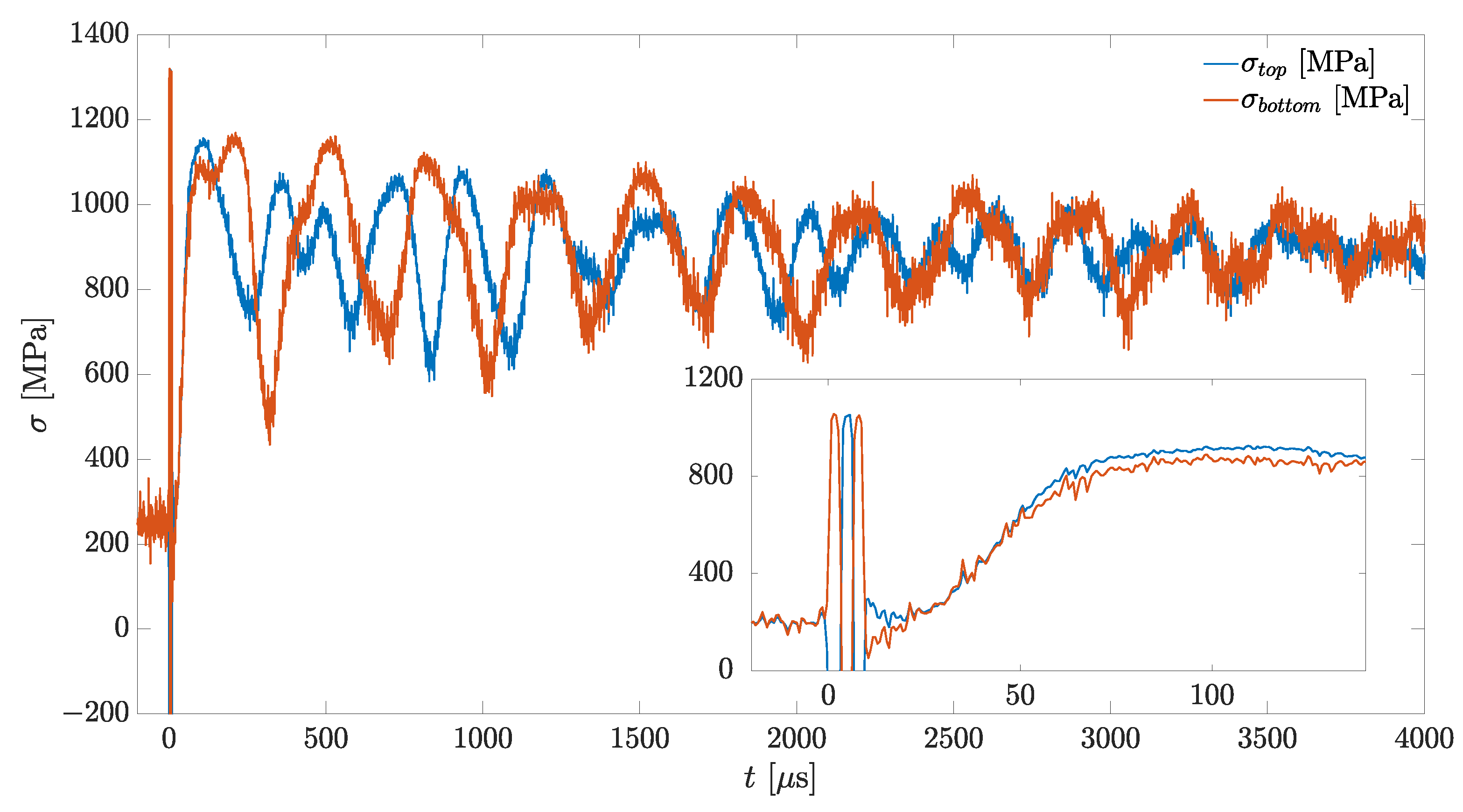

38]. In this configuration, momentum transfer is negligible and does not restrict the rate of the phase transformation. The curves in

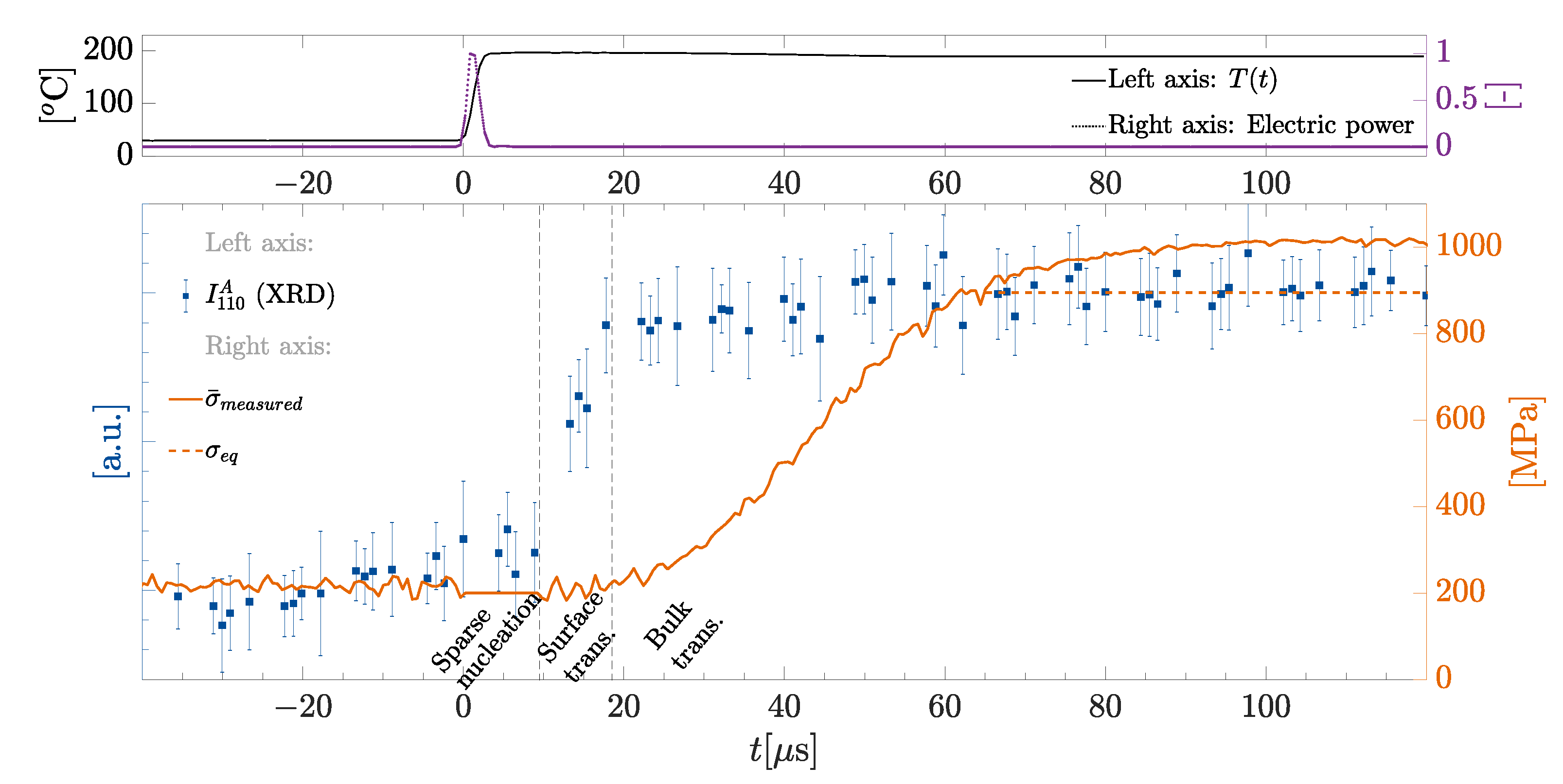

Figure 5 present the typical evolution of stress in time, measured by two force sensors, which were attached to both ends of the SMA wire, during the same test. Simultaneously, X-ray diffraction patterns were collected from a thin layer, approximately 1 μm in the radial direction, near the surface of the wire [

34]. Patterns were collected with a temporal resolution of approximately 1 μs. The volume fraction of austenite is presented by the blue squares in

Figure 6, normalized with respect to its mean final value (i.e., mean of plateau after 20 μs).

Two main differences with respect to the stress versus time presented in

Figure 4 are observed. First, in

Figure 6 prior to the heat pulse the stress is held at a constant predefined stress

(200 MPa in this test) that is applied by pre-stretching the SMA wire. (The 200 MPa stress, representing the detwinning stress in the Flexinol wires, was determined based on the method specified by Vollach et al. (2016) [

33].) Second, after the first stress peak, the force oscillates (see

Figure 5) around a plateau value until the vibrations dampen and the stress settles at an equilibrium value,

, denoted by the horizontal dashed line in

Figure 6. The increase of the stress decreases the driving force for the transformation to the austenite phase, until at

, a thermodynamic equilibrium between the austenite and martensite phases is achieved. At this stage, the austenite volume fraction,

, is significantly smaller than unity, indicating that the transformation is incomplete. In that aspect, experiments performed under the clamp-clamp conditions are different than those under the clamp-free conditions, in which the motion of the mass (especially at times larger than the mechanical response of the system) releases the stress and allows the phase transformation to complete.

Measurements at longer time scales (e.g.,

Figure 5) show that the stress remains constant at

for 1–2 s and returns to approximately

upon cooling. This is in contrast with the behavior shown in

Figure 4, showing results obtained using the clamp-free configuration, in which the stress decreases to zero within few milliseconds due to the motion of the free end of the wire.

There are several similarities in the behavior of the stress versus time curves presented in

Figure 4c and

Figure 6 during the first 1000 μs. Both experiments display a dead time

–30 μs between the time at which the heat pulse is applied and the time at which the stress starts rising. After the dead time, in both experiments the stress begins to increase rapidly and reaches a maximum within

–50 μs. The times

and

are clearly observed in the inset of

Figure 5 and

Figure 6, which show a zoom-in on the beginning of the test. In addition, both

Figure 4 and

Figure 5 display force oscillations that are induced by string like-vibrations. In both cases, the force oscillations are not fully harmonic but can still be characterized by a time period

, which is approximately the same in

Figure 4 and

Figure 5. Due to the string-like vibrations, at times greater than 100 μs, the stress along the wire is not uniform, as is manifested by the difference between the readings of the two force sensors displayed in

Figure 5. Nevertheless, the two curves exhibit the same values of

,

,

, and

and differ only in the temporary phase of the force oscillations.

The observation that the two force sensors measure an identical value of

up to a temporal resolution of

μs (inset of

Figure 5) indicates that, at the macro (mm) scale, the wire responds homogeneously; therefore, the time that it takes for the longitudinal stress waves to travel along the wire has a negligible effect on the characteristic time

. In addition, the duration of the heat pulse and the time that it takes for the longitudinal stress waves to travel along the connector between the wire and the force sensor are smaller by an order of magnitude than

. This means that most of the dead time is attributed to a characteristic time of the phase transformation, which was called incubation time

. The incubation time describes a time interval during which the transformed volume is small so that macroscopic stress changes are negligible.

The microsecond-scale time-resolved XRD study of the transformation [

34] showed that the slow response of the macroscopic force in the wire is preceded by a fast, steep rise in the volume fraction of the austenite phase near the surface of the wire (blue squares in

Figure 6), indicating the nucleation and formation of a partially transformed martensite-austenitie layer in that region. However, the low macroscopic response implies that this layer is much smaller than the total volume of the wire. Furthermore, their X-ray beam probed a region with a length of approximately 1 mm along the wire axis, performing hundreds of XRD tests at different positions along various wires obtaining highly repeatable results. Dana et al. [

34] suggested that during the dead time the nucleation and formation of a cylindrical phase front takes place, and that the following rise time, is the propagation of this front from the periphery of the wire inwards. Unsurprisingly, previous slow [

47,

48] and high [

33] rate studies of Flexinol wires measured strain and temperature changes only at the surface and, therefore, could not observe such effects.

Volkov et al. [

35] studied the response of SMA wires at the very first stages, using a configuration in which the wire was completely free of mechanical loads and constrains. The incubation time in their case was approximately 1 μs. This observation is probably attributed to the absence of mechanical loads, constraints, or masses in their experiments, allowing the rapid transformation near the wire surface to induce measurable displacements. Another contribution to the different dead times may be the use of different SMA materials, having different grain sizes and different properties (e.g., a two-way versus one-way shape memory effect).

The dependence of the transformation rate on the temperature has been studied by performing sets of tests using the same wire but applying different input energies and in accordance different temperature jumps. The typical results, presented in

Figure 7a, show that the rise time does not depend on the temperature. To explain this result, Vollach et al. [

38] developed a model for the transformation kinetics during the third stage of the phase transformation (i.e., at

). The main assumption of the model is a linear (overdamped) kinetic law between the rate of change of the austenite volume fraction,

, and the thermodynamic driving force for the phase transformation,

g,

where

is a mobility coefficient.

The wire is clamped at both ends; hence, the overall strain change during the test is approximately zero, i.e.,

The first term in Equation (

14) represents the change in the elastic strain, where

is an effective Young’s modulus that depends on the volume fraction,

x, and

is the Young’s modulus of the martensite phase. Ultrasonic measurements showed that, at high rates, the Young’s moduli of the austenite and martensite phases are almost the same and are approximately equal to 60–70 GPa [

45]. The second term in Equation (

14) represents the strain change due to the phase transformation, and the last term represents the plastic strain, which was measured and found to be negligible (see discussion in

Section 4). Using the approximations that

and

, the authors obtained an approximate expression for the volume fraction,

The maximal value of

x is the equilibrium value

, which is obtained when

. A substitution of typical values in Equation (

15) showed that

. For this value, the latent heat term in Equation (

3) is negligible (typically smaller than 7 K); therefore, the temperature during the clamp-clamp experiments is approximately constant. Thus,

in Equation (

13) is approximately constant. Note that this approximation is not valid for the clamp-free configuration, in which

reaches unity.

The substitution of Equation (

15) into Equation (

13) provides the first order, linear ordinary differential equation (ODE),

The solution of Equation (

16), together with the initial condition

, provides a universal normalized expression of the form

where

is a basic material property, defined by

The expression in Equation (

18) describes the characteristic response time of the phase transformation under all experimental conditions. Note that the only influence of the temperature on

comes from

; therefore, the rise time, which is determined by

, is temperature independent.

Figure 7b presents the measured data presented in

Figure 7a in terms of the normalized expression on the left hand side of Equation (

17). In this representation, all curves collapse to a single universal curve, and the equilibrium stress,

, is scaled to unity, as depicted by the dashed black line in

Figure 7b. Note that the experimental results follow the model prediction only during the rise of the stress. At later times, the string-like vibrations result in oscillations around the model prediction. Additional sets of experiments (not shown in this article) demonstrated that the normalized stress versus time representation is also valid for tests that have been performed on different wires with different diameter and length [

34,

38]. All these experiments presented approximately the same value of the characteristic time

μs [

38].

The collapse of all experimental measurements, performed under different temperature jumps and various wire lengths and diameters, to a single universal analytical expression, given by Equation (

17), indicates that the assumed kinetic law, Equation (

13) properly describes the evolution of the phase transformation in the third stage. The physical meanings of this kinetic law, from a material science point of view, are discussed in Refs. [

38,

46]. In

Section 7, we will use this kinetic law to model and simulate the dynamic response in clamp-free experiments.

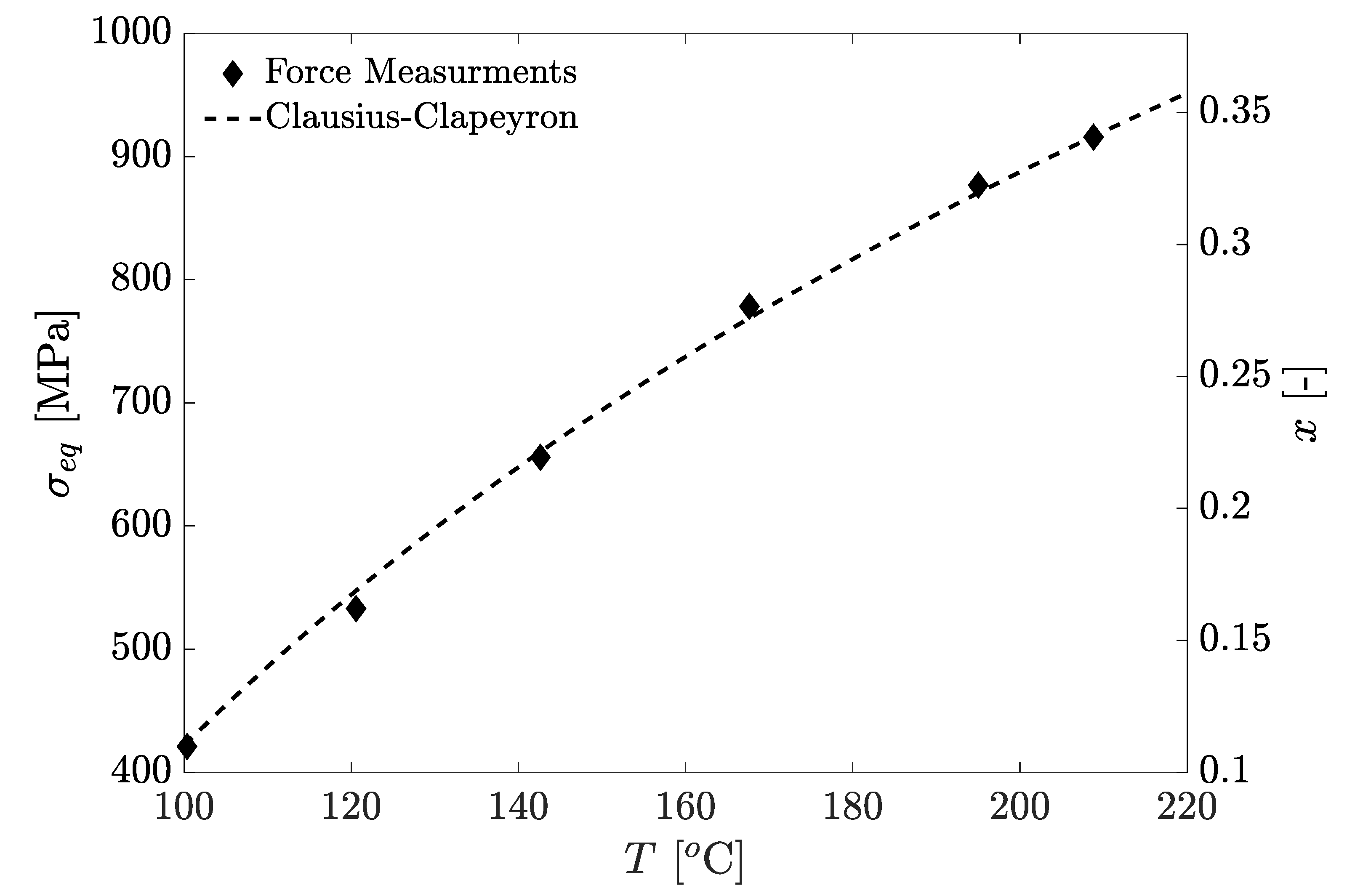

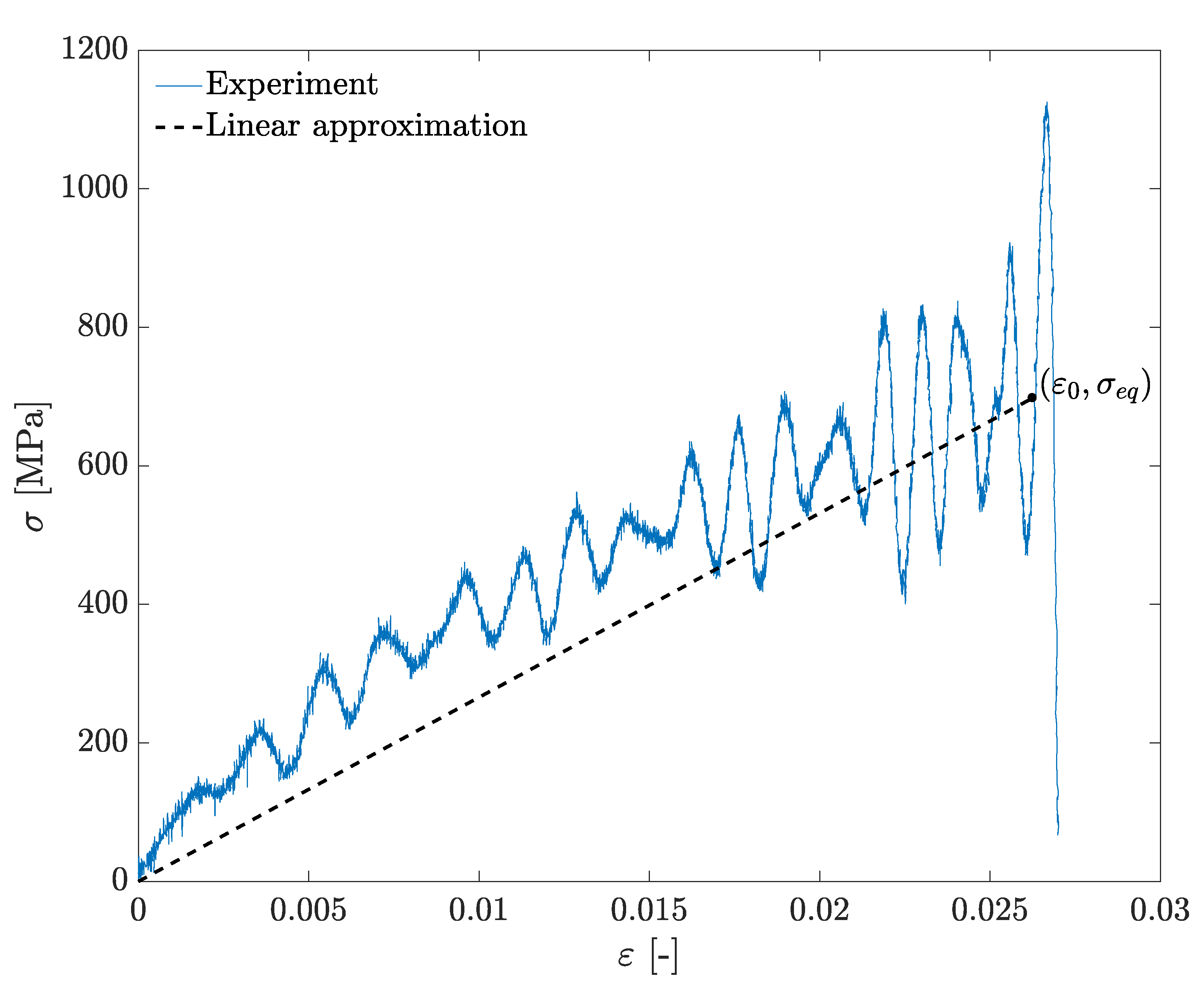

The dependence of the equilibrium stress on the temperature and the austenite volume fraction has been studied in Ref. [

39]. The equilibrium stress was evaluated based on the average stress during the time interval of

ms, as shown in

Figure 7c. A plot of the equilibrium stress as a function of temperature for a set of experiments, performed on a wire with a diameter of 0.2 mm and a length of 48 mm, is shown by the diamond markers in

Figure 8. The right axis in

Figure 8 also provides information on the austenite volume fraction,

, at the equilibrium stress, obtained by substituting the equilibrium stress values into Equation (

15).

The experimental results presented in

Figure 8 can be partially explained based on the adjusted Clausius-Clapeyron relation as expressed in Equation (

2). Integration of this equation provides

where

is a reference point fulfilling the equilibrium conditions, i.e., a martensite to austenite transformation under a constant driving force. The transition temperature,

, is not a single value property. Instead, it depends on

x and changes between the austenite start,

, and austenite finish,

, temperatures. We comment that different characterization methods have different sensitivities to the onset and the end of the phase transformation [

39].

To evaluate

, slow-rate experiments, in which a constant stress was imposed on a clamp-free wire, were performed. Initially, a detwinning stress of approximately 200 MPa (following Vollach et al. (2016) [

33]) was imposed on the martensitic wire. Then, a freely hanging mass (equivalent to

MPa) was attached to one end of the wire. During the experiment, the wire was slowly heated using a DC current, and the length of the equilibrated wire was measured at each step. Measurements of

versus

x under a constant stress of

MPa are presented in

Figure 9. The results were fitted to a function of the form

where

C,

C,

C,

C,

and

. For the analysis of the clamp-clamp experiments, only Equation (20a) was used, as in all these tests

.

A fitting of the equilibrium stress results to the Clausius-Clapeyron Equation (

19) is presented by the dashed curve in

Figure 8. The curve fits well to the experimental results, showing its efficacy in predicting the evolved equilibrium stress.

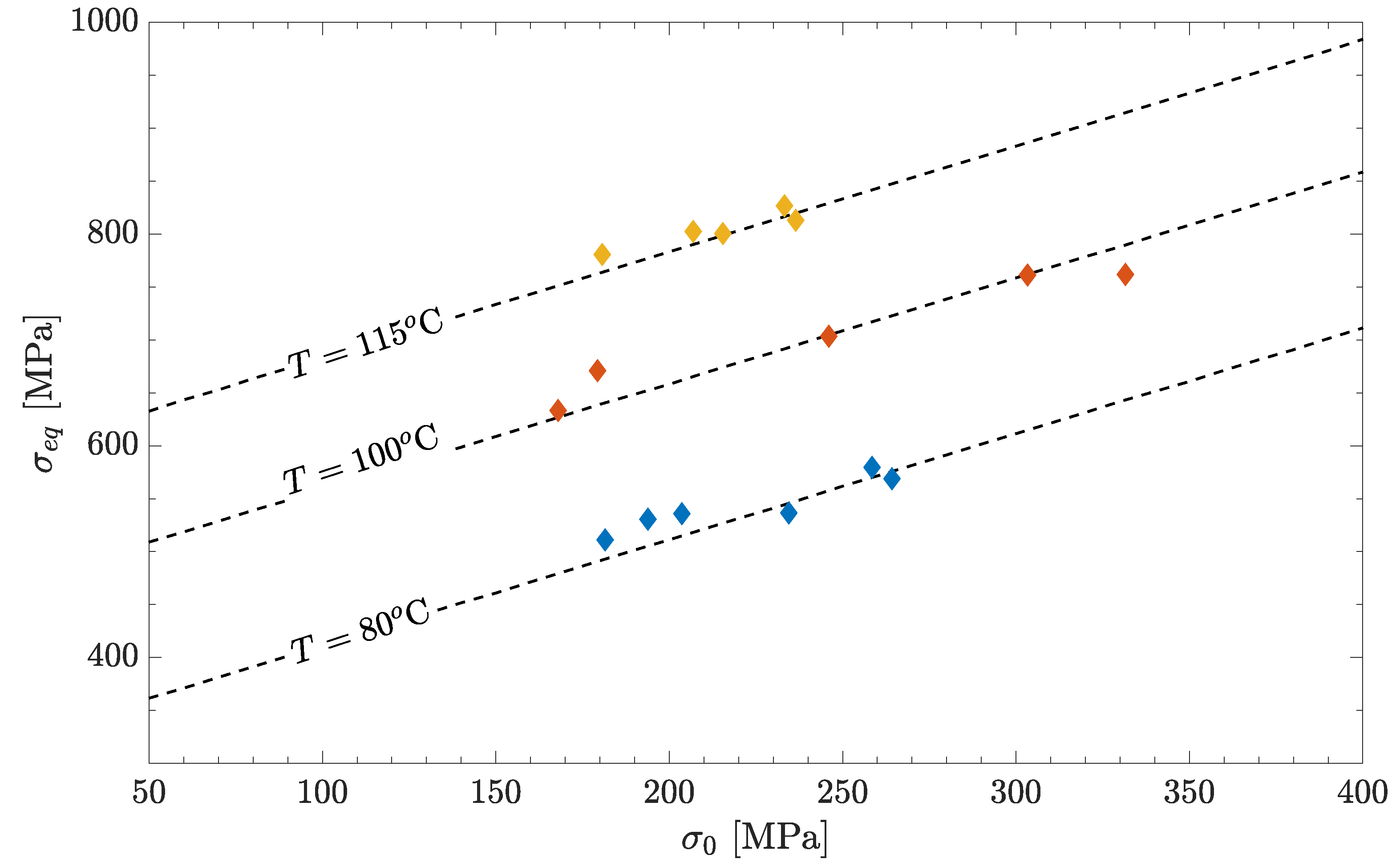

Figure 10 presents measurements of

versus

for three different temperatures,

C,

C, and

C, under the clamp-clamp configuration. These measurements were performed by applying the same temperature jump on the same wire, but changing the initial stress,

, that was applied in each test. The different values of

affected the values of

according to Equation (

15). The dashed lines presented in

Figure 10 are calculated based on Equations (

19) and (20a) for various constant values of

T. The calculated curves that best fit the measured data are those corresponding to

C,

C, and

C, i.e., negligible difference with respect to the calculated temperature values based on Equation (

3). The agreement between the calculated curves and the measured values in

Figure 10 is excellent, considering that the only fitted parameters are

,

, and

, which were determined based on a different independent experiment, presented in

Figure 9.

9. Discussion

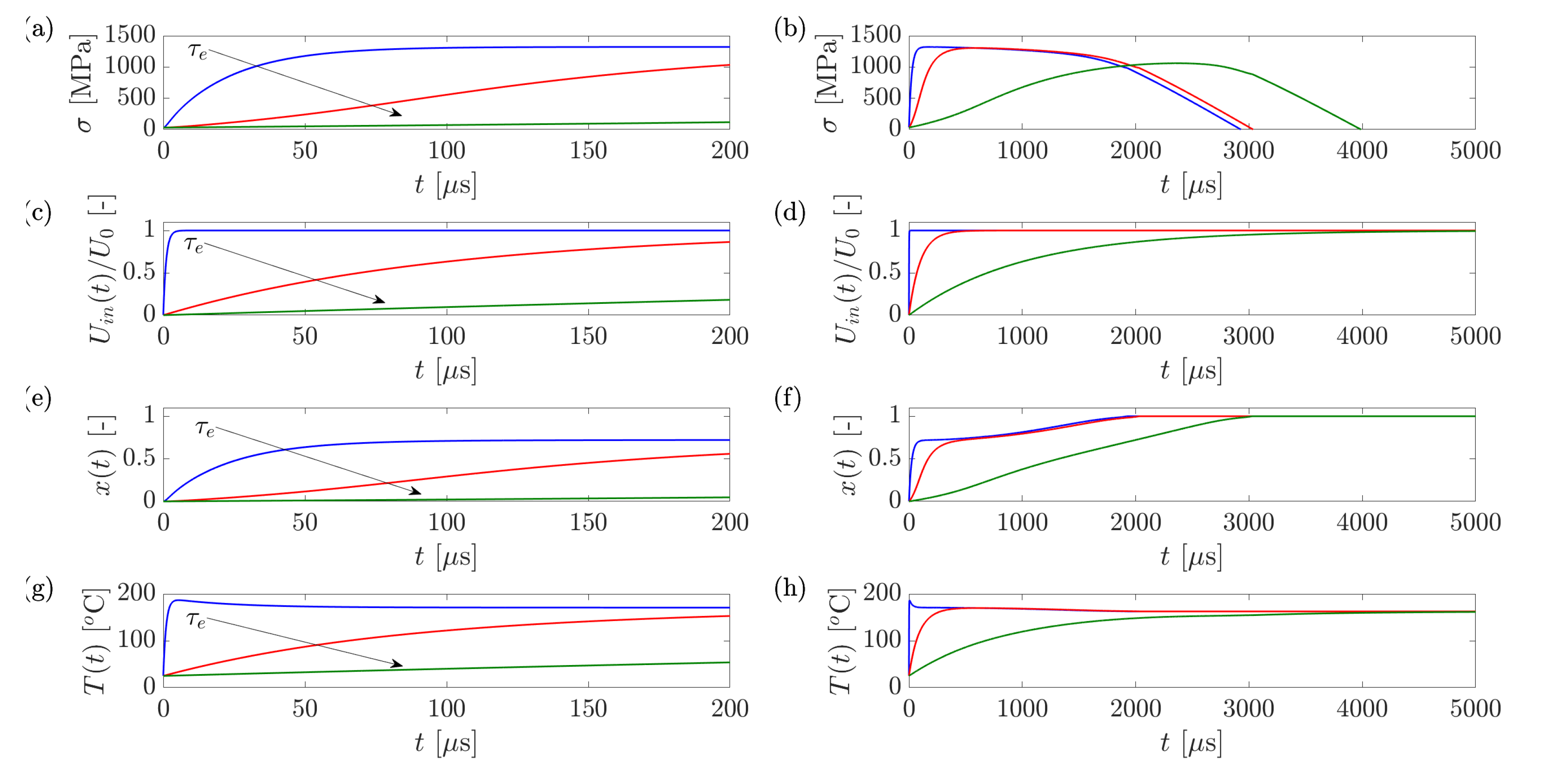

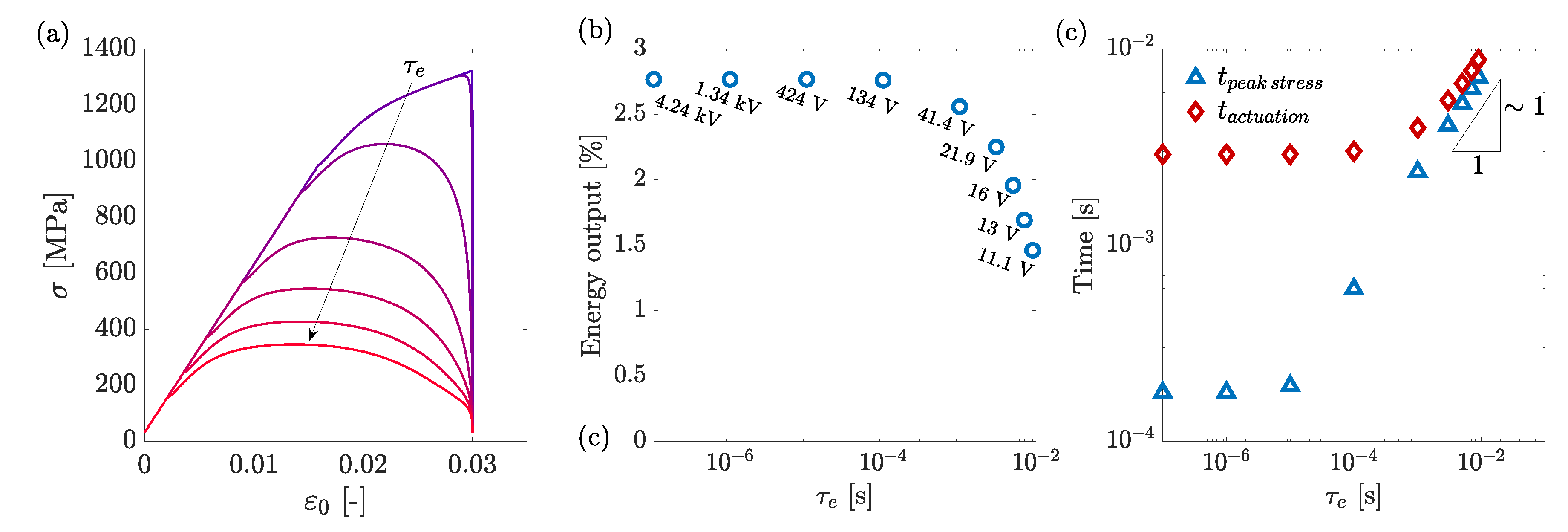

The previous section has shown that the performance of the actuated system strongly depends on the ratios between the heating time, , and two important characteristics of the system, the mechanical response time of the system, ; and the kinetic response of the phase transformation, . This leads to the identification of three different regimes:

; ; ;

; ; ;

; ; .

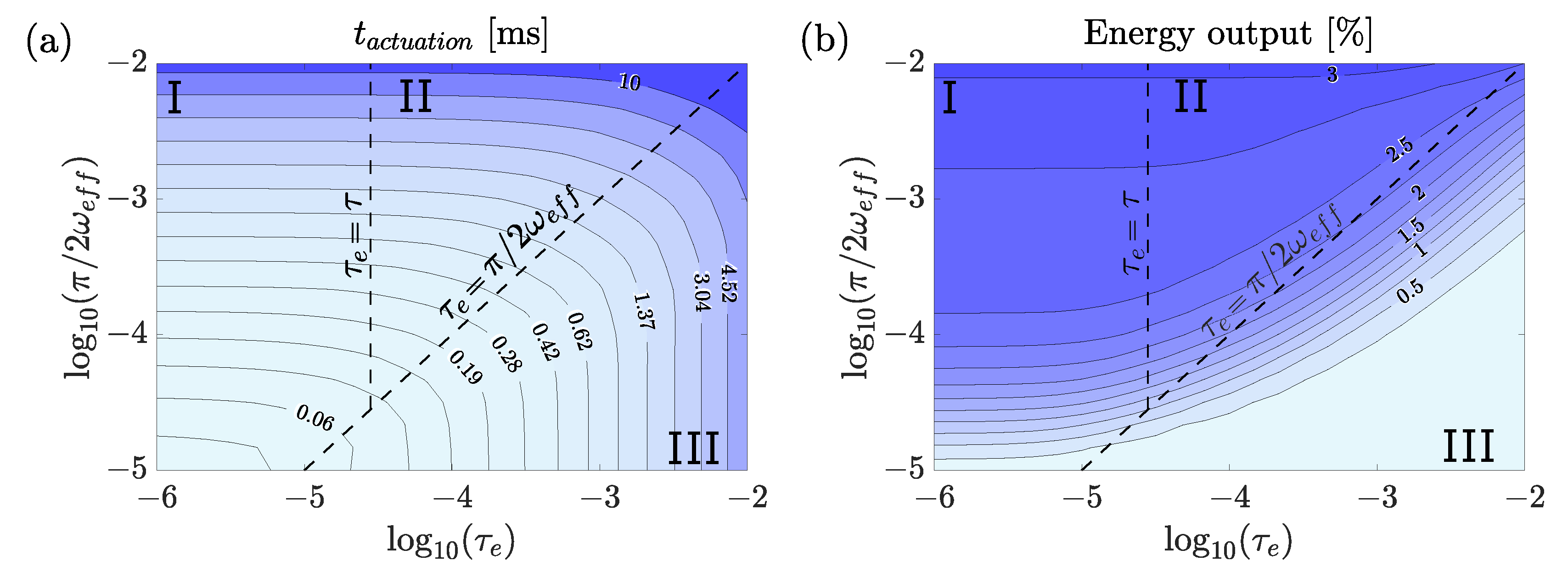

The actuator performance in the different regimes is demonstrated in

Figure 19, which shows two main characteristics, actuation time (in units of ms) and energy output (percent), using contour lines which were generated by our computational model for a range of mechanical response time values,

. The two dashed lines in each panel are the regime boundaries, representing the cases in which the heating time equals either the characteristic transformation time,

(in the vertical direction), or the mechanical response time,

(with a slope of unity).

For a given , regime I is characterized by a high energy efficiency and a relatively short actuation time, , determined by . Notably, systems already placed in regime I, show almost no sensitivity to a shorter heating time, , and so their desired performance can only be improved by increasing the value of , i.e., decreasing the mechanical response time, without a significant change in energy output. In regime II, the energy efficiency is slightly smaller, and the actuation time is slightly longer with respect to regime I. Regime III is characterized by a low energy efficiency, and long actuation times, , determined by .

Figure 20 shows the respective location of a selection of previous experimental studies (

Table 1) according to the three regimes. For example, Motzki et al. (2018) [

36] obtained high energy efficiency using relatively low voltages (<125 V) but had to pay in a long actuation time (tens of ms, due to their low mechanical frequency) and time to peak stress (due to their slow heating rate, i.e., on the ms scale). Otten et al. (2013) [

9] got shorter actuation times (compared to Motzki et al.) at relatively low voltages (<50 V), but had to pay in poor energy efficiency (due to their heating time being on the order of

). Vollach et al. (2016) [

33] used very high voltages (2–4 kV), obtaining high energy efficiency and very short time to peak stress (tens on μs), but their actuation time was moderate (few ms, due to their low mechanical response rate). Malka et al. (2017) applied the smallest

(for mm-scale systems) and moderate voltages (200–330 V) to obtain a heating rate,

, just slightly shorter than

. They got an energy efficiency that was just slightly lower than Vollach at al. and time to peak stress that was only slightly longer, but with a much shorter actuation time (by an order of magnitude).

All the aforementioned studies are examples for relatively large, mm-scale, actuators characterized by relatively large masses (with long mechanical response times) and large volumes of the SMA wire (affecting the required voltages for Joule-heating). At the same time, there is a recent growing interest in micro-scale actuator systems that are characterized by very small masses and small volumes of the SMA element [

27,

28,

29,

30,

31,

32]. Such systems have the potential to obtain very high energy efficiency values and short actuation times, if actuated using a fast electric pulse. Due to the small energy requirement, such short pulse duration can still be achieved using a low voltage. For example, Knick et al. (2019) used a MEMS bimorph actuator system based on a polymer layer (∼1 μm) with a thin layer (∼200 nm) of deposited NiTi. Their resulting mechanical response time of ∼25 μs is exceedingly small relative to the other systems, but their heating rate was much longer (0.3 ms). As a result, their actuator was operated in regime III and suffered from a poor energy efficiency. Nonetheless, a faster heating time of the small bimorph would quickly situate them in regimes I or II with an improved efficiency, along with a shorter time to peak stress and a shorter actuation time.

The unique characteristics of micro-scale systems, specifically their high mechanical response rate and low volume for heating make them prime candidates for high-rate actuation. Their low volumes typically result in a large resistance which allows for fast heating using low voltages, and they are typically able to provide relatively large forces with fast response rates in the μs-scale (e.g., References [

27,

28,

29]).

10. Summary and Conclusions

This article reviews the different aspects of high-rate actuation of shape memory alloy wires in the high-driving-force regime.

The clamp-free configuration [

9,

21,

24,

33,

35,

36] is characteristic to actuator devices, where a mass or a mass-spring setup are attached at the free end. The governing equations are presented, and the effect of the natural mechanical frequency,

, of the system is discussed. In particular, it was shown that, in a typical high-rate actuation, the characteristic time of the heating process should be much shorter than

.

An additional configuration (clamp-clamp), in which the wire was clamped at both ends [

25,

34,

38,

39], is used to study the intrinsic kinetics of the transformation. Under these boundary conditions, the transformation is unhindered by motion of masses or momentum transfer.

Section 1,

Section 2 and

Section 3 provided an introduction to the main aspects that have to be considered in the design of high-rate SMA actuators. These aspects include the required heating rate, applied force and the resulting energy input. High-rate actuation was also shown to result in excess kinetic energy following the end of the predefined actuator stroke, which can be utilised to increase the actuator travel-per-length. The basic insights introduced in these sections lead to rough design guidelines for the actuators and the selection of a suitable power source.

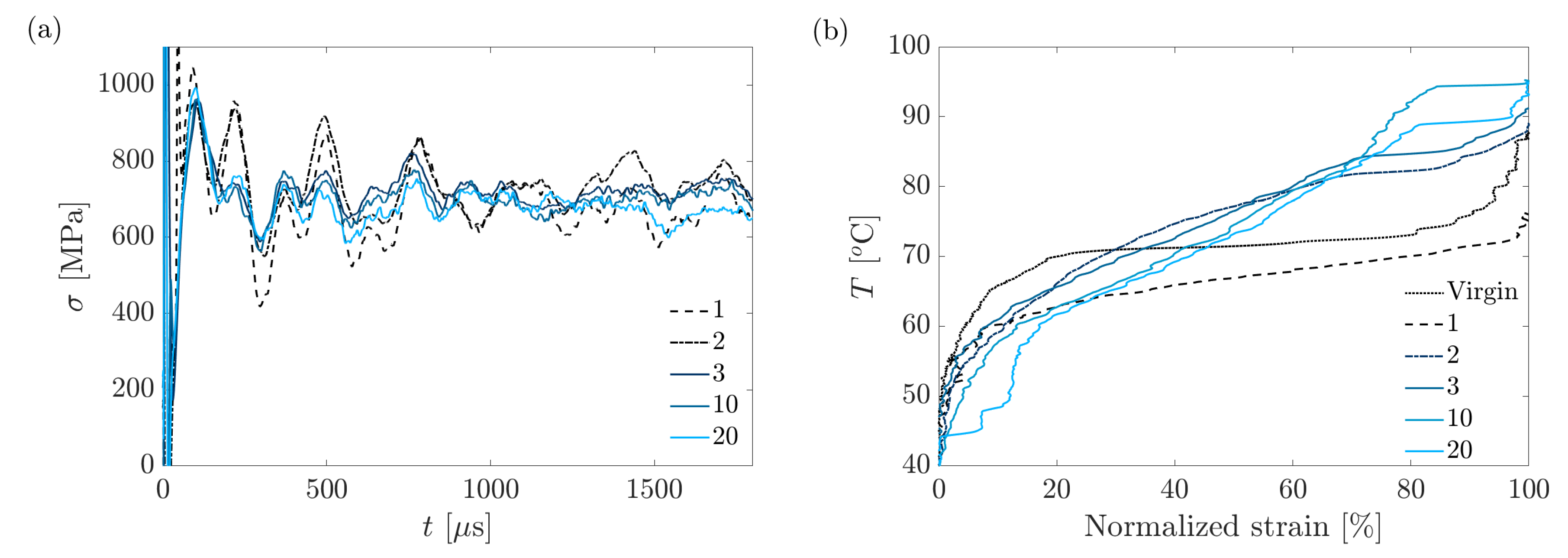

Section 4 and

Section 5 presented detailed studies of the material behavior under high-rate conditions. Typical experimental results of both the clamp-free and clamp-clamp configurations have shown that their behavior within a time period of approximately

from the onset of the heating pulse is similar, displaying a dead time followed by a rise in stress to a finite equilibrium stress plateau value, around which the stress oscillates due to string-like vibrations. At later times, behavior varies. The motion of the mass at the free end of the clamp-free configuration relieves the stress in the wire, allowing the volume fraction of the austenite phase to increase until the wire is fully at its austenite phase. The thermodynamic and kinetic rules presented in these sections are later used in the formulation of detailed model simulations.

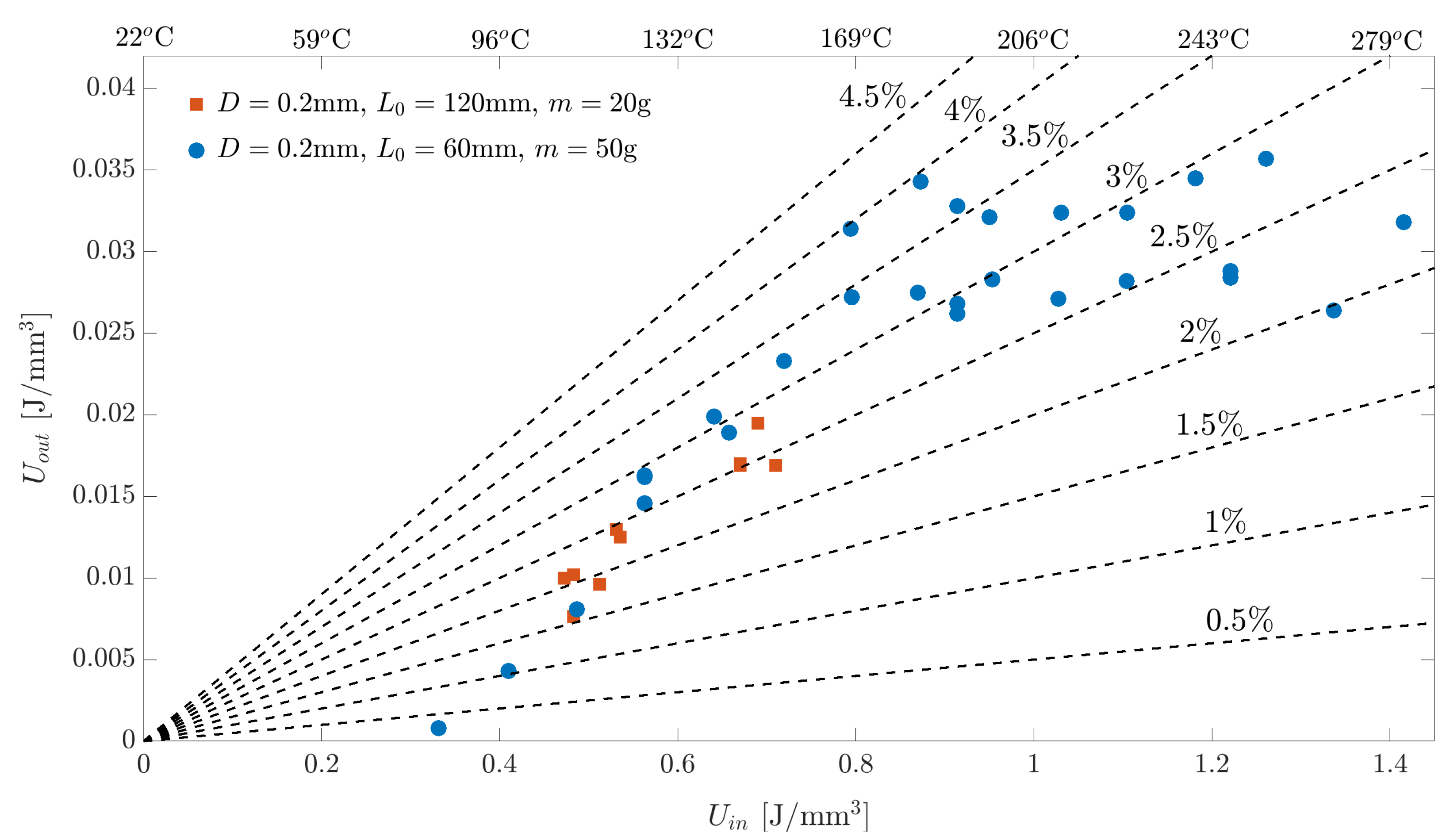

Section 6 presented phenomenological approximations of actuator performance, based on mappings the values of several key actuation characteristics under varying dimensions of the SMA wires and values of the actuated mass. Work outputs from a variety of experiments in the clamp-free configuration evaluated with respect to the specific input energy have shown that a large energy density provides an improved energy efficiency. Specifically, energy densities in the range 0.8–0.9 J/mm

were shown to represent optimal operating conditions.

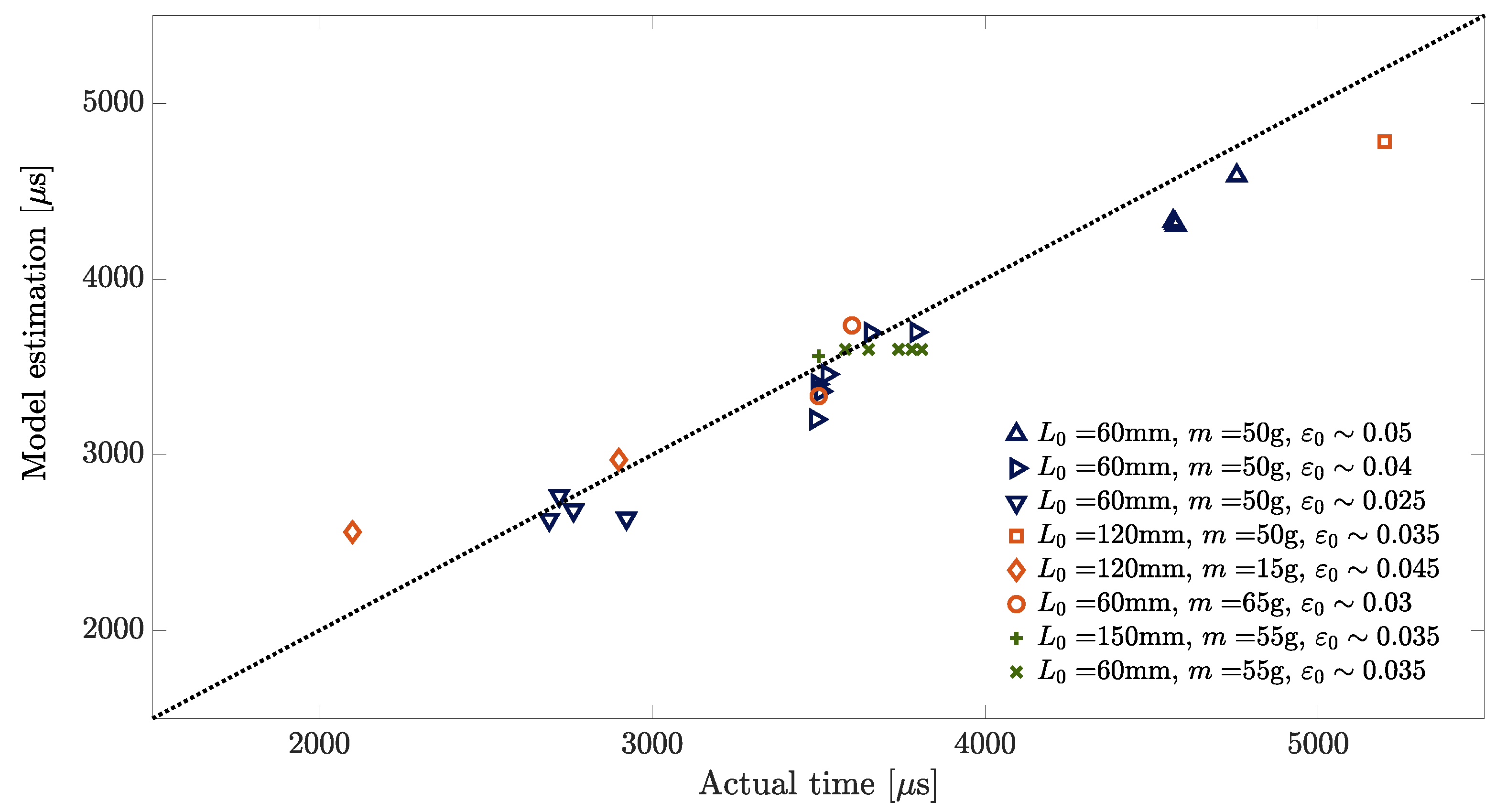

In

Section 7,

Section 8 and

Section 9, we constructed and solved detailed simulations of actuator response that can serve as accurate design tools for specific applications. Model results were generated to simulate a clamp-free actuator with a freely hanging mass at its end. Two main cases were considered.

In the first case, the parameters of the simulation were taken to directly match those in the previously presented experiment of a typical clamp-free configuration. The compared simulated and experimental results have shown to be in striking correlation with each other, assuring the validity of the proposed model. This is a notably impressive feat owing to the extraction of all parameters from previous experimental data in both the clamp-free and clamp-clamp configuration and nullifying the need for empirical curve-fitting of specific parameters.

In a second case, we considered a wire of different dimensions under varying operating conditions and the effect of the characteristic pulse duration, , was investigated. Characteristic heating durations up to the order of the characteristic response time of the phase transformation, , (i.e., on the microsecond scale) were shown to produce larger work-per-volume output and increased energy efficiency, as well as shorter response times (to peak stress) and total actuation times. Notably, longer heating durations, in which the heating ended only after the transformation was complete, resulted in excess energy which was wasted on raising the temperature of the fully austenitic wire.

An important part in the design process of a high-rate SMA actuator involves the optimization of the required operating conditions. In particular, the application of a pulse heating power source was shown to impose a trade off between the use of low voltages (for improved safety and portability) and the resulting actuator performance, such as the actuation time and energy efficiency.

Finally, three different regimes of actuator performance were identified based on the applied heating rate and the mechanical response frequency of the system. These regimes enable users to quickly evaluate the expected performance of their system and consider the conditions that will secure an enhanced performance in terms of energy efficiency and actuation duration based on their needs.