1. Introduction

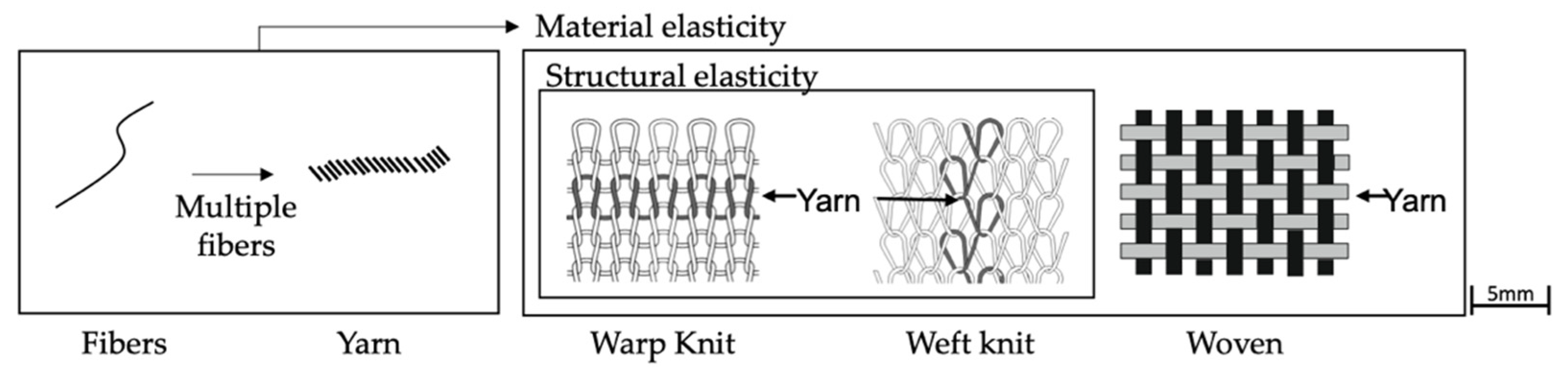

Textiles and textile products are available in different forms along the textile chain. The textile chain starts with the fiber, which is either obtained from natural resources such as cotton or wool or produced from polymers by spinning processes. The individual fibers are combined to form a yarn. The specific interlacing of the yarns creates textile fabrics (

Figure 1). The relevant processes are warp knitting, weft knitting, weaving, nonwoven production and braiding [

1]. The fabric can then be further processed either by combining it with other materials to form composite materials, e.g., in fiber-reinforced plastics (FRP) components for the automotive industry, or to form clothing through the combination of several fabric pieces. Textiles have a wide range of applications and are used in a variety of industries such as automotive, architecture and clothing. Textiles have a large surface area, are flexible and their porosity can be selectively adjusted. Textiles can also absorb high tensile forces. Material costs are low because of global mass production. The production of textiles can be considered a multi-scale additive manufacturing process.

The properties of textiles can be widely adjusted. They can be structural, sensorial and esthetical. While textiles for clothing have low strength, textiles for the automotive sector have high strength. The properties can be adjusted via the selection of the fiber material, their combination or finishing. In particular, the strengths and elastic elongation behavior can be adjusted directionally and locally over a wide range [

1].

Due to their versatile properties, textile materials are of high interest for different innovations. Textiles have either been used as a substrate for other technologies or been adapted to perform new properties.

1.1. Smart Textiles

There is a continuous demand for smart textiles, where both the above approaches have been followed. Smart textiles are defined as textiles with interaction and interactivity which allows for two-way electronic communication [

2].

For smart textiles, electronic components ranging from conductors to coils and conductor paths are applied or integrated to textile surfaces. The structures applied can either be of a classical nature (flexural rigid materials) or of a textile nature in the form of embroidered conductor paths [

3]. In both cases, the textile structure is used as a substrate (carrier structure). These developments find application in the field of textile wearables. In addition, conductive yarn is widely used for smart textile applications. Smart textiles are also used as sensors. These smart interfaces are designed to have one-way functions [

2]. Recent developments have investigated printing conductor paths or electronic functions on textiles [

3].

1.2. Additive Manufacturing

In addition to printing paint or conductor paths onto textile surfaces, additive manufacturing processes on textiles have gained attention by different research disciplines [

4]. These are generative manufacturing processes and volumetric bodies are built without tools or molds. Additive manufacturing technologies are defined according to the ISO 52,950 as “technologies that, based on a geometrical representation, create physical objects by successive addition of material” [

5]. Textile production methods such as weaving can therefore be considered as additive manufacturing process themselves. Different additive manufacturing technologies have been developed: binder jetting, directed energy deposition, material extrusion, material jetting, powder bed fusion, sheet lamination and vat photopolymerization [

5,

6]. Polymers are the most utilized material for additive manufacturing [

7].

Material extrusion is currently the most widely used process in this sector. Multi-jet modeling is the established process for multi-material printing [

8]. Three-dimensional printing has become a widely used synonym for additive manufacturing with 3D describing the three-dimensional creation of an object. Additive manufacturing processes have been applied to produce textiles such as clothing [

9] and jewelry [

10]. These processes can be classified as one-step and two-step processes. The two-step process is performed only when a second process is needed to give the final form to the manufactured artefact [

5]. It can be considered as a supplementing process. In the context of additive manufacturing on pre-stressed textiles, the material extrusion process is of specific interest. The polymer-based material is melted and extruded through a nozzle on a build plate. The object is built layer by layer. After finishing the process, the object is removed from the build plate.

With the upcoming of 3D printing on textiles, a new application field has been developed and instead of supplementing the textile, the textile itself gets included in the created structure. In the process of separating the object from the build plate, the textile stays connected to the object. The textile acts as a substrate and thus as a carrier material for the applied polymer-based structures [

11]. In most cases, production is carried out using the material extrusion process. If direct 3D printing on textiles is not possible, the sheet lamination process is used [

12].

1.3. 4D Printing

The process of 3D printing has now further developed into four-dimensional (4D) printing. The term was first defined in 2013 by Skylar Tibbits [

13]. In 4D printing, material structures are produced that can change their properties over time in a targeted manner. In addition to the three spatial dimensions, the fourth dimension describes the time in which a change in properties might occur after the 3D printing. The change is introduced by the influence of an external stimulus. The energy for the property change is stored in the material or is introduced by the stimulus [

13].

Materials used are smart materials that react to the external energy with a change in their properties or form [

8]. A change in polymer-specific properties, such as viscosity, also falls under this category. A distinction is made between active and passive materials and their homogenous or heterogeneous composition, gradationally varying in the manufacturing process [

14,

15]. Active materials are piezoelectric materials, shape-retaining materials, magnetostrictive materials, electrorheological materials and magnetorheological fluids [

8,

16]. Mitchell et al. and González-Henríquez et al. provided an extensive overview on specific materials [

17,

18]. Active materials are usually combined with basic or passive materials. Basic materials cannot change independently over time due to their properties. Base materials are used to fulfill functions such as the production of connections between different components or the limitation of sections [

8,

19]. They can be forced to change by adjacent materials. Base materials do not necessarily have to be polymer-based. However, in current applications, they often are.

Stimuli used to introduce a change in properties of the active materials are moisture, light and heat and their combination [

19]. Other stimuli include sound, flow, UV radiation, microwaves, chemicals, electricity and force [

20]. Additional influences are the intensity and duration of the stimulus. An example of printable smart materials are hydrogels (agarose), and that for non-printable smart materials are shape memory alloys (nitinol). In nitinol, heat is the stimulus; in agarose, it is moisture. Stimuli act locally in a point or area within or from the environment of the structure. The typical material changes can occur at the micro or macro level of the smart material [

21].

Four-dimensional printing artifacts can be categorized in three main categories: self-assembly, self-adaptability and self-repair [

19]. The change can be reversable or non-reversable. The fields of application for these materials are diverse and range from aerospace to medical devices [

14]. They can adapt to changing external environmental conditions, change their external shape and volume or adjust their mechanical, optical or thermodynamic properties.

Especially shape-changing materials are of interest. Shape-changing materials allow greater design freedom and customizability of products over their life cycle. In one production step, several functions can be integrated into a product based on materials and process costs can be saved compared to classic production sequences [

22]. In biomedical applications, 4D printed structures can be used to attain the dynamic properties of the living cells [

23]. Self-building materials also make it possible to initially manufacture and transport complex 3D products in a planar manner [

20].

Existing challenges of 4D printing artefacts are that the forces that can be achieved are not high enough to change larger structures [

24]. Mechanical degradation of the properties of smart materials or structures can occur due to repeated exposure to stimuli.

1.4. 4D Textiles

Applied to textiles, the 4D printing concept is extended to a hybrid, time-varying 4D material structure consisting of generatively produced, heterogeneous microlayers and textiles: 4D textiles [

25]. Other descriptions are programmable textiles [

26], post-forming composites [

27], self-shaping textiles [

28] and active textiles [

2]. These materials exhibit smart behavior. A 4D textile consists of a minimal one layer of textile which consists of smart materials or to which smart materials or smart structures are applied. Combining 3D printing with traditional technologies such as knitting can provide multi-material systems with novel characteristics, such as homogenously variable permeability or enhanced mechanical properties.

This paper presents a schematic overview on the current developments of textiles that can change shape or function over time based on additive manufacturing. In the understanding of this paper, additive not only includes 3D printing technologies but also other technologies which add additional layers of material to a textile-based material structure such as welding, laminating and gluing through form or chemical closure. The overview includes the perspectives of different research disciplines, mainly design, architecture and textile engineering. It includes recent materials and production technologies, conceptual attempts at form design and form giving and simulations and evaluation methods.

2. Methods

To identify the relevant literature on 4D textiles, a schematic literature research was followed. An electronic database search was conducted in the Web of Science and Scopus databases. By choosing these interdisciplinary databases, publications from both the natural sciences and engineering, as well as design sciences, could be considered.

The literature search was based on a free text search using a combination of the following search terms: “textile” and “actuator”, “shape change”, “self-folding”, “3D printing”, “4D printing”. Furthermore, the cross-references of relevant papers were reviewed. Only English language originals and systematic reviews published between 2014 and 2020 were included in the further literature analysis. The time restriction is based on the first mention of 4D textiles in 2015 and 2016, and the restriction of English as the language ensures the scope of the publication. The search resulted in a total of 1678 papers. Research focusing on fiber-based textile actuators when 3D printed was excluded since Persson et al. and Chatterjee and Ghosh already provided a relatively new review on these [

2,

29]. The same applied to research on 3D printed textiles and 3D printing on non-pre-stressed textiles, reviewed by Sitotaw et al. [

4]. This review of titles and abstracts resulted in a review of the full text of 29 papers.

Persson et.al described, in a review, the role of different smart actuators and their integration into textile products [

2]. They highlighted three challenges:

Force and stress are low, especially for everyday applications;

Reversibility (repeatability of the actuation) is difficult due to the high energy input required;

Automatically activated or controlled means triggering the effect whenever the change occurs or controlled when it is needed.

Sitotaw et al. looked at additive manufacturing and textiles from three perspectives: 3D printing on textiles, 3D printing of flexible structures and 3D printing of elastic materials [

4]. They showed that as a subcategory of 3D printing on textiles, 4D printing with textiles has the potential to be used as a future technology for environmental sensors and actuators. Besides a rough overview, they did not investigate 4D textiles further. In particular, they did not discuss the differences of using the textile either as an active or passive component. A major difference between 3D printing on textiles and 4D textiles is that the structural properties of the textile are considered. Persson et al. did not address functionalization as an actuator through additive manufacturing as well. Printing of smart materials on textiles was not considered [

2].

Therefore, the aim of this paper is to bridge the research gap between smart materials for use in textiles according to Persson et al. and additive manufacturing on textiles by Sitotaw et al. [

2,

4]. An overview of the currently used production technologies for 4D textiles and the selected materials are given. Since the change in shape or function is a key definition of 4D textiles, different form finding and form giving processes are compared. The need for standardized testing and simulation methods is elaborated and challenges and next steps are worked out. An overview on the research is given in

Table 1.

3. 4D Textiles

The functional principle of 4D textiles is based on the interaction of the properties of an elastically tensioned textile surface and beam-shaped reinforcements. This characteristic makes the material describable by the underlying mechanics of the structural mechanics of the membrane structures. In the case of 4D textiles, the membrane—the textile surface—is elastically pre-stressed and thus absorbs potential energy as an anisotropic spring store. Defined areas of the textile are then printed on. When the pre-tension is released, a restoring force is generated in the textile, which is opposed by the elastic stiffness of the reinforcement in the printed areas. The formation of an energetic equilibrium state causes the change in shape from a planar printed structure to a spatial shape [

42].

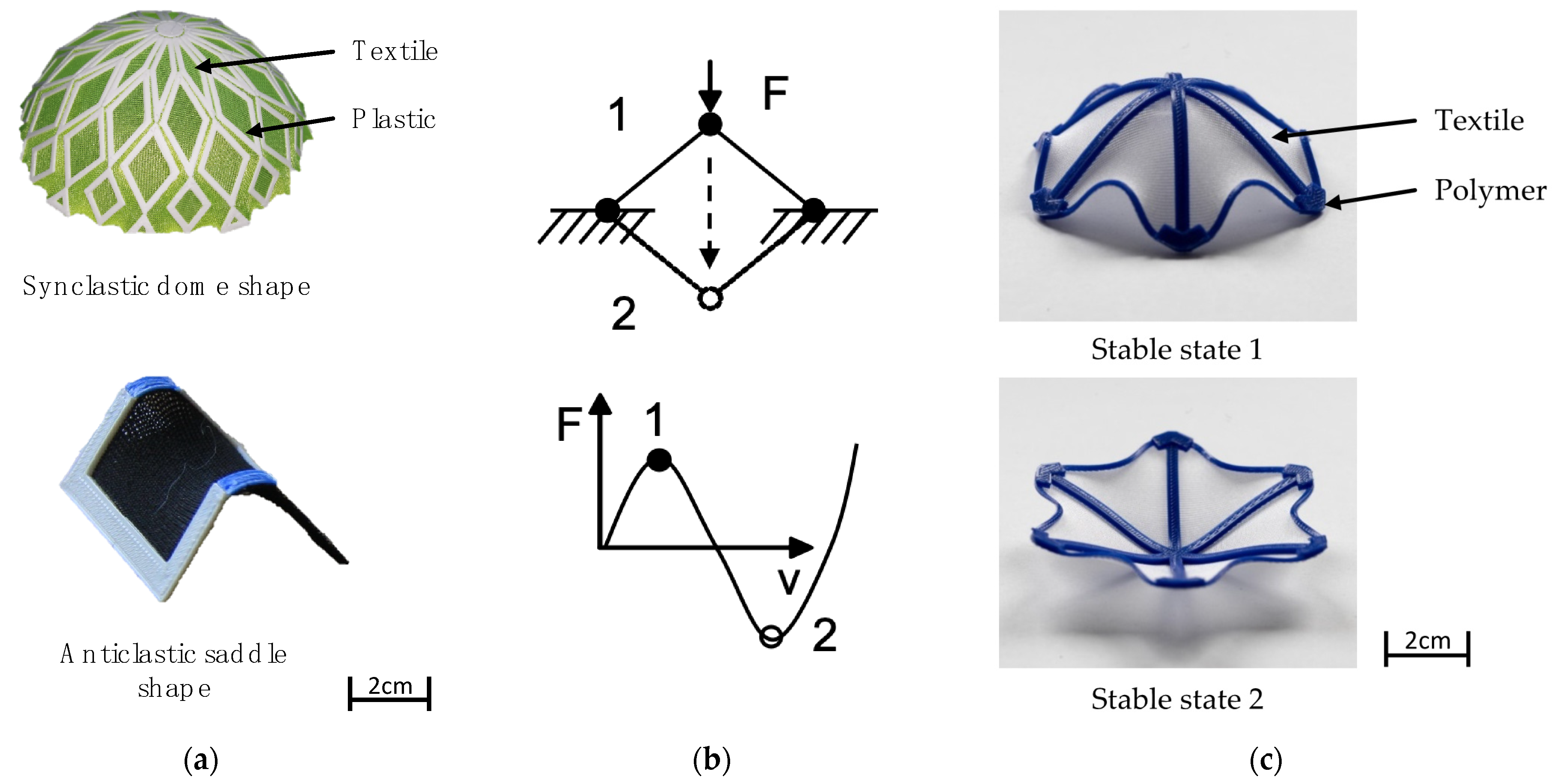

In this process, the textile forms double-curved surfaces, which represent the lowest possible energy level. Depending on whether the circumference of the structure can decrease when the pre-stress is released or is prevented from doing so by the reinforcements, synclastic, dome-shaped surfaces or anticlastic saddle surfaces are formed (

Figure 2). Influenced by the stiffness of the chosen material, the reinforcements have either curved—in the case of an elastic material—or straight shapes [

43]. In addition, the tensions cause 4D textiles to form more than one equilibrium state, enabling a shape change. By applying an initial force, the structures can thus switch between two or more metastable states (

Figure 2).

The surface is characterized with respect to the interface and mechanics. The force–strain behavior of the textile surface determines the macroscopic deformation. The force strain is introduced in the production process.

3.1. Additive Manufacturing

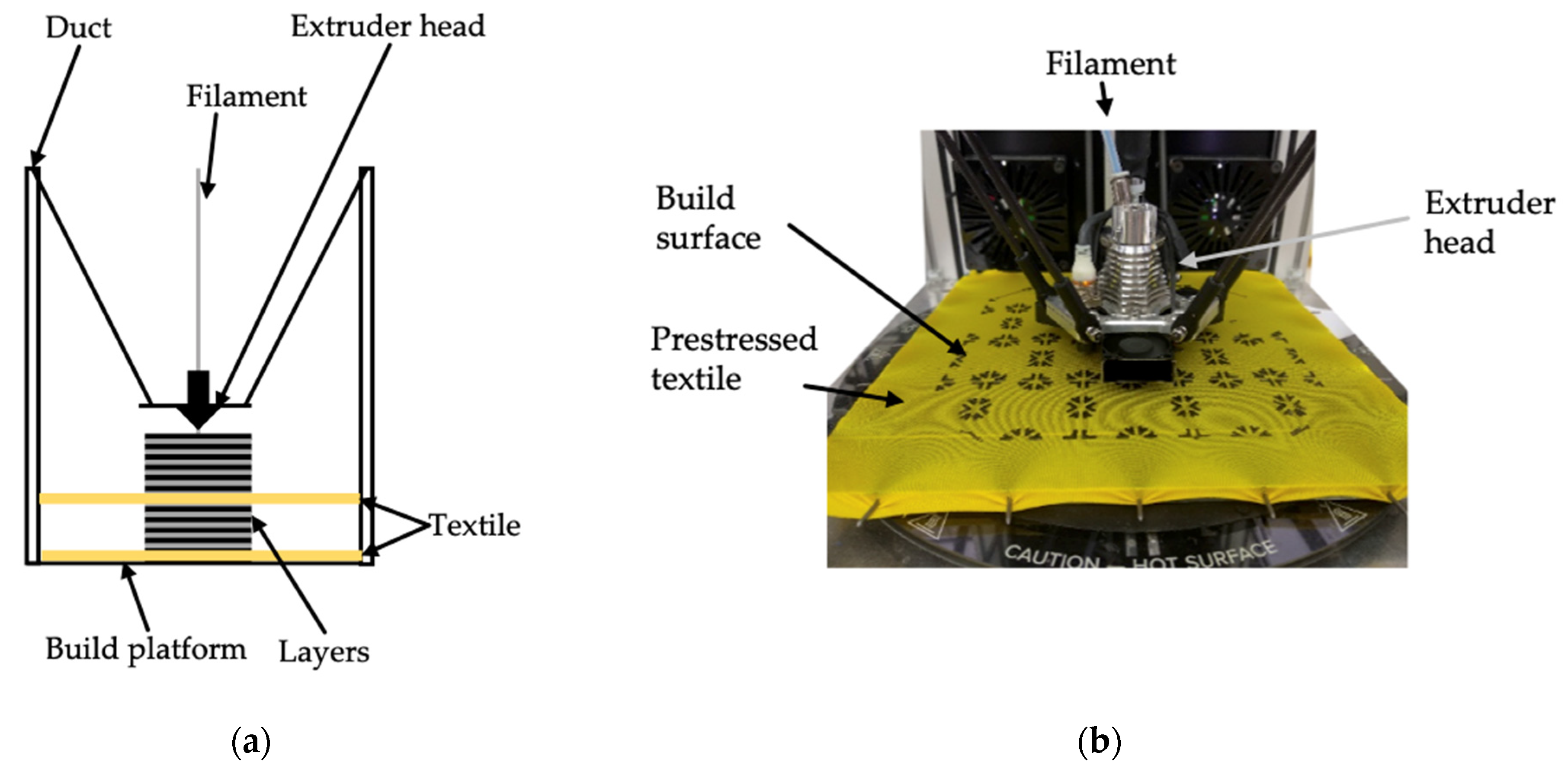

Four-dimensional textiles are hybrid systems consisting of a minimum of two materials which are additively combined. For 3D printing on textiles, material extrusion processes are mainly used [

4]. Therefore, the textile is placed on the build plate and can be considered the new build surface. The process is shown in

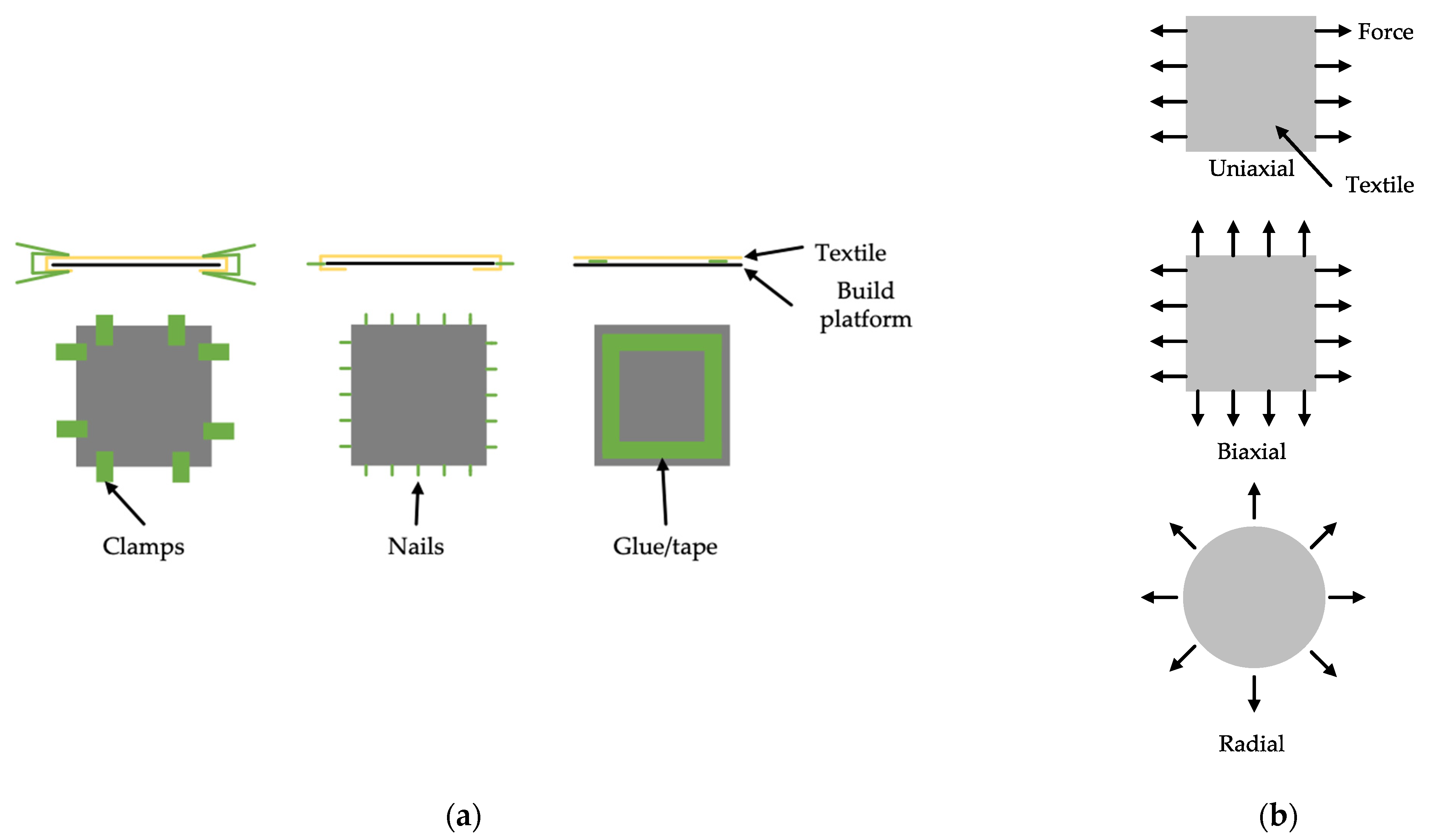

Figure 3. To store energy, it needs to be pre-stressed and the build plate needs an additional stretching unit. Different approaches have been applied: to fix the textile in the print bed, a double-sided adhesive tape can be used [

31]. The disadvantage of this method is the lack of exact repeatability of the process. Alternatively, a tension board with nails or a tension bed for stretching the textile can be used [

25]. A disadvantage is the damage to the textile caused by the nails. This is solved when using clamps to pre-stress the textile with having less accuracy [

32]. Other methods used are glue and double-sided tape [

40]. The textile can be either pre-stressed biaxially or uniaxially. Rivera et al. seemed to pre-stress radially but did not mention it explicitly [

10]. Different stretching methods are shown in

Figure 4.

The polymer is then extruded on the textile through the nozzle. To create multilayer structures, more than one textile layer can be integrated in the process [

10,

25]. To produce these structures, it is necessary to pause the printing process at the time another textile layer needs to be added [

10]. The process is shown in

Figure 3. The melted material is introduced into the surface pores of the textile. As soon as the additive has hardened, a form–closure connection is created.

Most researchers use a standard 3D printer ranging from an Ultimaker 2 + 3D [

12], a WHANHAo Duplicator [

31] or an X400 from RepRap GmbH [

33] to a Massportal Pharaoh XD [

35] or a Orcabot XXL from Prodim [

31]. All these printers come with the limitations of a small build envelope size which results in small samples sizes.

Grothe et al. used a Photon S 3D printer and thus depicted the first processes with the UV curing (digital light processing) method. The structure is consolidated with UV. For this, the textile is fixed in the pressure bed, the material is applied and the structures are washed with isopropanol. They initially observed only the influence on the color of the textiles. Depending on the textile substrate, composite formation can also occur in this process, which allows the polymer to penetrate completely through the textile [

36]. Both technologies come with the limitation that the textile needs to lie horizontally in the printing bed.

A solution to these challenges is laminating or gluing the plastic structure to the textile. Agkathidis and Berdos 3D printed elastic–plastic fibers and laminated them on pre-stressed textiles [

12]. A cyanoacrylate glue was used. This process allows the combination of materials and avoids the insertion of a clamping system in a 3D printer. It also allows the printing temperature of the filament to be higher than the melting temperature of the textile. Damage to the textile is avoided. Adding material from both sides of the textile could be solved that way. An alternative is to use a use an in-space robotic 3D printing process [

30].

3.2. Advanced Manufacturing Materials

3.2.1. Textiles

The textile is the energy storage medium and fulfills the functions of a spring via the adjustable elastic properties. The energy storage capacity can be achieved either by the yarn material used (fibers) on the material side or by the connection of the individual yarns, i.e., structurally (

Figure 1).

To use both the structural and material elasticity, Lycra textile sheets [

12,

30] and a polyester elastane knit are used [

28,

32]. Only to profit from the structural elasticity, knits based on natural fibers or man-made fibers can be used. To enhance the structural effect of form giving of the hybrid material, custom-knitted patterns can be used [

32,

44]. For adhesion tests, also cotton-based woven structures are used [

45].

As a conclusion, knitted and warp-knitted fabrics are used as textile substrates. Both structures have in common the ability store structural energy. This behavior is rooted in the structure itself. The individual yarns are in a non-linear form integrated in the fabric. By applying a force for pre-stressing, the yarns are stretched, and energy is stored in the structure. By applying a (selectively) stiffening structure, the recovery is different over the surface. By using elastane components in the yarns, additional elasticity can be introduced into the structure on the material side. Elastane fibers have a high elongation of up to 800% on the material side. Elastane fibers are polyurethane elastomer fibers consisting of at least 85% by mass of segmented polyurethanes [

46].

3.2.2. Filaments

All investigated literature reported on additively manufactured basis materials on textiles. The additive, though, must be sufficiently dominant to have a significant effect on the multi-material system.

The filaments used are either thermoplastic or thermoplastic elastomers. Thermoplastic elastomers such as TPU 95 and polypropylene filaments [

12,

37], soft PLA and Ninjaflex [

33,

38] are used to print the form-defining structures. The most used thermoplastic filament is PLA which has been proven to have the highest adhesion and is biobased [

32,

45]. Schmelzeisen et al. also printed with PLA, TPU and acrylonitrile butadiene styrene (ABS) [

25]. ABS is also used to print with the robotic printer [

30]. PLA is identified as a shape memory polymer to be used in material extrusion [

12].

The selection of the filaments is conducted with a different purpose, for example, adapting the filament use to the requirements of the application and with a user focus [

10,

25]. Colors are changed to fit esthetic needs. Printing smart materials on textiles has not been scientifically investigated according to the literature.

3.3. Design

3.3.1. Pattern

The arrangement of base and functional materials has a great influence on the formation and change properties of the active structure [

8]. The evaluation of the structure of 4D textiles can be made based on the classification of the structure made for 4D printing, according to Choi et al. [

20].

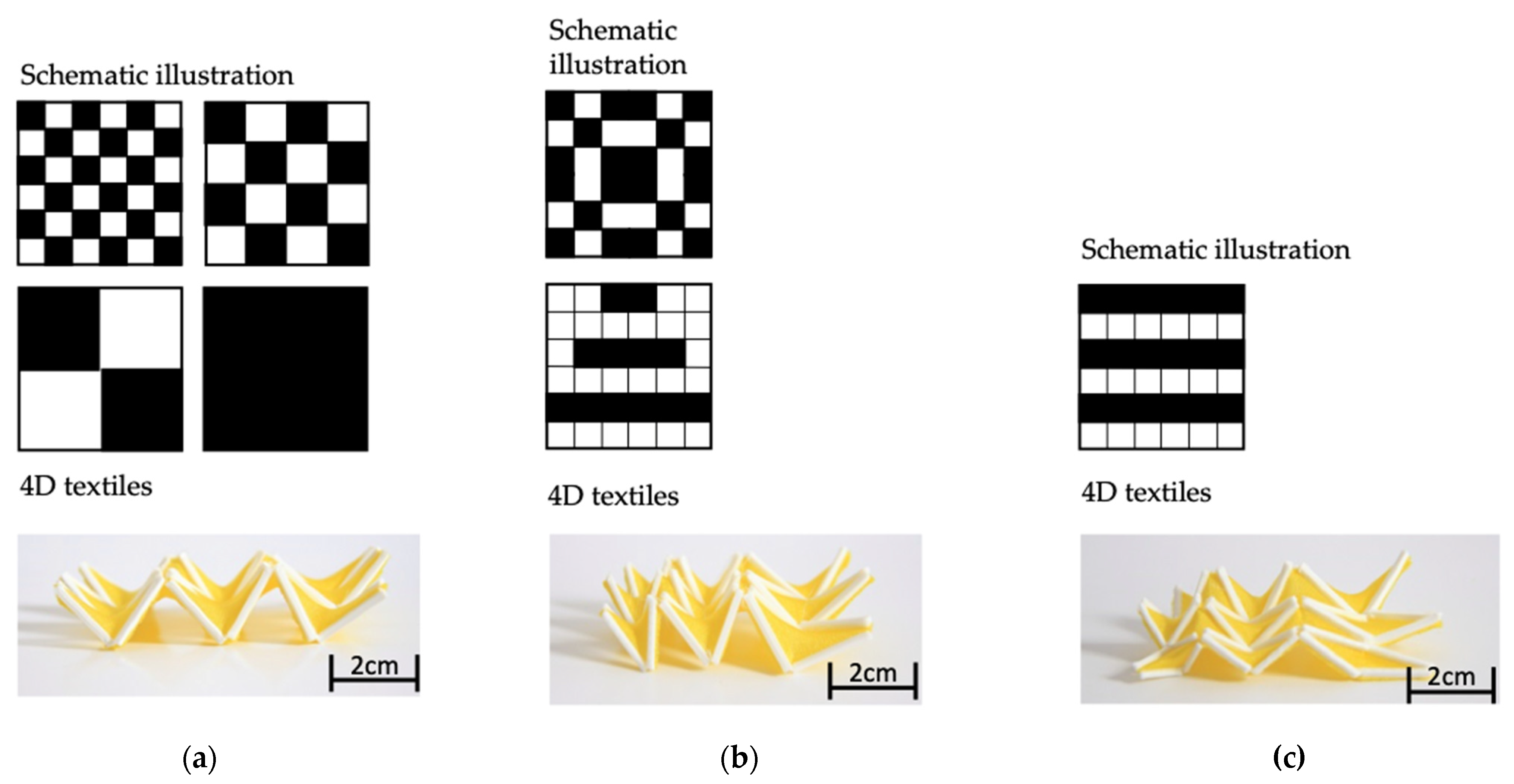

Possible arrangements are shown in

Figure 5. By means of the arrangement, a change, its direction and its shape can be predicted and controlled.

The stiffening structure is only partially applied to the textile. This results in larger free areas of textiles. If these are pre-stressed during manufacture, they recede. They therefore have a major influence on the shaping. Under stimulus influence, the materials interact with each other.

Different approaches to structures can be found in the literature. The resulting structures can be categorized as membranes, tessellations and compliant mechanisms. If membrane-like structures are to be produced, large areas of textiles are left free, which are bounded by beams.

Tessellation can occur in combination with membranes. In this case, tessellation is used for repeatable shaping. Tessellation can also occur to create planar bistable structures. Tessellation strategies that are used are: Voronoi [

47], auxetics [

31], circular (concentric rings or radial libs) [

32] and geometric tessellations based on rectangles, triangles or hexagons [

25]. Grimmelsmann et al. identified a high degree of elasticity for the effect of auxetic behavior [

31].

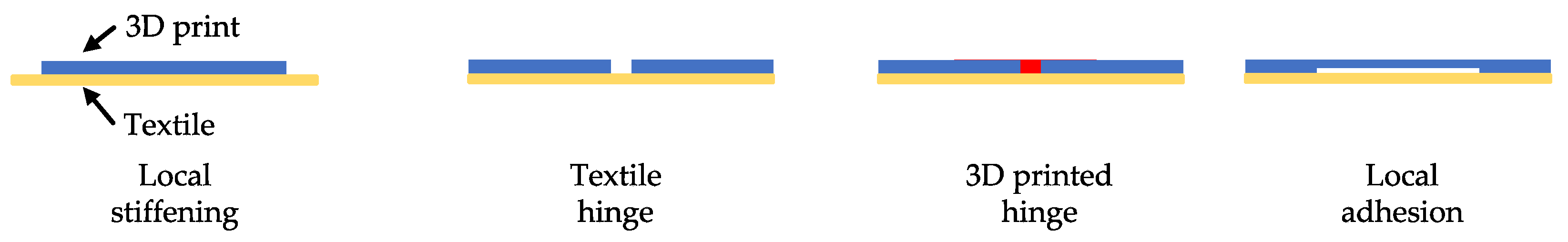

Compliant mechanisms can also occur in combination with membranes. Compliant mechanisms are flexible mechanisms that transmit motion or force via elastic deformation. The behavior depends on the design of the joints, which are applied between two beams on textiles. These joints can be designed in textiles, textiles and plastics or textiles and two different polymers [

25] (

Figure 6).

The properties of the structures can further be controlled by two design primitives: selective stiffening and selective adhesion. Selective stiffening is achieved, for example, by the partial application of a plastic to a textile. Selective adhesion is achieved by partial contact of a melted plastic and a textile. By means of selective adhesion, control of stretching and bending in the plane of the textile is possible [

10]. Printing from both sides on the pre-stressed textiles allows for synclastic primitives and anticlastic primitives [

30]. The shape-changing behavior of the structures is essential to design dedicated functions with the material structure.

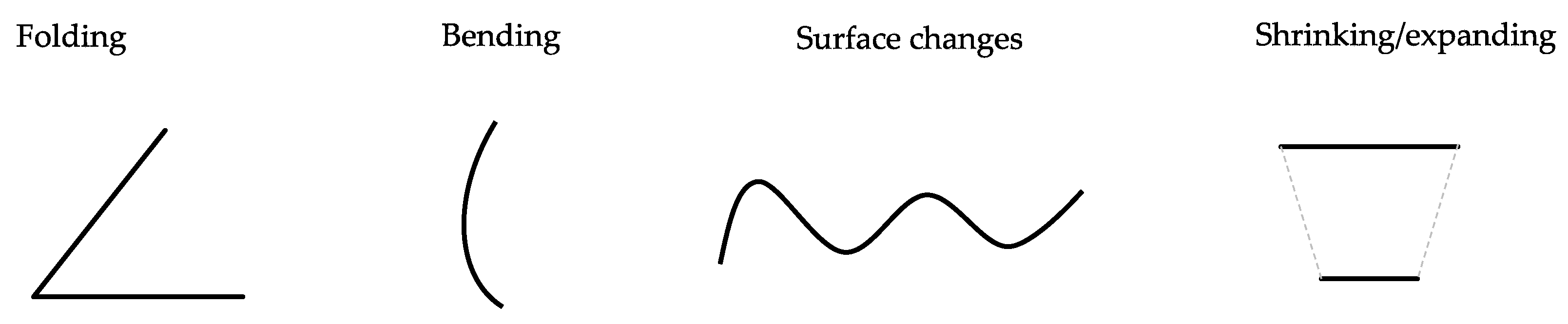

3.3.2. Shape Change

The change in shape can be divided into the following behaviors: folding, bending, surface changes and shrinking or expanding (

Figure 7). These behaviors can be referred to the behavior of actuators as described by Persson et al. [

2].

Folding describes a local change in shape that causes a change in the position of the structures connected to the functional material fold. Bending describes a global change in the shape of the structure. This has an influence on the change in position, shape and properties of the connected structures. In the case of a surface change, a geometric change in the surface occurs which has an influence on the associated structures in terms of position, shape and properties. Shrinkage or expansion scales the structure. All types of shape change can occur between or within dimensions. In the literature, different approaches to design these shape changes are described. Rivera et al. investigated primitives for designing the bending behavior of a hybrid textile structure. Depending on the space between the printed beams, the bending behavior can be adjusted. They also showed that the design of hinges helps to define the form giving (

Figure 6).

Form giving can also be designed by the properties of the printed structures. The material forming properties can be influenced by varying the material thickness of the printed structure, either globally [

47] or locally [

37]. A transition between the shapes can be designed by differing the printing height [

43].

Most projects focused on one layer of a textile to be used in the material structures [

31,

32,

47]. Adding additional layers results in structures that have chambers, and the material sides differ in look and function from each other [

25]. Similar effects can be achieved by selective adhesion and spatial extrusion. Usually the tension-active elements meet the bending-active ones in a linear fashion. The elastic beam actuates the textile in a boundary or a ridge condition [

30].

Orientation for the form giving design can also be found in nature. Kycia and Guiducci transferred insights from flat sheet deformations in nature to 4D textiles. They pointed out that in nature, out-of-plane deformations are the most energy-efficient to deal with material access, whereas with the pre-stressed fabric, the embodied energy acts in the opposite direction. Adding 3D printed material creates wrinkles and curls [

28]. In addition, they presented a surface design tool according to their research.

The described that form finding processes have been applied to small surfaces. The scaling of the described effects might lead to other effects since the material behavior is non-linear [

32]. The shape changing process is introduced by stimuli.

3.4. Stimuli and Reversibility

The systematics for stimuli can be adopted from 4D printing. Textiles often consist of blends of fiber materials. When stimuli are applied, therefore, the properties of the textile materials must be considered in addition to the properties of the printed materials. In the case of exposure to heat, for example, this is the softening temperature. Therefore, primarily pressure or tension is used as a stimulus [

25,

32]. Neuss et al. applied temperature to produce a change in shape [

34].

The described structures are reversible if an external stimulus is applied again or an existing stimulus is removed. Additional active material such as nitinol is used to reverse the shape change in the hybrid material [

32].

3.5. Material Characterization

Adhesion is essential for the resulting material structure properties. The additive manufacturing process can be considered a thermal welding method. Kozior et al. provided an overview on experimental research on adhesion properties between 3D printed structures and fabric [

38]. Three key parameters were identified for the adhesion design of 3D printing on textiles: wetting, diffusion and pressure. While wetting and diffusion are material properties, pressure is a production property.

In a more detailed analysis from a production point of view, the extruder temperature (linear effect explained by diffusion theory of polymers), platform temperature and printing speed (quadratic effect explained by diffusion theory) can have a significant effect on the adhesion properties [

48]. The distance between the nozzle and textile has a significant impact on the adhesion force [

45]. With a decreasing distance, clogging of the nozzle can appear as a problem. With an increase in the temperature of the nozzle and the printing bed, thus decreasing the viscosity, it is possible to increase the distance [

45].

From a material point of view, a high adhesion force can be achieved when similar materials used as with PLA fabrics and PLA filaments are printed on it. A decreasing surface roughness increases the pull-off force [

48]. Korger et al. specified the topography with the weave, roughness and hairiness and the wettability of the textile by a molten polymer. The wettability is influenced by washing, finishing or plasma treatment [

33]. An increase in the adhesion of 3D printed structures on textiles is achieved with coating the textile first. A significant improvement was achieved with the PLA coating and the PLA printing filament [

39]. No discussion was made on the influence of the coating on the textile behavior. From a structural perspective, the circularity of the pores of the textile gives a better peel strength in general [

35]. If the fabric width exceeds the printed polymer width, the peel strength increases [

35]. Parameters tested are either related to the textile or the polymer or the combination of both.

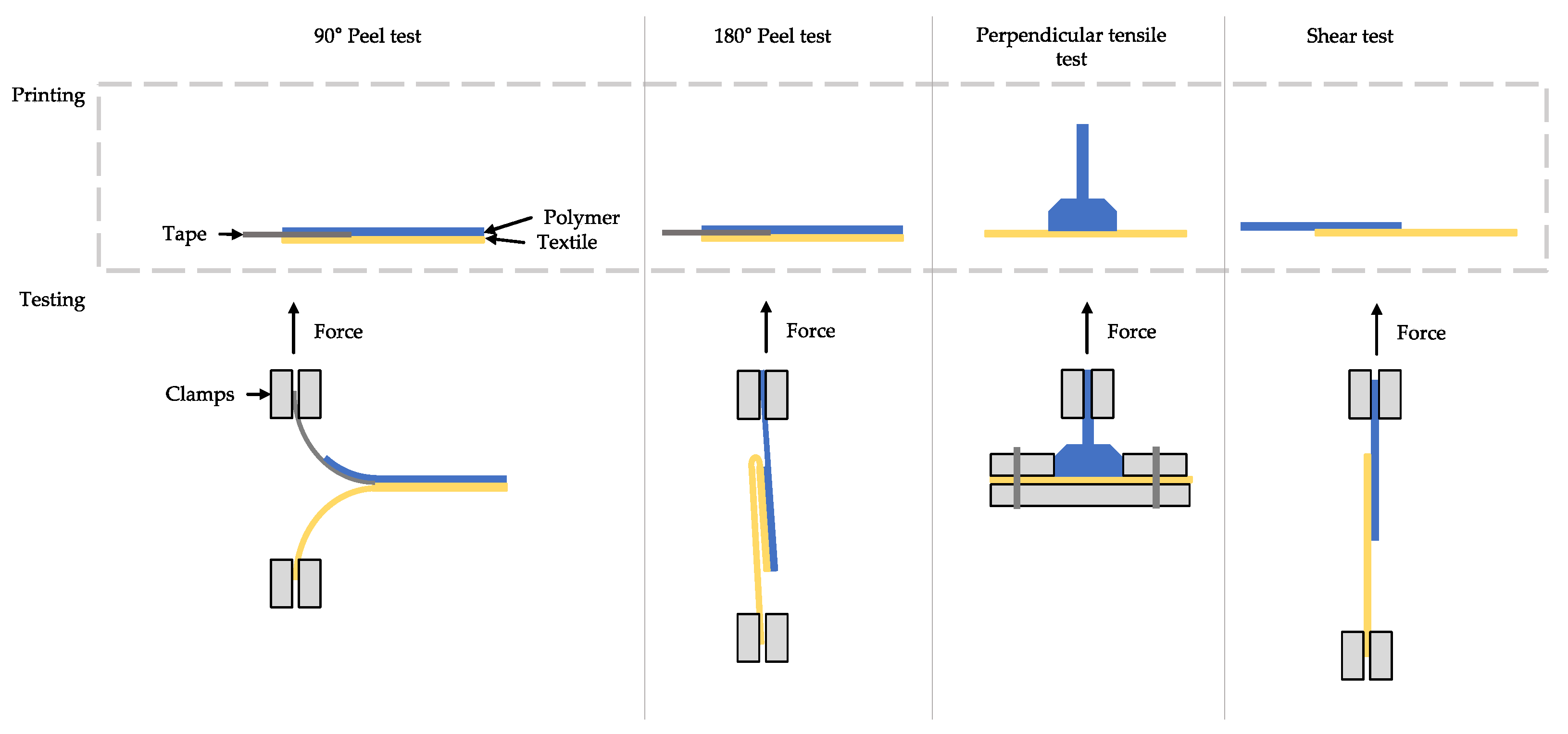

Different testing methods can be applied: Sanatgar et al. combined a sampling method with the standard peeling method SS-EN ISO 11,339:2010 using a Zwick/Z010 tensile tester to investigate the dependencies for 3D printing on textiles [

48]. Korger et al. used an adhesion test according to DIN 53,530 which is usually applied for testing the separating layers of laminated woven fabrics [

33]. Narula et al. identified the ASTM D5170 testing method for hook and loop material as the most appropriate [

35]. They argued that the method used by Korger et al. is appropriate for woven structures but the pull-out of the polymer “pins” in knitted structures interferes with the results. Malengier et al. proposed a perpendicular tensile test as best suited for the adhesion test [

40]. Therefore, a pawn-shaped object is directly printed on the textile. The maximum force to detach the object from the textile was measured. Additionally, they applied a shear test (EN1373) with a rectangular plate printed on the textile and a peel test for six different woven fabrics. A T-peel adhesion test was considered appropriate for 3D printing on woven fabric [

41]. Optical analysis was used to investigate the necessary pore geometry of the textile substrate in relation to the adhesion [

35]. In

Figure 8, different preparation and testing methods are shown.

Three-dimensional scanning and picture analysis is used to identify the amplitude of curling of a single line printed on textiles. It is affected by the height of the lines, whereas the stretch affects the wavelength [

32]. For the surface tessellation, the distance between printed structures, though only connected through the textile, is key to eliminate or create influences between them.

Kozior et al. suggested further research on the printing speed and after treatment [

38]. They did not focus on the testing procedure. An overview on the influencing factors was given, as well as the techniques used so far. Overall, there is no clear distinction between non-pre-stressed and pre-stressed textiles in the print bed.

3.6. Simulation and Modeling

The modeling of hybrid material structures is necessary to predict and create reliable applications. Pre-stressed knitted structures without additives are not yet fully describable. This also influences the modeling of 4D textiles and should be considered for the following descriptions. For finite element modeling (FEM) of textile hybrid structures by additive manufacturing, this review yields the results of Stapleton et al. Using Abaqus

®, a finite element model was set up. Four- and three-sided shell elements (S4R and S3) were used for the reinforcements. The shell centerline was offset upward by half the thickness of the reinforcements. The offset of the centerline accounts for the bond between the textile and the reinforcement [

26].

Three-dimensional membrane elements with three and four nodes (M3D4R and M3D3) with an element size of 0.5 mm were used for the model of the textile surface. When using shell elements with the measured textile thickness, the bending stiffness is overestimated [

26].

The results show variations. It is necessary to consider the thickness of the additive layer. The amount of deformation can be adjusted by the pre-stress, the geometry of the beams and the geometry of the membrane. No additional change in shape is observed above a preload [

26].

Instead of modeling or simulating the resulting shape, Agkathidis et al. applied stress line simulation to understand the behavior mechanisms of the structure before printing [

47].

3.7. Applications

There is no research published on concrete applications of 4D textiles. The material structure has therefore not yet been used commercially. There are various visions for the application. Agkathidis et al. envisioned 4D textiles for resilient architectural skins, shading dividers and large-scale temporary buildings or tents [

47], and Schmelzeisen et al. outlined applications in sound-absorbing textiles, adaptive footwear or jewelry [

25]. Kycia also envisioned architectural applications [

37].

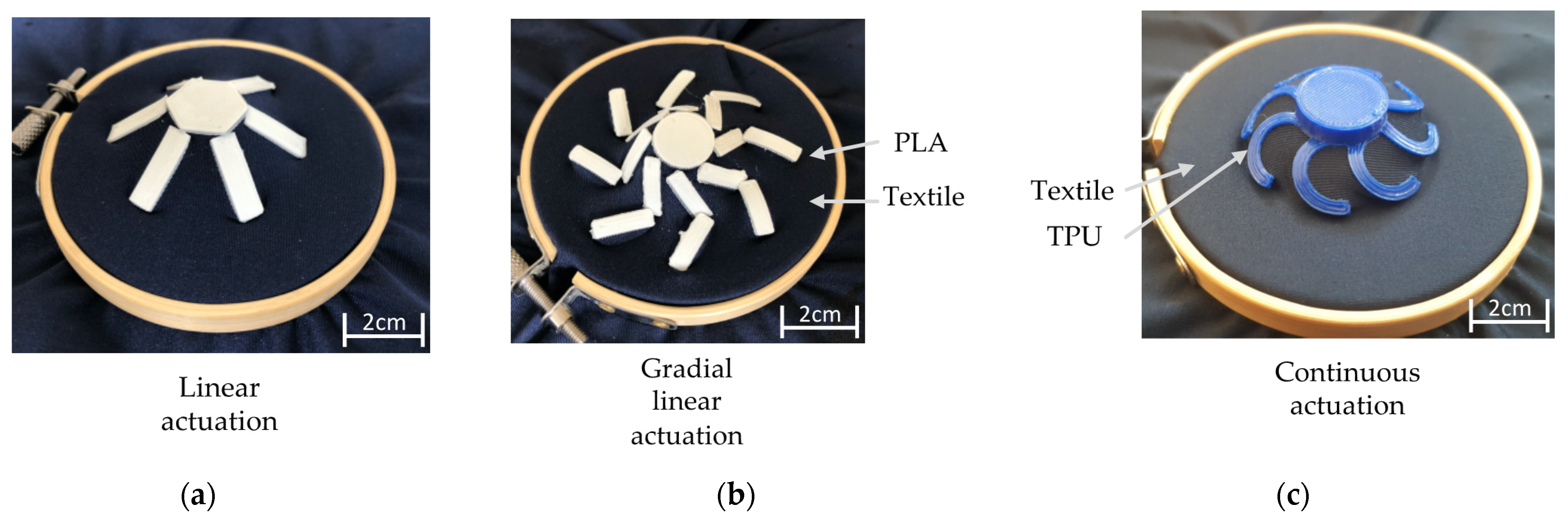

The function to be able to change shape means that 4D textiles in a material structure can be used as an actuator. Three key factors are to be considered: the intensity of the shape change force, the effective amplitude of the movement and the time in which the movement can occur. In addition, the combination of active elements (an additive and a textile) and passive elements (only a textile) allows for locally designed actuation. Through the pattern design, different states of actuation can be performed. In

Figure 9, it is shown how this concept in translated into buttons to be used in an interface. In particular, in applications designed for interaction with humans, the energy capacity of the human and the acceptance of the human need should be considered. The buttons shown can be performed with the force strength of a human. The textile surface is an accepted surface. A Massportal Pharaoh XD 20 was used. As filaments, PLA (printing temperature: 220 °C, density: 1.24 g/m

3, tensile modulus: 3145 MPa) and TPU (printing temperature: 240 °C, density: 1.14 g/cc, tensile modulus: 95 MPa) were processed. The textile is a polyester–spandex blended knitted structure and the textile was pre-stressed at 170% with nails. The diameter of the buttons is 20 mm. To enable interaction with the buttons, they were clamped with 10% pre-stress in embroidery hoops (see

Figure 9).

4. Discussion and Conclusions

The pre-stressing of textiles can introduce additional energy into a morphing system. Thus, textiles have great potential to further develop 4D printing. Studies on printed smart materials on textiles are still scare.

The design of 4D textiles continues to be driven by the functionalization of textile components along the entire textile chain. The interplay of manipulating the textile structure and additive manufacturing has been little considered and yet contains potential, as the properties of the overall composite are influenced, particularly structurally.

No uniform standards for testing methods were identified. This is particularly important with regard to the different textile substrates, woven and knitted fabrics. This leads to no comparable data and the specimen design also differs. The activation of the 4D textiles is performed with force or heat. Not data exist on using smart materials to print on textiles.

So far, the scaling of the technology to larger samples could not be investigated. There is a lack of production technology and its clear focus on printing on textiles. Towards real application in the envisioned application fields, a scaling is unavoidable. The existing FEM models around the behavior are not yet fully sufficient to describe the material behavior. The material structure has been investigated mainly by architecture, design and textile engineering researchers. The different research disciplines have found different descriptions of the material structure, though they mainly use the same materials.

A cooperation between the disciplines of design, material science and architecture can lead to a stronger standardization, e.g., in uniform testing methods of the structure, and thus to a concrete application. For the realization of applications, ways must be found to make the material accessible to users. Building on the idea of programmable textiles, a digital design tool and a physical equivalent are needed.

Author Contributions

Conceptualization, literature review and visualization, H.C.K.; writing—original draft preparation, H.C.K. and D.S.; writing—review and editing and supervision, T.G. All authors have read and agreed to the published version of the manuscript.

Funding

Funded by the Deutsche Forschungsgemeinschaft (DFG, German Research Foundation) under Germany’s Excellence Strategy—EXC-2023 Internet of Production—39062161.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Conflicts of Interest

The authors declare no conflict of interest. The funders had no role in the design of the review; in the collection, analyses, or interpretation of data; in the writing of the manuscript, or in the decision to publish the results.

References

- Gries, T.; Veit, D.; Wulfhorst, B. Textile Technology—An Introduction; Hanser Publishers: Munich Cinncinatti, OH, USA, 2015; ISBN 978-1-56990-566-1. [Google Scholar]

- Persson, N.-K.; Martinez, J.G.; Zhong, Y.; Maziz, A.; Jager, E.W.H. Actuating Textiles: Next Generation of Smart Textiles. Adv. Mater. Technol. 2018, 3, 1–12. [Google Scholar] [CrossRef]

- Gehrke, I.; Tenner, V.; Lutz, V.; Schmelzeisen, D.; Gries, T. Smart Textiles Production—Overview of Materials, Sensor and Production Technologies for Industrial Smart Textiles; MDPI: Basel, Switzerland, 2019. [Google Scholar] [CrossRef]

- Sitotaw, D.B.; Ahrendt, D.; Kyosev, Y.; Kabish, A.K. Additive Manufacturing and Textiles—State-of-the-Art. Appl. Sci. 2020, 10, 5033. [Google Scholar] [CrossRef]

- ISO. ISO/ASTM DIS 52950. In Additive Manufacturing—General Principles—Overview of Data Processing; ASTM International: West Conshohocken, PA, USA, 2019. [Google Scholar] [CrossRef]

- Gebhardt, A. 3D-Drucken. Grundlagen und Anwendungen des Additive Manufacturing (AM); Carl Hanser: München, Germany, 2014. [Google Scholar]

- Ligon, S.C.; Liska, R.; Stampfl, J.; Gurr, M.; Mülhaupt, R. Polymers for 3D Printing and Customized Additive Manufacturing. Chem. Rev. 2017, 117, 10212–10290. [Google Scholar] [CrossRef]

- Khoo, Z.X.; Teoh, J.E.M.; Liu, Y.; Chua, C.K.; Yang, S.; An, J.; Leong, K.F.; Yeong, W.Y. 3D printing of smart materials: A review on recent progresses in 4D printing. Virtual Phys. Prototyp. 2015, 10, 103–122. [Google Scholar] [CrossRef]

- Spahiu, T.; Canaj, E.; Shehi, E. 3D printing for clothing production. J. Eng. Fibers Fabr. 2020, 15, 15. [Google Scholar] [CrossRef]

- Rivera, M.L.; Moukperian, M.; Ashbrook, D.; Mankoff, J.; Hudson, S.E. Stretching the Bounds of 3D Printing with Embedded Textiles. In Proceedings of the of the 2017 CHI Conference on Human Factors in Computing Systems, Denver, CO, USA, 6–11 May 2017; pp. 497–508. [Google Scholar] [CrossRef]

- Pei, E.; Shen, J.; Watling, J. Direct 3D printing of polymers onto textiles: Experimental studies and applications. Rapid Prototyp. J. 2015, 21, 556–571. [Google Scholar] [CrossRef]

- Agkathidis, A.; Berdos, Y.; Brown, A. Active membranes: 3D printing of elastic fibre patterns on pre-stretched textiles. Int. J. Arch. Comput. 2019, 17, 74–87. [Google Scholar] [CrossRef]

- Tibbits, S. The Emergence of 4D Printing. Available online: https://www.ted.com/talks/skylar_tibbits_the_emer-gence_of_4d_printing?language=de (accessed on 11 December 2020).

- Pei, E.; Loh, G.H. Technological considerations for 4D printing: An overview. Prog. Addit. Manuf. 2018, 3, 95–107. [Google Scholar] [CrossRef]

- Loh, G.H.; Pei, E.; Harrison, D.; Monzón, M.D. An overview of functionally graded additive manufacturing. Addit. Manuf. 2018, 23, 34–44. [Google Scholar] [CrossRef]

- Haberland, C.; Elahinia, M.; Walker, J.M.; Meier, H.; Frenzel, J. On the development of high quality NiTi shape memory and pseudoelastic parts by additive manufacturing. Smart Mater. Struct. 2014, 23. [Google Scholar] [CrossRef]

- Mitchell, A.; Lafont, U.; Hołyńska, M.; Semprimoschnig, C. Additive manufacturing—A review of 4D printing and future applications. Addit. Manuf. 2018, 24, 606–626. [Google Scholar] [CrossRef]

- González-Henríquez, C.M.; Sarabia-Vallejos, M.A.; Rodriguez-Hernandez, J. Polymers for additive manufacturing and 4D-printing: Materials, methodologies, and biomedical applications. Prog. Polym. Sci. 2019, 94, 57–116. [Google Scholar] [CrossRef]

- Momeni, F.; Hassani, N.S.M.; Liu, X.; Ni, J. A review of 4D printing. Mater. Des. 2017, 122, 42–79. [Google Scholar] [CrossRef]

- Choi, J.; Kwon, O.-C.; Jo, W.; Lee, H.J.; Moon, M.-W. 4D Printing Technology: A Review. 3D Print. Addit. Manuf. 2015, 2, 159–167. [Google Scholar] [CrossRef]

- Whitesides, G.M. Self-Assembly at All Scales. Science 2002, 295, 2418–2421. [Google Scholar] [CrossRef] [PubMed]

- Momeni, F.; Ni, J. Invited Article: 4D Printing as a New Paradigm for Manufacturing with Minimum Energy Consumption. arXiv 2018, arXiv:1811.12609, 1–14. [Google Scholar]

- Piedade, A.P. 4D Printing: The Shape-Morphing in Additive Manufacturing. J. Funct. Biomater. 2019, 10, 9. [Google Scholar] [CrossRef]

- Melly, S.K.; Liu, L.; Liu, Y.; Leng, J. Active composites based on shape memory polymers: Overview, fabrication methods, applications, and future prospects. J. Mater. Sci. 2020, 55, 10975–11051. [Google Scholar] [CrossRef]

- Schmelzeisen, D.; Koch, H.; Pastore, C.; Gries, T. 4D Textiles: Hybrid Textile Structures that Can Change Structural Form with Time by 3D Printing. Narrow Smart Text. 2017, 189–201. [Google Scholar] [CrossRef]

- Stapleton, S.E.; Kaufmann, D.; Krieger, H.; Schenk, J.; Gries, T.; Schmelzeisen, D. Finite element modeling to predict the steady-state structural behavior of 4D textiles. Text. Res. J. 2018, 89, 3484–3498. [Google Scholar] [CrossRef]

- Ahlquist, S.; Shah, K. Post-forming composite morphologies materialization and design methods for inducing form through textile material behavior. In Proceedings of the 34th Annual Conference of the Association for Computer Aided Design in Architecture (ACADIA), Los Angeles, LA, USA, 23–25 October 2014; pp. 267–276. [Google Scholar]

- Kycia, A.; Guiducci, L. Self-shaping textiles a material platform for digitally designed material-informed surface elements. In Proceedings of the Anthropologic: Architecture and Fabrication in the Cognitive Age—Proceedings of the 38th eCAADe Conference, Berlin, Germany, 16–18 September 2020; Werner, L., Koering, D., Eds.; TU Berlin: Berlin, Germany, 2020; Volume 2, pp. 21–30. [Google Scholar]

- Chatterjee, K.; Ghosh, T. 3D Printing of Textiles: Potential Roadmap to Printing with Fibers. Adv. Mater. 2019, 32, e1902086. [Google Scholar] [CrossRef] [PubMed]

- Christie, J. Spatial textile hybrids: Computing a self-forming behavior. In Proceedings of the 3rd International Conference of Biodigital Architecture and Genetics, Barcelona, Spain, 7–10 June 2017. [Google Scholar]

- Grimmelsmann, N.; Meissner, H.; Ehrmann, A. 3D printed auxetic forms on knitted fabrics for adjustable permeability and mechanical properties. IOP Conf. Ser. Mater. Sci. Eng. 2016, 137, 012011. [Google Scholar] [CrossRef]

- Kycia, A. Form finding of performative surfaces through 3D printing on prestressed textiles. In Proceedings of the CA2RE+ Trondheim PROCEEDINGS, Trondheim, Norway, 10–12 June 2020; pp. 1–13. [Google Scholar]

- Korger, M.; Bergschneider, J.; Lutz, M.; Mahltig, B.; Finsterbusch, K.; Rabe, M. Possible Applications of 3D Printing Technology on Textile Substrates. IOP Conf. Ser. Mater. Sci. Eng. 2016, 141, 012011. [Google Scholar] [CrossRef]

- Neuß, J.; Kreuziger, M.; Grimmelsmann, N.; Korger, M.; Ehrmann, A. Interaction between 3D deformation of textile fabrics and imprinted lamellae. In Proceedings of the Aachen-Dresden-Denkendorf International Textile Conference, Dresden, Germany, 24–25 November 2016; p. 6. [Google Scholar]

- Narula, A.; Pastore, C.M.; Schmelzeisen, D.; El Basri, S.; Schenk, J.; Shajoo, S. Effect of knit and print parameters on peel strength of hybrid 3-D printed textiles. J. Text. Fibrous Mater. 2018, 1, 251522111774925. [Google Scholar] [CrossRef]

- Grothe, T.; Brockhagen, B.; Storck, J. Three-dimensional printing resin on different textile substrates using stereolithography: A proof of concept. J. Eng. Fibers Fabr. 2020, 15, 15. [Google Scholar] [CrossRef]

- Kycia, A. Material form-finding of modular textile structures. In Proceedings of the CA2RE, Aarhus School of Architecture, Aarhus, Denmark, 13–16 April 2018. [Google Scholar]

- Kozior, T.; Blachowicz, T.; Ehrmann, A. Adhesion of three-dimensional printing on textile fabrics: Inspiration from and for other research areas. J. Eng. Fibers Fabr. 2020, 15, 15. [Google Scholar] [CrossRef]

- Unger, L.; Scheideler, M.; Meyer, P.; Harland, J.; Gorzen, A.; Wortmann, M.; Dreyer, A.; Ehrmann, A. Increasing adhesion of 3D printing on textile fabrics by polymer coating. Tekstilec 2018, 61, 265–271. [Google Scholar] [CrossRef]

- Malengier, B.; Hertleer, C.; Cardon, L.; Van Langenhove, L. 3D Printing on Textiles: Testing of Adhesion. J. Fash. Technol. Text. Eng. 2018, 4, 1–6. [Google Scholar] [CrossRef]

- Čuk, M.; Bizjak, M.; Muck, D.; Kočevar, T.N. 3D printing and functionalization of textiles. In Proceedings of the 10th International Symposium GRID, Novi Sad, Serbia, 12–14 November 2020. [Google Scholar] [CrossRef]

- Gengnagel, C. Mobile Membrankonstruktionen, Schriftenreihe des Lehrstuhls für Tragwerksplanung; Inst. füt Entwerfen und Baukonstruktion: München, Germany, 2005; ISBN 978-3-938660-07-2. [Google Scholar]

- Aldinger, L.; Margariti, G.; Körner, A.; Suzuki, S.; Knippers, J. Tailoring Self-Formation fabrication and simulation of membrane-actuated stiffness gradient composites. In Proceedings of the IASS Symposium 2018—Creativity in Structural Design, Boston, MA, USA, 16–20 July 2018; p. 141. [Google Scholar]

- Sharmin, S.; Ahlquist, S. Knit architecture. Posthuman Frontiers: Data, Designers, and Cognitive Machines (ACADIA’16). In Proceedings of the 36th Annual Conference of the Association for Computer Aided Design in Architecture, Ann Arbor, MI, USA, 27–29 October 2016; pp. 254–259. [Google Scholar]

- Spahiu, T.; Al-Arabiyat, M.; Martens, Y.; Ehrmann, A.; Piperi, E.; Shehi, E. Adhesion of 3D printing polymers on textile fabrics for garment production. IOP Conf. Ser. Mater. Sci. Eng. 2018, 459, 012065. [Google Scholar] [CrossRef]

- Gries, T. Elastische Textilien: Garne, Verarbeitung, Anwendung; Melliand Edition Textiltechnik: Frankfurt, Germany, 2005. [Google Scholar]

- Barletta, M.; Gisario, A.; Mehrpouya, M. 4D printing of shape memory polylactic acid (PLA) components: Investigating the role of the operational parameters in fused deposition modelling (FDM). J. Manuf. Process. 2021, 61, 473–480. [Google Scholar] [CrossRef]

- Sanatgar, R.H.; Campagne, C.; Nierstrasz, V. Investigation of the adhesion properties of direct 3D printing of polymers and nanocomposites on textiles: Effect of FDM printing process parameters. Appl. Surf. Sci. 2017, 403, 551–563. [Google Scholar] [CrossRef]

| Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).