1. Introduction

Micromirrors and microscanners are key technologies for numerous optical applications, including laser projection [

1], optical communication [

2], displays [

3,

4,

5,

6,

7], medical imaging [

8,

9], and light detection and ranging (LiDAR) [

10,

11,

12,

13]. This widest range of varying applications is down to their superior production costs, compact dimensions, and energy efficiency. A consequence of their popularity is the number of designs, which are commonly categorized by their actuation principle and degrees of freedom (DOFs). Actuating a micromirror typically employs either electrostatic [

3,

6], piezoelectric [

14], electromagnetic [

7,

15,

16], or thermoelectric [

17,

18] effects. These physical effects mainly differ in speed of actuation, displacement magnitude, required space and operating voltage. A micromirror’s DOFs determine its number of rotational and potentially translational axes. Each design features its own maximum deflection angle and operating frequencies.

However, all these concepts share one common design aspect: the rotating mirror is mounted using structural connections as there are no ball bearings in microtechnology. Consequently, these links restrict the maximum deflection angle and cause restoring forces that the actuator has to overcome. This deficit limits the classical micromirror’s use in certain applications, such as tracking, as they require large quasistatic deflections [

19,

20].

A novel actuator design has been proposed to overcome this limitation by omitting all structural suspensions [

20]. In contrast, an unconnected hemispherical micromirror is rotated by periodic bouncing elicited by contact to an elliptically oscillating stage. This design achieves a resonant deflection angle of

and a maximum angular velocity of

[

20]. As each contact induces rotational momentum, stepwise rotation is achieved. Up till now, challenging physics such as mechanical contact impede accurate modeling and closed-loop control, limiting the approach to a proof of concept.

The kick and catch research project [

21] aims to extend this innovative system by more sophisticated actuators and highly accurate models, enabling model-based closed-loop control [

22,

23,

24]. In this approach, a cooperation of a kick-actuator and a catch-actuator achieves multistable motion of the hemisphere. The former corresponds to a more sophisticated version of the stage [

20], offering more control of the hemisphere’s launch and landing; The latter introduces controllable forces acting on the hemisphere, thus providing access to the closed-loop control.

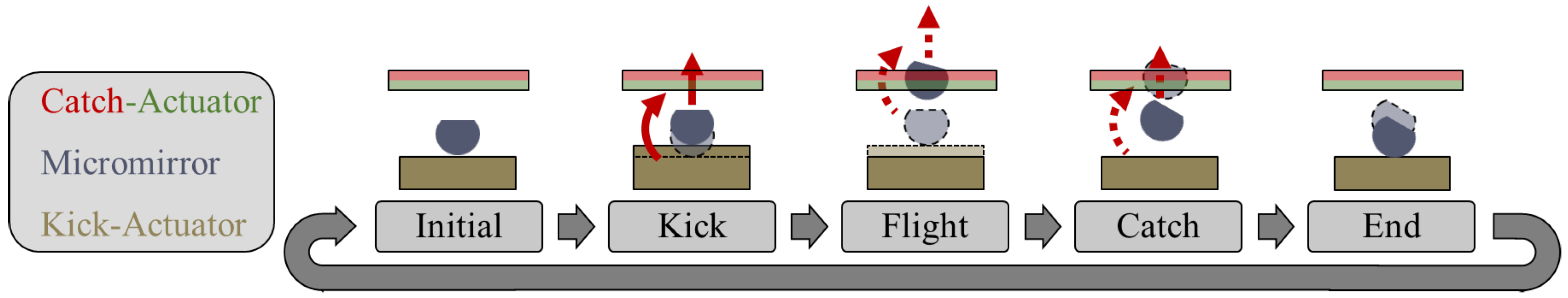

Figure 1 illustrates the concept’s basic operating principle: first, the piezoelectric kick-actuator expands. Mechanical contact transfers these sudden forces to the micromirror, launching it into a flight phase with potential rotation. During the flight, the electromagnetic catch-actuator adjusts the hemisphere’s trajectory and softens its landing. Finally, the rotated micromirror lands on the kick-actuator. Repeating this sequence achieves larger rotations.

As optical applications require high-level accuracy, reliable system-level models are of crucial importance. This is especially true for the kick-actuator due to its mechanical contact to the hemisphere as well as its multiphysical actuation. The finite element method (FEM) allows the accurate modeling of these effects, but its computational demand prevents any system-level application.

This gap is closed by MOR methodology [

25], generating system-level models of extraordinary accuracy based on, for example, finite element (FE) models. MOR reduces a model’s initially high dimension by several orders of magnitude while forfeiting almost no precision. Methods to generate reduced order models (ROMs) are well established for linear systems [

26], whereas mechanical contact remains challenging due to its nonlinearity and inequality constraints [

27]. Another obstacle in reducing contact are mainly its three different FE implementations: Lagrange multipliers, penalty, or augmented Lagrange multipliers [

28]. To enforce non-penetration, they introduce additional DOFs, penetration-opposing stiffness, or both.

General nonlinear MOR is accompanied by two particular problems: finding a reduced basis and efficiently evaluating nonlinearities [

29]. The data-driven proper orthogonal

decomposition (POD) [

27,

30,

31,

32] is the state-of-the-art method for constructing a reduced basis for a nonlinear system. Techniques [

33] that do not rely on data created by extensive simulations, such as modal [

34] or static derivatives, are less popular. A recent contact-specific approach separates the DOFs of the full order model (FOM) into displacements and Lagrange multipliers prior to reduction, relying on Lagrange-like contact implementation [

27,

35]. Evaluating nonlinearities is accompanied by extremely high computational costs and must thus be approximated to maintain the ROM’s efficiency. This approximation step is known as hyper-reduction, estimating the full nonlinearity based on few local evaluations [

29]. Prominent methods include the data-driven discrete empirical interpolation method (DEIM) [

36] and the technique of energy conserving mesh sampling and weighting (ECSW) [

27,

31,

37,

38]. Although these methods can achieve excellent precision even for contact problems [

27,

31,

39], they require numerous expensive FOM solutions, also referred to as snapshots. Moreover, their prediction quality is limited to cases included in their training, making data-driven ROMs less robust.

A noteworthy technique exists for reducing systems with their nonlinearities exclusively in their input, which are referred to as weakly nonlinear systems. In this case, the inputs can be grouped to reduce the number of nonlinearities [

40]. The inputs of a mechanical system are external forces and grouping inputs means merging almost equal forces into a single but distributed force. The reduced number of forces allows them to be efficiently handled as nonlinear inputs for a linear ROM. Although this approach requires simple geometries, a-priori knowledge of the forces’ location and mergeable forces, it offers two remarkable advantages: firstly, in contrast to state-of-the-art data-driven MOR, it does not rely on computationally expensive snapshots. Consequently, such an ROM is not restricted by its training input. Secondly, well-established methods of linear MOR, such as Krylov-subspace-generated bases [

41], become available. This also includes robust methods for parametric model order reduction (pMOR), enabling the inclusion of parameters arising from material properties or geometry.

This paper applies the aforementioned reduction of weakly nonlinear systems to an impact problem on a piezoelectric kick-actuator. Hence, the method’s scope is extended from contact as a boundary condition [

40] to penalty-based contact between two bodies. The novel approach for this extension is to separate the kick-actuator and a sphere into individual models. The model of the kick-actuator is reduced separately and is rejoined with the sphere via contact at the system-level. This separation relocates the multibody system’s nonlinearity from the stiffness matrix to the individual systems’ inputs. Hence, penalty-based contact can be considered nonlinear external forces, granting access to the methodology of [

40]. Further enhancement is provided through considering the expected load distribution in the FE mesh’s design. As a result, the grouping-induced error is reduced compared to [

40]. The final ROM complements preceding work on the electromagnetic catch-actuator [

23,

24] and enables system-level simulation of the entire actuator system.

The remainder of this paper is structured as follows:

Section 2 provides more details on the actuator system, its FE models, their reduction by means of MOR, and a final application at system-level, demonstrating feasibility. Numerical experiments evaluate the ROM’s accuracy and computational efficiency by comparing its solution to the reference. Both intermediate and final results are presented in

Section 3. Finally,

Section 4 offers a conclusion and identifies aspects for future investigation.

2. Materials and Methods

This section specifies the design of the kick and catch actuator system and introduces simplifications applied in this study. Subsequently, FE models of the piezoelectric kick-actuator and the electromagnetic catch-actuator are described. MOR generates system-level models deployed in a full system-level simulation. The catch-actuator has been the subject of earlier work [

23,

24]. Corresponding paragraphs will, therefore, be confined to summaries and updates.

2.1. Actuator System Design

The kick and catch actuator system constitutes an innovative architecture for micromirrors as it omits all structural connections. Due to this work’s focus being on methods of nonlinear MOR, the system is simplified as shown in

Figure 2:

A sphere replaces the hemisphere;

The sphere’s motion is restricted to vertical displacement;

The kick-actuator comprises a single piezoelectric chip actuator;

All of the components are arranged concentrically.

Even though the mirror’s rotation is not modeled, these changes do not neglect physical effects and include the working principle shown in

Figure 1: the expanding piezoelectric kick-actuator accelerates the sphere via mechanical contact. Subsequently, the catch-actuator controls the magnetic sphere’s position via electromagnetic forces. Therefore, the setup suffices to develop methods for generating system-level models. In addition, preliminary experiments are planned using the same configuration. For that reason, all of the components were chosen from those commercially available.

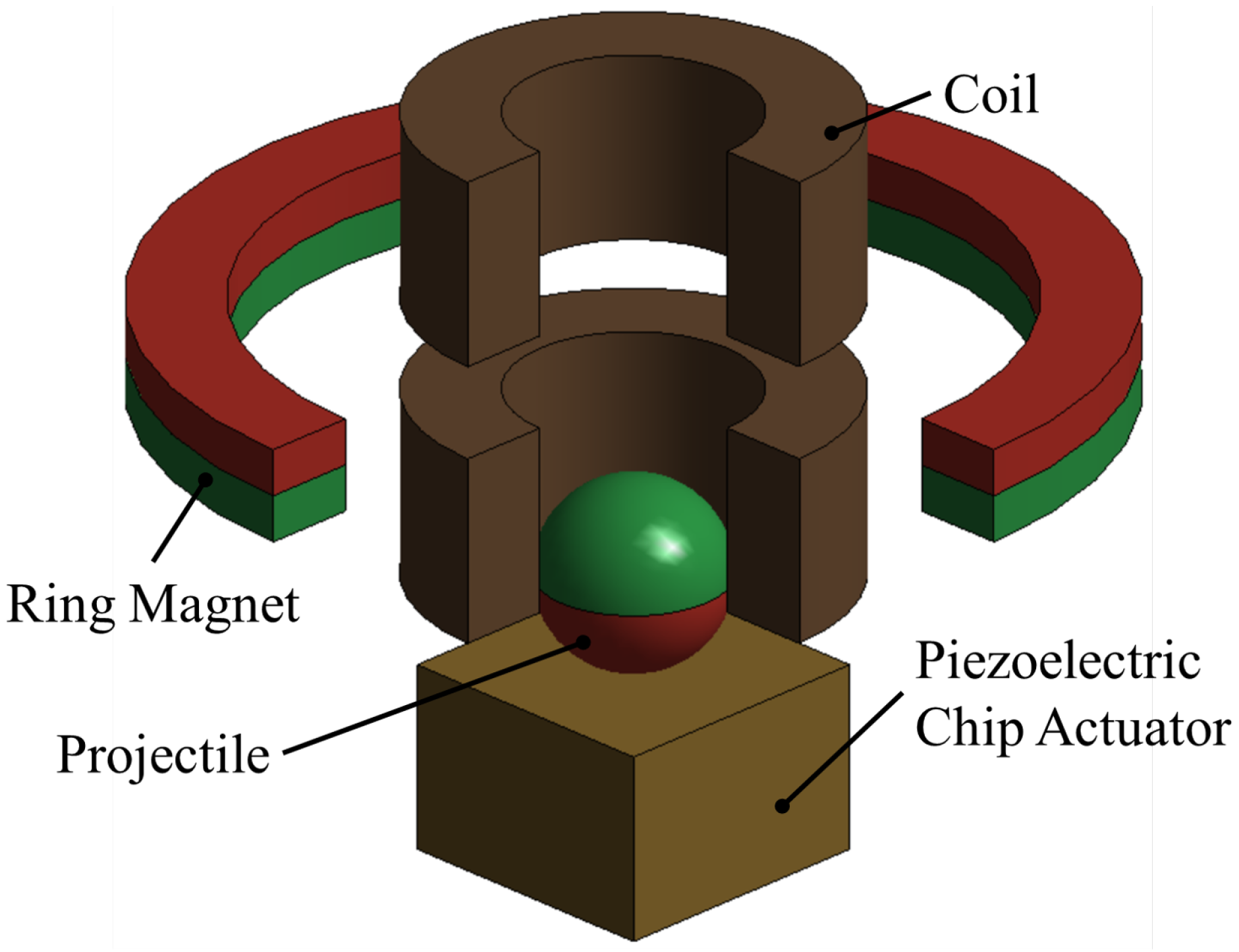

For the kick-actuator, a piezoelectric PA3JEAW chip actuator by Thorlabs is deployed. A total of 33 piezoelectric layers of lead zirconate titanate (PZT)-based THP51 [

42] with alternating polarization stack up to a chip actuator of

. Silver electrodes in between collect or distribute electric charges. A ceramic coating prevents moisture from entering the actuator.

Appendix A.2 presents all material data relevant for simulation.

The magnets employ commercial products, whereas the coils will be custom-manufactured.

Table 1 denotes the cylindrical parts’ dimensions and their vertical positions. Leaving a radial gap for potential guiding structures, the coils’ inner radii are chosen to be

. The two coils’ geometries are identical and deploy a copper wire with a diameter of

. Each solenoid comprises 4074 windings, assuming a fill factor of 100%.

Although the setup of this work is macro-scale, a miniaturization is targeted in the long term. A corresponding design will presumably rely on following cornerstones: microcoils might be manufactured by wirebonding technology from IMTEK, Freiburg. Stacked layers of metglas allow for magnets with tailored properties. Additional mechanical leverage might extend the stroke of piezoelectric actuators.

2.2. Finite Element Models

In general, physical problems are rendered into partial differential equations (PDEs) ones that can rarely be solved analytically. The FEM spatially discretizes the computational domain, transforming a PDE into a large-scale system of ordinary differential equations (ODEs). In addition, numerical integration schemes discretize time and thus transform the system of ODEs into a system of algebraic equations. Therefore, methods of linear algebra can solve the initial physical problem. If properties of the system depend on its solution, the system is classified as nonlinear. In this case, the solution process deploys iterative schemes where each iteration solves a linearized system. For a transient analysis, these iterations arise at each time step, multiplying computational effort.

The actuator system comprises two single actuators with distinct physical domains. While the catch-actuator is an electromagnetic scenario, the kick-actuator relies on piezoelectricity and contact mechanics. As the physics of the two actuators do not effectively interfere with each other, they were investigated in separate FE analyses. All electromagnetic analyses were conducted in ANSYS Maxwell 2020 R2, all piezoelectric analyses in ANSYS Mechanical 2020 R2 and all system-level simulations in ANSYS TwinBuilder 2020 R2. A system of an AMD Ryzen 5 3600 and 16 GB RAM was employed for all analyses.

2.2.1. Electromagnetic Catch-Actuator

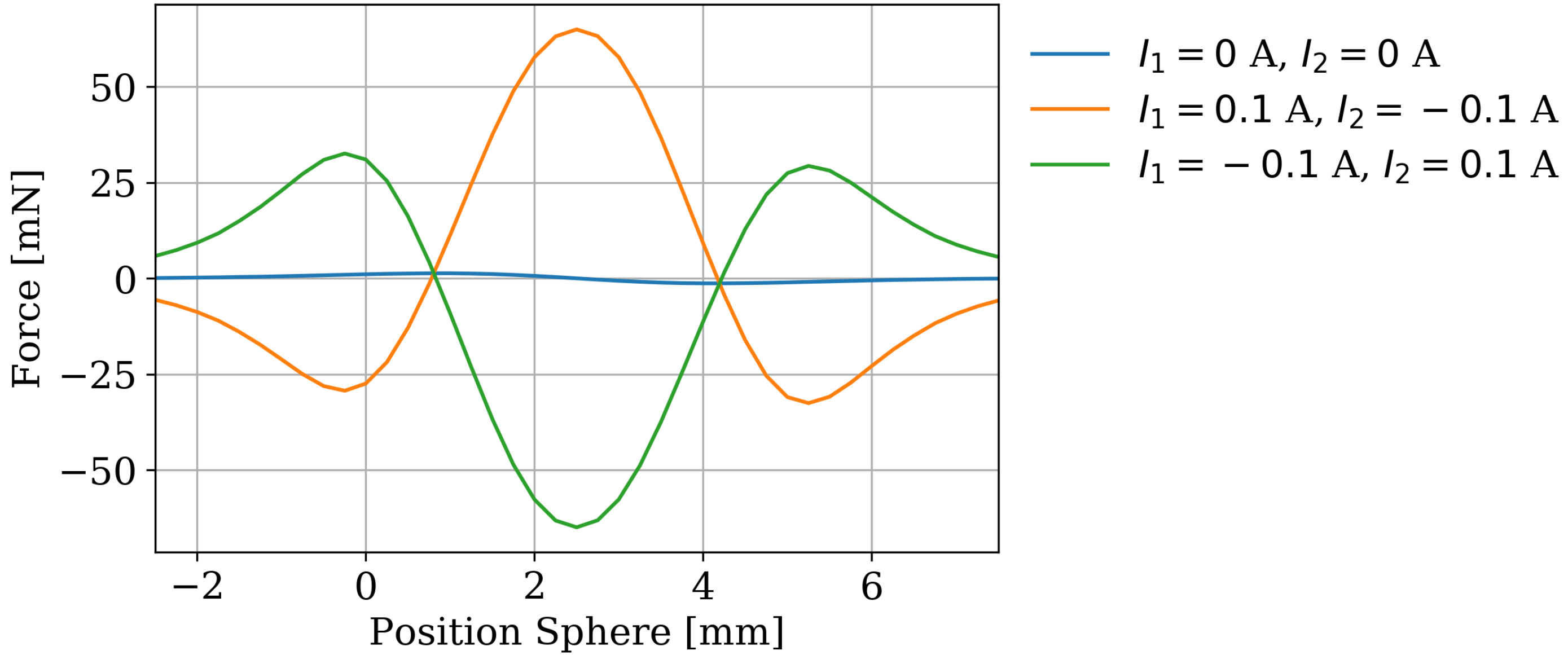

The catch-actuator electromagnetically controls the micromirror’s position and orientation. Simplifying the device as described in

Section 2.1, the mirror is exchanged with a sphere and restricted to vertical motion. Consequently, the catch-actuator interacts with the sphere via a vertical force. This electromagnetic force depends predominantly on the sphere’s vertical position and the electrical currents in the solenoids. Transient effects can be ignored.

The catch-actuator’s FE model exploits its rotational symmetry, allowing a two-dimensional analysis setup. An enclosing air region is introduced in addition to the geometries of the magnet, the coils and the sphere. This region represents the air between the components and in their surroundings, taking the far field into account. Its geometry in three dimensions corresponds to a cylinder of

and

, centered around the actuator. All material data are given in

Table A1 and assumed to be linear, reducing the complexity of a later system-level model. As mesh resolution is crucial for a FE analysis’ accuracy, adaptive meshing is applied. This process convergence criteria are set to either a maximal relative error of 5 ∗ 10

-6 or 30 iterations. To compute the electromagnetic force on the sphere with respect to its dependencies, both coil currents and the sphere’s position are parameterized. The sphere’s vertical position ranges from −2.5

to 7.5

in 41 steps, the coil currents from −0.1

to 0.1

in increments of

. Finally, the catch-actuator is analyzed in a set of 369 static electromagnetic simulations. A more extensive description is available in [

23,

24].

2.2.2. Piezoelectric Kick-Actuator

The kick-actuator launches the hemispherical mirror by a sudden transfer of momentum and also serves as a landing platform. In the context of this work, the PA3JEAW actuator launches a rigid sphere in response to an electrical excitation. Although simplified, this sequence features transient multiphysics and nonlinearities due to piezoelectricity and mechanical contact.

The modeled geometry represents the piezoelectric chip actuator defined in

Section 2.1. Both the ceramic coating and the electrodes have little influence on the actuator’s mechanical behavior. Therefore, their geometry is excluded from the model. All electrodes are considered ideally conductive, allowing for coupling electrical DOFs of all anodes and cathodes respectively. Moreover, the cathode is grounded and electric loads may be applied to the anode. The 33 piezoelectric layers of alternating polarization are modeled as one block of THP51. A mapped layered mesh reintroduces their structure and

Appendix A.2 provides the THP51’s material data. The sphere is considered rigid to reduce complexity of nonlinear iterations. Thus, only the sphere’s density of

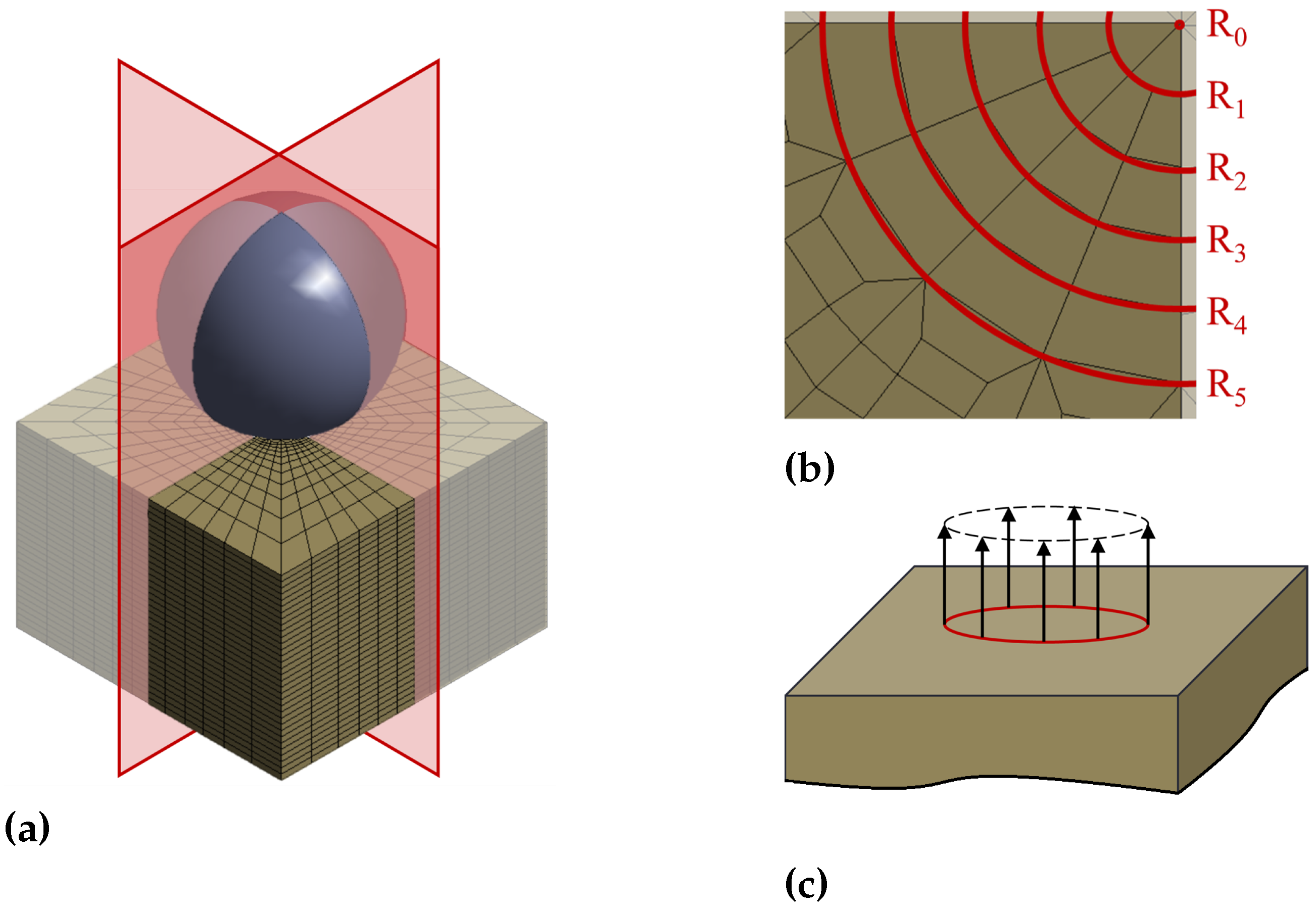

remains relevant. In addition, several symmetries are introduced by restricting the sphere to vertical motion. As a result, modeling a quarter of the setup as shown in

Figure 3a suffices, significantly saving computational resources. This is particularly useful for transient nonlinear analyses. Furthermore, any vertical displacement of the bottom face is set to zero, representing an adhesive connection. Additional displacement constraints prevent rigid body motion of the chip actuator. Simulating initial rigid body motion in impact setups brings no insights at full computational costs for each time step. To minimize this issue, the sphere is modeled 1 μm above the actuator’s top surface and assigned an initial velocity. The transient analysis deploys an implicit Newmark time integration with a time-step of 50 ns to an end time of 15 μs.

The chip actuator is spatially discretized into a linear mapped FE mesh for three reasons: firstly, a mapped mesh allows to accurately model the piezoelectric layers. Secondly, a mapped instead of a free mesh avoids numerically induced asymmetries in the contact forces. Thirdly, and most importantly, this part of the mesh is the basis for efficiently reducing contact. The procedure in [

40] groups together nodes of equal external forces. Hence, it is crucially important to have a mesh that supports such clustering. As a sphere causes the contact forces, locations on a concentric circle experience effectively equal vertical forces. No radial forces occur due to settings chosen for contact modeling. Therefore, meshing the contact area in five concentric rings as illustrated in

Figure 3b is an appropriate choice. The rings have a radial distance of 50 μm as a fine mesh in contact regions improves accuracy and nonlinear convergence.

Excluding contact and the sphere for now, the kick-actuator constitutes a linear piezoelectric problem. Employing a strong coupling, such a system is governed by a system Σ

P of ODEs expressed as:

where

,

,

are the mass, damping and stiffness matrices. The blockmatrices’ subscripts indicate their physical domain: “

” corresponds to structural mechanics, “

” to electrics and “

”/“

” to their coupling. Consequently, the state vector

incorporates

nodal displacements

and

nodal electrical potentials

. Further, the input vector is denoted by

, the user-defined output vector by

. The matrix

distributes the inputs, whereas

computes the outputs. From a physical perspective, the columns of

contain “force shapes” that are scaled by

. Thus, their product

equals a vector of total external forces

. When using Rayleigh damping, the mechanical damping matrix

is given as a weighted sum of mass and stiffness matrix. With constant Rayleigh coefficients

and

, the relation is expressed by:

Contact in FE analyses adds two steps to the solution process [

27]: first, the solver checks for contact. If contact is detected, non-penetration is enforced via nonlinear iterations. Three methods have been established to handle this constraint: Lagrange multipliers, penalty and augmented Lagrange multipliers. This work deploys the penalty method which introduces virtual springs opposing penetration. Their force depends linearly on the penetrating volume or distance and vanishes as soon as the bodies leave contact. Although this method tolerates small penetrations and may cause ill-conditioning, it offers superior convergence and does not introduce new DOF [

43]. A constant contact stiffness of 100,000

has been chosen. The setup is assumed to be frictionless, as friction barely contributes due to the model’s simplifications. This assumption might not yield accurate results for more complex scenarios. Further, adhesion is neglected as corresponding physical effects do not contribute in relevant orders of magnitude.

Contact occurs if the distance

between certain nodes falls below zero. Mathematically, this condition is denoted by the following inequality constraints [

39,

44]:

where each row represents one of the

inequality constraints. The matrix

selects nodal displacements for each constraint and

denotes initial gap sizes. Since

is unknown, the contact status can only be determined upon solution. Therefore, the contact is adjusted in iterative solutions until convergence. If

, penetration occurs and Equation (

3) is violated. In this case, the penalty algorithm introduces counteracting forces

, approximately restoring

. Only violated constraints are enforced and thus contact forces are applied to a corresponding subset

of all

constraints. These forces linearly depend on penetration via a penalty stiffness

and read as:

Here, the subscript “

” denotes subsets of respective quantities that exclusively contain violated constraints. Since detecting constraint violations requires the solution, the subsets depend on

and may change for each iteration. Rewriting the forces as contact stiffness

and contact force

emphasizes their physical interpretation as additional stiffness. Their nonlinearity is indicated as a function of

, replacing their subscript “

”. Combining Equations (

1) and (

4) provides the system

of piezoelectric contact as:

Contact analyses usually feature multiple bodies that do not interact until they are in contact. Therefore, all system matrices are block diagonal until contact introduces , coupling the bodies. In the case of a rigid body, its blocks in the system matrices are of dimension .

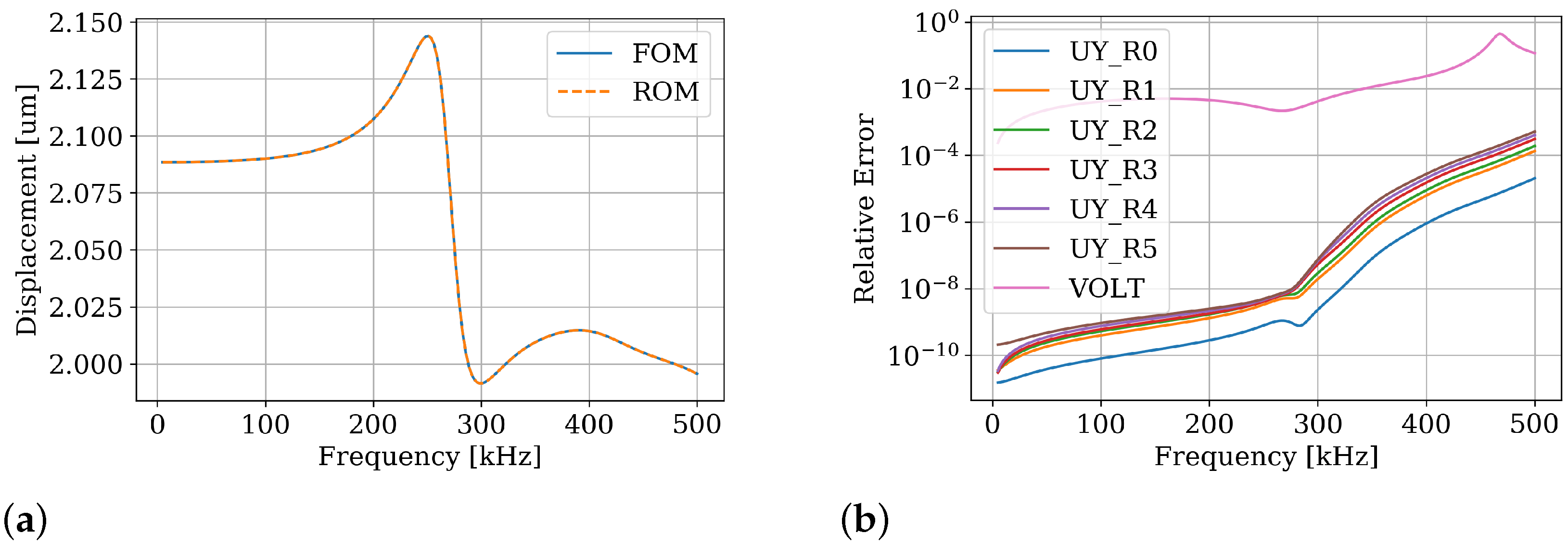

2.3. Model Order Reduction

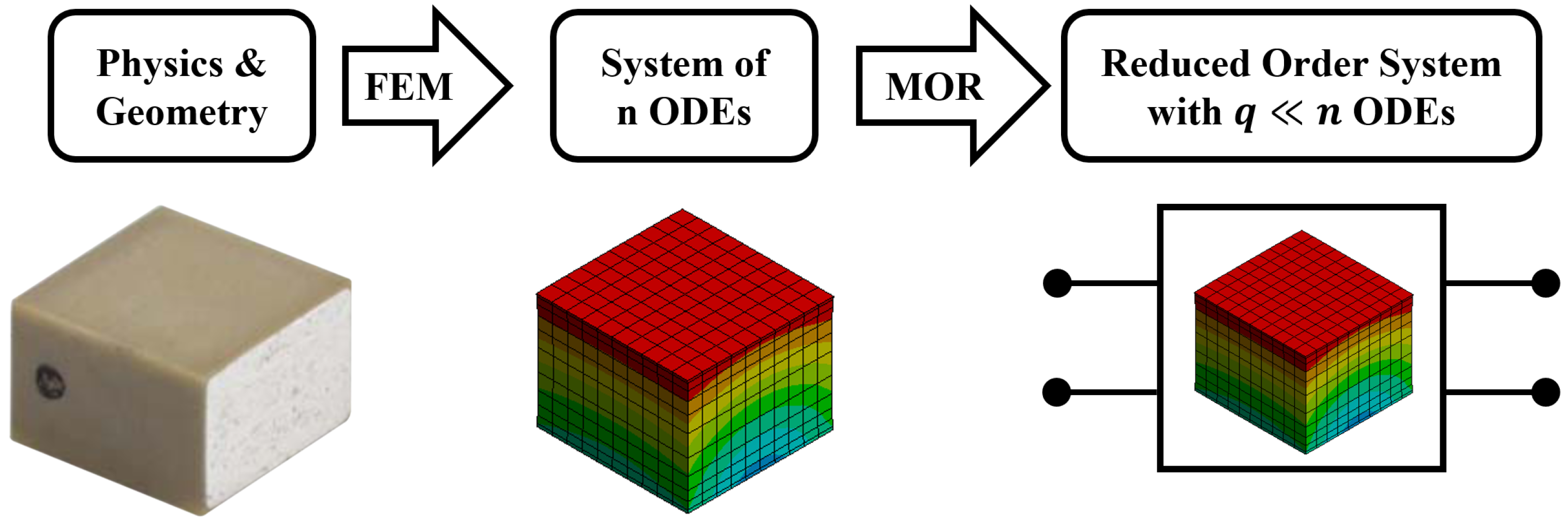

MOR approximates a large-scale system by an ROM of a drastically smaller dimension. The ROM hardly forfeits any accuracy while providing a speed-up of several orders of magnitude. FE solvers are a natural application for MOR, as they assemble and solve large-scale systems of ODEs.

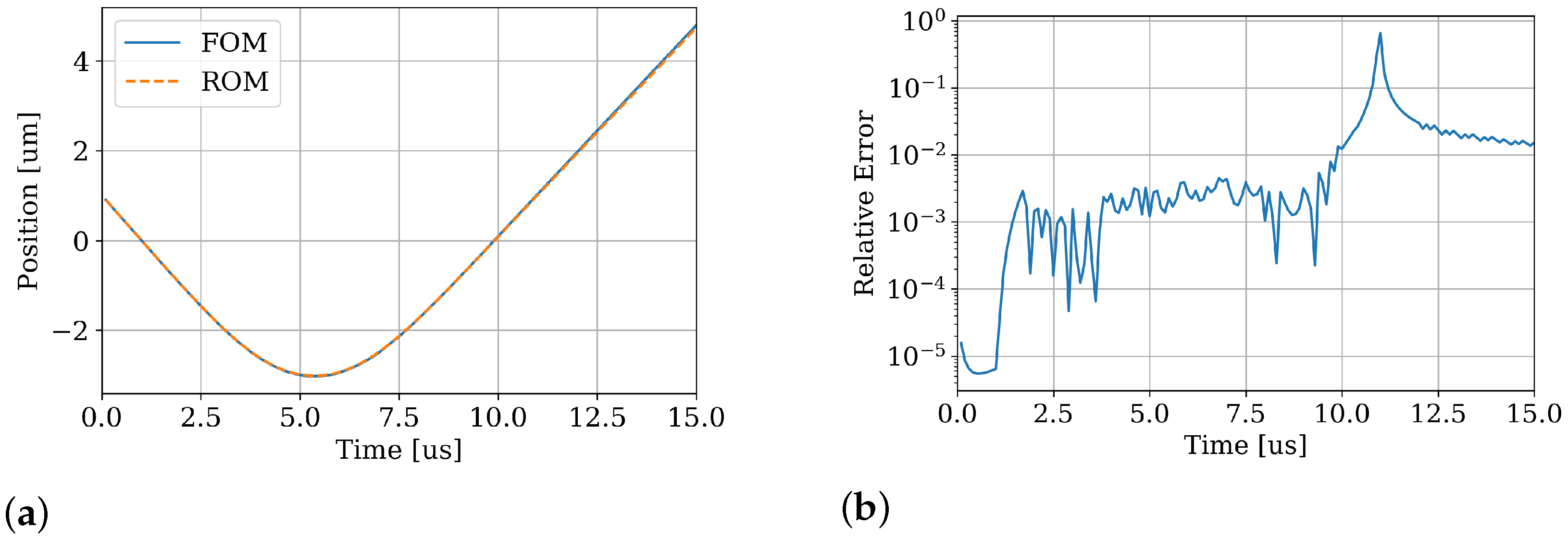

Figure 4 illustrates this idea for the piezoelectric kick-actuator.

One robust and accurate method for linear models is projecting a large-scale system onto a low-dimensional Krylov subspace [

41,

46]. For this approach, the state vector

is expressed as:

where

is the orthogonal basis of the corresponding Krylov subspace and

is the reduced state vector. The approximation error

is cut off and contains the part of

that does not lie in the Krylov subspace. The subspace’s basis vectors may be orthonormalized by the block Arnoldi algorithm. Its dimension

q is several orders of magnitude smaller than

n, that is,

. Projecting the linear second order system

in Equation (

1) onto

, one obtains the reduced model:

The projection significantly reduces the system’s dimension to , , and . In addition, the reduction preserves all inputs and outputs . However, the projected system lacks physical meaning.

MOR expresses the state vector as a linear combination of predefined “shapes” (columns of ). Further, the reduced state vector corresponds to the weights of each shape. From a mathematical perspective, Krylov subspace-based MOR matches the Taylor expansions of the ROM’s and the FOM’s transfer functions around a frequency for the first q moments.

However, such reduction of multiphysical systems does not necessarily preserve its stability [

47,

48,

49]. Therefore, Schur after MOR [

48] is applied to reintroduce stability to the piezoelectric system’s ROM. Translating the reduced system into very high speed integrated circuit hardware description language (VHDL) creates a convenient interface to commercial system-level simulation software.

As mentioned in

Section 1, additional challenges accompany nonlinear MOR as a nonlinear system cannot be directly reduced. If the nonlinearities can be moved to the input, methods of linear MOR can be applied. In this case, the ROM evaluates the same nonlinear forces as the FOM. However, efficiency decreases with each nonlinear evaluation. If some nonlinear forces are almost the same, they can be approximated by computing a single force and distributing it to relevant nodes [

40]. Therefore, the number of nonlinearities is reduced and the ROM gains efficiency. Obviously, the grouping process introduces errors depending on how similar the forces are. An appropriately designed mesh diminishes the error and also supports the choice of which forces to group.

However, penalty-based contact not only introduces nonlinear external forces, but also a nonlinear stiffness matrix as shown in Equation (

5). The method of [

40] only applies to the former, but cannot handle the latter. Compatibility can be achieved by separately modeling and reducing the bodies. The separation recasts the nonlinear coupling within the stiffness matrix of the multibody system into external nonlinear forces of the separated systems. Subsequently, these forces can be grouped for each body as proposed in [

40]. Since the sphere is considered rigid and is restricted to vertical motion, it can be represented by a point mass. Moreover, its dynamics only depend on the total vertical contact force.

Therefore, only contact forces acting on the kick-actuator must be grouped. Because these forces result from contact to a sphere, circles around the center of impact each have almost identical vertical forces, as shown in

Figure 3c. In addition, a FE mesh of a center node and five concentric rings as displayed in

Figure 3b minimizes errors and facilitates the grouping process. The vertical forces are grouped for each ring, resulting in a total of six penetration-dependent forces. To compute the penetrations, the system’s outputs must include all the rings’ vertical displacements. Furthermore, the kick-actuator also requires the electric charge on the actuator’s coupled anodes

as an input and their voltage

as an output. The resulting weakly nonlinear system

of the kick-actuator is given by:

The differences to the general piezoelectric system in Equation (

1) are the system’s inputs and outputs. The output vector

includes all rings’ vertical displacements

as they are required to compute the penetrations. The output matrix

includes six normalized ring-based force shapes as illustrated in

Figure 3c and the electric charge distribution on the anodes. Accordingly, the nonlinear input vector

scales each force shape by the corresponding ring’s total contact force

. For a ring

, this force depends on the kick-actuator’s deformation

and the position of the sphere

; it is denoted by:

where

is the vertical displacement of ring

and

is the initial vertical gap between the ring and the sphere.

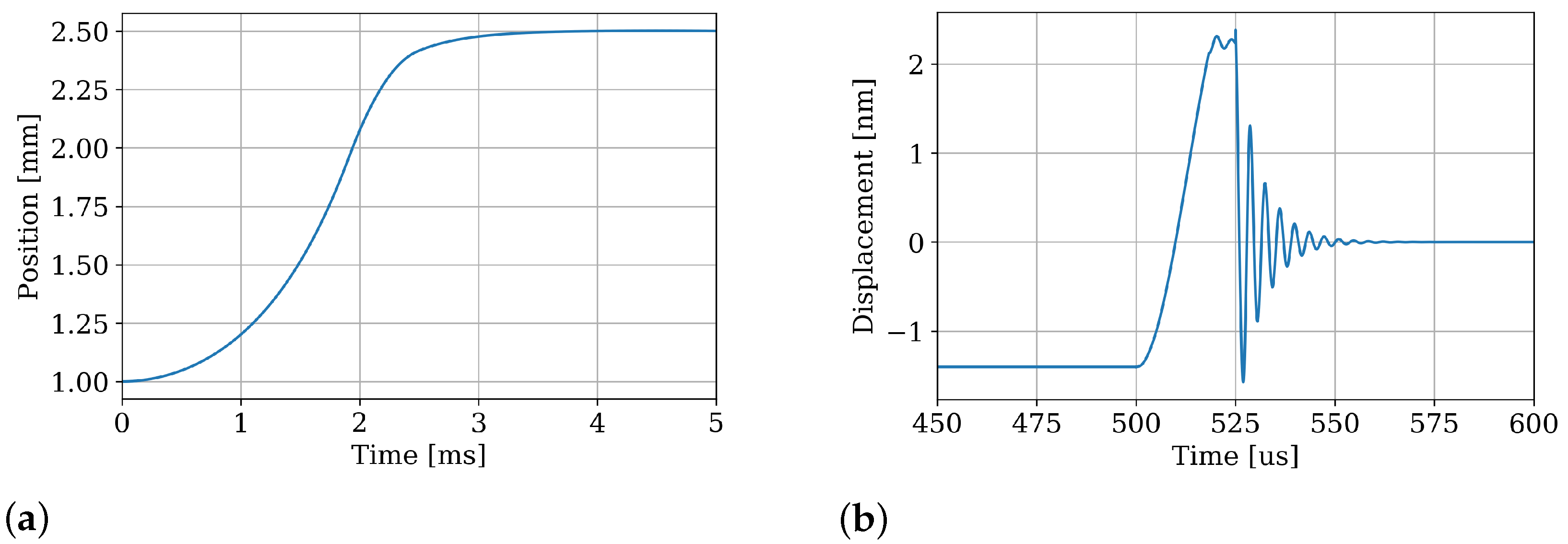

2.4. System-Level Simulation

This section deploys a full system-level simulation of the simplified kick and catch actuator system, demonstrating feasibility. System-level simulation is highly beneficial for several reasons: first, the simulations are multiple orders of magnitude faster than at device-level with comparable accuracy. This speed-up allows us to efficiently study different load cases. Further, sub-models from different physical domains can be combined. In addition, co-simulation with driving/control circuitry becomes feasible, thus improving the system’s development as a whole. Although the output quantities have to be chosen beforehand, every quantity involved in the calculation can be promoted to an output.

In order to model the actuator system, the kick-actuator’s ROM and the sphere’s point mass are coupled via six lumped contact springs. Each spring represents a single ring’s vertical contact. If a spring detects penetration, it applies a corresponding force to the two bodies. For the kick-actuator’s ROM, each spring force scales its corresponding force shape as indicated in

Figure 3c.

After contact is reestablished, an equivalent circuit (EC) of the electromagnetic catch-actuator complements the actuator system. An EC is a lookup table based on parametric simulation and is an industrial standard method. Here, the EC provides the electromagnetic force on the sphere with respect to its vertical position and the two coil currents.

Section 2.2.1 describes each parameter’s range and resolution.

A PID-based closed-loop control of the kicked sphere’s position constitutes a representative application. The global coordinate system’s origin is located at the kick actuator’s top surface and, hence, the sphere starts at 1

. To launch the sphere, a heuristically determined rectangular pulse voltage of 100

and 25 μs is applied. The control aims to catch the sphere at a set point of

. Although the system is nonlinear and requires sophisticated control strategies, a PID is deployed for the sake of demonstration. This controller applies the same current to both coils but negates the lower solenoid’s input. The controller’s three gains are determined via optimization, aiming for little overshoot and settling time. They are given by

,

, and

.

Figure 5 provides the complete schematic diagram of the controlled kick and catch actuator system.

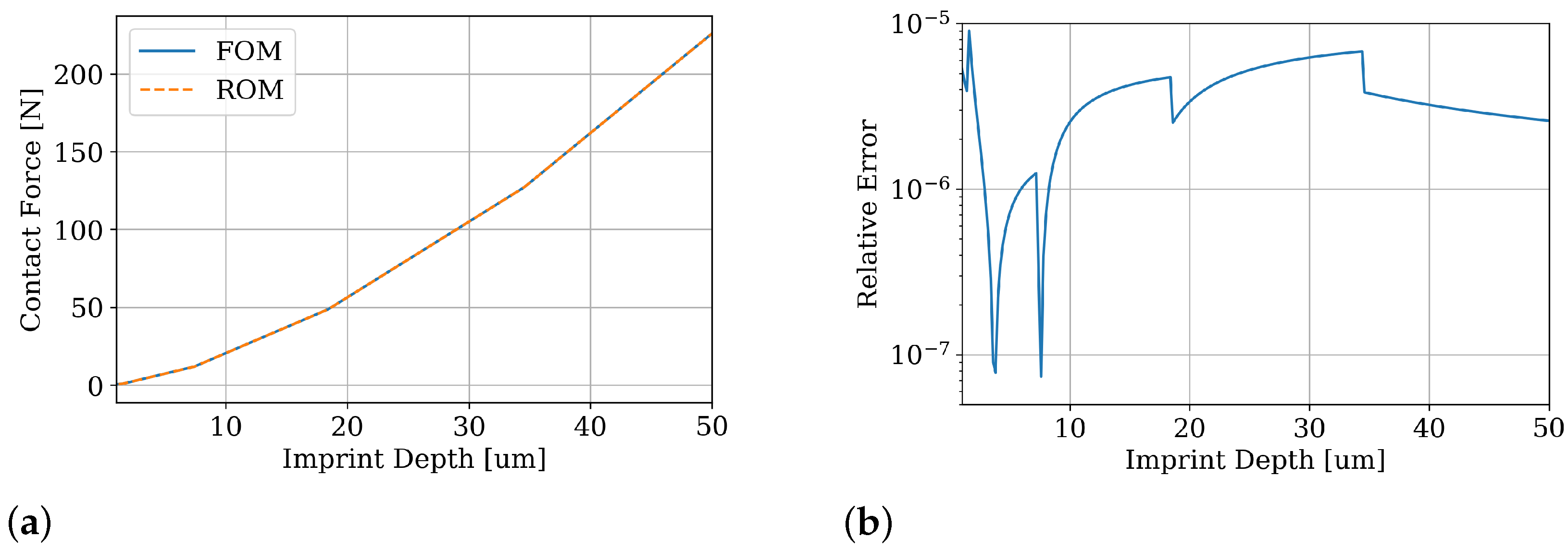

4. Discussion and Outlook

This work presents a system-level model of cooperating kick and catch microactuators. The key contribution of this work is creating a FE-based system-level model of the kick-actuator including its mechanical contact to a spherical micromirror. By separately analyzing the contact bodies, their nonlinear coupling within the stiffness matrix can be transferred into an input nonlinearity. This modification leads to a linear FE model with nonlinear input including the penalty-based contact. Therefore, methods of linear MOR and techniques to reduce the number of nonlinearities [

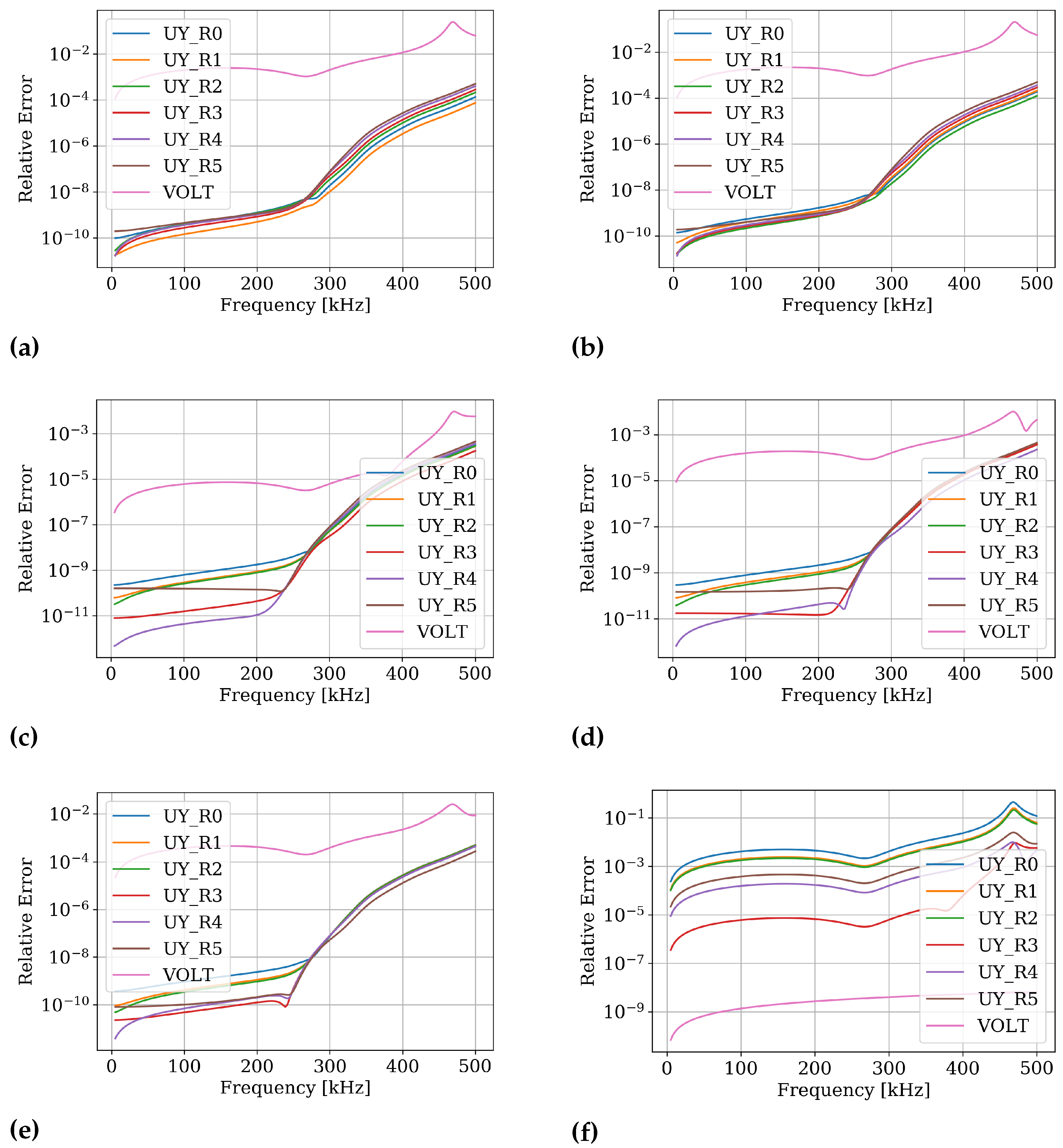

40] can be employed. A further enhancement includes considering the distribution of nonlinear forces in the spatial FE discretization, which improves accuracy. The resulting reduced order model achieves excellent accuracy and decreases the CPU time of transient simulation by several orders of magnitude. In the static comparison in

Section 3.2.2, the ROM has a maximal relative error of less than

with respect to the original finite element model. Such efficient and accurate ROM can be used for optimization of control circuitry. Please note that this methodology is not limited to the kick-actuator considered here, but will perform equally well on similar contact scenarios.

However, our method requires an appropriately designed mesh in the location of impact. Hence, the location must be known in advance and remain constant during impact. Parametric model order reduction would allow dynamical repositioning of the impact location. Further, this work makes use of a rigid body of simple shape. Flexible bodies may be included, but require matching meshes in the contact region. More complex geometries can be handled, but may require preceding simulations to determine the distribution of contact forces. Aside from that, the kick-actuator’s contact only covers imprints of limited depth. This depth can be arbitrarily chosen and deeper impacts would leave the scope of linear elasticity. Therefore, the depth is more a parameter of the model than a limitation. A potential challenge for the proposed method is friction: while Coulomb friction can be introduced easily, more sophisticated friction models remain challenging. In conclusion, this approach is highly advantageous, but is limited to problems of a certain structure.

Future research will aim to extend the method’s scope to more general problems. A combination with parametric MOR seems promising, especially since it is well-suited to linear systems. In the context of the kick-actuator, this extension might allow an unrestricted movement of the sphere. Another goal is to apply the proposed methodology to a different design of the kick-actuator, featuring electrostatic pull-in similar to [

20]. Furthermore, experimental investigations are ongoing and comparisons to simulations are planned. The design of the actuator will gradually become more complex to achieve the targeted motion cycle.