Design of a 2DoF Ankle Exoskeleton with a Polycentric Structure and a Bi-Directional Tendon-Driven Actuator Controlled Using a PID Neural Network

Abstract

1. Introduction

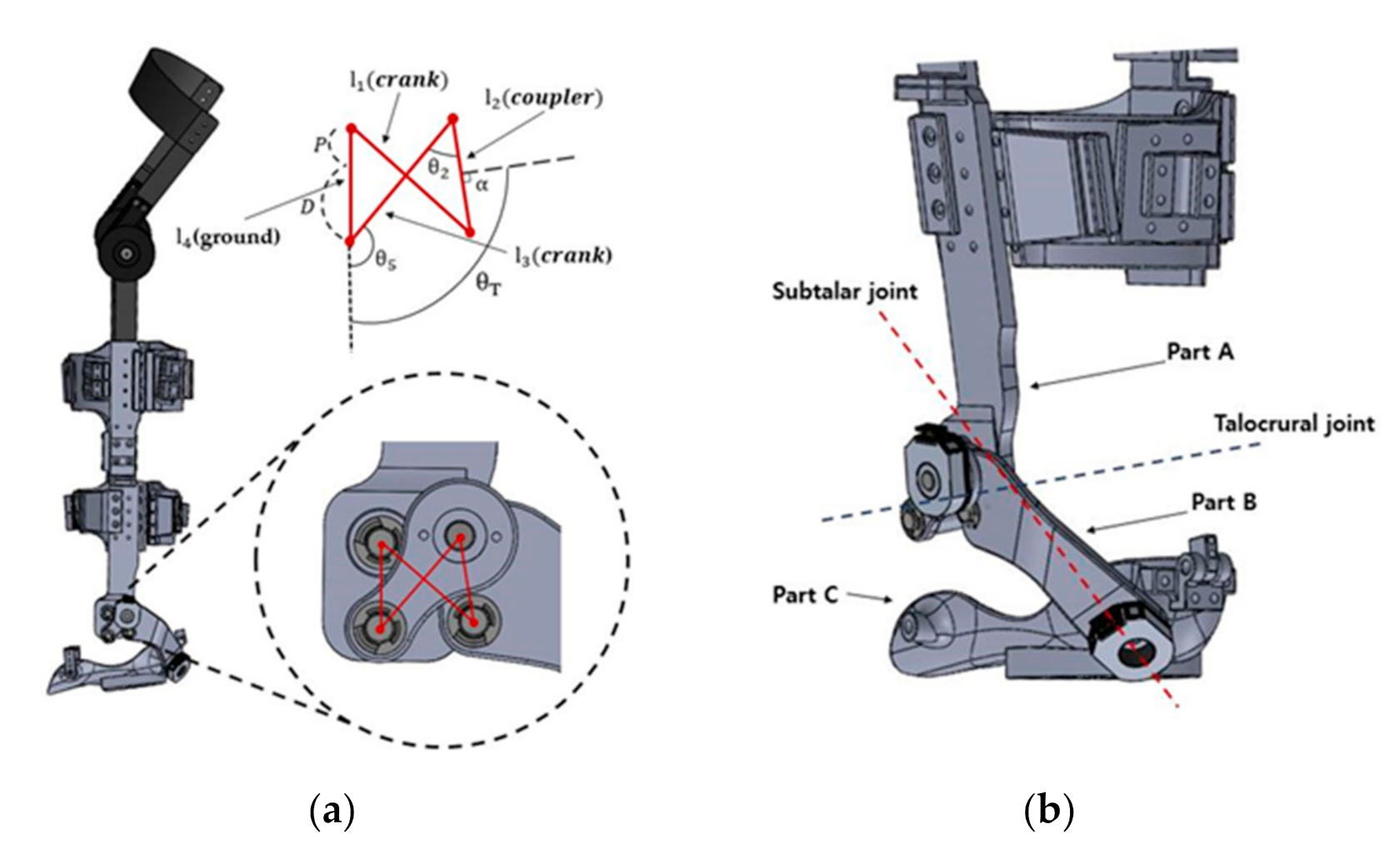

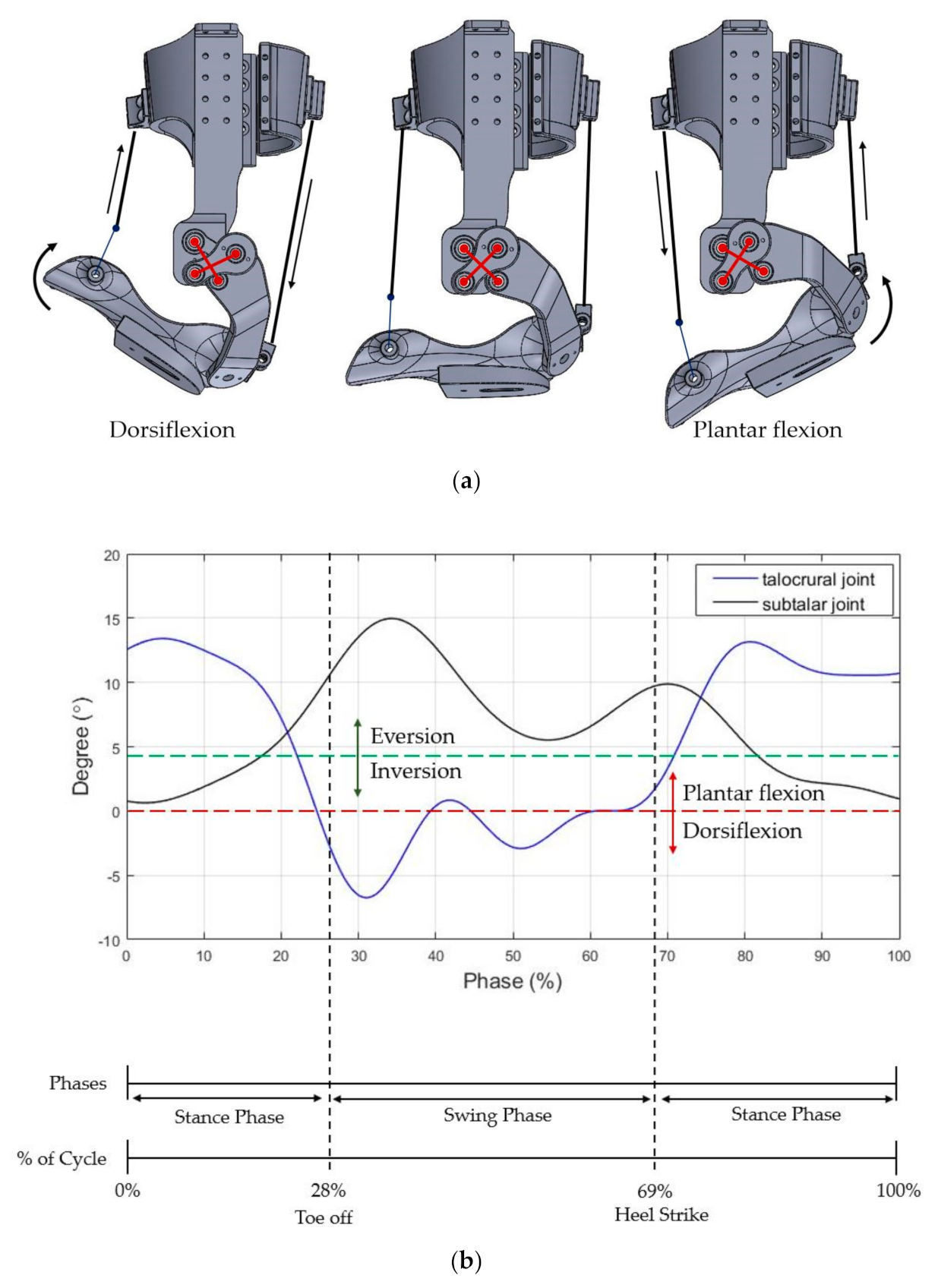

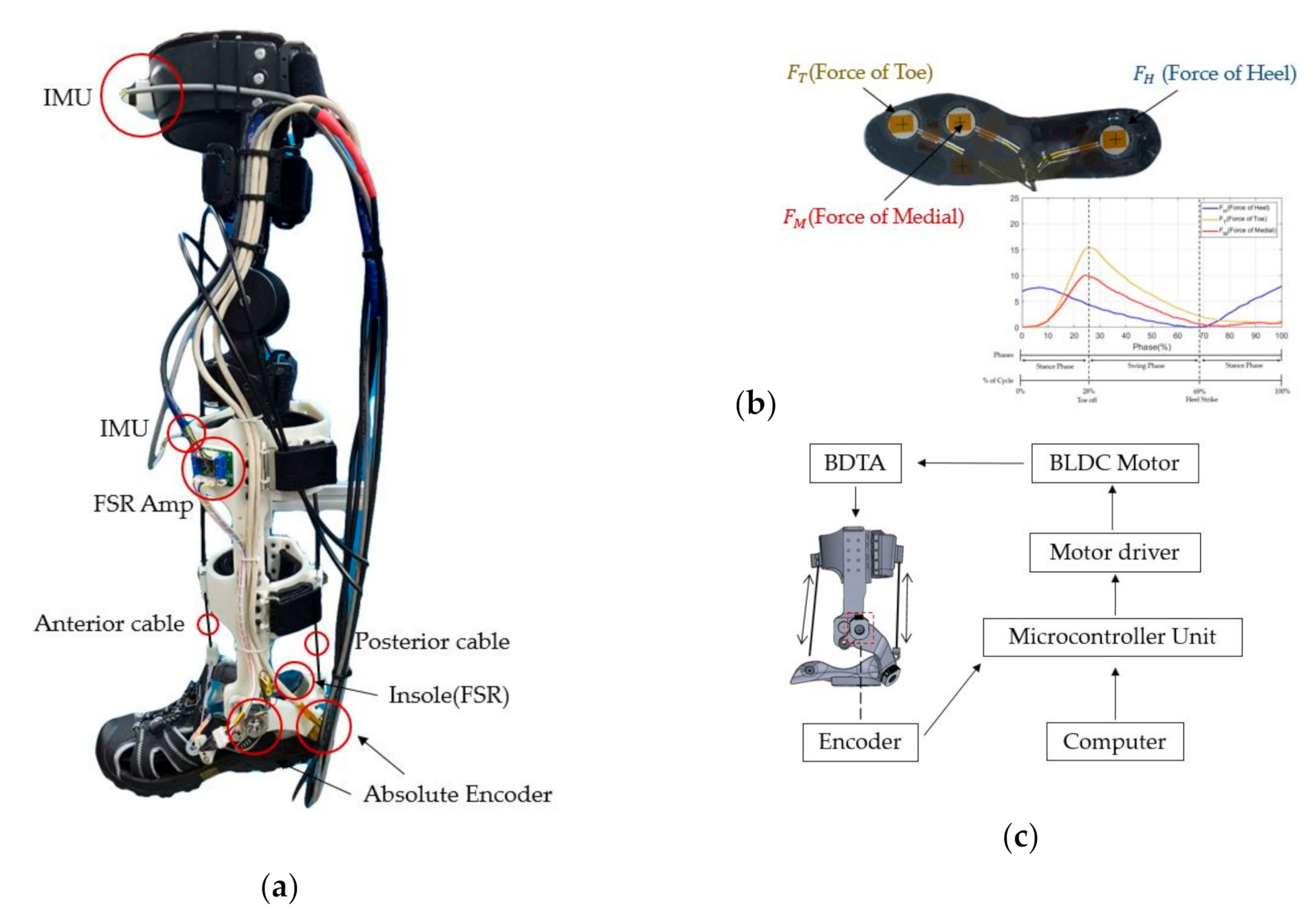

2. Mechanical Design of the Polycentric Ankle Joint

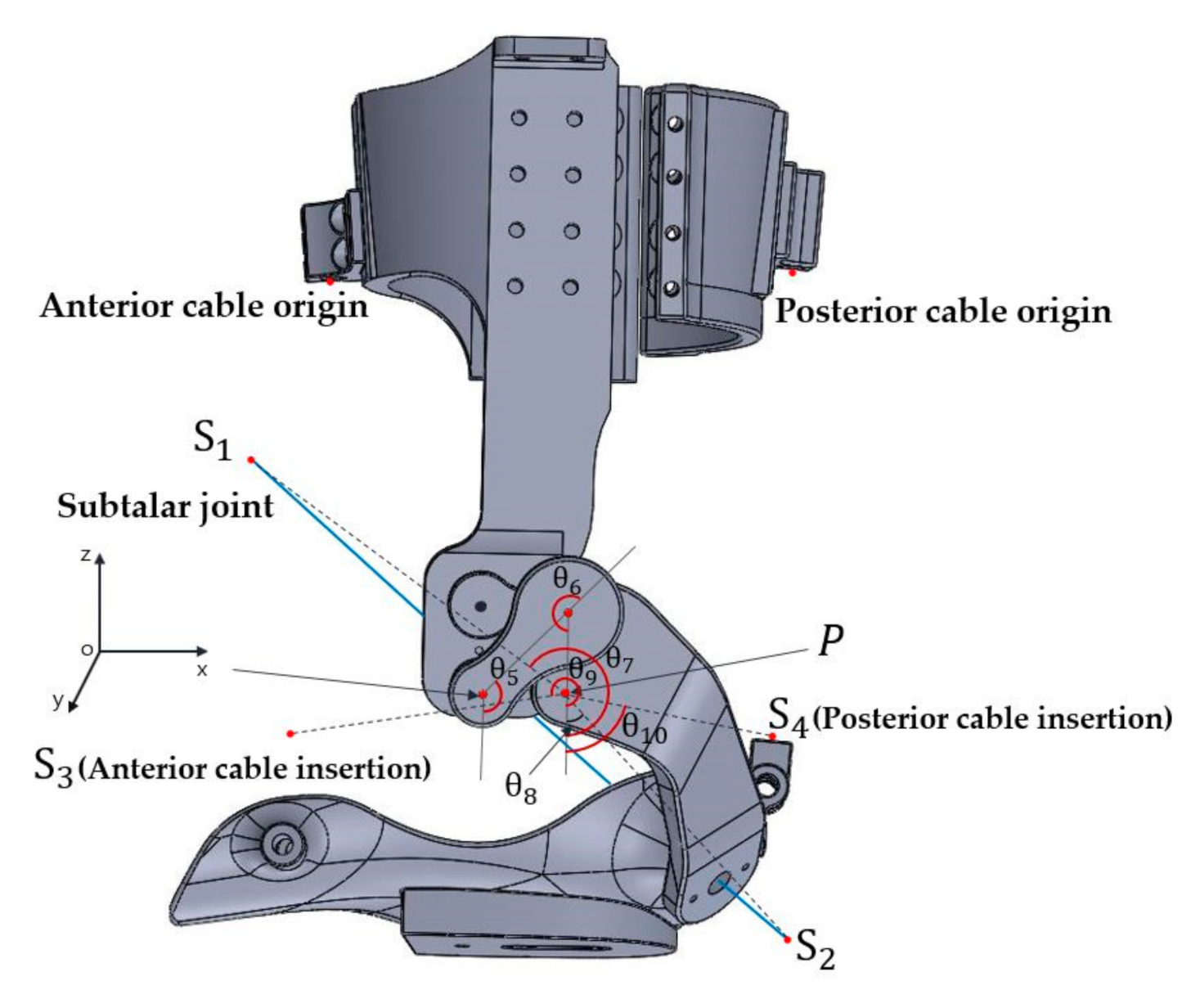

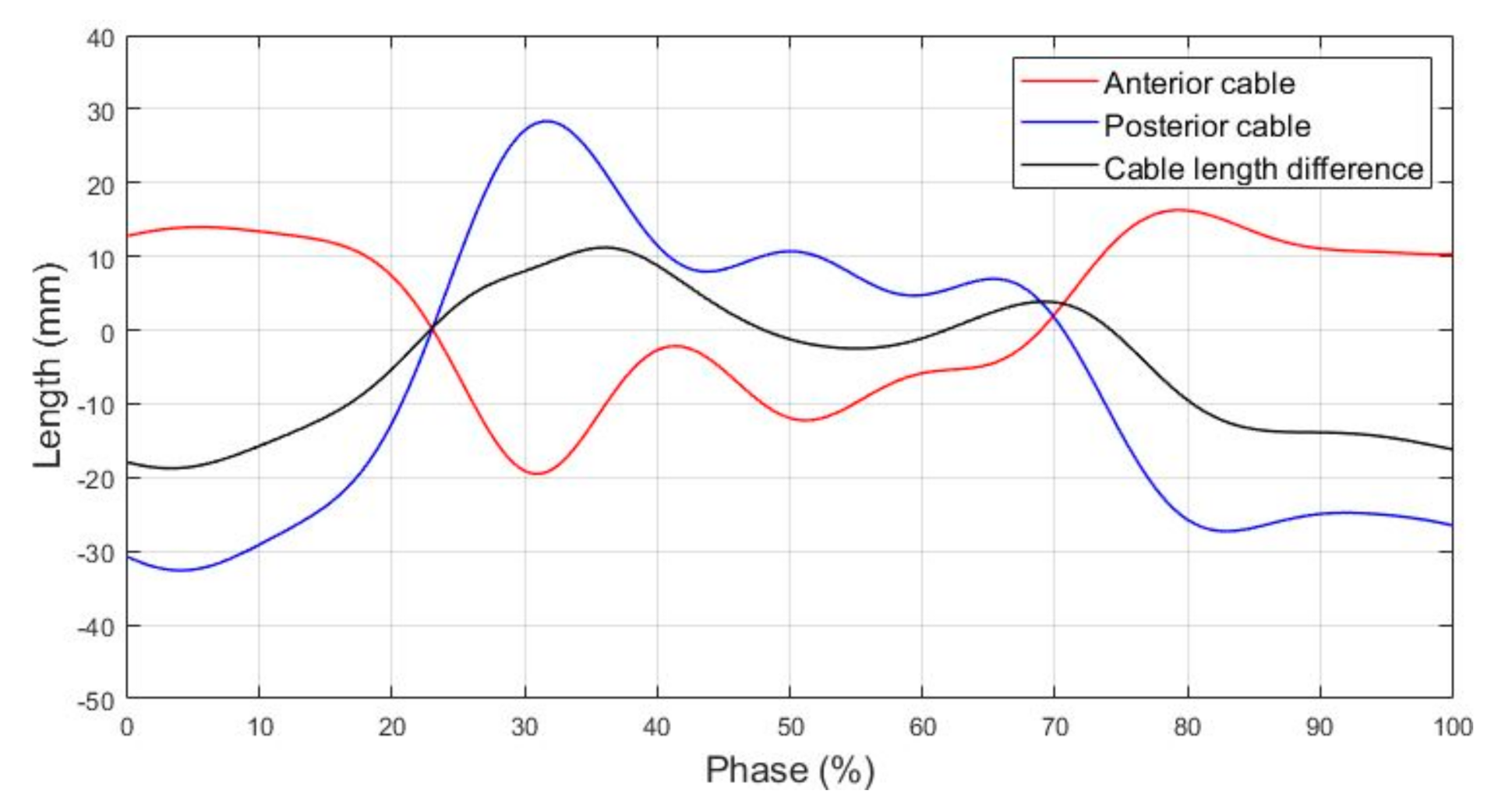

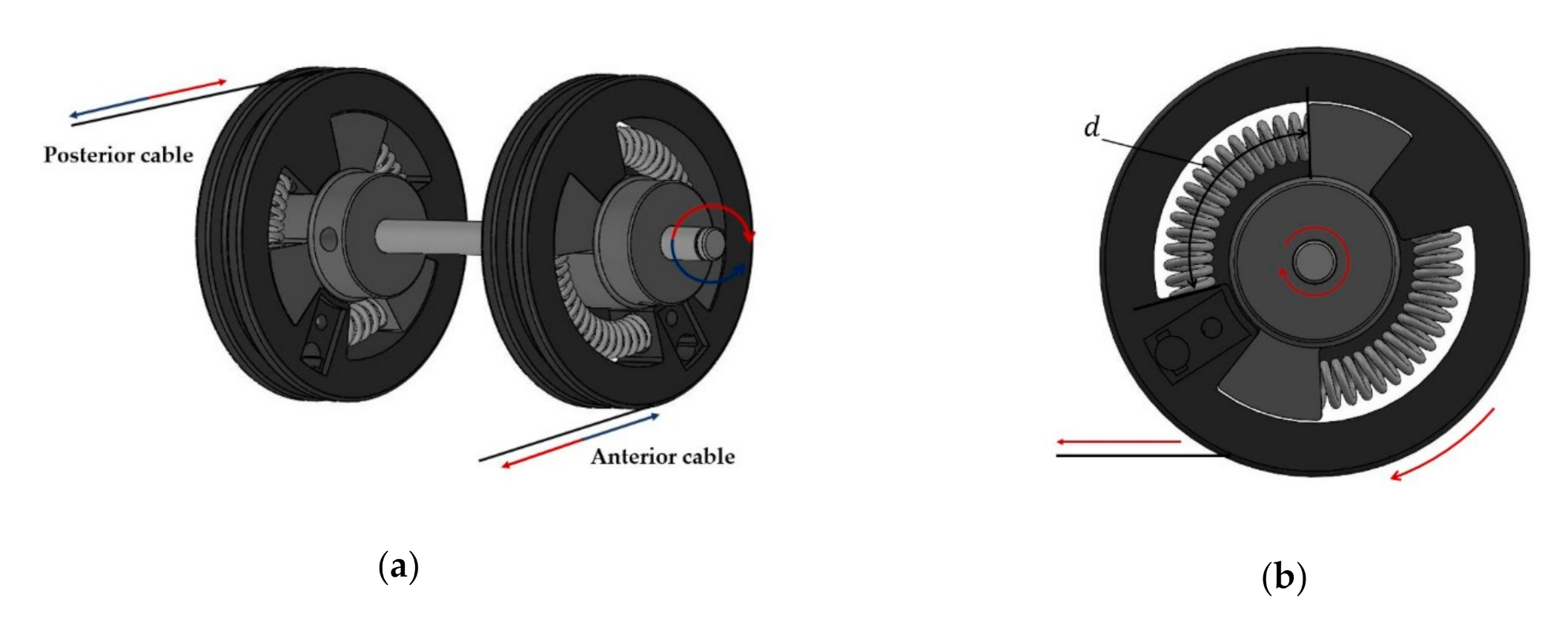

3. Design of the Bi-Directional Tendon-Driven Actuator (BTDA)

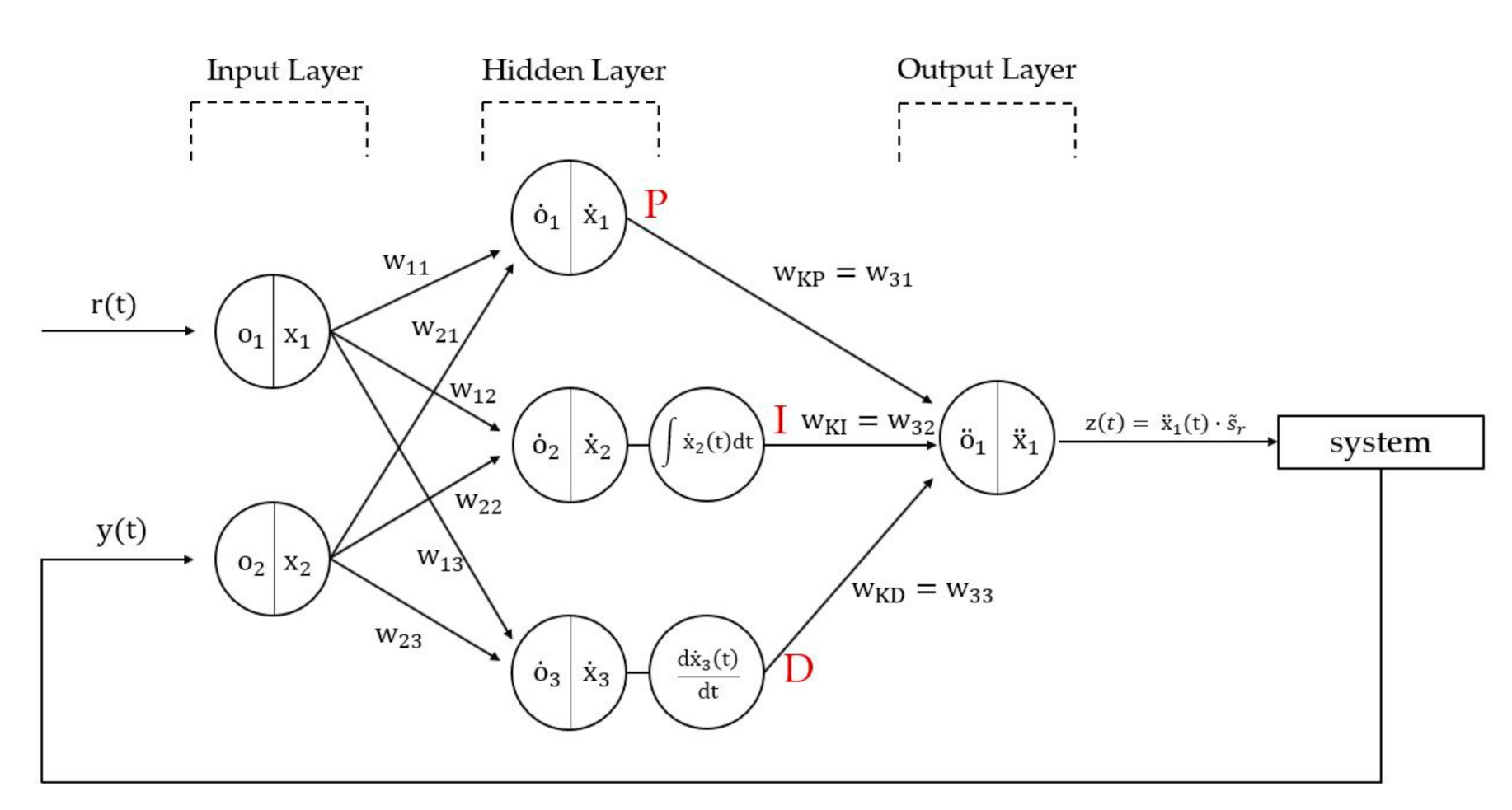

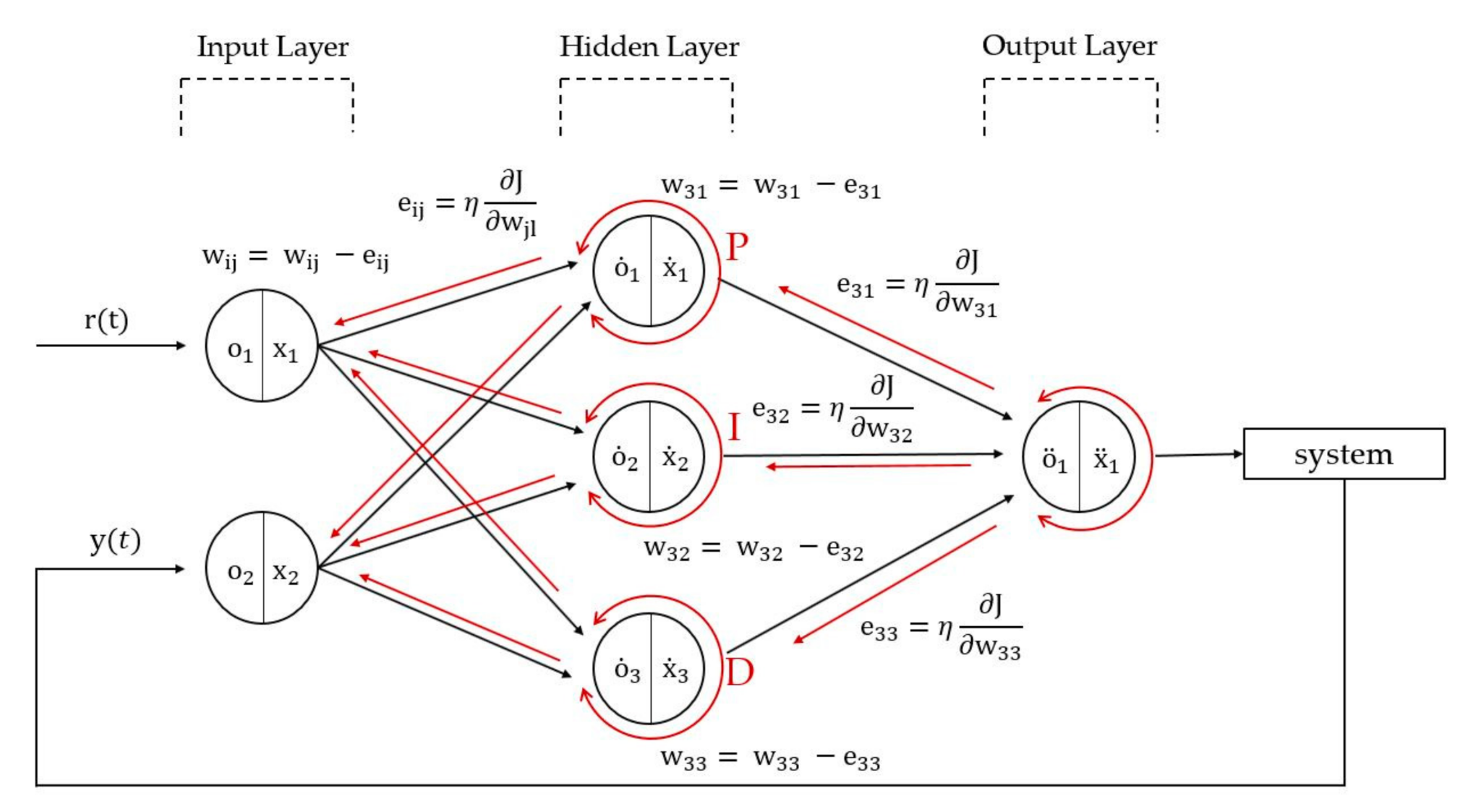

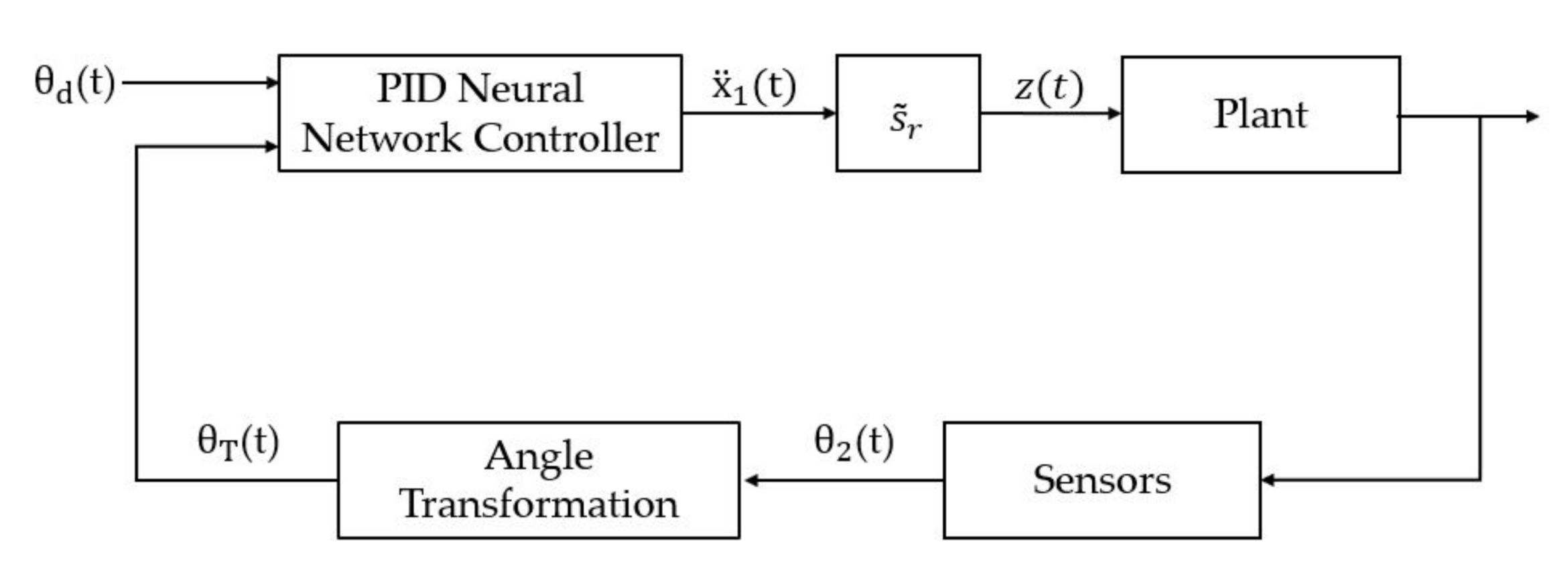

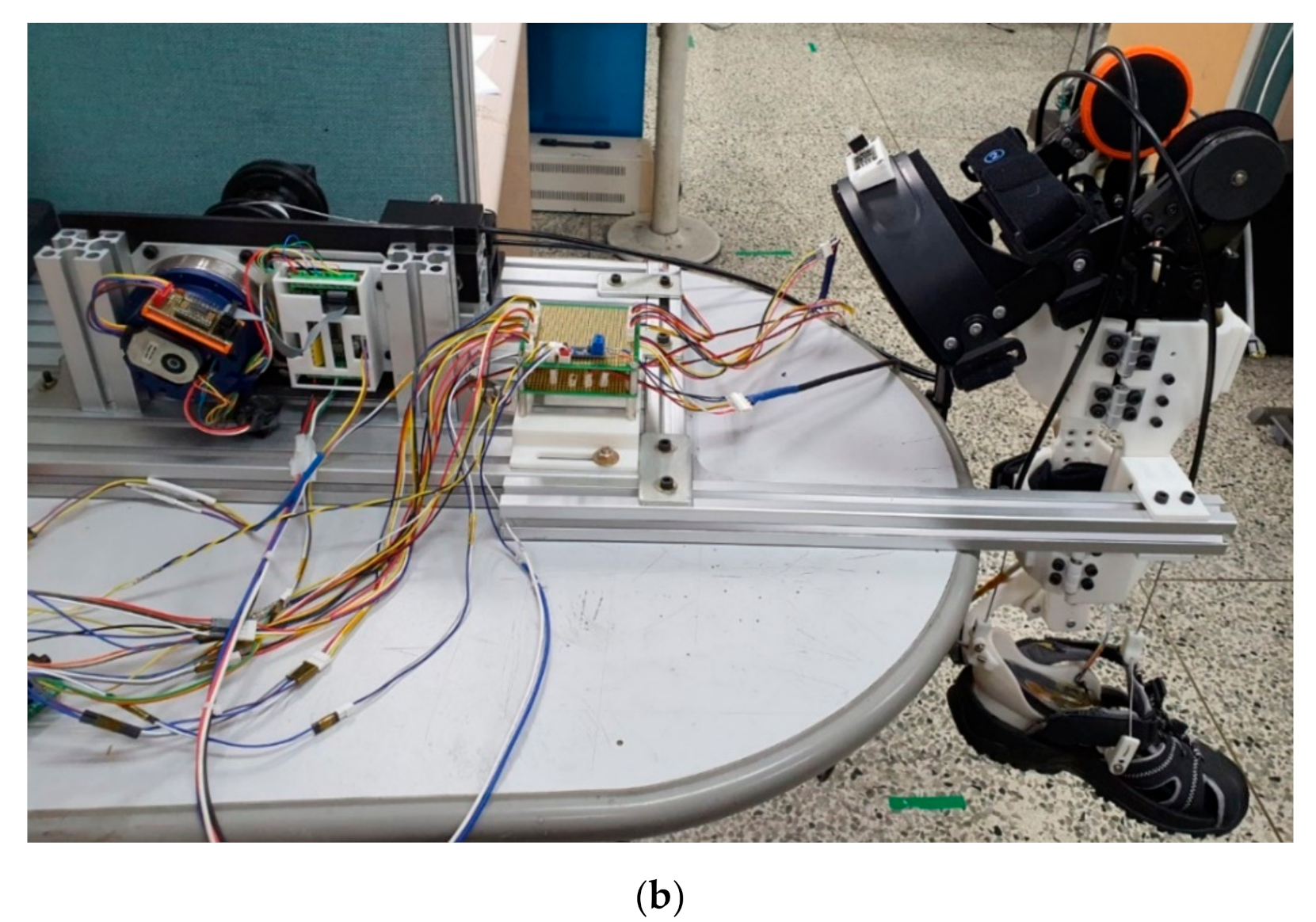

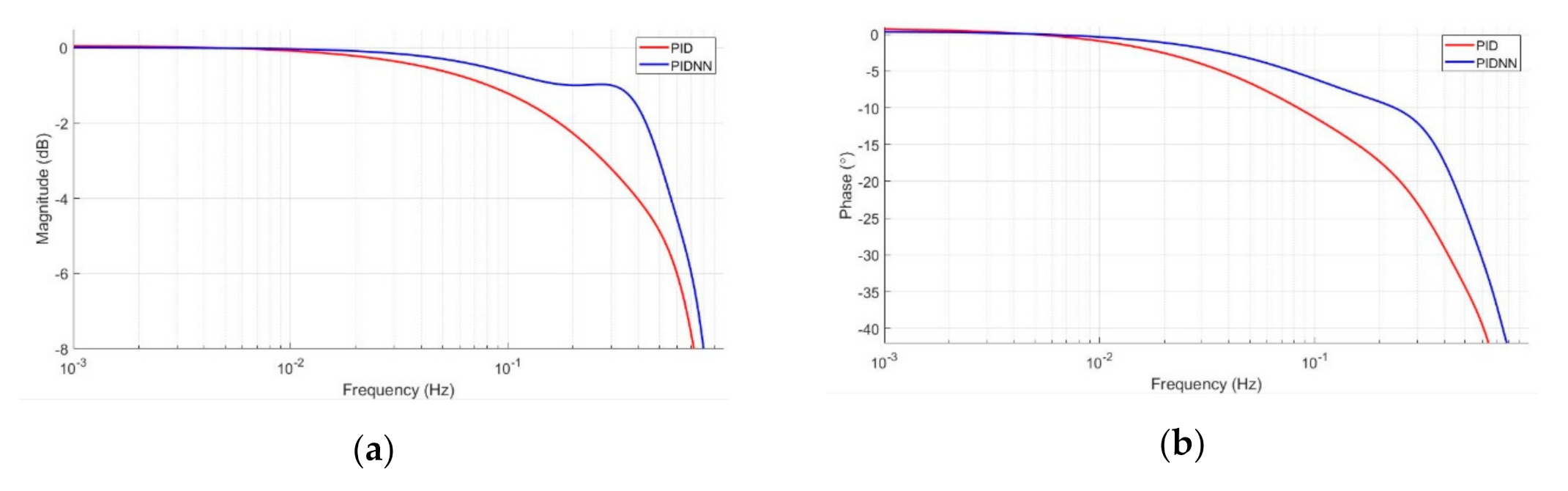

4. Design of the PID Neural Network Controller

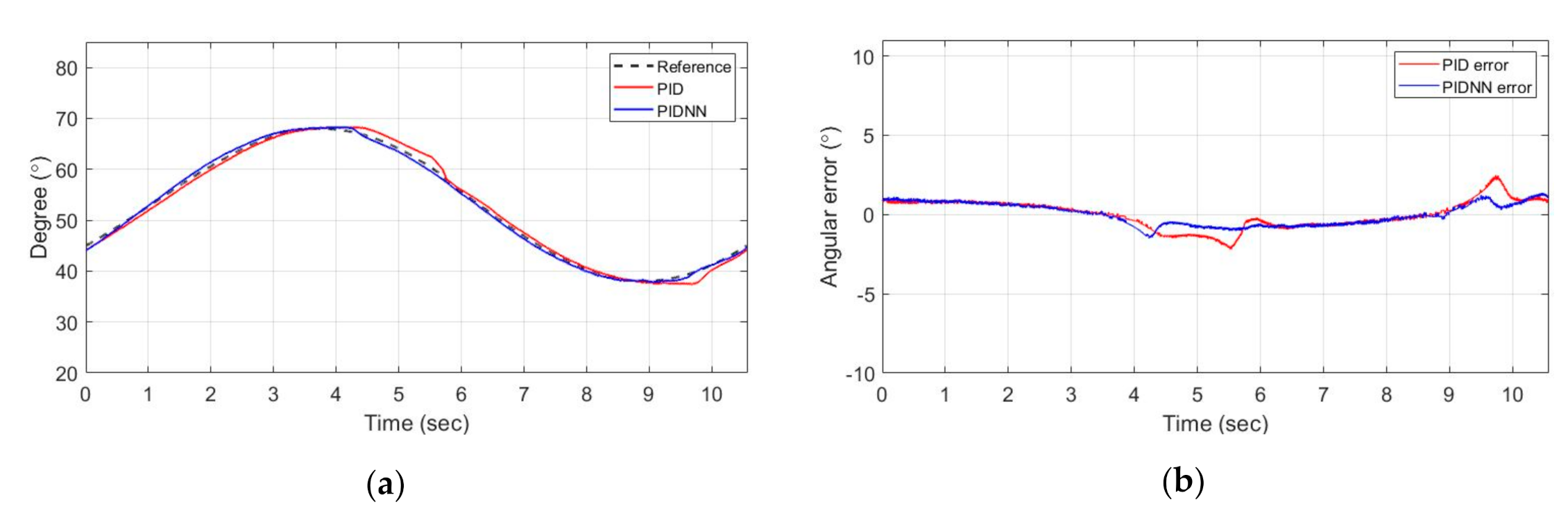

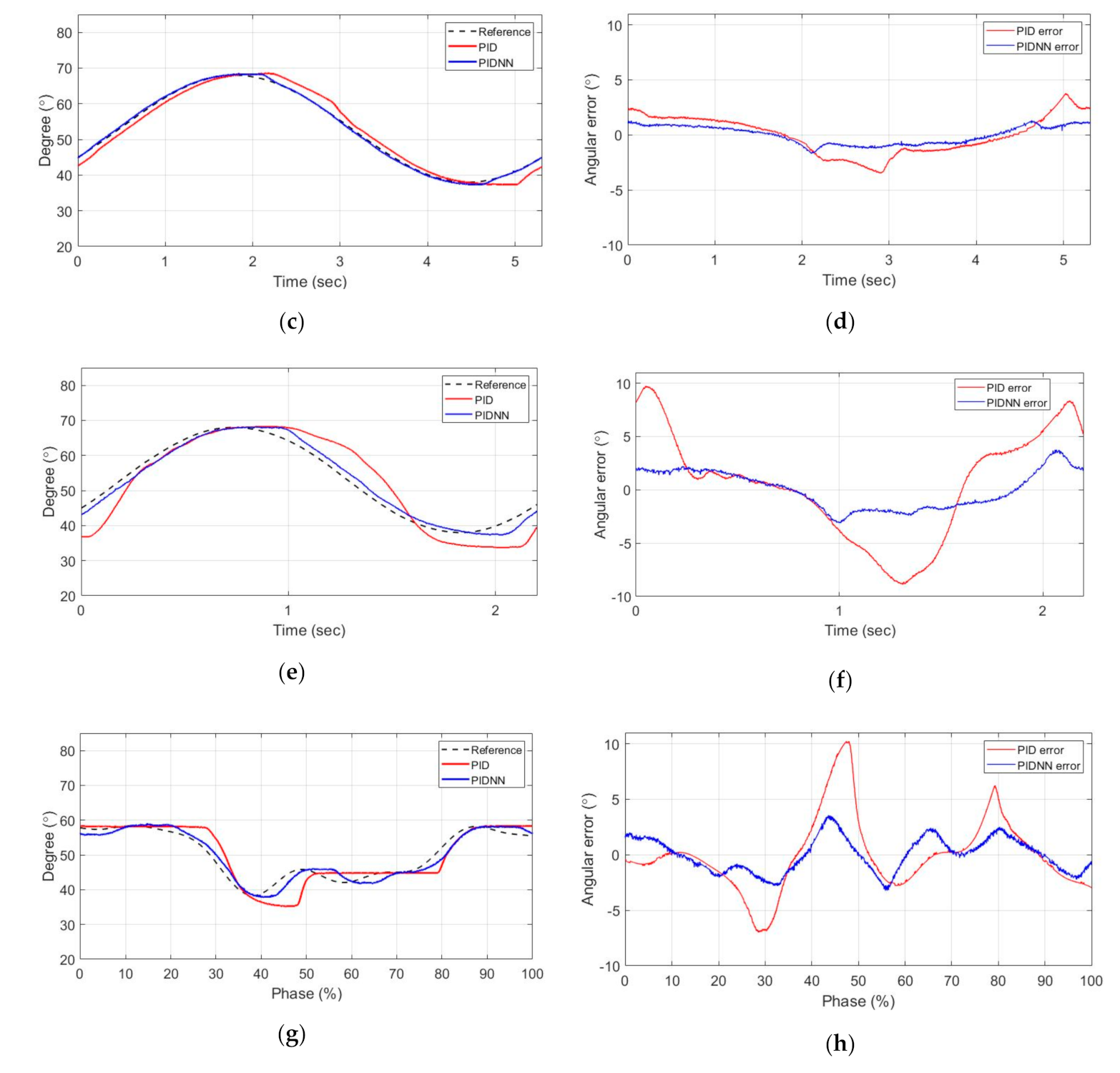

5. Experimental Setting and Results

6. Discussion

7. Conclusions and Future Work

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Blank, A.A.; French, J.A.; Pehlivan, A.U.; O’Malley, M.K. Current Trends in Robot-Assisted Upper-Limb Stroke Rehabilitation: Promoting Patient Engagement in Therapy. Curr. Phys. Med. Rehabil. Rep. 2014, 2, 184–195. [Google Scholar] [CrossRef] [PubMed]

- Dzahir, M.A.M.; Yamamoto, S.-I. Recent Trends in Lower-Limb Robotic Rehabilitation Orthosis: Control Scheme and Strategy for Pneumatic Muscle Actuated Gait Trainers. Robotics 2014, 3, 120–148. [Google Scholar] [CrossRef]

- Veale, A.J.; Xie, S.Q. Towards compliant and wearable robotic orthoses: A review of current and emerging actuator technologies. Med Eng. Phys. 2016, 38, 317–325. [Google Scholar] [CrossRef]

- United Nations, Department of Economic and Social A_airs. Available online: https://www.un.org/en/development/desa/population/publications/pdf/ageing/WPA2017_Highlights.pdf (accessed on 4 January 2021).

- Pirker, W.; Katzenschlager, R. Gait disorders in adults and the elderly. Wien. Klin. Wochenschr. 2017, 129, 81–95. [Google Scholar] [CrossRef] [PubMed]

- Nef, T.; Mihelj, M.; Kiefer, G.; Perndl, C.; Muller, R.; Riener, R. ARMin—Exoskeleton for Arm Therapy in Stroke Patients. In Proceedings of the 2007 IEEE 10th International Conference on Rehabilitation Robotics, Noordwijk, The Netherlands, 13–15 June 2007; pp. 68–74. [Google Scholar]

- Visintin, M.; Barbeau, H.; Korner-Bitensky, N.; Mayo, N.E. A New Approach to Retrain Gait in Stroke Patients Through Body Weight Support and Treadmill Stimulation. Stroke 1998, 29, 1122–1128. [Google Scholar] [CrossRef]

- Isman, R.E.; Inman, V.T.; Poor, P.M. Anthropometric studies of the human foot and ankle. Bull Prosthet Res. 1969, 11, 129. [Google Scholar]

- Brockett, C.L.; Chapman, G.J. Biomechanics of the ankle. Orthop. Trauma 2016, 30, 232–238. [Google Scholar] [CrossRef]

- Alexander, N.B.; Goldberg, A. Gait disorders: Search for multiple causes. Clevel. Clin. J. Med. 2005, 72, 586. [Google Scholar] [CrossRef]

- Morgenroth, D.C.; Orendurff, M.S.; Shakir, A.; Segal, A.; Shofer, J.; Czerniecki, J.M. The Relationship Between Lumbar Spine Kinematics during Gait and Low-Back Pain in Transfemoral Amputees. Am. J. Phys. Med. Rehabil. 2010, 89, 635–643. [Google Scholar] [CrossRef]

- Kerrigan, D.C.; Frates, E.P.; Rogan, S.; Riley, P.O. Hip hiking and circumduction: Quantitative definitions. Am. J. Phys. Med. Rehabil. 2000, 79, 247–252. [Google Scholar] [CrossRef]

- Miao, Q.; Zhang, M.; Wang, C.; Li, H. Towards Optimal Platform-Based Robot Design for Ankle Rehabilitation: The State of the Art and Future Prospects. J. Heal. Eng. 2018, 2018, 1–9. [Google Scholar] [CrossRef]

- Asbeck, A.T.; De Rossi, S.M.; Holt, K.G.; Walsh, C.J. A biologically inspired soft exosuit for walking assistance. Int. J. Robot. Res. 2015, 34, 744–762. [Google Scholar] [CrossRef]

- Galle, S.; Malcolm, P.; Collins, S.H.; De Clercq, D. Reducing the metabolic cost of walking with an ankle exoskeleton: Interaction between actuation timing and power. J. Neuroeng. Rehabil. 2017, 14, 1–16. [Google Scholar] [CrossRef]

- Wiggin, M.B.; Sawicki, G.S.; Collins, S.H. An exoskeleton using controlled energy storage and release to aid ankle propulsion. In Proceedings of the 2011 IEEE International Conference on Rehabilitation Robotics, Zurich, Switzerland, 29 June–1 July 2011; pp. 1–5. [Google Scholar]

- Van Dijk, W.; Meijneke, C.; Van Der Kooij, H. Evaluation of the Achilles ankle exoskeleton. IEEE Trans. Neural Syst. Rehabil. Eng. 2016, 25, 151–160. [Google Scholar] [CrossRef] [PubMed]

- Gordon, K.E.; Ferris, D.P. Learning to walk with a robotic ankle exoskeleton. J. Biomech. 2007, 40, 2636–2644. [Google Scholar] [CrossRef] [PubMed]

- Bae, J.; Siviy, C.; Rouleau, M.; Menard, N.; O’Donnell, K.; Geliana, I.; Athanassiu, M.; Ryan, D.; Bibeau, C.; Sloot, L.; et al. A Lightweight and Efficient Portable Soft Exosuit for Paretic Ankle Assistance in Walking After Stroke. In Proceedings of the 2018 IEEE International Conference on Robotics and Automation (ICRA), Brisbane, QLD, Australia, 21–25 May 2018; pp. 2820–2827. [Google Scholar]

- Lerner, Z.F.; Harvey, T.A.; Lawson, J.L. A battery-powered ankle exoskeleton improves gait mechanics in a feasibility study of individuals with cerebral palsy. Annals Biomed. Eng. 2019, 47, 1345–1356. [Google Scholar] [CrossRef] [PubMed]

- Bartenbach, V.; Gort, M.; Riener, R. Concept and design of a modular lower limb exoskeleton. In Proceedings of the 2016 6th IEEE International Conference on Biomedical Robotics and Biomechatronics (BioRob), Singapore, 26–29 June 2016; pp. 649–654. [Google Scholar]

- Hyun, D.J.; Park, H.; Ha, T.; Park, S.; Jung, K. Biomechanical design of an agile, electricity-powered lower-limb exoskeleton for weight-bearing assistance. Robot. Auton. Syst. 2017, 95, 181–195. [Google Scholar] [CrossRef]

- Moltedo, M.; Baček, T.; Verstraten, T.; Rodriguez-Guerrero, C.; Vanderborght, B.; Lefeber, D. Powered ankle-foot orthoses: The effects of the assistance on healthy and impaired users while walking. J. NeuroEng. Rehabil. 2018, 15, 86. [Google Scholar] [CrossRef]

- Beil, J.; Marquardt, C.; Asfour, T. Self-aligning exoskeleton hip joint: Kinematic design with five revolute, three prismatic and one ball joint. In Proceedings of the 2017 International Conference on Rehabilitation Robotics (ICORR), London, UK, 17–20 July 2017; pp. 1349–1355. [Google Scholar]

- Beil, J.; Asfour, T. New mechanism for a 3 DOF exoskeleton hip joint with five revolute and two prismatic joints. In Proceedings of the 2016 6th IEEE International Conference on Biomedical Robotics and Biomechatronics (BioRob), Singapore, 26–29 June 2016; pp. 787–792. [Google Scholar]

- Lee, T.; Lee, D.; Song, B.; Baek, Y.S. Design and Control of a Polycentric Knee Exoskeleton Using an Electro-Hydraulic Actuator. Sensors 2019, 20, 211. [Google Scholar] [CrossRef]

- Choi, H.S.; Lee, C.H.; Baek, Y.S. Design of a Pneumatic Actuated Ankle-Foot Orthosis which has Talocrural and Subtalar Joint. In Proceedings of the 2019 IEEE 16th International Conference on Rehabilitation Robotics (ICORR), Toronto, ON, Canada, 24–28 June 2019; pp. 276–281. [Google Scholar]

- Lundberg, A.; Svensson, O.; Nemeth, G.; Selvik, G. The axis of rotation of the ankle joint. J. Bone Jt. Surgery. Br. Vol. 1989, 71, 94–99. [Google Scholar] [CrossRef]

- Lundberg, A. Kinematics of the ankle and foot: In vivo roentgen stereophotogrammetry. Acta Orthop. Scand. 1989, 60, 1–26. [Google Scholar] [CrossRef]

- Fatone, S.; Hansen, A.H. A Model to Predict the Effect of Ankle Joint Misalignment on Calf Band Movement in Ankle-Foot Orthoses. Prosthetics Orthot. Int. 2007, 31, 76–87. [Google Scholar] [CrossRef] [PubMed]

- Sumiya, T.; Suzuki, Y.; Kasahara, T.; Ogata, H. Instantaneous centers of rotation in dorsi/plantar flexion movements of posterior-type plastic ankle-foot orthoses. J. Rehabil. Res. Dev. 1997, 34, 279. [Google Scholar] [PubMed]

- Tzu-wei, P.H.; Kuo, A.D. Mechanics and energetics of load carriage during human walking. J. Exp. Biol. 2014, 217, 605–613. [Google Scholar]

- Kumpati, S.N.; Kannan, P. Identification and control of dynamical systems using neural networks. IEEE Trans. Neural Netw. 1990, 1, 4–27. [Google Scholar]

- Shu, H.; Pi, Y. PID neural networks for time-delay systems. Comput. Chem. Eng. 2000, 24, 859–862. [Google Scholar] [CrossRef]

- Yongquan, Y.; Ying, H.; Bi, Z. A PID neural network controller. In Proceedings of the International Joint Conference on Neural Networks, Portland, OR, USA, 24–27 July 2003; pp. 1933–1938. [Google Scholar]

- Kumar, R.; Srivastava, S.; Gupta, J.R. Artificial neural network based PID controller for online control of dynamical systems. In Proceedings of the 2016 IEEE 1st International Conference on Power Electronics, Intelligent Control and Energy Systems (ICPEICES), Delhi, India, 4–6 July 2016; pp. 1–6. [Google Scholar]

- Kim, J.-H.; Shim, M.; Ahn, D.H.; Son, B.J.; Kim, S.-Y.; Kim, D.Y.; Baek, Y.S.; Cho, B.-K. Design of a Knee Exoskeleton Using Foot Pressure and Knee Torque Sensors. Int. J. Adv. Robot. Syst. 2015, 12, 112. [Google Scholar] [CrossRef]

- Bapat, G.M.; Sujatha, S. A Method for Optimal Synthesis of a Biomimetic Four-Bar Linkage Knee Joint for a Knee-Ankle-Foot Orthosis. J. Biomimetics, Biomater. Biomed. Eng. 2017, 32, 20–28. [Google Scholar] [CrossRef]

- Donatelli, R. Normal Biomechanics of the Foot and Ankle. J. Orthop. Sports Phys. Ther. 1985, 7, 91–95. [Google Scholar] [CrossRef]

- Murray, M.P.; Drought, A.B.; Kory, R.C. Walking Patterns of Normal Men. IJBS 1964, 46, 335–360. [Google Scholar] [CrossRef]

- Piña, E. Rotations with Rodrigues’ vector. Eur. J. Phys. 2011, 32, 1171. [Google Scholar] [CrossRef]

- Grimmer, M.; Seyfarth, A. Mimicking human-like leg function in prosthetic limbs. In Neuro-Robotics; Springer: Dordrecht, The Netherlands, 2014; pp. 105–155. [Google Scholar]

- Pratt, J.E.; Krupp, B.T. Series elastic actuators for legged robots. In Unmanned Ground Vehicle Technology Vi; International Society for Optics and Photonics: Orlando, FL, USA, 2004; pp. 135–144. [Google Scholar]

| Parameter | Specification (mm) |

|---|---|

| 32 | |

| 22.54 | |

| 32 | |

| 22.54 | |

| 17.1 | |

| 5.44 |

| Frequency | PID Gain | PIDNN Gain |

|---|---|---|

| 0.1 Hz | , | |

| 0.2 Hz | , | |

| 0.4 Hz | , |

| Walking Pattern | PID Gain | PIDNN Gain |

|---|---|---|

| 1 km/h | , | , |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, T.; Kim, I.; Baek, Y.S. Design of a 2DoF Ankle Exoskeleton with a Polycentric Structure and a Bi-Directional Tendon-Driven Actuator Controlled Using a PID Neural Network. Actuators 2021, 10, 9. https://doi.org/10.3390/act10010009

Lee T, Kim I, Baek YS. Design of a 2DoF Ankle Exoskeleton with a Polycentric Structure and a Bi-Directional Tendon-Driven Actuator Controlled Using a PID Neural Network. Actuators. 2021; 10(1):9. https://doi.org/10.3390/act10010009

Chicago/Turabian StyleLee, Taehoon, Inwoo Kim, and Yoon Su Baek. 2021. "Design of a 2DoF Ankle Exoskeleton with a Polycentric Structure and a Bi-Directional Tendon-Driven Actuator Controlled Using a PID Neural Network" Actuators 10, no. 1: 9. https://doi.org/10.3390/act10010009

APA StyleLee, T., Kim, I., & Baek, Y. S. (2021). Design of a 2DoF Ankle Exoskeleton with a Polycentric Structure and a Bi-Directional Tendon-Driven Actuator Controlled Using a PID Neural Network. Actuators, 10(1), 9. https://doi.org/10.3390/act10010009