Improved Method for Distributed Parameter Model of Solenoid Valve Based on Kriging Basis Function Predictive Identification Program

Abstract

1. Introduction

2. The Error Correction Method of DPM Based on Kriging Model

- Particle Swarm Optimization(PSO)

- Response Surface (RS)

- Linear Second order moment (LS)

- Monte Carlo (MC)

3. MFL Permeance Prejudge the Error Data Based on Kriging PIP

4. The Error Correction of MFL Permeance and Soft Magnetic Resistance of Solenoid Valves

5. Conclusions

- Based on the characteristics of the kriging basis function curve, the relationship between the kriging basis function and the MFL permeance error data can be obtained, and an appropriate function is selected by contrasting various basis functions with error data curves. Then it is applied to gain error compensation between the FEM and DMP data. The PIP is introduced to prejudge the error data by comparing the standard function to the selected basis function. The modified MFL permeance and the soft magnetic resistance data are then substituted into the DPM of the electromagnetic device to calculate the attraction force.

- The proposed method can effectively improve the calculation accuracy of the solenoid valve electromagnetic system. Compared with the FEM data, the unmodified MFL permeance of the DPM mean error is 13.1%, and the modified MFL permeance of the DPM mean error is 4.7%. The unmodified MFL permeance of the DPM mean error is 9.94%, and the modified MFL permeance of the DPM mean error is 3.7%.

- The results of the DPM solenoid valve electromagnetic system in the case study showed a significant improvement. Particularly, the calculation accuracy improved by reducing the DPM mean error from 10.2% to 3.8%.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Hong, D.K.; Woo, B.C.; Koo, D.H.; Lee, K.C. Electromagnet Weight Reduction in a Magnetic Levitation System for Contactless Delivery Applications. Sensors 2010, 10, 6718–6729. [Google Scholar] [CrossRef] [PubMed]

- Yang, X.M.; Guo, X.L.; Ouyang, H.J.; Li, D.S. A Kriging Model Based Finite Element Model Updating Method for Damage Detection. Appl. Sci. 2017, 7, 1039. [Google Scholar] [CrossRef]

- Zhang, X.X.; Liu, G.D.; Wang, K.T.; Li, X.D. Application of a Hybrid Interpolation Method Based on Support Vector Machine in the Precipitation Spatial Interpolation of Basins. Water 2017, 9, 760. [Google Scholar] [CrossRef]

- Zhang, D.W.; Li, W.L.; Wu, X.H.; Liu, T. An Efficient Regional Sensitivity Analysis Method Based on Failure Probability with Hybrid Uncertainty. Energies 2018, 11, 1684. [Google Scholar] [CrossRef]

- Li, Y.K.; Song, B.W.; Mao, Z.Y.; Tian, W.L. Analysis and Optimization of the Electromagnetic Performance of a Novel Stator Modular Ring Drive Thruster Motor. Energies 2018, 11, 1598. [Google Scholar] [CrossRef]

- Kwon, J.W.; Lee, J.H.; Zhao, W.L.; Kwon, B.I. Flux-Switching Permanent Magnet Machine with Phase-Group Concentrated-Coil Windings and Cogging Torque Reduction Technique. Energies 2018, 11, 2758. [Google Scholar] [CrossRef]

- You, Y.M. Multi-Objective Optimal Design of Permanent Magnet Synchronous Motor for Electric Vehicle Based on Deep Learning. Appl. Sci. 2020, 10, 482. [Google Scholar] [CrossRef]

- Pan, R.C.; Song, Z.Y.; Liu, B. Optimization Design and Analysis of Supersonic Tandem Rotor Blades. Energies 2020, 13, 3228. [Google Scholar] [CrossRef]

- Bae, T.S.; Lee, K.H. Structural Design of a Main Starting Valve Based on the First Axiom. Int. J. Precis. Eng. Manuf. 2012, 13, 685–691. [Google Scholar] [CrossRef]

- Lee, Y.M.; Choi, D.H. Design Optimization of an Automotive Vent Valve Using Kriging Models. Trans. KSAE 2011, 16, 1–9. [Google Scholar]

- Kim, S.P.; Lee, K.H. Structural Optimization of a Manifold Valve for Pressure Vessel. J. Korean Soc. Precis. Eng. 2009, 26, 102–109. [Google Scholar]

- Xue, X.F.; Wang, Y.Z.; Lu, C.; Zhang, Y.P. Sinking Velocity Impact-Analysis for the Carrier-Based Aircraft Using the Response Surface Method-Based Improved Kriging Algorithm. Adv. Mater. Sci. Eng. 2020, 6, 1–13. [Google Scholar] [CrossRef]

- Rashki, M.; Azarkish, H.; Rostamian, M.; Bahrpeyma, A. Classification Correction of Polynomial Response Surface Methods for Accurate Reliability Estimation. Struct. Saf. 2019, 81, 101869. [Google Scholar] [CrossRef]

- Sumiya, U.; Kwon, H.H. Development of bias correction scheme for high resolution precipitation forecast. J. Korea Water Resour. Assoc. 2018, 51, 575–584. [Google Scholar]

- Wang, X.; Babovic, V.; Li, X. Application of Spatial-Temporal Error Correction in Updating Hydrodynamic Model. J. Hydro Environ. Res. 2017, 16, 45–57. [Google Scholar] [CrossRef]

- Rathore, P.; Kumar, D.; Rajasegarar, S.; Palaniswami, M. Maximum Entropy-Based Auto Drift Correction Using High-and Low-Precision Sensors. ACM Trans. Sens. Netw. 2017, 13, 1–41. [Google Scholar] [CrossRef]

- Alexeeff, S.E.; Carroll, R.J.; Coull, B. Spatial measurement error and correction by spatial SIMEX in linear regression models when using predicted air pollution exposures. Biostatistics 2016, 17, 377–389. [Google Scholar] [CrossRef] [PubMed]

- Xia, B.; Lee, T.W.; Choi, K.; Koh, C.S. A Novel Adaptive Dynamic Taylor Kriging and Its Application to Optimal Design of Electromagnetic Devices. IEEE Trans. Magn. 2016, 52, 1–4. [Google Scholar] [CrossRef]

- Zhang, C.; Qang, Z.; Shafieezadeh, A. Value of Information Analysis via Active Learning and Knowledge Sharing in Error-Controlled Adaptive Kriging. IEEE Access 2020, 8, 51021–51034. [Google Scholar] [CrossRef]

- Chen, D.C.; Liu, D.Z.; Li, Y.H.; Meng, L.; Yang, X.J. Improve Spatiotemporal Kriging with Magnitude and Direction Information in Variogram Construction. Chin. J. Electron. 2016, 25, 527–532. [Google Scholar] [CrossRef]

- Zhang, J.H.; Xiao, M.; Gao, L.; Zhang, Y. MEAK-MCS: Metamodel Error Measure Function based Active Learning Kriging with Monte Carlo Simulation for Reliability Analysis. In Proceedings of the 2019 IEEE 23rd International Conference on Computer Supported Cooperative Work in Design, Porto, Portugal, 6–8 May 2019. [Google Scholar]

- Yan, Y.; Wang, J.; Zhang, Y.; Sun, Z. Kriging Model for Time-Dependent Reliability: Accuracy Measure and Efficient Time-Dependent Reliability Analysis Method. IEEE Access 2020, 8, 172362–172378. [Google Scholar] [CrossRef]

- Liu, X.; Li, X.S.; Huang, S.D. Parameters Optimization of the Permanent Magnet Linear Synchronous Machine Using Kriging-based Genetic Algorithm. In Proceedings of the 2019 22nd International Conference on Electrical Machines and Systems, Harbin, China, 11–14 August 2019. [Google Scholar]

- Yin, J.; Ng, S.H.; Ming, K. A study on the effects of parameter estimation on kriging model’s prediction error in stochastic simulations. In Proceedings of the 2009 Winter Simulation Conference, Austin, TX, USA, 13–16 December 2009. [Google Scholar]

- Yu, J.C. Evolutionary algorithm using progressive Kriging model and dynamic reliable region for expensive optimization problems. In Proceedings of the 2016 IEEE International Conference on Systems, Man, and Cybernetics, Budapest, Hungary, 9–12 October 2016. [Google Scholar]

- Pham, T.D. Kriging-based possibilistic entropy of biosignals. In Proceedings of the 20th European Signal Processing Conference, Bucharest, Romania, 27–31 August 2012. [Google Scholar]

- Rivera, R. A Low Rank Gaussian Process Prediction Model for Very Large Datasets. In Proceedings of the 2015 IEEE First International Conference on Big Data Computing Service and Applications, Redwood City, CA, USA, 30 March–2 April 2015. [Google Scholar]

- Jouhaud, J.C.; Sagaut, P.; Labeyrie, B. A kriging approach for CFD/wind-tunnel data comparison. J. Fluids Eng. Trans. ASME 2006, 128, 847–855. [Google Scholar] [CrossRef][Green Version]

- Han, S.Q.; Song, W.P.; Han, Z.H. An improved WENO method based on Gauss-kriging reconstruction with an optimized hyper-parameter. J. Comput. Phys. 2020, 422, 109742. [Google Scholar] [CrossRef]

- Cui, D.; Wang, G.Q.; Lu, Y.P.; Sun, K.K. Reliability design and optimization of the planetary gear by a GA based on the DEM and Kriging model. Reliab. Eng. Syst. Saf. 2020, 203, 107074. [Google Scholar] [CrossRef]

- Shin, Y.J.; Lee, S.H.; Choi, C.H.; Kim, J.H. Shape Optimization to Minimize The Response Time of Direct-acting Solenoid Valve. J. Magn. 2015, 20, 193–200. [Google Scholar] [CrossRef]

- Suh, Y.K. Multi-objective Optimization Strategy based on Kriging Metamodel and its Application to Design of Axial Piston Pumps. J. Adv. Mar. Eng. Technol. 2013, 37, 893–904. [Google Scholar]

- Qin, W.J.; He, J.Q. Optimum design of local cam profile of a valve train. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2010, 224, 2487–2492. [Google Scholar] [CrossRef]

- Li, T.Z.; Yang, X.L. An efficient uniform design for Kriging-based Response Surface Method and its Application. Comput. Geotechics 2019, 109, 12–22. [Google Scholar] [CrossRef]

- Trinchero, R.; Larbin, M.; Swaminathan, M.; Canavero, F.G. Statistical Analysis of the Efficiency of an Integrated Voltage Regulator by means of a Machine Learning Model Coupled with Kriging Regression. In Proceedings of the IEEE Workshop on Signal and Power Integrity, Chambery, France, 18–21 June 2019. [Google Scholar]

- Liang, H.M.; Zhang, K.; You, J.X. Analytical Method for the Magnetic Field Line Distribution of a Fan-shaped Permanent Magnet and the Calculation of Leakage Permeance. J. Magn. 2017, 22, 395–405. [Google Scholar] [CrossRef]

- You, J.X.; Zhang, K.; Zhu, Z.W.; Liang, H.M. Novel Design and Research for a High-retaining-force, Bi-directional, Electromagnetic Valve Actuator with Double-layer Permanent Magnets. J. Magn. 2016, 21, 65–71. [Google Scholar] [CrossRef]

- Zhang, K.; Liang, H.M.; You, J.X.; Yu, H. Distributed Parameter Model for Electromagnetic Valve Actuator with Permanent Magnet. In Proceedings of the IEEE International Magnetics Conference, Dublin, Ireland, 24–28 April 2017. [Google Scholar]

- Ye, X.R.; Chen, H.; Liang, H.M.; Chen, X.J.; You, J.X. Multi-Objective Optimization Design for Electromagnetic Devices with Permanent Magnet Based on Approximation Model and Distributed Cooperative Particle Swarm Optimization Algorithm. IEEE Trans. Magn. 2018, 54, 1–5. [Google Scholar]

- Ye, X.R.; Chen, H.; Chen, C.; Zhai, G.F. Life-cycle Dynamic Robust Design Optimization for Batch Production of Permanent Magnet Actuator. IEEE Trans. Ind. Electron. 2020, 11, 3026294. [Google Scholar] [CrossRef]

| Function | Algorithm | Iteration | Count | Time (s) |

|---|---|---|---|---|

| Gaussian | PSO | 132 | 660 | 987 |

| RS | 189 | 945 | 1229 | |

| LS | 147 | 588 | 1143 | |

| MC | - | 105 | 2961 | |

| Fourier | PSO | 162 | 810 | 1328 |

| RS | 198 | 990 | 1843 | |

| LS | 204 | 816 | 1687 | |

| MC | - | 105 | 3063 | |

| Polynomial | PSO | 153 | 765 | 1125 |

| RS | 207 | 1035 | 2063 | |

| LS | 192 | 768 | 1763 | |

| MC | - | 105 | 3012 |

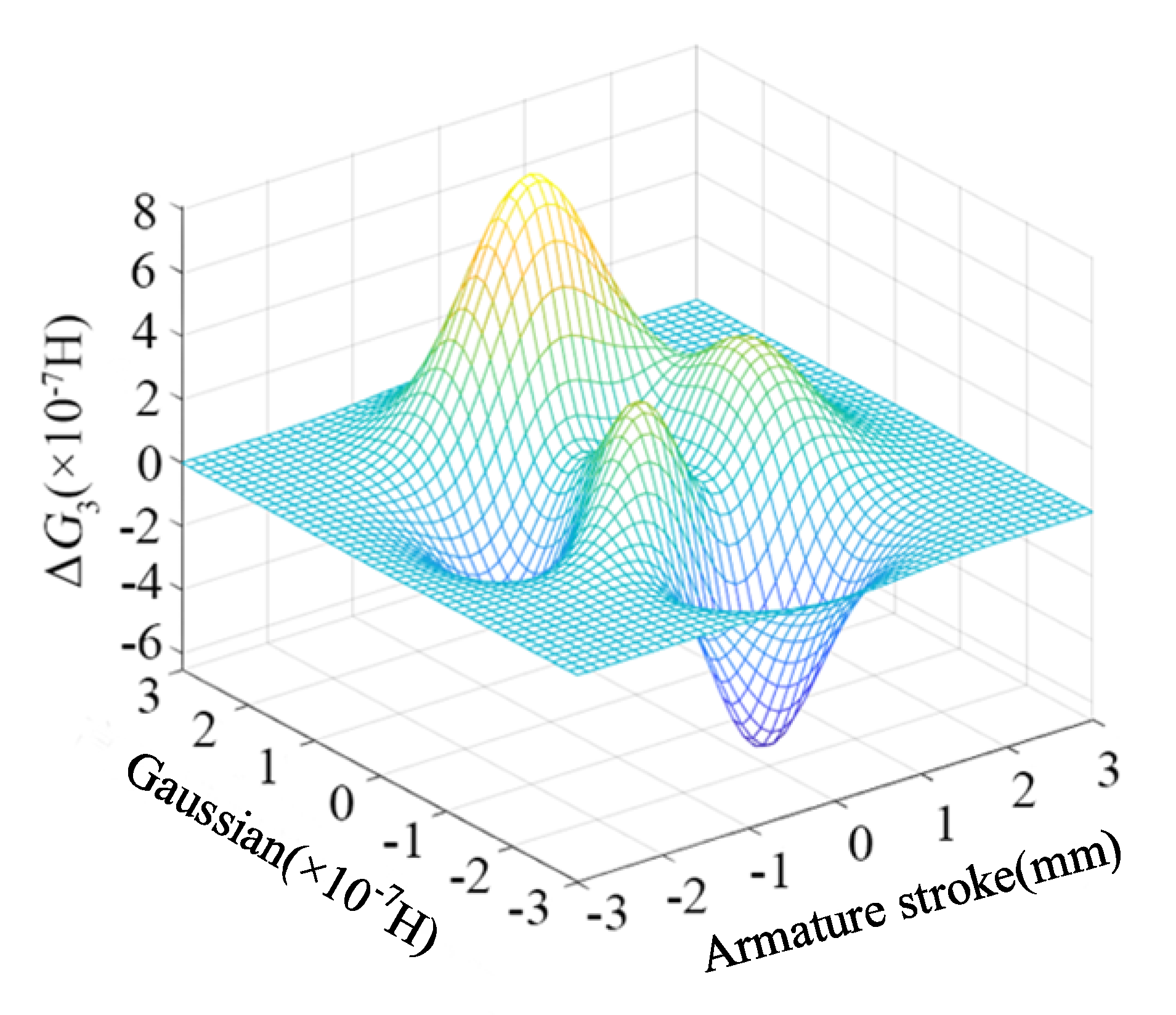

| Schwefel Similarity | ΔG1 | ΔG2 | ΔG3 | ΔG4 | ΔG5 | ΔG6 | ΔG7 |

| 0.005 | 0.0662 | 0.7654 | 0.7775 | 0.1674 | 0.5698 | 0.0013 |

| Trigonometric Similarity | ΔG1 | ΔG2 | ΔG3 | ΔG4 | ΔG5 | ΔG6 | ΔG7 |

| 0.8625 | 0.921 | 0.231 | 0.1922 | 0.8124 | 0.7958 | 0.7642 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

You, J.; Zhang, K.; Liang, H.; Feng, X.; Ruan, Y. Improved Method for Distributed Parameter Model of Solenoid Valve Based on Kriging Basis Function Predictive Identification Program. Actuators 2021, 10, 10. https://doi.org/10.3390/act10010010

You J, Zhang K, Liang H, Feng X, Ruan Y. Improved Method for Distributed Parameter Model of Solenoid Valve Based on Kriging Basis Function Predictive Identification Program. Actuators. 2021; 10(1):10. https://doi.org/10.3390/act10010010

Chicago/Turabian StyleYou, Jiaxin, Kun Zhang, Huimin Liang, Xiangdong Feng, and Yonggang Ruan. 2021. "Improved Method for Distributed Parameter Model of Solenoid Valve Based on Kriging Basis Function Predictive Identification Program" Actuators 10, no. 1: 10. https://doi.org/10.3390/act10010010

APA StyleYou, J., Zhang, K., Liang, H., Feng, X., & Ruan, Y. (2021). Improved Method for Distributed Parameter Model of Solenoid Valve Based on Kriging Basis Function Predictive Identification Program. Actuators, 10(1), 10. https://doi.org/10.3390/act10010010