Abstract

Robotic hands with unique designs, capabilities and applications have been presented in the literature focusing on sensing, actuation, control, powering and manufacturing, most of which are created by manual assembly process. However, due to advancements in additive manufacturing, new capabilities have replaced traditional methods of manufacturing. In this paper, we present a soft 3D-printed robotic hand actuated by custom-made coiled shape memory alloy (SMA) actuators. The hand uses additive manufacturing of flexible thermoplastic polyurethane (TPU) material, which allows flexing at the joint and hence eliminates the need for additional assembly. Here, we present the full characteristics of the robotic hand such as object grasping categorized by size and weight from the ARAT kit and others. The robotic hand is 425 mm in length, weighs 235 g and is able to operate at a frequency of 0.125 Hz without active cooling. It can grasp an object of 55–81 mm widths, weighing up to 133 g, while consuming an average power of 7.82 W. We also show the time domain response of our custom-made coiled SMA to different current inputs, and its corresponding force and displacement. The current design yields a lightweight and low cost artificial hand with significantly simplified manufacturing for applications in robotics and prosthetics.

1. Introduction

Robotic hands have been researched for many years due to the need of grasping and manipulating complex objects to perform assistive functions for humans. Robotic hands are the key components of social robots and industrial manipulators. A century of robotic hands has been recently presented by Piazza et al. [1], illustrating a century-old effort in realizing the perfect robotic hand. There are many challenges in the design and development of robotic hands, including selection of actuators, design, control and manufacturing methods. These design decisions are often related to the application where the hand is going to be used. Our objective in this work is to design and develop a robotic hand that has as many of the following properties and capabilities as possible:

- Size: Adult-sized hand and forearm, typical size of adult hand is 396–517 mm based on the 5–95th percentile of the human forearm length [2].

- Object manipulation: Be able to manipulate commonly used objects of size 50–100 mm size, such as handling of daily usage objects.

- Manufacturing: The design should be easy for manufacturing, customizable to desired size and preferably using 3D printing for modification in rapid prototyping systems.

- Weight: The design and the material should result in a lightweight structure that should be under 300 g.

- Cost: Material cost for manufacturing the robotic hand should be low; typically the material cost should be less than $200.

- Load capacity: The robotic hand should hold a mass of at least 100 g.

- Design for manufacturing: Adheres to design for manufacturing (DFM) and assembly (DFA) principles.

- Operating conditions: The operating temperature of the device is room temperature 20 degrees Celsius.

- Noise: Low or no noise generated from the system for silent operation.

In the meantime, we would like to perfect the design and manufacturing method and evaluate the performance of the hand, which can then be later transformed for prosthetic purposes. This approach allows for maturing the design iterations and making a gradual transition from robotics to humans. Light weight is especially essential in prosthetic applications, as heavy prosthetics are often uncomfortable due to cantilever moments transmitted to the residual limb [3,4]. Several efforts to achieve this have been made in many aspects of robotic hand design and development.

The Humanoid, Biorobotics and Smart Systems (HBS) lab at UT Dallas has designed and developed numerous unique robotic hands in the past few years. The modes of actuation vary, including RC (Radio Controlled) servo motors [5], shape memory alloy (SMA) wires [6], TCP (Twisted and Coiled Polymer) muscles [7], hybrid actuation using Dynamixel servo motors and TCP actuators [8] and robotic finger actuated by cold and hot water [9]. These experiences and test results have helped us to review all the required components for practical applications of robotic hands. Many of the necessary feedback systems and sensors (such as thermal and flex sensors) are readily available for implementation into newly developed artificial hands. This work focuses primarily on the development of the hand and its mechanical performance and strengths with custom-made actuators as the core component; sensors and feedback control will be implemented at a later time.

This paper outlines the design and implementation of a novel robotic hand that uses coiled shape memory alloy muscles. It also pioneers the usage of entirely 3D-printed flexible thermoplastic polyurethane (TPU) to construct the hand, allowing for ease of construction while still touting significant force output and response times. The electrical current provided to muscles is also varied to determine the effects it plays on overall actuation displacement and speed; such data can be utilized later for implementation of feedback control. The hand was found to be capable of grasping multiple objects and loads up to 133 g, while still achieving actuation frequencies of up to 0.125 Hz. The paper is organized as follows: first, we will present a literature review of related works on existing robotic hands and coiled SMA actuators. Next, we will discuss the design and construction of the robotic hand along with the components. This will be followed by the experimental setup to characterize the coiled SMA actuators and the robotic hand. Then, we will present experimental results such as actuation angles, grasping capacities and discussion. Finally, summary, conclusion and future work will be provided.

2. Literature Review

There are many artificial hands that have been developed for both robotic and prosthetic purposes in the past century, most of which attempt to mimic the dexterity and functionality of a human hand [10,11,12,13,14]. Although many hands have been built by academic labs, industrial efforts have also found their way to the marketplace [4,15]. However, such commercial hands tend to be extremely expensive, with prices ranging from 6600 to 100,000 USD [16]. Table 1 provides a comprehensive summary of existing robotic and prosthetic hands using different modes of actuation, including traditional electric motors [10,12,13,14,17,18,19], hydraulic/fluidic [3,20,21] pneumatic [22] and artificial muscles [7]. Analysis of design, manufacturing and performance of different robotic hands are also presented in numerous review articles [1,4,23,24,25]. While electric motors are considered standard due to their high efficiency and ease of control, they have the disadvantage of weight and bulkiness in comparison to recently developed artificial muscles such as twisted and coiled polymer (TCP) muscles [7] and shape memory alloy (SMA) muscles [26]. Furthermore, many of the hands in literature are quite complex in construction and consist of several revolute joints to accommodate each degree of freedom. In contrast, this paper presents a simple 3D printed soft robotic hand constructed from thermoplastic polyurethane and is actuated by coiled shape memory alloy muscles.

Table 1.

Characteristics of existing artificial hands and fingers compared with coiled shape memory alloy (SMA) actuated hand.

Nickel titanium (Ni-Ti/Nitinol) shape memory alloys (SMAs) have been used for various applications outside of just artificial muscles, including biomimetic robotics, soundproofing and aircraft control systems [27,28,29,30]. SMA muscles benefits from features such as compact size, high force-to-weight ratio and silent operation, but have low energy efficiency, low operational frequency and low stroke (approximately 5%) [31]. As a result, many of the applications using linear SMA muscles suffer from complex designs to implement routing systems that increase usable displacement of the muscles [26]. However, the stroke can be greatly increased by coiling the SMA into a helical structure, while frequency can be increased using active cooling techniques [32]. SMA plates have also been utilized in robotic hand actuation, but require embedding the actuator directly within the finger [33,34]. While linear SMA muscles have been widely used in artificial hand applications [26,35,36,37], there has been less applications of coiled shape memory alloy muscles in artificial hands. When the coiled form or the helical form of the SMA is used, force of the actuator will reduce significantly, while the actuation stroke will increase significantly. Therefore, a tradeoff between force and actuation strain is required depending on the application of the robotic hand [31].

Relevant information is provided in refs. [38,39,40,41,42,43,44,45,46] for a robotic hand or finger design, but one of the first usage of coiled shape memory alloy (SMA) muscles in a robotic finger via antagonistic pairs occurred in an earlier work in 1989. Bergamasco et al. demonstrated coiled SMA muscles (0.45 mm wire diameter, 1.5 mm spring diameter, 14 coils and length of 6.3 mm) capable of lifting 3.5 N load a height of 10 mm at 0.11 Hz [45]. A robotic hand using coiled shape memory alloy actuators for individual phalangeal control was demonstrated by Farias et al. [44]. Their hand has four fingers and 22 muscles (0.2 mm wire diameter, 1.3 mm spring diameter, 12 coils and a length of 7 mm) arranged in antagonistic pairs to control each of its 11 degrees of freedom robotic hand. It also implements magnetic locking structures to maintain finger positions without the need of continuous actuation of the muscles. In another work, Taniguchi et al. presented the concept of a child sized prosthetic hand using two coiled SMAs (0.5 mm wire diameter, 1 mm spring diameter, 20 coils and length of 20 mm) with coupled actuation and a biased return spring. While the hand uses conventional Joule heating for actuation, it also employs fluidic cooling of the muscles with fluorine refrigerant to increase frequency of actuation [46]. Recently in 2019, Park et al. [47] showed the usage of bundled coiled SMAs and fluidic heating/cooling pumps to simulate muscles (the SMA bundles) composed of muscle fibers (the individual coiled SMAs). Whereas the vast majority of SMA actuations are powered by resistive heating, their SMA bundles use hot water (40–93 degrees Celsius) to initiate actuation, and cold water (28 degrees Celsius) to cool the muscles. Their work shows the immense strength of coiled SMA muscle bundles, which can lift up to 10 kg at 50–58% strain and up to 1 Hz frequency. They also showed relatively higher frequency at 1.67 Hz, but the strain for the 10 kg lifting decreased to 28.7% strain. Park et al. also showed the usage of the SMA bundles in actuating an elbow joint of an arm, in which two bundles are mounted in an antagonistic pair.

Other novel artificial muscles used for robotic hands include those made from polymer fibers, such as twisted coiled polymer (TCP) muscles [7]. While these muscles are inexpensive to manufacture and boast fairly high force outputs with decent stroke, they require relatively high power consumption and low frequency of actuation. Furthermore, TCP muscles have limited lifespans, some of the reported life cycle for 6-ply TCP is 800 cycles at 0.25 Hz in water and 200 cycles at 0.017 Hz in air [48]. Although equally thermally inefficient, the small size of coiled SMA actuators reduces the total power consumption, while having higher actuation strain and frequency.

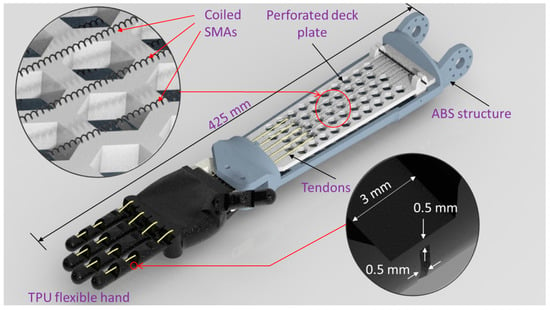

According to the literature review above, not much research has been done on coiled SMA for robotic hand application. In this paper, we demonstrated the first usage of 3D-printed soft thermoplastic polyurethane (TPU) elastomer in combination with coiled SMA in robotic hands, as shown in Figure 1. This unique hand is designed with 200-micron diameter coiled shape memory alloy actuators and the hand is capable of grasping objects up to 133 g without the help of thumb actuation. Although not often discussed by other authors, ease of manufacturing is a key benefit of this hand, as there are few parts beyond the actuators, all of which are 3D printed. This hand also has very simple assembly and has a lightweight overall structure as a result of the small coiled SMA actuators. Furthermore, the overall cost of the hand was low, while still demonstrating fair actuation for grasping in terms of strength and speed. The overall size of the hand was 425 mm in length, 120 mm in width and 75 mm in height. This size was considering the orientation of the thumb, which was at angle with the palm plane. The next section will discuss the detailed design and characteristics of the robotic hand.

Figure 1.

CAD (Computer Aided Design) model of the robotic hand actuated by helically wound shape memory alloy muscles with flexible thermoplastic polyurethane (TPU) fingers.

3. Design and Construction of the Robotic Hand

3.1. Mechanical Design

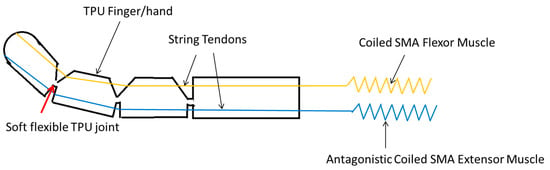

The primary principle of the soft robotic hand is shown in Figure 2. The 3D-printed TPU finger and hand were actuated by a pair of coiled shape memory alloy muscles in parallel antagonistic setup. The flexor muscle was actuated, contracting to perform flexion of the finger, while the antagonist flexor muscle stretched. To return the finger, the extensor muscle was actuated, creating an opposite motion. This kind of actuation of agonist and antagonistic pairs is quite common [40,44,49] and found to be effective in robotic hands.

Figure 2.

Schematic diagram of the robotic hand actuated by coiled SMA.

Each finger has three degrees of freedom (DOF), with three flexible joints connecting the proximal, intermediate and distal phalanges to the palm (metacarpals). The hand is considered underactuated, as all the joints are actuated by a single muscle and their motion is coupled. Thumb motion was not fully implemented due to its complexity, with the additional motions of abduction, adduction and opposition. This prototype only includes thumb flexion and extension, so the thumb is considered mostly obsolete, although it is theoretically functional.

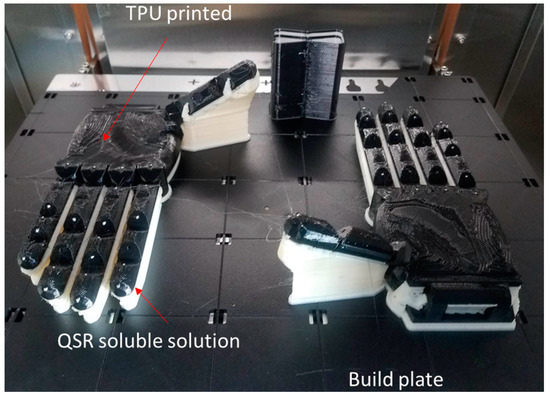

The hand was designed in PTC Creo Parametric CAD software using an adapted model from our previous robotic hand [7,50]. As shown in Figure 1, the hand consists of a new single solid body composed of finger parts connected via a thin 0.5 mm band (compliant joint), which acts as the flexible finger joint. The strength of such a thin geometrical feature was then verified by SolidWorks static simulation and was able to withstand an axial tensile force along the finger of 40 N (4 kgf, higher than the design specification of 100 g) without yielding. The hand was then 3D-printed from thermoplastic polyurethane (TPU) 92A plastic rubber using a Stratasys F370 3D printer, Figure 3. TPU 92A was selected as the material of choice due to a low flexural modulus (25.6 MPa) and high flexural strain while maintaining the ability to be 3D printed [51]. Recently, TPU has been used for multidirectional flexible joints in conjunction with metal pin joints [52]. However, the hand presented in this paper has only flexible TPU joints in the fingers and uses metal fasteners solely for coupling the hand to the forearm. The printed hand and build plate are shown in Figure 3. The TPU is black colored, and the white part is the QSR support material, which can easily dissolve in solvent. This manufacturing strategy significantly helps in the design and development of robotic hands, as it minimizes the assembly time and such capabilities were not available until recently. The total volume of material used to print one hand was 3 in3 (98 cm3) with a printing time of approximately 9 h. Solid infill pattern was used with a resolution (layer thickness) of 0.254 mm.

Figure 3.

3D-Printed soft TPU hand using the Stratasys F370 3D printer.

The remaining parts (wrist, forearm and “deck plate,” which holds the muscles), shown assembled with the hand in Figure 1, were 3D printed from acrylonitrile butadiene styrene (ABS) plastic. The forearm and deck plate both feature honeycomb cutout patterns to further reduce weight while maintaining structural integrity. In total, there are only four individual 3D printed parts, demonstrating ease of manufacturing and assembly, which supports DFMA principles. The overall hand including the forearm has a length of 425 mm, a volume of 232 cubic centimeters and a mass of 235 g.

3.2. Coiled SMA Fabrication

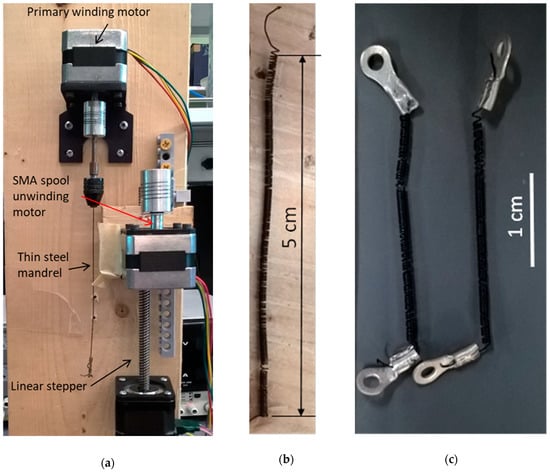

Coiled shape memory alloy (SMA) muscles were fabricated from Dynalloy 0.008 (0.20 mm) diameter Nitinol wire by tightly coiling it around a 0.64 mm diameter steel mandrel (piano wire from Precision Metals). This was done using a custom-made setup, shown in Figure 4a. The manufacturing setup consists of two stepper motors, a linear motor, a mandrel and SMA wire spool. The primary winding motor draws wire from the SMA spool unwinding motor and coils it around the thin mandrel. The pitch is controlled by the linear screw motor, which moves downwards as the coils are wound. The fabricated SMA had a pitch of 0.25 mm/coil and a total length of 50 mm, shown in Figure 4b.

Figure 4.

Muscle fabrication (a) custom coiled SMA fabrication setup; (b) annealed muscle (50 mm) and (c) muscle cut into two 25-mm halves and crimped. The two rotary motors are Adafruit NEMA-17 0.35 A 12 V Stepper motors, while the linear stepper is a Moons HD4001–20N Stepping Motor. The motors are controlled by an Arduino Uno microcontroller and two stacked Adafruit motor shields (V2). The motor shields are connected to a Topward 6306D power supply, with 12 V, 0.7 A for the two Adafruit motors and 0.25 A, 9 V for the Moons stepper. The Arduino has code written to synchronize the rotations of the motor such that the mandrel and spool have equal tangential velocities.

The Nitinol wire was then crimped to the mandrel and removed from the setup. The muscle was annealed in a Thermolyne FD1535M furnace at 350 °C for 45 min to set the desired shape memory properties. After the annealing was complete, the muscle was allowed to cool for 10 min, and then cut in half to form two muscles of 25 mm length each. Crimps were attached to assist connection of electrical wires. The final muscles are shown in Figure 4c.

The manufacturing process presented here is similar to the one by Potnuru and Tadesse [53]. However, the two stepper motors shown in Figure 4 help in holding the SMA wires tightly and fabricating of consistent actuators for use in the robotic hand, which was found to be more effective than the previous setup. Consistency was maintained as much as possible to prevent the fingers from actuating at unintended angles. The fabrication of these coiled SMAs was also generic and could therefore support varying dimensions of spring diameter and pitch for other applications as well.

3.3. Hand Construction

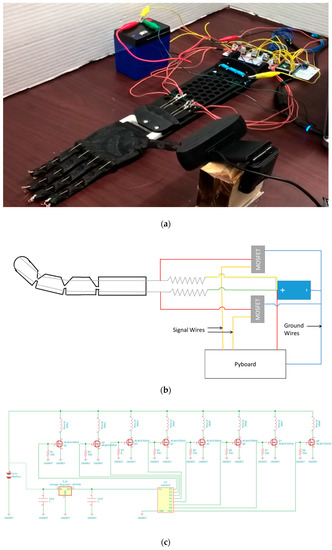

The assembly process is straightforward, as there are few parts to assemble. Each finger is threaded with sewing thread to act as tendons, which is tied to a lobster clamp to interface with the muscles. The hand, wrist and forearm are linked together via nuts and bolts. The deck plate acts as the static anchor for the muscles and is attached to the forearm via nails. The muscles are stretched via pretension to a length of 100 mm in order to attach the tendons to the rear anchor on the deck plate (stretched 400% of its original length). The properties of each muscle are shown in Table 2, and a slight variation in length of muscles (±2–3 mm) is observed, which will be discussed later in the section. While there is support for thumb flexors and extensors in both the circuitry and design of the hand/forearm, these muscles were not implemented due to the aforementioned incomplete nature of thumb abduction. The final constructed hand is shown in Figure 5a, while the operating schematic diagram of the hand is shown in Figure 5b.

Table 2.

Muscles used in the hand: length/voltages/power.

Figure 5.

(a) Image of hand and circuitry; (b) functional schematic of the wiring and (c) circuitry schematic.

3.4. Circuitry and Microcontroller

The actuation circuitry for the SMAs consists of ten MOSFET (Metal oxide silicon field effect transistors) and a voltage regulator that are soldered to a breadboard; each transistor controls a single muscle. Two are redundant, as they were intended to control the thumb, which is not being used. The voltage regulator provides 3 V to the MicroPython Pyboard 1.1 microcontroller. Each MOSFET receives a pulse width modulation (PWM) signal from the Pyboard microcontroller, which is programmed via a Python script. The MOSFET then functionally reduces the battery voltage via PWM to the necessary power and provides it to the muscle for actuation. The overall circuit diagram is shown in Figure 5c. The script was written from scratch and implements an object-oriented programming style, with a finger object being created to maintain records of each finger’s required PWM input, and relevant functions for flexion and extension. The code is provided in Appendix A. Power is provided from a 6.6 V, 30 Wh rechargeable battery and is projected to be able to operate continuously for 3.84 h at an actuation frequency of 0.1 Hz.

4. Experimental Results and Discussion

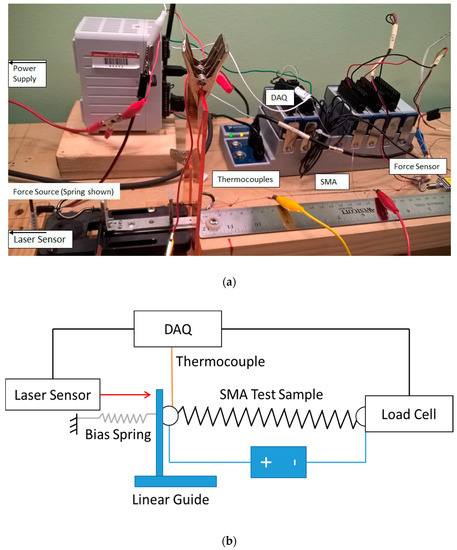

We conducted several tests to assess the performance of the coiled SMA-actuated robotic hand using the experimental setup shown in Figure 6. Initially, we characterized the fabricated SMA actuators for the time domain response, and then performed tests on the robotic hand such as finger bending angles, cyclic tests, grasping and holding objects.

Figure 6.

Muscle characterization setup (a) image and (b) schematic. A coiled shape memory alloy muscle was prepared with the characteristics listed in Table 3. The muscle was pretensioned to 100 mm, with one end attached to a force probe, while the other end was attached to the spring. A square wave of varying magnitudes (0.3, 0.5 and 0.7 A) was applied to the muscle, with a 2 s on and 8 s off cycle for 5 cycles.

4.1. Muscle Characterization

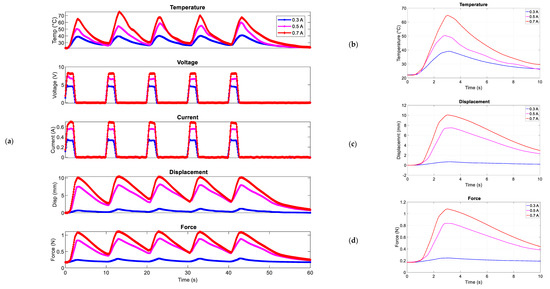

A single coiled shape memory alloy muscle was created to demonstrate the muscle capabilities, with characteristics shown in Table 3. The muscle was attached to a force sensor on one end, with the other end being attached to a spring (spring constant = 0.14 N/mm), illustrated in Figure 6a. The schematic diagram of the setup is shown in Figure 6b. Other parameters measured include displacement via a laser sensor and temperature via thermocouples attached to the muscle. Differing current amplitudes of 0.3, 0.5 and 0.7 A were then tested on the muscle for 2 s, followed by an off period of 8 s. This corresponds to a frequency of 0.1 Hz and duty cycle of 20%, for 5 cycles. As shown in Figure 7a, the 0.7 A pulse generated the highest temperature and corresponding force and displacement. The 0.3 A pulse generated significantly less displacement and force than both the 0.5 and 0.7 A pulses, likely because the heating time of 2 s was not enough to cause the necessary phase change temperature in the SMA. Since the 0.5 A pulse is shown to generate similar actuation displacement and force to the 0.7 A pulse, it is chosen as the default operating current to avoid damaging the muscles when actuated for long heating periods. It should be noted that the manufacturer recommended current input is 0.66 A for 1 s [54].

Table 3.

Coiled SMA muscle characteristics.

Figure 7.

Results of muscle characterization. (a) Overall results for five cycles; (b) magnified temperature plot of first cycle; (c) magnified displacement plot and (d) magnified force plot. The 0.7 A pulse was able to produce the highest temperature from the Joule heating, and a corresponding high displacement and force. The 0.3 A pulse had significantly lower displacement and force output.

Although variations in muscle length in the robotic hand are observed in Table 2, this does not significantly affect the muscle characteristics. Such slight deviations arise from the manufacturing process step of dividing the original 50 mm muscle in two to form muscles of 25 mm length each. However, due to the pre-tensioning method described in Section 3.3, the differences of ±2–3 mm are effectively negated by the much larger pretensioned length of 100 mm. Each muscle attempts to recover to its original length via the shape memory effect, but is limited to a maximum contraction of approximately 50 mm due to the geometry of the finger and placement of the muscles, and thus the variation is not noticeable in practice. This is also not reflected in the muscle characterization due to the bias spring limiting the displacement stroke to 10 mm maximum.

Temperature variations were observed between the first and later cycles (Figure 7). In the first 2 s heating interval, the muscle reached 41, 55 and 85 degrees Celsius (0.3, 0.5 and 0.7 A respectively) from the room temperature of 22 degrees Celsius. The muscle then cooled to slightly above room temperature (27, 31 and 35 degrees Celsius) during the 8 s cooling period. The maximum temperature was not reached until the later (usually second/third) cycles, peaking at 44, 71 and 99 degrees Celsius. However, it should be noted that the large variations in temperature with the 0.7 A pulse did not correspond with a significant change in force and displacement (Figure 7a), as the muscle produced a fairly consistent force (1.1 N) and displacement (10 mm). Additionally, since the maximum displacement is limited by the spring extension, it is not indicative of the usable recovery stroke of the pretensioned coiled SMA in the hand application. The magnified plots of the temperature, displacement and force of the first cycle are shown in Figure 7b–d illustrating the profiles of the curves corresponding to the electrical current magnitudes.

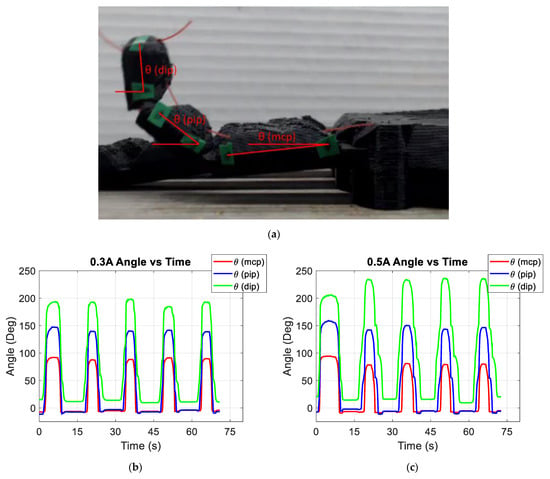

4.2. Preliminary Tests on a Single Finger

A single finger was first tested to observe the actuation of the muscles and flexibility of the TPU joints. Markers were placed on the side of the finger to indicate the start and end of each phalange, which were then used to calculate angular displacement from the horizontal plane, as shown in Figure 8a. Two current magnitudes, 0.3 and 0.5 A, were provided to the actuator on the fingers via the electrical circuitry, with a 5 s pulse to the flexor, and then a 10 s pulse to the extensor, which results in a period of 15 s. As shown in Figure 8b,c, the 0.5A pulse was able to generate higher angles, with a DIP angle (distal interphalangeal joint) of nearly 240 degrees, 50 degrees more than the 0.3 A pulse. In the preliminary tests 0.7 A was not utilized to avoid damaging the muscles due to the long constant heating times of 5 and 10 s. In both cases, the PIP (proximal interphalangeal joint) magnitude was almost the same and the MCP (metacarpophalangeal joint) had less magnitude at 0.5 A.

Figure 8.

Single finger testing: (a) diagram of θ (as measured from horizontal plane); (b) actuation angles for 0.3 A cycles and (c) angles for 0.5 A cycles. The heating cycle applied was 0.3/0.5 A to the flexor for 5 s, then the same amount to the extensor for 10 s. The period of actuation is thus 15 s.

4.3. Electrical Current Tests

After all the muscles (four muscles pair) were installed onto the hand and forearm, tests at different currents were conducted to observe effects on overall hand speed and actuation. The test current (0.4, 0.5 and 0.7 A) was applied to the flexor for 2 s, followed by a 1 s off period. The extensor was then powered by 0.5 A for 5 s, followed by a 5 s off period. This cycle was then repeated for 5 cycles. The heating cycle was changed from the preliminary tests (flexor heating for 2 s, extensor heating for 5 s) due to suboptimal usage of the resistive heating, as shown in the plateaued zero regions in Figure 8 where the finger is not moving. However, to compensate for the shorter flexor heating time, the lowest input current had to be raised to 0.4 A from 0.3 A for observable actuation. Safe and effective actuation is a combined effect of heating time and current magnitude, as long heating times at higher current will damage the muscles.

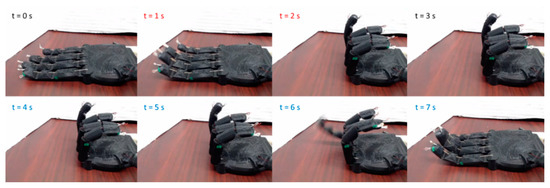

Figure 9 shows the general actuation process and is representative of a typical flexion and extension cycle of the entire hand. However, as shown in Supplementary Video S1, the 2 s 0.4 A pulse was not enough to bring the index and little fingers to close. The first cycle of the 0.5 A pulse was able to close, but then encountered the same issue with the index and little fingers afterwards. This is likely due to the fact that both the index and little fingers have increased friction on the tendons, as the tendons experience a slight change in direction in order to pass through the carpal tunnel. The actuators are placed in the forearm and connected to the fingers through tendons that bend at a sharper angle to the index and little fingers. Additionally, the little finger muscle was older than the remaining muscles, as it was used in the preliminary tests. Nevertheless, the 0.7 A pulse shown in Figure 9 demonstrates promising actuation given the short pulse time and high actuation response, although the fingers were not always able to open back up fully during the extensor heating period.

Figure 9.

Actuation of soft TPU hand at 0.7 A. Black indicates all muscles off. Red indicates flexor on, extensor off. Blue indicates extensor on, flexor off.

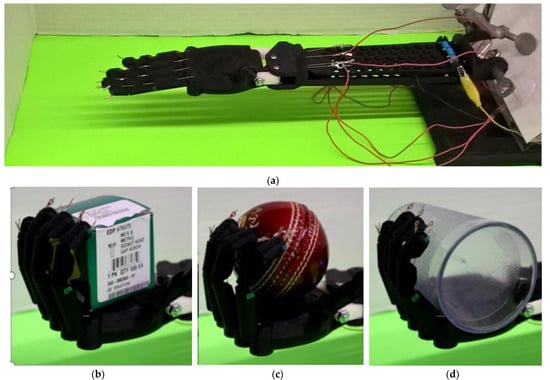

4.4. Horizontal Grasping Tests

To test the capability of the hand in conforming to different shapes, the hand was mounted horizontally (Figure 10a) on a test stand and different shapes were placed into the palm. The heating cycle used was 0.5 A to the flexor for 4 s, followed by a 0.2 A pulse to the flexor for another 5 s (to maintain the heat within the muscle), and then a 1 s off period. A 7 s 0.5 A was then applied to the extensor to extend the fingers. As shown in Figure 10b–d, the hand was able to conform to the shape of a sphere (73 mm diameter, 160 g), box (56 mm, 85 g) and cup (70 mm, 12 g). These objects were taken from the standard action research arm test (ARAT) kit. Upon opening its grasp, the sphere and cup rolled out of the hand, demonstrating a firm grasp. Due to the non-cyclic nature of the grasping tests, the index and little fingers did not encounter any of the flexion issues observed from the cyclic current tests. See Supplementary Video S2.

Figure 10.

Horizontal grasping of objects from the ARAT kit and others: (a) experimental setup; (b) box; (c) ball and (d) cup. In horizontal grasping tests, mass is irrelevant as the palm bears the weight. The fingers prevent the object from rolling out of its grasp (see accompanying videos). The heating cycle used was 0.5 A (flexors) for 4 s (to flex the fingers), followed by 0.2 A (flexors) for 5 s (holding), 1 s off and then 0.5 A (extensors) for 7 s (to extend the fingers).

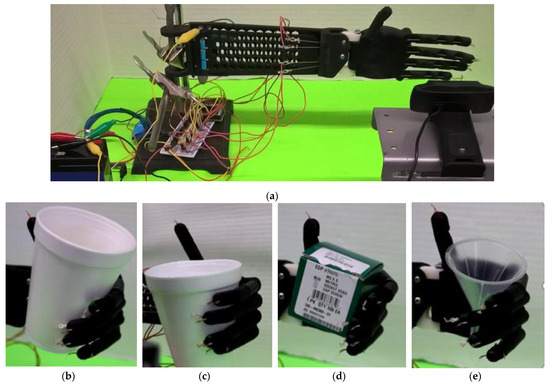

4.5. Vertical Grasping and Mass Tests

The hand was then reoriented and mounted vertically (Figure 11a), and objects were placed facing the palm to test how much mass the hand could carry. The heating cycle was the same as the horizontal grasping tests. Different shapes such as a cup, box and funnel were tested, as illustrated in Figure 11b–e. The weight capacity was tested by placing a cup filled with water into the hand’s grasp. The water in the cup was increased at 5 g intervals, until the failure criteria of dropping the cup was met. The hand was able to hold a maximum weight of 133 g (a 3 g cup filled with 130 g of water). See Supplementary Video S3. Such tests are essential because one of the purposes of robotic hands is for handling daily used objects.

Figure 11.

Vertical grasping of objects: (a) experimental setup; (b) empty cup, 3 g; (c) cup with water, 133 g; (d) box, 12.67 g and (e) funnel, 7.3 g. Since the thumb is not in use, the gripping force is generated purely from the main fingers. As shown in (c), the thumb is not assisting the grip. It should also be noted that the increased weight from the water causes the cup to sink in the hand’s grip. Heating cycle remained the same as the horizontal grasping, with 0.7 A (flexors) for 2 s (to flex the fingers, followed by 0.2 A (flexors) for 10 s (holding) and then 0.5 A (extensors) for 8 s (to extend the fingers).

4.6. Frequency Tests

Differing actuation cycles were also applied to increase the frequency of actuation of the hand. Three tests, 8, 10 and 12 s cycles (0.125, 0.100 and 0.083 Hz, respectively), were run with the following heating methods. A current of 0.5 A was provided to the flexor for 2 s, followed by a 1 s off period. Then, the extensor was powered by 0.5 A for 4, 5 and 6 s, followed by a 1, 2 and 3 s off period, respectively. As shown in Supplementary Video S4, all of the cycles demonstrated good initial actuation on the first iteration; however, later iterations of the 8 and 10 s cycle showed issues with actuation of the index and little fingers. Again, due to the reasons outlined earlier in Section 4.3, the little finger had less angular displacement than the other fingers and in some cases did not move.

While the maximum frequency of 0.125 Hz is less than the maximum flexion frequency of 2 Hz for a human hand [55], cyclic actuation speed can be increased by implementing active cooling methods. As shown by Park et al. 2019, water-quenched coiled SMAs were able to reach frequencies up to 1.67 Hz while still maintaining significant force output [47]. However, to maintain the low material cost and lightweight properties and other characteristics as defined at the beginning of this paper, such cooling systems were not implemented. This can be a future research goal to investigate and implement such additions.

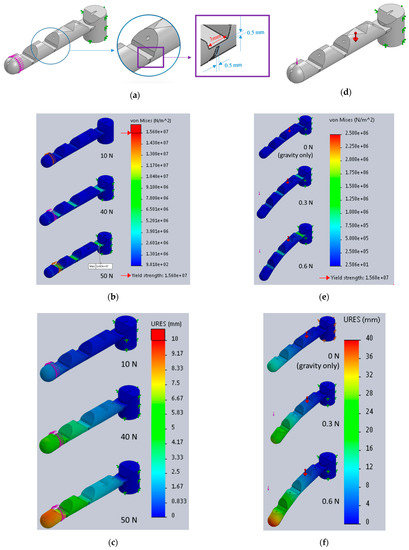

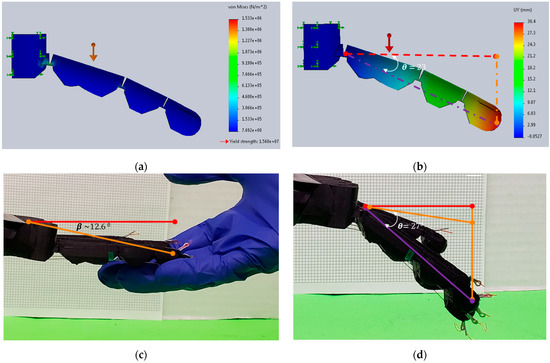

4.7. Structural Analysis

Since the finger is entirely made with TPU material with a very thin cross-section joint, we performed structural analysis by applying an axial force at the fingertip and fixing it at the “knuckle” (the vertical cylinder). Axial tension force with different magnitude 10, 40 and 50 N were then applied to the fingertip. While 10 N is the desired operating regime for most purposes, the finger is still capable of withstanding a 40 N load with a safety factor of 1.24. However, the 50 N load causes yielding on the underside of the joint. Figure 12a–c show the boundary and loading conditions and the stress and deflection results corresponding to applied axial forces.

Figure 12.

Static stress simulation for axial (a–c) and perpendicular (d–f) loading: (a,d) loading and boundary conditions of finger, (b,e) resultant stress and (c,f) resultant displacement.

A perpendicular loading simulation was also performed, shown in Figure 12d–f. Gravity was applied to the finger, and a small additional point load at the finger tip of 0, 0.3 and 0.6 N. While large displacement is observed due to the cantilever loading, this is not a typical loading condition of the hand when in use, as loads are usually applied to the palm. However, low stresses are observed, and using linear extrapolation, we can assume that the finger can likely sustain higher loads without yielding. Another configuration against gravity was also tested on one finger while the finger is placed downward without pretensioning as shown in Figure 13. In this case, we can see in both experimental and simulation results, the finger bends comparable magnitude of displacement 30 mm due to gravity (bending angle of 23° for simulation and 27° experimental). The large deflection is usually compensated by the agonist and antagonist configuration of actuation when it is used in the robotic hand.

Figure 13.

Simulation and experiment of the index finger bending due to gravity, without tendons and actuators, and upside down configuration: (a) stress due to gravity load; (b) displacement due to gravity; (c) supporting the hand with gravity towards downward and (d) bending of the finger due to gravity.

5. Conclusions and Summary

As shown in the experimental results and accompanying videos, the TPU hand is capable of carrying significant amounts of weight (up to 130 g) with relatively fast response flexion times. The hand is also lightweight, with a total mass of 235 g including the forearm and 656 g when the battery is added. It also touts higher frequency of actuation, with 12 s actuation cycles demonstrating decent actuation. While shape memory alloys are generally considered to be inefficient, with a thermal efficiency of 1–2%, the muscles used in the hand are very small (20–25 mm contracted length) and only have an overall power draw of around 2 W. However, such limitations are countered by the benefits of the muscle being incredibly lightweight and having very high power density, with the demonstrated 0.343 g muscle outputting 1.1 N of force, or approximately 112 g of force (300 times its own weight). The 3D-printed hand presented in this paper, actuated by our custom-made coiled SMA actuators, has potential for applications in robotic and prosthetic hands featuring low-noise and compact design. The summary of the robotic hand characteristics is shown in Table 4.

Table 4.

Summary of the robotic hand characteristics.

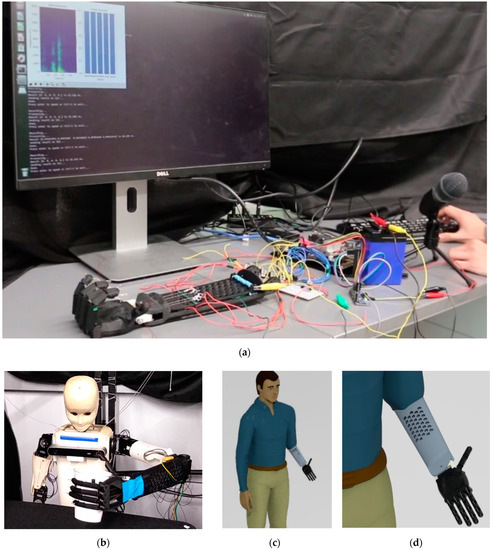

6. Future Work

The presented artificial hand has been used in corresponding research developments in the HBS laboratory, including end-to-end speech control interface as shown in Figure 14a [56] and the social robot named HBS-2 (Figure 14b). Further work would include modifying the forearm and adapting it for prosthetic purposes as shown in Figure 14c,d. In such an application, the circuitry can be reduced by utilizing a printed circuit board (PCB) in tandem with smaller lithium ion batteries that can be housed within the forearm to make the hand more compact. In addition to implementing sensors and a feedback control system by changing parameters in electrical current and heating time via the microcontroller, the prosthetic adaptation could use electromyography (EMG) signals and sensory feedback to allow amputees to better control actuation of the fingers.

Figure 14.

Future work concepts use in conjunction with: (a) speech control interface, (b) social robot, (c) prosthetic application and (d) enlarged view showing similar sizing of the current design to the adult hand.

Some mechanical improvements can be made to the TPU hand to include thumb abduction and adduction, and reworking the carpal tunnel to decrease friction between the tendons. Smaller diameter coiled shape memory alloys or utilizing the SMA bundles presented by Park et al. [47] could be used to increase force output of the muscles and further increase actuation displacement. Active cooling techniques such as water cooling or fans can also be implemented to increase actuation frequency [32]. Such future developments will allow for even further performance enhancements in artificial hand strength and speed.

Supplementary Materials

Video S1 Cyclic Actuation of Hand at Various Electrical Currents. All of the finger flexors are actuated at the electrical currents of 0.4 A (increased from 0.3 A because the predetermined 2 s heating time was insufficient for such low currents), 0.5 and 0.7 A. The heating cycle used was 2 s at 0.4, 0.5 and 0.7 A to the flexor, 1 s off, then 0.5 A to the extensor for 5 s. This was repeated for 5 cycles. The video is also available in the following HBS lab YouTube link: https://youtu.be/_2xYi5oBvkk. Video S2 Grasping of Different Shaped Objects. The hand is shown grasping different shaped objects such as a spherical ball, rectangular box, and cylindrical cups in both horizontal and vertical positions. The actuation of the hand mostly conforms to the shapes of these objects. The video is also available in the following HBS lab YouTube link: https://youtu.be/Wqm0hpa_8P8. Video S3 Vertical Grasping of Objects at Different Masses. A cup of varying amounts of water was held by the hand without assistance of the thumb. The total masses were 8, 53, 103 and 133 g. Although the higher weights slid lower in the hand’s grasp, they were still firmly held up to 103 g. The video is also available in the following HBS lab YouTube link: https://youtu.be/PSyabmWQReA. Video S4 Cyclic Actuation of Hand at Different Frequencies. Different heating cycles were used to attempt to achieve 8, 10 and 12 s actuation cycles (0.125, 0.100 and 0.083 Hz, respectively). All the fingers responded to the 10 and 12 s cycles, with exception to little finger issues, as described in the main text. The 8-s cycles started seeing issues with full flexion of all the fingers, as the extensors did not receive sufficient time to cool and thus provide additional resistance against the flexors. The video is also available in the following HBS lab YouTube link: https://youtu.be/CLl_NhxdmV8.

Author Contributions

E.D. designed the robotic hand, manufactured and characterized the SMA actuators, as well as integrated the actuators in the robotic hand and tested them. E.D. also performed simulation and drafted the paper. Y.T. directed the research, contributed to the technical writing and editing of the manuscript. All authors have read and agreed to the published version of the manuscript.

Funding

This research was partially supported by Internal fund from Research Enhancement.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data is contained within the article as figures or supplementary video materials.

Conflicts of Interest

The authors declare no conflict of interest.

Appendix A. Code

import pyb

# import _thread

#define timers for the pins

timer2 = pyb.Timer(2, freq = 1000)

timer8 = pyb.Timer(8, freq = 1000)

timer4 = pyb.Timer(4, freq = 1000)

#assign channels to timers

indexFlexor = timer2.channel(1, pyb.Timer.PWM, pin = pyb.Pin.board.X1, pulse_width_percent = 0)

indexExtensor = timer2.channel(2, pyb.Timer.PWM, pin = pyb.Pin.board.X2, pulse_width_percent = 0)

middleFlexor = timer2.channel(3, pyb.Timer.PWM, pin = pyb.Pin.board.X3, pulse_width_percent = 0)

middleExtensor = timer2.channel(4, pyb.Timer.PWM, pin = pyb.Pin.board.X4, pulse_width_percent = 0)

ringFlexor = timer8.channel(1, pyb.Timer.PWM, pin = pyb.Pin.board.Y1, pulse_width_percent = 0)

ringExtensor = timer8.channel(2, pyb.Timer.PWM, pin = pyb.Pin.board.Y2, pulse_width_percent = 0)

pinkyFlexor = timer4.channel(1, pyb.Timer.PWM, pin = pyb.Pin.board.X9, pulse_width_percent = 0)

pinkyExtensor = timer4.channel(2, pyb.Timer.PWM, pin = pyb.Pin.board.X10, pulse_width_percent = 0)

thumbFlexor = timer4.channel(3, pyb.Timer.PWM, pin = pyb.Pin.board.Y3, pulse_width_percent = 0)

thumbExtensor = timer4.channel(4, pyb.Timer.PWM, pin = pyb.Pin.board.Y4, pulse_width_percent = 0)

#define Finger object

class Finger:

staticLEDNum = 0

def __init__(self, flexorChannel, extensorChannel, flexorPWM, extensorPWM):

self.flexorChannel = flexorChannel

self.extensorChannel = extensorChannel

self.flexorPWM = flexorPWM

self.extensorPWM = extensorPWM

Finger.staticLEDNum = (Finger.staticLEDNum % 4) + 1

self.LEDNum = Finger.staticLEDNum

print(self.LEDNum)

#blocks until finished

def actuate(self, timeOn, timeOff):

print(self.LEDNum)

self.flexion()

pyb.LED(self.LEDNum).on()

pyb.delay(timeOn * 1000)

self.extension()

pyb.LED(self.LEDNum).off()

pyb.delay(timeOff * 1000)

self.off()

#for “threading”

def flexion(self):

self.extensorChannel.pulse_width_percent(0)

self.flexorChannel.pulse_width_percent(self.flexorPWM)

def extension(self):

self.flexorChannel.pulse_width_percent(0)

self.extensorChannel.pulse_width_percent(self.extensorPWM)

def off(self):

self.flexorChannel.pulse_width_percent(0)

self.extensorChannel.pulse_width_percent(0)

indexFinger = Finger(indexFlexor, indexExtensor, 60.61, 60.61)

middleFinger = Finger(middleFlexor, middleExtensor, 66.67, 56.06)

ringFinger = Finger(ringFlexor, ringExtensor, 62.12, 54.54)

pinkyFinger = Finger(pinkyFlexor, pinkyExtensor, 62.12, 62.12)

thumb = Finger(thumbFlexor, thumbExtensor, 0, 0)

#Single finger actuation

for i in range(5):

indexFinger.actuate(5, 10)

#Full hand flexion/extension

fingers = [indexFinger, middleFinger, ringFinger, pinkyFinger]

for i in range(5):

for finger in fingers:

finger.flexion()

pyb.delay(2000)

for finger in fingers:

finger.off()

pyb.delay(1000)

for finger in fingers:

finger.extension()

pyb.delay(5000)

for finger in fingers:

finger.off()

pyb.delay(1000)

References

- Piazza, C.; Grioli, G.; Catalano, M.G.; Bicchi, A. A century of robotic hands. Annu. Rev. Control Robot. Auton. Syst. 2019, 2, 1–32. [Google Scholar] [CrossRef]

- Huston, R. Principles of Biomechanics; CRC Press: Boca Raton, FL, USA, 2009. [Google Scholar]

- Schulz, S.; Pylatiuk, C.; Bretthauer, G. A new ultralight anthropomorphic hand. In Proceedings of the 2001 ICRA, IEEE International Conference on Robotics and Automation (Cat. No. 01CH37164), Seoul, Korea, 21–26 May 2001. [Google Scholar]

- Belter, J.T.; Segil, J.L.; Dollar, A.M.; Weir, R.F. Mechanical design and performance specifications of anthropomorphic prosthetic hands: A review. J. Rehabil. Res. Dev. 2013, 50, 599–618. [Google Scholar] [CrossRef] [PubMed]

- Lanigan, D.; Tadesse, Y. Low cost robotic hand that senses heat and pressure. In Proceedings of the 2017 ASEE Gulf-Southwest Section Annual Conference, Richardson, TX, USA, 25–28 June 2017. [Google Scholar]

- Wu, L.; Tadesse, Y. Humanoid robot hand with sma actuators and servo motors. In ASME International Mechanical Engineering Congress and Exposition; American Society of Mechanical Engineers: Montreal, QC, Canada, 2014. [Google Scholar]

- Wu, L.; Jung de Andrade, M.; Saharan, L.K.; Rome, R.S.; Baughman, R.H.; Tadesse, Y. Compact and low-cost humanoid hand powered by nylon artificial muscles. Bioinspir. Biomim. 2017, 12, 026004. [Google Scholar] [CrossRef] [PubMed]

- Wu, L.; Larkin, M.; Potnuru, A.; Tadesse, Y. HBS-1: A modular child-size 3D printed humanoid. Robotics 2016, 5, 1. [Google Scholar] [CrossRef]

- Wu, L.; Jung de Andrade, M.; Rome, R.S.; Haines, C.; Lima, M.D.; Baughman, R.H.; Tadesse, Y. Nylon-muscle-actuated robotic finger. In Active and Passive Smart Structures and Integrated Systems 2015; International Society for Optics and Photonics: Bellingham, WA, USA, 2015. [Google Scholar]

- Salisbury, J.K.; Craig, J.J. Articulated hands force control and kinematic issues. Int. J. Robot. Res. 1982, 1, 4–17. [Google Scholar] [CrossRef]

- Guo, G.; Gruver, W.A.; Qian, X. A robotic hand mechanism with rotating fingertips and motor-tendon actuation. In Proceedings of the 1991 IEEE International Conference on Systems, Man, and Cybernetics: Decision Aiding for Complex Systems, Charlottesville, VA, USA, 13–16 October 1991. [Google Scholar]

- Kurita, Y.; Ono, Y.; Ikeda, A.; Ogasawara, T. Human-sized anthropomorphic robot hand with detachable mechanism at the wrist. Mech. Mach. Theory 2011, 46, 53–66. [Google Scholar] [CrossRef]

- Jang, G.; Lee, C.; Lee, H.; Choi, Y. Robotic index finger prosthesis using stackable double 4-BAR mechanisms. Mechatronics 2013, 23, 318–325. [Google Scholar] [CrossRef]

- Thayer, N.; Priya, S. Design and implementation of a dexterous anthropomorphic robotic typing (DART) hand. Smart Mater. Struct. 2011, 20, 035010. [Google Scholar] [CrossRef]

- George, J.A.; Kluger, D.T.; Davis, T.S.; Wendelken, S.M.; Okorokova, E.V.; He, Q.; Duncan, C.C.; Hutchinson, D.T.; Thumser, Z.C.; Beckler, D.T.; et al. Biomimetic sensory feedback through peripheral nerve stimulation improves dexterous use of a bionic hand. Sci. Robot. 2019, 4, eaax2352. [Google Scholar] [CrossRef]

- Calado, A.; Soares, F.; Matos, D. A review on commercially available anthropomorphic myoelectric prosthetic hands, pattern-recognition-based microcontrollers and sEMG sensors used for prosthetic control. In Proceedings of the 2019 IEEE International Conference on Autonomous Robot Systems and Competitions (ICARSC), Porto, Portugal, 24–26 April 2019. [Google Scholar]

- Ueda, J.; Kondo, M.; Ogasawara, T. The multifingered NAIST hand system for robot in-hand manipulation. Mech. Mach. Theory 2010, 45, 224–238. [Google Scholar] [CrossRef]

- Lotti, F.; Tiezzi, P.; Vassura, G.; Biagiotti, L.; Palli, G.; Melchiorri, C. Development of UB hand 3: Early results. In Proceedings of the 2005 IEEE International Conference on Robotics and Automation, Barcelona, Spain, 18–22 April 2005. [Google Scholar]

- Diftler, M.; Ambrose, R.O. Robonaut: A robotic astronaut assistant. In Proceedings of the 6th International Symposium on Artificial Intelligence and Robotics & Automation in Space: i-SAIRAS 2001, Montreal, QC, Canada, 18–22, June, 2001. [Google Scholar]

- Kargov, A.; Werner, T.; Pylatiuk, C.; Schulz, S. Development of a miniaturised hydraulic actuation system for artificial hands. Sens. Actuators A Phys. 2008, 141, 548–557. [Google Scholar] [CrossRef]

- Pylatiuk, C.; Mounier, S.; Kargov, A.; Schulz, S.; Brethauer, G. Progress in the development of a multifunctional hand prosthesis. In Proceedings of the 26th Annual International Conference of the IEEE Engineering in Medicine and Biology Society, San Francisco, CA, USA, 1–5 September 2004. [Google Scholar]

- Jacobsen, S.C.; Wood, J.E.; Knutti, D.F.; Biggers, K.B. The UTAH/MIT dextrous hand: Work in progress. Int. J. Robot. Res. 1984, 3, 21–50. [Google Scholar] [CrossRef]

- Pons, J.; Ceres, R.; Pfeiffer, F. Multifingered dextrous robotics hand design and control: A review. Robotica 1999, 17, 661–674. [Google Scholar] [CrossRef]

- Bicchi, A.; Kumar, V. Robotic grasping and contact: A review. In Proceedings of the 2000 ICRA, Millennium Conference, IEEE International Conference on Robotics and Automation, Symposia Proceedings (Cat. No. 00CH37065), San Francisco, CA, USA, 24–28 April 2000. [Google Scholar]

- Martell, J.S.; Gini, G. Robotic hands: Design review and proposal of new design process. World Acad. Sci. Eng. Technol. 2007, 26, 85–90. [Google Scholar]

- Simone, F.; York, A.; Seelecke, S. Design and fabrication of a three-finger prosthetic hand using SMA muscle wires. In Proceedings of the Bioinspiration, Biomimetics, and Bioreplication 2015, San Diego, CA, USA, 9–11 March 2015; International Society for Optics and Photonics (SPIE): Bellingham, WA, USA, 2015. [Google Scholar]

- Tadesse, Y.; Hong, D.; Priya, S. Twelve degree of freedom baby humanoid head using shape memory alloy actuators. J. Mech. Robot. 2011, 3, 011008. [Google Scholar] [CrossRef]

- Cianchetti, M.; Licofonte, A.; Follador, M.; Rogai, F.; Laschi, C. Bioinspired soft actuation system using shape memory alloys. Actuators 2014, 3, 226–244. [Google Scholar] [CrossRef]

- Ameduri, S.; Brindisi, A.; Ciminello, M.; Concillio, A.; Quaranta, V.; Brandizzi, M. Car Soundproof Improvement through an SMA Adaptive System. Actuators 2018, 7, 88. [Google Scholar] [CrossRef]

- Sinn, T.; Barrett, R. Design, Manufacturing and Test of a High Lift Secondary Flight Control Surface with Shape Memory Alloy Post-Buckled Precompressed Actuators. Actuators 2015, 4, 156–171. [Google Scholar] [CrossRef]

- Boyraz, P.; Runge, G.; Raatz, A. An overview of novel actuators for soft robotics. Actuators 2018, 7, 48. [Google Scholar] [CrossRef]

- Tadesse, Y.; Thayer, N.; Priya, S. Tailoring the response time of shape memory alloy wires through active cooling and pre-stress. J. Intell. Mater. Syst. Struct. 2010, 21, 19–40. [Google Scholar] [CrossRef]

- Engeberg, E.D.; Dilibal, S.; Vatani, M.; Choi, J.-W.; Lavery, J. Anthropomorphic finger antagonistically actuated by SMA plates. Bioinspir. Biomim. 2015, 10, 056002. [Google Scholar] [CrossRef] [PubMed]

- She, Y.; Li, C.; Su, H.-J. Design and fabrication of a soft robotic hand with embedded actuators and sensors. J. Mech. Robot. 2015, 7. [Google Scholar] [CrossRef]

- De Laurentis, K.J.; Mavroidis, C. Mechanical design of a shape memory alloy actuated prosthetic hand. Technol. Health Care 2002, 10, 91–106. [Google Scholar] [CrossRef]

- Dilibal, S.; Guner, E.; Akturk, N. Three-finger SMA robot hand and its practical analysis. Robotica 2002, 20, 175. [Google Scholar] [CrossRef]

- Price, A.; Jnifene, A.; Naguib, H. Design and control of a shape memory alloy based dexterous robot hand. Smart Mater. Struct. 2007, 16, 1401. [Google Scholar] [CrossRef]

- Garg, K. BD Chaurasia’s Human Anatomy–Regional and Applied Dissection and Clinical: Volume 1 Upper Limb and Thorax; CBS Publishers and Distributors: New Delhi, India, 2004. [Google Scholar]

- Liu, H.; Yang, D.; Jiang, L.; Fan, S. Development of a multi-DOF prosthetic hand with intrinsic actuation, intuitive control and sensory feedback. Ind. Robot 2014, 41, 381–392. [Google Scholar] [CrossRef]

- Xu, Z.; Todorov, E. Design of a highly biomimetic anthropomorphic robotic hand towards artificial limb regeneration. In Proceedings of the 2016 IEEE International Conference on Robotics and Automation (ICRA)., Stockholm, Sweden, 16–21 May 2016. [Google Scholar]

- Della Santina, C.; Piazza, C.; Grioli, G.; Catalano, M.G.; Bicchi, A. Toward dexterous manipulation with augmented adaptive synergies: The Pisa/IIT SoftHand 2. IEEE Trans. Robot. 2018, 5, 1141–1156. [Google Scholar] [CrossRef]

- Tavakoli, M.; Batista, R.; Sgrigna, L. The UC softhand: Light weight adaptive bionic hand with a compact twisted string actuation system. Actuators 2016, 5, 1. [Google Scholar] [CrossRef]

- Simone, F.; Rizzello, G.; Motzki, P.; Seelecke, S. A soft five-fingered hand actuated by Shape Memory Alloy wires: design, manufacturing, and evaluation. Front. Robot. AI 2020, 7, 608841. [Google Scholar] [CrossRef]

- Farias, V.; Solis, L.; Melendez, L.; Garcia, C.; Velázquez, R. A four-fingered robot hand with shape memory alloys. In Proceedings of the AFRICON 2009, Nairobi, Kenya, 23–25 September 2009. [Google Scholar]

- Bergamasco, M.; Salsedo, F.; Dario, P. Shape memory alloy micromotors for direct-drive actuation of dexterous artificial hands. Sens. Actuators 1989, 17, 115–119. [Google Scholar] [CrossRef]

- Taniguchi, H.; Hashimoto, A.; Izuhara, S. Design of a Functional Prosthetic Hand for Children using Novel Shape Memory Alloy Actuators. Int. J. Innov. Eng. Technol. 2014, 57–63. [Google Scholar]

- Park, C.H.; Choi, K.J.; Son, Y.S. Shape memory alloy-based spring bundle actuator controlled by water temperature. IEEE/ASME Trans. Mechatron. 2019, 24, 1798–1807. [Google Scholar] [CrossRef]

- Hamidi, A.; Almubak, Y.; Rupawat, Y.M.; Warren, J.; Tadesse, Y. Poly-Saora robotic jellyfish: Swimming underwater by twisted and coiled polymer actuators. Smart Mater. Struct. 2020, 29, 045039. [Google Scholar] [CrossRef]

- Bergamasco, M.; Salsedo, F.; Dario, P. A linear SMA motor as direct-drive robotic actuator. In Proceedings of the 1989 International Conference on Robotics and Automation, Scottsdale, AZ, USA, 14–19 May 1989. [Google Scholar]

- Wu, L.; Karami, F.; Hamidi, A.; Tadesse, Y. Biorobotic systems design and development using TCP muscles. In Proceedings of the Electroactive Polymer Actuators and Devices (EAPAD) XX, Denver, CO, USA, 5–8 March 2018; International Society for Optics and Photonics (SPIE): Bellingham, WA, USA, 2018. [Google Scholar]

- Stratasys. FDM TPU 92A: Flexible Elastomer TPU 3D Printing Material. Available online: https://www.stratasys.com/materials/search/fdm-tpu-92a (accessed on 2 October 2020).

- Leonardis, D.; Frisoli, A. CORA hand: A 3D printed robotic hand designed for robustness and compliance. Meccanica 2020, 55, 1–16. [Google Scholar] [CrossRef]

- Potnuru, A.; Tadesse, Y. Characterization of coiled SMA actuators for humanoid robot. In Proceedings of the Active and Passive Smart Structures and Integrated Systems, Portland, OR, USA, 25–29 March 2017; International Society for Optics and Photonics (SPIE): Bellingham, WA, USA, 2017. [Google Scholar]

- Dynalloy, I. Flexinol® Actuator Wire Technical and Design Data. 2017. Available online: https://www.dynalloy.com/tech_data_wire.php (accessed on 24 November 2020).

- Häger-Ross, C.; Schieber, M.H. Quantifying the independence of human finger movements: Comparisons of digits, hands, and movement frequencies. J. Neurosci. 2000, 20, 8542–8550. [Google Scholar] [CrossRef] [PubMed]

- Jafarzadeh, M.; Tadesse, Y. End-to-End Learning of Speech 2D Feature-Trajectory for Prosthetic Hands. In Proceedings of the 2020 IEEE Second International Conference on Transdisciplinary AI (TransAI), Irvine, CA, USA, 21–23 September 2020. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).