Is Labor a Suitable Input in LCA + DEA Studies? Insights on the Combined Use of Economic, Environmental and Social Parameters

Abstract

:1. Introduction

2. Material and Methods

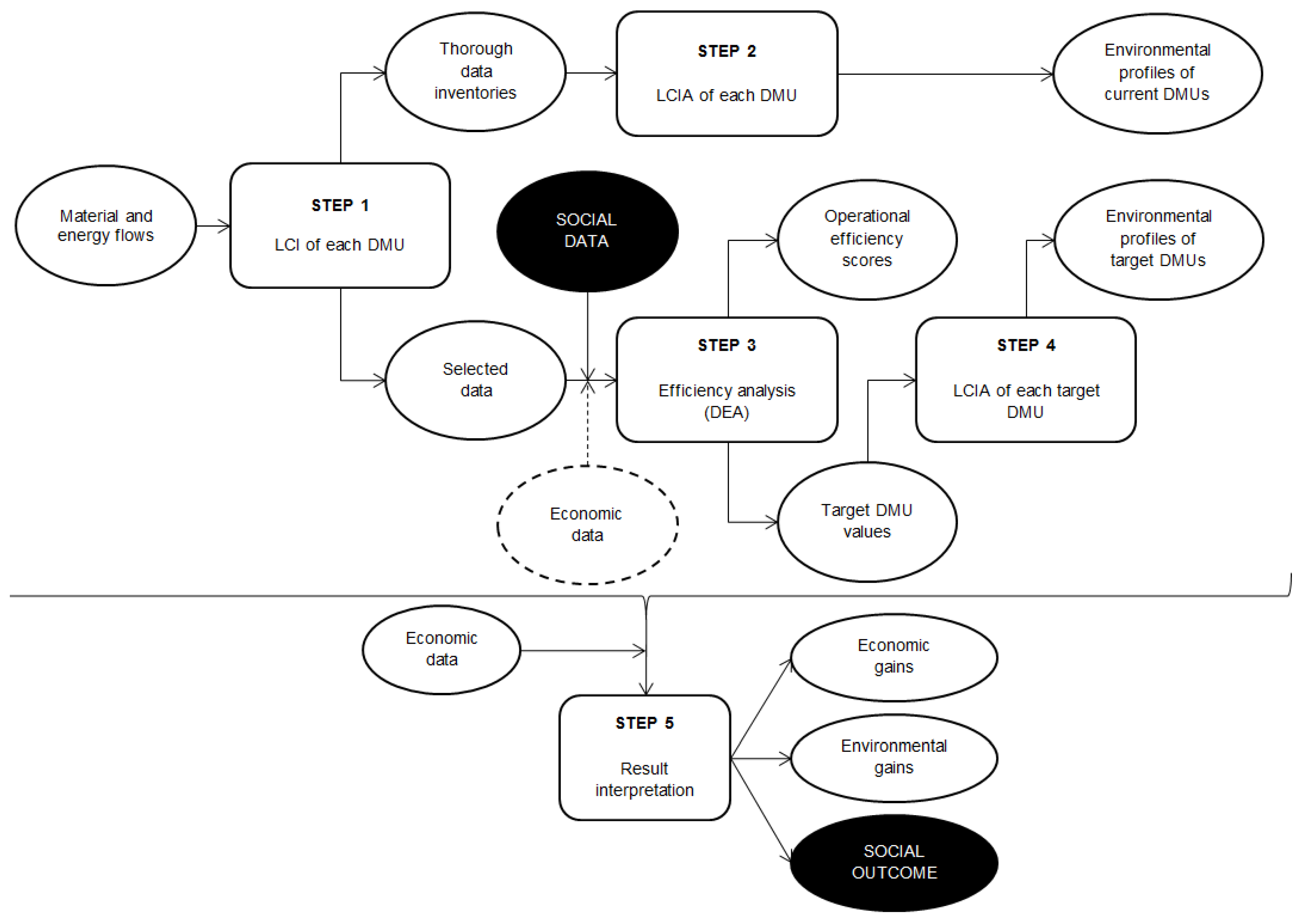

2.1. The Five-Step LCA + DEA Method

2.2. Selection of Inputs and Outputs

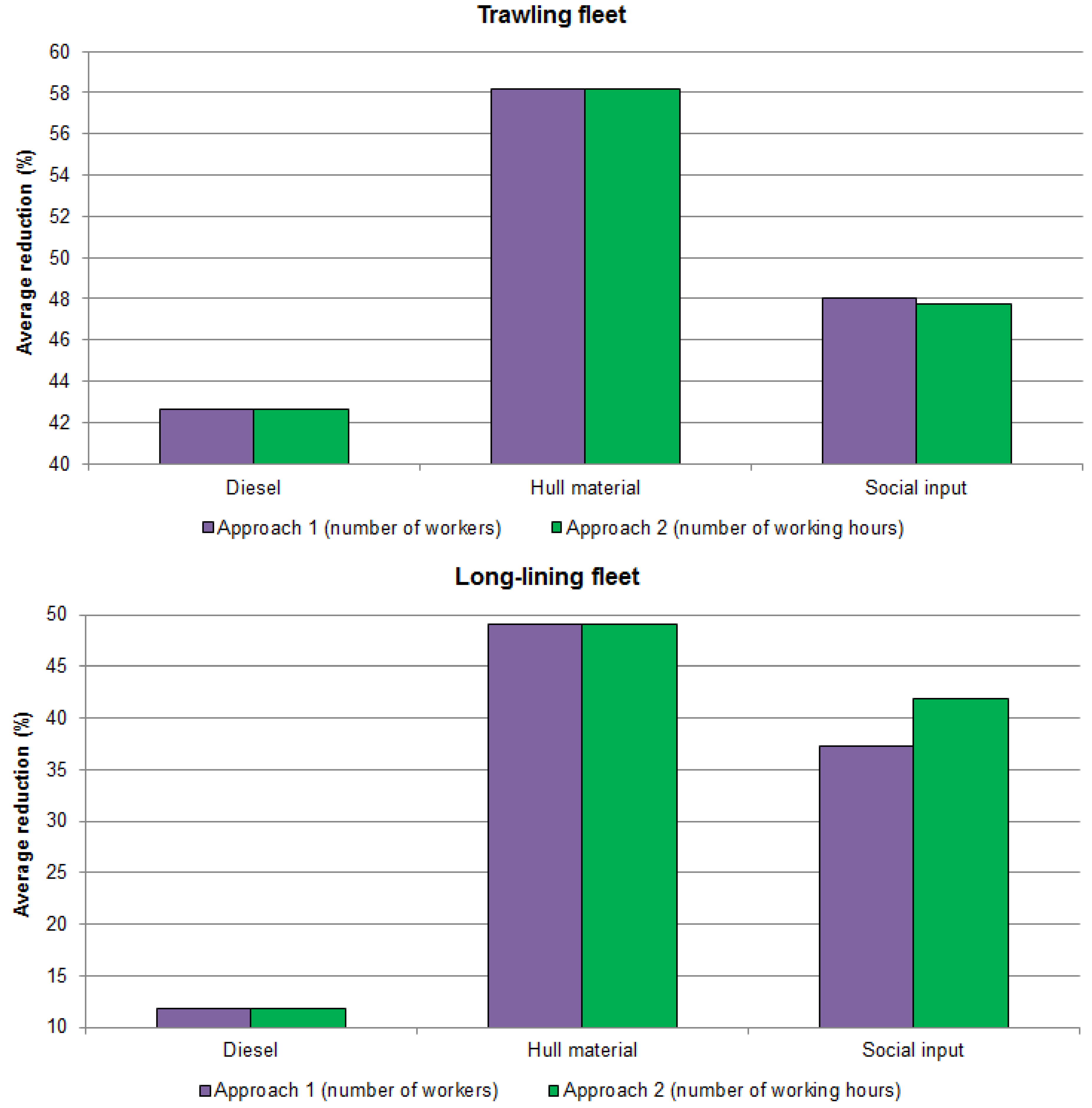

3. Implementation of Labor into LCA + DEA Studies

| DMU | Input 1 | Input 2 | Input 3 | Alternative Input 3 | Output |

|---|---|---|---|---|---|

| Diesel (kg/year) | Hull material (kg/year) | Crew size (units) | Working hours(h/year) | Catch value (€/year) | |

| Trawling fishing fleet | |||||

| Vessel T-1 | 404,000 | 3,933 | 8 | 21,120 | 443,996 |

| Vessel T-2 | 404,000 | 3,074 | 9 | 25,920 | 718,655 |

| Vessel T-3 | 404,000 | 2,416 | 9 | 25,920 | 718,655 |

| Vessel T-4 | 440,000 | 4,333 | 10 | 26,400 | 917,952 |

| Vessel T-5 | 480,000 | 4,333 | 10 | 26,400 | 917,952 |

| Vessel T-6 | 404,000 | 4,840 | 10 | 24,240 | 796,224 |

| Vessel T-7 | 350,000 | 4,707 | 10 | 28,800 | 1,214,898 |

| Vessel T-8 | 347,000 | 3,330 | 10 | 28,800 | 1,214,898 |

| Vessel T-9 | 404,000 | 3,032 | 10 | 26,400 | 521,226 |

| Vessel T-10 | 404,000 | 3,712 | 10 | 26,400 | 521,226 |

| Vessel T-11 | 330,000 | 2,781 | 8 | 21,120 | 1,005,718 |

| Vessel T-12 | 355,000 | 2,390 | 8 | 21,120 | 1,005,718 |

| Vessel T-13 | 292,900 | 3,257 | 7 | 18,480 | 1,326,989 |

| Vessel T-14 | 305,000 | 1,827 | 7 | 18,480 | 1,326,989 |

| Vessel T-15 | 383,800 | 2,222 | 12 | 31,680 | 1,353,235 |

| Vessel T-16 | 242,400 | 3,234 | 7 | 16,968 | 575,377 |

| Vessel T-17 | 250,400 | 3,773 | 7 | 16,968 | 575,377 |

| Vessel T-18 | 303,000 | 3,029 | 8 | 19,392 | 660,298 |

| Vessel T-19 | 378,375 | 2,809 | 10 | 24,240 | 928,290 |

| Vessel T-20 | 242,400 | 3,029 | 9 | 21,816 | 565,931 |

| Long-lining fishing fleet | |||||

| Vessel L-1 | 680,000 | 3,138 | 16 | 36,000 | 1,633,578 |

| Vessel L-2 | 654,000 | 3,450 | 16 | 36,000 | 1,583,310 |

| Vessel L-3 | 952,000 | 6,320 | 16 | 48,000 | 945,792 |

| Vessel L-4 | 349,550 | 4,067 | 15 | 42,000 | 472,936 |

| Vessel L-5 | 315,000 | 3,983 | 14 | 40,600 | 726,600 |

| Vessel L-6 | 300,000 | 4,240 | 15 | 33,750 | 691,900 |

| Vessel L-7 | 340,000 | 4,182 | 16 | 36,800 | 690,700 |

| Vessel L-8 | 325,000 | 2,829 | 15 | 36,750 | 792,410 |

| Vessel L-9 | 320,000 | 2,954 | 14 | 35,700 | 643,910 |

| Vessel L-10 | 258,400 | 5,000 | 16 | 43,200 | 771,328 |

| Vessel L-11 | 163,200 | 2,819 | 16 | 43,200 | 732,448 |

| Vessel L-12 | 353,600 | 5,067 | 15 | 40,500 | 849,152 |

| DMU | Efficiency score (%) | Target 1 | Target 2 | Target 3 |

|---|---|---|---|---|

| Diesel (kg/year) | Hull material (kg/year) | Crew size (units) | ||

| Trawling fishing fleet | ||||

| Vessel T-1 | 23.36 | 102,050 | 611 | 2 |

| Vessel T-2 | 38.40 | 165,178 | 989 | 4 |

| Vessel T-3 | 41.32 | 165,178 | 989 | 4 |

| Vessel T-4 | 41.84 | 210,985 | 1,264 | 5 |

| Vessel T-5 | 40.51 | 210,985 | 1,264 | 5 |

| Vessel T-6 | 36.65 | 183,007 | 1,096 | 4 |

| Vessel T-7 | 59.80 | 279,237 | 1,672 | 6 |

| Vessel T-8 | 64.93 | 279,237 | 1,672 | 6 |

| Vessel T-9 | 26.94 | 119,800 | 717 | 3 |

| Vessel T-10 | 25.49 | 119,800 | 717 | 3 |

| Vessel T-11 | 62.05 | 231,158 | 1,384 | 5 |

| Vessel T-12 | 63.12 | 231,158 | 1,384 | 5 |

| Vessel T-13 | 100.00 | 292,900 | 3,257 | 7 |

| Vessel T-14 | 100.00 | 305,000 | 1,827 | 7 |

| Vessel T-15 | 74.79 | 311,032 | 1,863 | 7 |

| Vessel T-16 | 40.80 | 132,247 | 792 | 3 |

| Vessel T-17 | 39.05 | 132,247 | 792 | 3 |

| Vessel T-18 | 41.21 | 151,765 | 909 | 3 |

| Vessel T-19 | 50.26 | 213,362 | 1,278 | 5 |

| Vessel T-20 | 37.52 | 130,076 | 779 | 3 |

| Long-lining fishing fleet | ||||

| Vessel L-1 | 100.00 | 680,000 | 3,138 | 16 |

| Vessel L-2 | 96.17 | 654,000 | 3,092 | 16 |

| Vessel L-3 | 42.67 | 393,699 | 1,817 | 9 |

| Vessel L-4 | 36.51 | 196,866 | 908 | 5 |

| Vessel L-5 | 60.63 | 302,458 | 1,396 | 7 |

| Vessel L-6 | 57.51 | 288,013 | 1,329 | 7 |

| Vessel L-7 | 52.86 | 287,514 | 1,327 | 7 |

| Vessel L-8 | 69.76 | 325,000 | 1,571 | 8 |

| Vessel L-9 | 56.89 | 268,037 | 1,237 | 6 |

| Vessel L-10 | 71.25 | 258,400 | 2,106 | 11 |

| Vessel L-11 | 100.00 | 163,200 | 2,819 | 16 |

| Vessel L-12 | 62.53 | 353,472 | 1,631 | 8 |

| DMU | Efficiency score (%) | Target 1 | Target 2 | Target 3 |

|---|---|---|---|---|

| Diesel (kg/year) | Hull material (kg/year) | Working hours (h/year) | ||

| Trawling fishing fleet | ||||

| Vessel T-1 | 23.36 | 102,050 | 611 | 6,183 |

| Vessel T-2 | 37.23 | 165,178 | 989 | 10,008 |

| Vessel T-3 | 40.15 | 165,178 | 989 | 10,008 |

| Vessel T-4 | 41.84 | 210,985 | 1,264 | 12,784 |

| Vessel T-5 | 40.51 | 210,985 | 1,264 | 12,784 |

| Vessel T-6 | 37.90 | 183,007 | 1,096 | 11,088 |

| Vessel T-7 | 58.02 | 279,237 | 1,672 | 16,919 |

| Vessel T-8 | 63.15 | 279,237 | 1,672 | 16,919 |

| Vessel T-9 | 26.94 | 119,800 | 717 | 7,259 |

| Vessel T-10 | 25.49 | 119,800 | 717 | 7,259 |

| Vessel T-11 | 62.05 | 231,158 | 1,384 | 14,006 |

| Vessel T-12 | 63.12 | 231,158 | 1,384 | 14,006 |

| Vessel T-13 | 100.00 | 292,900 | 3,257 | 18,480 |

| Vessel T-14 | 100.00 | 305,000 | 1,827 | 18,480 |

| Vessel T-15 | 74.79 | 311,032 | 1,863 | 18,846 |

| Vessel T-16 | 42.09 | 132,247 | 792 | 8,013 |

| Vessel T-17 | 40.34 | 132,247 | 792 | 8,013 |

| Vessel T-18 | 42.51 | 151,765 | 909 | 9,195 |

| Vessel T-19 | 51.72 | 213,362 | 1,278 | 12,928 |

| Vessel T-20 | 38.50 | 130,076 | 779 | 7,881 |

| Long-lining fishing fleet | ||||

| Vessel L-1 | 100.00 | 680,000 | 3,138 | 36,000 |

| Vessel L-2 | 96.41 | 654,000 | 3,092 | 35,861 |

| Vessel L-3 | 37.84 | 393,699 | 1,817 | 20,843 |

| Vessel L-4 | 34.49 | 196,866 | 908 | 10,422 |

| Vessel L-5 | 56.83 | 302,458 | 1,396 | 16,012 |

| Vessel L-6 | 57.51 | 288,013 | 1,329 | 15,248 |

| Vessel L-7 | 52.55 | 287,514 | 1,327 | 15,221 |

| Vessel L-8 | 68.52 | 325,000 | 1,571 | 18,389 |

| Vessel L-9 | 55.13 | 268,037 | 1,237 | 14,190 |

| Vessel L-10 | 69.73 | 258,400 | 2,106 | 28,967 |

| Vessel L-11 | 100.00 | 163,200 | 2,819 | 43,200 |

| Vessel L-12 | 59.45 | 353,472 | 1,631 | 18,713 |

4. Discussion

4.1. Limitations of Labor as a Social Item in LCA + DEA Studies

4.2. Perspectives

5. Conclusions

Acknowledgements

Conflict of Interest

Abbreviations

References

- World Commission on Environment and Development. Our Common Future. Oxford: Oxford University Press, 1987. [Google Scholar]

- International Organization for Standardization. ISO 14040:2006—Environmental Management—Life Cycle Assessment—Principles and Framework. Geneva: ISO, 2006. [Google Scholar]

- International Organization for Standardization. ISO 14044:2006—Environmental Management—Life Cycle Assessment—Requirements and Guidelines. Geneva: ISO, 2006. [Google Scholar]

- United Nations Environment Programme. Guidelines for Social Life Cycle Assessment of Products. Paris: UNEP, 2009. [Google Scholar]

- Helias A. Udo de Haes. “The scientific basis of SLCA—Comments to: Life cycle sustainability assessment of products.” International Journal of Life Cycle Assessment 13, no. 2 (2008): 95. [Google Scholar]

- Lidija Čuček, Jiří J. Klemeš, and Zdravko Kravanja. “A review of footprint analysis tools for monitoring impacts on sustainability.” Journal of Cleaner Production 34, no. 1 (2012): 9–20. [Google Scholar] [CrossRef]

- Jeroen B. Guinée, Reinout Heijungs, Gjalt Huppes, Alessandra Zamagni, Paolo Masoni, Roberto Buonamici, Tomas Ekvall, and Tomas Ryedberg. “Life cycle assessment: Past, present, and future.” Environmental Science & Technology 45, no. 1 (2011): 90–96. [Google Scholar]

- Walter Kloepffer. “Life cycle sustainability assessment of products.” International Journal of Life Cycle Assessment 13, no. 2 (2008): 89–95. [Google Scholar] [CrossRef]

- Alessandra Zamagni. “Life cycle sustainability assessment.” International Journal of Life Cycle Assessment 17, no. 4 (2012): 373–76. [Google Scholar] [CrossRef]

- Harish K. Jeswani, Adisa Azapagic, Philipp Schepelmann, and Michael Ritthoff. “Options for broadening and deepening the LCA approaches.” Journal of Cleaner Production 18, no. 2 (2010): 120–27. [Google Scholar] [CrossRef]

- Diego Iribarren. Life Cycle Assessment of Mussel and Turbot Aquaculture: Application and Insights. Santiago de Compostela: University of Santiago de Compostela, 2010. [Google Scholar]

- Ian Vázquez-Rowe, Diego Iribarren, María T. Moreira, and Gumersindo Feijoo. “Combined application of life cycle assessment and data envelopment analysis as a methodological approach for the assessment of fisheries.” International Journal of Life Cycle Assessment 15, no. 3 (2010): 272–83. [Google Scholar] [CrossRef]

- William W. Cooper, Lawrence M. Seiford, and Kaoru Tone. Data Envelopment Analysis: A Comprehensive Text with Models, Applications, References and DEA-Solver Software. New York: Springer, 2007. [Google Scholar]

- Kaoru Tone. “A slacks-based measure of efficiency in data envelopment analysis.” European Journal of Operational Research 130, no. 3 (2001): 498–509. [Google Scholar] [CrossRef]

- John Reap, Felipe Roman, Scott Duncan, and Bert Bras. “A survey of unresolved problems in life cycle assessment—Part 2: Impact assessment and interpretation.” International Journal of Life Cycle Assessment 13, no. 5 (2008): 374–88. [Google Scholar] [CrossRef]

- Bo P. Weidema, and Marianne S. Wesnæs. “Data quality management for life cycle inventories: An example of using data quality indicators.” Journal of Cleaner Production 4, no. 3–4 (1996): 167–74. [Google Scholar] [CrossRef]

- Sebastián Lozano, Diego Iribarren, María T. Moreira, and Gumersindo Feijoo. “The link between operational efficiency and environmental impacts: A joint application of life cycle assessment and data envelopment analysis.” Science of the Total Environment 407, no. 5 (2009): 1744–54. [Google Scholar] [CrossRef] [PubMed]

- John Reap, Felipe Roman, Scott Duncan, and Bert Bras. “A survey of unresolved problems in life cycle assessment—Part 1: Goal and scope and inventory analysis.” International Journal of Life Cycle Assessment 13, no. 4 (2008): 290–300. [Google Scholar] [CrossRef]

- Diego Iribarren, Ian Vázquez-Rowe, María T. Moreira, and Gumersindo Feijoo. “Further potentials in the joint implementation of life cycle assessment and data envelopment analysis.” Science of the Total Environment 408, no. 22 (2010): 5265–72. [Google Scholar] [CrossRef] [PubMed]

- Stephan Schmidheiny. Changing Course: A Global Business Perspective on Development and the Environment. Massachusetts: MIT Press, 1992. [Google Scholar]

- Ian Vázquez-Rowe, Diego Iribarren, Almudena Hospido, María T. Moreira, and Gumersindo Feijoo. “Computation of operational and environmental benchmarks within selected Galician fishing fleets (NW Spain).” Journal of Industrial Ecology 15, no. 5 (2011): 776–95. [Google Scholar] [CrossRef]

- Diego Iribarren, Almudena Hospido, María T. Moreira, and Gumersindo Feijoo. “Benchmarking environmental and operational parameters through eco-efficiency criteria for dairy farms.” Science of the Total Environment 409, no. 10 (2011): 1786–98. [Google Scholar] [CrossRef] [PubMed]

- Ian Vázquez-Rowe, Pedro Villanueva-Rey, Diego Iribarren, María T. Moreira, and Gumersindo Feijoo. “Joint life cycle assessment and data envelopment analysis of grape production for vinification in the Rías Baixas appellation (NW Spain).” Journal of Cleaner Production 27, no. 1 (2012): 92–102. [Google Scholar] [CrossRef]

- Ali Mohammadi, Tommy Dalgaard, Marie Trydeman Knudsen, Shahin Rafiee, Seyed H. Mousavi-Avval, and John E. Hermansen. “Potential greenhouse gas emission reductions in soybean farming: A combined use of life cycle assessment and data envelopment analysis.” Journal of Cleaner Production 54, no. 1 (2013): 89–100. [Google Scholar] [CrossRef]

- Shu-Kun Lin. “Social Sciences and Sustainability.” Social Sciences 1, no. 1 (2012): 1. [Google Scholar] [CrossRef]

- Sebastián Lozano, Diego Iribarren, María T. Moreira, and Gumersindo Feijoo. “Environmental impact efficiency in mussel cultivation.” Resources, Conservation & Recycling 54, no. 12 (2010): 1269–77. [Google Scholar]

- William H. Greene. “Frontier production functions.” In Handbook of Applied Econometrics. Edited by Mohammad H. Pesaran and Peter Schmidt. Oxford: Blackwell Publishing, 1999, Volume 2, pp. 81–166. [Google Scholar]

- Ian Vázquez-Rowe, and Peter Tyedmers. “Identifying the importance of the ‘skipper effect’ within sources of measured inefficiency in fisheries through data envelopment analysis (DEA).” Marine Policy 38, no. 1 (2013): 387–96. [Google Scholar] [CrossRef]

- Rajiv D. Banker. “Estimating most productive scale size using data envelopment analysis.” European Journal of Operational Research 17, no. 1 (1984): 35–44. [Google Scholar] [CrossRef]

- “Data envelopment analysis software.” 2013. Available online: http://www.saitech-inc.com/Products/Prod-DSP.asp (accessed on 24 April 2013).

- Gokhan Egilmez, Murat Kucukvar, and Omer Tatari. “Sustainability assessment of U.S. manufacturing sectors: An economic input output-based frontier approach.” Journal of Cleaner Production 53, no. 1 (2013): 91–102. [Google Scholar] [CrossRef]

- Andreas Jørgensen. “Social LCA–a way ahead? ” International Journal of Life Cycle Assessment 18, no. 2 (2013): 296–99. [Google Scholar] [CrossRef]

- Joram Krozer, and Jan C. Vis. “How to get LCA in the right direction? ” Journal of Cleaner Production 6, no. 1 (1998): 53–61. [Google Scholar] [CrossRef]

- Benedetto Rugani, Daryna Panasiuk, and Enrico Benetto. “An input-output based framework to evaluate human labour in life cycle assessment.” International Journal of Life Cycle Assessment 17, no. 6 (2012): 795–812. [Google Scholar] [CrossRef]

- Andreas Jørgensen, Louise C. Dreyer, and Arne Wangel. “Addressing the effect of social life cycle assessments.” International Journal of Life Cycle Assessment 17, no. 6 (2012): 828–39. [Google Scholar] [CrossRef]

- Clara Valente, Raffaele Spinelli, and Bengt G. Hillring. “LCA of environmental and socio-economic impacts related to wood energy production in alpine conditions: Valle di Fiemme (Italy).” Journal of Cleaner Production 19, no. 17–18 (2011): 1931–38. [Google Scholar] [CrossRef]

- Carin Labuschagne, and Alan C. Brent. “Social indicators for sustainable project and technology life cycle management in the process industry.” International Journal of Life Cycle Assessment 11, no. 1 (2006): 3–15. [Google Scholar]

- David Hunkeler. “Societal LCA methodology and case study.” International Journal of Life Cycle Assessment 11, no. 6 (2006): 371–82. [Google Scholar]

- Kaoru Tone. “A slacks-based measure of super-efficiency in data envelopment analysis.” European Journal of Operational Research 143, no. 1 (2002): 32–41. [Google Scholar] [CrossRef]

- Christine Chauvin, and Gilbert Le Bouar. “Occupational injury in the French sea fishing industry: A comparative study between the 1980s and today.” Accident Analysis & Prevention 39, no. 1 (2007): 79–85. [Google Scholar]

- Murat Kucukvar, and Omer Tatari. “Towards a triple bottom-line sustainability assessment of the U.S. construction industry.” International Journal of Life Cycle Assessment 18, no. 5 (2013): 958–72. [Google Scholar] [CrossRef]

- Thomas O. Wiedmann, Manfred Lenzen, and John R. Barrett. “Companies on the scale: Comparing and benchmarking the sustainability performance of businesses.” Journal of Industrial Ecology 13, no. 3 (2009): 361–83. [Google Scholar] [CrossRef]

© 2013 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Iribarren, D.; Vázquez-Rowe, I. Is Labor a Suitable Input in LCA + DEA Studies? Insights on the Combined Use of Economic, Environmental and Social Parameters. Soc. Sci. 2013, 2, 114-130. https://doi.org/10.3390/socsci2030114

Iribarren D, Vázquez-Rowe I. Is Labor a Suitable Input in LCA + DEA Studies? Insights on the Combined Use of Economic, Environmental and Social Parameters. Social Sciences. 2013; 2(3):114-130. https://doi.org/10.3390/socsci2030114

Chicago/Turabian StyleIribarren, Diego, and Ian Vázquez-Rowe. 2013. "Is Labor a Suitable Input in LCA + DEA Studies? Insights on the Combined Use of Economic, Environmental and Social Parameters" Social Sciences 2, no. 3: 114-130. https://doi.org/10.3390/socsci2030114

APA StyleIribarren, D., & Vázquez-Rowe, I. (2013). Is Labor a Suitable Input in LCA + DEA Studies? Insights on the Combined Use of Economic, Environmental and Social Parameters. Social Sciences, 2(3), 114-130. https://doi.org/10.3390/socsci2030114