As the bungled firing provided such surprising results, a change in direction of the work led to the current research; a new aim was developed to encourage, rather than eliminate, flow and movement of imagery within the glass. It combines approaches relevant to the layered fused imagery in Encyclopaedia with the natural movement of the glass that is common to Studio Glass. Gravity and inflation are used to change the shape of glass, and this transformation is recorded on and within the resulting objects. Contemporary examples include the ‘weaving’ of decorative cane patterns of Italian-inspired blown glass by Tobias Møhl, and the veiling between individual elements melting together in castings by British glass artist Colin Reid.

2.1. In Search of Graphic Swim

To begin testing, the initial failed firing was restaged at a smaller scale, with the intent of understanding the flow of the printed image and controlling the results. The approach to firing is informed by a process originally developed by Bullseye Glass Co. It is manifest in their fabrication of the large-scale glass works by Jun Kaneko (

Kaneko 2007), and explained in web-based educational videos on ‘Harnessing Flow’ (

Bullseye Glass Co. 2018). Building on their research, flow is applied to printed imagery in glass. In initial testing (

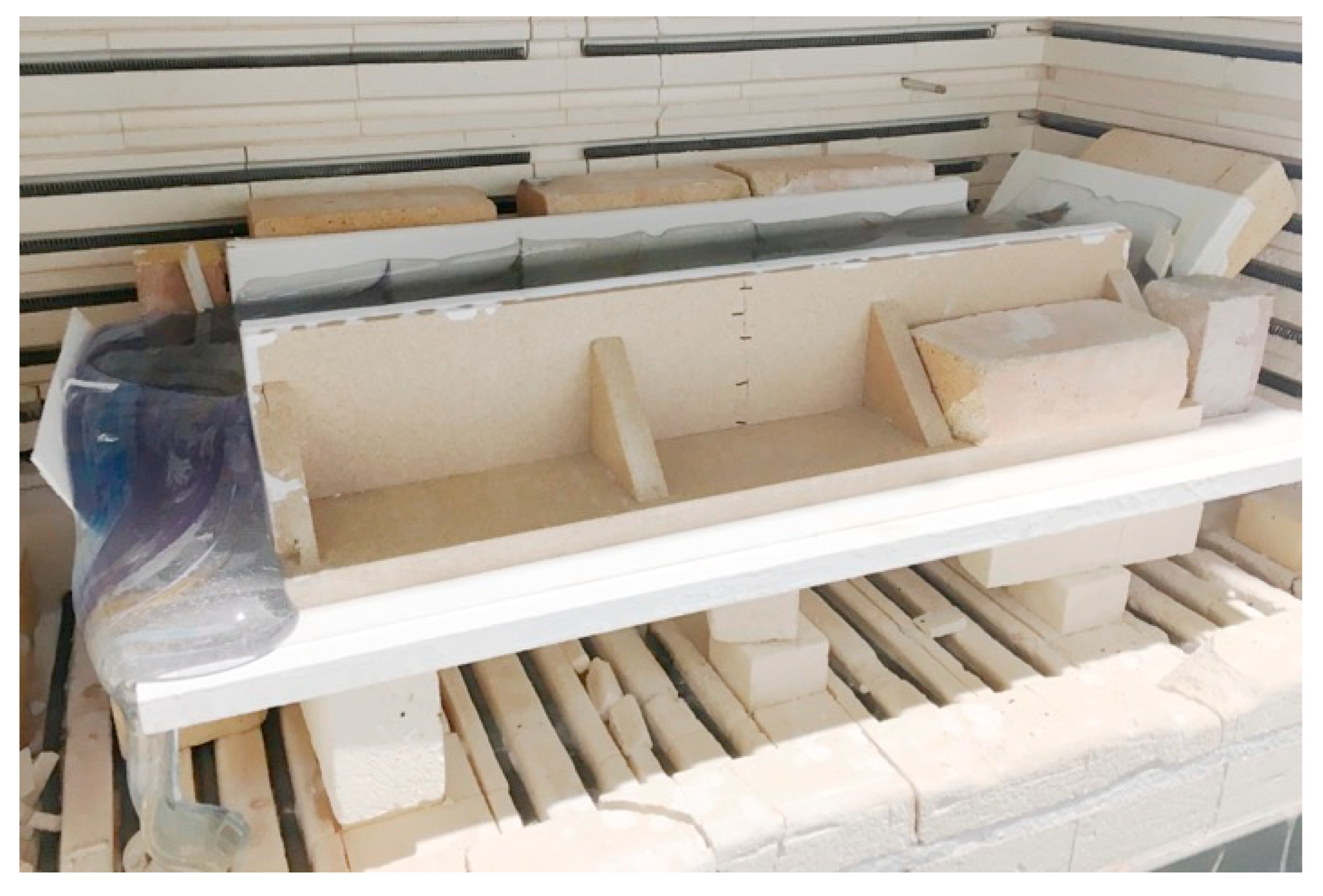

Figure 4), a basic grid was printed to the glass, which clearly demonstrates and visualizes the movement of layered imagery within a fused glass block. These glass sheets were then cut down and fused together in several sections, which would then be set on edge inside a mold for a second fusing cycle. A mold of cut and kiln-washed refractory furniture was made to accommodate the target dimensions for the final fused object, and the amount of glass was measured by weight to achieve the correct volume. The displacement in the melting process shifts the imagery, and the movement is controlled by varying the layout and dimensions of the glass sections within the mold.

This process was then utilized as the center of a 5-day workshop at Bullseye Glass under the title Graphic Swim. The focus of the workshop was the transformation of layered imagery through the processes of screenprinting and kilnforming. Students were instructed and coached through the process described above, using a combination of imagery pre-selected for the class as well as their own graphic work. This provided an opportunity to see the effect of movement on different choices of graphic text, image, and pattern. Results of the workshop revealed several possibilities that encourage the direction of flow and the intensity of the shift of imagery (

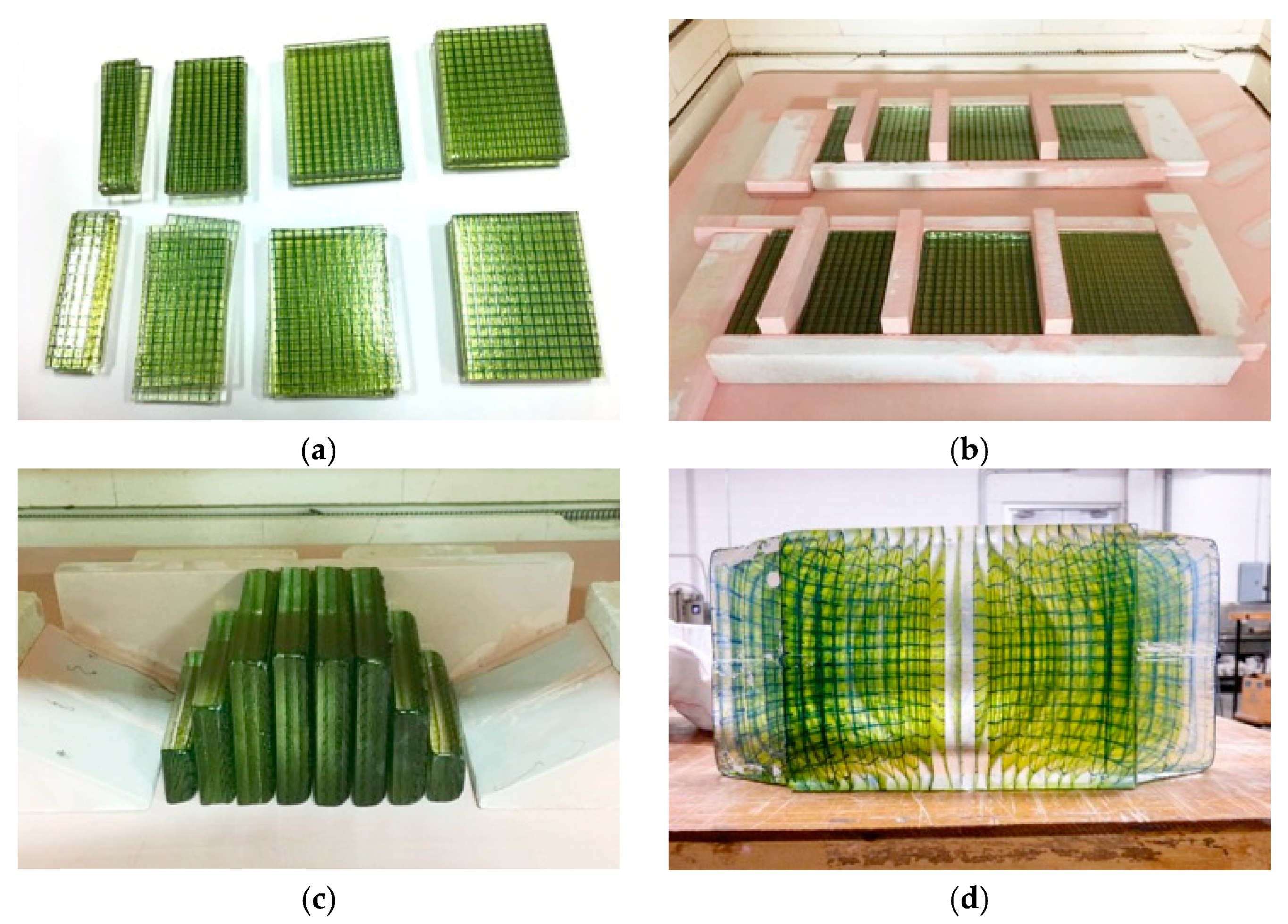

Figure 5). The direction of flow (outward, inward, or sideways) could be controlled through the placement of pre-fused sections. The intensity could be varied through varying the height of these sections, giving some imagery further to flow than others as the glass melts into a homogenous rectangular solid. Students were encouraged to consider their adaptations of the prescribed process, and in so doing they developed alternative layouts of sections to encourage assymetrical flow as well as combinations of still and shifted imagery. Their outcomes provided useful information that advanced an understanding of graphic swim.

2.2. A Fusion of 2D and 3D Printing Approaches

Seeking possibilities beyond the glass block, the next phase of the project explored how printed imagery could be embedded into objects in the round. The mold structure for the Encyclopaedia artworks and the Graphic Swim workshops is simple. Four weight-supported walls hold melting glass in place produce a rectangular solid in which displacement is easy to predict. Replacing this with an investment mold of a three-dimensional form would encourage a dynamic flow of the glass and embedded images. Again, it is possible to use exclusively analogue techniques in the making of this work. However, in the same way that software provides precision and complexity in the 2D printed image, a similar approach was taken to incorporate emerging 3D printing techniques into the process.

Explored in depth by

Thwaites (

2018), a 3D print from a digital model is used as a single-use positive form in PLA plastic, which is then ‘lost’ through a melt-out of a refractory investment before being cast in glass or other materials. For the artist and craftsperson, the key advantages to this process are an expansion of possible forms through digital scanning and modelling; and the ability to bypass silicone and wax, two materials traditionally to create positives for lost-wax casting. In the early weeks of the artist residency, a silicone mold and waxes were made in the interest of time, for the sake of moving the kilnforming tests forward while the 3D printing process was being established. It was however quickly discovered to be untidy, costly, and time-consuming. The main disadvantage of analogue lost-wax is a lack of flexibility; resources must be committed to multiples or variations of specific forms, when in fact the goal in this project was to create a variety of forms to cast. A maker working with a 3D printer can alter the scale and correct forms as well as produce multiples, thereby engaging a workflow that allows for continuous development of the digital model and print. Its relative accessibility allows the author to take approaches to collection, variation, and collage used to cultivate uniqueness in his screenprinted glass work.

2.3. Building a Vocabulary of Things

The Encyclopaedia series involves the compilation and creation of hundreds of images, which could be considered a vocabulary of texts, shapes, diagrams, photographs. Considering the transformation in three dimensions of the image through graphic swim, it was also conceived that there could be a transformation not only of the image but also of the object. Is it possible to compile and build a vocabulary of ‘things’ to correspond to the imagery? The body of artworks created in the research and residency sought to work out these possibilities.

Much of the author’s artwork including

Encyclopaedia could be considered a form of self-portrait in that it records experience over time. In her interpretation of this body of work,

Vigna (

2007) writes, ‘The richness of all of this information reminds us that personal identity is complex—something that goes well beyond (but does include) the tangible elements of a human being’ (p. 20). An appropriate form to begin this experimentation was a literal self-portrait, albeit this one in three dimensions. A 3D scanner was utilized to capture a model of the artist’s head. Portrait scanning is a trope in digital craft as photogrammetry is often utilized to create a 3D ‘selfie’ (

Warnier et al. 2015, p. 34). It is also an obvious form to test detail in the outcome as an accurate likeness can be easily recognized. Furthermore, the choice was also practical in that considering the movement of glass, the imagery would need to melt into the form and would be distorted by any constrictions in the mold, and with few undercuts the form of a head is a relatively simple shape to cast.

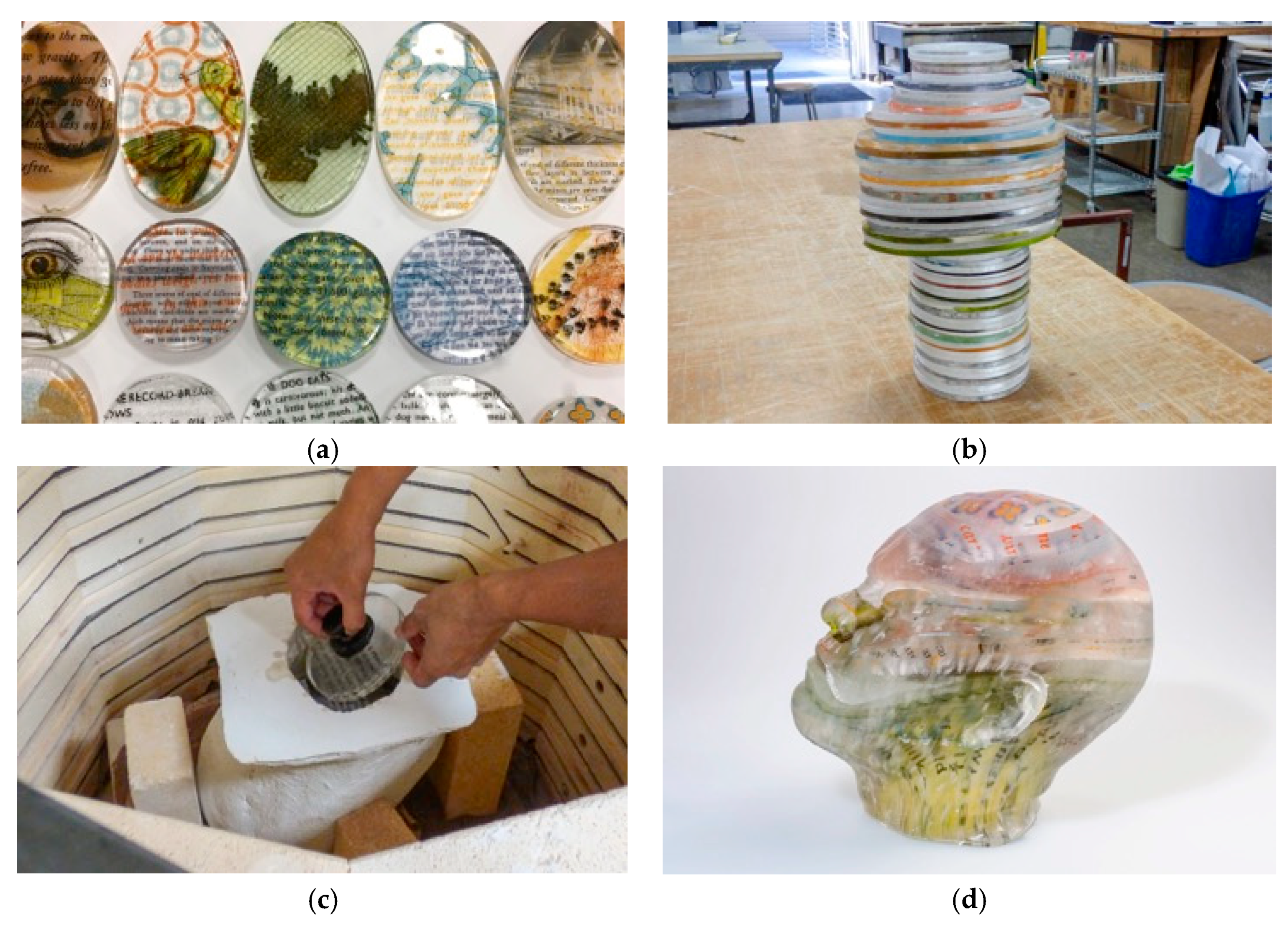

From the resulting 3D printed heads, investment molds for glass casting were created. These are normally filled using a flowerpot with an enlarged hole as a crucible to contain the glass to be cast. As this method would force the screenprinted glass through a small aperture during firing, the imagery would become distorted to the point of complete illegibility. Therefore alternative approaches to filling the mold with glass were developed. Several tests were generated using these forms, exploring strategies for controlling the movement of the printed images. This would vary the distance the printed glass would have to travel as it melted as well as the amount of the void the melted glass would have to fill through the casting process.

The first setup (

Figure 6) uses a simple block-shaped feed into which pre-fused elements are laid on edge. Using an indicative printed grid, the flow of the imagery could be seen clearly in the finished object. What became visible, however, is that during the melt, the glass becomes fluid. Imagery in the center of the fused sections would drop more quickly than imagery on the edges as the mold filled. Therefore, heavy distortion would lead to illegible graphics other than bold patterns.

Partial filling of the mold with printed glass sections offered the possibility of reducing this kind of distortion and would preserve some of the legibility of the images by preventing them from moving. The second setup utilized a single shape of a long cylinder consisting of stacked glass discs (matching the volume required to fill the mold) laid into the bottom of the mold and held by a ceramic pot as a feeder. The result of this test (

Figure 7) was an increased legibility of the imagery directly inside of the mold. The flow into the form was still possible as the disc was only as large as the smallest opening and the printed images spread throughout the casting as it filled the cavity inside the mold. In the third version of the setup (

Figure 8), contours from the 3D model of the head were taken to approximate the shapes that would fit more tightly, and glass was cut and fused to fit into the mold cavity. This test produced the least movement of all.