Developing Techniques for Closed-Loop-Recycling Soda-Lime Glass Fines through Robotic Deposition

Abstract

:1. Introduction

2. Maintaining Recycled Soda-Lime Glass Fines in the Closed-Loop Industrial Cycle

3. State of the Art for Research into Robotic Deposition of Recycled Soda-Lime Glass Fines

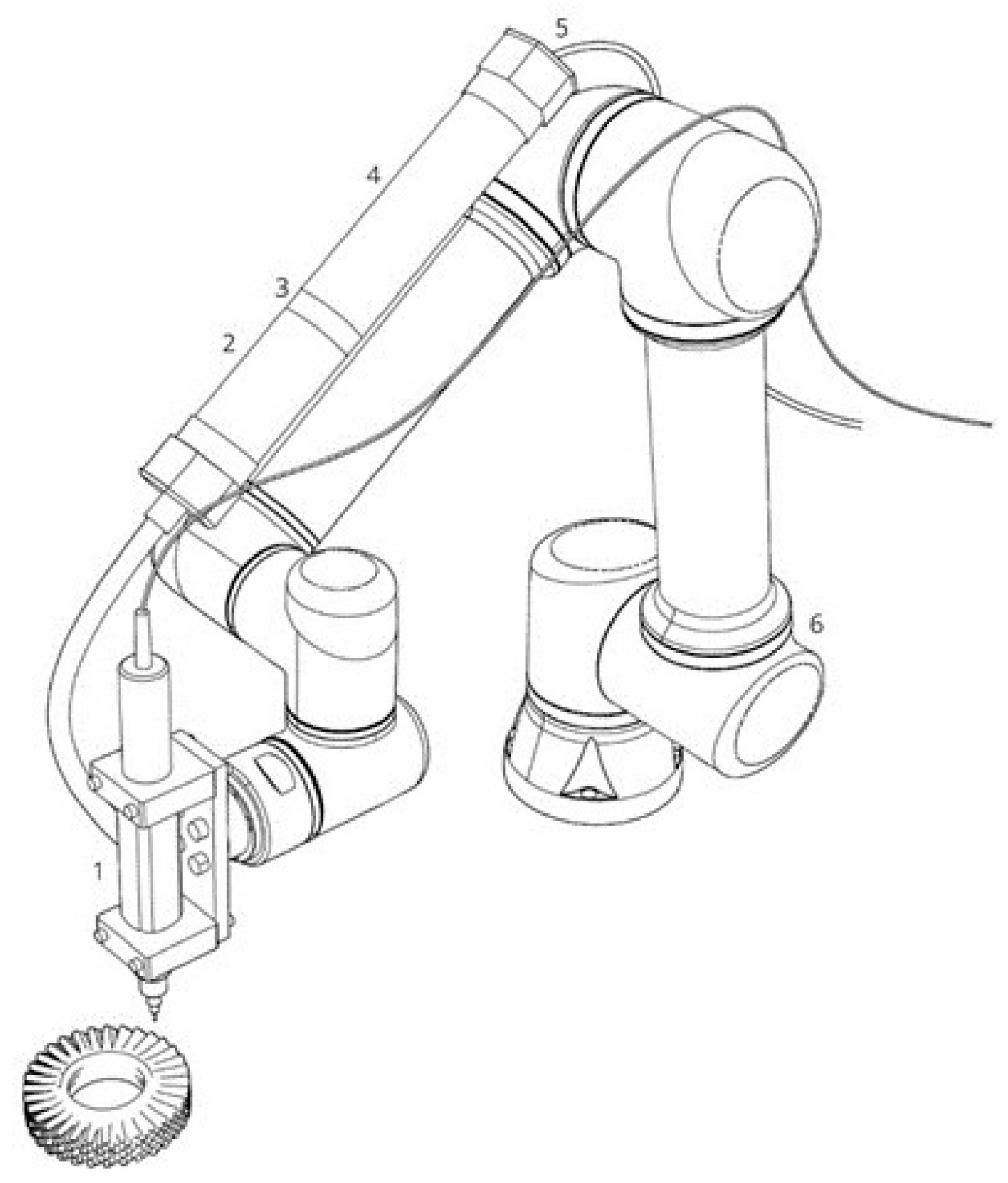

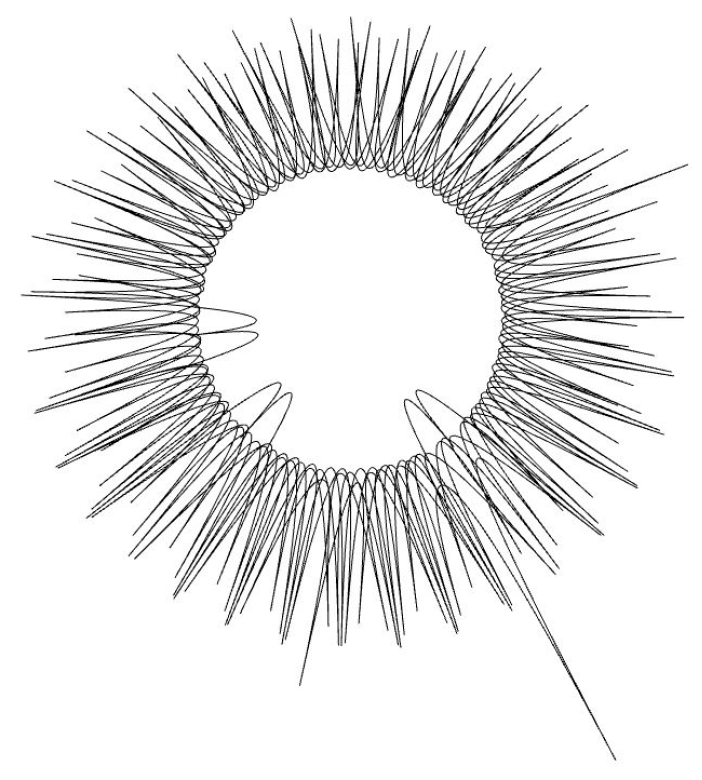

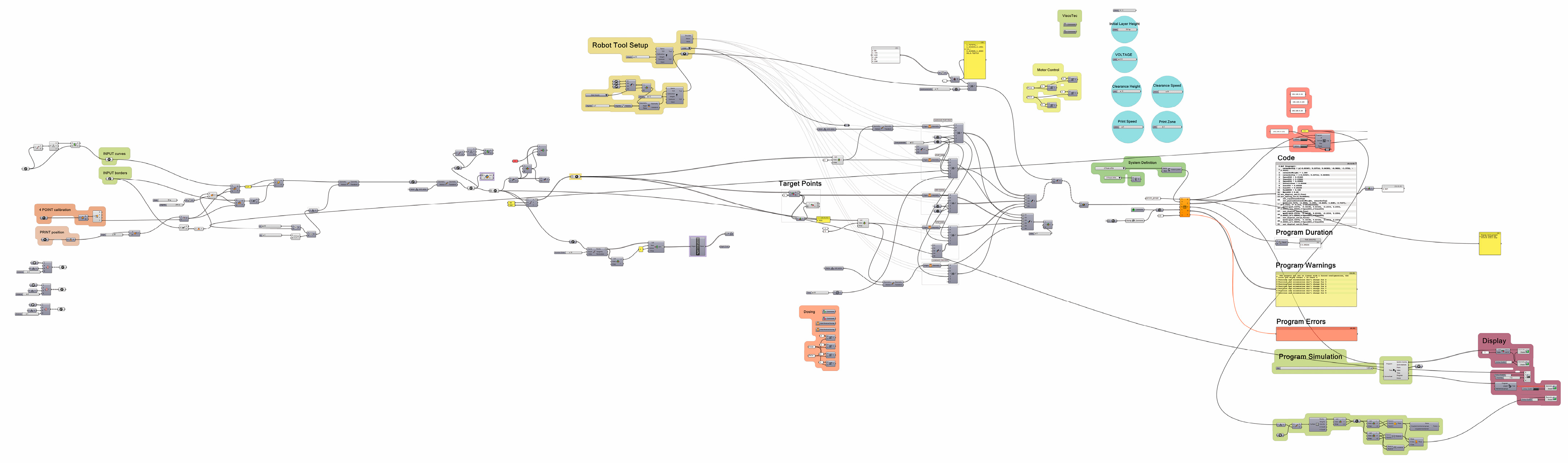

4. Printing RSFG

5. Testing Material Composition

- cloaking or clumping during extrusion;

- time interval for binding of the layers;

- sensitivity to changing environmental conditions (humidity, temperature).

- binding of layers;

- stability during print process;

- possible overhang of layers.

- degree of slumping;

- shrinkage;

- cracking;

- deformation.

- porosity;

- strength;

- glass look;

- translucency.

6. Techniques for Artistic Applications of the 3D Printed RSGF

- attaching the 3D prints to prefabricated cast recycled container glass blanks in a cold application process followed by thermal sintering;

- attaching the 3D prints to blown recycled container glass in a hot process;

- attaching the 3D prints to blown RSGF in a hot process;

- 3D printing of RSGF, including the addition of ceramic stains.

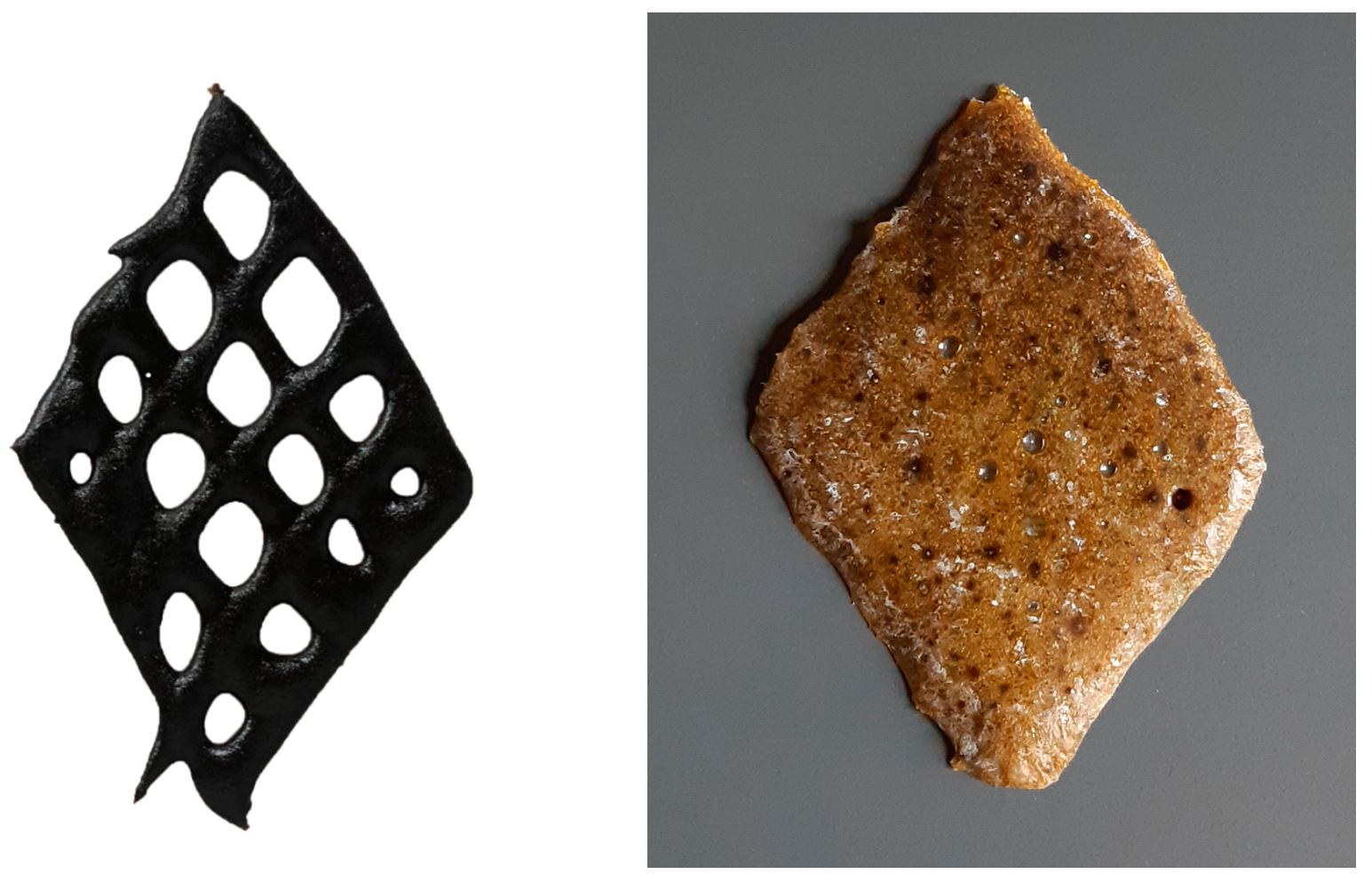

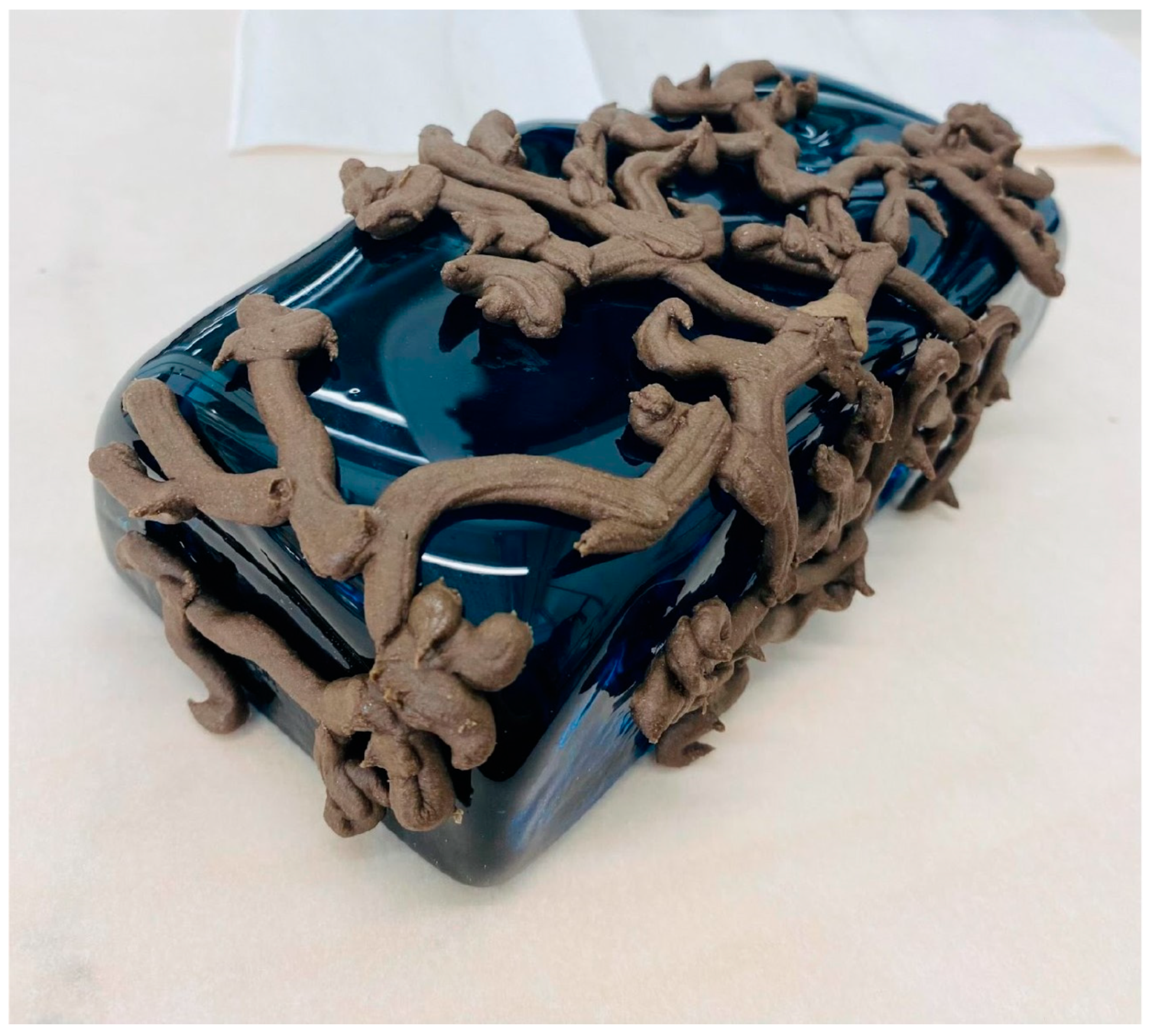

6.1. 3D Printed RSGF Objects Combined with Clear Cast Recycled Container Glass

6.1.1. Technical Material Analysis of RSGF Combined with Cast Recycled Container Glass

6.1.2. Aesthetical Analysis of RSGF Combined with Cast Recycled Container Glass

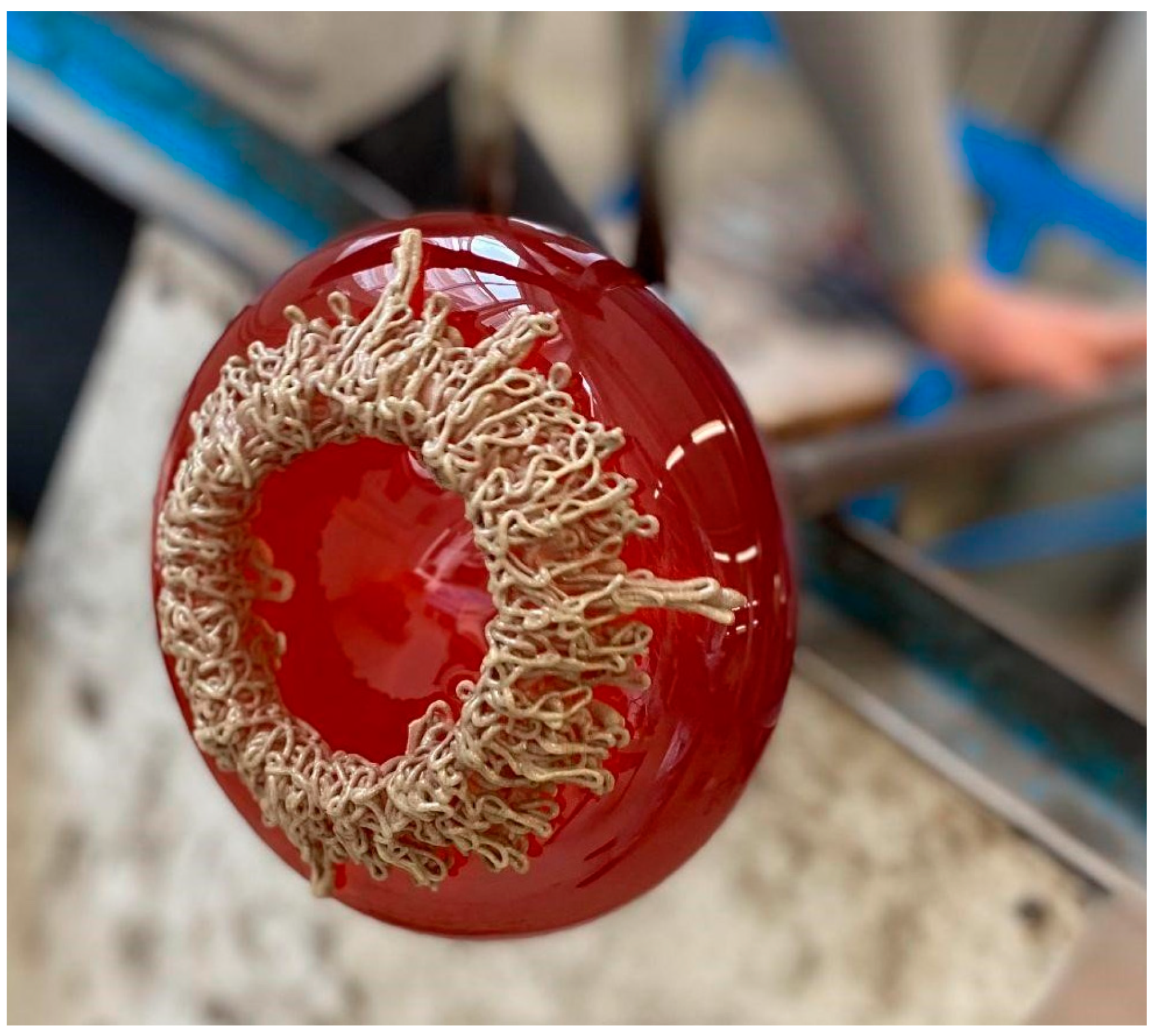

6.2. 3D Printed RSGF Combined with Transparent Blown Recycled Container Glass

6.2.1. Technical Material Analysis of RSGF Combined with Blown Recycled Container Glass

6.2.2. Aesthetic Analysis of RSGF Combined with Blown Recycled Container Glass

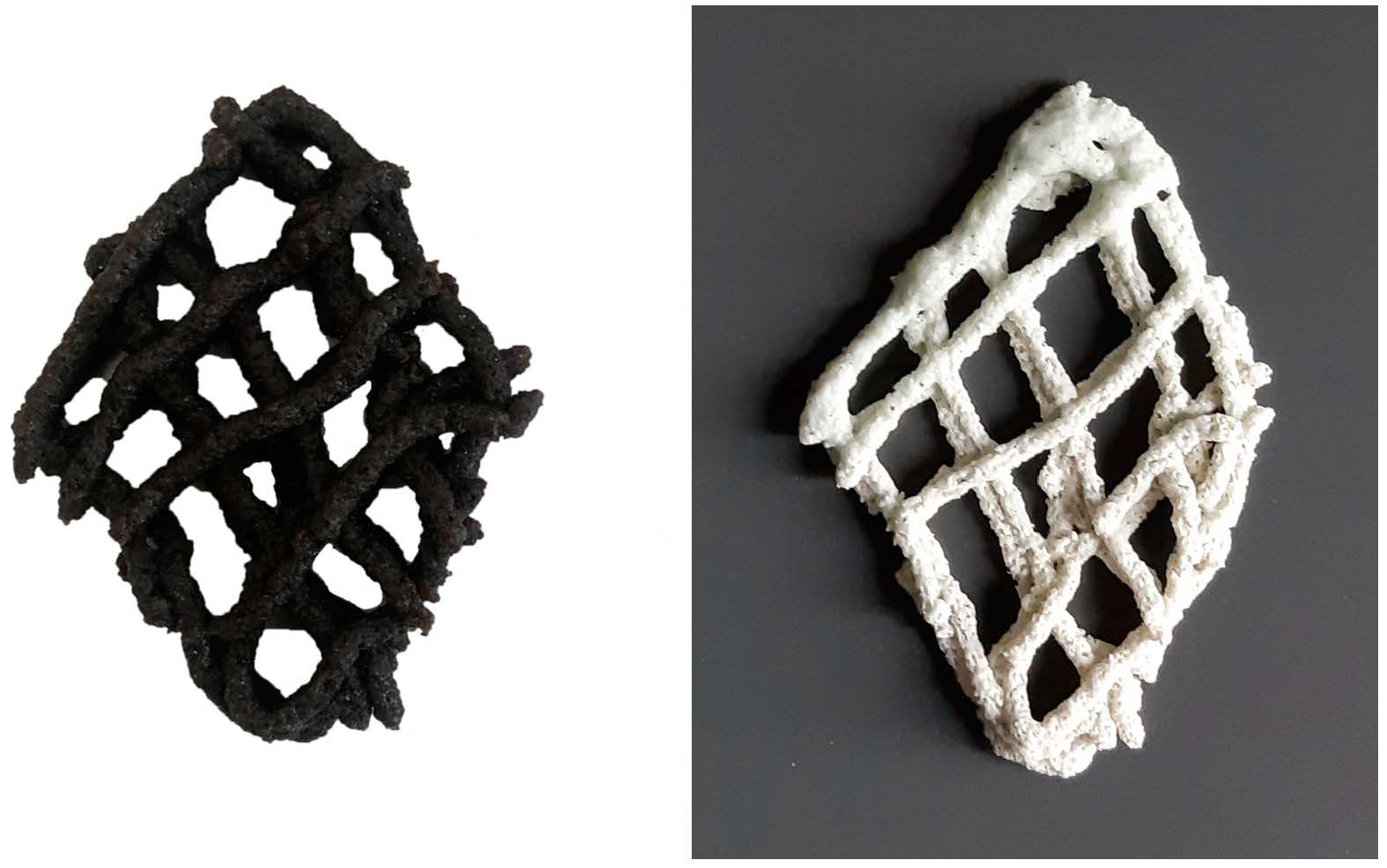

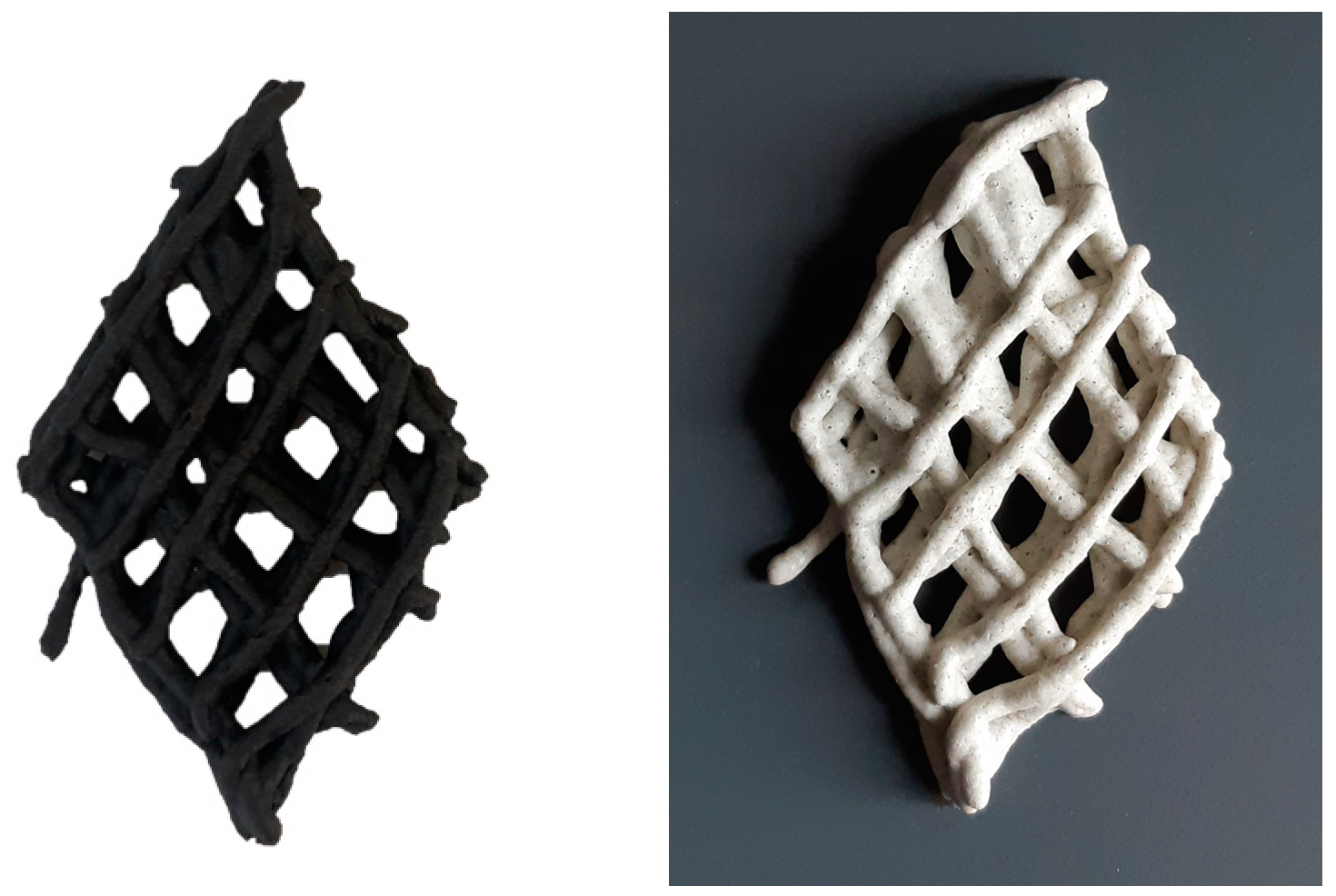

6.3. 3D printed RSGF Combined with Blown RSGF

6.3.1. Technical Material Analysis of 3D Printed RSGF Combined with Blown RSGF

6.3.2. Aesthetic Analysis of 3D Printed RSGF Combined with Blown RSGF

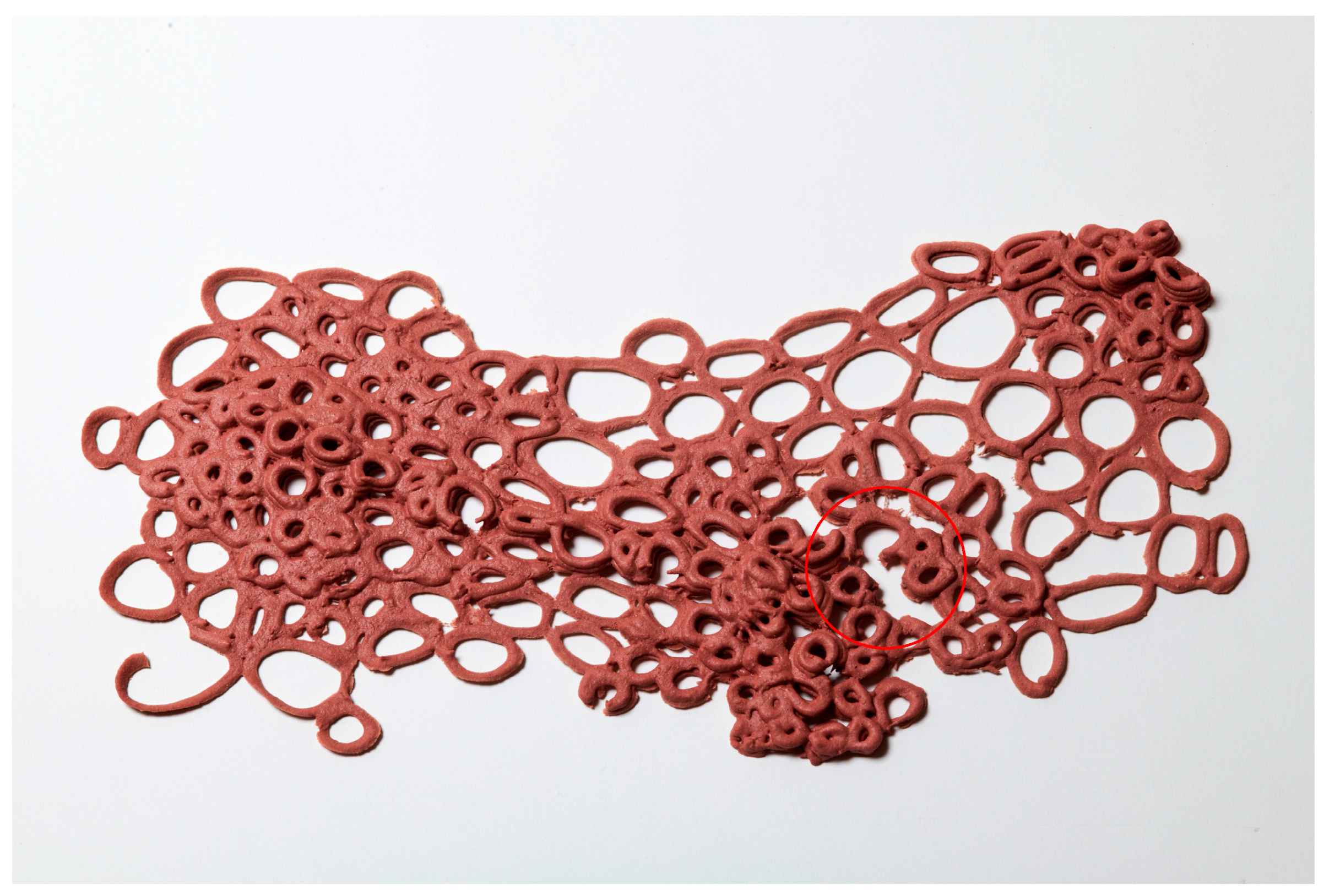

6.4. 3D Printing and Coloring Options for RSGF

6.4.1. Technical Material Analysis of 3D Printed and Colored RSGF

6.4.2. Aesthetic Analysis of 3D Printed and Colored RSGF

7. Sustainable Development of Artistic Glass through Robotic Deposition of RSGF

8. Method: Experimental Material Research for Sustainable Development

9. Conclusions

- development of technical material knowledge of how to solve issues of 3D printing RSGF into resilient form-stabile objects;

- development of new tacit knowledge of the processes involved in the production of geometries that are more resilient to firing treatment;

- enabling 3D printing of a material into forms that would be difficult to achieve in any other technique;

- expanding the color range for recycled container glass for artistic applications.

- 3D printing followed by sintering at 970 °C allows for a lower energy consumption;

- blowing as well as 3D printing allows for returning RSGF into the circular model for recycled container glass.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Blicher-Nordkvist, Jesper. 2022. Reiling Glasrecycling ApS, Næstved, Denmark. Personal communication.

- Del Rio, Dylan D. Furszyfer, Benjamin K. Sovacool, Aoife M. Foley, Steve Griffiths, Morgan Bazilian, Jinsoo Kim, and David Rooney. 2022. Decarbonizing the glass industry: A critical and systematic review of developments, sociotechnical systems and policy options. Renewable and Sustainable Energy Reviews 155: 111885. [Google Scholar] [CrossRef]

- Dyer, Thomas D. 2014. Glass Recycling. In Handbook of Recycling: State-of-the-Art for Practitioners, Analysts, and Scientists. Amsterdam: Elsevier, pp. 191–209. [Google Scholar] [CrossRef]

- Ellen MacArthur Foundation. 2023. The Butterfly Diagram: Visualising the Circular Economy. Available online: https://Ellenmacarthurfoundation.Org/Circular-Economy-Diagram (accessed on 18 April 2023).

- Flood, Michael, Tanmay Bhat, Everson Kandare, Liam Fennessy, Simon Lockrey, Areli Avendano, and Judith Glover. 2018. Glass Fines—Final Report. Melbourne: RMIT University. [Google Scholar]

- Ford, Simon, and Mélanie Despeisse. 2016. Additive manufacturing and sustainability: An exploratory study of the advantages and challenges. Journal of Cleaner Production 137: 1573–87. [Google Scholar] [CrossRef]

- Hansen, Flemming Tvede, and Priska Falin. 2016. 3D printing as a Ceramic Craft Tool in Its Own Right. In Ceramics and its Dimensions: Shaping the Future, 2016th ed. Edited by Maarit Mäkelä. Espoo: Aalto University School of Arts, Design and Architecture, vol. 4, pp. 114–28. [Google Scholar]

- Hodkin, Frederick William, and Arnold Cousen. 1925. A Textbook of Glass Technology. London: Constable & Company Ltd. [Google Scholar]

- Ignorance Is Bliss. 2023. Sources of Waste. Available online: https://ignorance-bliss.com/#metal-waste-is-bliss (accessed on 5 June 2023).

- Latour, Bruno. 1996. On actor-network theory: A few clarifications. Soziale Welt 47: 369–81. Available online: http://www.jstor.org/stable/40878163 (accessed on 18 April 2023).

- Lynggaard, Finn. 1998. The Story of Studio Glass. Copenhagen: Rhodos. [Google Scholar]

- Pajunen, John, Matti Tedre, and Nella Moisseinen. 2013. Viewpoints of Computing to the Epistemology of Experiments. Presented at the 2013 Meeting of the International Association for Computing and Philosophy (IACAP 2013): Minds, Machines and Morals, College Park, MD, USA, July 15–17. [Google Scholar]

- Polanyi, Michael. 1966. The Tacit Dimension. Chicago and London: The University of Chicago Press. [Google Scholar]

- Schön, Donald A. 1991. The Reflective Practitioner: How Professionals Think in Action. London: Routledge. [Google Scholar]

- Thomsen, Mette Ramsgaard, Martin Tamke, Maria Sparre-Petersen, Emil F. Buchwald, and Simona Hnídková. 2020. Silica A circular material paradigm by 3D printing recycled glass. In Paper presented at the Anthropologic-Architecture and Fabrication in the Cognitive Age: Proceedings of the 38th eCAADe Conference, Berlin, Germany, September 16–17; vol. 2, pp. 613–22. [Google Scholar]

- Ting, Guan Heng Andrew, Yi Wei Daniel Tay, and Ming Jen Tan. 2021. Experimental measurement on the effects of recycled glass cullets as aggregates for construction 3D printing. Journal of Cleaner Production 300: 126919. [Google Scholar] [CrossRef]

- United Nations Environment Programme. 2019. Sand and Sustainability: Finding New Solutions for Environmental Governance of Global Sand Resources. Available online: https://wedocs.unep.org/20.500.11822/28163 (accessed on 5 June 2023).

- United Nations. 2015. Transforming Our World: The 2030 Agenda for Sustainable Development. Available online: https://sdgs.un.org/sites/default/files/publications/21252030%20Agenda%20for%20Sustainable%20Development%20web.pdf (accessed on 5 May 2023).

- UTS. 2022. Green Houses Made from Glass Waste. September 28. Available online: https://www.uts.edu.au/news/tech-design/green-houses-made-glass-waste (accessed on 5 May 2023).

| Time | Temperature | Holding Time | |

|---|---|---|---|

| Initial heat | 3 h | 570 °C | - |

| Rapid heat | 10 min | 970 °C | 10 min |

| Rapid cool | 10 min | 564 °C | End |

| Material | Extrudability/Printability | 3D Structure | Performance during Drying | Performance after Firing |

|---|---|---|---|---|

| Sugar | 5 | 2 | 4 | 1 |

| Gelatin | 1 | 4 | 3 | 2 |

| Dispex | 3 | 2 | 4 | 4 |

| Water glass | 5 | 1 | 4 | 4 |

| Bentonite | 3 | 4 | 4 | 3 |

| Titebond | 4 | 5 | 4 | 4 |

| Time | Temperature | Holding Time | |

|---|---|---|---|

| Initial heat | 10 h | 600 °C | - |

| Rapid heat | skip | 785 °C | 10 min |

| Rapid cool | skip | 564 °C | 5 h |

| Anneal drop | 15 h | 420 | - |

| End |

| Time | Temperature | Holding Time | |

|---|---|---|---|

| Initial heat | 8 h | 600 °C | - |

| Rapid heat | skip | 850 °C | until pick-up |

| End |

| Time | Temperature | Holding Time | |

|---|---|---|---|

| Soak | 4 h | 564 °C | - |

| Annealing cool | 8 h | 420 °C | - |

| End |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sparre-Petersen, M.; Hnídková, S. Developing Techniques for Closed-Loop-Recycling Soda-Lime Glass Fines through Robotic Deposition. Arts 2023, 12, 166. https://doi.org/10.3390/arts12040166

Sparre-Petersen M, Hnídková S. Developing Techniques for Closed-Loop-Recycling Soda-Lime Glass Fines through Robotic Deposition. Arts. 2023; 12(4):166. https://doi.org/10.3390/arts12040166

Chicago/Turabian StyleSparre-Petersen, Maria, and Simona Hnídková. 2023. "Developing Techniques for Closed-Loop-Recycling Soda-Lime Glass Fines through Robotic Deposition" Arts 12, no. 4: 166. https://doi.org/10.3390/arts12040166

APA StyleSparre-Petersen, M., & Hnídková, S. (2023). Developing Techniques for Closed-Loop-Recycling Soda-Lime Glass Fines through Robotic Deposition. Arts, 12(4), 166. https://doi.org/10.3390/arts12040166