Using Life Cycle Assessment to Inform Decision-Making for Sustainable Buildings

Abstract

:1. Introduction

1.1. Context Research

1.2. State-of-the-Art

1.3. Aims of this Study

- -

- Is it useful to consider future refurbishments?

- -

- What is the influence of new construction on the outcomes compared to transformation?

- -

- What is the influence of a demountable detailing on the outcomes compared to conventional detailing?

2. Methodology

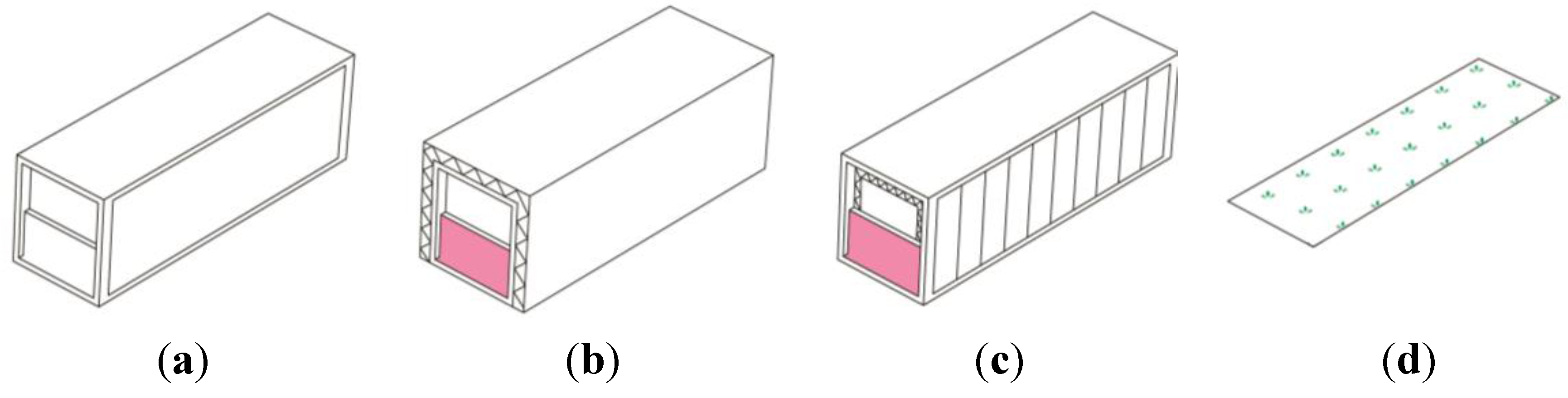

2.1. Case Study

2.2. Elaboration of Design Strategies

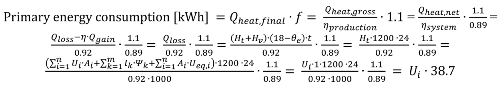

2.3. Evaluation of Design Strategies

2.3.1. System Boundaries

2.3.2. Functional Unit

2.3.3. Environmental Impact Assessment

| Building element | Material | Material from Ecoinvent Database | Amount |

|---|---|---|---|

| Roof Conventional | Bitumen | Bitumen seal | 4 kg/m2 |

| PUR | Polyurethane, rigid foam | 10 kg/m2 | |

| Wooden battens | Sawn wood, softwood, kiln, dried, planed | 0.004 m3/m2 | |

| Gypsum board | Gypsum plasterboard | 23 kg/m2 | |

| Roof Alternative | Gravel | Gravel, crushed | 85 kg/m2 |

| EPDM | n/a, based on [29] | 1 kg/m2 | |

| PUR | Polyurethane, rigid foam | 10 kg/m2 | |

| Wooden battens | Sawn wood, softwood, kiln, dried, planed | 0.004 m3/m2 | |

| Plywood | Plywood, for indoor use | 0.015 m3/m2 | |

| External wall Conventional | Paint, interior | Alkyd paint, without water | 1 kg/m2 |

| Plaster, interior | Cover plaster, mineral | 20 kg/m2 | |

| Sand-lime brick | Sand-lime brick | 200 kg/m2 | |

| EPS | Polystyrene, expandable | 6 kg/m2 | |

| Plaster, exterior | Cover plaster, mineral | 20 kg/m2 | |

| Paint, exterior | Alkyd paint, without water | 1 kg/m2 | |

| External wall Alternative | Plywood | Plywood, for indoor use | 0.075 m3/m2 |

| OSB | Oriented strand board | 0.015 m3/m2 | |

| Timber I-joists | Mix of sawn wood and fibreboard | 0.01 m3/m2 | |

| Mineral wool | Rock wool | 5 kg/m2 | |

| Wood fibre board | Fibreboard, hard | 0.02 m3/m2 | |

| Wooden studs and battens | Sawn wood, softwood, kiln, dried, planed | 0.008 m3/m2 | |

| Cement fibre board | Fibre cement facing tile | 19 kg/m2 |

2.3.4. Interpretation

| Environmental Indicator | Unit | Factor | Impact Method |

|---|---|---|---|

| Global warming potential | kg CO2 eqv. | 0.06 | ReCiPe midpoint |

| Ozone depletion | kg CFC11 eqv. | 49.1 | ReCiPe midpoint |

| Terrestrial acidification | kg SO2 eqv. | 0.85 | ReCiPe midpoint |

| Eutrophication, freshwater | kg P eqv. | 100 | ReCiPe midpoint |

| Eutrophication, marine | kg N eqv. | 18 | ReCiPe midpoint |

| Photochemical oxidant formation | kg NMVOC eqv. | 7.4 | ReCiPe midpoint |

| Depletion of non-fossil resources | kg Fe eqv. | 0.052 | ReCiPe midpoint |

| Human toxicity | DALY | 60000 | ReCiPe endpoint |

| Particulate matter formation | DALY | 60000 | ReCiPe endpoint |

| Ionising radiation | DALY | 60000 | ReCiPe endpoint |

| Ecotoxicity, terrestrial | kg 1.4 DB eqv. | 4.31 | ReCiPe midpoint |

| Ecotoxicity, freshwater | kg 1.4 DB eqv. | 0.0190 | ReCiPe midpoint |

| Ecotoxicity, marine | kg 1.4 DB eqv. | 0.0000014 | ReCiPe midpoint |

| Land occupation, urban | m2a | 0.036 | ReCiPe midpoint |

| Land occupation, forest | m2a | 0.181 | ReCiPe midpoint |

| Land transformation, tropical rain forest | m2 | 0.8 | ReCiPe midpoint |

2.4. Requirements

| Building element | Thermal Performance  | Fire Resistance  | Impact Sound  | Airborne Sound  |

|---|---|---|---|---|

| Floor at ground level | ≤0.30 W/m2K | / | / | / |

| Floor, suspended | ≤1 W/m2K | R60 EI60 | ≤61 dB | ≥56 dB |

| Roof, flat | ≤0.24 W/m2K | R30 EI30 (public/kitchen *) | / | ≥43 dB |

| Wall, external | ≤0.24 W/m2K | R30 (1 level) R60 (>1 level) | / | ≥43 dB |

| Joinery glazing | ≤1.1 W/m2K | / | / | ≥43 dB |

| Joinery framework | ≤1.8 W/m2K | / | / | ≥43 dB |

| Wall partition | ≤1 W/m2K | EI30 (1 level) EI60 (>1 level) | ≤61 dB | ≥56 dB |

| Wall, internal | / | EI60 (kitchen) * | / | ≥48 dB |

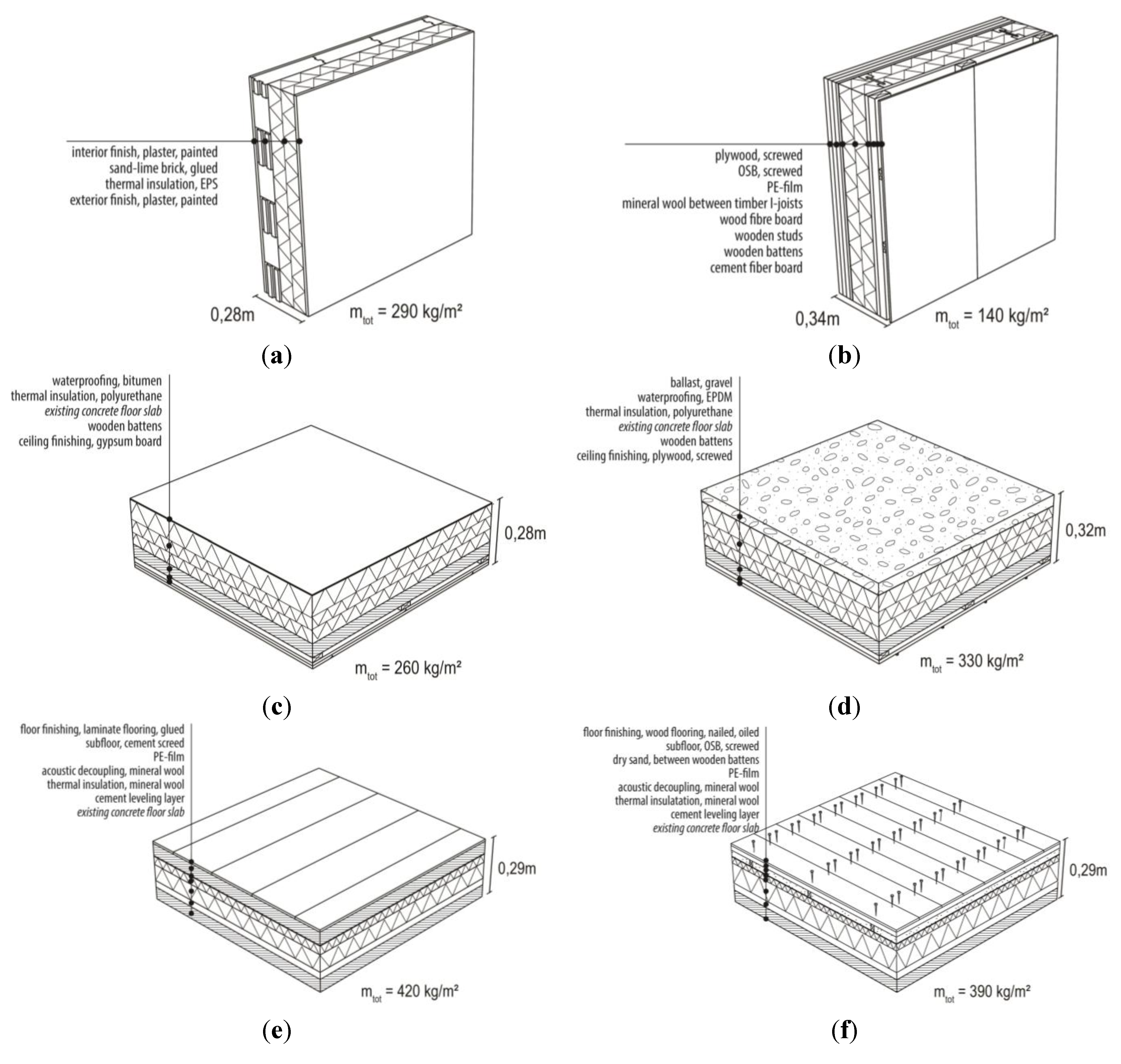

2.5. Detailing of the Building Elements

3. Results

3.1. Introduction

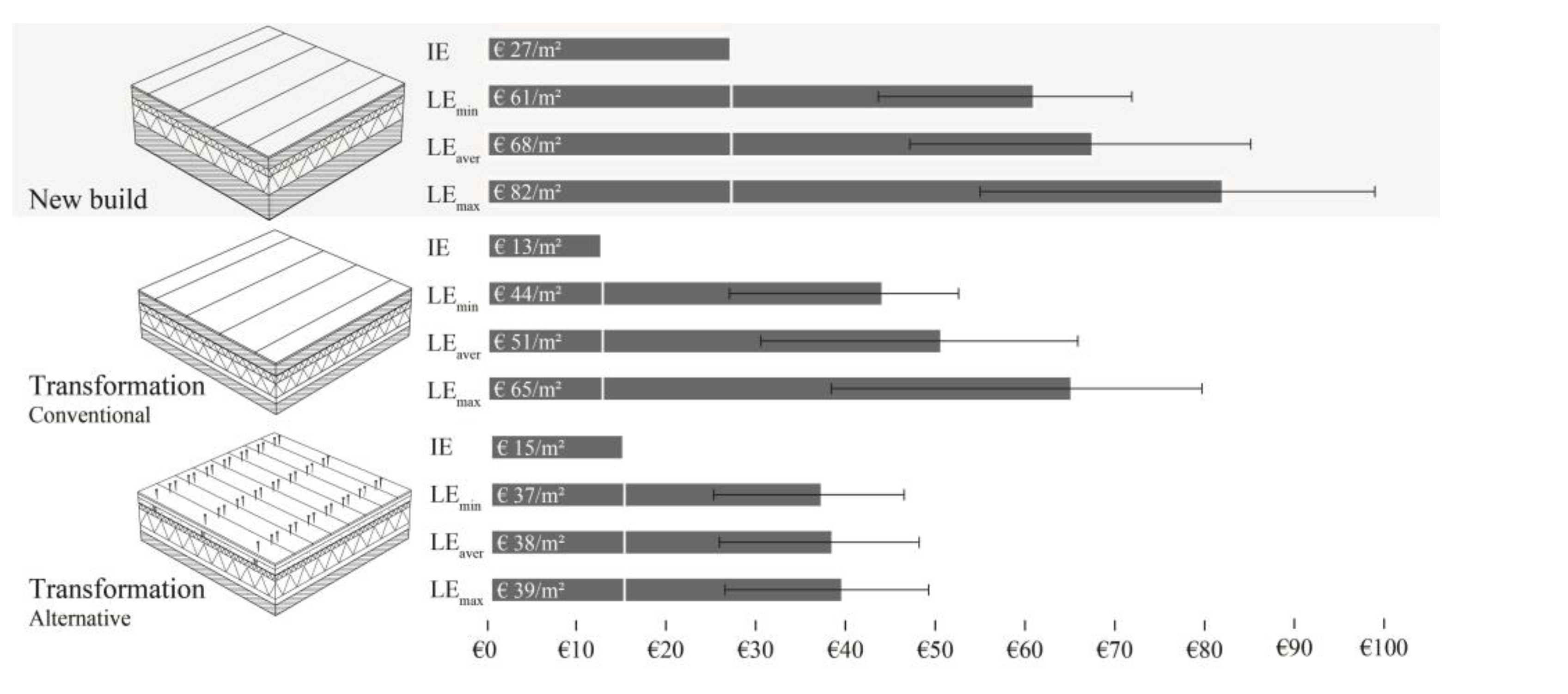

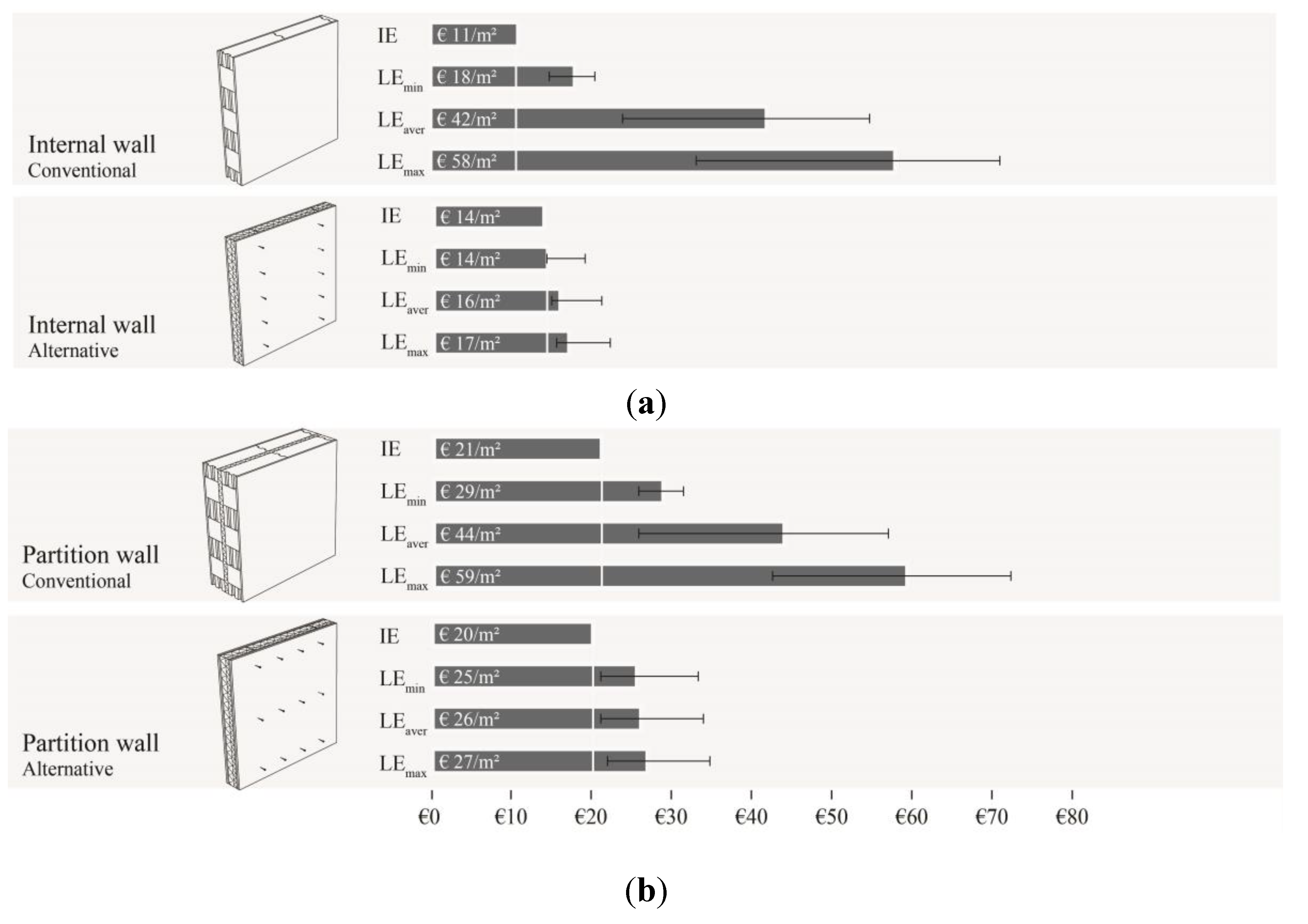

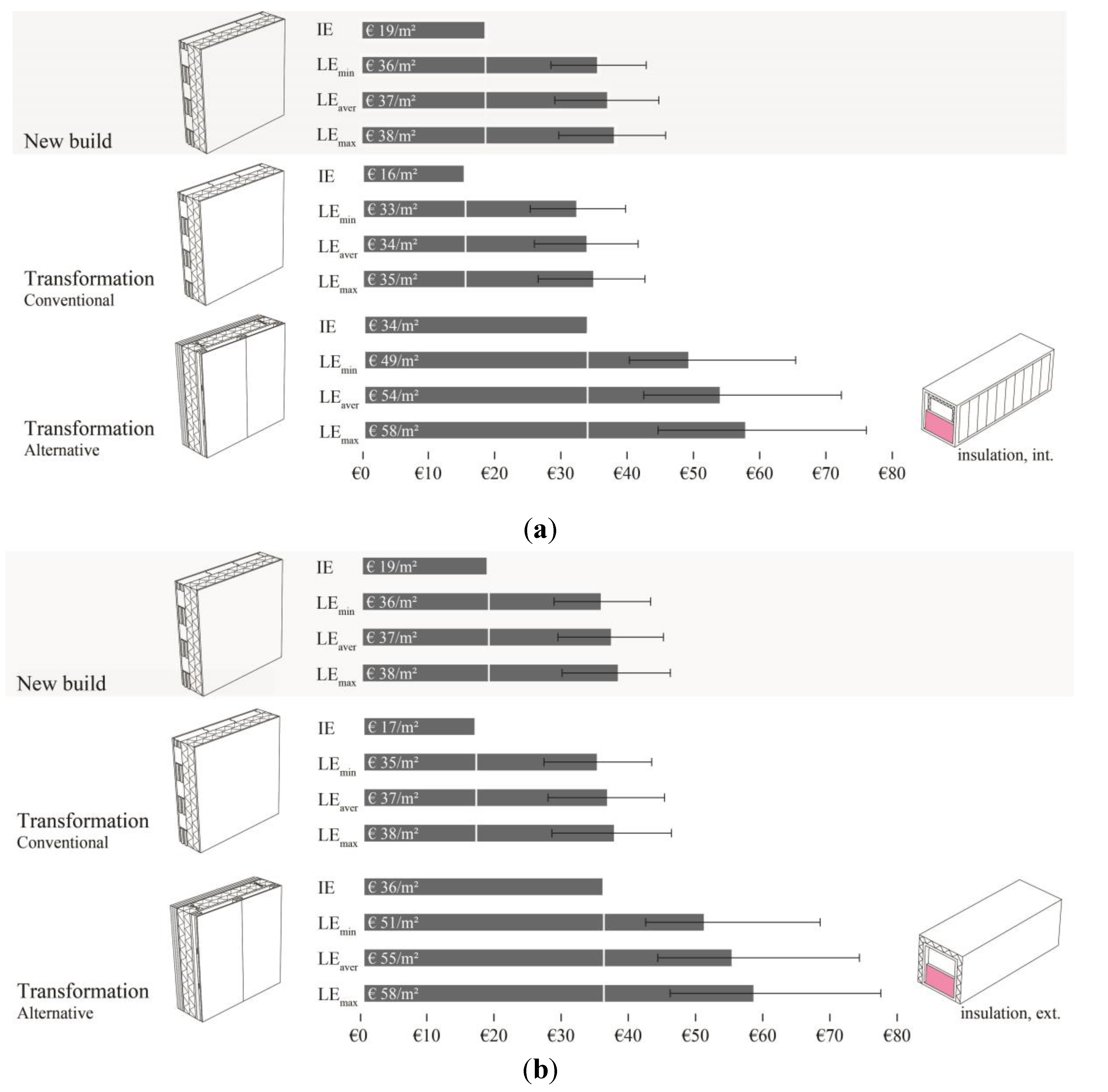

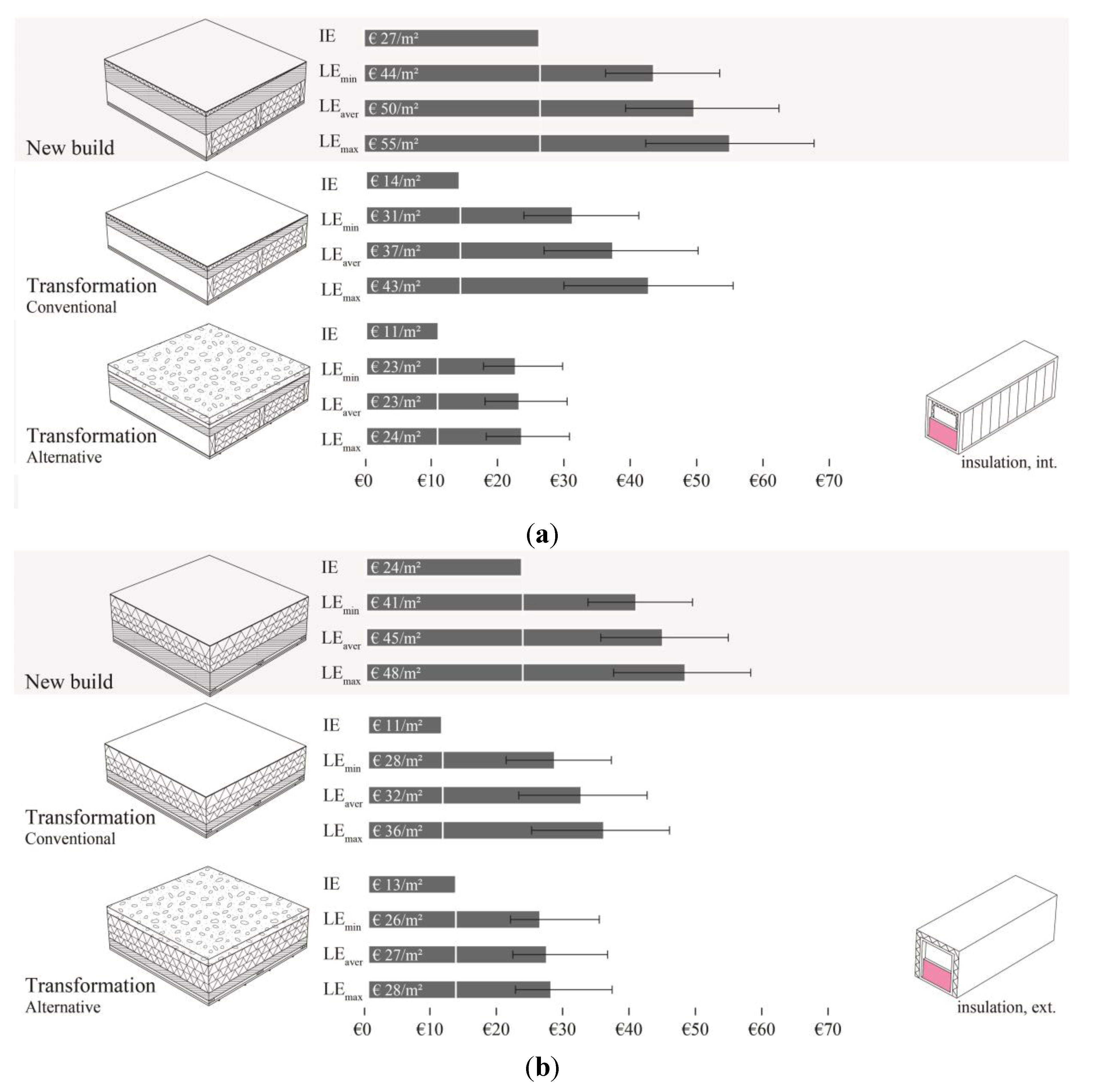

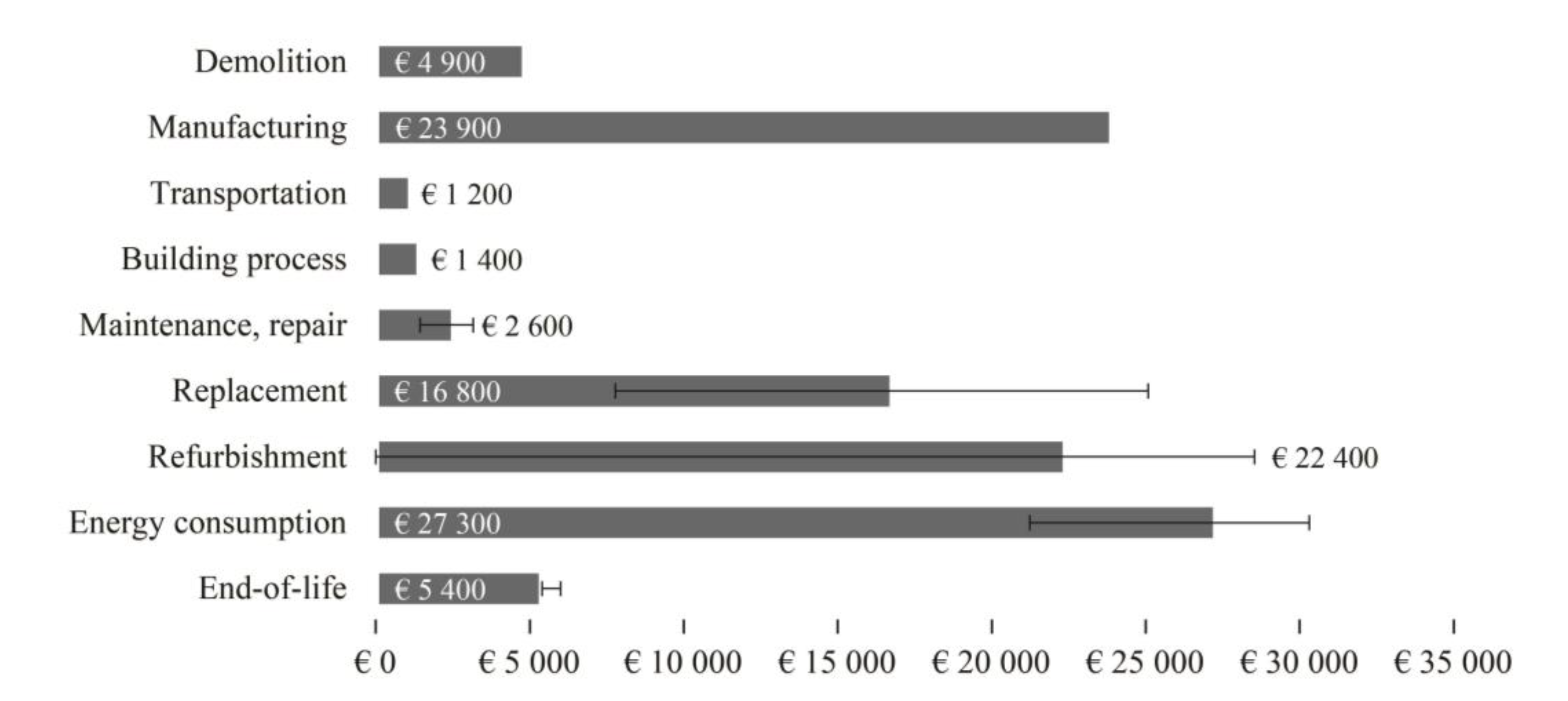

3.2. Evaluation at Element Level

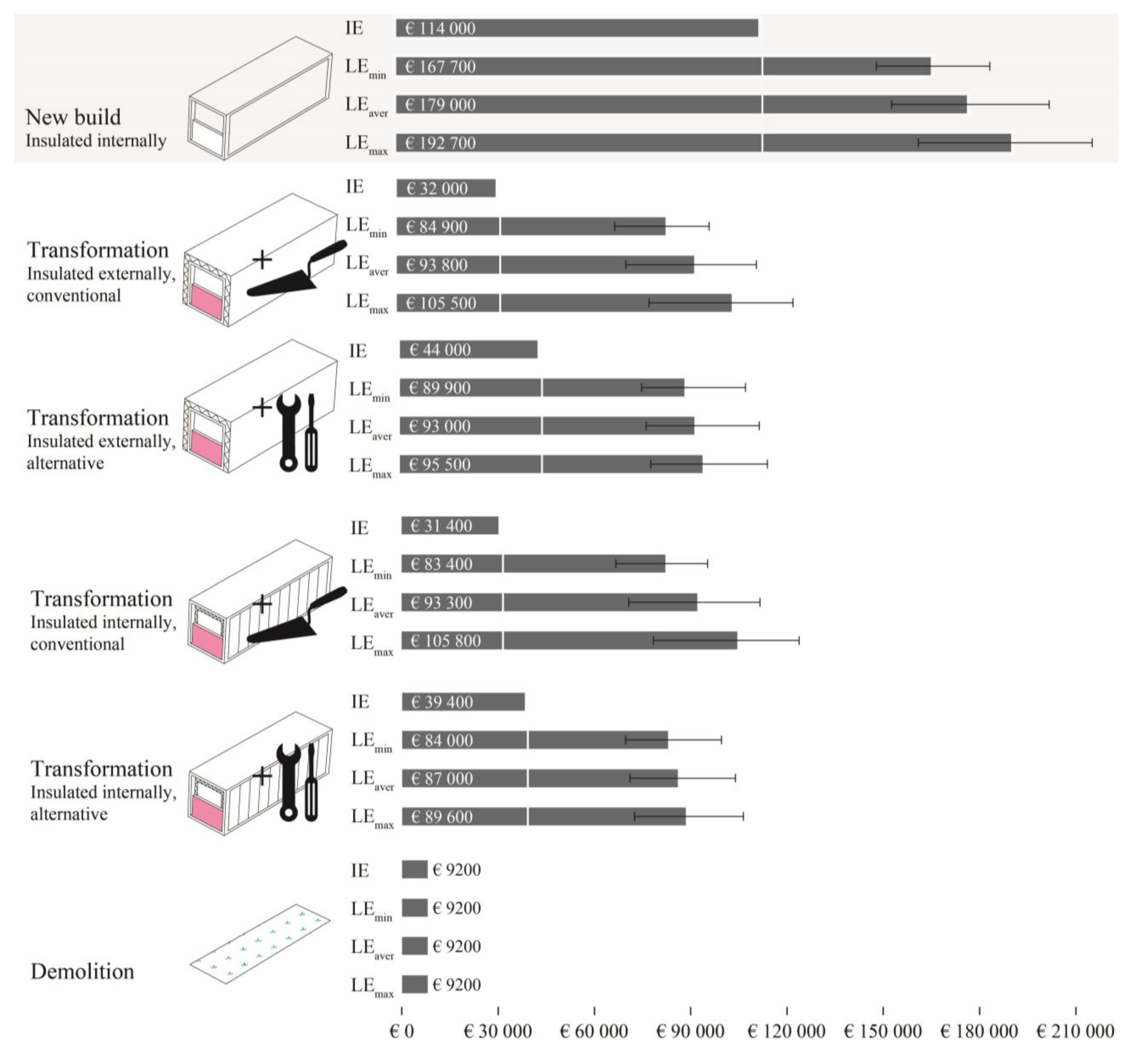

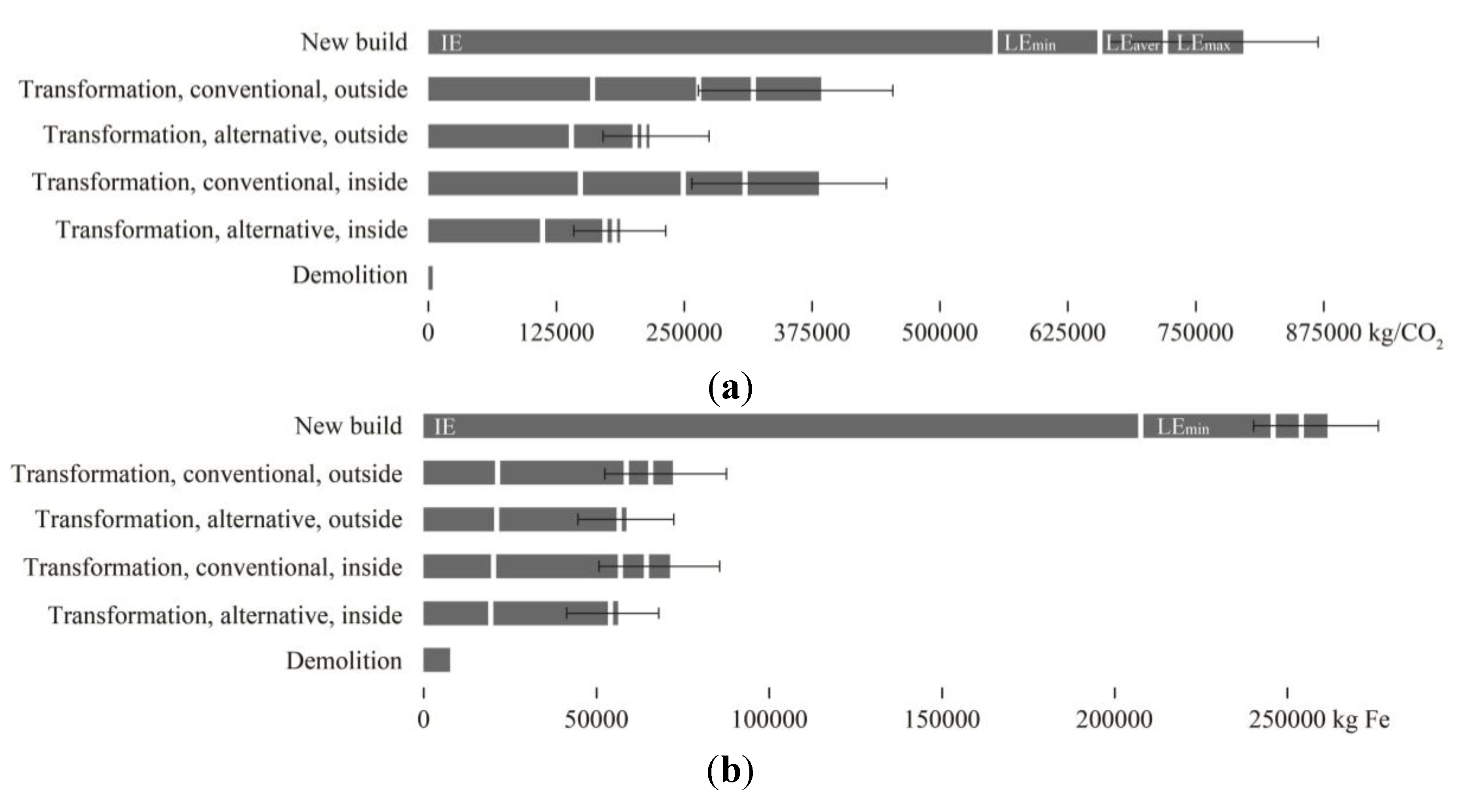

3.3. Evaluation at building level

4. Discussion

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Sodagar, B. Sustainability potentials of housing refurbishment. Buildings 2013, 3, 278–299. [Google Scholar] [CrossRef]

- Stephan, A.; Crawford, R.H.; de Myttenaere, K. A comprehensive assessment of the life cycle energy demand of passive houses. Appl. Energy 2013, 112, 3–34. [Google Scholar] [CrossRef]

- Trachte, S.; Massart, C. Reducing the environmental impact of new dwellings: Analyse of the balance between heating energy savings and environmental assessment of the building materials. Archit. Sustain. Dev. 2011, 2, 217–222. [Google Scholar]

- Paduart, A. Re-design for Change: A 4 Dimensional Renovation Approach towards a Dynamic and Sustainable Building Stock. Ph.D. Thesis, Vrije Universiteit Brussel, Brussels, Belgium, 2012. [Google Scholar]

- Crawford, R.H. Life Cycle Assessment in the Built Environment; Spon Press: London, UK, 2011. [Google Scholar]

- Ciambrone, D. Environmental Life Cycle Analysis; Boca Raton: New York, NY, USA, 1997. [Google Scholar]

- Verbeeck, G.; Hens, H. Life cycle inventory of buildings: A calculation method. Build. Environ. 2010, 45, 1037–1041. [Google Scholar] [CrossRef]

- Thormark, C. A low energy building in a life cycle—Its embodied energy, energy need for operation and recycling potential. Build. Environ. 2002, 37, 429–435. [Google Scholar] [CrossRef]

- Gustavsson, L.; Joelsson, A. Life cycle primary energy analysis of residential buildings. Energy Build. 2010, 42, 210–220. [Google Scholar] [CrossRef]

- Stephan, A.; Crawford, R.H.; de Myttenaere, K. Multi-scale life cycle energy analysis of a low-density suburban neighbourhood in Melbourne, Australia. Build. Environ. 2013, 68, 35–49. [Google Scholar] [CrossRef]

- Cabeza, L.; Rincón, L.; Vilariño, V.; Pérez, G.; Castell, A. Life cycle assessment (LCA) and life cycle energy analysis (LCEA) of buildings and the building sector: A review. Renew. Sustain. Energy Rev. 2014, 29, 394–416. [Google Scholar] [CrossRef]

- Ramesh, T.; Prakash, R.; Shukla, K.K. Life cycle energy analysis of buildings: An overview. Energy Build. 2010, 10, 592–600. [Google Scholar]

- Stephan, A.; Crawford, R.H.; de Myttenaere, K. Towards a comprehensive life cycle energy analysis framework for residential buildings. Energy Build. 2012, 55, 592–600. [Google Scholar] [CrossRef]

- Fay, R.; Treloar, G.; Iyer-Raniga, U. Life-cycle energy analysis of buildings: A case study. Build. Res. Inf. 2000, 28, 31–41. [Google Scholar] [CrossRef]

- Dahlstrøm, O.; Sørnes, K.; Eriksen, S.T.; Hertwich, E.G. Life cycle assessment of a single-family residence built to either conventional- or passive house standard. Energy Build. 2012, 54, 470–479. [Google Scholar] [CrossRef]

- Blom, I.; Itard, L.; Meijer, A. Environmental impact of building-related and user-related energy consumption in dwellings. Build. Environ. 2011, 46, 1657–1669. [Google Scholar] [CrossRef]

- Debacker, W.; Allacker, K.; Spirinckx, C.; Geerken, T.; De Troyer, F. Identification of environmental and financial cost efficient heating and ventilation services for a typical residential building in Belgium. J. Clean. Prod. 2013, 57, 188–199. [Google Scholar] [CrossRef]

- Rossi, B.; Marique, A.-F.; Glaumann, M.; Reiter, S. Life-cycle assessment of residential buildings in three different European locations, basic tool. Build. Environ. 2012, 51, 395–401. [Google Scholar] [CrossRef]

- Dodoo, A.; Gustavsson, L.; Sathre, R. Lifecycle primary energy analysis of low-energy timber building systems for multi-storey residential buildings. Energy Build. 2014, 81, 84–97. [Google Scholar] [CrossRef]

- Vrebos, H. De Studentenwijk (1971–1973) Van De Vrije Universiteit Brussel te Etterbeek: Industrialisatie Binnen Het Oeuvre van Willy Van Der Meeren (1923–2002). Master’s Thesis, Vrije Universiteit Brussel, Brussels, Belgium, 2012. [Google Scholar]

- Sels, G. Ieder zijn huis! De Standaard, 16 May 2012; D8–D9. (In Dutch) [Google Scholar]

- Krucker, B. Werk—Serie. Fritz Stucky Architekt und Unternehmer; Gta Verlag: Zürich, Switzerland, 2006. [Google Scholar]

- CEN. ISO 14040: Environmental Management—Life Cycle Assessment—Principles and Framework; European Committee for Standardization: Brussels, Belgium, 2006. [Google Scholar]

- CEN. ISO 14044: Environmental Management—Life Cycle Assessment—Requirements and Guidelines; European Committee for Standardization: Brussels, Belgium, 2006. [Google Scholar]

- SBR. Levensduur van Bouwproducten—Methode voor Referentiewaarden, 1st ed.; SBR: Rotterdam, the Netherlands, 2011; pp. 10–17. [Google Scholar]

- Frishknecht, R.; Althaus, H.-J.; Doka, G.; Dones, R.; Heck, T.; Helleweg, S.; Hischier, R.; Jungbluth, N.; Nemecek, T.; Rebitzer, G.; et al. Overview and Methodology; Swiss Centre for Life Cycle Inventories: Duebendorf, Switzerland, 2013. [Google Scholar]

- Allacker, K.; Debacker, W.; Delem, L.; De Nocker, L.; De Troyer, F.; Janssen, A.; Peeters, K.; Servaes, R.; Spirinckx, C.; Van Dessel, J. Environmental Profile of Building Elements: Towards an Integrated Environmental Assessment of the Use of Materials in Buildings; OVAM: Mechelen, Belgium, 2013. [Google Scholar]

- Kotaji, S.; Schuurmans, A.; Edwards, S. Life-cycle Assessment in Building and Construction: A State-of-the-Art Report; SETAC-Europe: Brussels, Belgium, 2003. [Google Scholar]

- Debacker, W.; Allacker, K.; De Troyer, F.; Janssen, A.; Delem, L.; Peeters, K.; De Nocker, L.; Spirinckx, C.; van Dessel, J. Milieugerelateerde Materiaalprestatie van Gebouwelementen; OVAM: Mechelen, Belgium, 2012. [Google Scholar]

- Allacker, K. Sustainable Building: The Development of an Evaluation Method. Ph.D. Thesis, KU Leuven, Leuven, Belgium, 2010. [Google Scholar]

- CEN. EN 15804: Sustainability of Construction Works—Environmental Product Declaration—Core Rules for the Product Category of Construction Products; European Committee for Standardization: Brussels, Belgium, 2012. [Google Scholar]

- De Haes, U.; Finnveden, G.; Goedkoop, M.; Hertwich, E.G.; Hofstetter, P.; Klöpffer, W.; Krewitt, W.; Lindeijer, E. Life Cycle Impact Assessment: Striving towards Best Practice; SETAC Press: Pensacola, FL, USA, 2002. [Google Scholar]

- Finnveden, G.; Hauschild, M.Z.; Ekvall, T.; Guinée, J.; Heijungs, R.; Hellweg, S.; Koehler, A.; Pennington, D.; Suh, S. Recent developments in Life Cycle Assessment. J. Environ. Manag. 2009, 91, 1–21. [Google Scholar] [CrossRef]

- Lenzen, M. Uncertainty in impact and externality assessments—Implications for decision-making. Int. J. Life Cycle Assess. 2006, 11, 189–199. [Google Scholar] [CrossRef]

- JRC-IES. ILCD Handbook: International Reference Life Cycle Data System, 1st ed.; European Union: Luxemburg, Luxemburg, 2011. [Google Scholar]

- Goedkoop, M.; Heijungs, R.; Huijbregts, M.; De Schryver, A.; Struijs, J.; van Zelm, R. ReCiPe 2008, A Life Cycle Impact Assessment Method Which Comprises Harmonised Category Indicators at the Midpoint and the Endpoint Level, 1st ed.; RVIM: Bilthoven, the Netherlands, 2013. [Google Scholar]

- De Brusselse Hoofdstedelijke Regering. Besluit van de Brusselse Hoofdstedelijke Regering tot vaststelling van de eisen op het vlak van de energieprestatie en het binnenklimaat van gebouwen; De Brusselse Hoofdstedelijke Regering: Brussels, Belgium, 2008. [Google Scholar]

- BIM. Asbest in uw Woning: Praktische Tips; Leefmilieu Brussel: Brussels, Belgium, 2014. [Google Scholar]

- Belgisch Staatsblad. Koninklijk Besluit van 12 Juli 2012 tot Wijziging van Het Koninklijk Besluit van 7 Juli 1994 Tot Vaststelling van de Basisnormen Voor de Preventie van Brand en Ontploffing Waaraan de Nieuwe Gebouwen Moeten Voldoen; Belgisch Staatsblad: Brussels, Belgium, 2012. [Google Scholar]

- NBN. NBN S01–401: Akoestiek—Grenswaarden voor de Geluidsniveaus Om Het Gebrek aan Komfort in Gebouwen te Vermijden; Bureau voor Normalisatie: Brussels, Belgium, 1987. [Google Scholar]

- Haas, M. NIBE’s Basiswerk Milieuclassificaties Bouwproducten: De Leidraad Bij Het Realiseren van Duurzame en Gezonde Woning—En Utiliteitsbouw, 1st ed.; NIBE Research bv: Bussum, the Netherlands, 2012. [Google Scholar]

- Paduart, A.; De Temmerman, N.; Trigaux, D.; De Troyer, F.; Debacker, W.; Danschutter, S. Casestudy Ontwerp van Gebouwen in Functie van Aanpasbaarheid: Mahatma Gandhiwijk; OVAM: Mechelen, Belgium, 2013. [Google Scholar]

- Blengini, G.A.; Di Carlo, T. The changing role of life cycle phases, subsystems and materials in the LCA of low energy buildings. Energy Build. 2010, 42, 869–880. [Google Scholar] [CrossRef]

- Winistorfer, P.; Chen, Z.; Lippke, B.; Stevens, N. Energy consumption and greenhouse gas emissions related to the use, maintenance, and disposal of a residential structure. Wood Fiber Sci. 2005, 37, 28–139. [Google Scholar]

- Suh, S.; Lenzen, M.; Treloar, G.J.; Hondo, H.; Horvath, A.; Huppes, G.; Jolliet, O.; Klann, U.; Krewitt, W.; Moriguchi, Y.; et al. System boundary selection in life-cycle inventories using hybrid approaches. Environ. Sci. Technol. 2004, 38, 657–664. [Google Scholar] [CrossRef] [PubMed]

- Crawford, R.H. Validation of a hybrid life-cycle inventory analysis method. J. Environ. Manag. 2008, 88, 496–506. [Google Scholar] [CrossRef]

- Treloar, G.J. Environmental assessment using both financial and physical quantities. In Proceedings of the 41st Annual Conference of the Architectural Science Association ANZAScA, Victoria, Australia, 14–16 November 2007.

- Treloar, G.J.; Crawford, R.H. Database of Embodied Energy and Water Values for Materials; The University of Melbourne: Melbourne, Australia, 2010. [Google Scholar]

- Stephan, A.; Stephan, L. Reducing the total life cycle energy demand of recent residential buildings in Lebanon. Energy 2014, 74, 618–637. [Google Scholar] [CrossRef]

- Majeau-Bettez, G.; Strømman, A.H.; Hertwich, E.G. Evaluation of process- and input-output-based life cycle inventory data with regard to truncation and aggregation issues. Environ. Sci. Technol. 2011, 45, 10170–10177. [Google Scholar] [CrossRef] [PubMed]

- Sharma, A.; Saxena, A.; Sethi, M.; Shree, V.; Varun. Life cycle assessment of buildings: A review. Renew. Sustain. Energy Rev. 2011, 15, 871–875. [Google Scholar] [CrossRef]

- Hansen, O.J. Status of Life Cycle Assessment (LCA) activities in the Nordic region. Int. J. Life Cycle Assess. 1999, 44, 315–320. [Google Scholar] [CrossRef]

- Galle, W.; Vandenbroucke, M.; De Temmerman, N. Life Cycle Costing as an Early Stage Feasibility Analysis: The Adaptable Transformation Of Willy Van Der Meeren’s Student Residences. Procedia Econ. Financ. 2015, 21, 14–22. [Google Scholar] [CrossRef]

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vandenbroucke, M.; Galle, W.; De Temmerman, N.; Debacker, W.; Paduart, A. Using Life Cycle Assessment to Inform Decision-Making for Sustainable Buildings. Buildings 2015, 5, 536-559. https://doi.org/10.3390/buildings5020536

Vandenbroucke M, Galle W, De Temmerman N, Debacker W, Paduart A. Using Life Cycle Assessment to Inform Decision-Making for Sustainable Buildings. Buildings. 2015; 5(2):536-559. https://doi.org/10.3390/buildings5020536

Chicago/Turabian StyleVandenbroucke, Mieke, Waldo Galle, Niels De Temmerman, Wim Debacker, and Anne Paduart. 2015. "Using Life Cycle Assessment to Inform Decision-Making for Sustainable Buildings" Buildings 5, no. 2: 536-559. https://doi.org/10.3390/buildings5020536

APA StyleVandenbroucke, M., Galle, W., De Temmerman, N., Debacker, W., & Paduart, A. (2015). Using Life Cycle Assessment to Inform Decision-Making for Sustainable Buildings. Buildings, 5(2), 536-559. https://doi.org/10.3390/buildings5020536