Abstract

As a polymer-like organic material, asphalt often undergoes aging during service life. Regeneration technology is the main approach to achieve its recycling; therefore, the rejuvenator is an important factor affecting the regeneration effect. In order to evaluate the rejuvenation effects of rejuvenators on aged asphalt, fluid catalytic cracking (FCC) slurry and a penetrant containing epoxy functional groups were used to prepare conventional rejuvenators (CR1 and CR2) and a penetrable rejuvenator (PR). The impact of the penetrant on the physical properties of the rejuvenator was investigated, and the rejuvenation effects of different rejuvenators on mild and severe aged asphalt were evaluated through physical and rheological tests. Results show that the penetrant effectively lubricates the movement of rejuvenator molecules, improving the high temperature stability and aging resistance of the rejuvenator. CR1 and CR2 are more suitable for mild aged asphalt, as mild aging has a relatively minimal effect on the chemical composition and colloidal structure of asphalt. At a 25% dosage, the PR significantly restores the physical properties of severe aged asphalt, while CR1 and CR2 still fail to meet specifications. The PR is more effective for severe aged asphalt because it not only dissolves and disperses asphaltenes but also weakens interactions between asphaltenes, which facilitates a more effective restoration of the colloidal structure and significantly enhances the rejuvenation effect. The findings of this study provide insights into the design of penetrable rejuvenators for a more efficient utilization of reclaimed asphalt pavement (RAP).

1. Introduction

Asphalt, an organic material, is widely used for pavement construction [1,2,3]. During its service life, it undergoes aging due to the combined effects of heat, oxygen, and UV exposure [4,5,6]. This aging process causes aromatics in asphalt to transform into resins, which are then converted into asphaltenes, disrupting the chemical balance and altering the colloidal structure of asphalt [7,8,9], ultimately leading to a deterioration in pavement performance and the development of distresses such as ruts, cracks, potholes, and fatigue cracking [10,11]. As a result, rehabilitation or even reconstruction of the pavement is required, which generates significant amounts of reclaimed asphalt pavement (RAP). If not properly utilized, the substantial amount of RAP contributes to an increased environmental burden, contradicting the principles of sustainable development. Fortunately, this challenge can be effectively addressed through the rejuvenation and reuse of aged bitumen. The rejuvenation of aged asphalt, meaning reversing the aging process, involves the addition of rejuvenators to restore chemical composition and colloidal structure, which improves its performance [12,13]. According to the colloidal theory, rejuvenators, which increase aromatics and reduce asphaltenes, restore chemical composition to improve the performance of aged asphalt. For instance, Shi et al. [14] investigated the effectiveness of waste soybean oil on aged asphalt. Zhao et al. [15] showed that waste cooking oil can restore the chemical composition of aged asphalt, with the aging resistance of its fractions primarily influenced by their carbon chain length. Luo et al. [16] investigated the fatigue performance of rejuvenated asphalt and concluded that the degree of integration between new and aged asphalt determines its fatigue life, which can be significantly improved by rejuvenators with higher levels of light components and better penetration ability. Wang et al. [17] evaluated the rejuvenation effects of various bio-oils on aged asphalt and discovered that vegetable oil and gutter oil significantly affected the rutting resistance of aged asphalt, whereas castor oil, soybean oil, and straw oil were more effective in improving the percent recovery and non-recoverable compliance of aged asphalt.

Fluid catalytic cracking slurry (FCC slurry) is the product obtained at the bottom of a distillation column after vacuum residue undergoes catalytic cracking in a fluidized catalytic cracking unit [18]. It is commonly used in rubber processing, where it enhances the plasticity of rubber, reduces the viscosity and mixing temperature of the compound, and acts as a lubricant in calendering and extrusion processes. FCC slurry contains a high concentration of polycyclic aromatic hydrocarbons, the aromatic content of which exceeds 70%, making it frequently used as a rejuvenator for asphalt [19,20,21].

Rejuvenators must penetrate the inner layers of aged asphalt to restore its chemical composition and colloidal structure. In reclaimed asphalt pavement (RAP), however, aged asphalt contains a high concentration of asphaltenes, which aggregate to form a spatial network [22,23,24], and this network obstructs the penetration of rejuvenator molecules into the deeper layers of asphalt. If the rejuvenator used fails to penetrate aged asphalt effectively before the resurfacing and compaction of the rejuvenated asphalt mixture and instead remains only on the surface, it will not only fail to regenerate asphalt but may also negatively affect the performance of the rejuvenated mixture [25,26]. Despite the prevalent focus on rejuvenators enriched with light components, there has been a notable lack of attention to their penetration ability, a critical factor that impedes the advanced utilization of RAP. In order to overcome this challenge, the rejuvenator needs to possess an enhanced dissolving ability for asphaltenes, which could improve its penetration into the deeper layers of aged asphalt and significantly boost its effectiveness.

In this work, FCC slurry and a penetrant containing epoxy functional groups were used to prepare conventional rejuvenators (CR1 and CR2) and a penetrable rejuvenator (PR). The rejuvenation effects of rejuvenators on asphalt with varying levels of aging were investigated through physical and rheological property tests.

2. Materials and Methods

2.1. Materials

Base asphalt was used to prepare aged asphalt, and its physical properties and chemical components are shown in Table 1. The penetrant is a substance containing epoxy functional groups, with its physical properties shown in Table 2. FCC slurry, rich in aromatics, was utilized, and its physical properties are shown in Table 3. To modify the performance of rejuvenators, an additive for viscosity modification was also used during the preparation process.

Table 1.

Physical properties and components of asphalt.

Table 2.

Physical properties of penetrant.

Table 3.

Physical properties of fluid catalytic cracking slurry oil.

2.2. Preparation of Rejuvenators

Preparation of the conventional rejuvenator: FCC slurry, heated to a flowable state, was mixed with a viscosity modifier in the appropriate proportion and added to a reaction vessel. The blend was then stirred in an oil bath at 140 °C for 20 min. Two traditional rejuvenators with different viscosities, CR1 and CR2, were prepared for comparison.

Preparation of the penetrable rejuvenator: A certain proportion of the penetrant was added to CR1, and then the blend was stirred in an oil bath at 140 °C for 15 min to obtain the penetrable rejuvenator (PR).

The physical properties of the prepared rejuvenators are shown in Table 4.

Table 4.

Physical properties of prepared rejuvenators.

2.3. Preparation of Rejuvenated Asphalt

- (1)

- Aging treatment

A thin-film oven test (TFOT) as per JTG E20-2011 [27] was used to simulate the aging behavior of asphalt. A total of (50 ± 0.5) g of asphalt was placed in a flat-bottomed circular dish with a 140 mm inner diameter and aged in a 163 °C film oven for 25 h and 50 h. The physical properties of aged asphalt are summarized in Table 5. The aging degree of asphalt is typically assessed by its penetration. As shown in Table 5, after aging for 25 h and 50 h, the penetration values were 32 dmm and 14 dmm, indicating mild and severe aging, respectively.

Table 5.

Physical properties of aged asphalt.

- (2)

- Rejuvenation of asphalt

Aged and fresh asphalt, preheated to a molten state, were thoroughly blended. Different types and quantities of rejuvenators were then added to the blend to prepare rejuvenated asphalt. The physical properties of rejuvenated asphalt without rejuvenators, obtained by mixing aged asphalt with fresh asphalt at a 50:50 mass ratio and stirring for 30 min at 140 °C, are shown in Table 6. It is evident that adding fresh asphalt to aged asphalt does not effectively restore their physical properties. Therefore, subsequent experiments involved adding rejuvenators to rejuvenated asphalt based on the weight of aged asphalt.

Table 6.

Regenerated asphalt without rejuvenators.

2.4. Measurements

- (1)

- Physical property test

The physical properties of rejuvenated asphalt samples were tested as per JTG E20-2011, including penetration (25 °C), softening point, ductility (15 °C), and viscosity (135 °C).

- (2)

- Rheological property test

An MCR-101 dynamic shear rheometer (DSR) (Anton Paar GmbH, Graz, Austria) was used for the rheological property test as per JTG E20-2011. A temperature scanning test was conducted in strain-controlled mode within a range of 20 °C to 70 °C. For temperatures below 20 °C, the disk diameter was 8 mm, with a 2 mm gap between the plates, and above 20 °C, the disk diameter was increased to 25 mm and the gap was reduced to 1 mm.

3. Results and Discussion

3.1. Effect of Penetrant on Rejuvenator

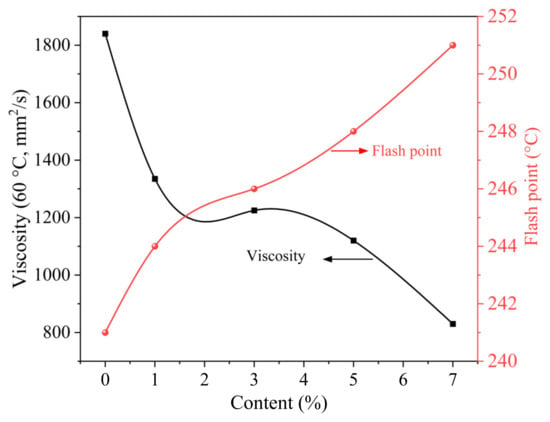

Figure 1 illustrates the effect of the penetrant on viscosity and flash point of the rejuvenator. As the penetrant dosage increases, the viscosity of the rejuvenator decreases, as the penetrant, with its low viscosity and great flowability, acts as a lubricant for rejuvenator molecules, which reduces the resistance to their movement. The flash point of the rejuvenator also increases as the content of the penetrant increases. Before the addition of the penetrant, the flash point is 241 °C, but after adding 7% of the penetrant, it increases to 251 °C, which indicates an enhanced high-temperature stability of the rejuvenator. On the one hand, the penetrant has a relatively high flash point, offering better high-temperature resistance; on the other hand, by reducing the relative content of FCC slurry in the rejuvenator, the addition of the penetrant lowers the content of light components, raising the flash point of the rejuvenator.

Figure 1.

Effect of penetrant on physical properties of rejuvenator.

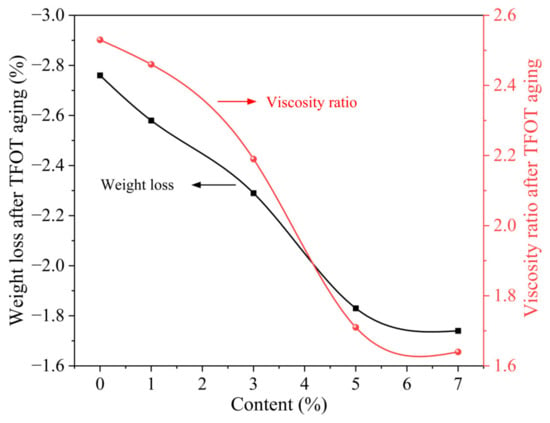

Figure 2 shows the effect of the penetrant on the mass loss and viscosity of the rejuvenator after TFOT. It can be observed that as the dosage of the penetrant increases, the mass loss and viscosity change in the rejuvenator after aging decrease, indicating that the penetrant improves the anti-aging performance of the rejuvenator. The weight loss of the rejuvenator after TFOT aging reaches 1.74% at a penetrant dosage of 7%. The improvement can be attributed to the fact that the addition of the penetrant reduces the relative content of FCC slurry, which lowers light components and reduces the content of volatiles lost at high temperatures. Additionally, the penetrant, with its excellent high-temperature resistance, contributes to the overall enhancement of the high-temperature stability of the rejuvenator.

Figure 2.

Effect of penetrant on aging properties of rejuvenator.

3.2. Effect of Rejuvenator on Physical Properties of Mild Aged Asphalt

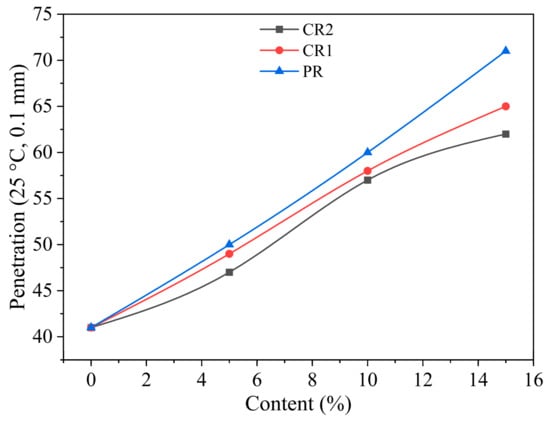

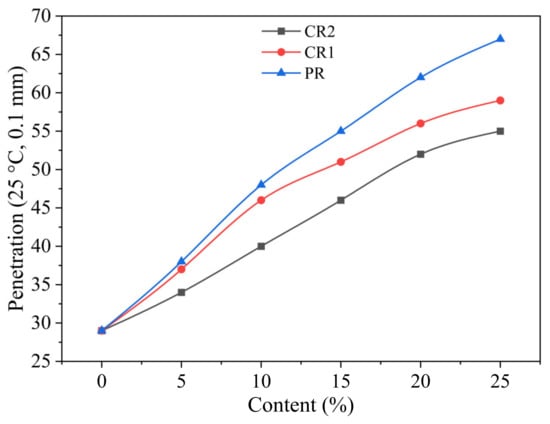

3.2.1. Penetration

The effect of rejuvenators on the penetration of mild aged asphalt is shown in Figure 3. The penetration of rejuvenated asphalt steadily increases as the dosage of the rejuvenator increases. It is evident that the penetration of rejuvenated asphalt meets specifications when the dosage of three rejuvenators reaches 15%. Additionally, it is interesting that the rate of increase in penetration with the addition of the PR is significantly higher than that with CR1 and CR2, which indicates that the PR is more effective in improving the penetration of mild aged asphalt compared to CR1 and CR2. This can be attributed to the fact that the penetrant in the PR not only dissolves and disperses asphaltenes effectively but also contains epoxy groups, which by chemically interacting with asphaltenes in aged asphalt reduce the intermolecular forces between asphaltenes. This, in turn, allows asphaltenes to be more evenly dispersed within asphalt, leading to a more uniform distribution and improving the colloidal structure of aged asphalt. As a result, the PR demonstrates a significantly stronger effect on enhancing the penetration of mild aged asphalt compared to CR1 and CR2.

Figure 3.

Effect of rejuvenator on penetration of mild aged asphalt.

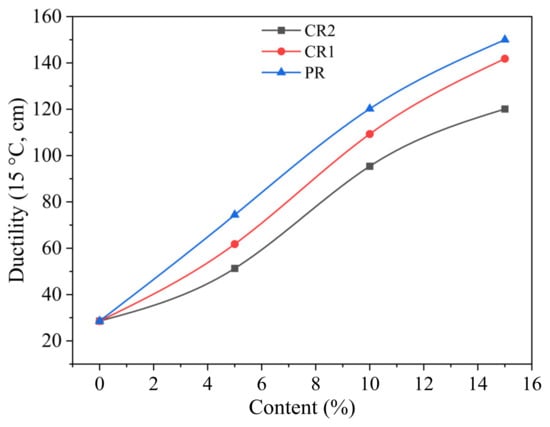

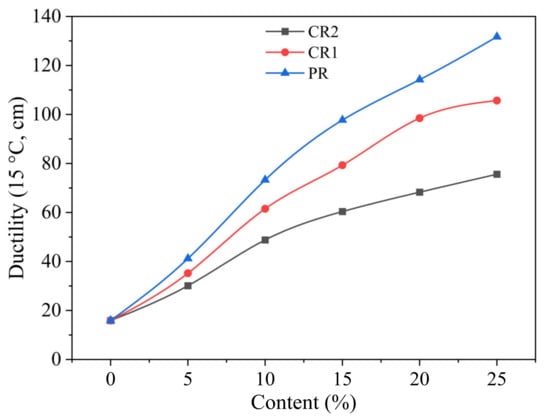

3.2.2. Ductility

The effect of rejuvenators on the ductility of mild aged asphalt is displayed in Figure 4. As the dosage of the rejuvenator increases, the ductility of rejuvenated asphalt improves. It is significant that the dosage of all three rejuvenators reaches 15%, at which the ductility of the rejuvenated asphalt meets specifications. As can be observed, at dosages of 15% for CR1, CR2, and the PR, the ductility of the rejuvenated asphalt increases by 5.0 times, 4.2 times, and 5.3 times, respectively, which indicates that the PR is more effective in improving the low-temperature ductility of mild aged asphalt than CR1 and CR2.

Figure 4.

Effect of rejuvenator on ductility of mild aged asphalt.

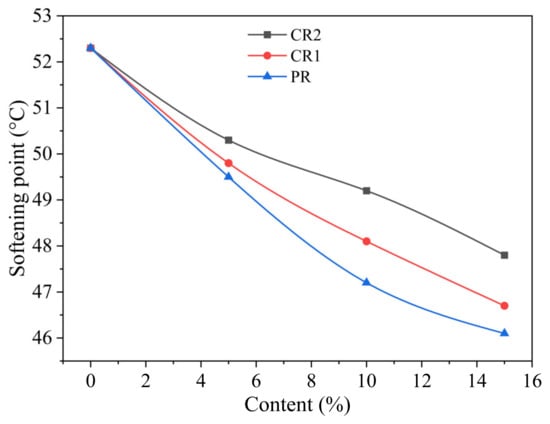

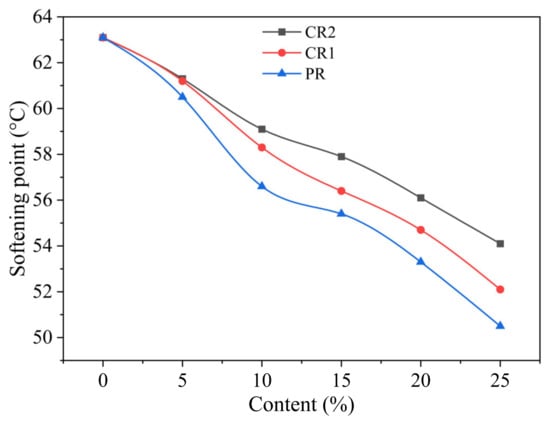

3.2.3. Softening Point

Figure 5 displays the effect of rejuvenators on the softening point of mild aged asphalt. Three rejuvenators effectively reduce the softening point of aged asphalt, with the softening point of rejuvenated asphalt closely approaching that of fresh asphalt at dosages of 10% to 15%. Moreover, the reduction in softening point is more pronounced with the addition of the PR compared to CR1 and CR2. It can be explained that the PR not only dissolves and disperses asphaltenes but also weakens the intermolecular interactions between asphaltenes. As a result, the resistance to asphalt molecular movement is lowered, enhancing the flowability of aged asphalt. It is also evident that the PR is more effective in lowering the softening point of aged asphalt, which is due to its interaction with asphaltenes. Since the softening point of mild aged asphalt does not increase significantly, it is concerning that the substantial reduction in the softening point caused by the PR may weaken the high-temperature performance of the asphalt mixture. Therefore, for the rejuvenation of mild aged asphalt, CR1 and CR2 are recommended.

Figure 5.

Effect of rejuvenator on softening point of mild aged asphalt.

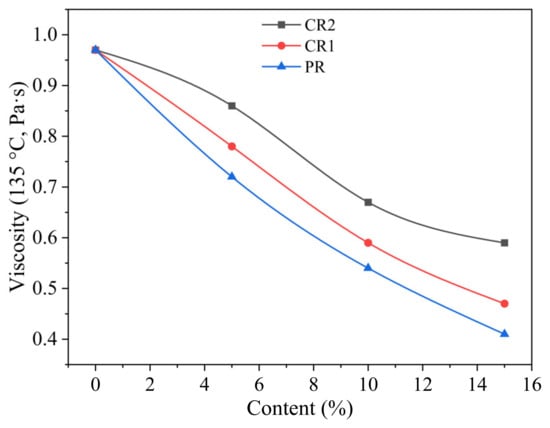

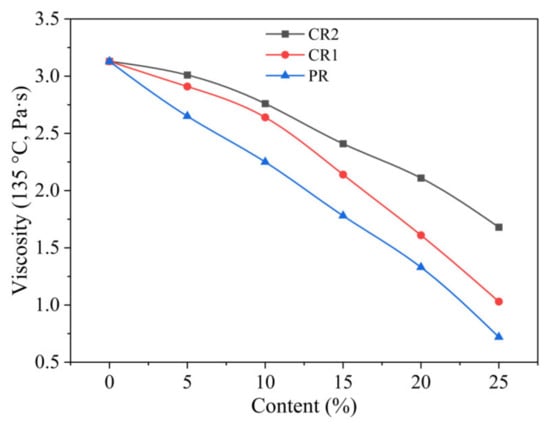

3.2.4. Viscosity

Figure 6 shows the effect of rejuvenators on the viscosity of mild aged asphalt. The viscosity of mild aged asphalt decreases with increasing dosages of rejuvenators, indicating that rejuvenators reduce the flow resistance. Notably, the reduction in viscosity with increasing PR dosage is more significant than with CR1 and CR2. The viscosity of rejuvenated asphalt approaches that of fresh asphalt when the PR dosage reaches 15%, which highlights that the PR is more effective in restoring the colloidal structure of aged asphalt. This improvement is largely attributed to the penetrant in the PR, which has a stronger dissolving effect on asphaltenes. Moreover, the PR has the lowest viscosity among the three rejuvenators, enhancing its ability to reduce the viscosity of aged asphalt. The impact of mild aging on the viscosity of asphalt is limited, and the weakening of high-temperature performance caused by the PR makes it less suitable as a rejuvenator for mild aged asphalt than CR1 and CR2.

Figure 6.

Effect of rejuvenator on viscosity of mild aged asphalt.

3.3. Effect of Rejuvenator on Physical Properties of Severe Aged Asphalt

3.3.1. Penetration

Figure 7 illustrates the effect of rejuvenators on the penetration of severe aged asphalt. It can be seen that the penetration of severe aged asphalt increases with the addition of rejuvenators. Prior to the addition of rejuvenators, the penetration of the rejuvenated asphalt, a blend of 40% severe aged asphalt and 60% fresh asphalt, was 29 dmm. The penetration of rejuvenated asphalt increased to 67 dmm, 59 dmm, and 55 dmm when the dosages of PR, CR1, and CR2 reach 25%, corresponding to increases of 131.03%, 103.45%, and 89.66%, respectively. It is interesting to note that the PR significantly restores the penetration of severe aged asphalt, meeting the specifications, while CR1 and CR2, even at a dosage of 25%, do not meet the specifications. This can be attributed to the higher asphaltene content in severe aged asphalt compared to mild aged asphalt, which leads to a dramatic increase in viscosity. CR1 and CR2 can only improve the colloidal structure of severe aged asphalt to a limited extent by modifying the aromatic and asphaltene content. In contrast, the PR not only dissolves and disperses asphaltenes through the penetrant but also aids in redistributing asphaltenes within asphalt, effectively modifying the colloidal structure of severe aged asphalt.

Figure 7.

Effect of rejuvenator on penetration of severe aged asphalt.

3.3.2. Ductility

Figure 8 depicts the effect of rejuvenators on the ductility of severe aged asphalt. It can be seen that the ductility of severe aged asphalt increases as the dosage of rejuvenators rises. The ductility reaches 131.7 cm, 105.7 cm, and 75.6 cm at 25% dosages of PR, CR1, and CR2, respectively. Both PR and CR1 are effective in restoring the ductility of severe aged asphalt to meet specifications; however, CR2 fails to achieve specifications, even at a 25% dosage. This difference is mainly due to the high asphaltene content and viscosity in severe aged asphalt. Conventional rejuvenators, which only modify the aromatic and asphaltene content, cannot effectively restore the colloidal structure of asphalt, resulting in a limited improvement in ductility. The PR not only dissolves and disperses asphaltenes with the help of a penetrant but also weakens the strong intermolecular interactions between asphaltene molecules, which enhances the mobility of asphalt molecules and improves the plastic deformation capacity of asphalt during stretching.

Figure 8.

Effect of rejuvenator on ductility of severe aged asphalt.

3.3.3. Softening Point

The effect of rejuvenators on the softening point of severe aged asphalt is shown in Figure 9. It can be observed that the softening point of severe aged asphalt decreases with the increasing dosage of rejuvenators, which indicates that the rejuvenators improve the flow resistance of asphalt. The PR has a more pronounced effect on lowering the softening point of severe aged asphalt compared to CR1 and CR2. Before the addition of rejuvenators, the softening point of asphalt was 63.1 °C, and the softening point of severe aged asphalt decreased to 54.1 °C after adding 25% CR2, while adding the same dosage of the PR reduced the softening point to 50.5 °C, a difference of 3.6 °C, which highlights that the PR, with its lower viscosity and ability to dissolve and disperse asphaltenes, is more effective in improving the softening point of severe aged asphalt.

Figure 9.

Effect of rejuvenator on softening point of severe aged asphalt.

3.3.4. Viscosity

Figure 10 shows the effect of rejuvenators on the viscosity of severe aged asphalt. It can be seen that the viscosity of the severe aged asphalt decreases with increasing rejuvenator dosages, which indicates an improvement in the high-temperature flowability of asphalt. The viscosity reduction rate is faster with the addition of the PR than with CR1 and CR2. Before adding rejuvenators, the viscosity of the severe aged asphalt blended with fresh asphalt is 3.13 Pa·s. The viscosity decreases to 1.68 Pa·s when 25% CR2 is added, a reduction of 46.33%. However, the viscosity decreases to 0.72 Pa·s when the same amount of the PR is added, a reduction of 77%, which highlights that the PR is more effective in enhancing the flowability of severe aged asphalt. This can be explained by the fact that CR1 and CR2 only alter the aromatics and asphaltenes of aged asphalt, which is insufficient to restore its colloidal structure effectively, leading to a weaker impact on viscosity. Conversely, the PR dissolves, disperses, and breaks up asphaltenes, which allows for a more effective adjustment of the colloidal structure, and the PR itself has a lower viscosity, further improving the reduction in viscosity in aged asphalt.

Figure 10.

Effect of rejuvenator on viscosity of severe aged asphalt.

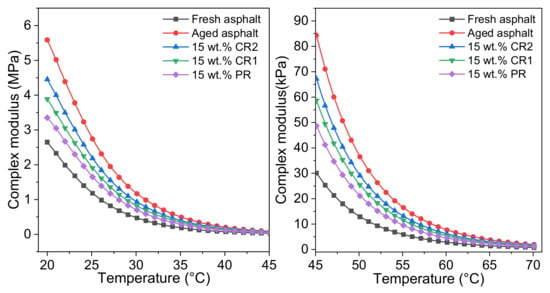

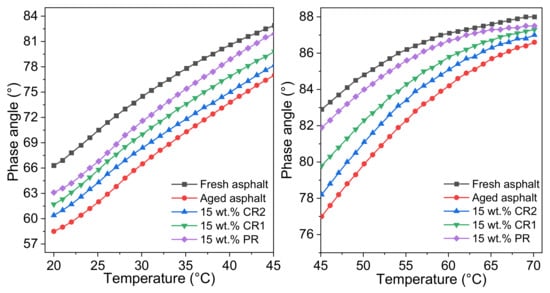

3.4. Effect of Rejuvenator on Rheological Properties of Aged Asphalt

Figure 11 and Figure 12 display the variation in the complex modulus and phase angle with temperature for fresh asphalt, severe aged asphalt, and rejuvenated asphalt. It can be seen that the addition of rejuvenators leads to a decrease in the complex modulus and an increase in the phase angle for aged asphalt, suggesting that rejuvenators reduce the elastic component while enhancing the viscous component. In fact, rejuvenators are able to dissolve and disperse aggregated asphaltenes in aged asphalt, which aids in restoring its colloidal structure. Notably, PR, CR1, and CR2 have different effects on the complex modulus and phase angle of aged asphalt. Among them, the PR shows a more pronounced effect in reducing the complex modulus and increasing the phase angle, as it promotes a better blending of fresh and aged asphalt, which contributes to the restoration of the colloidal structure and results in more significant changes in the complex modulus and phase angle.

Figure 11.

Effect of rejuvenator on complex modulus of aged asphalt.

Figure 12.

Effect of rejuvenator on phase angle of aged asphalt.

4. Conclusions

- (1)

- The penetrant, with its low viscosity and good fluidity, provides an effective lubrication for the movement of rejuvenator molecules, which improves the viscosity of the rejuvenator. And the addition of the penetrant enhances the high-temperature stability and aging resistance of the rejuvenator, which benefits the regeneration of aged asphalt.

- (2)

- Regarding mild aged asphalt, the PR exhibits a more pronounced effect on reducing the softening point and viscosity compared to CR1 and CR2 as its dosage increases, with reductions of 5.4%, 9.8%, and 11.9%, respectively. This indicates that the PR effectively dissolves and disperses asphaltenes while weakening their interactions. In addition, CR1 and CR2 are more suitable than the PR for rejuvenating mild aged asphalt.

- (3)

- Severe aging significantly increases the asphaltene content, which intensifies the spatial hindrance of asphaltenes. At dosages of 25% for the PR, CR1, and CR2, the PR significantly restores the physical properties of severe aged asphalt, whereas CR1 and CR2 still fail to meet the specifications. The PR, in contrast to CR1 and CR2, not only dissolves and disperses asphaltenes but also disrupts their interactions, leading to a more effective restoration of the colloidal structure of severe aged asphalt, which enhances the rejuvenation effect.

- (4)

- Three rejuvenators can reduce the elastic component while increasing the viscous component of aged asphalt. Among them, the PR promotes the blending of fresh and aged asphalt, aiding in the restoration of the colloidal structure, which effectively lowers the complex modulus and increases the phase angle of aged asphalt.

5. Future Suggestions

This work focuses on the evaluation of the effect of the penetrable rejuvenator on different types of aged asphalt through physical and rheological tests. Given the complexity of aged bitumen components, the effect of the penetrable rejuvenator on the functional groups, colloidal structure, and molecular weight of aged asphalt will be further investigated to better understand the rejuvenation mechanism. Moreover, ultraviolet (UV) aging is another significant factor in asphalt aging, and the rejuvenation effect on UV-aged asphalt will be a priority in future research.

Author Contributions

J.W. (Jian Wang): investigation, formal analysis, writing—original draft, writing—review and editing. S.X.: conceptualization, supervision, resources, project administration, data curation, funding acquisition, writing—original draft, writing—review and editing. J.C.: resources, formal analysis, writing—review and editing. W.X.: validation, investigation, writing—review and editing. X.C.: formal analysis, writing—review and editing. J.W. (Jiahao Wang): resources, investigation. Y.K.: investigation, validation. All authors have read and agreed to the published version of the manuscript.

Funding

This work is supported by the Natural Science Foundation of Fujian Province (no. 2023J01061) and the National Natural Science Foundation of China (no. 52278446). The authors gratefully acknowledge their financial support.

Data Availability Statement

Some or all of the data, models, or code that support the findings of this study are available from the corresponding author upon reasonable request.

Conflicts of Interest

Authors Jian Wang, Jiang Chen, Weibin Xie, Xuehong Cheng and Jiahao Wang were employed by Taizhou Construction & Industrial Technology Development Co., Ltd. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Meng, Y.J.; Wang, Z.; Lei, J.C.; Liao, Y.J.; Zhao, X.Y.; Qin, Y.; Fang, G.P.; Zhang, C.Y. Study on aging resistance and micro characteristics of bio-asphalt/TLA composite modified asphalt binder. Constr. Build. Mater. 2022, 359, 129566. [Google Scholar] [CrossRef]

- Shi, C.Y.; Ge, J.G.; Yu, H.A.; Qian, G.P.; Zhou, H.Y.; Ma, Y.T.; Nian, T.F.; Yao, D.; Wang, Y.; Zhong, Y.X. Interfacial adhesion properties and debonding mechanisms in rejuvenated asphalt mixtures. Constr. Build. Mater. 2024, 425, 135973. [Google Scholar] [CrossRef]

- Riekstins, A.; Haritonovs, V.; Straupe, V.; Izaks, R.; Merijs-Meri, R.; Zicans, J. Comparative environmental and economic assessment of a road pavement containing multiple sustainable materials and technologies. Constr. Build. Mater. 2024, 432, 136522. [Google Scholar] [CrossRef]

- Li, Y.Y.; Wu, S.P.; Dai, Y.; Pang, L.; Liu, Q.T.; Nie, S.; Li, H.C.; Wang, Z.F. Laboratory and field evaluation of sodium stearate organically modified LDHs effect on the anti aging performance of asphalt mixtures. Constr. Build. Mater. 2018, 189, 366–374. [Google Scholar] [CrossRef]

- Zhao, Y.; Wu, X.Q.; Chao, Y.B.; Liang, N.X.; Zhou, P.Y.; Li, Z.; Mei, Y.J. Aging characteristics and microscopic mechanisms of SBS asphalt based on coupled light-heat-water aging. Constr. Build. Mater. 2024, 456, 139190. [Google Scholar] [CrossRef]

- Liu, H.B.; Zhang, Z.Q.; Tian, Z.N.; Lu, C. Exploration for UV Aging Characteristics of Asphalt Binders based on Response Surface Methodology: Insights from the UV Aging Influencing Factors and Their Interactions. Constr. Build. Mater. 2022, 347, 128460. [Google Scholar] [CrossRef]

- Sun, Y.; Li, H.; Yang, B.; Han, Y.Z.; Zou, Z.X. Investigation on rheological properties and aging mechanism of asphalt under multiple environmental conditions. Constr. Build. Mater. 2024, 443, 137713. [Google Scholar] [CrossRef]

- Xu, S.; Jia, X.J.; Huang, R.Y.; Fang, L.; Ma, Z.R.; Zhang, C.L.; Que, Y. Preparation and performance evaluation of different bitumens modified by antioxidant/PABA-LDHs composites. Constr. Build. Mater. 2023, 367, 130286. [Google Scholar] [CrossRef]

- Sun, E.Y.; Cai, R.; Zhao, Y.Q.; Fu, G.Z.; Che, T.K. Microstructural and micromechanical evolution features of asphalt with aging: An atomic force microscopy study. Constr. Build. Mater. 2024, 441, 137518. [Google Scholar] [CrossRef]

- Du, P.F.; Long, J.; Duan, H.H.; Luo, H.; Zhang, H.L. Laboratory performance and aging resistance evaluation of zinc oxide/expanded vermiculite composite modified asphalt binder and mixture. Constr. Build. Mater. 2022, 358, 129385. [Google Scholar] [CrossRef]

- Wen, Y.; Wang, Y.H. Effect of Oxidative Aging on Dynamic Modulus of Hot-Mix Asphalt Mixtures. J. Mater. Civ. Eng. 2019, 31, 04018348. [Google Scholar] [CrossRef]

- Yuan, J.; Li, T.H.; Ya, X.; Li, H.Y.; Sun, W.W. Evaluation of pine needle oil recycled asphalt: Rheological characterization and molecular simulation. Constr. Build. Mater. 2024, 453, 13980. [Google Scholar] [CrossRef]

- Xu, B.; Ding, R.D.; Yang, Z.H.; Sun, Y.R.; Zhang, J.C.; Lu, K.J.; Cao, D.W.; Gao, A.D. Investigation on performance of mineral-oil-based rejuvenating agent for aged high viscosity modified asphalt of porous asphalt pavement. J. Clean. Prod. 2023, 395, 136285. [Google Scholar] [CrossRef]

- Shi, K.; Ma, F.; Fu, Z.; Liu, J.Y.; Song, R.M.; Yuan, D.D.; Tang, Y.J. Molecular dynamics simulation insights into rejuvenating aged asphalt with waste soybean oil and polymers. Constr. Build. Mater. 2024, 439, 137260. [Google Scholar] [CrossRef]

- Zhao, Y.C.; Chen, M.Z.; Shen, J.N.; Shi, P.C.; Wu, S.P.; Chen, D.Y.; Zhang, J.W.; Zhao, Z.G. Aging behaviors of asphalt binders rejuvenated by different chemical fractions from waste cooking oil. Constr. Build. Mater. 2024, 435, 136867. [Google Scholar] [CrossRef]

- Luo, Y.H.; Guo, P.; Gao, J.F.; Meng, J.W.; Dai, Y.K. Application of Design-Expert response surface methodology for the prediction of rejuvenated asphalt fatigue life. J. Clean. Prod. 2022, 379, 134427. [Google Scholar] [CrossRef]

- Wang, J.P.; Lv, S.T.; Liu, J.; Peng, X.H.; Lu, W.W.; Wang, Z.Y.; Xie, N.S. Performance evaluation of aged asphalt rejuvenated with various bio-oils based on rheological property index. J. Clean. Prod. 2023, 385, 135593. [Google Scholar] [CrossRef]

- Xu, X.; Yu, J.Y.; Xue, L.H.; Zhang, C.L.; He, B.Y.; Wu, M. Structure and performance evaluation on aged SBS modified bitumen with bi- or tri-epoxy reactive rejuvenating system. Constr. Build. Mater. 2017, 151, 479–486. [Google Scholar] [CrossRef]

- Xin, X.; Jiang, H.G.; Liang, M.; Yao, Z.Y.; Zhang, J.Z.; Luo, W.X.; Zhang, X.M. Chemical, rheological properties and microstructure of road asphalt prepared from deoiled asphalt, slurry oil and polymers. Constr. Build. Mater. 2020, 257, 119571. [Google Scholar] [CrossRef]

- Cui, L.R.; Xu, J.; Cen, L.; Ren, M.N.; Cao, F.H. Molecular engineering and modification of FCC slurry oil residue for improving ageing resistance of high quality paving asphalt. Constr. Build. Mater. 2021, 299, 124234. [Google Scholar] [CrossRef]

- Feng, Y.; Lu, M.; Sun, Y. Structure and Composition of Aromatics in Fluid Catalytic Cracking Slurry Oils From Different Crudes. Acta Pet. Sin. Pet. Process. Sect. 2022, 38, 191–198. [Google Scholar]

- Deng, M.; Cao, X.J.; Yuan, Y.; Yang, X.Y.; Tang, B.M.; Li, X.Y. Response of oxidized asphaltene aggregations in presence of rejuvenators and characteristics of molecular assembly behavior. Constr. Build. Mater. 2023, 397, 132468. [Google Scholar] [CrossRef]

- Hu, M.J.; Sun, D.Q.; Zhu, X.Y.; Sun, G.Q.; Hofko, B.; Mirwald, J.; Primerano, K. Molecular-atomic scale insights into polymer-asphalt interactions induced by the oxidation of reactive oxygen species via computational simulation and multifield microscopy characterization. J. Mol. Liq. 2024, 409, 125492. [Google Scholar] [CrossRef]

- Fini, E.; Rajib, A.I.; Oldham, D.; Samieadel, A.; Hosseinnezhad, S. Role of Chemical Composition of Recycling Agents in Their Interactions with Oxidized Asphaltene Molecules. J. Mater. Civ. Eng. 2020, 32, 04020268. [Google Scholar] [CrossRef]

- Fang, Y.; Zhang, Z.Q.; Yang, J.H.; Wang, Y.Y. Research on interfacial fusion characteristics of rejuvenator-aged asphalt system: Wettability, permeability and molecular simulation. Constr. Build. Mater. 2024, 443, 137646. [Google Scholar] [CrossRef]

- Fang, Y.; Zhang, Z.Q.; Shi, J.R.; Yang, X.H.; Li, X.J. Insights into permeability of rejuvenator in old asphalt based on permeation theory: Permeation behaviors and micro characteristics. Constr. Build. Mater. 2022, 325, 126765. [Google Scholar] [CrossRef]

- JTG E20-2011; Test Specifications for Asphalt and Asphalt Mixtures in Highway Engineering. Standardization Administration of China: Beijing, China, 2011.

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).