Study on the Basic Mechanical Properties of Waste Steel Fiber Reinforced Concrete After High-Temperature Exposure

Abstract

1. Introduction

2. Materials and Methods

2.1. Test Materials

2.1.1. Cement

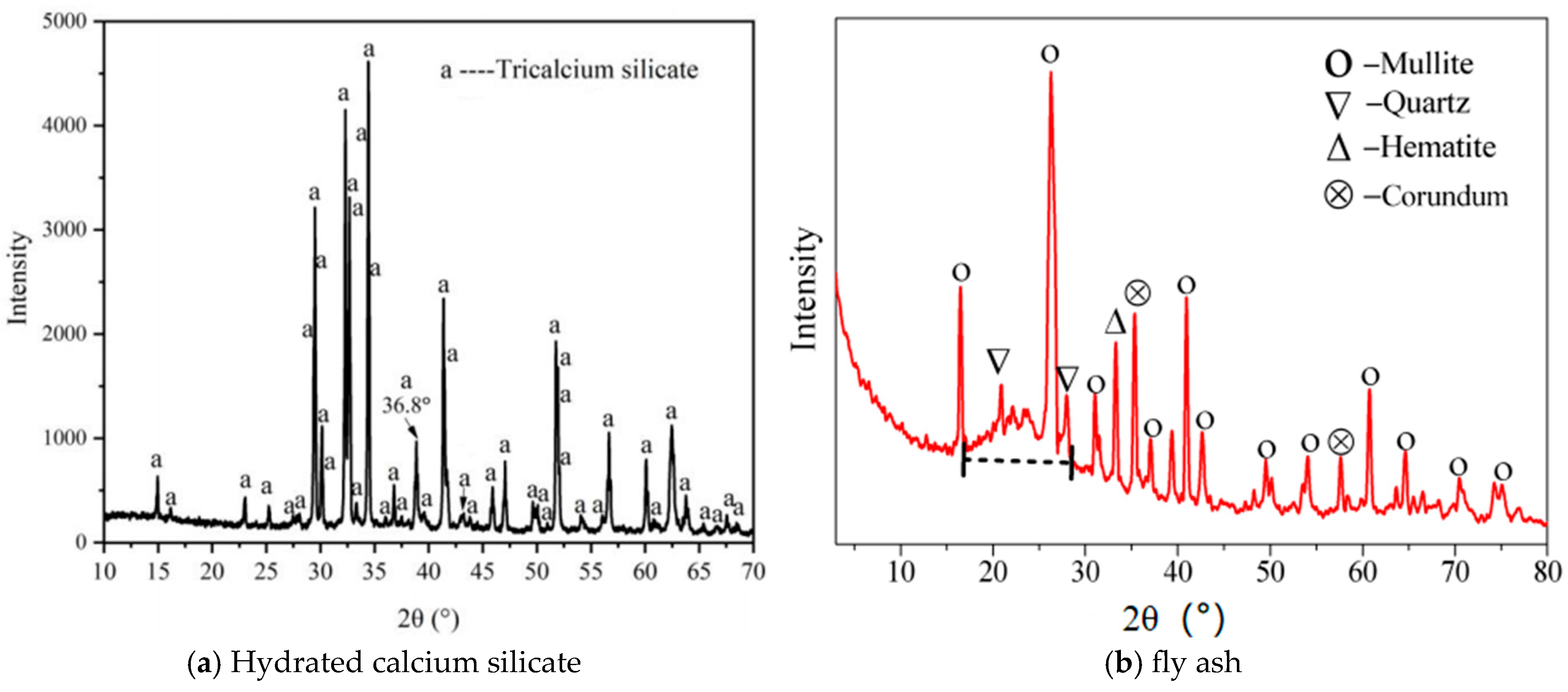

2.1.2. Fly Ash

2.1.3. Aggregates

2.1.4. Waste Steel Fibers

2.2. Mix Proportion Design

2.3. Heating Equipment

3. Experimental Process and Result Analysis

3.1. Testing Process

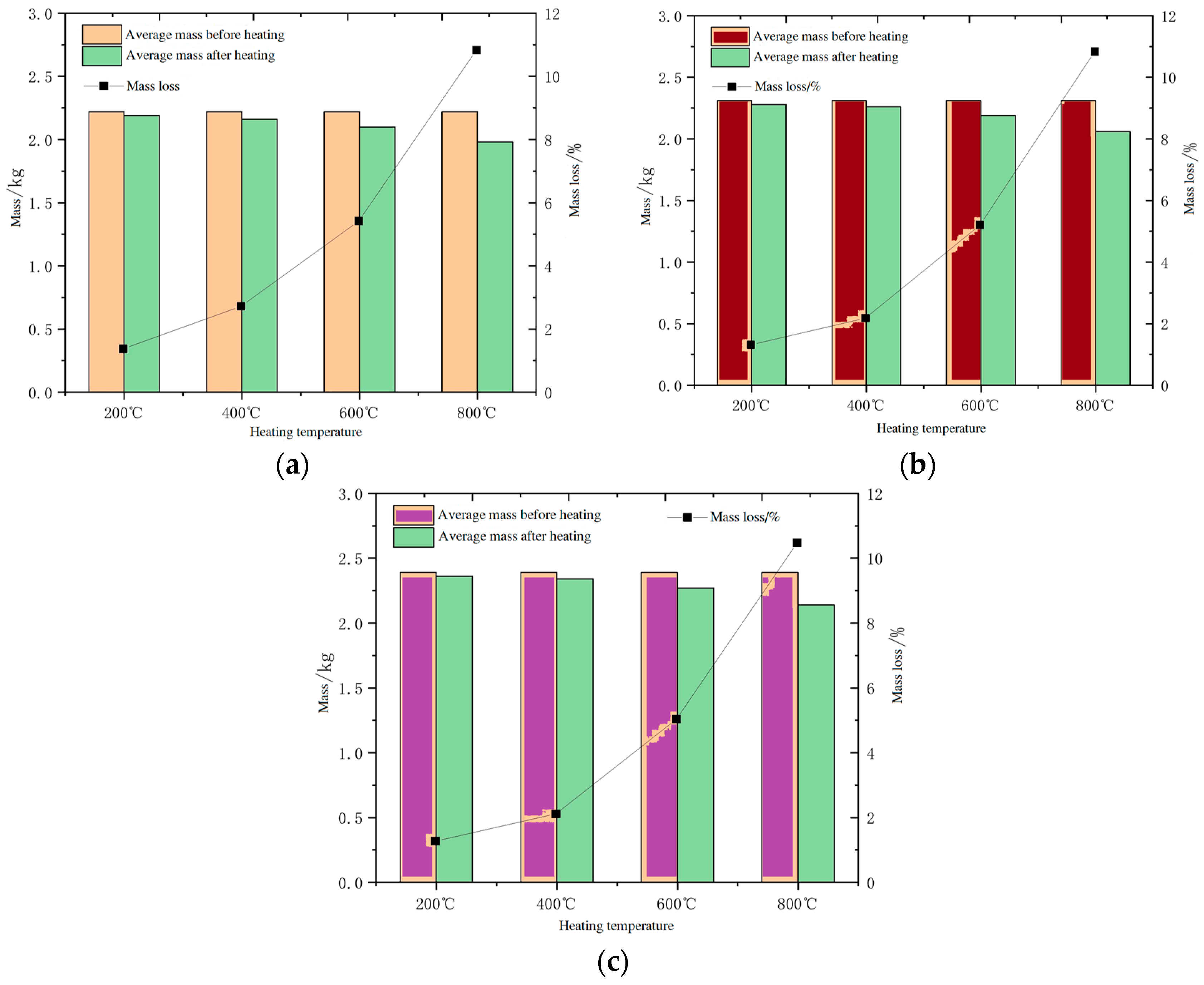

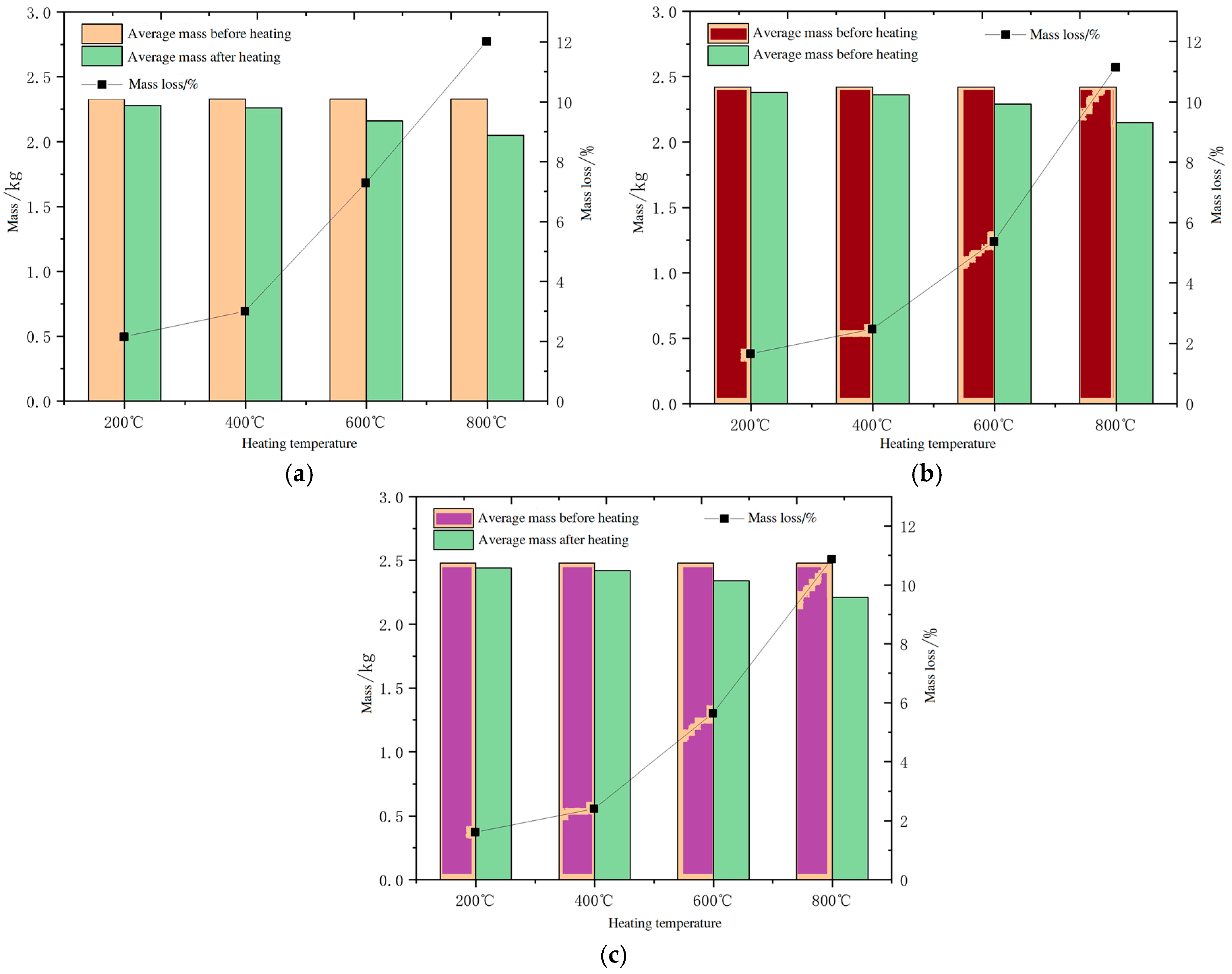

3.2. Quality Loss of WSFC After High Temperature

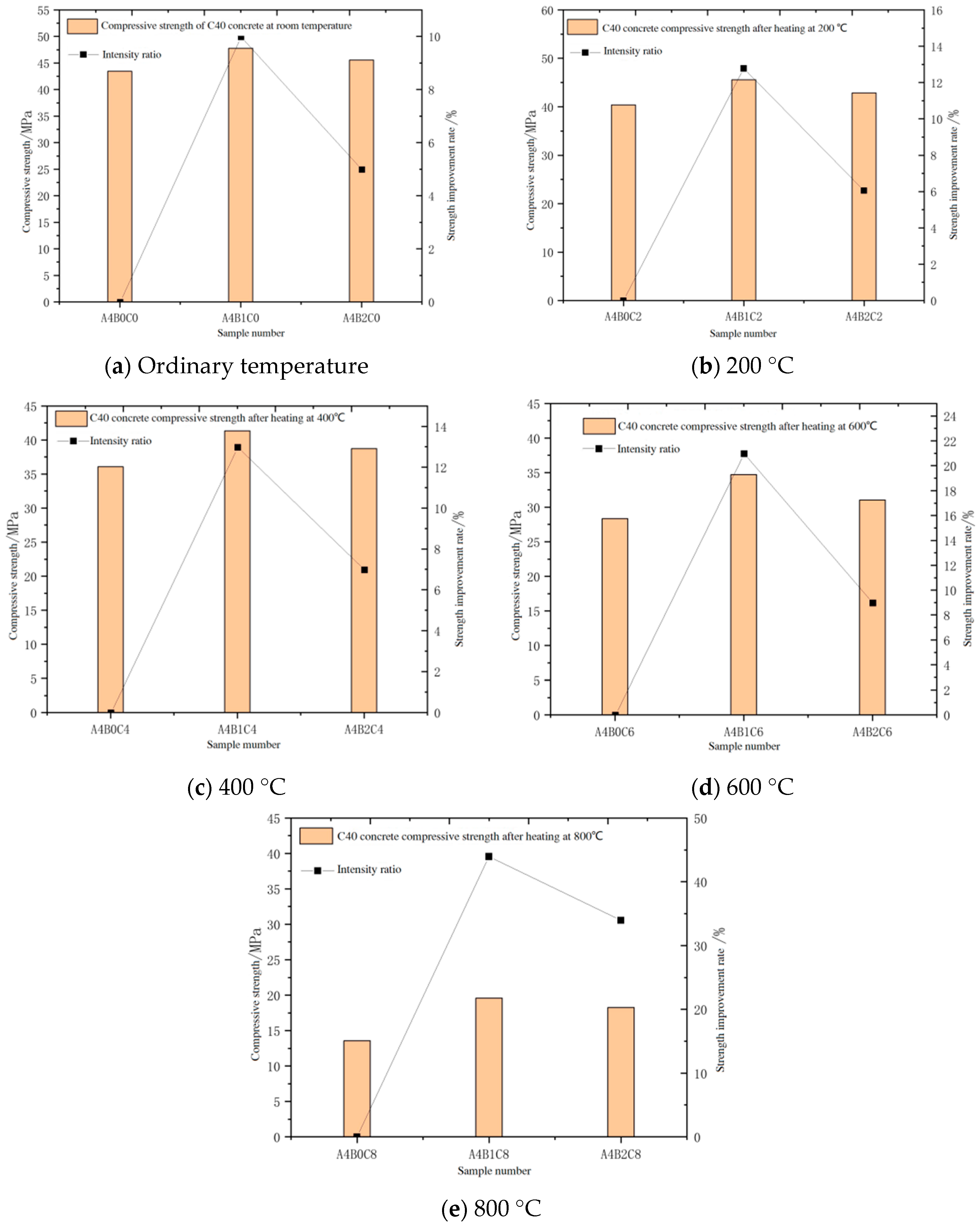

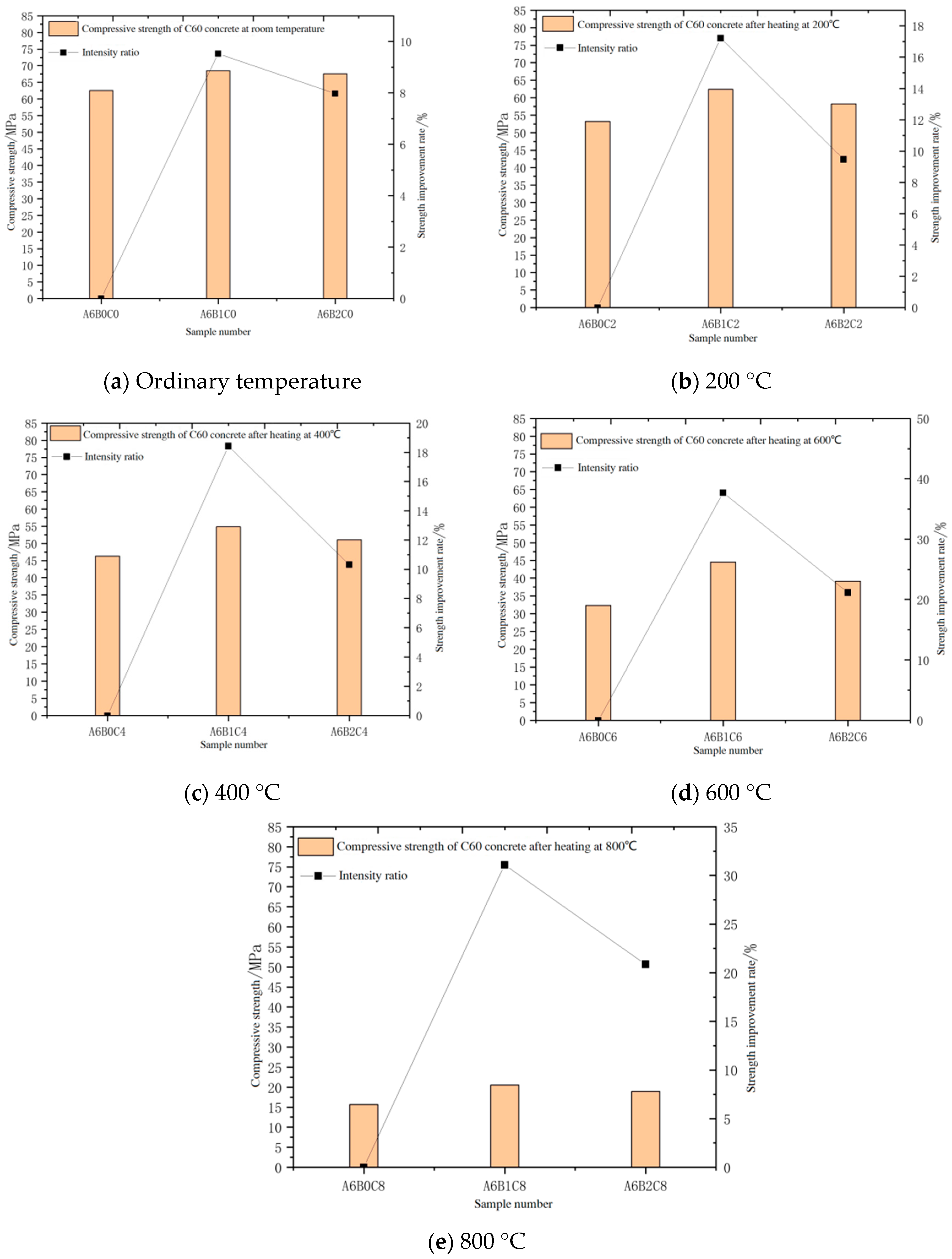

3.3. Compressive Strength Test

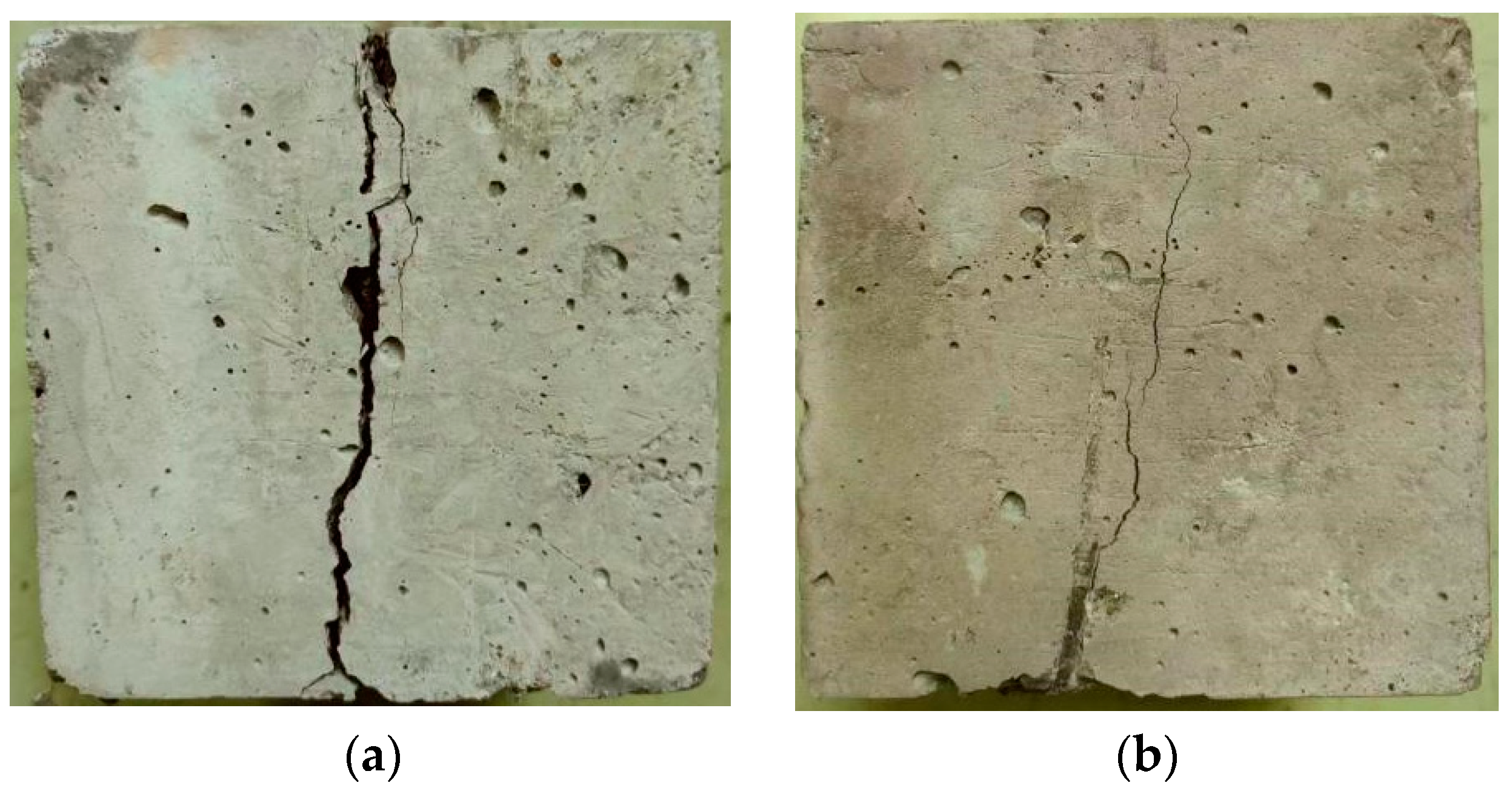

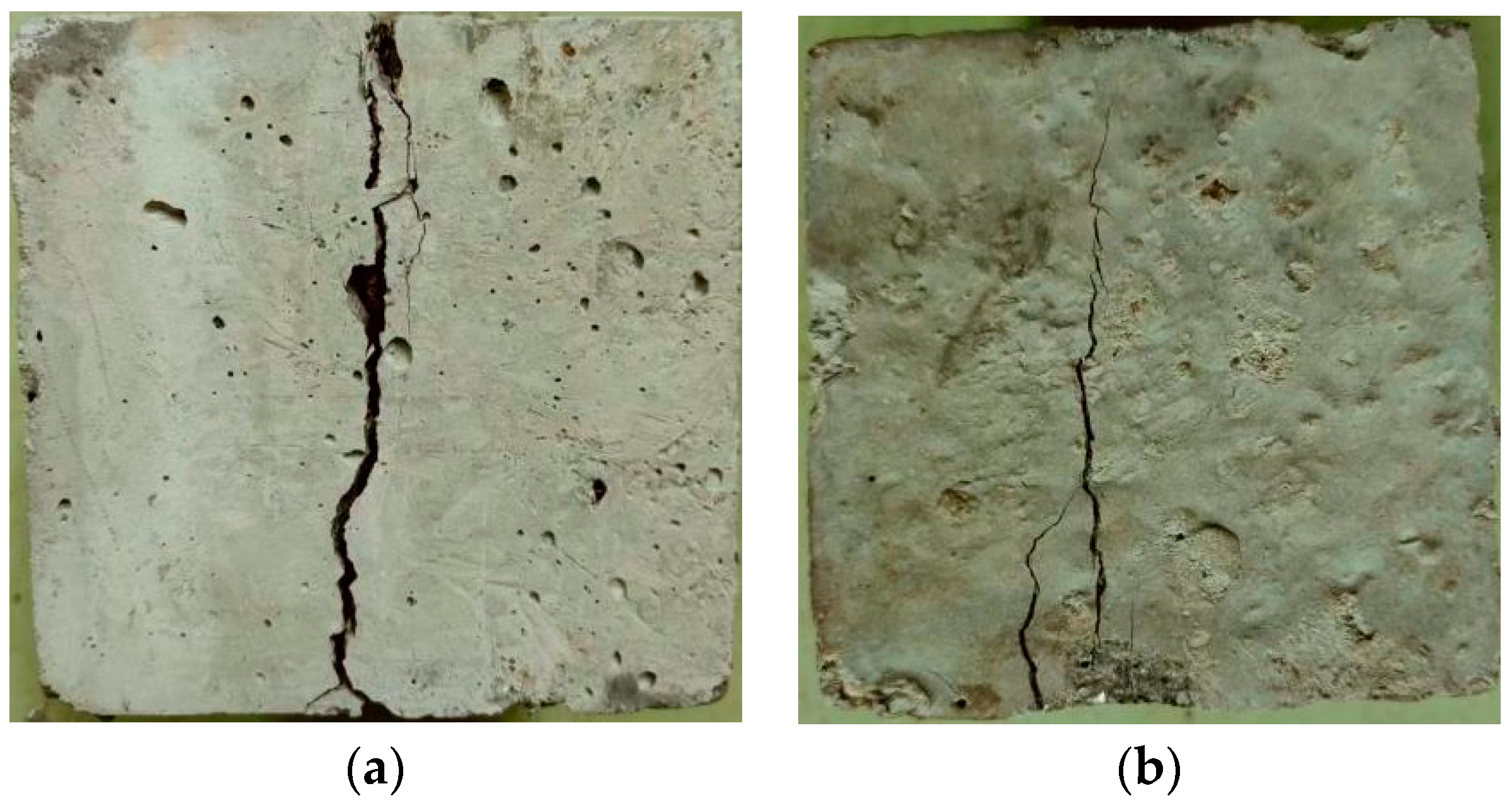

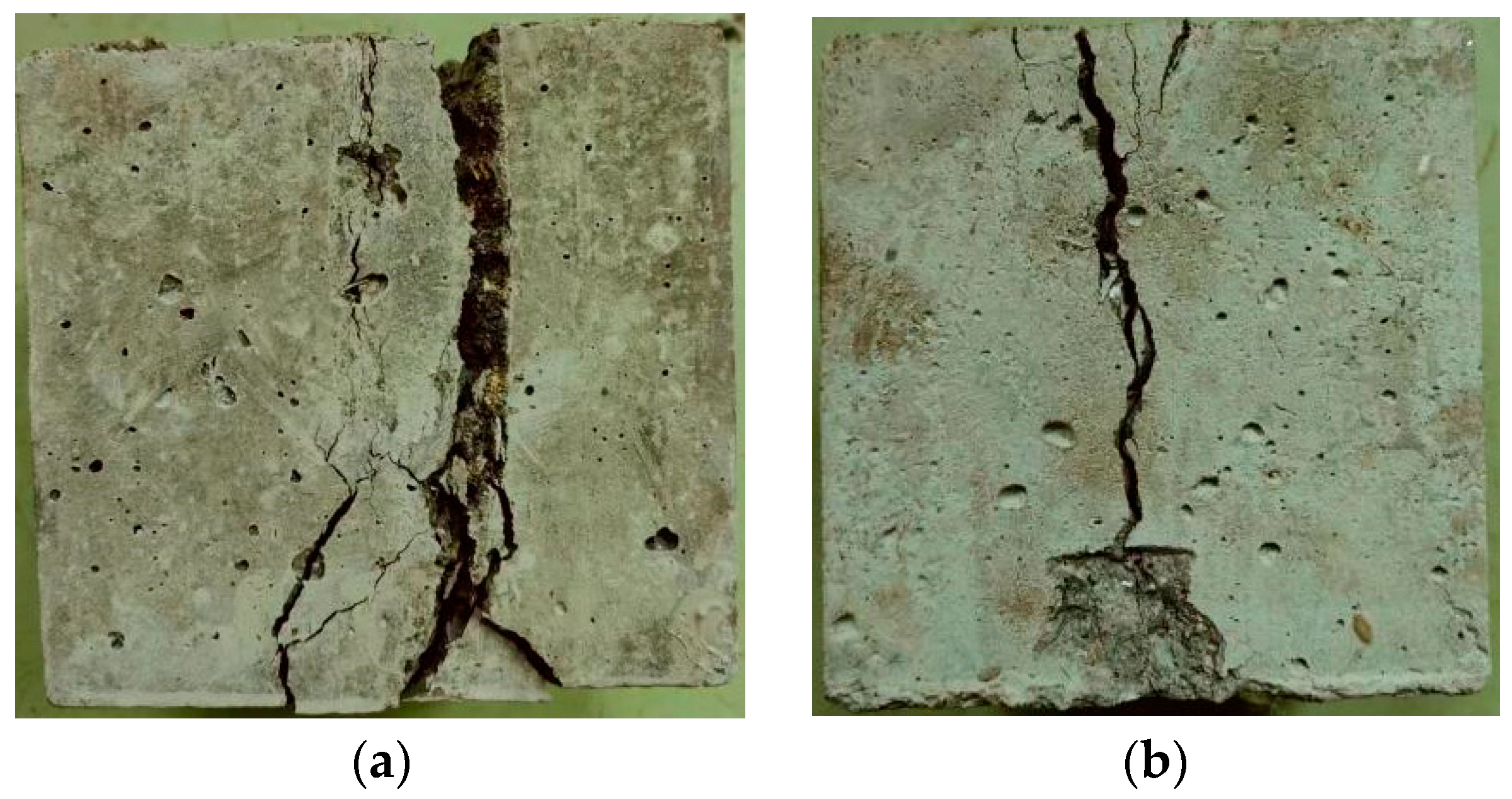

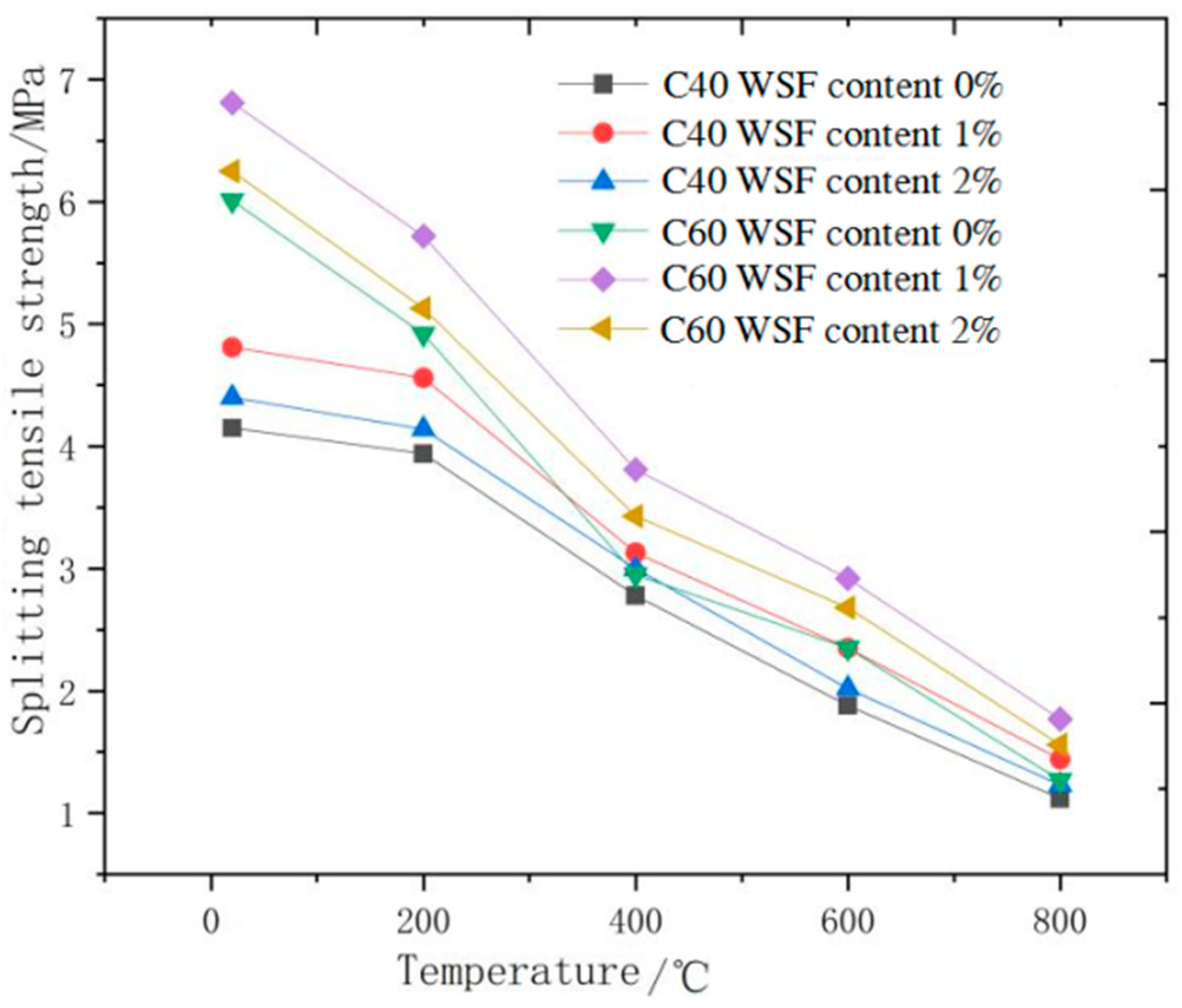

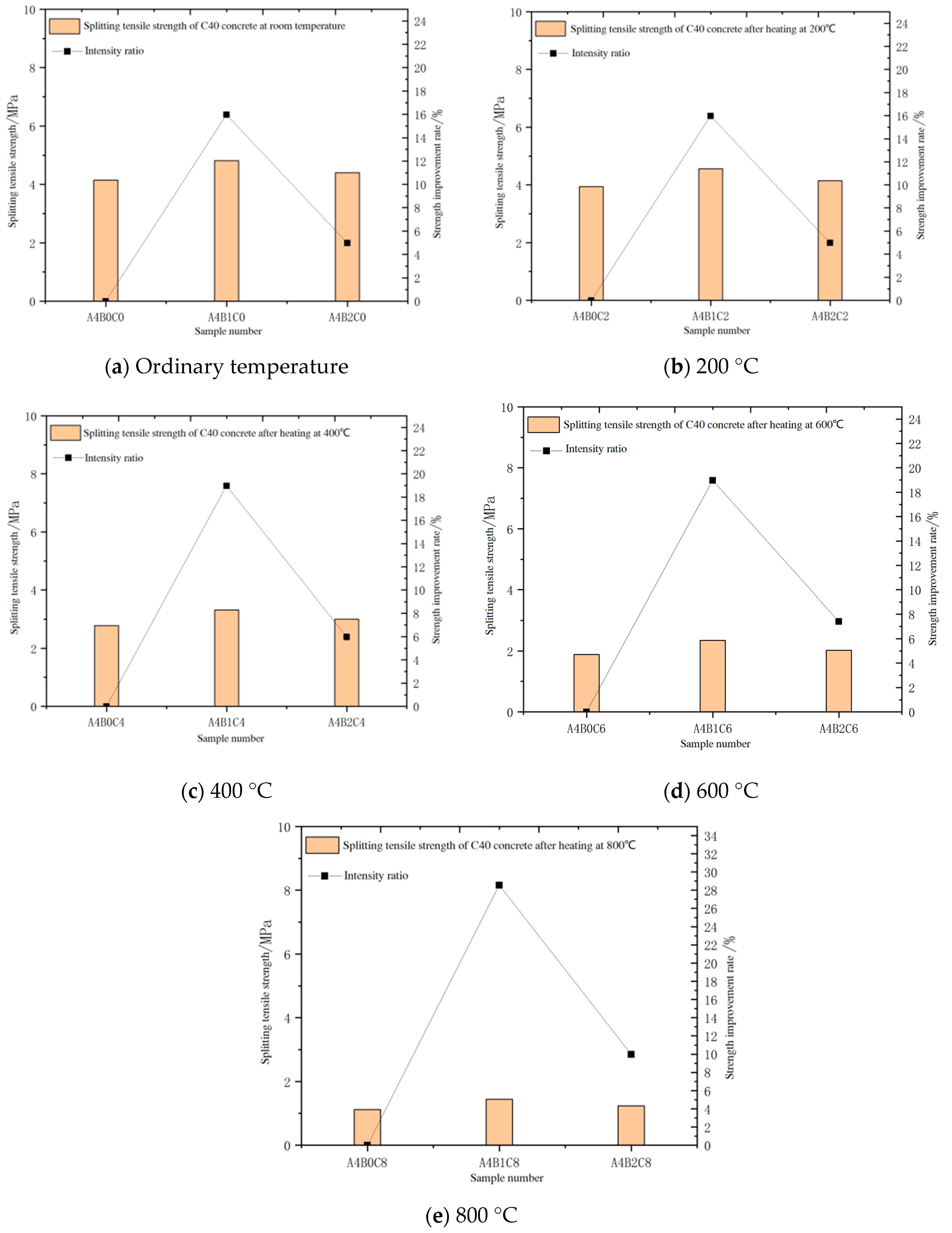

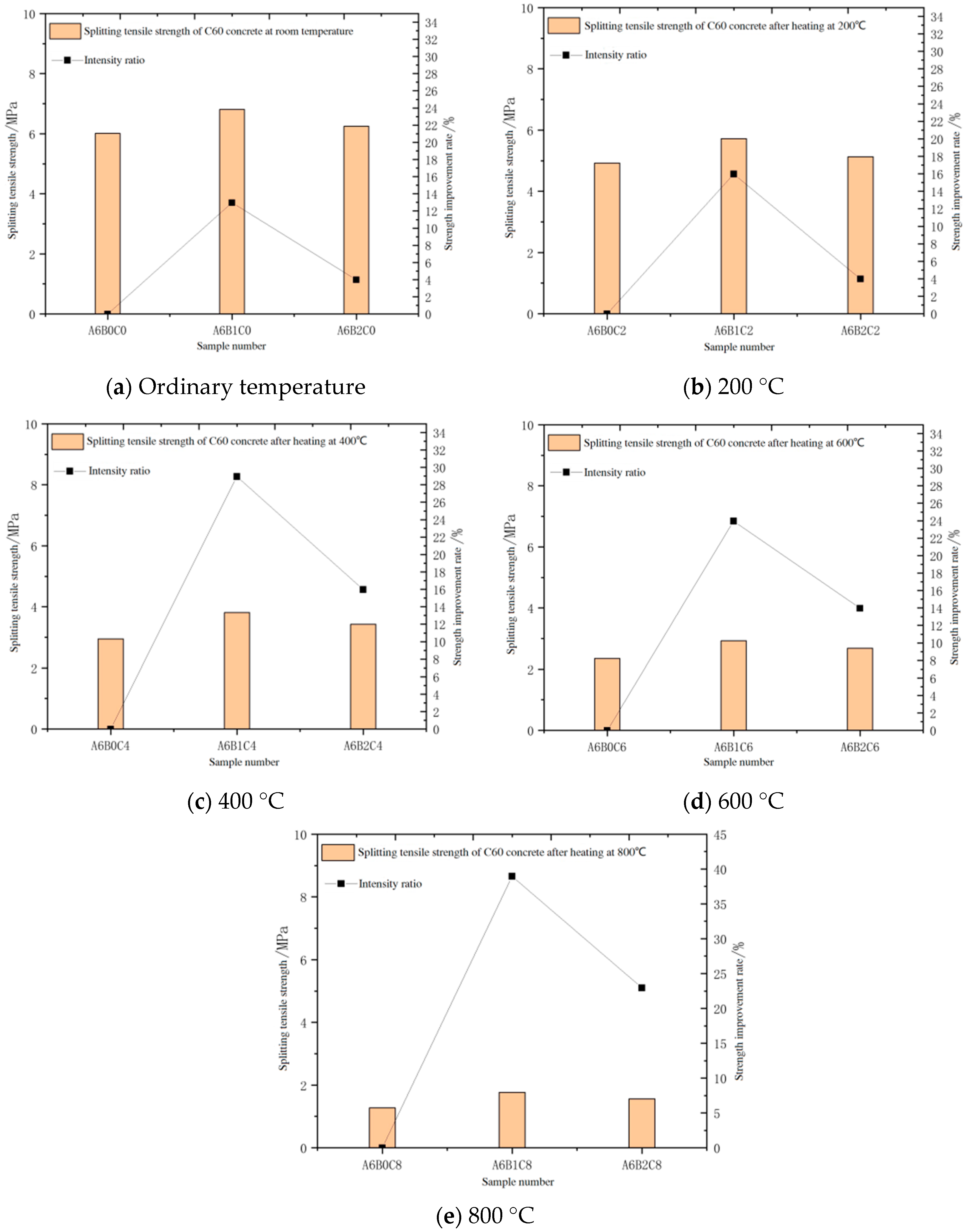

3.4. Splitting Tensile Strength

4. Conclusions

- (1)

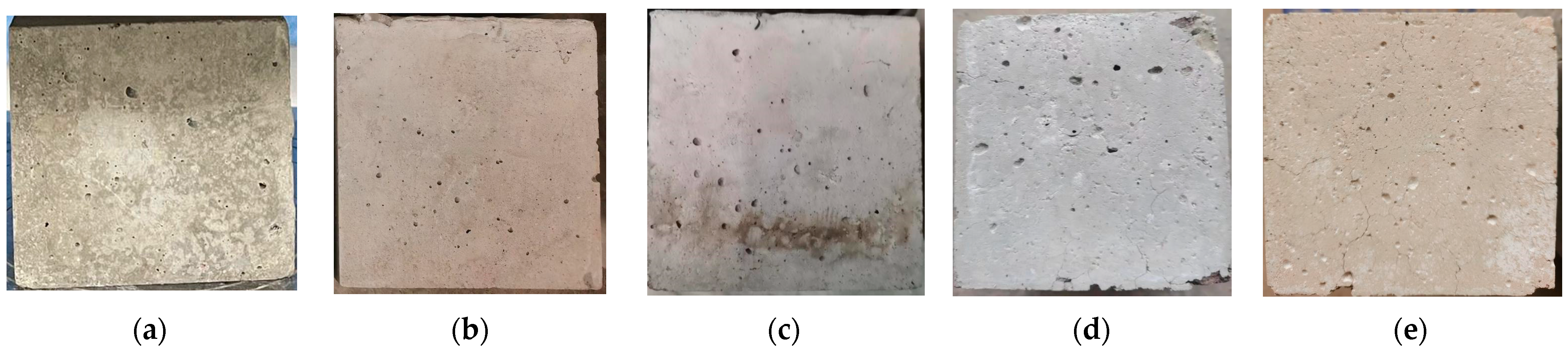

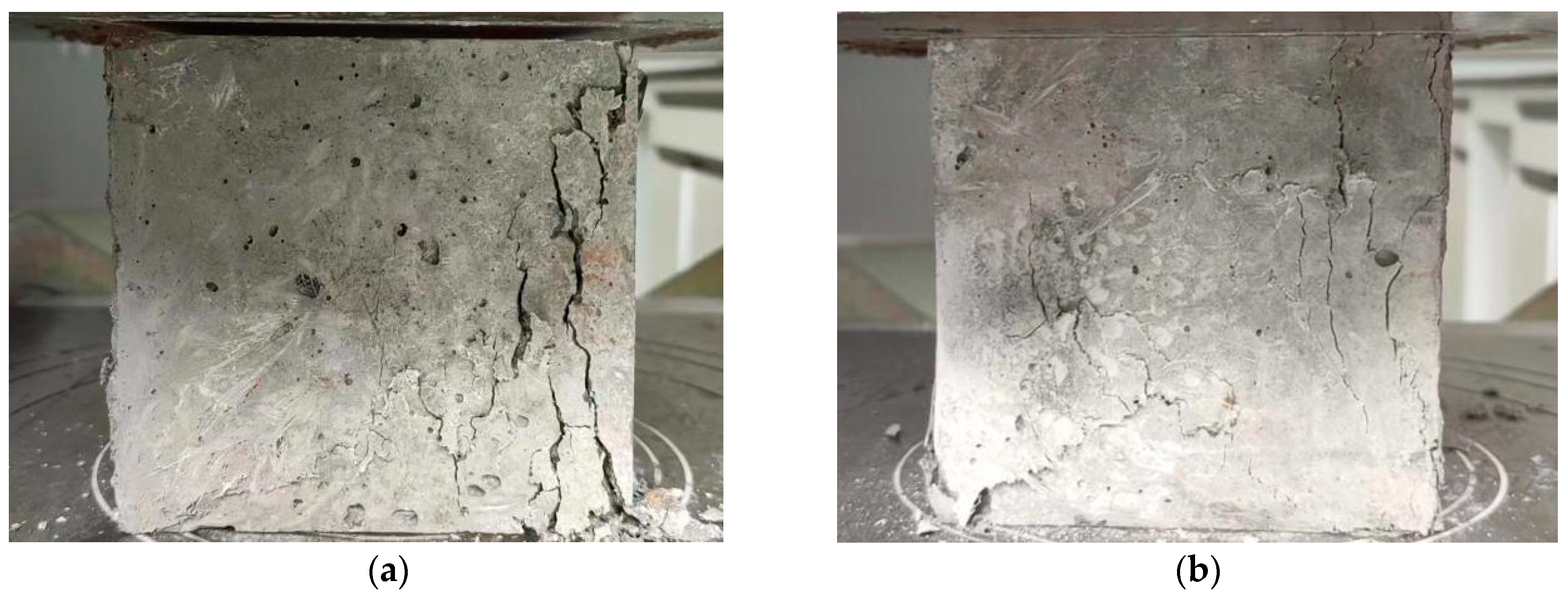

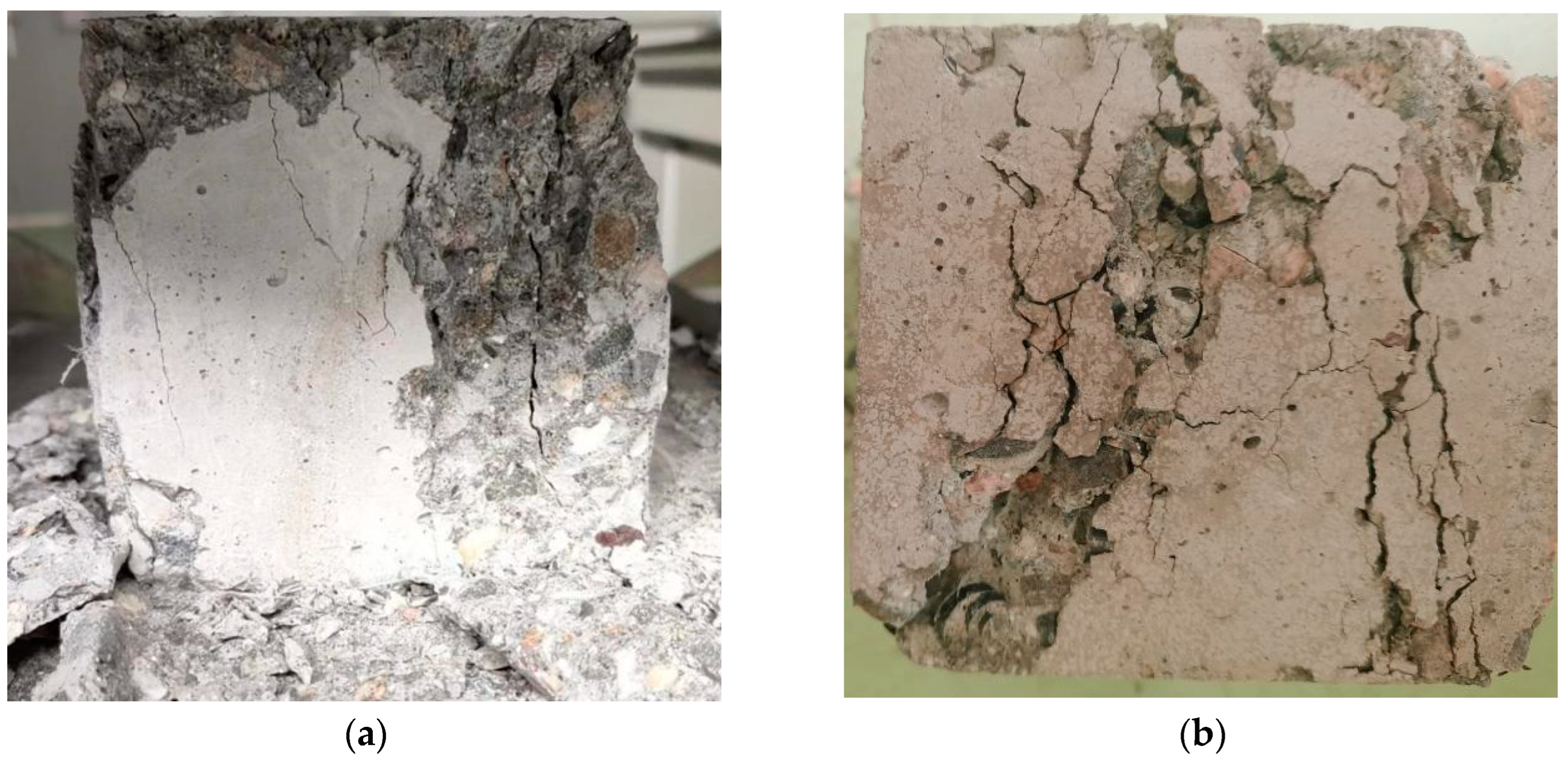

- Upon examination, it was revealed that the influence of steel fiber content on the apparent characteristics of the samples subsequent to exposure to high temperatures was not particularly pronounced. As the temperature progressively rose, the visual appearance of the samples underwent a transformation, shifting from a dark gray hue initially to a white-gray shade and further evolving into a light yellow color. Concurrently, the surface cracks on the samples became more numerous and pronounced. Moreover, an upward trend was observed in the mass loss rate of the samples in tandem with the increase in temperature, indicating a direct correlation between the two variables.

- (2)

- The comprehensive analysis of mechanical test phenomena and the underlying data mechanisms, both before and after high-temperature exposure in concrete, demonstrates that waste steel fibers (WSF) play a significant and effective role. They notably augment the compressive and splitting tensile strength of concrete cubes, leading to an improvement in the ultimate failure mode of test blocks and bolstering the overall structural integrity of the specimens. Notably, the optimal enhancement in the mechanical strength of concrete is attained when the fiber content reaches 1%. At this concentration, WSF are most efficacious in counteracting the detrimental effects of high temperature on concrete properties, thereby ensuring that the concrete retains greater strength and durability even under extreme thermal conditions. This finding not only highlights the importance of WSF in concrete applications but also provides a practical guideline for engineers and researchers when designing concrete mixes for high-temperature environments.

- (3)

- An in-depth examination of the mechanical strength data of concrete with varying strength grades under high-temperature circumstances reveals a rather intriguing finding. When subjected to elevated temperatures, C60 concrete demonstrates comparatively less favorable mechanical properties in contrast to C40 concrete. Specifically, at an identical temperature level, the mass loss rate and strength attenuation rate of C60 concrete are both noticeably greater than those of C40 concrete. This disparity can likely be attributed to the differences in the internal microstructure and composition of the two types of concrete. The denser microstructure of C60 concrete, which is engineered to achieve higher strength under normal conditions, may impede the release of internal vapor pressure during heating, thereby exacerbating the damage caused by high temperatures and leading to more pronounced mass and strength losses. In contrast, C40 concrete, with its relatively more porous structure, allows for better dissipation of vapor pressure, resulting in relatively milder degradation. These insights not only deepen our understanding of the behavior of different strength grades of concrete under high temperatures but also offer valuable guidance for the selection and design of concrete in applications where high-temperature exposure is anticipated.

5. Research Prospect—Advancements in Non-Destructive Evaluation of Fire-Damaged Concrete

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Shen, X.G.; Li, X.; Liu, L.; Chen, X.Z.; Du, J. Research on Mechanical Properties of Steel-Polypropylene Fiber-Reinforced Concrete after High-Temperature Treatments. Appl. Sci. 2024, 14, 3861. [Google Scholar] [CrossRef]

- Abid, S.R.; Abbass, A.A.; Murali, G.; Al-Sarray, M.L.J.; Nader, I.A.; Ali, S.H. Post-High-Temperature Exposure Repeated Impact Response of Steel-Fiber-Reinforced Concrete. Buildings 2022, 12, 1364. [Google Scholar] [CrossRef]

- Janga, S.; Raut, A.N.; Adamu, M.; Ibrahim, Y.E. Thermo-mechanical performance assessment of geopolymer synthesized with steel slag and glass powder at elevated temperatures. Powder Technol. 2024, 444, 120047. [Google Scholar]

- Li, X.D.; Lu, C.D.; Cui, Y.F.; Zhou, L.C. Study on the bond properties between steel bar and fiber reinforced concrete after high temperatures. Structures 2023, 49, 889–902. [Google Scholar]

- Khan, A.A.; Usmani, A.; Torero, J.L. Evolution of fire models for estimating structural fire-resistance. Fire Saf. J. 2021, 124, 103367. [Google Scholar]

- Kordosky, A.N.; Drury, M.M.; Quiel, S.E. Structural fire resistance of partially restrained, partially composite floor beams, I: Experiments. J. Constr. Steel Res. 2020, 167, 105945. [Google Scholar]

- Pang, S.J.; Ahn, K.S.; Oh, J.W.; Lee, H.S.; Kang, S.G.; Oh, J.K. Fire Resistance of Structural Wooden Walls Covered by Gypsum and Diatomite Board. Bioresources 2023, 18, 991–1007. [Google Scholar]

- Ogrin, A.; Hozjan, T. Fire resistance of timber-concrete composite slabs A simplified method. Mater. Struct. 2020, 53, 106. [Google Scholar]

- Gedam, B.A. Fire resistance design method for reinforced concrete beams to evaluate fire-resistance rating. Structures 2021, 33, 855–877. [Google Scholar]

- Choi, J.H.; Yang, D.H.; Choi, S.J.; Yi, S.T.; Kim, J.H.J. Fire resistance of bi-directionally prestressed concrete under extreme fire loading. Proc. Inst. Civ. Eng.-Struct. Build. 2021, 174, 749–764. [Google Scholar]

- Luhar, S.; Nicolaides, D.; Luhar, I. Fire Resistance Behaviour of Geopolymer Concrete: An Overview. Buildings 2021, 11, 82. [Google Scholar] [CrossRef]

- Wen, B.; Zhang, L.; Wu, B.; Niu, D.T.; Wang, L.Z.; Zhang, Y.L. Fire resistance of earthquake damaged reinforced concrete columns. Struct. Infrastruct. Eng. 2022, 18, 789–806. [Google Scholar]

- Grubega, I.N.; Markovic, B.; Gojevic, A.; Brdaric, J. Effect of hemp fibers on fire resistance of concrete. Constr. Build. Mater. 2018, 184, 473–484. [Google Scholar]

- Pekgökgöz, R.K.; Avcil, F. Effect of steel fibres on reinforced concrete beam-column joints under reversed cyclic loading. Gradevinar 2021, 73, 1185–1194. [Google Scholar]

- Yun, H.D.; Jeong, G.Y.; Choi, W.C. Shear Strengthening of High Strength Concrete Beams That Contain Hooked-End Steel Fiber. Materials 2022, 151, 17. [Google Scholar]

- Ibrahim, S.K.; Hadi, N.A.; Rad, M.M. Experimental and Numerical Analysis of Steel-Polypropylene Hybrid Fibre Reinforced Concrete Deep Beams. Polymers 2023, 15, 2340. [Google Scholar] [CrossRef]

- Shen, W.; Chen, S.P.; Zhang, J.B. Calculation of Cracks in Partially Steel Fiber Reinforced Concrete Beams with BFRP Bars. Adv. Mater. Sci. Eng. 2022, 2022, 9158379. [Google Scholar]

- Kim, D.J.; Kim, S.H.; Choi, W.C. Characteristics of Restrained Drying Shrinkage on Arched Steel Fiber-Reinforced Concrete. Appl. Sci. 2021, 11, 7537. [Google Scholar] [CrossRef]

- Domski, J.; Zakrzewski, M. Deflection of Steel Fiber Reinforced Concrete Beams Based on Waste Sand. Materials 2020, 13, 392. [Google Scholar] [CrossRef]

- Di Carlo, F.; Spagnuolo, S. Cracking behavior of steel fiber-reinforced concrete members subjected to pure tension. Struct. Concr. 2019, 20, 2069–2080. [Google Scholar]

- He, F.Z.; Biolzi, L.; Carvelli, V.; Feng, X.W. A review on the mechanical characteristics of thermally damaged steel and polypropylene hybrid fiber-reinforced concretes. Arch. Civ. Mech. Eng. 2024, 24, 69. [Google Scholar]

- Al-Attar, A.A.; Abdulrahman, M.B.; Hamada, H.M.; Tayeh, B.A. Investigating the behaviour of hybrid fibre-reinforced reactive powder concrete beams after exposure to elevated temperatures. J. Mater. Res. Technol.-JMR&T 2020, 9, 1966–1977. [Google Scholar]

- Jiang, J.; Wu, M.; Ye, M. Prediction of fire spalling behaviour of fiber reinforced concrete. Mag. Concr. Res. 2023, 76, 229–244. [Google Scholar]

- Wu, H.Y.; Lin, X.S.; Zhou, A.N. A review of mechanical properties of fibre reinforced concrete at elevated temperatures. Cem. Concr. Res. 2020, 135, 106117. [Google Scholar]

- Tretyakov, A.; Tkalenko, I.; Wald, F. Fire response model of the steel fibre reinforced concrete filled tubular column. J. Constr. Steel Res. 2021, 186, 106884. [Google Scholar]

- Ponikiewski, T.; Katzer, J.; Kilijanek, A.; Kuzminska, E. Mechanical behaviour of steel fibre reinforced SCC after being exposed to fire. Adv. Concr. Constr. 2018, 6, 631–643. [Google Scholar]

- Zhang, C.; Li, Z.H.; Ding, Y.N. Post-fire flexural performance of hybrid-fibre-reinforced SCC symmetric inclination beams. Mag. Concr. Res. 2019, 71, 1025–1042. [Google Scholar]

- Li, H.Y.; Chen, B.G.; Zhu, K.C.; Gong, X.L. Flexural Toughness Test and Inversion Research on a Thermal Conductivity Formula on Steel Fiber-Reinforced Concrete Components Post-Fire. Materials 2022, 15, 5103. [Google Scholar] [CrossRef]

- Figueiredo, F.P.; Huang, S.S.; Angelakopoulos, H.; Pilakoutas, K.; Burgess, I. Effects of Recycled Steel and Polymer Fibres on Explosive Fire Spalling of Concrete. Fire Technol. 2019, 55, 1495–1516. [Google Scholar]

- Rashid, K.; Balouch, N. Influence of steel fibers extracted from waste tires on shear behavior of reinforced concrete beams. Struct. Concr. 2017, 18, 589–596. [Google Scholar]

- Qin, X.; Huang, X.; Kaewunruen, S. Sustainable design and carbon-credited application framework of recycled steel fibre reinforced concrete. Dev. Built Environ. 2024, 18, 100404. [Google Scholar]

- Fakoor, M.; Nematzadeh, M. Evaluation of post-fire pull-out behavior of steel rebars in high-strength concrete containing waste PET and steel fibers: Experimental and theoretical study. Constr. Build. Mater. 2021, 299, 123917. [Google Scholar] [CrossRef]

- Khaliq, W.; Kodur, V. Effectiveness of Polypropylene and Steel Fibers in Enhancing Fire Resistance of High-Strength Concrete Columns. J. Struct. Eng. 2018, 144, 04017224. [Google Scholar]

- Zhang, C.; Liu, J.C.; Han, S.C.; Hua, Y. Pore pressure and spalling in fire-exposed high-strength self-consolidating concrete reinforced with hybrid fibres. Eur. J. Environ. Civ. Eng. 2021, 25, 337–367. [Google Scholar]

- Santos, P.R.; Stochero, N.P.; Marangon, E.; Tier, M.D. Mechanical and thermal behavior of kaolin/rice-husk ash matrix composites reinforced with corrugated steel fibers. Ceram. Int. 2018, 44, 14291–14296. [Google Scholar]

- Dogruyol, M.; Ayhan, E.; Karasin, A. Effect of waste steel fiber use on concrete behavior at high temperature. Case Stud. Constr. Mater. 2024, 20, e03051. [Google Scholar]

- Wang, J.J.; Xie, J.H.; He, J.H.; Sun, M.W.; Yang, J.; Li, L.J. Combined use of silica fume and steel fibre to improve fracture properties of recycled aggregate concrete exposed to elevated temperature. J. Mater. Cycles Waste Manag. 2020, 22, 862–877. [Google Scholar]

- Simalti, A.; Singh, A.P. Comparative study on performance of manufactured steel fiber and shredded tire recycled steel fiber reinforced self-consolidating concrete. Constr. Build. Mater. 2021, 266, 121102. [Google Scholar]

- Chen, G.M.; Yang, H.; Lin, C.; Chen, J.F.; He, Y.H.; Zhang, H.Z. Fracture behaviour of steel fibre reinforced recycled aggregate concrete after exposure to elevated temperatures. Constr. Build. Mater. 2016, 128, 272–286. [Google Scholar] [CrossRef]

- Ahmad, J.; Zhou, Z.G. Waste marble based self compacting concrete reinforced with steel fiber exposed to aggressive environment. J. Build. Eng. 2024, 81, 108142. [Google Scholar]

- Chen, G.M.; He, Y.H.; Yang, H.; Chen, J.F.; Guo, Y.C. Compressive behavior of steel fiber reinforced recycled aggregate concrete after exposure to elevated temperatures. Constr. Build. Mater. 2014, 71, 1–15. [Google Scholar] [CrossRef]

- Ahmed, W.; Lim, C.W.; Akbar, A. Influence of Elevated Temperatures on the Mechanical Performance of Sustainable-Fiber-Reinforced Recycled Aggregate Concrete: A Review. Buildings 2022, 12, 487. [Google Scholar] [CrossRef]

- Wang, T.; Yu, M.; Shan, W.T.; Xu, L.H.; Cheng, S.S.; Li, L.Y. Post-fire compressive stress-strain behaviour of steel fibre reinforced recycled aggregate concrete. Compos. Struct. 2023, 309, 116735. [Google Scholar] [CrossRef]

- Pachideh, G.; Gholhaki, M.; Moshtagh, A. Performance of concrete containing recycled springs in post-fire conditions. Proc. Inst. Civ. Eng.-Struct. Build. 2020, 173, 3–16. [Google Scholar] [CrossRef]

- Tayebi, M.; Nematzadeh, M. Effect of hot-compacted waste nylon fine aggregate on compressive stress-strain behavior of steel fiber-reinforced concrete after exposure to fire: Experiments and optimization. Constr. Build. Mater. 2021, 284, 122742. [Google Scholar] [CrossRef]

- Caverzan, A.; Colombo, M.; di Prisco, M.; Rivolta, B. High performance steel fibre reinforced concrete: Residual behaviour at high temperature. Mater. Struct. 2015, 48, 3317–3329. [Google Scholar] [CrossRef]

- Nematzadeh, M.; Karimi, A.; Fallah-Valukolaee, S. Compressive performance of steel fiber-reinforced rubberized concrete core detached from heated CFST. Constr. Build. Mater. 2020, 239, 117832. [Google Scholar] [CrossRef]

- Netinger, I.; Kesegic, I.; Guljas, I. The effect of high temperatures on the mechanical properties of concrete made with different types of aggregates. Fire Saf. J. 2011, 46, 425–430. [Google Scholar] [CrossRef]

- Nematzadeh, M.; Mousavi, R. Post-fire flexural behavior of functionally graded fiber-reinforced concrete containing rubber. Comput. Concr. 2021, 27, 417–435. [Google Scholar]

- Nematzadeh, M.; Nazari, A.; Tayebi, M. Post-fire impact behavior and durability of steel fiber-reinforced concrete containing blended cement-zeolite and recycled nylon granules as partial aggregate replacement. Arch. Civ. Mech. Eng. 2021, 22, 5. [Google Scholar] [CrossRef]

- Gao, Y.T.; Wang, B.; Liu, C.J.; Hui, D.; Xu, Q.; Zhao, Q.H.; Wei, J.C.; Hong, X.Y. Experimental study on basic mechanical properties of recycled steel fiber reinforced concrete. Rev. Adv. Mater. Sci. 2022, 611, 417–429. [Google Scholar]

- Yan, J.Q.; Gao, Y.T.; Tang, M.G.; Ding, N.S.; Xu, Q.; Peng, M.; Zhao, H. Experimental study on the mechanical properties of recycled spiral steel fiber-reinforced rubber concrete. Buildings 2024, 14, 897. [Google Scholar] [CrossRef]

- Yan, J.Q.; Gao, Y.T.; Fan, T.; Xu, Q.; Yuan, W.G.; Zhao, X. Experimental Study on Flexural Performance of Recycled Steel Fiber Concrete Beams. Buildings 2023, 13, 3046. [Google Scholar] [CrossRef]

- JGJ/T221-2010; Industry Standards of the People’s Republic of China. Technical Specification for Application of Fiber Reinforced Concrete. China Architecture & Building Press: Beijing, China, 2010.

- JGJ55-2011; Industry Standards of the People’s Republic of China. Code for Design of Ordinary Concrete Mix Proportion. China Architecture & Building Press: Beijing, China, 2011.

- ASTM E119-23; American Society for Testing and Materials. Standard Test Methods for Fire Tests of Building Construction and Materials. ASTM International: West Conshohocken, PA, USA, 2023.

- ISO 834-1:1999; International Organization for Standardization. Fire-Resistance Tests—Elements of Building Construction—Part 1: General Requirements. ISO: Geneva, Switzerland, 1999.

- EN 1363-1:2020; European Committee for Standardization. Fire Resistance Tests—Part 1: General Requirements. CEN: Brussels, Belgium, 2020.

- Mpalaskas, A.C.; Kytinou, V.K.; Zapris, A.G.; Matikas, T.E. Optimizing Building Rehabilitation through Nondestructive Evaluation of Fire-Damaged Steel-Fiber-Reinforced Concrete. Sensors 2024, 24, 5668. [Google Scholar] [CrossRef]

- Petr, M.; Josef, N.; Jakub, H. Destructive and non-destructive experimental investigation of polypropylene fibre reinforced concrete subjected to high temperature. J. Build. Eng. 2019, 26, 100906. [Google Scholar]

| Loss on Ignition /% | SO3 /% | MgO /% | Cl− /% | Set Time /min | Final Setting Time /min |

| 2.96 | 1.93 | 3.13 | 0.019 | 259 | 318 |

| Composition of Fly Ash | Indicator Requirements/% | Test Result/% |

|---|---|---|

| Al2O3 | ≤30 | 27.7 |

| SiO2 | ≤50 | 42.4 |

| Cl− | ≤0.02 | 0.012 |

| SO3 | ≤3 | 1.7 |

| CaO | ≤10 | 7.1 |

| f-CaO | ≤1 | 0.78 |

| HO− | ≤1.5 | 0.9 |

| Fe3+ | 0.8~1.0 | 0.89 |

| Water content | ≤1 | 0.75 |

| Composition | Fe/% | C/% | Si/% | Mn/% | P/% | S/% | Cd/% | Ni/% | Mo/% |

|---|---|---|---|---|---|---|---|---|---|

| Proportion | 93 | 0.09 | 0.08 | 0.21 | 0.024 | 0.021 | 0.49 | 7.9 | 1.8 |

| Strength Grade | Water /kg/m3 | Cement /kg/m3 | Fly Ash /kg/m3 | Stones /kg/m3 | Sand /kg/m3 | WSF/kg/m3 | |

|---|---|---|---|---|---|---|---|

| 1% | 2% | ||||||

| C40 | 190 | 411.25 | 41.13 | 1161.65 | 547.14 | 79.3 | 158.6 |

| C60 | 249 | 870.91 | 87.09 | 786 | 405 | 79.3 | 158.6 |

| Serial Number | Sample Code | Number | Strength Grade | Heating Temperature/℃ | WSF Content/% |

|---|---|---|---|---|---|

| 1 | A4B0C0 | 8 | C40 | Ordinary temperature | 0 |

| 2 | A4B0C2 | 8 | C40 | 200 | 0 |

| 3 | A4B0C4 | 8 | C40 | 400 | 0 |

| 4 | A4B0C6 | 8 | C40 | 600 | 0 |

| 5 | A4B0C8 | 8 | C40 | 800 | 0 |

| 6 | A4B1C0 | 8 | C40 | Ordinary temperature | 1 |

| 7 | A4B1C2 | 8 | C40 | 200 | 1 |

| 8 | A4B1C4 | 8 | C40 | 400 | 1 |

| 9 | A4B1C6 | 8 | C40 | 600 | 1 |

| 10 | A4B1C8 | 8 | C40 | 800 | 1 |

| 11 | A4B2C0 | 8 | C40 | Ordinary temperature | 2 |

| 12 | A4B2C2 | 8 | C40 | 200 | 2 |

| 13 | A4B2C4 | 8 | C40 | 400 | 2 |

| 14 | A4B2C6 | 8 | C40 | 600 | 2 |

| 15 | A4B2C8 | 8 | C40 | 800 | 2 |

| 16 | A6B0C0 | 8 | C60 | Ordinary temperature | 0 |

| 17 | A6B0C2 | 8 | C60 | 200 | 0 |

| 18 | A6B0C4 | 8 | C60 | 400 | 0 |

| 19 | A6B0C6 | 8 | C60 | 600 | 0 |

| 20 | A6B0C8 | 8 | C60 | 800 | 0 |

| 21 | A6B1C0 | 8 | C60 | Ordinary temperature | 1 |

| 22 | A6B1C2 | 8 | C60 | 200 | 1 |

| 23 | A6B1C4 | 8 | C60 | 400 | 1 |

| 24 | A6B1C6 | 8 | C60 | 600 | 1 |

| 25 | A6B1C8 | 8 | C60 | 800 | 1 |

| 26 | A6B2C0 | 8 | C60 | Ordinary temperature | 2 |

| 27 | A6B2C2 | 8 | C60 | 200 | 2 |

| 28 | A6B2C4 | 8 | C60 | 400 | 2 |

| 29 | A6B2C6 | 8 | C60 | 600 | 2 |

| 30 | A6B2C8 | 8 | C60 | 800 | 2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, D.; Ren, X.; Gao, Y.; Fan, T.; Li, M.; Lv, H. Study on the Basic Mechanical Properties of Waste Steel Fiber Reinforced Concrete After High-Temperature Exposure. Buildings 2025, 15, 1025. https://doi.org/10.3390/buildings15071025

Yang D, Ren X, Gao Y, Fan T, Li M, Lv H. Study on the Basic Mechanical Properties of Waste Steel Fiber Reinforced Concrete After High-Temperature Exposure. Buildings. 2025; 15(7):1025. https://doi.org/10.3390/buildings15071025

Chicago/Turabian StyleYang, Dan, Xiaopeng Ren, Yongtao Gao, Tao Fan, Mingshuai Li, and Hui Lv. 2025. "Study on the Basic Mechanical Properties of Waste Steel Fiber Reinforced Concrete After High-Temperature Exposure" Buildings 15, no. 7: 1025. https://doi.org/10.3390/buildings15071025

APA StyleYang, D., Ren, X., Gao, Y., Fan, T., Li, M., & Lv, H. (2025). Study on the Basic Mechanical Properties of Waste Steel Fiber Reinforced Concrete After High-Temperature Exposure. Buildings, 15(7), 1025. https://doi.org/10.3390/buildings15071025