1. Introduction

Portugal, with its magnificent history and culture, is rich in traditional buildings that reflect its identity and architectural heritage. Wattle and daub walls, commonly found in constructions up to the mid-20th century in historic centres and many Portuguese villages, are significant examples of this architectural legacy, both vernacular and urban.

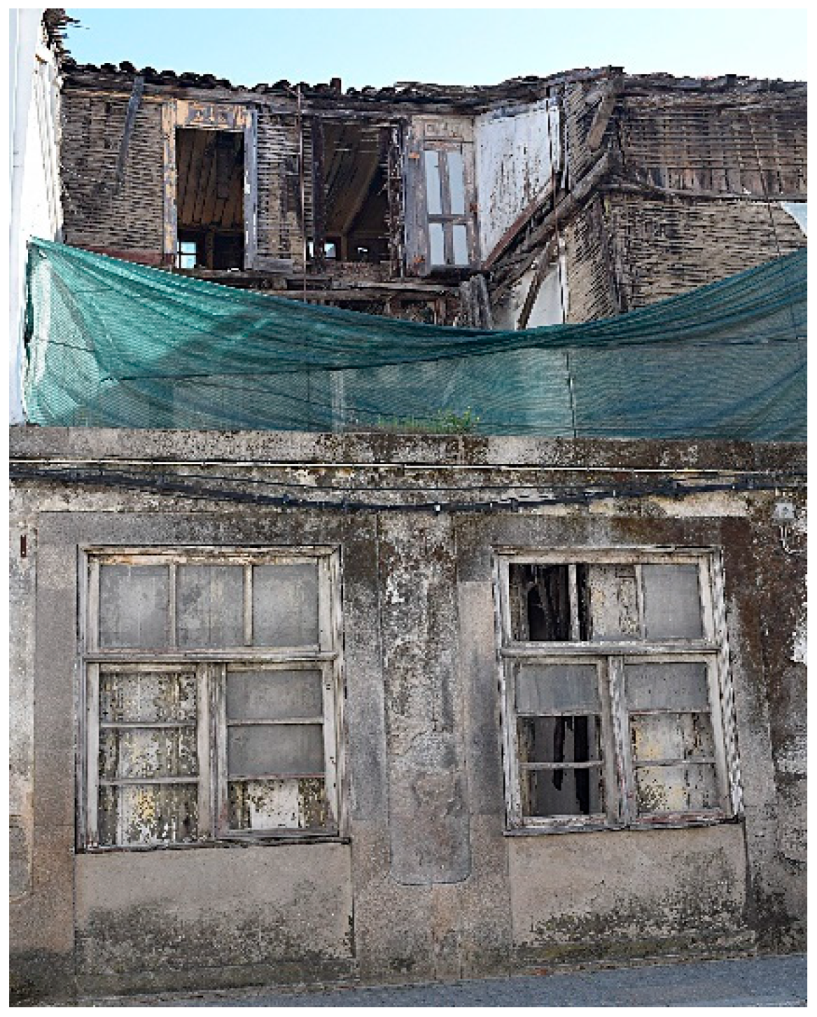

The rehabilitation of wattle and daub constructions emerges as a relevant solution in the current context, both due to the extent of its use and the risks currently associated with it. It is a fact that a significant portion of the wattle- and daub-built heritage in Portugal is in a state of degradation. This scenario is mainly due to the lack of regular maintenance actions or the complete abandonment of these structures, particularly regarding rendering mortars. These mortars serve the primary function of protecting and ensuring the durability of the surfaces to which they are applied while also contributing to the comfort and healthiness of the buildings. Additionally, it is evident that insufficient importance is given to this constructive element, as it often becomes a target for demolition, even when in good condition.

In a study analysing 127 external wattle and daub walls, the authors of [

1] observed that approximately 40% of the constructions exhibited detachment of rendering mortars, while around 83% showed cracks. Humidity stains were also frequent, affecting approximately 74.8% of the constructions analysed.

Despite the identified pathologies, it is important to highlight that the existence of buildings with wattle and daub walls in good condition proves that this construction system has durability compatible with modern standards. The rehabilitation of such constructions, in addition to helping reduce the housing deficit with minimal environmental impact, would promote the appreciation of heritage and the urban landscape, as well as the preservation and dissemination of this cultural legacy for future generations.

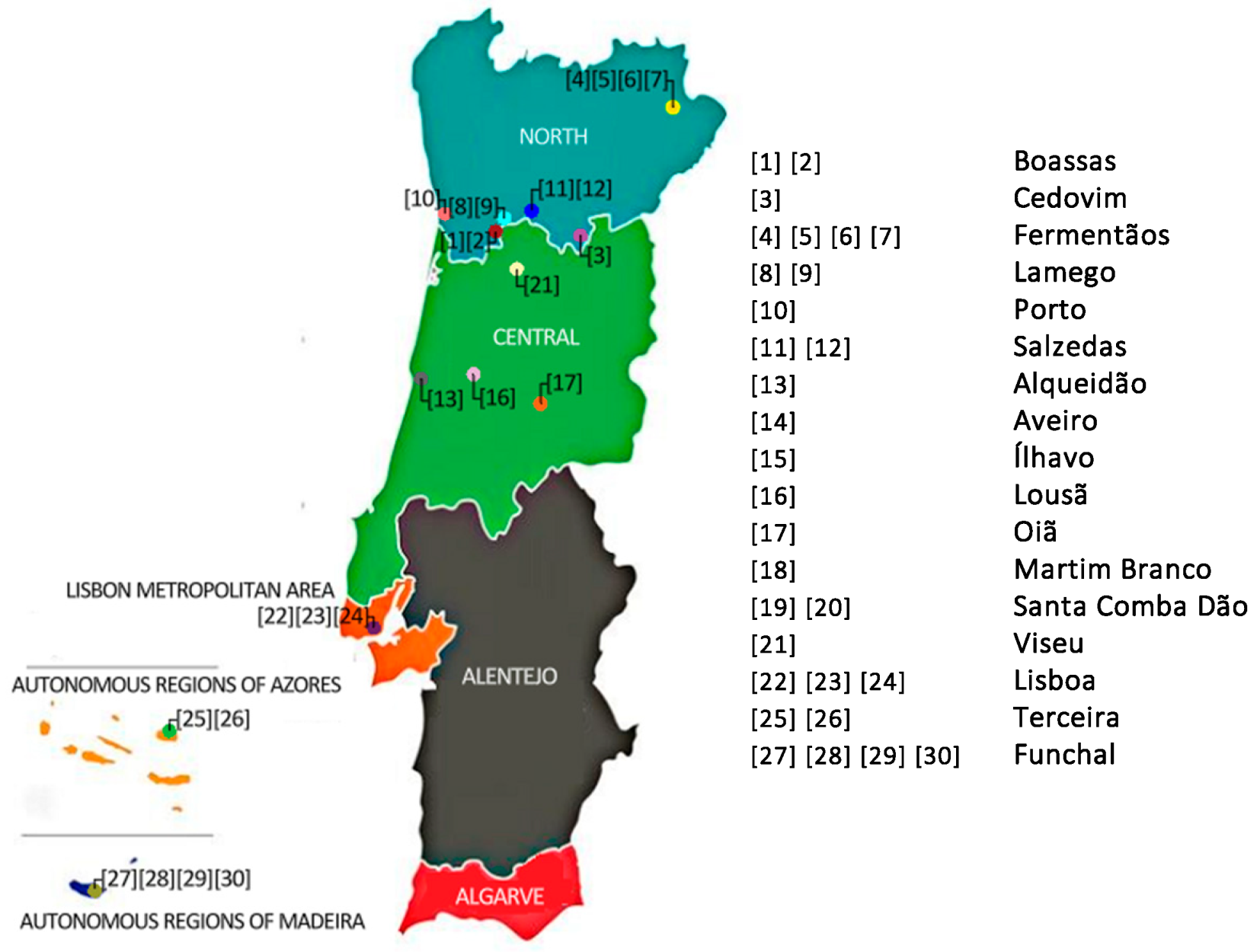

Over the past 20 years, research into wattle and daub constructions in Portugal has intensified. Regarding the study of construction typologies, the published literature has predominantly focused on the northern region of mainland Portugal, encompassing the sub-regions of Douro, Porto Metropolitan Area, Alto Tâmega, Terras de Trás-os-Montes, and Tâmega e Sousa [

2,

3,

4,

5,

6,

7,

8]. In addition, studies have been highlighted in the central region, specifically in the Viseu Dão Lafões sub-region [

9,

10], and the Lisbon Metropolitan Area [

11,

12].

Despite the progress made, Portugal comprises 25 sub-regions, of which approximately 70% still lack systematic records on wattle and daub constructions. This scenario reinforces the need to expand research areas to include underexplored regions. It is therefore proposed to extend studies on the construction typologies of wattle and daub walls to other areas of central and southern mainland Portugal, as well as to the Autonomous Regions of the Azores and Madeira.

Another proposal of this article aims to expand the scientific knowledge about wattle and daub walls in Portugal by providing detailed information to the academic and technical communities and society at large. This information, which includes the pre-existing characteristics of materials and construction processes, is fundamental for promoting the preservation of this tangible and cultural heritage. Such preservation is not limited to the production of literary records but also aims to support interventions in the built heritage. A comprehensive understanding of the structural and functional behaviour of wattle and daub walls is crucial to informing choices regarding intervention processes and repair materials. This synthesis of information is an indispensable prerequisite to ensuring compatibility between pre-existing and new elements, thereby promoting the durability of the constructions.

Through a thorough scientific analysis, this study highlights the importance of preserving the sustainable character of this construction typology in architectural heritage rehabilitation. This approach not only addresses the practical demand for integrating tradition and innovation but also honours the history and cultural identity of the community.

The other objective of this study is to emphasise the intrinsic sustainable nature of this construction typology, particularly in interventions aimed at rehabilitating architectural heritage. This approach is grounded in the need to balance technical performance criteria, such as energy efficiency and durability, with the conservation of historical and cultural values. Moreover, the integration of traditional construction practices with innovative solutions not only meets contemporary demands for sustainability and functionality but also safeguards the authenticity and cultural identity of the communities associated with this heritage.

2. Wattle and Daub Construction: An Ancient Tradition Around the World

Tabique constructions, as they are known in Portugal, have been used in Europe, the Americas, and Asia and are referred to as

pau-a-pique in Brazil,

quincha in Argentina, Chile, Peru, and Spain,

bahareque in Colombia, Venezuela, and El Salvador,

cuje in Cuba,

torchis in France,

lehmbewurf in Germany, wattle and daub in the United Kingdom and the United States, and

tsuchikabe in Japan, [

2].

2.1. Wattle and Daub Walls in Brazil

Wattle and daub walls in Brazil, found in nearly all states, have historically been known by various regional names, including pau-a-pique, taipa de mão, taipa de sopapo, taipa de sebe, taipa de pescoção, taipa de tapona, and barro armado, depending on the region and period. The origin of this construction technique in Brazil is attributed to the confluence of Indigenous, African, and Portuguese building practices. It was widely employed from the earliest Portuguese settlements until the 19th century.

The pau-a-pique construction method follows a structured process. Initially, vertical wooden stakes with a square cross-section of approximately a palm’s width—usually made from durable native species—are fixed into the ground at regular intervals to create a primary structural framework. Horizontal beams, typically crafted from bamboo or other flexible materials, are then interwoven among these vertical elements, forming frames ranging from 5 to 20 cm in size, and secured using natural fibres such as lianas, vines, or creepers.

Once the structural lattice is in place, a clay-based mixture, often combined with straw or other fibrous materials to enhance cohesion, is applied to fill the gaps, forming a solid wall. This technique results in a breathable and thermally efficient structure that has historically been adapted to various climatic conditions in Brazil. Although it is still utilised in some rural regions, primarily in rustic buildings, contemporary applications of this method tend to be highly rudimentary, often lacking the stability, durability, and comfort that characterised colonial-era constructions [

13].

Figure 1 illustrates one of the largest

pau-a-pique buildings in the country, the Santa Clara Farm, constructed between 1760 and 1780 in Santa Rita de Jacutinga, Minas Gerais.

2.2. Wattle and Daub in Chile

In Chile, before the colonial period (1541–1818), the quincha construction technique was widely used across the Atacama and Araucanía regions, taking advantage of the abundant availability of wood and earth.

During Spanish colonisation, rammed earth became the predominant construction method, particularly in urban areas. However, quincha remained in use, primarily on farms and in rural residences.

In recent decades, Chilean architects and builders have revived the use of natural materials, such as earth and plant fibres, driven by the growing concern for sustainability and cultural heritage preservation. This movement has reinvigorated quincha, incorporating it into new contemporary typologies that blend tradition with innovation.

In [

14], the authors identify six contemporary

quincha construction typologies, classified based on the materials used in the primary and secondary structural elements, as well as the infill material.

Regarding the structural materials, contemporary quincha construction typologies can be categorised as follows:

Wood–Wood: Both the primary and secondary structures are made of wood.

Wood–Metal: The primary structure is made of wood, while the secondary structure consists of welded wire mesh.

Metal–Metal: Both the primary structure (steel) and the secondary structure (welded wire mesh) are made of metal.

With respect to the infill materials, contemporary quincha typologies can be classified as follows:

Wet: Plastic-state clay mixed with plant fibres.

Light-Wet: A slurry with plant fibres.

Light-Dry: Dry plant fibres.

Without Infill: No filling material is used.

Figure 2 presents a schematic drawing of a

quincha system featuring a primary wooden structure and a secondary structure composed of welded wire mesh.

2.3. Wattle and Daub in Colombia, El Salvador, Costa Rica, Ecuador, and the Philippines

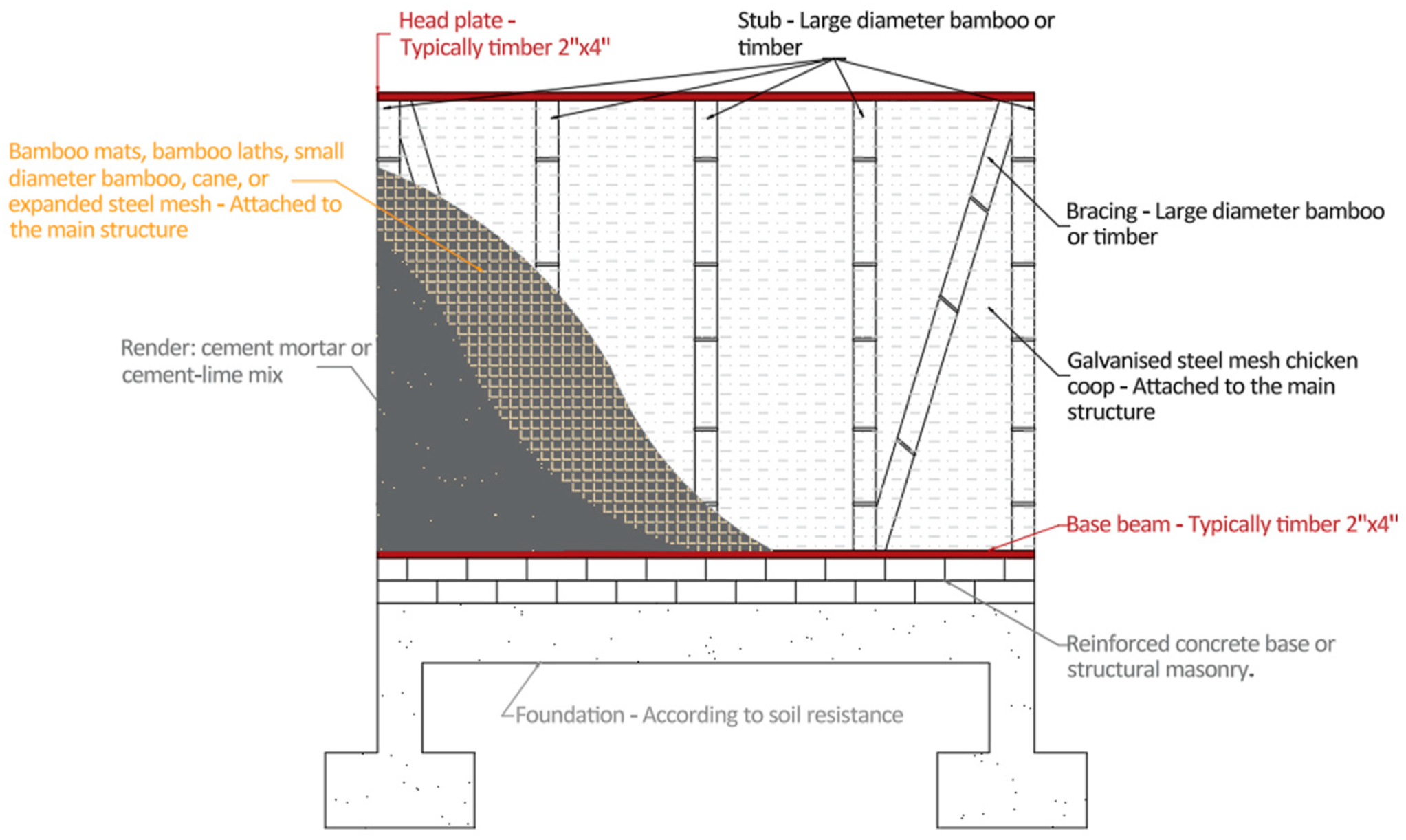

Bahareque is a traditional construction technique like pau-a-pique, characterised by a wooden or bamboo framework infilled with a mixture of clay and straw. In countries such as Colombia, El Salvador, Costa Rica, Ecuador, and the Philippines, this technique has been refined, leading to the development of cemented bahareque.

Cemented bahareque represents an improved vernacular construction system that integrates modern materials, knowledge, and techniques to enhance the traditional bahareque method. This system typically comprises a reinforced concrete foundation supporting a masonry base, upon which a structural framework of bamboo and/or timber is assembled. A matrix of small-diameter bamboo, cane, or wooden slats is nailed to the frame and reinforced with galvanised chicken wire. The walls are then finished with a cement mortar plaster, ensuring greater structural integrity and durability. The roofing is typically composed of fibre–cement or clay tiles.

Figure 3 illustrates the construction scheme in cemented

bahareque. 2.4. Wattle and Daub Walls in France

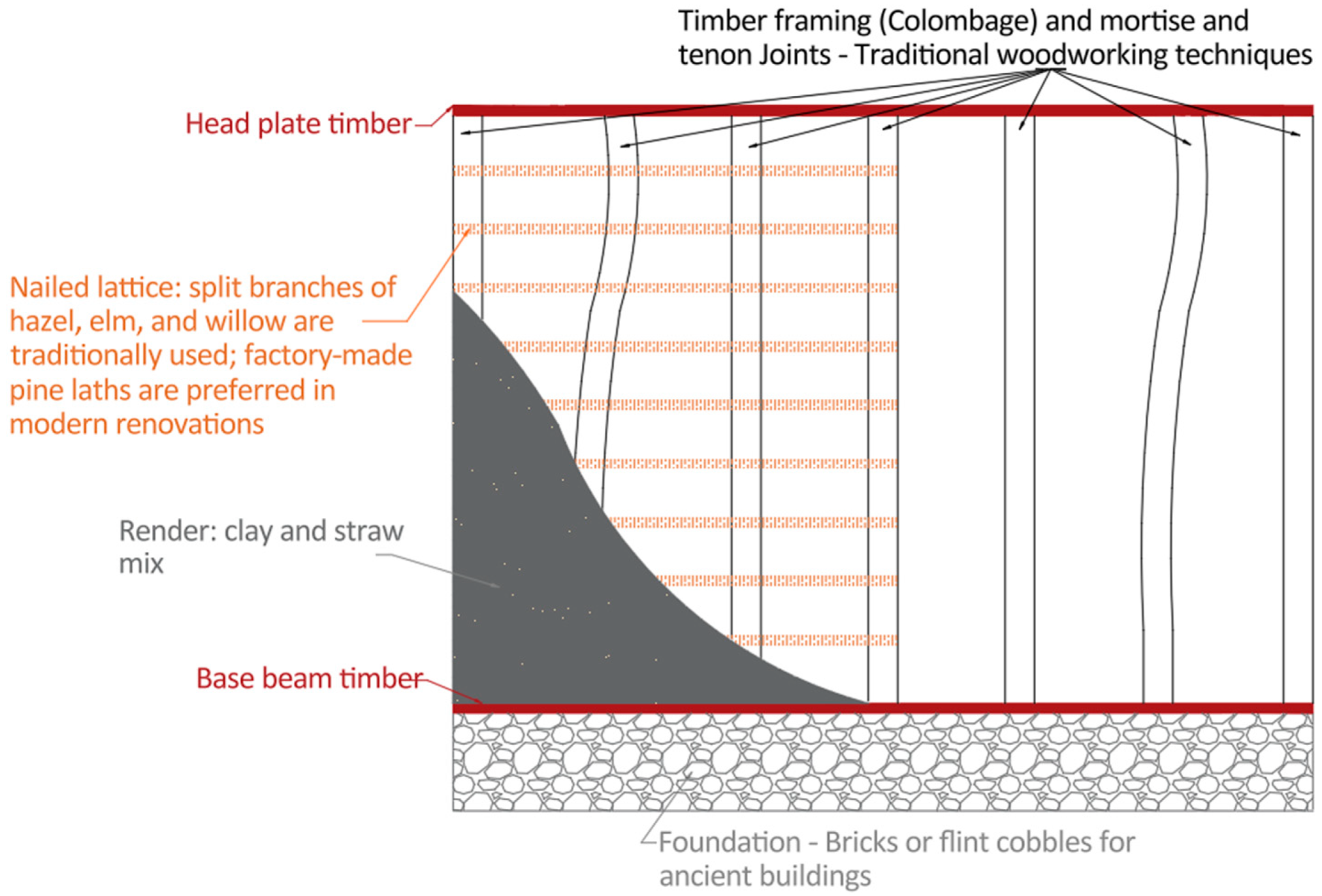

The torchis, as the wattle and daub technique is known in France, is a construction method like pau-a-pique that involves applying a mixture of clay and straw onto an interwoven wooden framework. Its use dates to the Middle Ages and remained common until the 19th century, particularly in rural areas of France.

According to studies conducted by the authors of [

16], in northern France,

torchis constructions were typically built on a brick foundation to protect the clay and wooden materials from ground moisture. The wooden laths used in the structure had variable spacing, generally ranging from 4 to 10 cm. The local silty clay was compacted against the framework either manually or with the aid of specific tools.

Figure 4 presents a generic diagram of

torchis construction in northern France.

2.5. Wattle and Daub in Japan

Tsuchikabe is a traditional Japanese technique that involves applying earth onto a bamboo or wooden framework. In Japan, this technique has been in use since the Jomon period (14,000 BCE–300 BCE) and remained predominant until the Edo period (1603–1868).

The

tsuchikabe method encompasses various wall construction techniques, including

shinkabe and

ookabe, which are primarily used in residential buildings. In the

shinkabe technique, the peripheral structure (pillars and beams) remains exposed, whereas in

ookabe, this structural framework is concealed, meaning that the pillars and beams are fully integrated into the wall structure [

17].

Figure 5 illustrates the construction stages of a

shinkabe wall.

These traditional techniques reflect human ingenuity in utilising local and sustainable materials for constructing dwellings adapted to the climate and culture of each region. Although some of these methods have fallen into disuse with the advent of modern materials, there is a growing movement to revive and appreciate these vernacular construction practices.

3. General Characterisation of Portuguese Wattle and Daub Walls

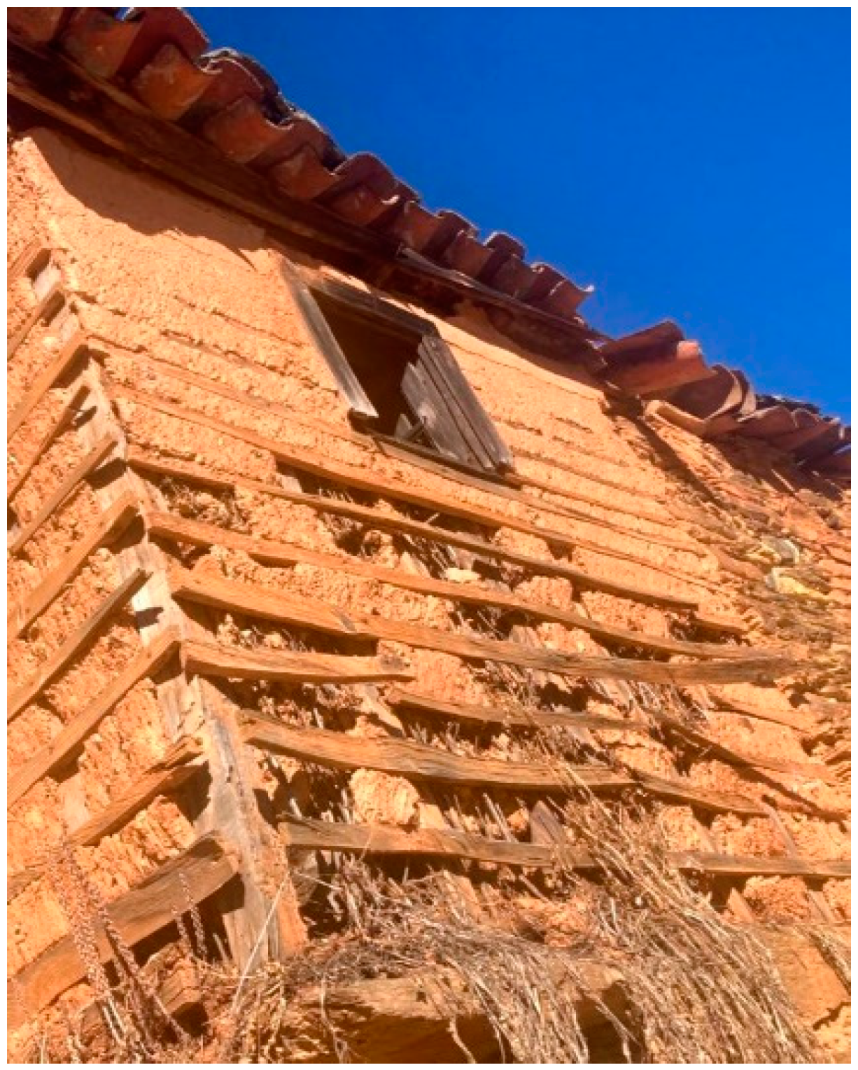

In Portugal, the wattle and daub technique was predominantly used for interior partitions, less frequently for external walls, ceilings, and, in more limited cases, chimneys. These constructions did not adhere to rigid normative standards, resulting in significant variability in both the materials used for the timber structural components and the arrangement of these elements. The structure typically comprised a framework with an essentially load-bearing function, consisting of boards, uprights, beams, and wooden slats joined by metal connectors.

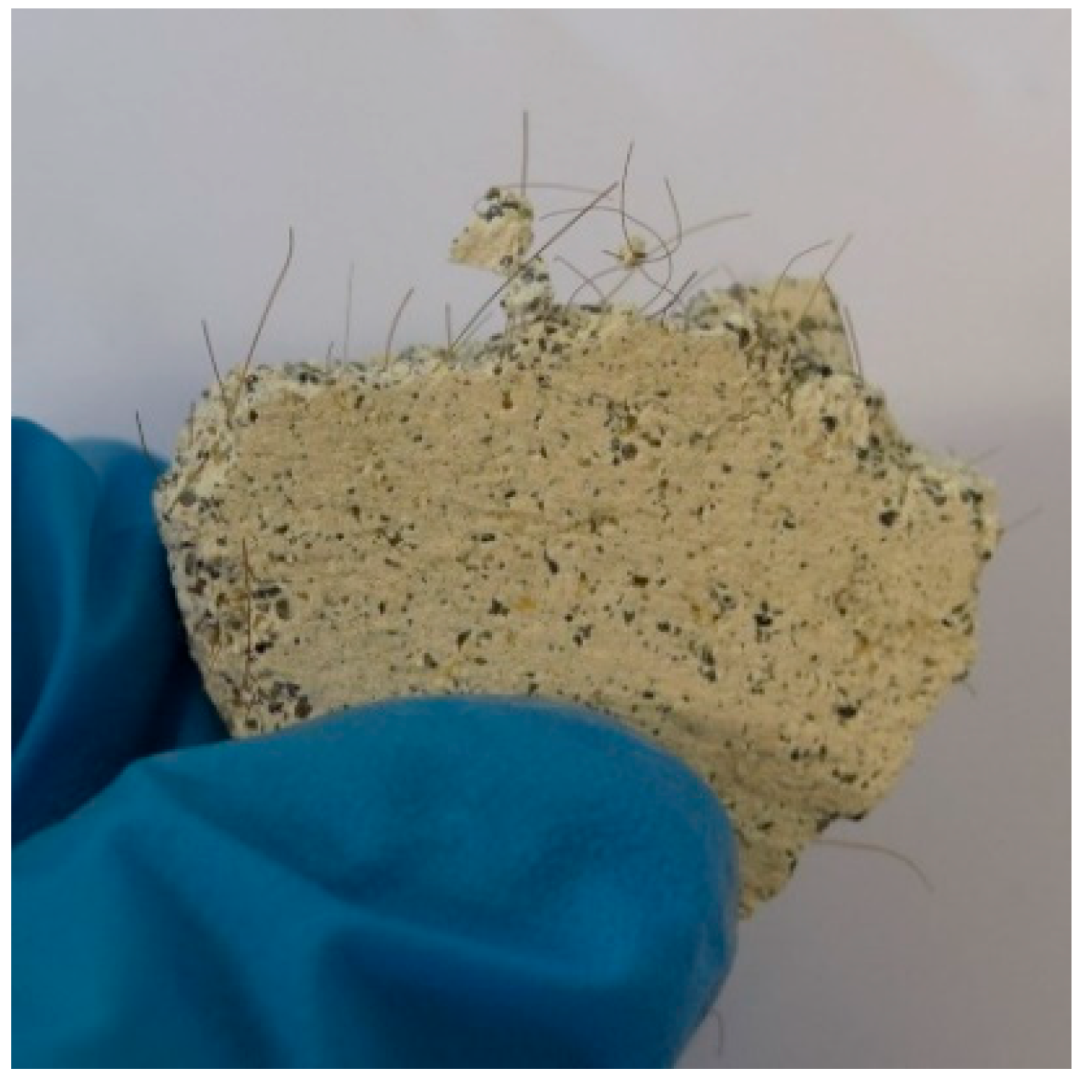

The infill materials for the fasquios—a set of wood battens—and the coatings varied widely, although earth-based mortars and, in some cases, sand mortars with added lime were most common. These coatings served an essential role in protecting the timber structure, acting as a barrier against biological agents and fire, thereby contributing to the durability and preservation of wattle and daub constructions [

2].

Wattle and daub constructions exhibit distinct characteristics even in regions with similar conditions or within the same locality. This diversity can be attributed to the interplay of factors such as the availability of local natural resources, the technical knowledge of builders, the financial capacity of owners, the intended use of the building, its structural function, and local climatic conditions. Such factors encouraged the incorporation of animal and plant fibres in both the infill and coating materials, commonly including onion stalks, wood shavings, rye or wheat straw, maize cobs, horsehair, ceramic tile fragments, stone pieces, vegetable oils, and whale oil.

The primary function of adding plant or animal fibres was to mitigate shrinkage in the mortars, thereby reducing the occurrence of cracks. Oils were primarily incorporated to enhance the water-repellent properties of the mortars. As for the infill materials, these were used to facilitate application, reduce mortar consumption, and, in some cases, provide additional structural strength. From a contemporary perspective, the incorporation of local and recyclable materials in wattle and daub constructions represents a sustainable and economical solution, as it promotes the reuse of locally available resources [

2,

3,

4,

18].

Wattle and daub constructions stand out for their sustainable and economical nature, offering numerous environmental and functional advantages. These buildings predominantly use natural and local materials, characterised by low greenhouse gas emissions. Furthermore, their construction does not require specialised equipment or highly skilled labour, thereby reducing costs and the environmental impact of the building process. The continued existence of wattle and daub buildings in good condition today confirms their durability.

Research by the authors of [

19], comparing the properties of pre-existing wattle and daub mortars with current normative values and bibliographic references, indicates that these constructions meet contemporary performance standards, particularly regarding capillary water absorption, drying index, open porosity, and compressive strength. The results corroborate the durability and viability of these buildings, demonstrating that the wattle and daub construction system remains suitable for current conservation and functionality standards.

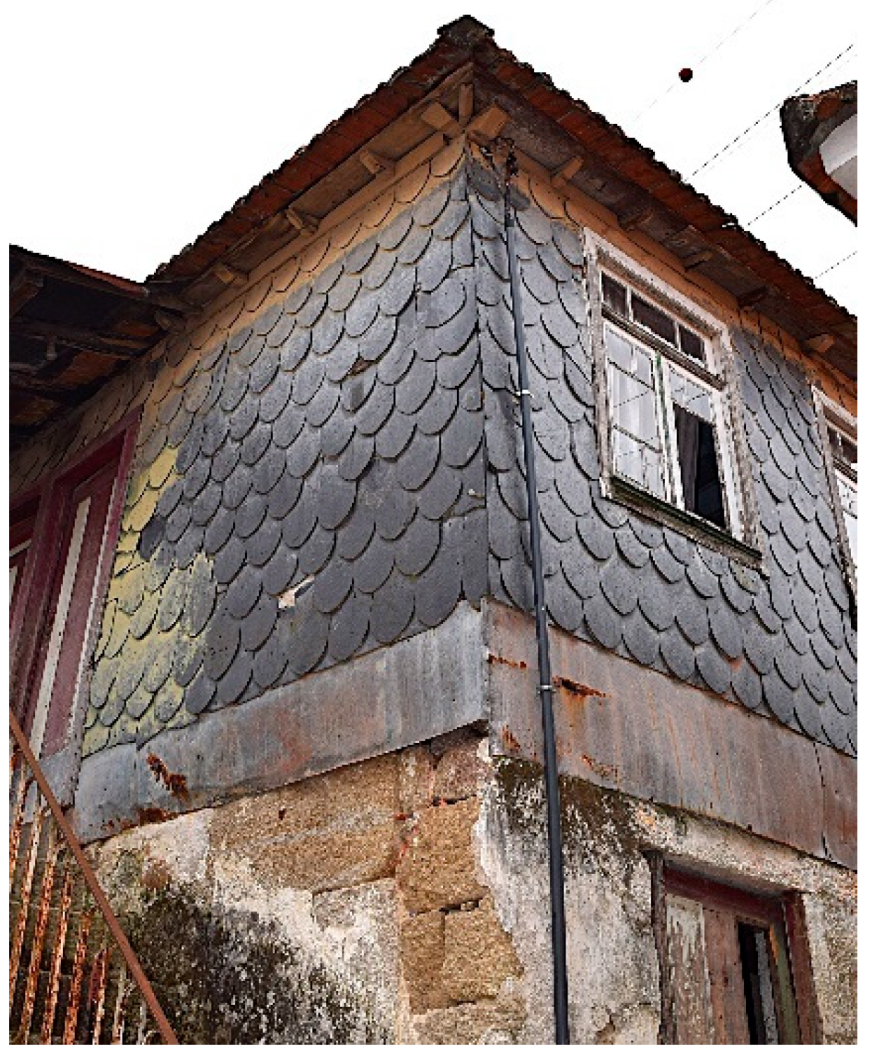

Focusing on the northern region of Portugal, studies on the characterisation of wattle and daub walls have been conducted over the past two decades. These investigations revealed that wattle and daub is most used in one- or two-story dwellings, where the ground floor is generally allocated to storage or commercial purposes. In most of these buildings, the ground-floor walls are built of stone masonry, while the external and internal walls of the upper floor are wattle and daub. Another identified solution involves the use of stone masonry for external walls and reserving wattle and daub for partition walls [

18].

The external wattle and daub walls were usually coated with lime-based mortar and, in some cases, protected with materials such as slate tiles or zinc sheets, as described by [

5,

6,

7,

8,

20,

21].

Regarding the types of wood used in structural elements, research in the northern region identified the use of native species such as maritime pine (

Pinus pinaster), sweet chestnut (

Castanea sativa), poplar (

Populus sp), and linden (

Tilia cordata) [

4]. In the Autonomous Region of Madeira, some of the identified wood species were also native, including sweet chestnut (

Castanea sativa), maritime pine (

Pinus pinaster Aiton), and the Madeira cedar or Canary Islands juniper (Juniperus cedrus) [

22]. Although bamboo (

Bambusa vulgaris) is not a wood species, it was used as a lath in Funchal, originating from Asia. In the Azores, maritime pine (

Pinus pinaster Aiton) and Azorean cedar (

Juniperus brevifolia) were predominant [

23].

The laths exhibited four main types of cross-sections: rectangular with a double bevel, rectangular with a single bevel, regular rectangular, and irregular rectangular. As for the uprights, their cross-sections varied between square, square with rounded edges, and rectangular. The boards could have regular or irregular rectangular sections, in addition to waney-edge boards [

2].

The research also revealed that nails used in the construction of wattle and daub walls acted as mechanical connectors, predominantly made of iron. The coatings applied to these walls played a fundamental role in protecting and preserving the properties of the materials used.

Figure 6 illustrates the three geometric types of nails identified in these studies: nails with a constant circular cross-section (CØ), nails with a constant square cross-section (C□), and nails with a variable square cross-section (V□), [

2,

9,

10].

Finally, it was found that natural earth, or earth mixed with a lime-based binder, was widely used in the preparation of mortars [

21]. A study conducted by [

24] showed that 74.07% of the examined mortars contained lime content ranging between 22% and 26%.

4. Methodology

The methodology employed in this scientific research is based on two main approaches: bibliographic research and exploratory research.

In the bibliographic research phase, relevant published works were identified to understand and analyse the topic of wattle and daub construction methodologies in Portugal. This involved consulting books, scientific articles, theses, dissertations, yearbooks, journals, legislation, and other types of written sources. At the conclusion of this phase, gaps in the existing knowledge were mapped, guiding the subsequent actions in the exploratory phase.

The purpose of the exploratory research was to refine and update the knowledge previously gathered. It aimed to answer the following questions:

- ⮚

What is the geographical distribution of the wattle and daub construction typology in Portugal? Is this typology predominantly concentrated in the northern region, with sporadic occurrences in other regions of mainland Portugal? How prevalent is it in the autonomous islands of Madeira and the Azores?

- ⮚

Do the typical construction typologies differ across regions? If so, how are these differences manifested? Are there any construction-specific characteristics that remain uncatalogued?

Following the identification of relevant buildings—with support from Municipal councils as well as other public and private institutions in Portugal—details of their construction were recorded using both qualitative and quantitative approaches. The procedures involved visual observation, measurement of sections, and photographic documentation. The data collected to characterise construction typologies and related information were organised into descriptive records, spreadsheets, sketches, and maps.

Finally, a deductive approach was employed to formulate conclusions, based on a descending chain of reasoning that moved from general analysis to specific analysis.

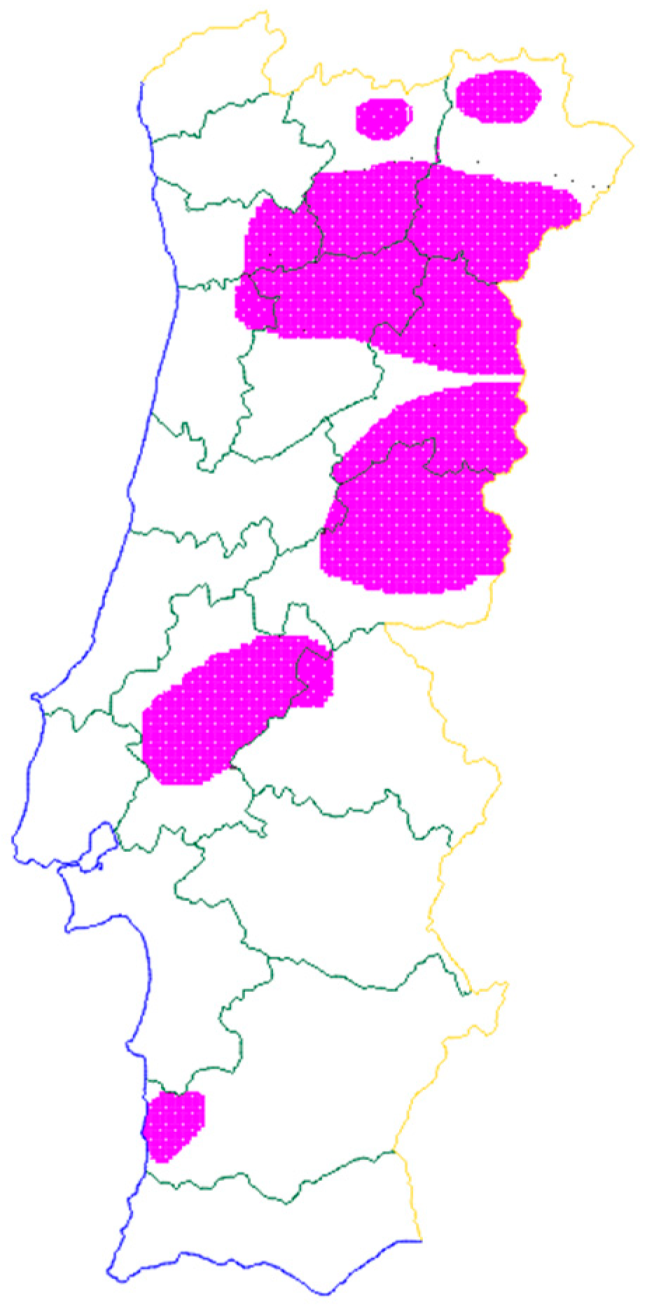

5. Location of the Samples

Figure 7 shows the locations of the buildings analysed in this research, while

Figure 8 displays the geographic distribution of the regions in mainland Portugal where wattle and daub constructions were studied by the authors of [

25]. Comparing the data from the two Figures reveals an expansion of the study area for wattle and daub constructions in mainland Portugal, now including areas to the west of the northern and central regions, as well as the Lisbon Metropolitan Area.

It is worth noting that no wattle and daub constructions were identified in the Algarve region.

Regarding the prevalence of areas with wattle and daub constructions in mainland Portugal, it can be said that the northern, central, and Lisbon Metropolitan regions are prominent, with the Alentejo region featuring to a lesser extent and no notable presence in the Algarve. Additionally, in the Autonomous Regions of the Azores and Madeira, the presence of wattle and daub buildings is not significant.

6. Characteristics of the Studied Buildings

The wattle and daub construction systems are versatile and can be used in various types of buildings. However, their use is not recommended in locations with direct contact with the ground or where there is no assurance of adequate ventilation renewal.

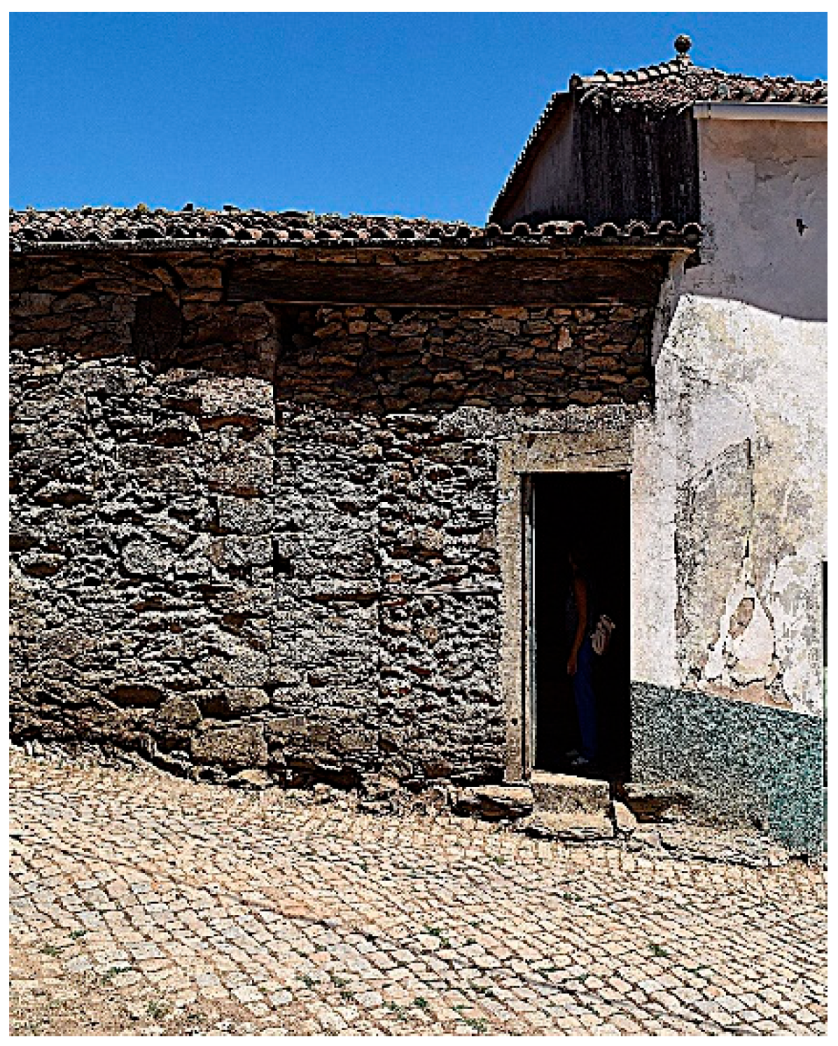

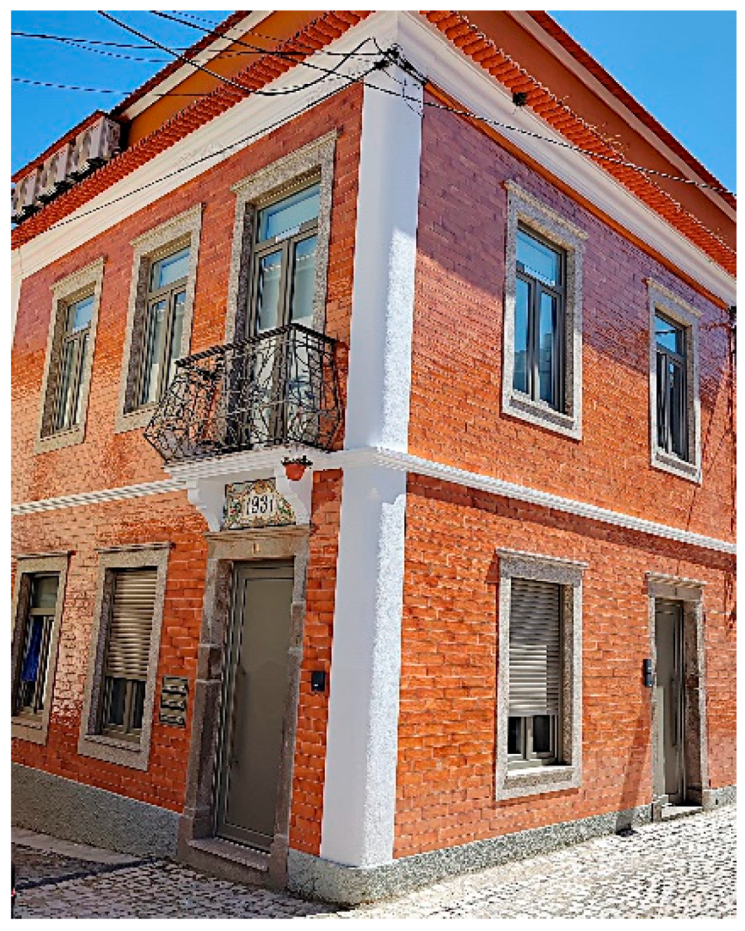

Table 1 lists the types of buildings featuring wattle and daub walls, along with their usage and the region where they are located.

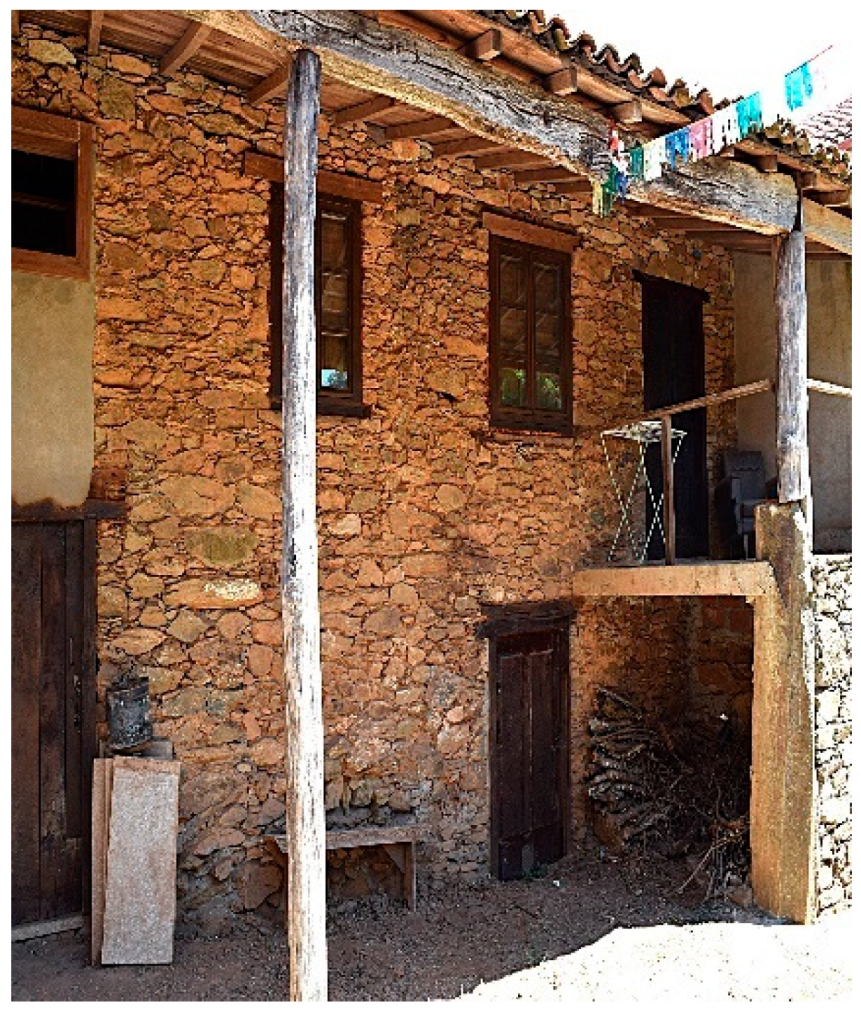

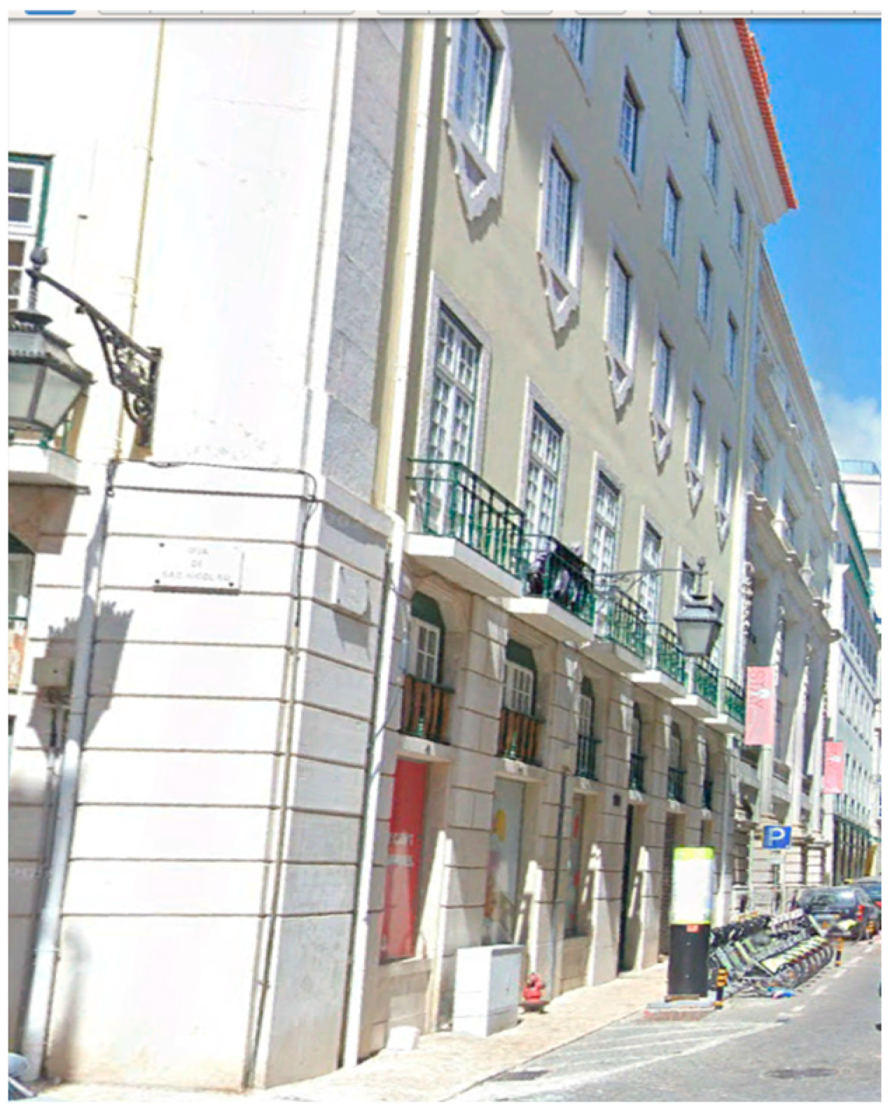

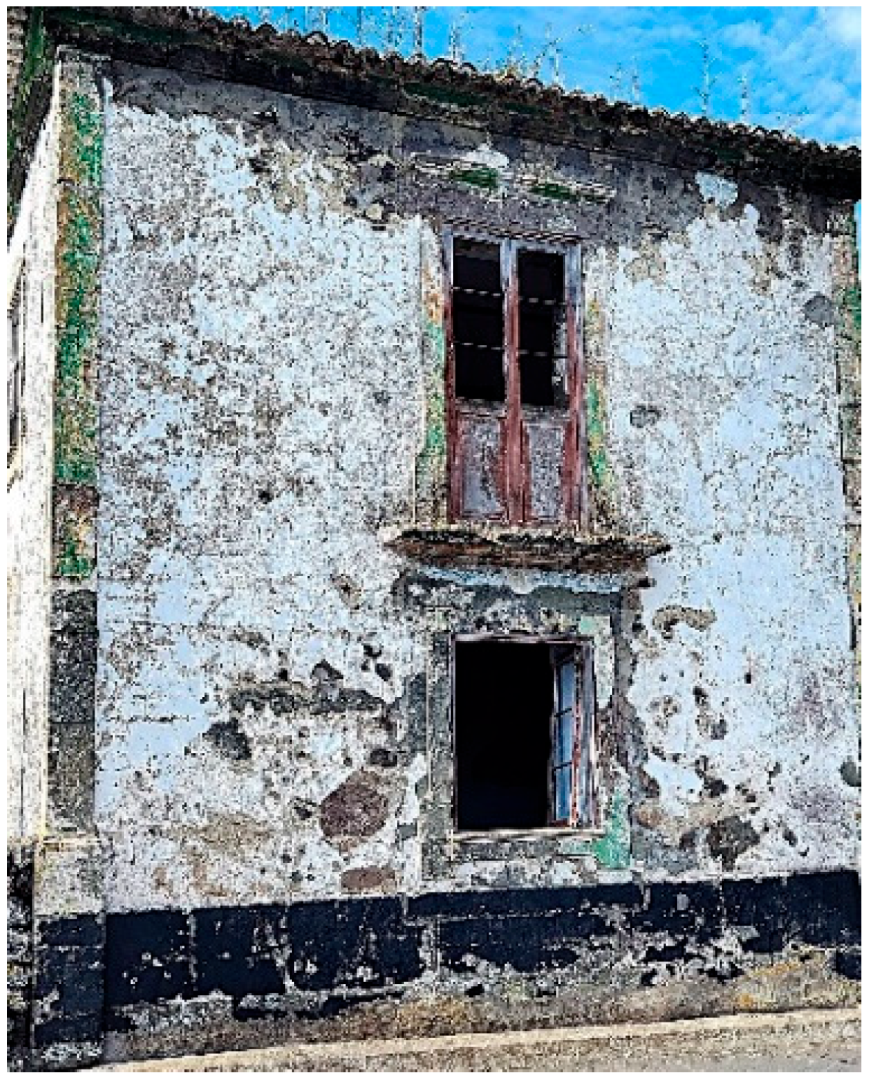

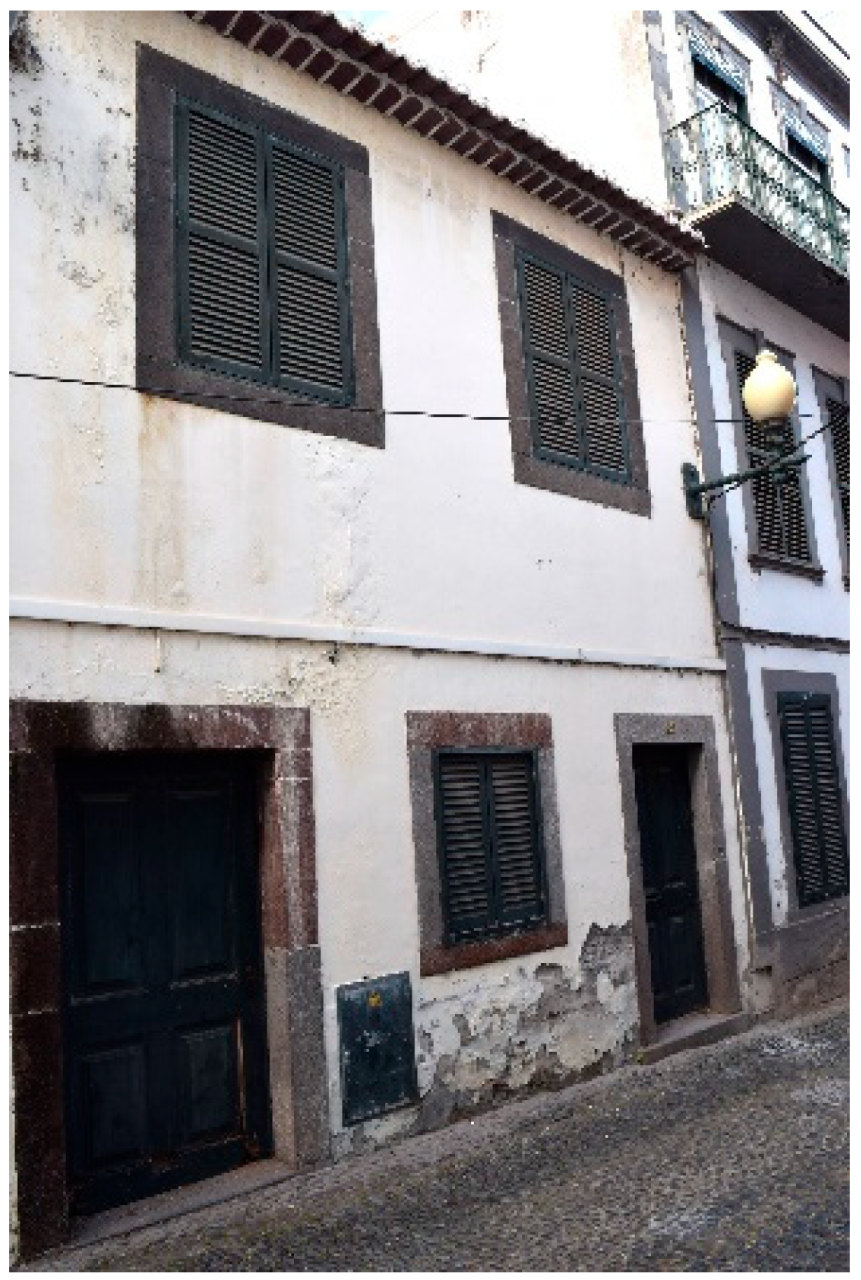

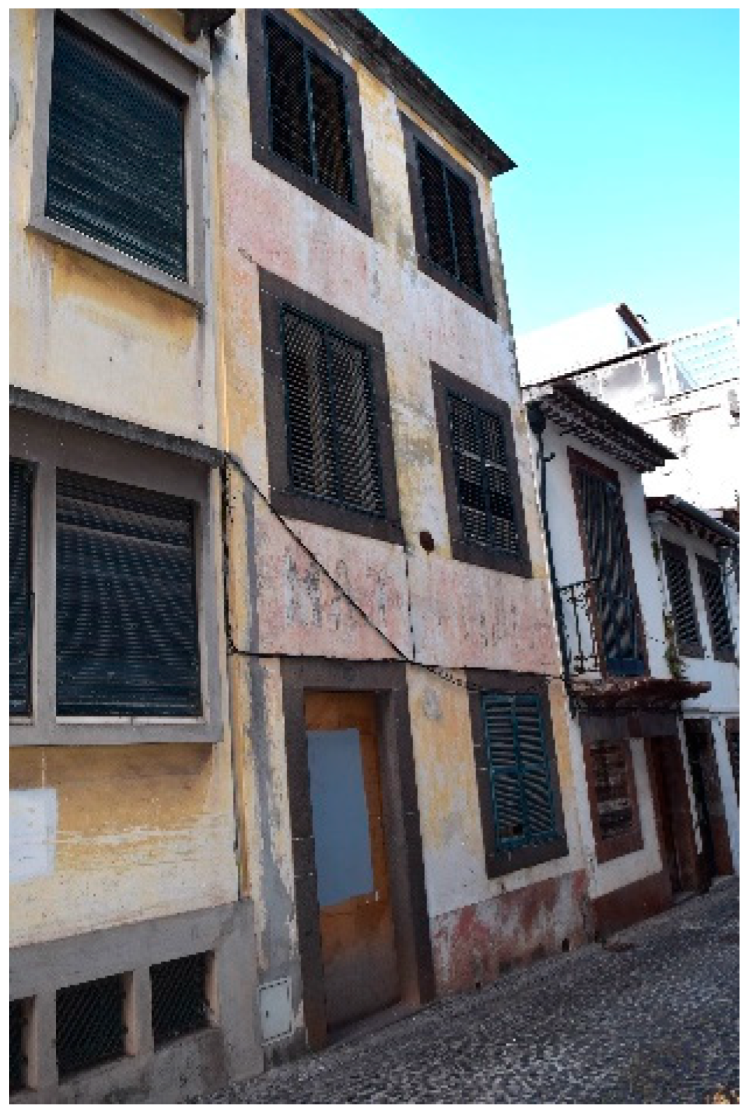

In

Table 2, the types of coatings used on wattle and daub walls and their areas of occurrence are presented.

In

Figure 9,

Figure 10,

Figure 11,

Figure 12,

Figure 13,

Figure 14,

Figure 15,

Figure 16,

Figure 17,

Figure 18,

Figure 19,

Figure 20,

Figure 21,

Figure 22,

Figure 23,

Figure 24,

Figure 25,

Figure 26,

Figure 27,

Figure 28,

Figure 29,

Figure 30,

Figure 31,

Figure 32,

Figure 33,

Figure 34,

Figure 35,

Figure 36,

Figure 37 and

Figure 38, the buildings studied in this research are presented and exemplify the constructive diversity found in Portugal with the incorporation of wattle and daub.

7. Constructive Characterisation of Wattle and Daub Walls

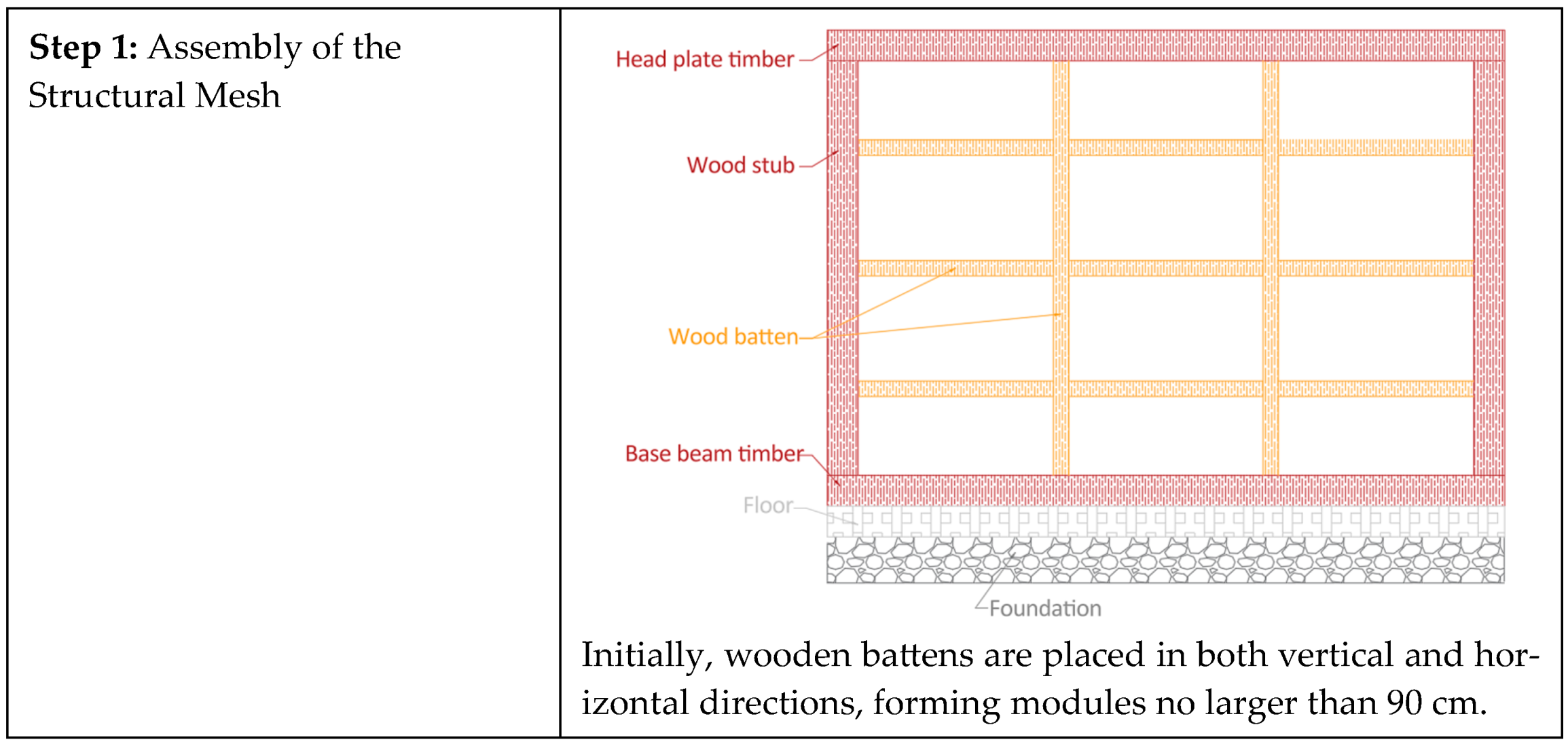

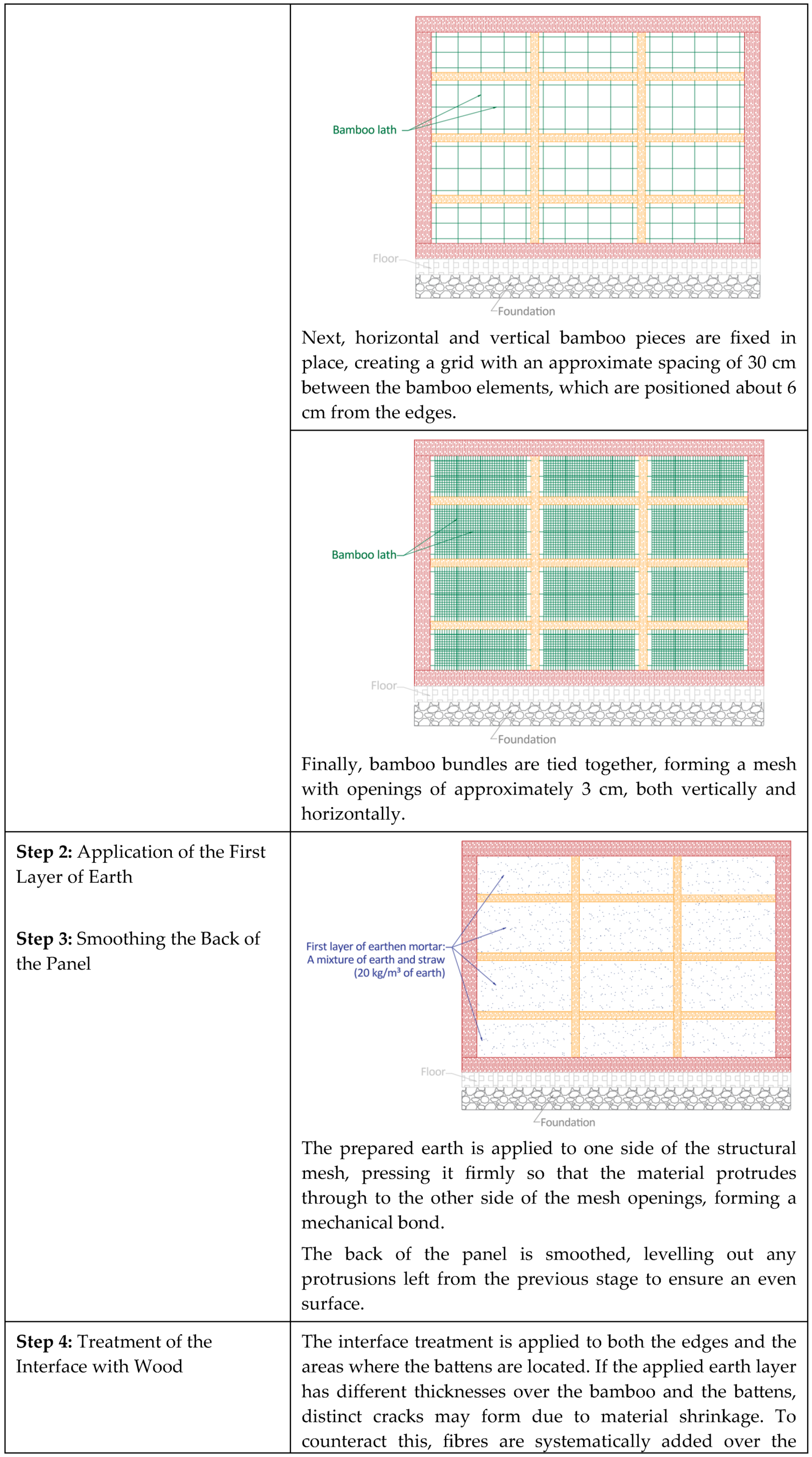

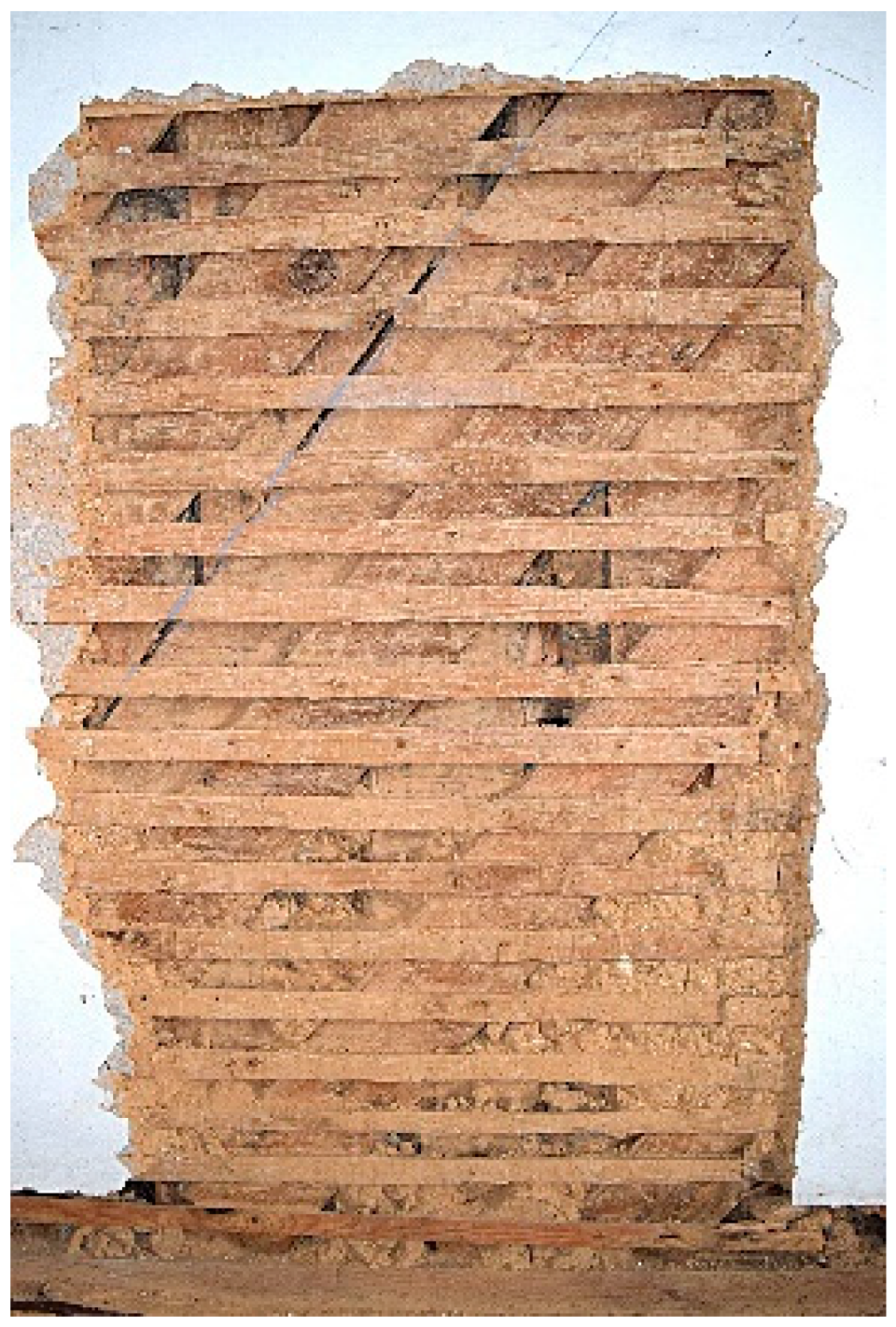

7.1. The Fasquio

The fasquio is a set of wooden laths or bamboo rods arranged horizontally, with a rough surface and no final finishing. The sections and arrangements of the laths do not require construction precision, even within a single wall.

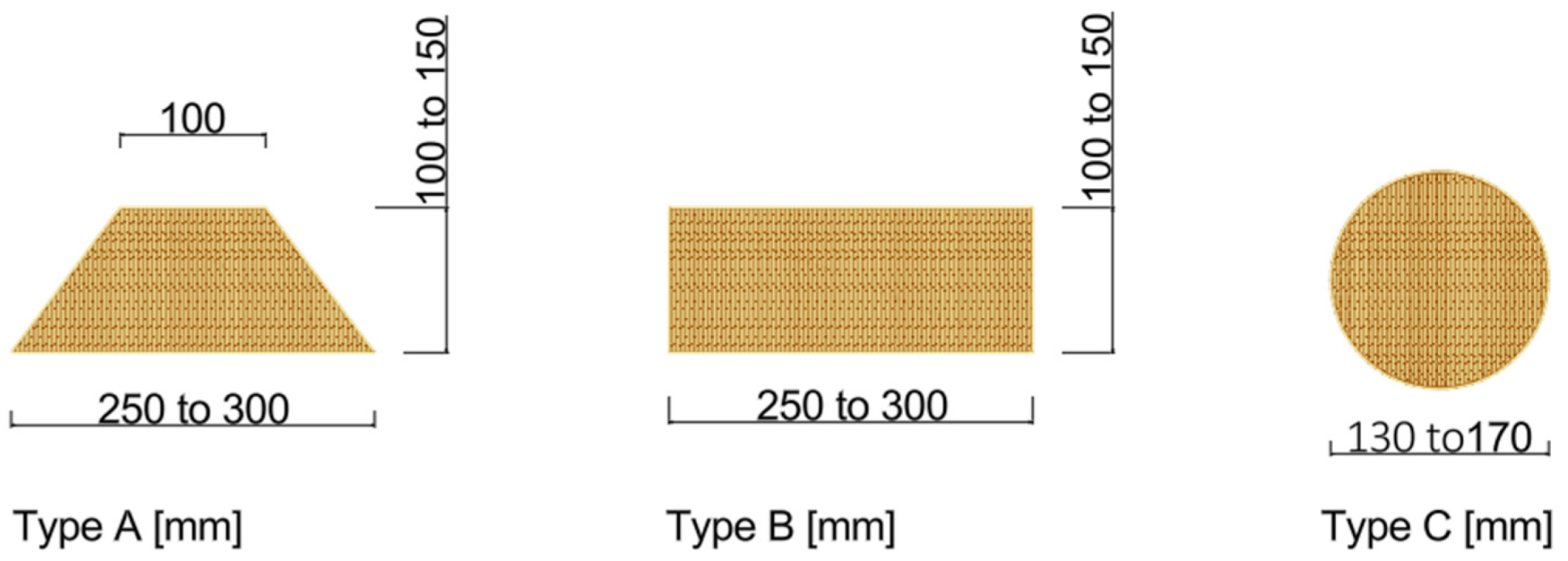

Figure 39 presents the typical cross-sections of the laths comprising the

fasquio in the studied samples: Type A: Rectangular cross-section with a double chamfer. Type B: Rectangular cross-section. Type C: Circular cross-section.

7.2. Wattle and Daub Structure

Depending on the width of the walls, they were referred to as wattle and daub or frontal. The wattle and daub form secondary partitions in relation to the frontals. According to [

26], the frontals were subdivided into French frontal, Galician frontal, and Lattice frontal, while the wattle and daub were classified as single wattle and daub, double-faced wattle and daub, lightened wattle and daub, and light wattle and daub.

The following sections detail the constructional characteristics of the frontals and wattle and daub found in the studied buildings. Where applicable, the terminology used aligns with that used in [

26].

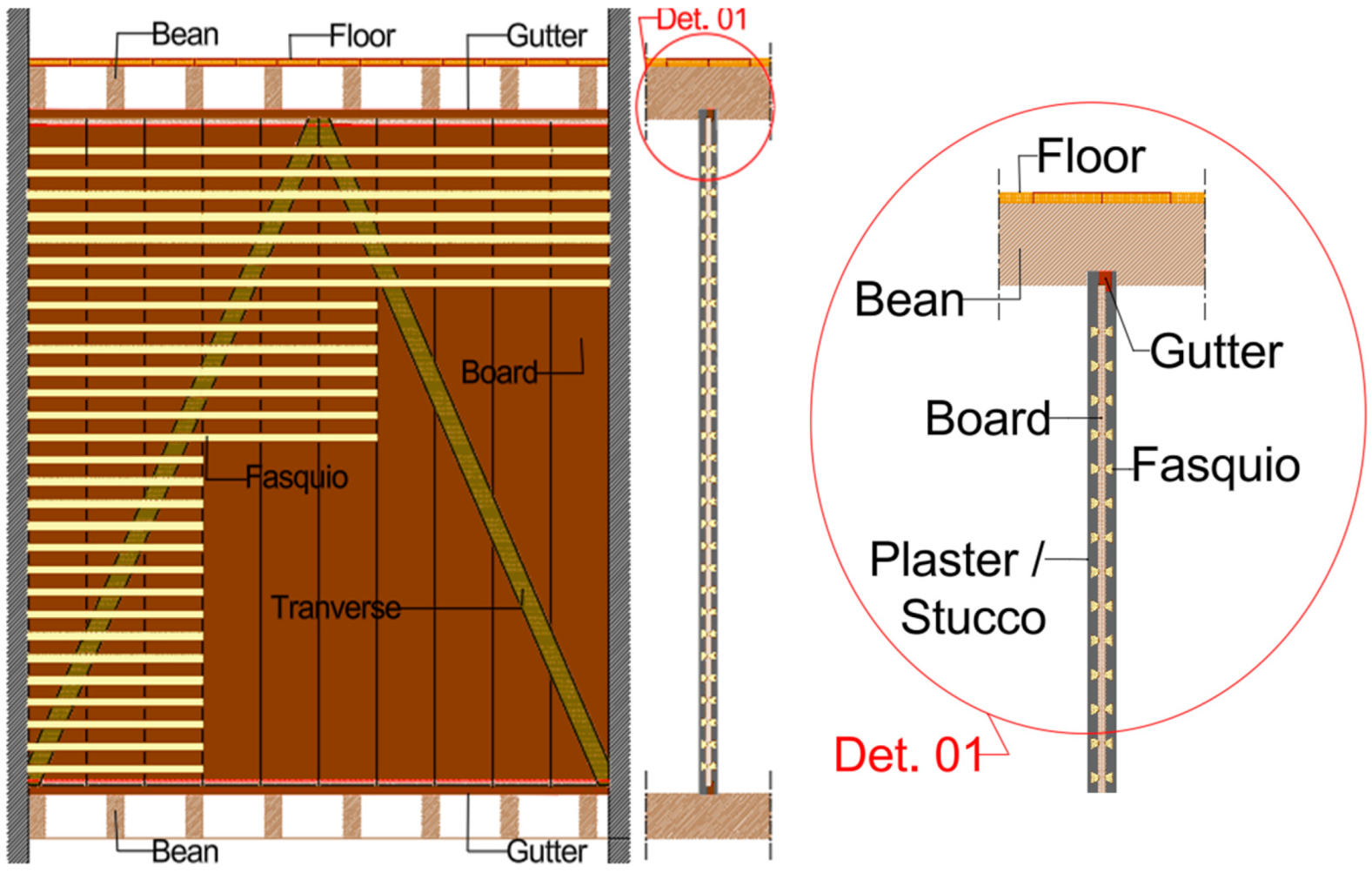

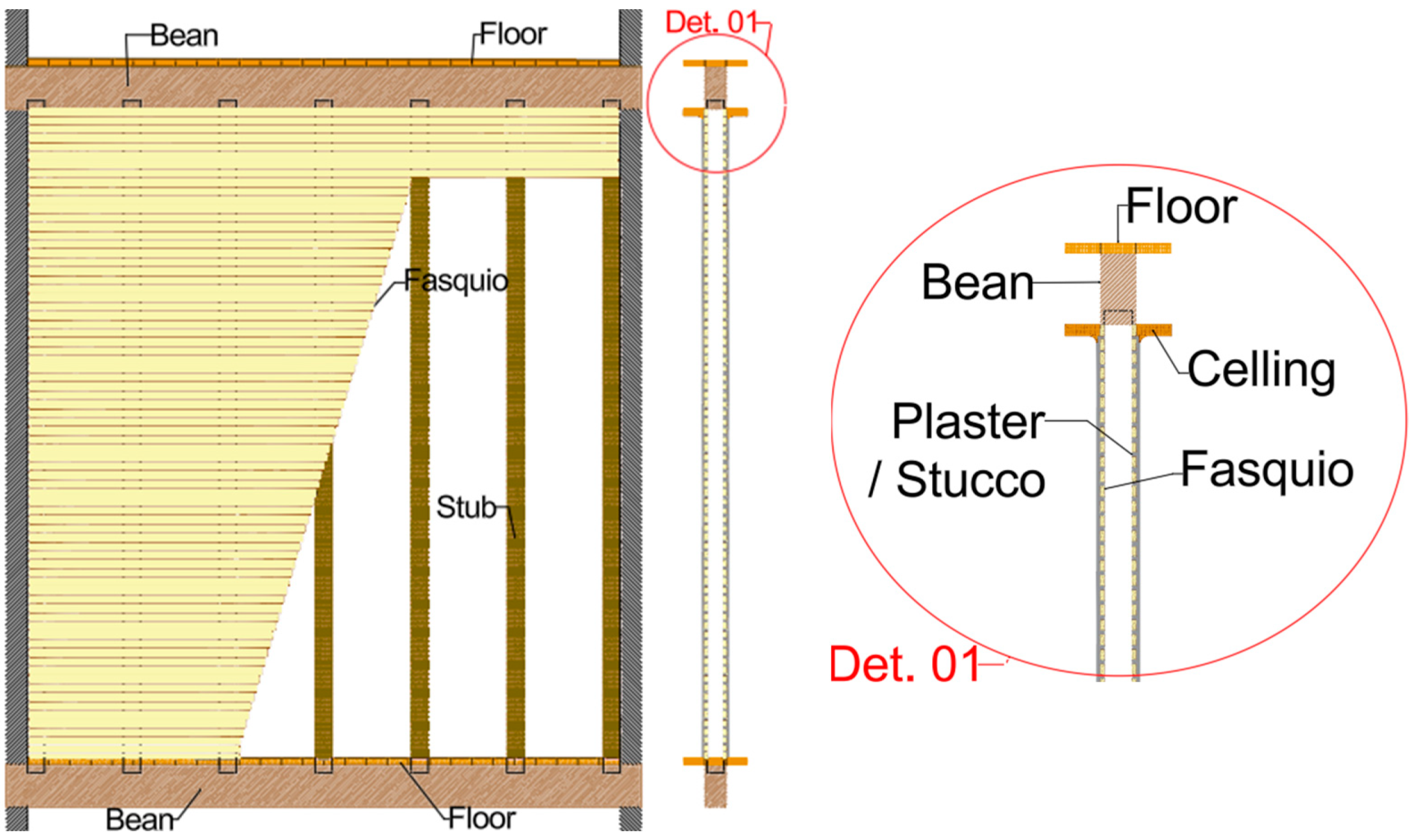

7.2.1. Galician Frontal

In

Figure 43, a schematic drawing of the Galician frontal, commonly found in exterior walls, is presented.

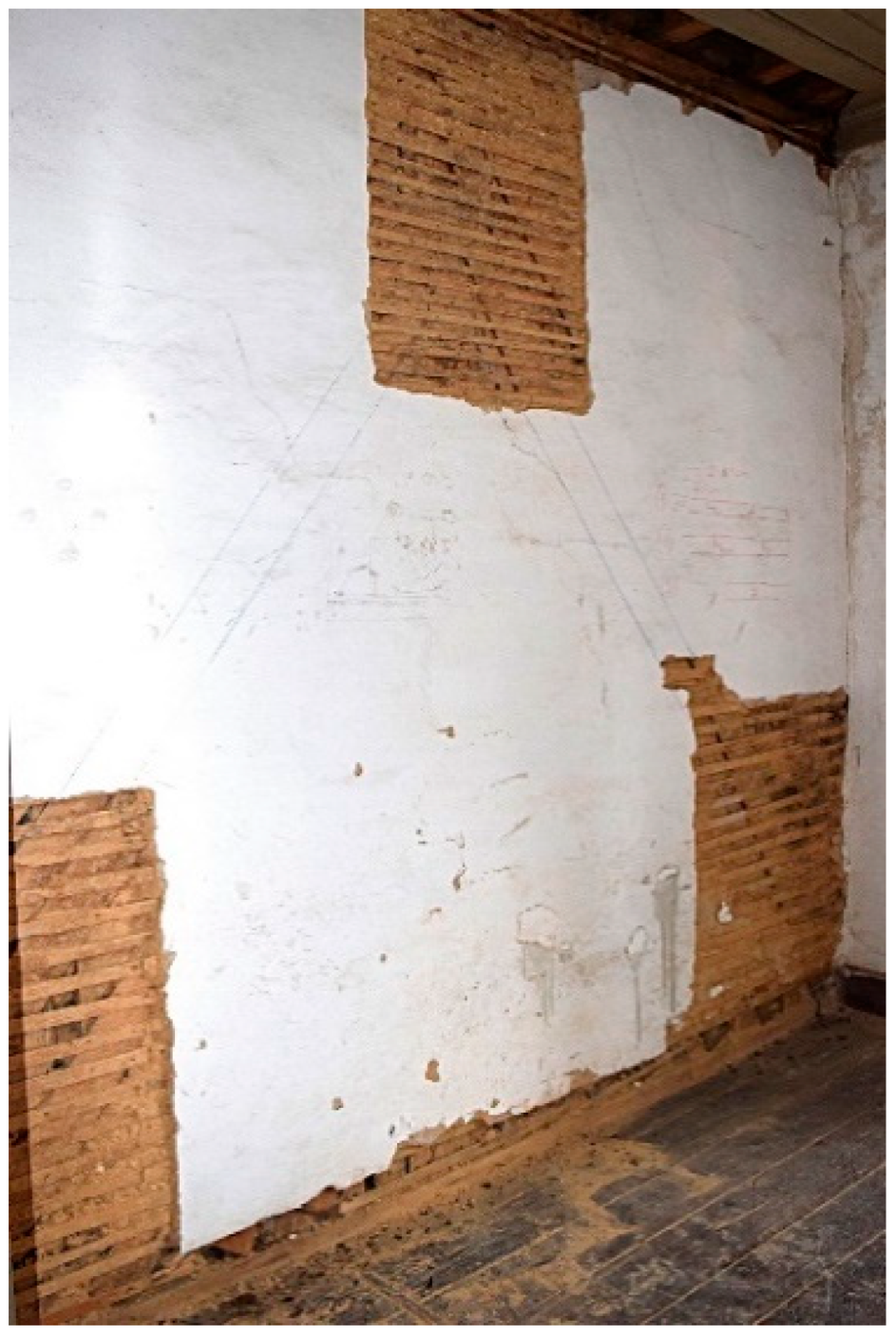

The framework of the Galician frontal has an approximate width of 15 cm. Its construction begins with the placement of vertical posts, with the width in these cases having cross-sections of approximately 8 × 8 cm and 10 × 10 cm. These posts are erected on the floor beams and connected to the ceiling beams. Once the posts are in place, the fasquios is installed. In the studied cases, the laths varied significantly in size, with average dimensions of approximately 4 to 6 cm in width and 2.5 cm in thickness, type B. The laths were spaced 20 to 40 cm apart and arranged alternately between the two faces of the wall.

The spaces between posts and laths were filled with an earthen mortar mixed with vegetable fibres. According to the authors of [

26], other materials such as brick fragments and small stones could also be incorporated into the infill mortar. Although the analysed frontals were not plastered, the usual practice is to apply plaster once the infill is thoroughly dry, using the same mortar to cover the wattle and daub faces completely.

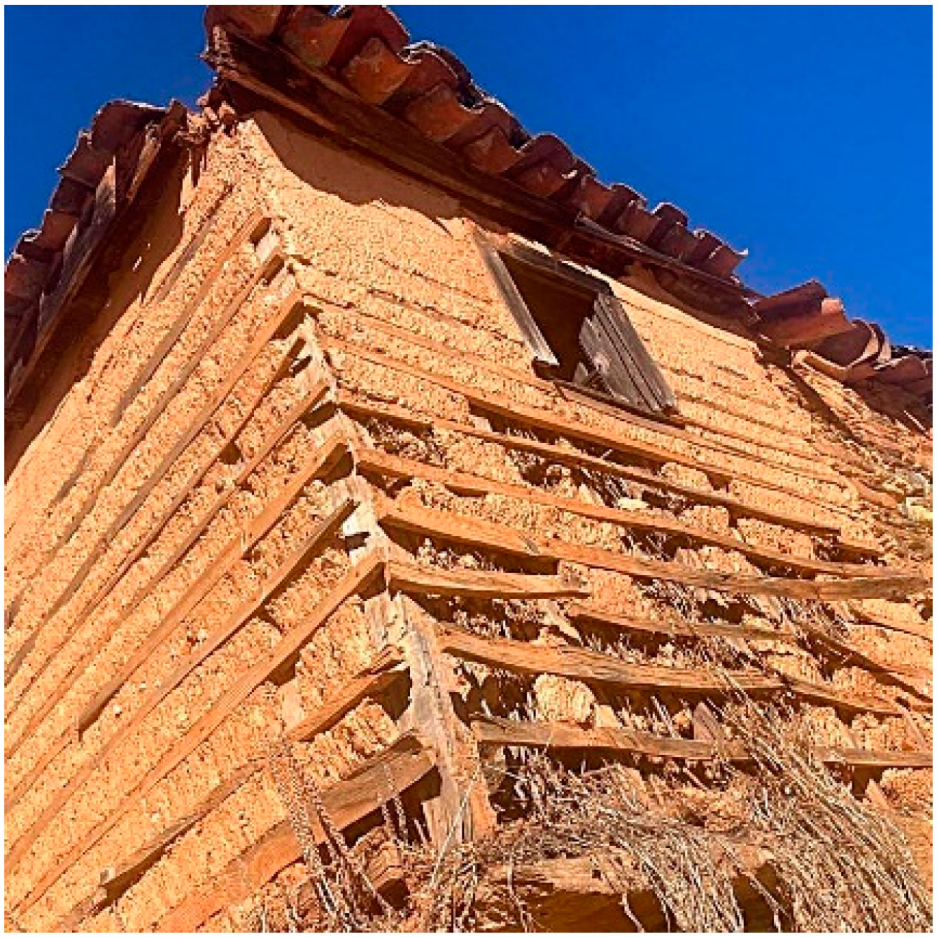

Figure 44,

Figure 45 and

Figure 46 correspond to the exterior walls of dwellings located in the northern region of Portugal. The walls shown in

Figure 44 and

Figure 45 belong to type 1 dwellings located in Salzedas. The wall in

Figure 46 belongs to a type 3 dwelling located in Martim Branco.

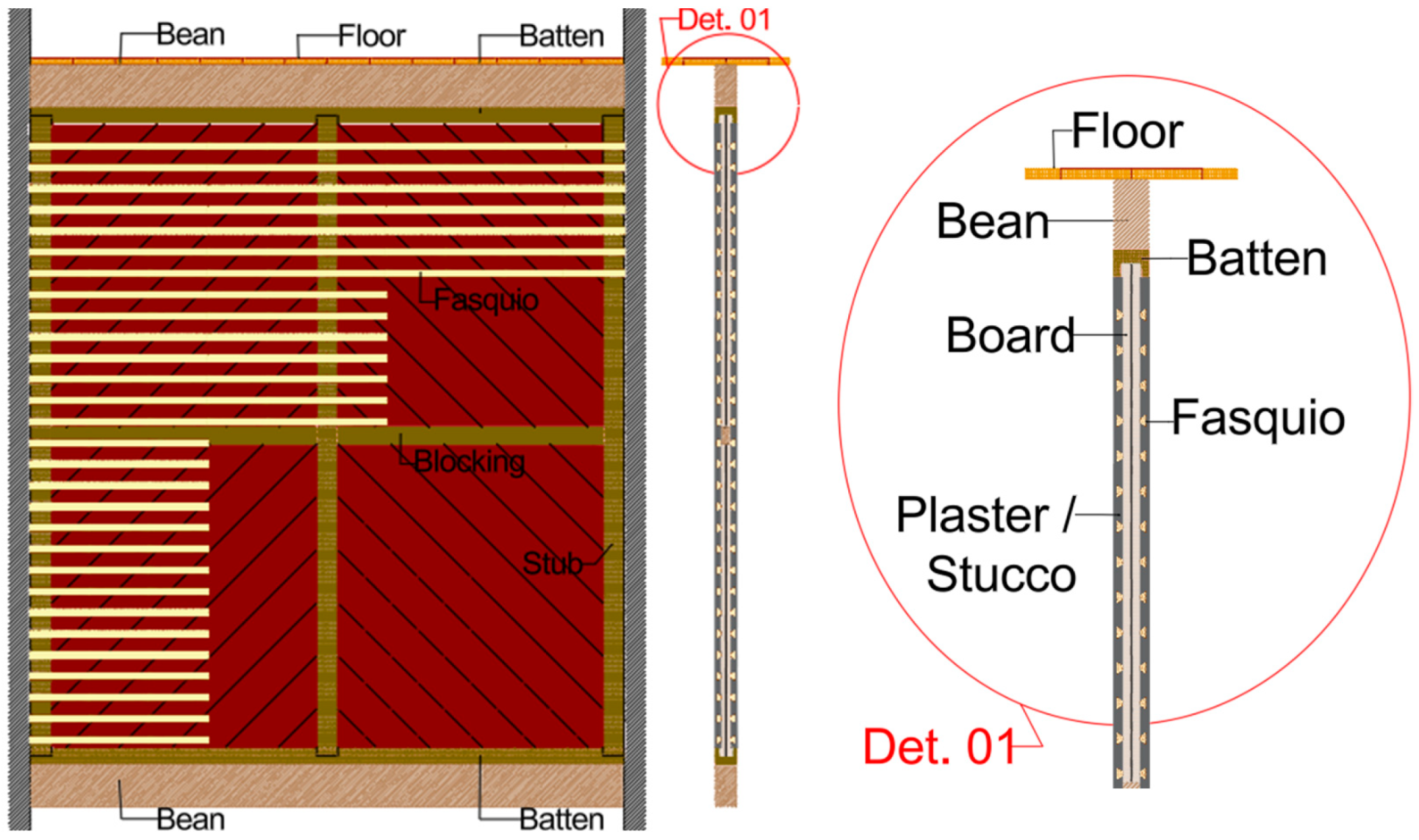

7.2.2. Lattice Frontal

The Lattice frontal, also known as the Pombaline cage, is an earthquake-resistant construction system inspired by shipbuilding techniques. It was extensively used in the reconstruction of the Baixa Pombalina in Lisbon after the 1755 earthquake.

Figure 47 presents a schematic drawing of the Lattice frontal. Like the Galician frontal, the width of the framework is around 15 cm. For the study of these frontals, small windows were opened in the walls, and it was not possible to obtain measurements of the spacing between vertical posts, crossbeams, and diagonals. Therefore, studies by the authors of [

11,

12,

27] were used to create the description and construction scheme.

According to these researchers, the length of the frontal is divided into sections approximately 1 metre wide, using posts with a section of ±10 × 10 cm, nailed to the floor beams below and to the ceiling beams above. The height of the ceiling is then divided into equal parts, with horizontal crossbeams placed between the posts. In the rectangles formed between the posts and crossbeams, diagonal braces are placed—

Figure 47.

The laths are then fixed between each side of the framework, spaced approximately 3 to 4 cm apart. Once the wooden framework is built, it is filled up to the outer faces with earthen mortar, incorporating or not fragments of brick or small stones. After this infill is thoroughly dry, the plastering is applied with the same mortar to cover the faces of the fasquio.

In the specific cases studied, the sections of the posts and the spacing between the laths were like those in the literature. The laths presented sections of type A and type B. It was noted that in some cases, before the wattle and daub were fixed, seam boards were placed, as shown in Figure 51, positioned as explained for the double wattle and daub (Item 5.2.4). In the case of the infill and plaster mortars, they are sandy and do not contain fragments of brick or stone.

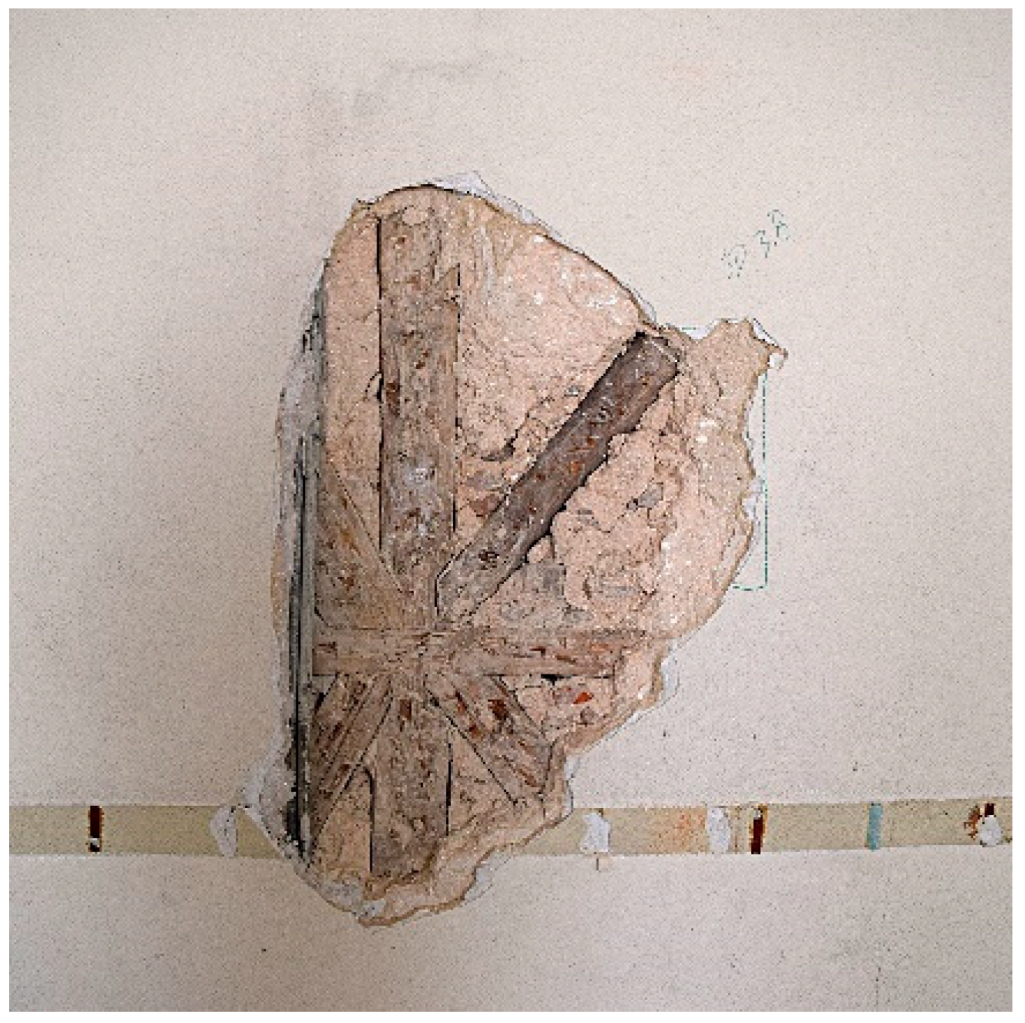

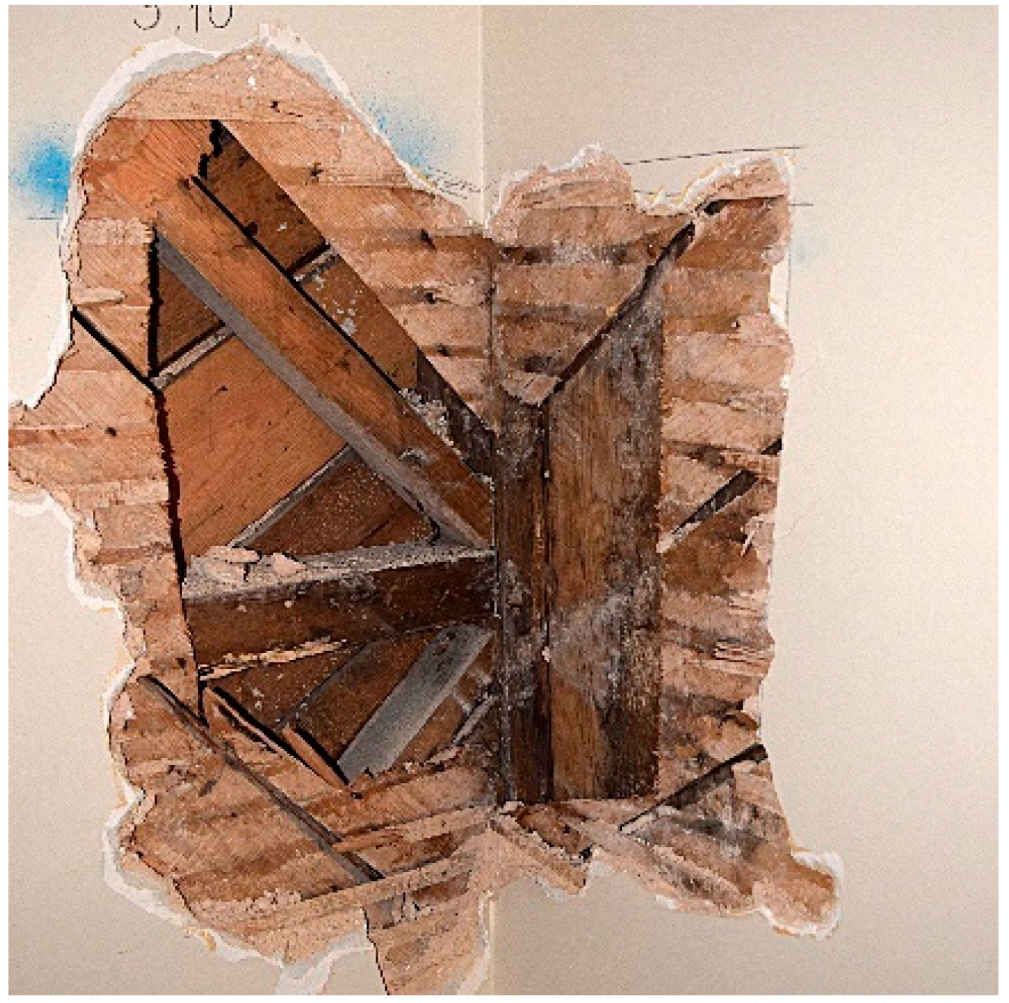

Both walls shown in

Figure 48,

Figure 49 and

Figure 50 correspond to the partition walls of type 9 dwellings located in the city of Lisbon.

7.2.3. Single Wattle and Daub

The structure of the single wattle and daub,

Figure 51, is made up of a series of seams boards nailed to auxiliary beams that are fixed to the beams that structure the floor and ceiling. These auxiliary beams support the vertical placement of the seaming boards and are about 4 cm high, with an overhang of about 2.5 cm. Once the wall structure has been assembled, with a width of around ±10 cm, the

fasquio are fixed on both sides of the structure.

In the buildings analysed, the laths were of Type A and Type B, arranged horizontally and spaced about 2 to 3 cm apart. When the partitions are of considerable length, they are reinforced with crossbeams from one side to the other, or, in some cases, uprights are added to provide greater robustness, with struts used to reduce weight [

26].

In the case of

Figure 52, depicting an external wall of a type 5 dwelling located in Cedovim, in the northern region, sandy mortars were used.

Figure 53 shows a partition wall of a type 5 dwelling, used for housing animals and storing agricultural products, located in Fermentãos, northern region, where earthen mortars were used, incorporating plant fibres such as straw and maize cobs. Finally,

Figure 54 refers to a partition wall on the first floor of a type 6 dwelling located in Alqueidão, in the central region, where earthen mortars were used for plastering and for infilling between the laths.

7.2.4. Double Wattle and Daub

The double wattle and daub,

Figure 55, also known as double-faced, is structured with two layers of seam boards or, sometimes, floorboards. The structure of upright and crossbeams is first built. Then, the seam boards are nailed diagonally, on either side, in opposite directions, for instance, diagonally from left to right on one side and from right to left on the other. The width of the wood framework is approximately 10 cm.

Figure 56 and

Figure 57 correspond to partition walls of a type 2 dwelling located in Santa Comba Dão, in the central region, where the system was also supported by struts and diagonal braces. The slats forming the

fasquio were type A, spaced 3 to 4 cm apart. The infill mortar was sandy with straw incorporated, while the rendering mortar did not include fibres or other elements.

7.2.5. Lath Wattle and Daub

Figure 58 represents the structure of the Lath wattle and daub, with the width of the framework at about 10 cm. In this type of wattle and daub, the posts are erected, with an approximate section of 10 × 8 cm, placed on each of the floor beams, which will connect to the ceiling beams. After the posts are set, the laths of type B are placed side by side, with no spacing between them. After

fasquio assembly, the plastering is applied.

The walls shown in

Figure 59 and

Figure 60 are located on the island of Terceira, in the Autonomous Region of the Azores. Both are partition walls of type 11 dwellings. The wall shown in

Figure 59, located in Biscoito, has a sandy plaster, while the wall shown in

Figure 60, located in Porto Judeu, also has a sandy plaster with the incorporation of animal hair.

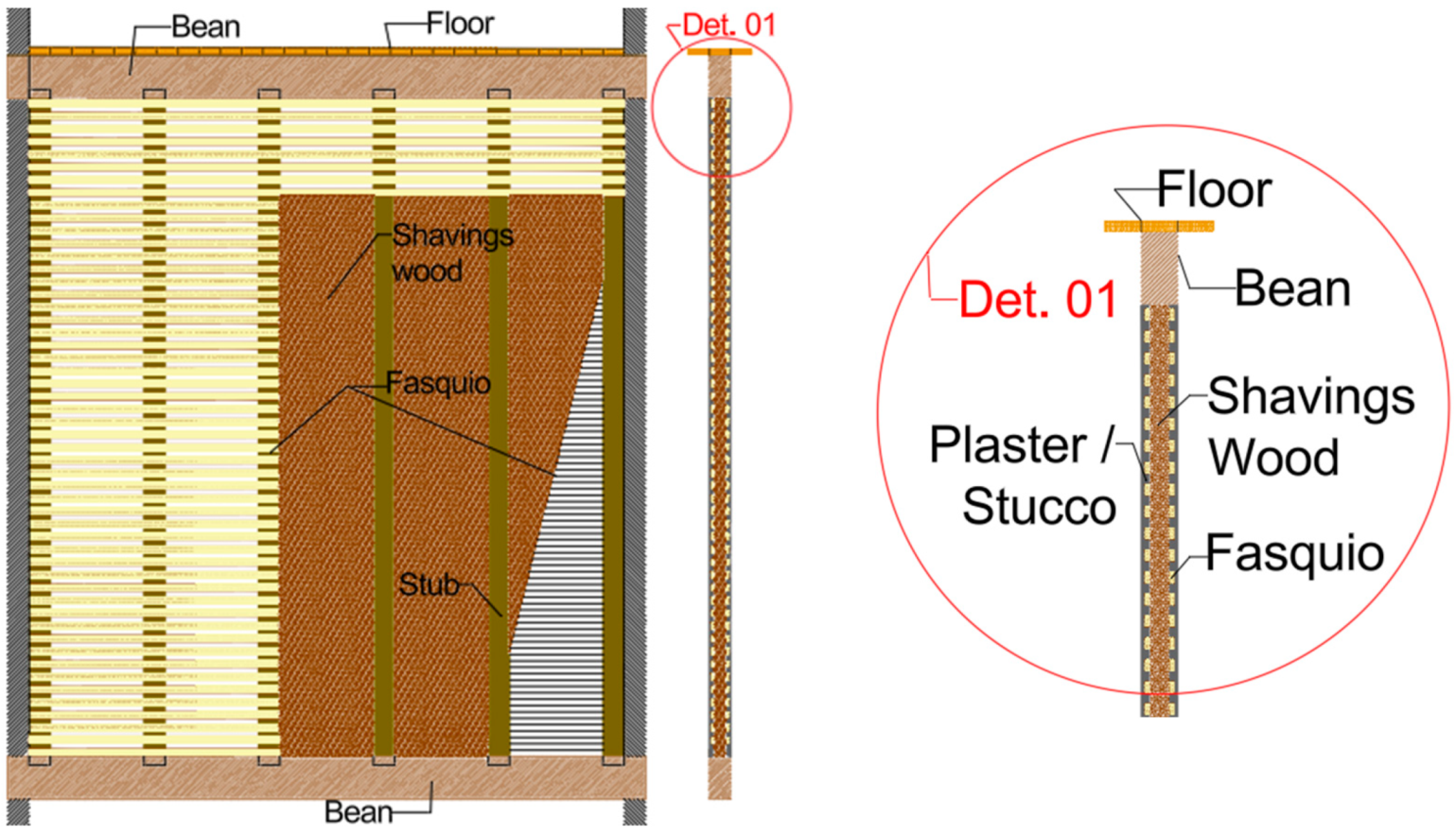

7.2.6. Wood Shavings Wattle and Daub

The structure of the wood shavings wattle and daub is shown in

Figure 61, and the width of the framework is about 10 cm. In this type of wattle and daub, the posts, with an approximate section of 10 × 8 cm, are erected between each of the floor and ceiling beams. After the posts are set, the laths of Type B,

Figure 62 and

Figure 63, spaced approximately 3.0 cm apart, or Type C (bamboo),

Figure 64, with spaces between 1.5 and 2.0 cm, are installed. In all of the cases studied, the gaps between the posts were filled with wood shavings. The plasters used do not incorporate fibres or other elements. All of the walls are partition walls, of type 10 dwellings, located in Funchal, in the Autonomous Region of Madeira.

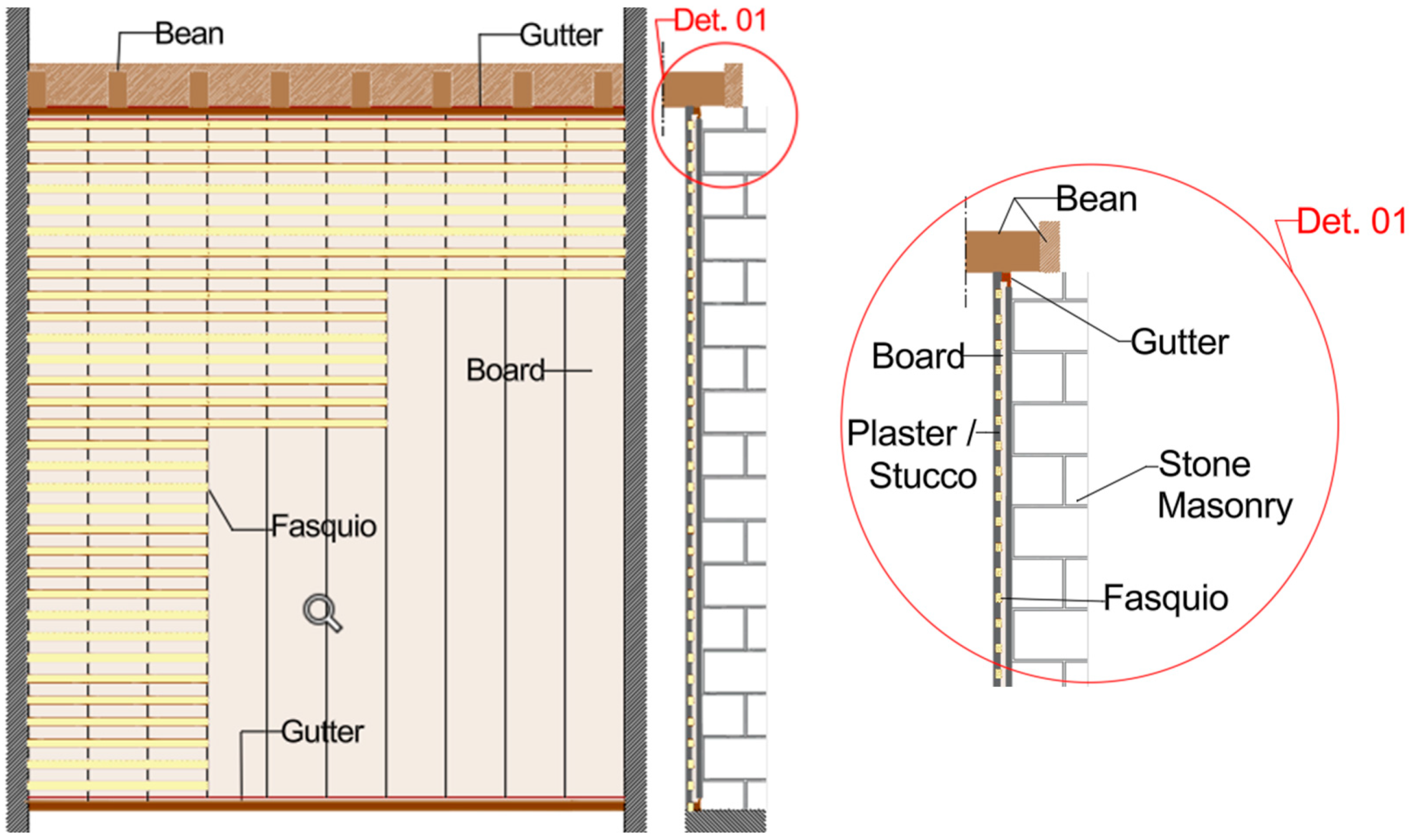

7.2.7. Insulating Wattle and Daub

The insulating wattle and daub structure is shown in

Figure 65. Not very common, it was identified in the city of Boassas, in the northern region, internally covering an exterior stone wall of a type 4 dwelling—

Figure 66.

It differs from the single wattle and daub by having laths on the side of the seam boards facing the interior of the dwelling. The width of the framework of the insulating wattle and daub is approximately 8 cm. The infill between the posts and between the slats was filled with sandy mortar, incorporated with vegetable fibre straw.

7.3. The Mortars

During the fieldwork, it was also possible to quickly assess the type of filling material used in the various wattle and daub walls. This analysis revealed that, in addition to the use of earth-based mortar, sandy lime mortar was also employed. In both types, situations were found with and without the incorporation of vegetable fibres, animal hairs, fragments of bricks, and stones, among others.

Figure 67,

Figure 68,

Figure 69,

Figure 70,

Figure 71 and

Figure 72 illustrate the presence of these incorporated elements.

8. Discussion

Timber-framed wattle and daub walls exhibit remarkable construction versatility, characterised by the absence of rigid regulations, which allows for the use of a wide variety of materials and different configurations of structural wooden elements. This flexibility enables the adaptation of this technique to various climatic conditions and its application across different types of buildings, regardless of their intended use. In addition to meeting both architectural and economic requirements, wattle and daub stands out for its inherent sustainability, which is intrinsic to this traditional and vernacular construction methodology.

8.1. Climate Adaptability

Climate does not constitute a limiting factor for the application of the wattle and daub construction technique, even in rainy regions. This climatic adaptability has been a determining factor in the expansion of this technology in Portugal and other countries. However, it is essential to consider aspects related to moisture, such as the direct contact of the wooden structure with the ground and the need to ensure adequate ventilation renewal in indoor environments. The absence of appropriate measures to mitigate moisture can compromise the durability and structural performance of these buildings.

In Portugal, climatic diversity is significantly evident. In the north of the country, the predominant climate is oceanic–Mediterranean, characterised by cold and rainy winters and moderate summers. In the central region, the temperate Mediterranean climate features harsher winters in the interior and hot, dry summers. The Lisbon Metropolitan Area is marked by a Mediterranean climate with Atlantic influence, characterised by mild and rainy winters and hot, dry summers. In Alentejo, a hot Mediterranean climate is observed, with semi-arid characteristics in some areas, evidenced by very hot, dry summers and cold, rainy winters. In the Autonomous Region of Madeira, the subtropical oceanic climate presents mild temperatures throughout the year, with low thermal amplitude. In the Azores, the temperate oceanic climate is characterised by mild temperatures year-round, high humidity, and frequent precipitation.

The wattle and daub construction technique is also used globally in regions with equatorial, semi-arid, tropical, subtropical, temperate continental, cold continental, and Mediterranean climates, demonstrating its feasibility in different environmental contexts. This broad climatic range has significantly contributed to the methodological evolution of wattle and daub construction, reaffirming its adaptability to ensure the durability and performance of buildings in response to climatic variations.

8.2. Applications and Structural Adaptability

Wattle and daub constructions in Portugal have demonstrated significant versatility in terms of use, with them being employed in single-family and multi-family residences, offices, commercial establishments, agricultural storage warehouses, and animal shelters. This diversity of applications highlights the adaptability of this construction technique over time and across various functional contexts.

From a typological perspective, wattle and daub partition walls have been widely utilised, regardless of the intended use or the number of floors in the building. In Lisbon, for example, these internal partition walls were adapted with anti-seismic systems, reinforcing the construction system’s ability to respond to the region’s geological and climatic conditions.

Regarding external wattle and daub walls, structural limitations can be observed, as research indicates that such constructions have been identified mainly in buildings of up to two stories. This restriction arises from the structural resistance of the material and regulatory requirements associated with building safety.

Additionally, in more sporadic cases, timber framing has been used in the construction of chimneys and as thermal insulation in external stone walls, demonstrating its complementary application in improving the thermal comfort of buildings.

8.3. Wattle and Daub Constructions in Portuguese Architectural Styles

The wattle and daub construction technique has a long-standing tradition in Portugal, having been widely used from the Middle Ages until the mid-19th century. It has played a fundamental role in Portuguese architecture not only in terms of adaptation to different architectural styles but also in its structural and functional versatility.

Building upon this legacy, timber framing has been present in various architectural styles over the centuries, demonstrating remarkable adaptability. It has seamlessly integrated into different Portuguese architectural styles, standing out for its flexibility and ability to meet the needs of each era:

- ❖

Traditional Vernacular Architecture (16th–19th centuries): Widely used in regions such as Minho, Trás-os-Montes, and Beira Interior, where wattle and daub was employed in both internal and external walls.

- ❖

Pombaline Architecture (post-1755 Earthquake): Incorporated as part of the structural system of the Pombaline cage, wattle and daub was essential in enhancing the flexibility and earthquake resistance of buildings. A representative example is the Pombal Palace, where wattle and daub was used in the interiors.

- ❖

Baroque and Rococo Styles (17th–18th centuries): Employed in buildings such as the National Palace of Mafra (internal partitions) and the National Palace of Queluz (service areas and interiors).

- ❖

Neoclassical Architecture (18th–19th centuries): Notably used in the National Theatre D. Maria II in Lisbon, where wattle and daub was applied in internal structures.

- ❖

Romantic Architecture (19th century): A prominent example is the Pena Palace, where wattle and daub was used in some internal divisions.

- ❖

Art Nouveau (early 20th century): Represented by the Major Pessoa House in Aveiro (1907–1909), where the technique was adapted to meet the stylistic demands of the period.

8.4. The Economic Dimension of Wattle and Daub Construction

Beyond its architectural versatility, wattle and daub also stands out for its economic feasibility. The combination of readily available materials and adaptable construction methods has allowed its use both in low-income housing and in more elaborate buildings.

Economic differences directly influenced the typologies of wattle and daub construction:

- ❖

Popular Housing: Simpler versions were used, such as lath wattle and daub, single wattle and daub, and the Galician frontal technique, which required fewer structural elements and allowed for quicker execution.

- ❖

Mid-to-High-Standard Buildings: More sophisticated techniques were preferred, such as the lattice frontal method and double wattle and daub, providing greater stability and thermal comfort.

Another distinguishing factor was the composition of the mortars used:

- ❖

In popular and mid-range houses, earthen mortars incorporating plant fibres, brick residues, stones, and animal-based elements were commonly used in the clay mixture.

- ❖

In high-standard constructions, lime and sand mortars were predominant, ensuring greater durability and a refined finish.

8.5. Energy Efficiency and Heat Transfer Coefficient

From a sustainability perspective, wattle and daub construction offers several advantages, including energy efficiency, a low carbon footprint, and a sustainable life cycle.

This section highlights the key factors that make wattle and daub construction a viable ecological alternative, addressing the heat transfer coefficient, the use of local materials, durability, maintenance, material life cycle, and greenhouse gas (GHG) emissions.

8.5.1. Thermal Performance

The thermal performance of wattle and daub constructions is one of their most notable sustainable attributes. Walls composed of wood, clay, and plant fibres exhibit a relatively low heat transfer coefficient (U-value), ensuring effective thermal insulation.

Studies indicate that wattle and daub walls have thermal transfer coefficients ranging from 0.4 to 1.2 W/m²K, depending on thickness and the materials used [

28]. These values align with recommended parameters for energy-efficient buildings, reducing the need for artificial climate control and consequently lowering energy consumption.

Studies conducted by the authors of [

28] indicate that

Tabique walls, when plastered, clad with slate panels, or covered with metal sheeting, exhibit thermal transmittance coefficients of 1.59 W/m²·K, 1.15 W/m²·K, and 1.45 W/m²·K, respectively. These values are lower than those reported in studies by the authors of [

29] for conventional masonry systems, such as concrete block walls (2.86 W/m²·K) and brick masonry (2.59 W/m²·K). Therefore,

Tabique walls demonstrate approximately 50% higher energy efficiency compared to traditional masonry, enhancing the thermal performance of buildings.

8.5.2. Use of Local Materials and Reduction in Environmental Impact

One of the primary advantages of wattle and daub construction is the predominant use of locally sourced, low-impact materials. The main components include the following:

- ❖

Wood (pine, chestnut, poplar, and oak) obtained from sustainably managed local forests.

- ❖

Clay and earth, extracted regionally, minimising transport-related environmental impacts.

- ❖

Plant fibres and organic residues, such as straw and horsehair, which enhance material cohesion and structural reinforcement without requiring polluting industrial processes.

The use of local materials significantly reduces CO2 emissions associated with the transport and production of conventional materials such as cement and industrial bricks.

8.5.3. Durability and Maintenance

Wattle and daub constructions can be highly durable when properly maintained. Buildings constructed over 200 years ago remain in use, demonstrating the resilience of this construction system.

Maintenance of these constructions is simplified, as materials can be easily replaced or repaired without the need for heavy machinery or complex industrial processes. Furthermore, the use of natural coatings, such as lime, reduces long-term degradation and enhances moisture protection.

8.5.4. Material Life Cycle and Sustainability

The life cycle of materials used in wattle and daub construction is one of its main environmental advantages. Unlike concrete or fired bricks, which require high-energy manufacturing processes, materials used in wattle and daub construction can be reused or reintegrated into the environment with minimal impact.

According to the Life Cycle Assessment (LCA) methodology used by [

30],

Tabique walls exhibit the lowest potential for Stratospheric Ozone Depletion (SOD), measured in kg CFC-11-eq. The results show significantly lower values for

Tabique walls (1.38 × 10

−9) compared to brick masonry (2.21 × 10

−7), block masonry (1.06 × 10

−6), and plasterboard (2.00 × 10

−7). This reduced impact helps mitigate greenhouse gas emissions and enhances the environmental sustainability of wattle and daub construction.

8.5.5. Greenhouse Gas Emissions (GHG) and Carbon Footprint

The construction sector is one of the largest contributors to GHG emissions, accounting for approximately 40% of global CO

2 emissions [

31]. However, wattle and daub have a lower carbon footprint due to the following factors:

- ❖

Reduced energy consumption during construction.

- ❖

The absence of Portland cement, which has a highly polluting production process.

- ❖

The use of biodegradable and recyclable materials, minimising environmental impact at the end of the building’s life cycle.

Studies estimate that the carbon footprint of a timber-framed construction is approximately 30% lower than that of a concrete or industrial brick building, primarily due to the reduced energy consumption required for material extraction and processing [

32].

8.5.6. Wattle and Daub Construction in Portugal vs. The World

The timber-framed construction technique is a global vernacular tradition, found in various regions with significant variations. Below are the most notable differences between timber-framed construction in Portugal and the rest of the world:

- ❖

Structural System: Globally, timber-framed construction has typically been used for internal and external walls without structural concerns. In Portugal, however, the system incorporated reinforcement elements using vertical board panels (simple timber frame) and diagonal board panels (double timber frame). Although not serving a structural function, it was the only system studied that refined secondary elements to aid in mortar and plaster adhesion—namely, trapezoidal laths. In Portugal, timber-framed construction was widely used for internal partitions and, in some cases, for external walls in buildings up to two stories high.

- ❖

Function and Application: In many countries, such as the United Kingdom, France, and Germany, timber-framed construction was traditionally used as the primary method for rural houses and small buildings, whereas in Latin America, the system was adapted for colonial dwellings. In Portugal, it is found in both vernacular and high-end buildings, including palaces and theatres. In Japan, similar techniques were employed in castles and temples.

- ❖

Seismic Influence: The introduction of the Pombaline cage system made wattle and daub construction an essential element for earthquake-resistant buildings, establishing Lisbon as one of the first urban centres to adopt seismic-resistant construction principles.

- ❖

Materials Used: Although wood remains the primary structural element, the infill composition varies according to local resources. In some regions, such as Latin America, Africa, and Southeast Asia, the earth mixture contained animal excrement, dung, or ash. In Portugal, it was more common to incorporate stone, ceramic shards, and plant fibres such as maize straw.

9. Conclusions

This study aimed to expand knowledge on wattle and daub construction in mainland Portugal and the Autonomous Regions of Madeira and the Azores, covering an extensive geographical area. The study included the northern region, encompassing the sub-regions of the Porto Metropolitan Area, Alto Tâmega and Sousa, Douro, and Terras de Trás-os-Montes. In the central region, it covered the sub-regions of Aveiro, Coimbra, Viseu Dão Lafões, and Beira Baixa. Additionally, the Lisbon Metropolitan Area and the Autonomous Regions of the Azores and Madeira were analysed, representing a total of 50% of Portugal’s 23 sub-regions.

With this broad geographical coverage, it can be concluded that the presence of wattle and daub constructions is extensive in the northern and central regions, as well as in the Lisbon Metropolitan Area, while significantly less common in the Alentejo and virtually absent in the Algarve. This construction typology is also not particularly relevant in the Autonomous Regions of the Azores and Madeira.

Regarding the objective of expanding scientific knowledge about wattle and daub walls in Portugal, the study provides detailed information for the academic and technical communities, as well as for society at large. Notably, it documents the construction methods used in the Autonomous Regions of Madeira and the Azores and analyses the role of wattle and daub walls as a contributing factor to thermal insulation.

The versatility and accessibility of this technique—characterised by the use of local materials, the lack of need for specialised labour, and its adaptability to different climatic and structural conditions—have facilitated its adoption in various types of buildings, consolidating a significant architectural legacy in Portugal.

In terms of construction typologies observed across mainland Portugal and the Autonomous Regions of Madeira and the Azores, most buildings featured one or two stories, with external walls made of stone masonry and internal partitions constructed with wattle and daub walls. These buildings were typically residential, while two-story structures often had commercial spaces on the ground floor. Notably, in the Lisbon Metropolitan Area, the Pombaline anti-seismic system was employed for internal partitions in multi-story buildings used for multifamily housing and office spaces. Additionally, wattle and daub construction was frequently used for agricultural storage buildings and animal shelters, particularly in rural areas of northern Portugal.

The wattle and daub walls studied exhibit notable construction variability due to the absence of rigid standards. This is reflected in the arrangement of wooden structural elements and the diversity of materials used. Examples include the use of earthen mortar with plant fibres, animal hair, and fragments of bricks and stones, as well as lime and sand mortars. The versatility of materials and structural design allowed for adaptations based on economic status and the intended function of the building. Simpler wattle and daub walls and mortars incorporating waste materials were common in more modest constructions, whereas enforce structures, higher-quality wood, and more refined mortars were used in higher-end buildings.

Wattle and daub construction in Portugal has proven to be an exceptionally versatile architectural and economic solution over the centuries. It has adapted to different architectural styles, climatic and geological conditions, and economic circumstances, allowing for both affordable housing for the lower classes and the refinement of aristocratic residences.

The longevity and continued presence of wattle and daub buildings across various regions of the country highlight its significance as a sustainable construction method. It combines thermal efficiency, the use of ecological materials, low carbon emissions, and a favorable life cycle. With an appropriate heat transfer coefficient and reliance on renewable resources, this technique remains a viable alternative for modern construction, supporting environmental conservation and energy efficiency in heritage rehabilitation initiatives and ensuring the preservation of this culturally and environmentally valuable tradition.