Key Factors Influencing Building Components’ Remanufacturing Strategy: A Comprehensive Literature Review

Abstract

1. Introduction

- (1)

- What factors can impact the core’s condition of BCs?

- (2)

- What factors exert influence over remanufacturing strategies?

- (3)

- How can these factors be harnessed to devise optimal remanufacturing strategies?

2. Background and Concepts

2.1. Concept and Application of BCs

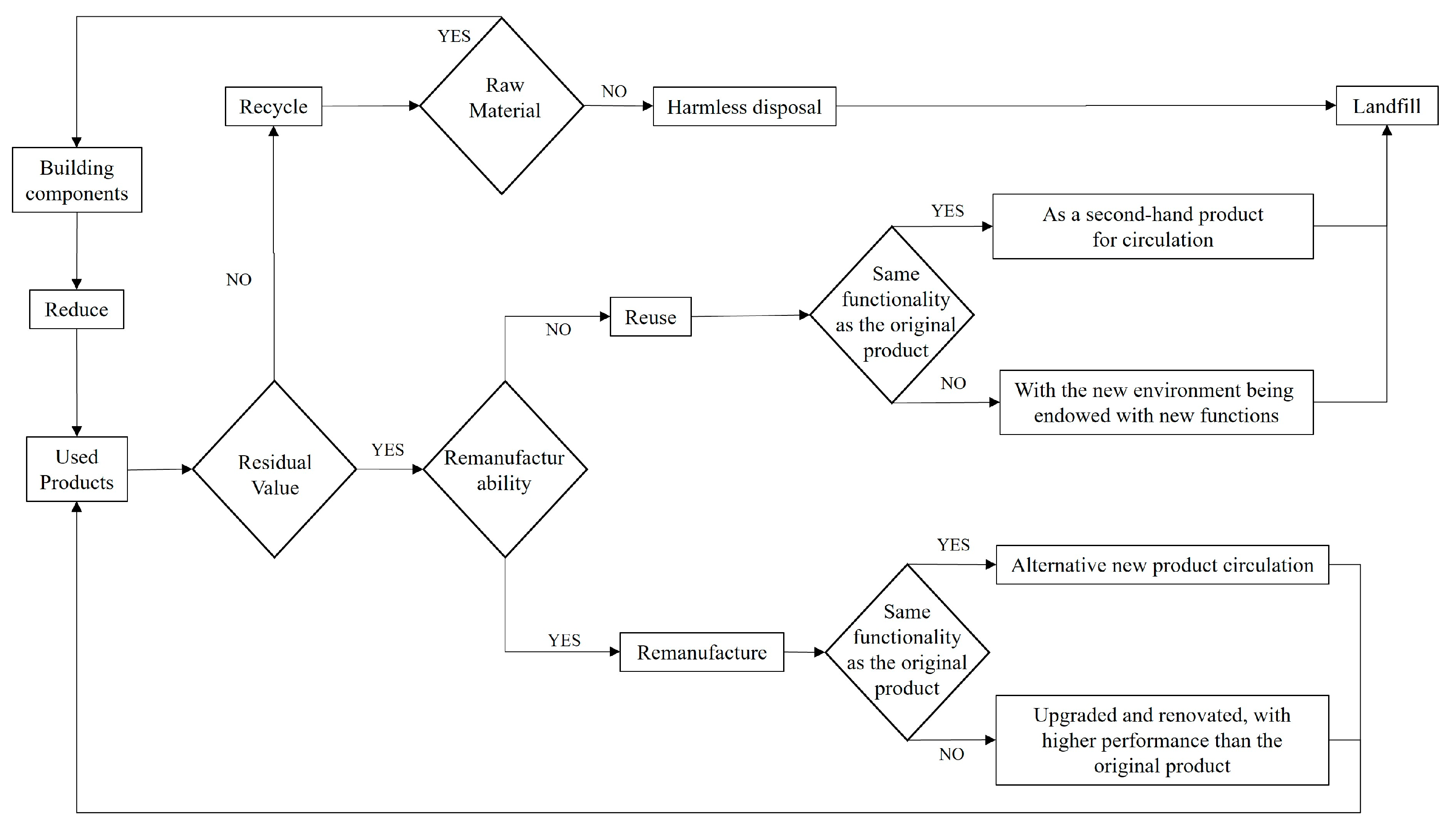

2.2. Differentiating Remanufacture from Reduce, Reuse, and Recycle Concepts

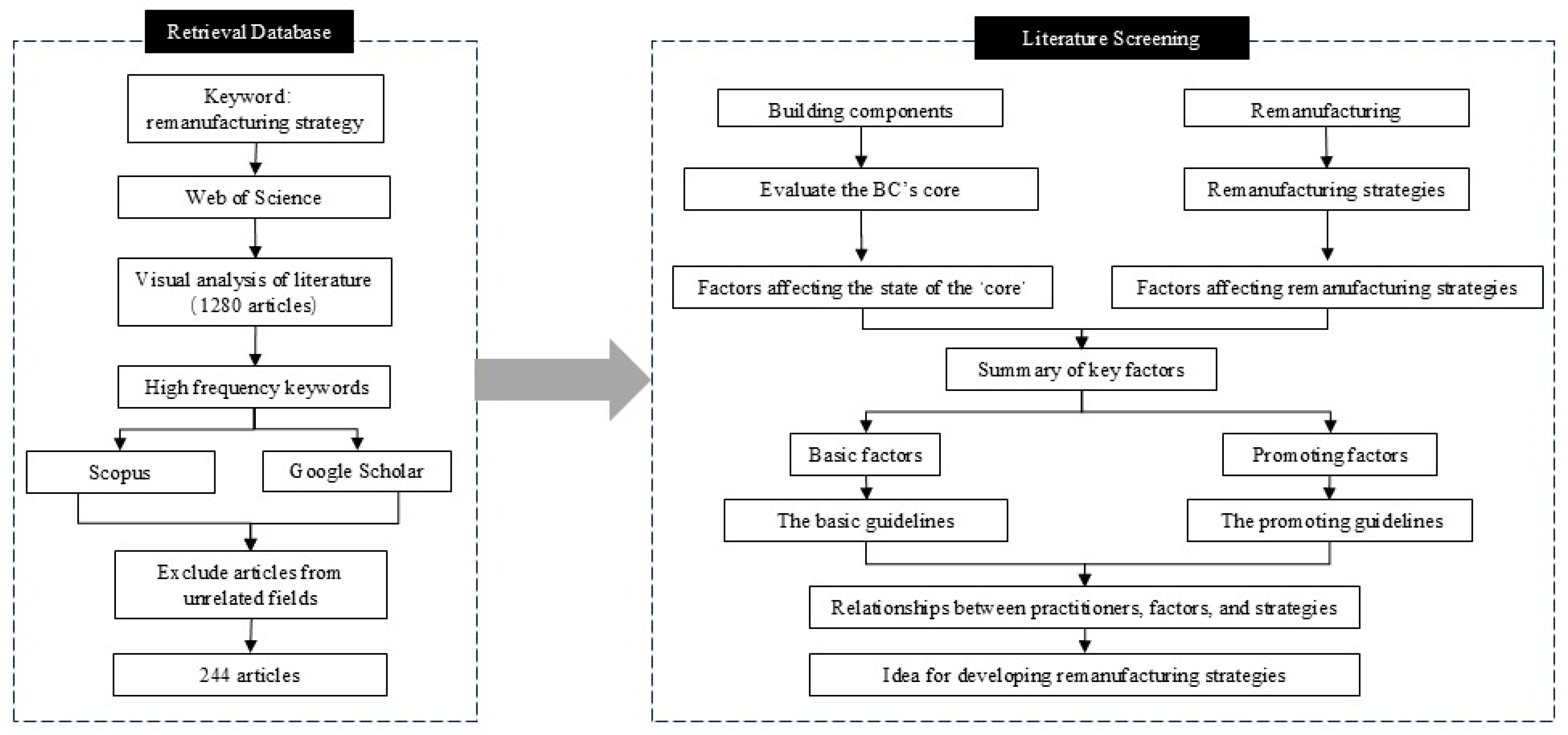

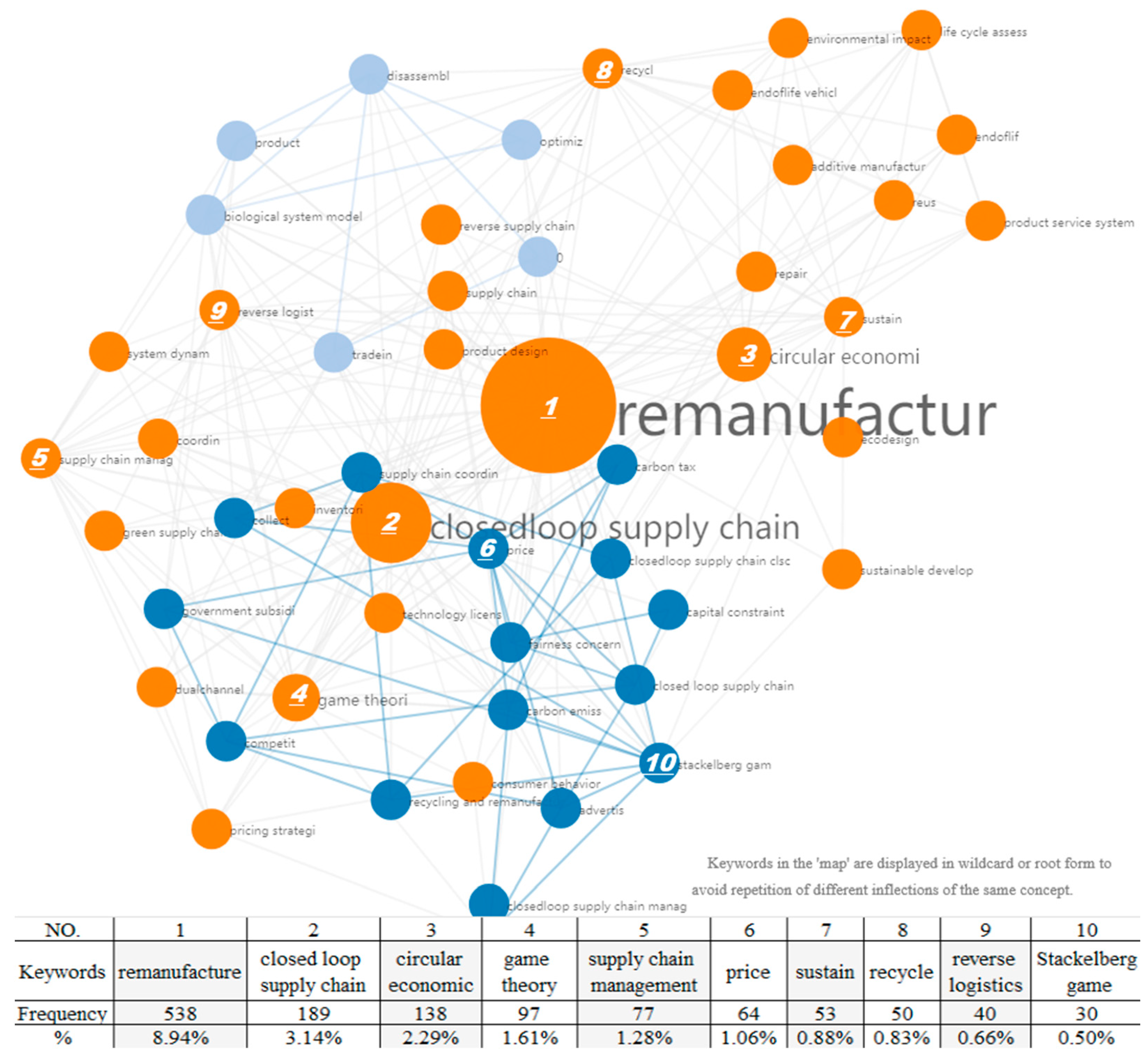

3. Research Methodology

4. Factors Affecting BC Remanufacturing

4.1. Core’s Remanufacturability Factors

4.1.1. Step 1: Core’s Condition Check

4.1.2. Step 2: Assessment of the Original Component’s Characteristics

4.1.3. Step 3: Assessment of Potential Economic Value

4.2. Factors Affecting Remanufacturing Strategies

- (a)

- ‘Man (A)’ related issues in remanufacturing are common in employee skills, organizational structure, customer needs, and conflicts among other stakeholders.

- (b)

- ‘Machinery (B)’ refers to software, equipment, and digital tools.

- (c)

- ‘Material (C)’ in remanufacturing often refers to the ‘core’.

- (d)

- ‘Method (D)’ refers to manufacturing processes that involve continuous sequences.

- (e)

- ‘Milieu (E)’ encompasses the internal organizational environment, external macro-environmental opportunities and threats.

- (f)

- ‘Marketing (F)’ refers to a variety of business activities that commence with customer needs.

- (g)

- ‘Sustainability (G)’ refers to the development of sustainability at the macro level.

4.3. Analysis and Understanding of Remanufacturing Strategy Factors

4.3.1. Marketing (F)

4.3.2. Milieu (E)

4.3.3. Method (D)

4.3.4. Man (A)

4.3.5. Material (C)

4.3.6. Machinery (B)

4.3.7. Sustainability (G)

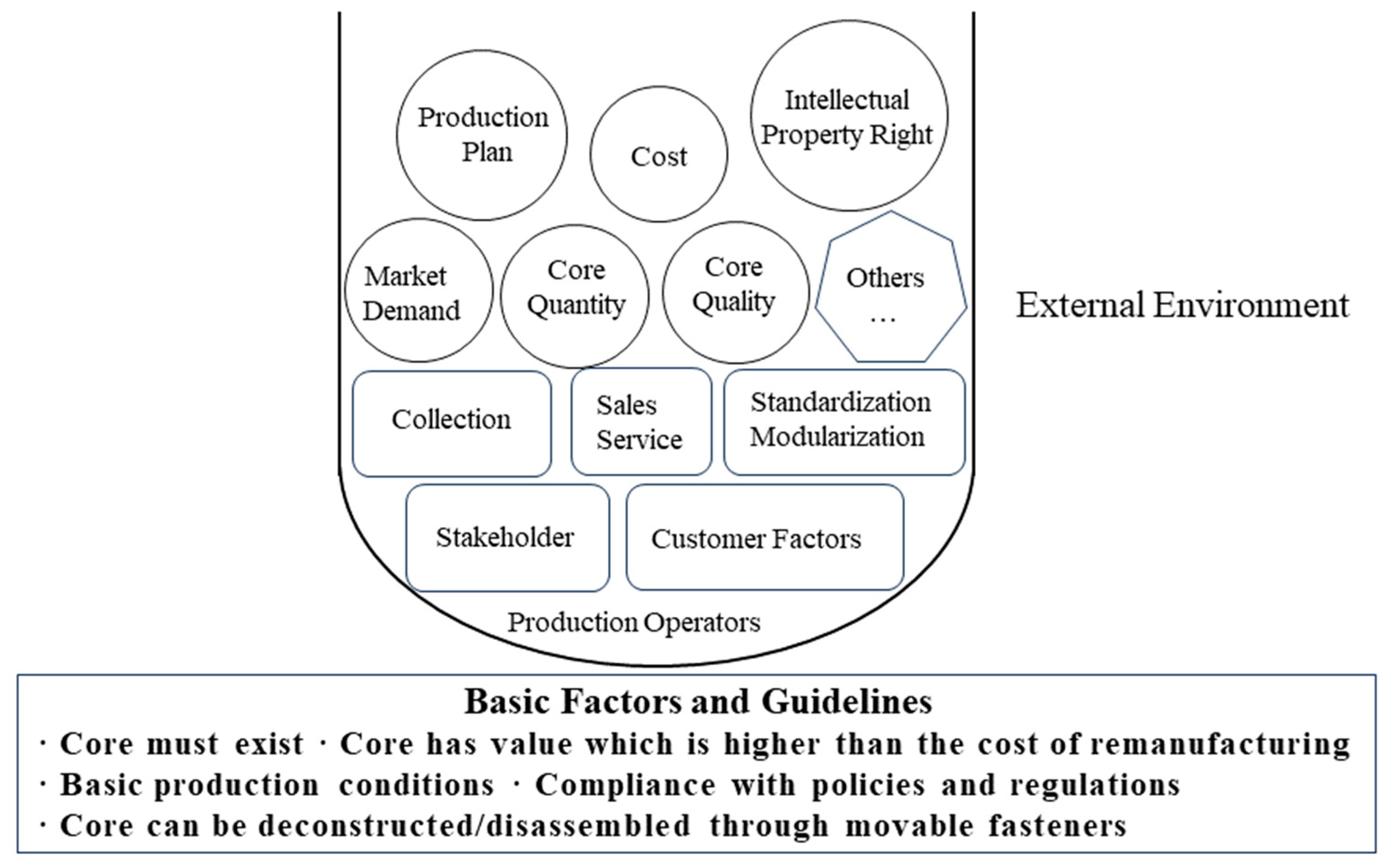

5. Analysis and Discussion

5.1. Basic Factors and Guidelines for Remanufacturing Strategies

- (a)

- The cores of BCs must exist.

- (b)

- The cores of BCs must have residual values.

- (c)

- The residual values of BCs must exceed the remanufacturing cost.

- (d)

- Basic production conditions for remanufacturing must be met, including personnel, technology, equipment and tools, and facilities.

- (e)

- BCs must be dismantled using moveable fasteners.

- (f)

- The entire operational process should be consistent with local policies and regulations.

5.2. Promoting Factors and Implementation Guidelines for Remanufacturing Strategies

- (1)

- Policy Environment (E4/13);

- (2)

- Cost (F2/8);

- (3)

- Stakeholders (A4/8);

- (4)

- Customer Factors (A3/7);

- (5)

- Deconstruction/Disassembly (D3/6);

- (6)

- Collection (D2/5);

- (7)

- Sales Service (F3/5).

- (a)

- To investigate stakeholder characteristics and create suitable business partnership models.

- (b)

- Pay comprehensive attention to consumer awareness and demand for remanufactured products.

- (c)

- Using after-sales service to establish a strong relationship between customers and remanufacturers.

- (d)

- Explore cores’ collection strategies and the possibility of combining several strategies.

- (e)

- Standardize or modularize the core’s design.

5.3. Recommendations for Formulating Remanufacturing Strategies

6. Future Research

7. Implications of This Study

8. Conclusions

Funding

Conflicts of Interest

Abbreviations

| BC | Building component |

| 3R | Reduce, Reuse, Recycle |

| OEM | Original equipment manufacturers |

| IR | Independent remanufacturer |

| MCDM | Multi-Criteria Decision Analysis |

Appendix A

| Stage | Pre-Remanufacturing Condition Assessment (Core’s Status Checking) | Original Component’s Characteristics | Potential Economic Value Assessment | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Item | The primary portion of existence | Physical damage grade | Residual functionality | Available quantity/Supply | Individuation/Aesthetic | Carbon footprint | Technical feasibility | Assembly/Deconstructive design | Standardization/Modularization | Dimensions/Specifications | Versatility/Substitutability | Durability/Reliability | Ingredients/Additives | Pricing/Profit/Cost | Labor availability | Core’s values | Customer requirements | Value added | ||

| Literature | 1 | Lund [28] | √ * | √ | √ | √ | √ | √ | √ | √ | √ | |||||||||

| 2 | Zheng [107] | √ | √ | |||||||||||||||||

| 3 | Brütting et al. [7] | √ | √ | √ | ||||||||||||||||

| 4 | Zaman et al. [108] | √ | √ | √ | √ | √ | ||||||||||||||

| 5 | Duberg et al. [109] | √ | √ | √ | √ | √ | ||||||||||||||

| 6 | Sakao and Sundin [41] | √ | √ | √ | √ | |||||||||||||||

| 7 | Zheng et al. [110] | √ | √ | √ | ||||||||||||||||

| 8 | Ajayabi et al. [111] | √ | √ | √ | √ | √ | √ | |||||||||||||

| 9 | Cobut et al. [37] | √ | √ | √ | √ | √ | √ | √ | √ | √ | ||||||||||

| 10 | Yu [112] | √ | √ | √ | √ | √ | ||||||||||||||

| 11 | Boorsma et al. [30] | √ | √ | √ | √ | √ | √ | |||||||||||||

| 12 | Alanya-Rosenbaum et al. [113] | √ | √ | √ | √ | √ | ||||||||||||||

| 13 | Teunter and Flapper [114] | √ | √ | √ | ||||||||||||||||

| 14 | European Remanufacturing Council [115] | √ | √ | √ | √ | √ | √ | √ | ||||||||||||

| Remanufacturer | 15 | Cat Reman [38] | √ | √ | √ | √ | √ | √ | √ | √ | √ | |||||||||

| 16 | Asiawood Lumbers [116] | √ | √ | √ | √ | √ | √ | √ | ||||||||||||

| 17 | Structural Steel Systems Ltd. [117] | √ | √ | √ | √ | √ | √ | |||||||||||||

| 18 | Rembos [118] | √ | √ | √ | √ | √ | √ | |||||||||||||

| 19 | Re-NetTA Research [119] | √ | √ | √ | √ | √ | √ | |||||||||||||

| Count | 5 | 7 | 11 | 13 | 2 | 5 | 6 | 6 | 4 | 7 | 8 | 7 | 2 | 10 | 4 | 4 | 2 | 3 | ||

| No. | Reference | Opinion/Conclusion | Code |

|---|---|---|---|

| 1 | Talamo et al. [8] | The capacity to use lean management is the key to advanced industrial construction solutions. | E3 |

| Improve communications and information technology to monitor building automation. | B1 | ||

| Verify if circular remanufacturing routes are indeed ecologically friendly. | G1 | ||

| 2 | Fang et al. [48] | When new product prices are high, and the quality advantages of independent remanufacturers are minimal, original equipment manufacturers benefit from it. | A4 |

| Independent remanufacturers have the advantages of low cost and quality assurance. | A4 | ||

| 3 | Tian et al. [61] | The three main production processes of remanufacturing systems are deconstruction, reprocessing, and reassembly. | D3 |

| D5 | |||

| D6 | |||

| Find the solution to the energy-efficient remanufacturing system scheduling problem. | B1 | ||

| 4 | Dulman and Gupta [62] | Collect product signals by connecting and embedding RFID sensors; capture, process, and update the core’s data. | B1 |

| The sensors embedded help with deconstruction processes. | D3 | ||

| 5 | Shang and Li [74] | Using a hybrid mix of remanufacturing strategy algorithms to strike a balance between overall aims and present optimality. | E7 |

| 6 | Vimal et al. [68] | Reduce unnecessary weight by making design modifications. | D1 |

| Select raw resources that have a lower carbon impact. | G1 | ||

| Use energy-saving processing techniques. | D6 | ||

| 7 | Jiang and Zheng [73] | No need to provide incentives when society has a high level of environmental consciousness. | E6 |

| Pricing must consider the cost of product collection in advance. | F1 | ||

| Third parties are required by the licensing model to consider the license price that was paid to the original equipment manufacturers. | F2 | ||

| 8 | Long et al. [54] | Business modes were studied, and it was determined that the competition mode between original equipment manufacturers and independent remanufacturers can be transformed into a cooperative remanufacturing mode to a certain extent. | A4 |

| The joint collection of the core’s information is beneficial for improving the profits of the various parties. | D2 | ||

| 9 | Cao et al. [69] | Amendment to scrapping/recycling/collection regulations. | E4 |

| Increased subsidies facilitate the launch of remanufacturing businesses. | F4 | ||

| Remanufacturing can grow on a larger scale with the assistance of sharing and lowering patent royalties. | F2 | ||

| Extend the routes of collection. | D2 | ||

| 10 | Saxena et al. [75] | The implementation of a carbon price regime is advised. | E4 |

| Using a carbon tax, incentive, and foreign exchange savings strategy is advised. | F6 | ||

| 11 | Cui et al. [43] | The two most significant consumer preferences are cost and quality. | A3 |

| Seeking profitability requires maintaining a high-cost coefficient rather than focusing on quality. | F2 | ||

| 12 | Manco et al. [63] | The percentage of goods that can be remanufactured is represented by the return rate factor. | C4 |

| Robotic deconstruction enhances high reproducibility and cuts down on processing time. | D3 | ||

| Knowing how much material must be added to each component ahead of time during the repair process is beneficial. | D6 | ||

| 13 | Cetin and Zaccour [55] | The launch of remanufactured items is significantly influenced by consumer perceptions of these products. | A3 |

| Remanufactured items are being introduced in large part because of their economic advantage. | F2 | ||

| R&D innovative parts can replace worn or old technology parts, producing upgraded and remanufactured products, both of which can replace new products and achieve maximum profit. | C1 | ||

| 14 | D’Adamo and Rosa [22] | Maintain client loyalty while attending to the obvious demands of the market. | A3 |

| Proactive strategy: expanding the product line and improving the brand’s reputation for sustainability. | F5 | ||

| Provide more services to boost financial benefits in the post-purchase phase. | F3 | ||

| 15 | Zhu et al. [65] | Laser cladding can restore the appearance of the gear before it breaks. | C2 |

| Remanufactured teeth have lower tensile properties but are harder and more wear-resistant. | C3 | ||

| 16 | Xu et al. [70] | Product collection laws lessen the damaging effects of manufacturing on the environment when collection costs are very high, but they also hurt original equipment manufacturers’ profits. | E4 |

| Even in the absence of collection laws, remanufacturers have a financial incentive to gather all old items when reverse operating costs are very low. | F2 | ||

| The best collection rate is established when reverse operating expenses are minimal and are combined with new production costs. | D2 | ||

| 17 | Yang et al. [56] | Customer remorse over overspending or underspending has an impact on business earnings. | A3 |

| The perceived value of remanufactured items among consumers is largely influenced by the source of remanufacturing (self-made versus third-party produced). | A4 | ||

| The pricing of remanufactured products significantly affects consumer perception. | F1 | ||

| After-sales actions should be implemented to lower consumers’ perceived risks associated with remanufactured items when market uncertainty is higher. | F3 | ||

| 18 | Wang et al. [72] | Remanufacturing may decrease because of higher collection objectives or lower carbon emission restrictions. | E4 |

| Adopting a dual supervisory system is recommended. | E4 | ||

| High collection objectives or low carbon emission limitations should be established for the environmental aspect. | E4 | ||

| Various legislative forms should be adopted by policymakers based on their goals. | E4 | ||

| 19 | Chakraborty et al. [76] | The remanufacturing subsector has enormous potential for reducing carbon emissions. | G1 |

| Marginal remanufacturing costs are a significant determinant. | F2 | ||

| Government aid is seen as a means of encouraging remanufacturing. | E4 | ||

| 20 | Ding et al. [77] | Legislation related to collection may have a greater impact on remanufacturing. | E4 |

| Improving the remanufacturing rate will reduce the production cost of new products for implementing enterprises as well as carbon emission costs. | F2 | ||

| The quantity of remanufactured goods rises in response to carbon taxation by governments. | F6 | ||

| 21 | Östlin et al. [57] | A product or component’s typical consumption and lifespan can be predicted in advance by calculating the number of cores that will need to be reflowed in the future. | C4 |

| Whether or not consumers are willing to return items affects how many will need to be returned in the future. | A3 | ||

| Original equipment manufacturers are in a stronger position to remanufacture. | A4 | ||

| Obtaining the best cores for remanufacturing will become the new approach as supply grows. | C4 | ||

| The coordination and management of collection systems are important aspects of supply chain management. | D2 | ||

| More opportunities for remanufacturing arise from the use of standardized and modular components. | C5 | ||

| Determine remanufactured product pricing according to the product’s life cycle stage. | F1 | ||

| 22 | Subramoniam et al. [51] | It is important for the original equipment manufacturer department to make judgments on remanufacturing early. | E3 |

| Lower the amount of material used and switch to services in place of goods. | F3 | ||

| Remanufactured enhancements can be made using generic parts. | C5 | ||

| Remanufacturing products impacts the ecology and dependence on resources. | G1 | ||

| When the uncertainty of remanufacturing increases, companies are more likely to establish bureaucratic or family governance mechanisms, which is not conducive to creating employment opportunities. | G2 | ||

| Unified ordering of remanufacturing evaluation equipment to promote remanufacturing testing and achieve economies of scale through better savings. | G3 | ||

| Create solutions by collaborating with all parties involved throughout the first phases of planning. | A4 | ||

| Another factor motivating suppliers to remanufacture products is intellectual property rights. | E8 | ||

| Provide comparative data to prove that remanufactured products are as good as new products. | C3 | ||

| The expense of disposing of products will become a significant factor in the future. | F2 | ||

| Remanufactured products could be eligible for green tax credits. | F6 | ||

| Government regulations can be an important driver of remanufacturing decisions. | E4 | ||

| High-volume plants and low-volume plants should be kept apart since they demand distinct services. | A4 | ||

| 23 | Atasu et al. [58] | The higher the profits from remanufacturing, the competition among new product enterprises becomes more intense. | A4 |

| Business-to-business remanufactured products ought to have a more aggressive pricing approach. | F1 | ||

| Market size impacts the time it takes to introduce remanufactured products. | F8 | ||

| Pricing for remanufacturing may be influenced by varying amounts of market competition or market structures. | E5 | ||

| 24 | Subramoniam et al. [26] | The choice to remanufacture a product may be adversely affected if there are no client needs for applications of the remanufactured product. | A3 |

| Decisions on remanufacturing may suffer from a lower core’s usable life. | C4 | ||

| Decisions on product remanufacturing are positively impacted by the enterprise’s strong product repurchase incentives. | F4 | ||

| 25 | Webster and Mitra [78] | Remanufacturer earnings will increase if government collective collection is implemented. | E4 |

| The tax burden on society will be decreased by implementing government communal collection. | E4 | ||

| Manufacturer-specific collecting might lead to the monopolization of the industry. | E5 | ||

| 26 | Wu [71] | Original equipment manufacturers’ production costs are decreased by high deconstruction. | D3 |

| Remanufacturers’ collecting expenses are decreased by high deconstruction. | D3 | ||

| The success of remanufacturing depends in part on the design for deconstruction. | D3 | ||

| Market structure has a significant impact on remanufacturing strategies, such as obtaining high profits from segmented markets or penetrating the entire market at low prices. | E5 | ||

| 27 | Ovchinnikov [59] | Remanufacturing decisions should minimize the impact of new product sales on the market size of remanufactured products. | F8 |

| A business must strike a balance between how many remanufactured items it wants to sell and how easy it is to remanufacture old components. | F8 | ||

| Increasing the collection of cores can reduce costs and competitive threats. | D2 | ||

| Knowing customer behavior benefits the business. | A3 | ||

| 28 | Dowlatshahi [66] | Proactive customer service has value. | F3 |

| Decisions for remanufacturing must take the enterprise’s entire strategy into consideration. | E3 | ||

| Operational factors are not the most crucial ones. | D6 | ||

| The specific needs of customers are very important. This includes meeting delivery times, providing items in a short period of time, as well as after-sales service and repairs. | F3 | ||

| The manufacturing resources, techniques, technology, and expertise that are currently in use determine how effective remanufacturing is. | E7 | ||

| 29 | Abdulrahman et al. [40] | Technical problems dominate the surveyed companies (more than 50%). | E7 |

| The main management factors that hinder remanufacturing are the lack of skilled labor and organizational structure integration. | A2 | ||

| Enforcing government regulations is a crucial aspect that might impact the future of remanufacturing in China. | E4 | ||

| Robust intellectual property protection is perceived as a hindrance to remanufacturing processes that are outsourced. | E8 |

References

- Mehra, A. The Built Environment and Fashion Industries are Primed to Lead the Recovery. 2020. Available online: https://www.weforum.org/agenda/2020/11/the-built-environment-and-fashion-industries-can-and-must-lead-the-recovery-this-is-why/ (accessed on 20 November 2024).

- Orsini, F.; Marrone, P. Approaches for a low-carbon production of building materials: A review. J. Clean. Prod. 2019, 241, 118380. [Google Scholar] [CrossRef]

- Mei, Z.; Xu, M.; Li, H.; Huang, Z.; Luo, S. Cooperation mode for concrete formwork reuse among construction sites. Sustain. Cities Soc. 2023, 95, 104584. [Google Scholar] [CrossRef]

- De Luca, P.; Carbone, I.; Nagy, J.B. Green Building Materials: A Review of State of the Art Studies of Innovative Materials. J. Green Build. 2017, 12, 141–161. [Google Scholar] [CrossRef]

- Atta, N. Remanufacturing towards circularity in the construction sector: The role of digital technologies. In Proceedings of the International Conference on Technological Imagination in the Green and Digital Transition, 30 June–July 2022, Rome, Italy; pp. 493–503. [CrossRef]

- American Institute of Steel Construction. More than Recycled Content:The Sustainable Characteristics of Structural Steel. 2017. Available online: https://www.aisc.org/why-steel/sustainability/ (accessed on 7 July 2024).

- Brütting, J.; De Wolf, C.; Fivet, C. The reuse of load-bearing components. In Proceedings of the IOP Conference Series: Earth and Environmental Science, Brussels, Belgium, 5–7 February 2019; p. 012025. [Google Scholar]

- Talamo, C.; Lavagna, M.; Monticelli, C.; Zanelli, A.; Campioli, A. Remanufacturing: Strategies to enhance the life extension of short-cycle building products. TECHNE-J. Technol. Archit. Environ. 2021, 22, 71–78. [Google Scholar] [CrossRef]

- Hopkinson, P.; Chen, H.-M.; Zhou, K.; Wang, Y.; Lam, D. Recovery and reuse of structural products from end-of-life buildings. Proc. Inst. Civ. Eng.-Eng. Sustain. 2018, 172, 119–128. [Google Scholar] [CrossRef]

- Peng, C.-L.; Scorpio, D.E.; Kibert, C.J. Strategies for successful construction and demolition waste recycling operations. Constr. Manag. Econ. 1997, 15, 49–58. [Google Scholar] [CrossRef]

- Jin, R.; Li, B.; Zhou, T.; Wanatowski, D.; Piroozfar, P. An empirical study of perceptions towards construction and demolition waste recycling and reuse in China. Resour. Conserv. Recycl. 2017, 126, 86–98. [Google Scholar] [CrossRef]

- Ong, S.K.; Fang, H.C.; Nee, A.Y.C. A Design Feature-based Approach for Product Remanufacturability Assessment and Analysis. Procedia CIRP 2016, 53, 15–20. [Google Scholar] [CrossRef]

- Lützkendorf, T. Application of “element”-method in sustainability assessment. In Proceedings of the IOP Conference Series: Earth and Environmental Science, 2019; Central Europe towards Sustainable Building (CESB19), Prague, Czech Republic, 2–4 July 2019; p. 012052. [Google Scholar] [CrossRef]

- Victoria, E. Construction and Demolition Waste Landfill Traffic and Compositional Surveys Final Report. 1998. Available online: https://citeseerx.ist.psu.edu/document?repid=rep1&type=pdf&doi=2a6307efd7461445e87476987e9e3ac472e00164 (accessed on 10 October 2024).

- Kibert, C.J.; Languell, J.L. Implementing Deconstruction in Florida: Materials Reuse Issues, Disassembly Techniques, Economics and Policy. Florida Center for Solid and Hazardouse Waste: Tallahassee, FL, USA, 2000. [Google Scholar]

- Kellenberger, D.; Althaus, H.-J. Relevance of simplifications in LCA of building components. Build. Environ. 2009, 44, 818–825. [Google Scholar] [CrossRef]

- Jipa, A.; Dillenburger, B. 3D printed formwork for concrete: State-of-the-art, opportunities, challenges, and applications. 3D Print. Addit. Manuf. 2022, 9, 84–107. [Google Scholar] [CrossRef]

- Sitnikov, V. Ice Formwork for High-Performance Concrete: A Model of Lean Production for Prefabricated Concrete Industry. Structures 2019, 18, 109–116. [Google Scholar] [CrossRef]

- Hamada, H.; Alattar, A.; Tayeh, B.; Yahaya, F.; Almeshal, I. Influence of different curing methods on the compressive strength of ultra-high-performance concrete: A comprehensive review. Case Stud. Constr. Mater. 2022, 17, e01390. [Google Scholar] [CrossRef]

- Mohammed, M.; Shafiq, N.; Elmansoury, A.; Al-Mekhlafi, A.-B.A.; Rached, E.F.; Zawawi, N.A.; Haruna, A.; Rafindadi, A.D.u.; Ibrahim, M.B. Modeling of 3R (reduce, reuse and recycle) for sustainable construction waste reduction: A partial least squares structural equation modeling (PLS-SEM). Sustainability 2021, 13, 10660. [Google Scholar] [CrossRef]

- UN-HABITAT. Solid Waste Management in the World’s Cities: Water and Sanitation in the World’s Cities 2010. Available online: https://unhabitat.org/solid-waste-management-in-the-worlds-cities-water-and-sanitation-in-the-worlds-cities-2010-2 (accessed on 25 June 2024).

- D’Adamo, I.; Rosa, P. Remanufacturing in industry: Advices from the field. Int. J. Adv. Manuf. Technol. 2016, 86, 2575–2584. [Google Scholar] [CrossRef]

- Hatcher, G.D.; Ijomah, W.L.; Windmill, J.F.C. Design for remanufacture: A literature review and future research needs. J. Clean. Prod. 2011, 19, 2004–2014. [Google Scholar] [CrossRef]

- Naderifar, M.; Goli, H.; Ghaljaie, F. Snowball sampling: A purposeful method of sampling in qualitative research. Strides Dev. Med. Educ. 2017, 14, 1–4. [Google Scholar] [CrossRef]

- Steeneck, D.W.; Sarin, S.C. Product design for leased products under remanufacturing. Int. J. Prod. Econ. 2018, 202, 132–144. [Google Scholar] [CrossRef]

- Subramoniam, R.; Huisingh, D.; Chinnam, R.B. Remanufacturing for the automotive aftermarket-strategic factors: Literature review and future research needs. J. Clean. Prod. 2009, 17, 1163–1174. [Google Scholar] [CrossRef]

- Kurilova-Palisaitiene, J.; Sundin, E.; Poksinska, B. Remanufacturing challenges and possible lean improvements. J. Clean. Prod. 2018, 172, 3225–3236. [Google Scholar] [CrossRef]

- Lund, R.T. Remanufacturing: The Experience of the United States and Implications for Developing Countries. 1984. Available online: https://documents1.worldbank.org/curated/en/792491468142480141/pdf/WTP310PUB0REPL00Box367874B00PUBLIC0.pdf (accessed on 28 September 2024).

- Song, S.; Liu, M.; Ke, Q.; Huang, H. Proactive remanufacturing timing determination method based on residual strength. Int. J. Prod. Res. 2015, 53, 5193–5206. [Google Scholar] [CrossRef]

- Boorsma, N.; Tsui, T.; Peck, D. Circular building products, a case study of soft barriers in design for remanufacturing. In Proceedings of the International conference of Remanufacturing, Amsterdam, The Netherlands, June 23–25 2019. [Google Scholar]

- Bao, Z. Developing circularity of construction waste for a sustainable built environment in emerging economies: New insights from China. Dev. Built Environ. 2023, 13, 100107. [Google Scholar] [CrossRef]

- Liu, B.; Holmbom, M.; Segerstedt, A.; Chen, W. Effects of carbon emission regulations on remanufacturing decisions with limited information of demand distribution. Int. J. Prod. Res. 2015, 53, 532–548. [Google Scholar] [CrossRef]

- Abdullah, Z.T. Assessment of end-of-life vehicle recycling: Remanufacturing waste sheet steel into mesh sheet. PLoS ONE 2021, 16, e0261079. [Google Scholar] [CrossRef]

- Bao, Z.; Laovisutthichai, V.; Tan, T.; Wang, Q.; Lu, W. Design for manufacture and assembly (DfMA) enablers for offsite interior design and construction. Build. Res. Inf. 2022, 50, 325–338. [Google Scholar] [CrossRef]

- Niu, S.; Zhuo, H.; Xue, K. DfRem-Driven closed-loop supply chain decision-making: A systematic framework for modeling research. Sustainability 2019, 11, 3299. [Google Scholar] [CrossRef]

- Liu, B.; Song, Q.; Zheng, H.; Ma, Y.; Li, K. Remanufacturing production decisions considering product life cycle and green consumers’ scale in the circular economy. Ind. Manag. Data Syst. 2023, 123, 1122–1156. [Google Scholar] [CrossRef]

- Cobut, A.; Blanchet, P.; Beauregard, R. Prospects for appearance wood products ecodesign in the context of nonresidential applications. For. Prod. J. 2016, 66, 196–210. [Google Scholar] [CrossRef]

- Cat Reman. The Circular Economy. 2022. Available online: https://www.cat.com/en_US/blog/the-circular-economy-cat-reman-and-sustainability.html (accessed on 11 November 2024).

- Paris, H.; Mandil, G. Process planning for combined additive and subtractive manufacturing technologies in a remanufacturing context. J. Manuf. Syst. 2017, 44, 243–254. [Google Scholar] [CrossRef]

- Abdulrahman, M.D.-A.; Subramanian, N.; Liu, C.; Shu, C. Viability of remanufacturing practice: A strategic decision making framework for Chinese auto-parts companies. J. Clean. Prod. 2015, 105, 311–323. [Google Scholar] [CrossRef]

- Sakao, T.; Sundin, E. How to improve remanufacturing?—A systematic analysis of practices and theories. J. Manuf. Sci. Eng. 2019, 141, 021004. [Google Scholar] [CrossRef]

- Sharma, V.; Garg, S.K.; Sharma, P.B. Identification of major drivers and roadblocks for remanufacturing in India. J. Clean. Prod. 2016, 112, 1882–1892. [Google Scholar] [CrossRef]

- Cui, L.; Wu, K.-J.; Tseng, M.-L. Selecting a remanufacturing quality strategy based on consumer preferences. J. Clean. Prod. 2017, 161, 1308–1316. [Google Scholar] [CrossRef]

- Stieven Montagna, L.; Ferreira de Melo Morgado, G.; Lemes, A.P.; Roberto Passador, F.; Cerqueira Rezende, M. Recycling of carbon fiber-reinforced thermoplastic and thermoset composites: A review. J. Thermoplast. Compos. Mater. 2023, 36, 3455–3480. [Google Scholar] [CrossRef]

- Duan, Z.; Singh, A.; Xiao, J.; Hou, S. Combined use of recycled powder and recycled coarse aggregate derived from construction and demolition waste in self-compacting concrete. Constr. Build. Mater. 2020, 254, 119323. [Google Scholar] [CrossRef]

- Ghani, N.; Zaini, S.; Abu, M. Assessment the unused capacity using time driven activity based costing in automotive manufacturing industry. J. Mod. Manuf. Syst. Technol. 2020, 4, 82–94. [Google Scholar] [CrossRef]

- Lund, R.T.; Skeels, F.D. Guidelines for an Original Equipment Manufacturer Starting a Remanufacturing Operation; U.S. Department of Energy Office of Scientific and Technical Information: Richland, WA, USA, 1983; p. 172. [Google Scholar]

- Fang, C.; Fan, S.; Chi, M.; Wang, W. The optimal remanufacturing strategy, returned quality choice and independent remanufacturers’ advantage for tackling extreme weather. Int. J. Prod. Econ. 2023, 259, 108819. [Google Scholar] [CrossRef]

- Bulmuş, S.C.; Zhu, S.X.; Teunter, R. Capacity and production decisions under a remanufacturing strategy. Int. J. Prod. Econ. 2013, 145, 359–370. [Google Scholar] [CrossRef]

- Siedlecki, S.L. Understanding descriptive research designs and methods. Clin. Nurse Spec. 2020, 34, 8–12. [Google Scholar] [CrossRef]

- Subramoniam, R.; Huisingh, D.; Chinnam, R.B. Aftermarket remanufacturing strategic planning decision-making framework: Theory & practice. J. Clean. Prod. 2010, 18, 1575–1586. [Google Scholar] [CrossRef]

- Barquet, A.P.; Rozenfeld, H.; Forcellini, F.A. An integrated approach to remanufacturing: Model of a remanufacturing system. J. Remanufacturing 2013, 3, 1–11. [Google Scholar] [CrossRef]

- Shi, T.; Chhajed, D.; Wan, Z.; Liu, Y. Distribution channel choice and divisional conflict in remanufacturing operations. Prod. Oper. Manag. 2020, 29, 1702–1719. [Google Scholar] [CrossRef]

- Long, X.; Ge, J.; Shu, T.; Liu, Y. Analysis for recycling and remanufacturing strategies in a supply chain considering consumers’ heterogeneous WTP. Resour. Conserv. Recycl. 2019, 148, 80–90. [Google Scholar] [CrossRef]

- Cetin, C.B.; Zaccour, G. Remanufacturing with innovative features: A strategic analysis. Eur. J. Oper. Res. 2023, 310, 655–669. [Google Scholar] [CrossRef]

- Yang, F.; Wang, M.; Ang, S. Optimal remanufacturing decisions in supply chains considering consumers’ anticipated regret and power structures. Transp. Res. Part E Logist. Transp. Rev. 2021, 148, 102267. [Google Scholar] [CrossRef]

- Östlin, J.; Sundin, E.; Björkman, M. Product life-cycle implications for remanufacturing strategies. J. Clean. Prod. 2009, 17, 999–1009. [Google Scholar] [CrossRef]

- Atasu, A.; Sarvary, M.; Van Wassenhove, L.N. Remanufacturing as a marketing strategy. Manag. Sci. 2008, 54, 1731–1746. [Google Scholar] [CrossRef]

- Ovchinnikov, A. Revenue and cost management for remanufactured products. Prod. Oper. Manag. 2011, 20, 824–840. [Google Scholar] [CrossRef]

- Yang, S.; MR, A.R.; Kaminski, J.; Pepin, H. Opportunities for industry 4.0 to support remanufacturing. Appl. Sci. 2018, 8, 1177. [Google Scholar] [CrossRef]

- Tian, G.; Wang, W.; Zhang, H.; Zhou, X.; Zhang, C.; Li, Z. Multi-objective optimization of energy-efficient remanufacturing system scheduling problem with lot-streaming production mode. Expert Syst. Appl. 2024, 237, 121309. [Google Scholar] [CrossRef]

- Dulman, M.T.; Gupta, S.M. Maintenance and remanufacturing strategy: Using sensors to predict the status of wind turbines. J. Remanufacturing 2018, 8, 131–152. [Google Scholar] [CrossRef]

- Manco, P.; Caterino, M.; Rinaldi, M.; Macchiaroli, R. A sustainability-oriented methodology to compare production strategies: The case of AM-based remanufacturing. J. Clean. Prod. 2023, 423, 138594. [Google Scholar] [CrossRef]

- Muranko, Z.; Andrews, D.; Chaer, I.; Newton, E.J. Circular economy and behaviour change: Using persuasive communication to encourage pro-circular behaviours towards the purchase of remanufactured refrigeration equipment. J. Clean. Prod. 2019, 222, 499–510. [Google Scholar] [CrossRef]

- Zhu, L.; Wang, S.; Pan, H.; Yuan, C.; Chen, X. Research on remanufacturing strategy for 45 steel gear using H13 steel powder based on laser cladding technology. J. Manuf. Process. 2020, 49, 344–354. [Google Scholar] [CrossRef]

- Dowlatshahi, S. A strategic framework for the design and implementation of remanufacturing operations in reverse logistics. Int. J. Prod. Res. 2005, 43, 3455–3480. [Google Scholar] [CrossRef]

- Kutz, M. Mechanical Engineers’ Handbook, Volume 2: Design, Instrumentation, and Controls; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2015; Volume 2. [Google Scholar]

- Vimal, K.; Kandasamy, J.; Duque, A.A. Integrating sustainability and remanufacturing strategies by remanufacturing quality function deployment (RQFD). Environ. Dev. Sustain. 2021, 23, 1–33. [Google Scholar] [CrossRef]

- Cao, J.; Chen, X.; Wu, S.; Kumar, S. Evolving remanufacturing strategies in China: An evolutionary game theory perspective. Environ. Dev. Sustain. 2021, 23, 14827–14853. [Google Scholar] [CrossRef]

- Xu, J.; Ng, C.; Cheng, T. Remanufacturing strategies under product take-back regulation. Int. J. Prod. Econ. 2021, 235, 108091. [Google Scholar] [CrossRef]

- Wu, C.-H. Product-design and pricing strategies with remanufacturing. Eur. J. Oper. Res. 2012, 222, 204–215. [Google Scholar] [CrossRef]

- Wang, Q.; Li, B.; Chen, B.; Cheng, Y.; Wang, Z. Implication of take-back and carbon emission capacity regulations on remanufacturing in a competitive market. J. Clean. Prod. 2021, 325, 129231. [Google Scholar] [CrossRef]

- Jiang, X.; Zheng, Y. Pricing decisions and remanufacturing strategies considering consumer recycling behavior. Ann. Oper. Res. 2023, 322, 755–792. [Google Scholar] [CrossRef]

- Shang, Y.; Li, S. Hybrid combinatorial remanufacturing strategy for medical equipment in the pandemic. Comput. Ind. Eng. 2022, 174, 108811. [Google Scholar] [CrossRef]

- Saxena, L.K.; Jain, P.K.; Sharma, A.K. A fuzzy goal programme with carbon tax policy for Brownfield Tyre remanufacturing strategic supply chain planning. J. Clean. Prod. 2018, 198, 737–753. [Google Scholar] [CrossRef]

- Chakraborty, K.; Mukherjee, K.; Mondal, S.; Mitra, S. A systematic literature review and bibliometric analysis based on pricing related decisions in remanufacturing. J. Clean. Prod. 2021, 310, 127265. [Google Scholar] [CrossRef]

- Ding, J.; Chen, W.; Wang, W. Production and carbon emission reduction decisions for remanufacturing firms under carbon tax and take-back legislation. Comput. Ind. Eng. 2020, 143, 106419. [Google Scholar] [CrossRef]

- Webster, S.; Mitra, S. Competitive strategy in remanufacturing and the impact of take-back laws. J. Oper. Manag. 2007, 25, 1123–1140. [Google Scholar] [CrossRef]

- Guidat, T.; Seidel, J.; Kohl, H.; Seliger, G. A comparison of best practices of public and private support incentives for the remanufacturing industry. Procedia Cirp 2017, 61, 177–182. [Google Scholar] [CrossRef]

- Mayer, A.L.; Thurston, H.W.; Pawlowski, C.W. The multidisciplinary influence of common sustainability indices. Front. Ecol. Environ. 2004, 2, 419–426. [Google Scholar] [CrossRef]

- Rinsatitnon, N.; Dijaroen, W.; Limpiwun, T.; Suktavee, G.; Chinda, T. Reverse logistics implementation in the construction industry: Paper waste focus. Songklanakarin J. Sci. Technol. 2018, 40, 798–805. [Google Scholar] [CrossRef]

- Thomsen, A.; Schultmann, F.; Kohler, N. Deconstruction, demolition and destruction. Build. Res. Inf. 2011, 39, 327–332. [Google Scholar] [CrossRef]

- De Wolf, C.; Hoxha, E.; Fivet, C. Comparison of environmental assessment methods when reusing building components: A case study. Sustain. Cities Soc. 2020, 61, 102322. [Google Scholar] [CrossRef]

- Yang, S.S.; Nasr, N.; Ong, S.K.; Nee, A.Y.C. Designing automotive products for remanufacturing from material selection perspective. J. Clean. Prod. 2017, 153, 570–579. [Google Scholar] [CrossRef]

- Akinade, O.O.; Oyedele, L.O.; Omoteso, K.; Ajayi, S.O.; Bilal, M.; Owolabi, H.A.; Alaka, H.A.; Ayris, L.; Henry Looney, J. BIM-based deconstruction tool: Towards essential functionalities. Int. J. Sustain. Built Environ. 2017, 6, 260–271. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, S.; Yang, B.; Zhu, L.; Liu, F. Big data driven Hierarchical Digital Twin Predictive Remanufacturing paradigm: Architecture, control mechanism, application scenario and benefits. J. Clean. Prod. 2020, 248, 119299. [Google Scholar] [CrossRef]

- Burger, C.; Kalverkamp, M.; Pehlken, A. Decision making and software solutions with regard to waste management. J. Clean. Prod. 2018, 205, 210–225. [Google Scholar] [CrossRef]

- Gao, K.Z.; He, Z.M.; Huang, Y.; Duan, P.Y.; Suganthan, P.N. A survey on meta-heuristics for solving disassembly line balancing, planning and scheduling problems in remanufacturing. Swarm Evol. Comput. 2020, 57, 100719. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, S.; Liu, Y.; Yang, H.; Li, M.; Huisingh, D.; Wang, L. The ‘Internet of Things’ enabled real-time scheduling for remanufacturing of automobile engines. J. Clean. Prod. 2018, 185, 562–575. [Google Scholar] [CrossRef]

- Stanitsas, M.; Kirytopoulos, K.; Leopoulos, V. Integrating sustainability indicators into project management: The case of construction industry. J. Clean. Prod. 2021, 279, 123774. [Google Scholar] [CrossRef]

- Wilson, J.; Tyedmers, P.; Pelot, R. Contrasting and comparing sustainable development indicator metrics. Ecol. Indic. 2007, 7, 299–314. [Google Scholar] [CrossRef]

- Gonzalez-Garcia, S.; Manteiga, R.; Moreira, M.T.; Feijoo, G. Assessing the sustainability of Spanish cities considering environmental and socio-economic indicators. J. Clean. Prod. 2018, 178, 599–610. [Google Scholar] [CrossRef]

- Shahbazi, S.; Johansen, K.; Sundin, E. Product design for automated remanufacturing—A case study of electric and electronic equipment in Sweden. Sustainability 2021, 13, 9039. [Google Scholar] [CrossRef]

- Kanazawa, T.; Matsumoto, M.; Yoshimoto, M.; Tahara, K. Environmental Impact of Remanufacturing Mining Machinery. Sustainability 2022, 14, 8118. [Google Scholar] [CrossRef]

- De Guimarães, J.C.F.; Severo, E.A.; Klein, L.L.; Dorion, E.C.H.; Lazzari, F. Antecedents of sustainable consumption of remanufactured products: A circular economy experiment in the Brazilian context. J. Clean. Prod. 2023, 385, 135571. [Google Scholar] [CrossRef]

- Zhang, Q.; Wang, L.; Zhou, D. Remanufacturing under energy performance contracting—An alternative insight from sustainable production. Environ. Sci. Pollut. Res. 2020, 27, 40811–40825. [Google Scholar] [CrossRef]

- Ahmad, S.; Wong, K.Y.; Rajoo, S. Sustainability indicators for manufacturing sectors: A literature survey and maturity analysis from the triple-bottom line perspective. J. Manuf. Technol. Manag. 2019, 30, 312–334. [Google Scholar] [CrossRef]

- Spangenberg, J.H.; Omann, I. Assessing social sustainability: Social sustainability and its multicriteria assessment in a sustainability scenario for Germany. Int. J. Innov. Sustain. Dev. 2006, 1, 318–348. [Google Scholar] [CrossRef]

- Rajesh, R. Exploring the sustainability performances of firms using environmental, social, and governance scores. J. Clean. Prod. 2020, 247, 119600. [Google Scholar] [CrossRef]

- Manandhar, R.; Kim, J.-H.; Kim, J.-T. Environmental, social and economic sustainability of bamboo and bamboo-based construction materials in buildings. J. Asian Archit. Build. Eng. 2019, 18, 49–59. [Google Scholar] [CrossRef]

- Ajmal, M.M.; Khan, M.; Hussain, M.; Helo, P. Conceptualizing and incorporating social sustainability in the business world. Int. J. Sustain. Dev. World Ecol. 2018, 25, 327–339. [Google Scholar] [CrossRef]

- Ghazilla, R.A.R.; Taha, Z.; Yusoff, S.; Rashid, S.H.A.; Sakundarini, N. Development of decision support system for fastener selection in product recovery oriented design. Int. J. Adv. Manuf. Technol. 2014, 70, 1403–1413. [Google Scholar] [CrossRef]

- Cao, J.; Chen, X.; Zhang, X.; Gao, Y.; Zhang, X.; Kumar, S. Overview of remanufacturing industry in China: Government policies, enterprise, and public awareness. J. Clean. Prod. 2020, 242, 118450. [Google Scholar] [CrossRef]

- Durugbo, C.M. After-sales services and aftermarket support: A systematic review, theory and future research directions. Int. J. Prod. Res. 2020, 58, 1857–1892. [Google Scholar] [CrossRef]

- Kushwaha, S.; Chan, F.T.; Chakraborty, K.; Pratap, S. Collection and remanufacturing channels selection under a product take-back regulation with remanufacturing target. Int. J. Prod. Res. 2022, 60, 7384–7410. [Google Scholar] [CrossRef]

- Wei, S.; Tang, O.; Liu, W. Refund policies for cores with quality variation in OEM remanufacturing. Int. J. Prod. Econ. 2015, 170, 629–640. [Google Scholar] [CrossRef]

- Zheng, Y. Intelligent and Automatic Inspection, Reconstruction and Process Planning Methods for Remanufacturing and Repair. PhD Dissertation, University of Alberta, The University of Alberta Libraries, Edmonton, AB, Canada, 2021. [Google Scholar]

- Zaman, A.; Arnott, J.; McLntyre, K.; Hannon, J. Resource Harvesting through a Systematic Deconstruction of the Residential House: A Case Study of the ‘Whole House Reuse’ Project in Christchurch, New Zealand. Sustainability 2018, 10, 3430. [Google Scholar] [CrossRef]

- Duberg, J.V.; Johansson, G.; Sundin, E.; Kurilova-Palisaitiene, J. Prerequisite factors for original equipment manufacturer remanufacturing. J. Clean. Prod. 2020, 270, 122309. [Google Scholar] [CrossRef]

- Zheng, Y.; Mamledesai, H.; Imam, H.; Ahmad, R. A novel deep learning-based automatic damage detection and localization method for remanufacturing/repair. Comput. -Aided Des. Appl. 2021, 18, 1359–1372. [Google Scholar] [CrossRef]

- Ajayabi, A.; Chen, H.-M.; Zhou, K.; Hopkinson, P.; Wang, Y.; Lam, D. REBUILD: Regenerative buildings and construction systems for a circular economy. In Proceedings of the IOP Conference Series: Earth and Environmental Science, Brussels, Belgium, 5–7 February 2019; p. 012015. [Google Scholar]

- Yu, C. Remanufacture and reuse of building products for modern construction. Indoor Built Environ. 2013, 22, 849–851. [Google Scholar] [CrossRef]

- Alanya-Rosenbaum, S.; Bergman, R.; Gething, B.; Mousavi-Avval, S.H. Life cycle assessment of the wood pallet repair and remanufacturing sector in the United States. Biofuels Bioprod. Biorefining 2022, 16, 1342–1352. [Google Scholar] [CrossRef]

- Teunter, R.H.; Flapper, S.D.P. Optimal core acquisition and remanufacturing policies under uncertain core quality fractions. Eur. J. Oper. Res. 2011, 210, 241–248. [Google Scholar] [CrossRef]

- European Remanufacturing Council. Remanufacturing: A Primer. 2020. Available online: https://www.remancouncil.eu/studies/0ba5005f0f998051c6e5.pdf (accessed on 6 June 2024).

- Asiawood Lumbers. Remanufactured and Repaired Wooden Pallets. 2023. Available online: https://www.asiawoodlumbers.com/wooden-pallets/remanufactured-and-repaired-wooden-pallets/ (accessed on 13 December 2024).

- Structural Steel Systems Ltd. The SSSL Remanufacturing Process. 2023. Available online: https://www.ssslmachinery.com/remanufacture/14 (accessed on 10 January 2025).

- Rembos. Why Should You Use Remanufactured Wood? 2016. Available online: https://www.rembos.ca/why-remanufactured-wood/ (accessed on 5 August 2024).

- Re-NetTA Research. Results of the Re-NetTA Project. 2022. Available online: https://www.remanufacturingforaec.polimi.it/en/reports/ (accessed on 23 January 2025).

| Factor/Code | Sub-factor | Sub-Code | Reference |

|---|---|---|---|

| Employee skills | A1 | Subramoniam et al. [51] Barquet et al. [52] Shi et al. [53] Fang et al. [48] Long et al. [54] Cui et al. [43] Cetin and Zaccour [55] D’Adamo and Rosa [22] Yang et al. [56] Östlin et al. [57] Atasu et al. [58] Ovchinnikov [59] Abdulrahman et al. [40] Subramoniam et al. [26] | |

| Man | Organizational structure/Management | A2 | |

| (A) | Customer factors | A3 | |

| Stakeholders | A4 | ||

| Machinery | Software | B1 | Yang et al. [60] Talamo et al. [8] Tian et al. [61] Dulman and Gupta [62] |

| (B) | Hardware | B2 | |

| Material | Research and development | C1 | Subramoniam et al. [51] Manco et al. [63] Abdulrahman et al. [40] Muranko et al. [64] Manco et al. [63] Cetin and Zaccour [55] Zhu et al. [65] Östlin et al. [57] Subramoniam et al. [26] |

| (C) | Exterior | C2 | |

| Capability | C3 | ||

| Core quality/Value | C4 | ||

| Standardization/Modularization | C5 | ||

| Method | Design | D1 | Manco et al. [63] Dowlatshahi [66] Abdulrahman et al. [40] Kutz [67] Tian et al. [61] Dulman and Gupta [62] Vimal et al. [68] Long et al. [54] Cao et al. [69] Östlin et al. [57] Xu et al. [70] Wu [71] Ovchinnikov [59] |

| (D) | Collection | D2 | |

| Deconstruction/Disassembly | D3 | ||

| Cleaning | D4 | ||

| Sorting | D5 | ||

| Processing | D6 | ||

| Assembly | D7 | ||

| Quality control | D8 | ||

| Warehousing | D9 | ||

| Transportation | D10 | ||

| Milieu | Working environment | E1 | Subramoniam et al. [51] Wang et al. [72] Jiang and Zheng [73] Talamo et al. [8] Shang and Li [74] Jiang and Zheng [73] Dowlatshahi [66] Cao et al. [69] Saxena et al. [75] Xu et al. [70] Chakraborty et al. [76] Ding et al. [77] Atasu et al. [58] Webster and Mitra [78] Wu [71] Abdulrahman et al. [40] |

| (E) | Production environment | E2 | |

| Corporate system/Culture | E3 | ||

| Policy environment | E4 | ||

| Market environment | E5 | ||

| Environmental awareness | E6 | ||

| Technological environment | E7 | ||

| Intellectual property | E8 | ||

| Marketing | Pricing | F1 | Dowlatshahi [66] Atasu et al. [58] Subramoniam et al. [51] Guidat et al. [79] Jiang and Zheng [73] Cao et al. [69] Saxena et al. [75] Cui et al. [43] Cetin and Zaccour [55] D’Adamo and Rosa [22] Xu et al. [70] Yang et al. [56] Chakraborty et al. [76] Ding et al. [77] Östlin et al. [57] Subramoniam et al. [51] Atasu et al. [58] Ovchinnikov [59] Subramoniam et al. [26] |

| (F) | Cost | F2 | |

| Sales service | F3 | ||

| Promotion/Monetary incentive | F4 | ||

| Public relationship | F5 | ||

| Carbon tax/Carbon currency | F6 | ||

| Sales/Marketing operations | F7 | ||

| Market size | F8 | ||

| Sustainability | Ecology | G1 | Subramoniam et al. [51] Mayer et al. [80] Talamo et al. [8] Vimal et al. [68] Chakraborty et al. [76] |

| (G) | Society | G2 | |

| Economy | G3 |

| Code | Frequency | Summary | Code | Frequency | Summary |

|---|---|---|---|---|---|

| A1 | 0 | 16 | E1 | 0 | 25 |

| A2 | 1 | E2 | 0 | ||

| A3 | 7 | E3 | 3 | ||

| A4 | 8 | E4 | 13 | ||

| B1 | 3 | 3 | E5 | 3 | |

| B2 | 0 | E6 | 1 | ||

| C1 | 1 | 10 | E7 | 3 | |

| C2 | 1 | E8 | 2 | ||

| C3 | 2 | F1 | 4 | 26 | |

| C4 | 4 | F2 | 8 | ||

| C5 | 2 | F3 | 5 | ||

| D1 | 1 | 17 | F4 | 2 | |

| D2 | 5 | F5 | 1 | ||

| D3 | 6 | F6 | 3 | ||

| D4 | 0 | F7 | 0 | ||

| D5 | 1 | F8 | 3 | ||

| D6 | 4 | G1 | 4 | 6 | |

| D7 | 0 | G2 | 1 | ||

| D8 | 0 | G3 | 1 | ||

| D9 | 0 | ||||

| D10 | 0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gao, C.M.; Wong, K.Y. Key Factors Influencing Building Components’ Remanufacturing Strategy: A Comprehensive Literature Review. Buildings 2025, 15, 934. https://doi.org/10.3390/buildings15060934

Gao CM, Wong KY. Key Factors Influencing Building Components’ Remanufacturing Strategy: A Comprehensive Literature Review. Buildings. 2025; 15(6):934. https://doi.org/10.3390/buildings15060934

Chicago/Turabian StyleGao, Can Miao, and Kuan Yew Wong. 2025. "Key Factors Influencing Building Components’ Remanufacturing Strategy: A Comprehensive Literature Review" Buildings 15, no. 6: 934. https://doi.org/10.3390/buildings15060934

APA StyleGao, C. M., & Wong, K. Y. (2025). Key Factors Influencing Building Components’ Remanufacturing Strategy: A Comprehensive Literature Review. Buildings, 15(6), 934. https://doi.org/10.3390/buildings15060934