Experimental Study and Numerical Analysis of Hydration Heat Effect on Precast Prestressed Concrete Box Girder

Abstract

1. Introduction

2. Background of the Project

3. Experimental Investigation

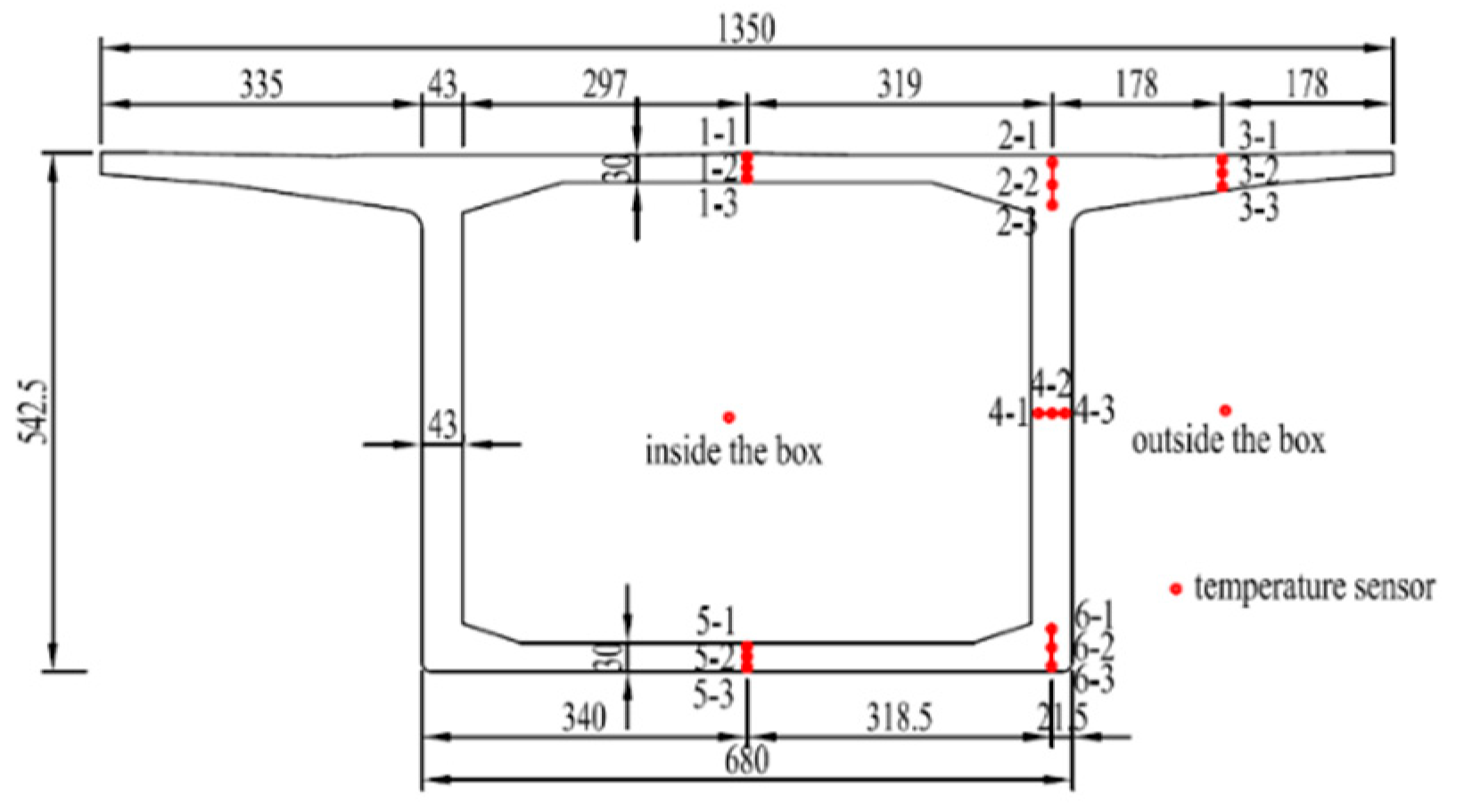

3.1. Distribution of Temperature Measurement Points

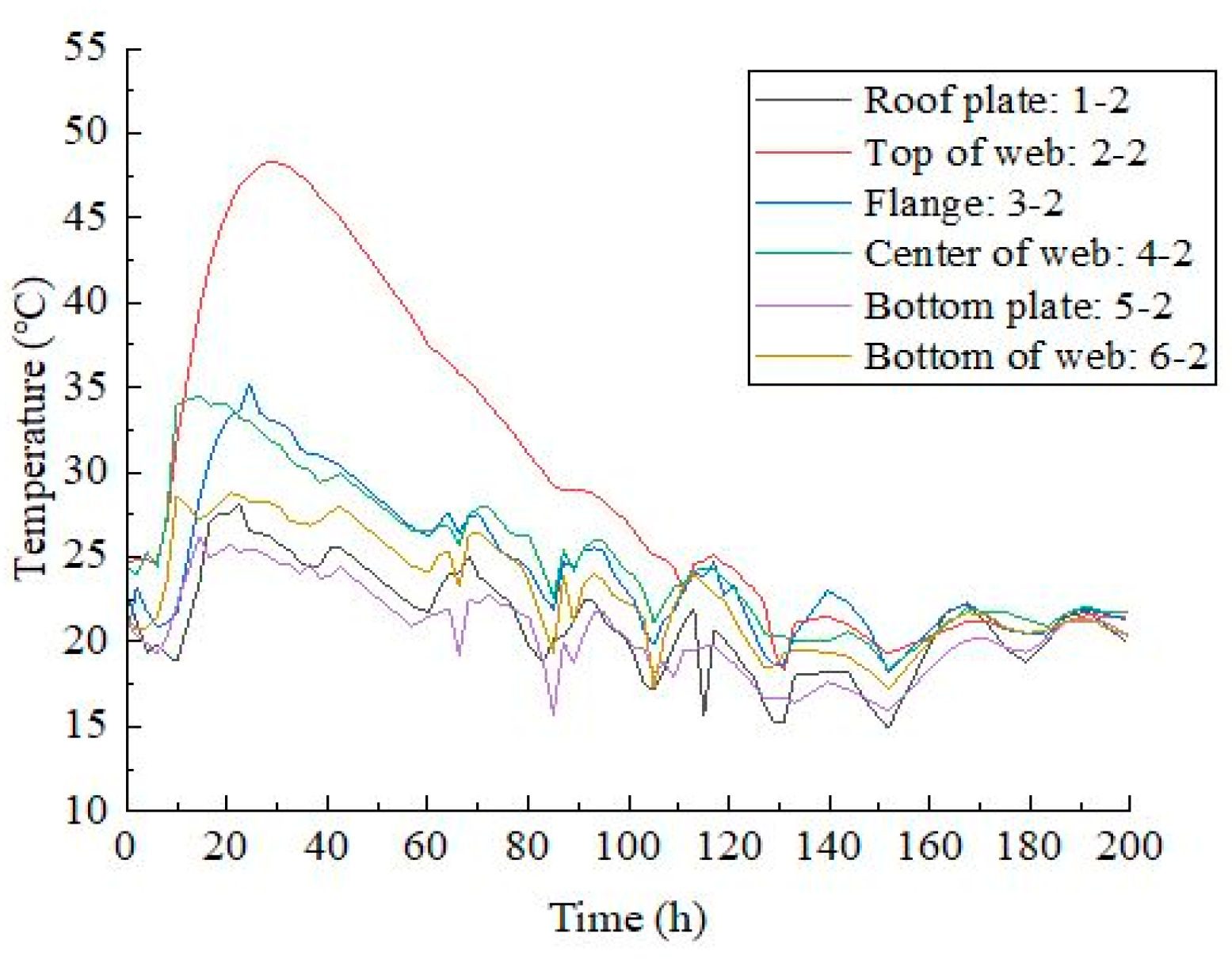

3.2. Results of Temperature Monitoring Points

4. Finite Element Analysis

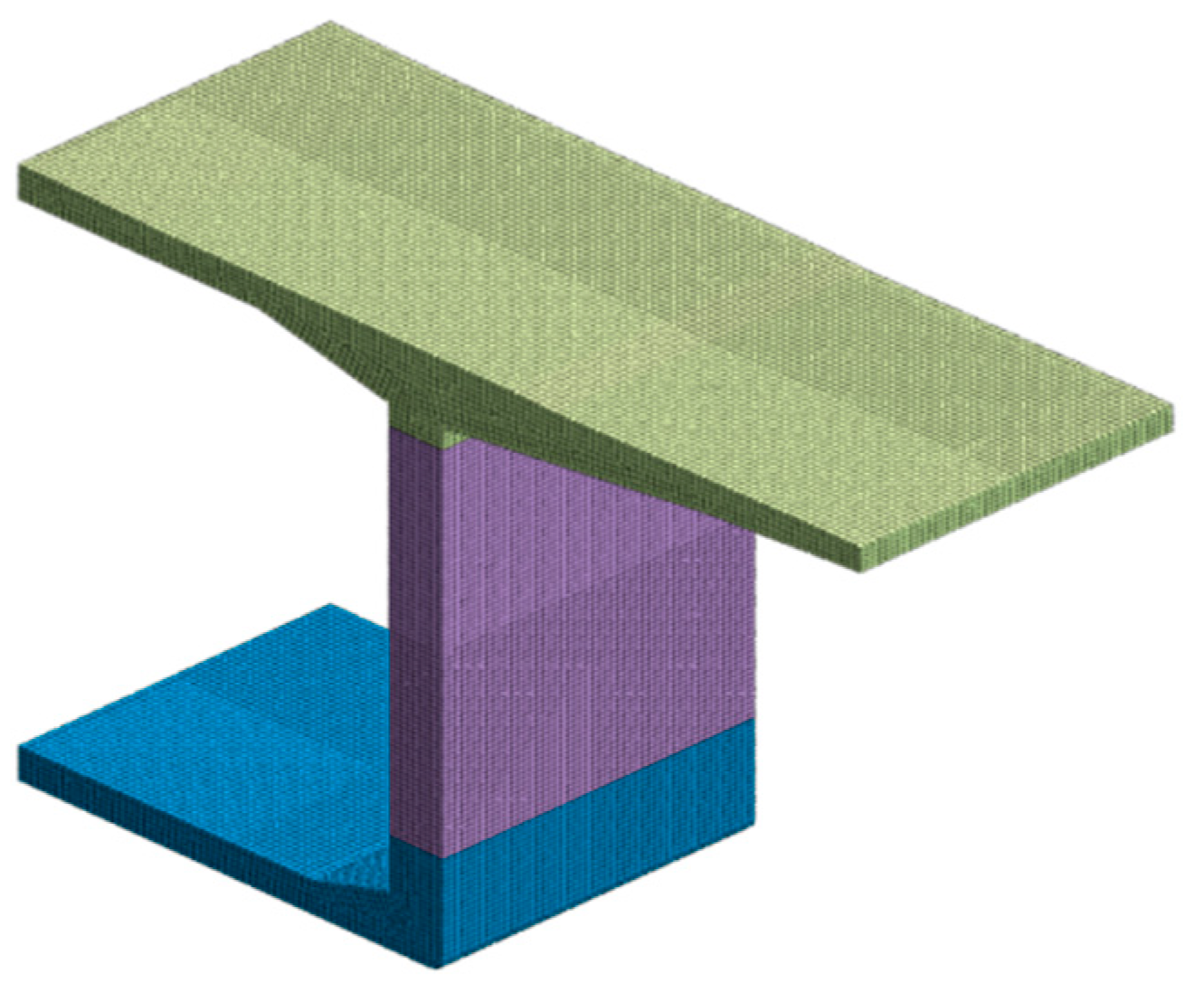

4.1. Finite Element Model

4.2. Model Parameters

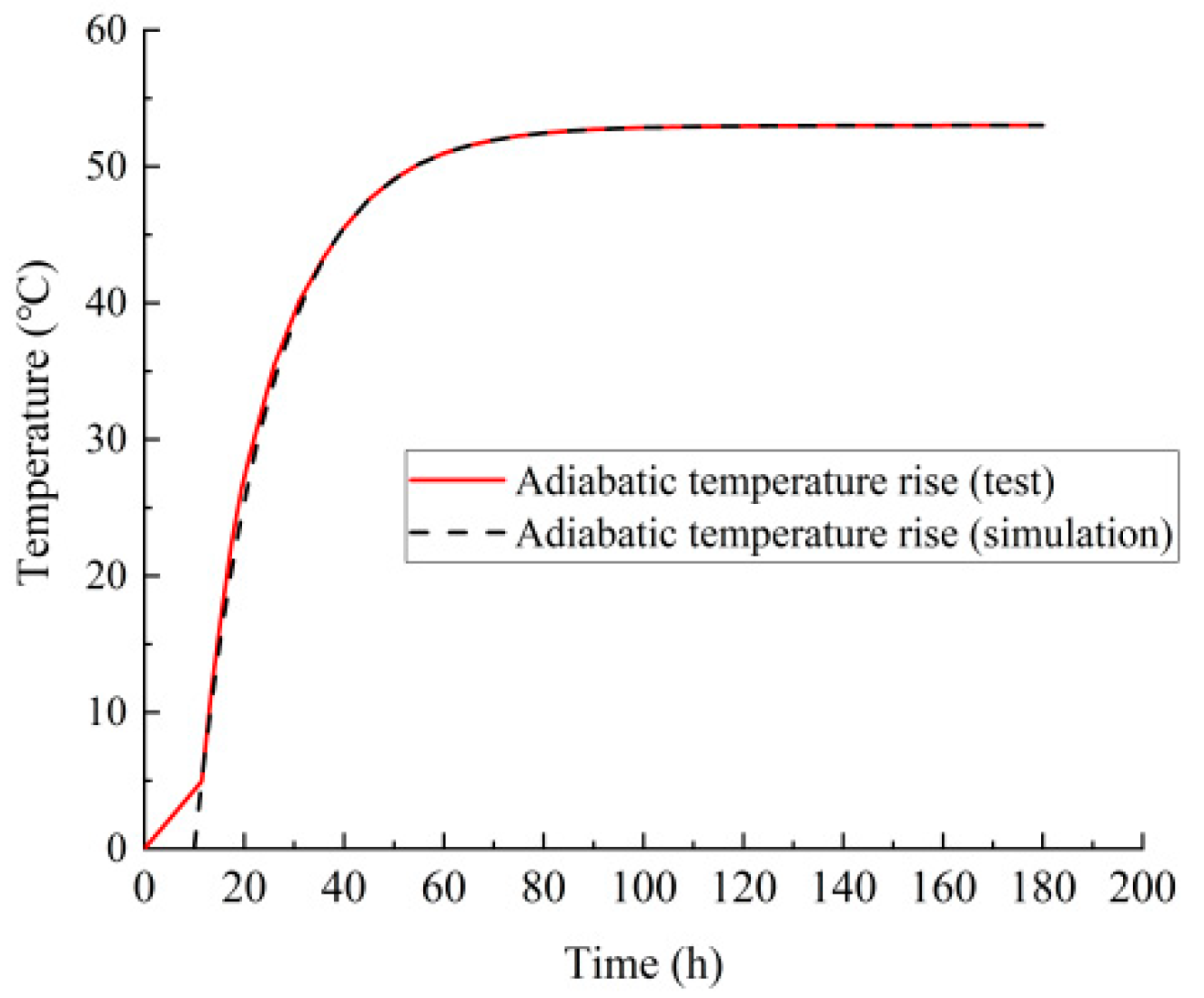

4.2.1. Concrete Characteristics

4.2.2. Thermodynamic Parameters of Concrete

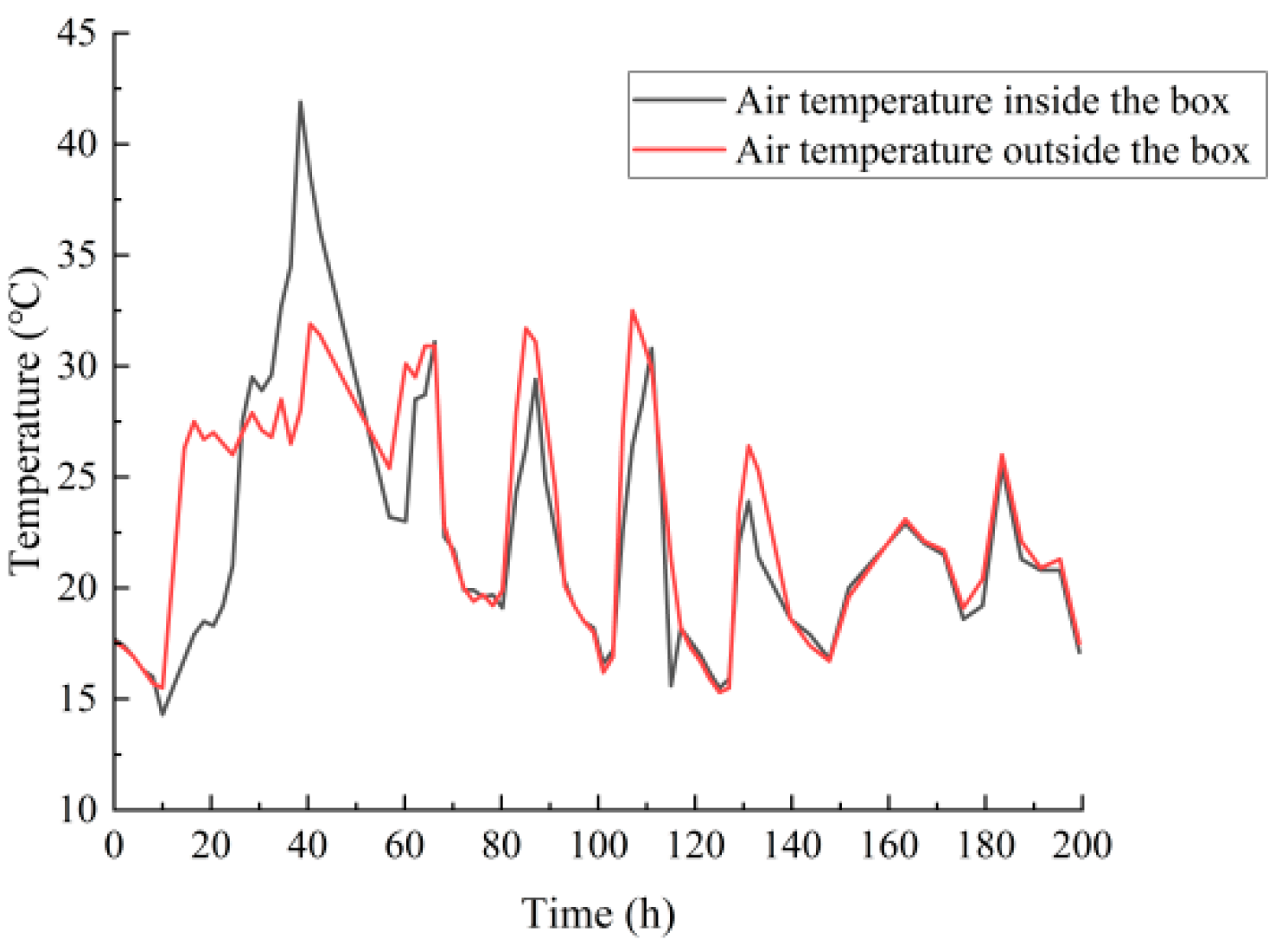

4.2.3. Measurement of Environmental Temperature

4.3. Construction Phase

4.4. Analysis of Calculation Results

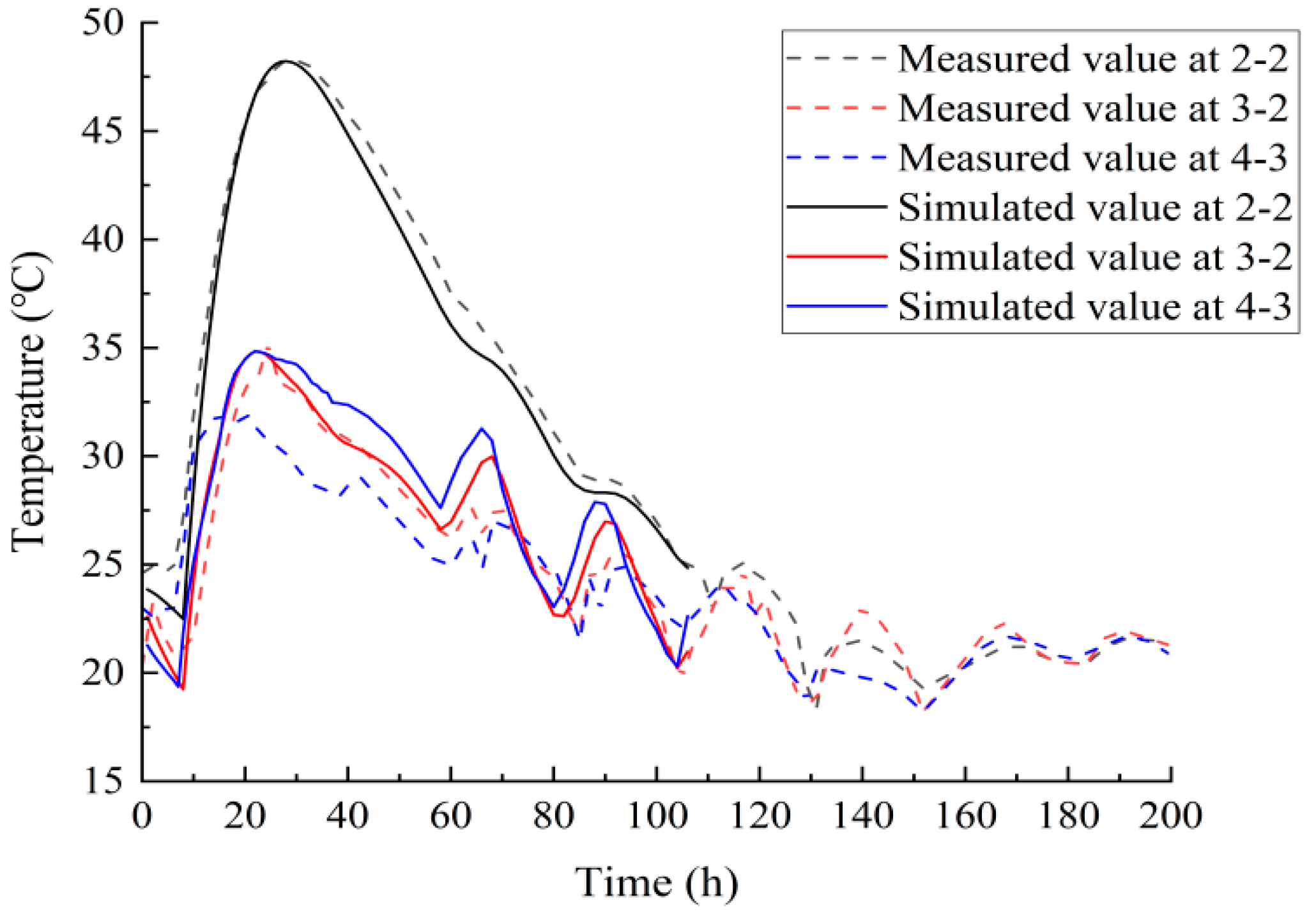

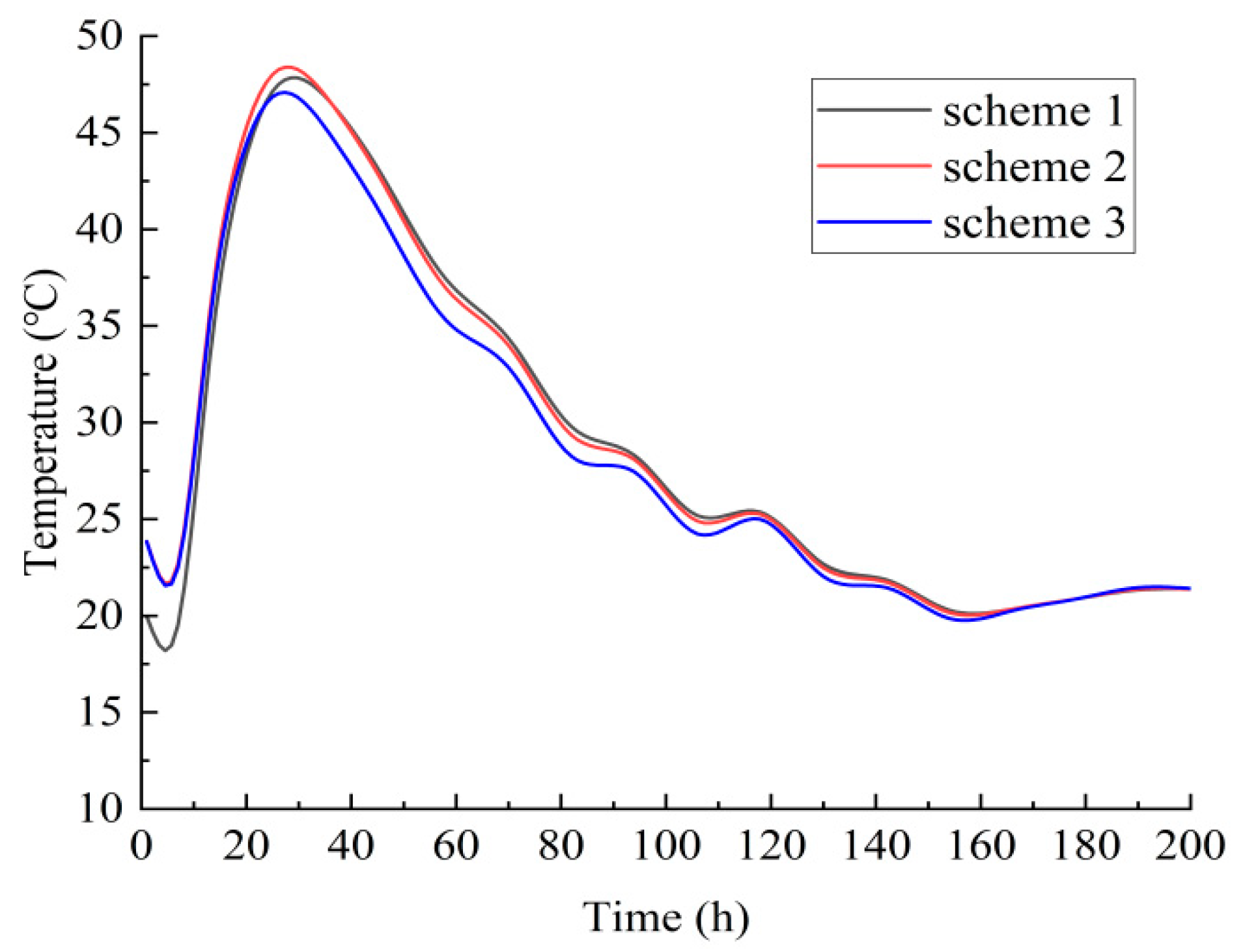

4.4.1. Analysis of Temperature Time History

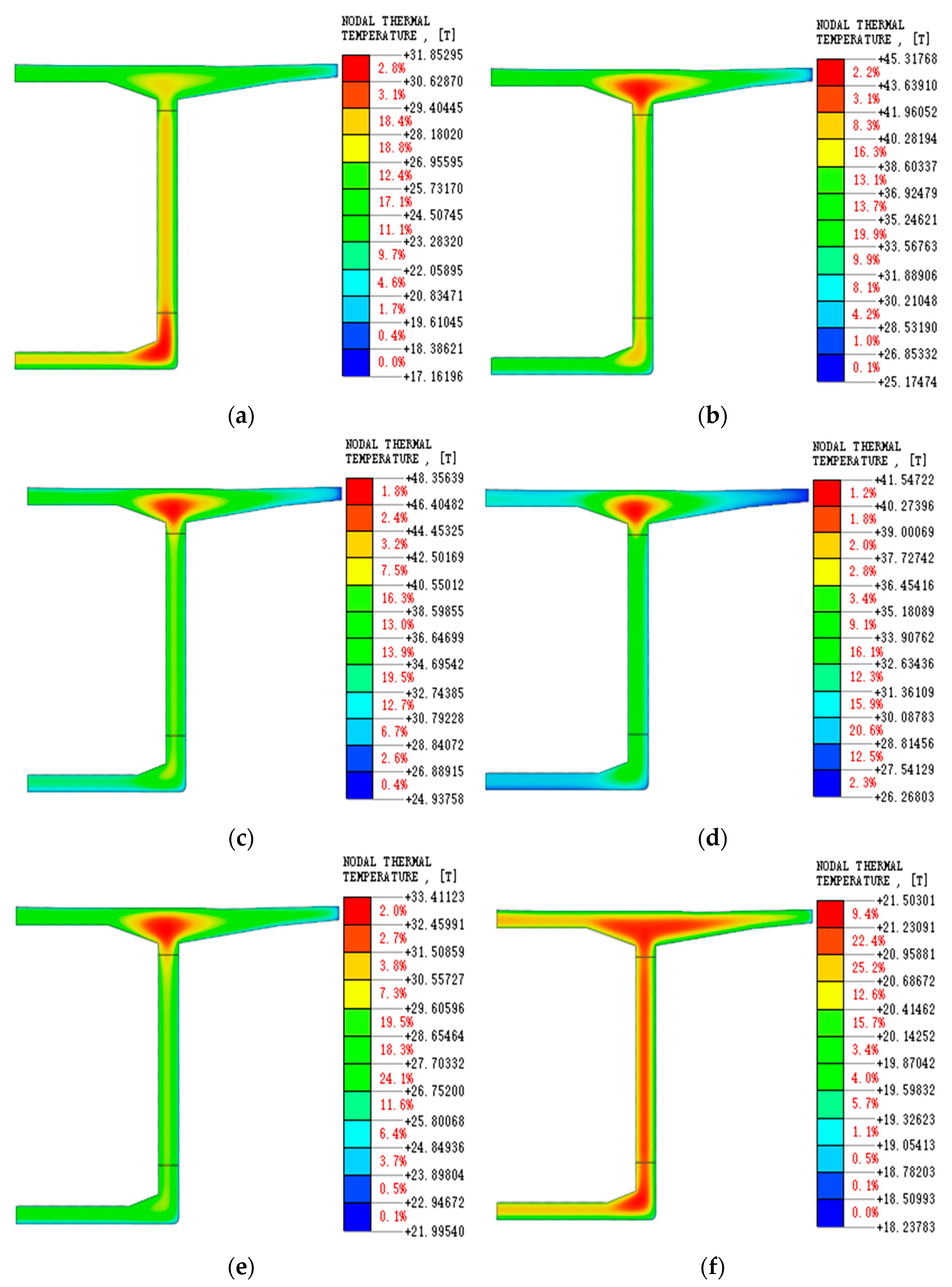

4.4.2. Temperature Field Distribution

4.4.3. Stress Field Distribution

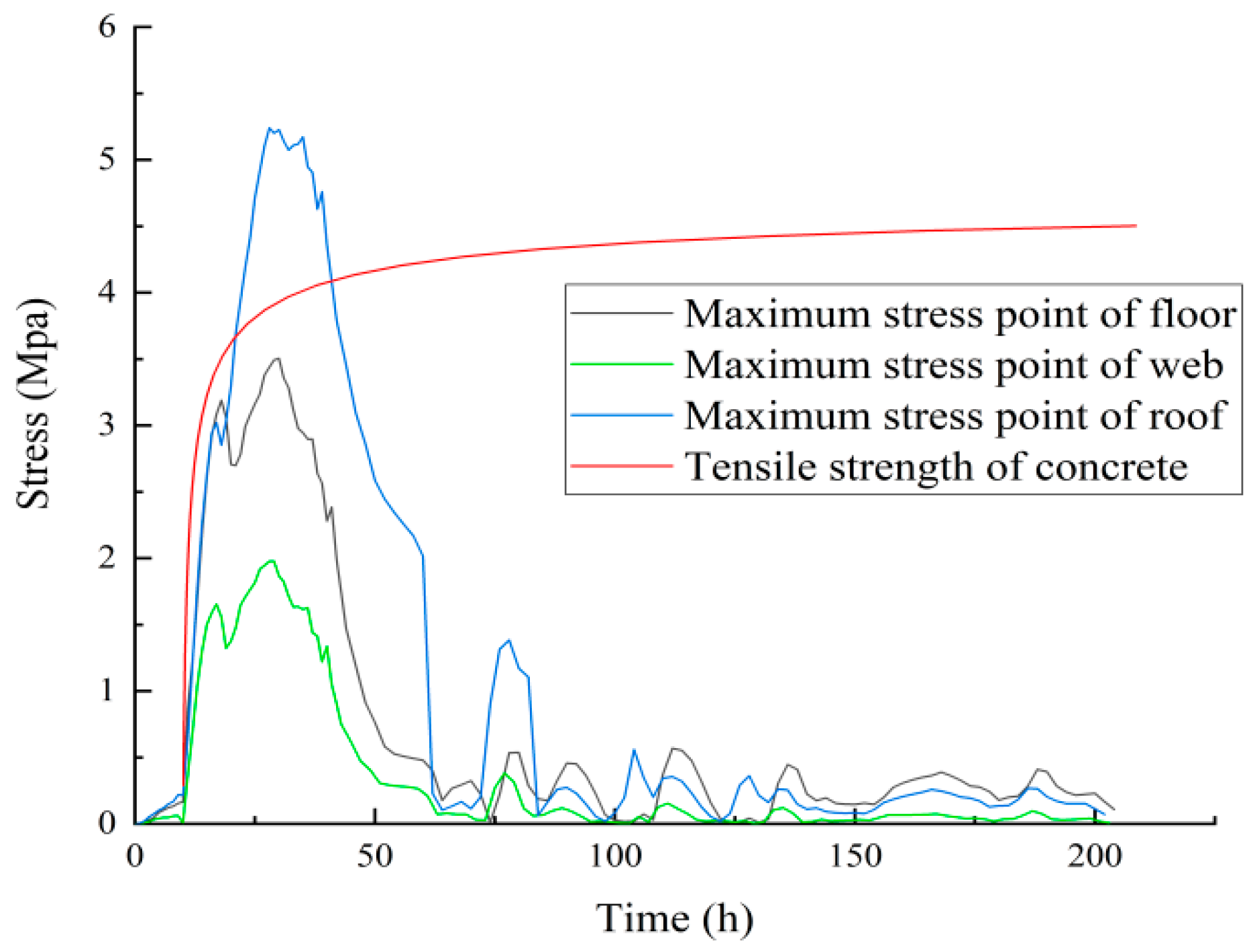

4.4.4. Stress Simulation Analysis

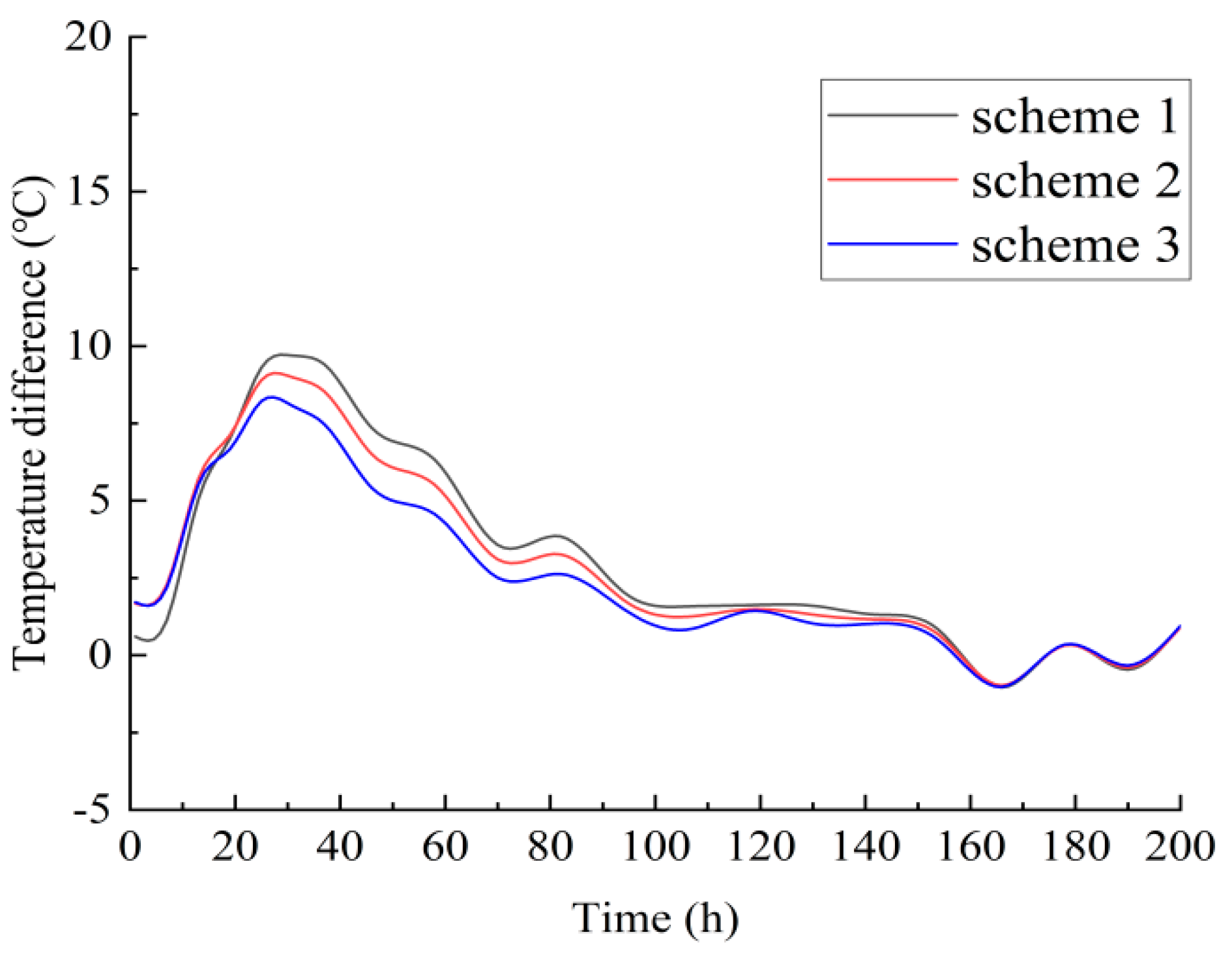

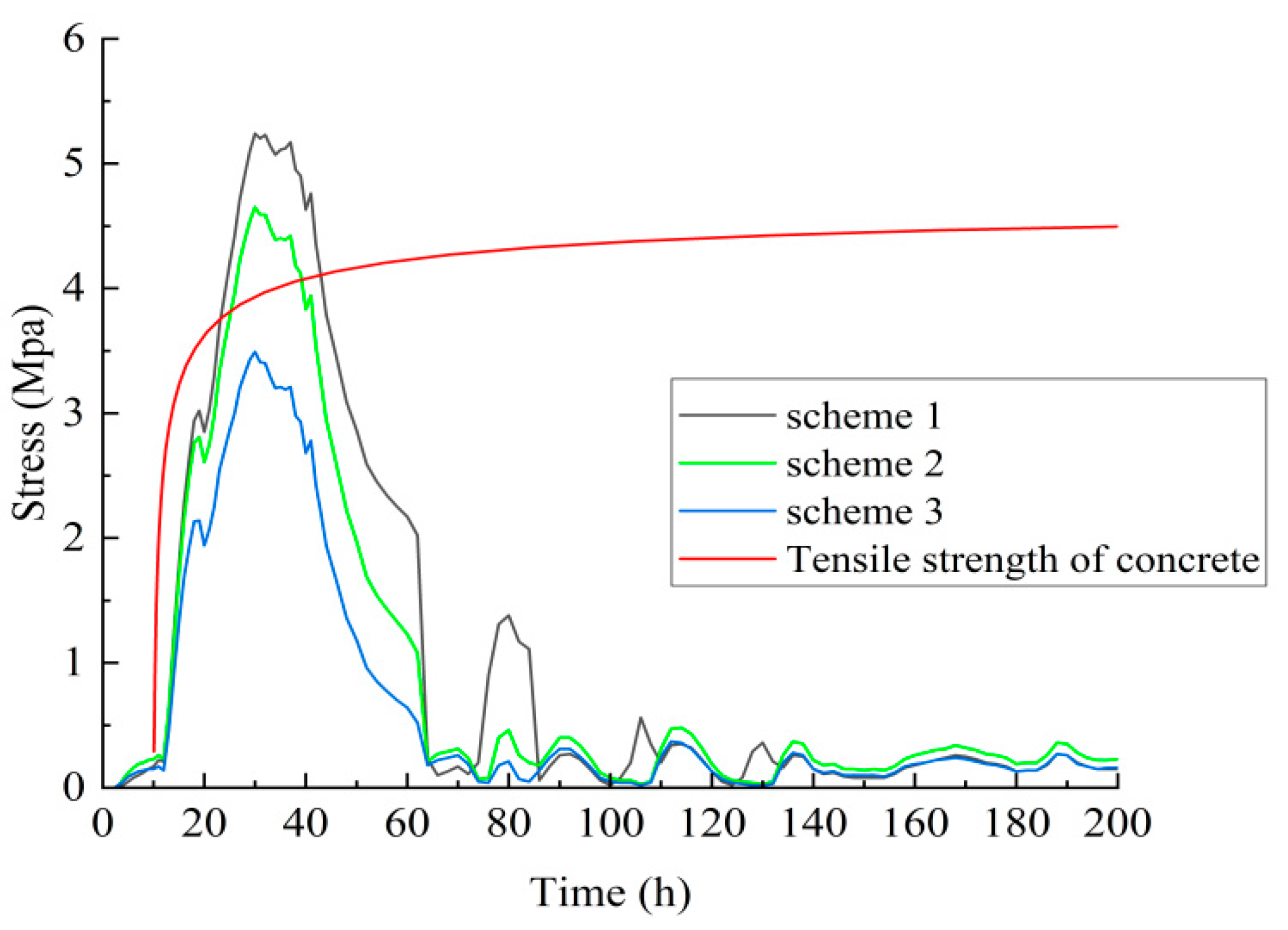

5. Comparison of Construction Schemes

5.1. Temperature Effect Evaluation

5.2. Stress Effect Evaluation

5.3. Cost-Effectiveness Evaluation

6. Conclusions

- The monitored maximum temperature shows a positive correlation with the cross-sectional dimensions of the structural member, where the larger the size, the higher the temperature. Meanwhile, the time taken for the concrete temperature to reach the maximum value is essentially proportional to the distance between the measurement point and the member’s surface. The smaller the distance, the shorter the time to reach the peak temperature.

- The measured and theoretical temperature time histories exhibit comparable trends, indicating that the developed finite element model accurately captures the thermal behavior induced by the hydration process in a representative 5 m long segment of the box girder. This finding can provide a foundation for the subsequent analysis of the hydration heat of an 80 m long segment of the prestressed concrete box girder of the Hangzhou Bay Cross-Sea Railway Bridge.

- The corresponding maximum principal stress increases with the temperature difference between the interior and the surface of concrete, demonstrating that hydration-induced differential thermal expansion between the core and surface regions greatly affects the tensile stress.

- To effectively prevent structural cracking risks during the concrete pouring and curing process of box girders, a scheme is proposed to maintain principal stress levels consistently below the concrete’s tensile strength threshold. For summer construction with a high concrete molding temperature, implementing strategic ventilation measures within the girder effectively reduces core-surface thermal gradients and early-age tensile stresses, thereby mitigating the initial concrete cracking potential.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhang, P.; Xiong, H.T.; Wang, R.M. Measurements and Numerical Simulations for Cast Temperature Field and Early-Age Thermal Stress in Zero Blocks of High-Strength Concrete Box Girders. Adv. Mech. Eng. 2022, 14, 16878132221091514. [Google Scholar] [CrossRef]

- Nassr, A.; Abd-el-Rahim, H.; Kaiser, F.; El-sokkary, A. Topology Optimization of Horizontally Curved Box Girder Diaphragms. Eng. Struct. 2022, 256, 113959. [Google Scholar] [CrossRef]

- Wang, J.Q.; Fang, Z.; Liu, J.; Zuo, Y.; Ma, Z.F. Research on the Construction Crack Resistance of Large-span Box Girder Bridge. JRES Eng. 2016, 33, 81–86. (In Chinese) [Google Scholar]

- Lin, Y.; Chen, H.L. Thermal Analysis and Adiabatic Calorimetry for Early-Age Concrete Members. J. Therm. Anal. Calorim. 2015, 122, 937–945. [Google Scholar] [CrossRef]

- Schackow, A.; Effting, C.; Gomes, I.R.; Patruni, I.Z.; Vicenzi, F.; Kramel, C. Temperature Variation in Concrete Samples Due to Cement Hydration. Appl. Therm. Eng. 2016, 103, 1362–1369. [Google Scholar] [CrossRef]

- Fairbairn, E.M.R.; Silvoso, M.M.; Toledo Filho, R.D.; Alves, J.L.D.; Ebecken, N.F.F. Optimization of Mass Concrete Construction Using Genetic Algorithms. Comput. Struct. 2004, 82, 281–299. [Google Scholar] [CrossRef]

- Rita, M.; Fairbairn, E.; Ribeiro, F.; Andrade, H.; Barbosa, H. Optimization of Mass Concrete Construction Using a Twofold Parallel Genetic Algorithm. Appl. Sci. 2018, 8, 399. [Google Scholar] [CrossRef]

- Yang, W.; Wu, T.; Fang, Z. Measurement and Analysis of Hydration Heat of Concrete Box Girderin Single-box Multi-cells. Highw. Eng. 2017, 42, 254–260. (In Chinese) [Google Scholar]

- Chang, S.; Yang, M.; Sun, Y.; Liu, K. Calculation Method of Early-Age Crack Width in Reinforced Concrete Bridge through a Nonlinear FEA Model. KSCE J. Civ. Eng. 2019, 23, 3088–3096. [Google Scholar] [CrossRef]

- Seo, T.S.; Kim, S.S.; Lim, C.K. Experimental Study on Hydration Heat Control of Mass Concrete by Vertical Pipe Cooling Method. J. Asian Arch. Build 2015, 14, 657–662. [Google Scholar] [CrossRef]

- Do, T.A.; Verdugo, D.; Tia, M.; Hoang, T.T. Effect of Volume-To-Surface Area Ratio and Heat of Hydration On Early-Age Thermal Behavior of Precast Concrete Segmental Box Girders. Case Stud. Therm. Eng. 2021, 28, 101448. [Google Scholar] [CrossRef]

- Kurylowicz-Cudowska, A. Determination of Thermophysical Parameters Involved in the Numerical Model to Predict the Temperature Field of Cast-In-Place Concrete Bridge Deck. Materials 2019, 12, 3089. [Google Scholar] [CrossRef]

- Pan, Y.M.; Prado, A.; Porras, R.; Hafez, O.M.; Bolander, J.E. Lattice Modeling of Early-Age Behavior of Structural Concrete. Materials 2017, 10, 231. [Google Scholar] [CrossRef] [PubMed]

- Nguyen, T.; Weiler, M.; Waldmann, D. Experimental and Numerical Analysis of Early Age Behavior in Non-Reinforced Concrete. Constr. Build. Mater. 2019, 210, 499–513. [Google Scholar] [CrossRef]

- Zhao, H.; Jiang, K.; Yang, R.; Tang, Y.; Liu, J. Experimental and Theoretical Analysis On Coupled Effect of Hydration, Temperature and Humidity in Early-Age Cement-Based Materials. Int. J. Heat Mass Tran. 2020, 146, 118784. [Google Scholar] [CrossRef]

- Zhang, F.; Liu, J.Y. Study On Temperature Distribution of Three-Cell Box Girder During the Hydration Process. J. Therm. Anal. Calorim. 2023, 148, 2629–2643. [Google Scholar] [CrossRef]

- Wei, D.Y.; Du, C.F.; Lin, Y.F.; Chang, B.M. Impact Factors of Hydration Heat of Cemented Tailings Backfill Based On Multi-Index Optimization. Case Stud. Therm. Eng. 2020, 18, 100601. [Google Scholar] [CrossRef]

- De Schutter, G. Finite Element Simulation of Thermal Cracking in Massive Hardening Concrete Elements Using Degree of Hydration Based Material Laws. Comput. Struct. 2002, 80, 2035–2042. [Google Scholar] [CrossRef]

- Dai, J.P.; Wang, Q.C.; Bi, R.X.; Wang, C.; Han, Z.W.; Du, W.T.; Chen, Z.Y. Research On Influencing Factors and Time-Varying Model of Thermal Conductivity of Concrete at Early Age. Constr. Build. Mater. 2022, 315, 125638. [Google Scholar] [CrossRef]

- Lim, C.; Kim, J.; Seo, T. Prediction of Concrete Adiabatic Temperature Rise Characteristic by Semi-Adiabatic Temperature Rise Test and FEM Analysis. Constr. Build. Mater. 2016, 125, 679–689. [Google Scholar] [CrossRef]

- Xin, J.; Zhang, G.; Liu, Y.; Wang, Z.; Wu, Z. Evaluation of Behavior and Cracking Potential of Early-Age Cementitious Systems Using Uniaxial Restraint Tests: A Review. Constr. Build. Mater. 2020, 231, 117146. [Google Scholar] [CrossRef]

- Xiao, M.; Xi, J.; Qiu, P.; Deng, C.; Li, F.; Wei, J.; Gao, P.; Yu, Q. Evaluation of Tensile Properties and Cracking Potential Evolution of Fly Ash-Cement Mortar at Early Age Based On Digital Image Correlation Method. Constr. Build. Mater. 2024, 412, 134855. [Google Scholar] [CrossRef]

- Cai, Y.L.; Wang, F.; Zhao, Z.; Lyu, Z.; Wang, Y.G.; Zou, P. Early-Hydration Heat and Influencing Factor Analysis of Large-Volume Concrete Box Girder Based on Equivalent Age. Structures 2023, 50, 1699–1713. [Google Scholar] [CrossRef]

- Do, T.A.; Tia, M.; Nguyen, T.H.; Hoang, T.T.; Tran, T.D. Assessment of Temperature Evolution and Early-Age Thermal Cracking Risk in Segmental High-Strength Concrete Box Girder Diaphragms. KSCE J. Civ. Eng. 2022, 26, 166–182. [Google Scholar] [CrossRef]

- Qiao, G.; Xue, G.; Zhu, G. A Precise Internal-Stress Calculation Algorithm for the Evolution of Cracking Risk of the Steam-Curing Box Girder. Constr. Build. Mater. 2022, 346, 128463. [Google Scholar] [CrossRef]

- Liu, J.; Liu, Y.J.; Zhang, N.; Ma, Z.Y.; Bai, Y.X. Research On Temperature Action and Cracking Risk of Steel-Concrete Composite Girder During the Hydration Process. Arch. Civ. Mech. Eng. 2020, 20, 47. [Google Scholar] [CrossRef]

- Yu, X.Z.; Chen, J.Y.; Xu, Q.; Zhou, Z. Research on the Influence Factors of Thermal Cracking in Mass Concrete by Model Experiments. KSCE J. Civ. Eng. 2018, 22, 2906–2915. [Google Scholar] [CrossRef]

- Lee, C.; Lee, S.; Nguyen, N. Modeling of Compressive Strength Development of High-Early-Strength-Concrete at Different Curing Temperatures. Int. J. Concr. Struct. Mater. 2016, 10, 205–219. [Google Scholar] [CrossRef]

- Zeng, Y.; Li, X.Q.; Jiang, D.; Ran, J.H. Study On the Effects of Innovative Curing Combinations On the Early Temperature Field of Concrete Box Girders. Buildings 2022, 12, 1808. [Google Scholar] [CrossRef]

- Comite Euro-International du Beton. CEB-FIP Model Code 1990; Thomas Telford Ltd.: London, UK, 1993. [Google Scholar]

- Zhu, B.F. Temperature Stresses and Temperature Control in Mass Concrete, 2nd ed.; China Water Conservancy and Hydropower Press: Beijing, China, 2012. (In Chinese) [Google Scholar]

| Materials | Cement | Coal Fly Ash | Mineral Powder | Sand | Crushed Stone | Water Reducer | Water |

|---|---|---|---|---|---|---|---|

| Mass/kg | 286 | 134 | 57 | 727 | 1046 | 5.72 | 144 |

| Specific heat capacity/ | 0.536 | 0.92 | 0.92 | 0.75 | 0.71 | / | 4.19 |

| 2.22 | 0.23 | 0.26 | 3.08 | 2.91 | / | 0.6 |

| Age of Concrete/d | Compressive Strength/MPa | Splitting Tensile Strength/MPa | Tensile Strength/MPa | Modulus of Elasticity/MPa |

|---|---|---|---|---|

| 2 | 32.3 | 2.32 | 4.218 | |

| 3 | 38.7 | 3.04 | 4.319 | |

| 5 | 49.3 | 3.33 | 4.422 | |

| 7 | 55.2 | 3.77 | 4.477 | |

| 28 | 68.1 | 4.48 | \ |

| Construction Phase | Time (h) | Step Size (h) |

|---|---|---|

| Floor pouring stage | 1 | 1/6 |

| Web pouring stage | 1 | 1/6 |

| Roof pouring stage | 2 | 1/3 |

| Curing stage 1 | 40 | 1 |

| Curing stage 2 | 160 | 2 |

| Scheme | Concrete Surface Wetting | Concrete Pouring Temperature | Internal Surface Ventilation of Box Girder |

|---|---|---|---|

| 1 | √ | 20 | 1 m/s |

| 2 | √ | 24 | 1 m/s |

| 3 | √ | 24 | 4 m/s |

| Structure | Materials | Amount of Material | Unit Material Cost | Cost of Various Materials/Thousand Yuan | Total Cost/ Thousand Yuan | ||

|---|---|---|---|---|---|---|---|

| m3 | t | Yuan/m3 | Yuan/t | ||||

| 5 m test section | C55 concrete | 34.11 | 399.72 | 13.6 | 61.6 | ||

| reinforcement | 15.32 | 3132 | 48.0 | ||||

| 80 m box girder structure | C55 concrete | 1079.87 | 399.72 | 431.6 | 1753.4 | ||

| reinforcement | 268.54 | 3132 | 841.1 | ||||

| 71.44 | 6729 | 480.7 | |||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, T.; Cai, J.; Feng, Q.; Jia, W.; He, Y. Experimental Study and Numerical Analysis of Hydration Heat Effect on Precast Prestressed Concrete Box Girder. Buildings 2025, 15, 859. https://doi.org/10.3390/buildings15060859

Wang T, Cai J, Feng Q, Jia W, He Y. Experimental Study and Numerical Analysis of Hydration Heat Effect on Precast Prestressed Concrete Box Girder. Buildings. 2025; 15(6):859. https://doi.org/10.3390/buildings15060859

Chicago/Turabian StyleWang, Tianyu, Jinbiao Cai, Qian Feng, Weizhong Jia, and Yongchao He. 2025. "Experimental Study and Numerical Analysis of Hydration Heat Effect on Precast Prestressed Concrete Box Girder" Buildings 15, no. 6: 859. https://doi.org/10.3390/buildings15060859

APA StyleWang, T., Cai, J., Feng, Q., Jia, W., & He, Y. (2025). Experimental Study and Numerical Analysis of Hydration Heat Effect on Precast Prestressed Concrete Box Girder. Buildings, 15(6), 859. https://doi.org/10.3390/buildings15060859