Wood Frame Walls Designed with Low Water Vapour Diffusion Resistance Wind Shields

Abstract

1. Introduction

- What is the minimum required wind-shield to vapour-retarder ratio for biobased wall constructions when the wind-shield Z-value is lower than 1 (m2·s·GPa)/kg?

- How much do these minimum requirements change in relation to the indoor moisture load from humidity class 1 to 3 and for different wall U-values?

- Are there significant differences between the use of various biobased insulation materials in relation to the effect of the indoor moisture load and wall U-value?

2. Materials and Methods

2.1. Wood Frame Wall

2.2. Material Properties

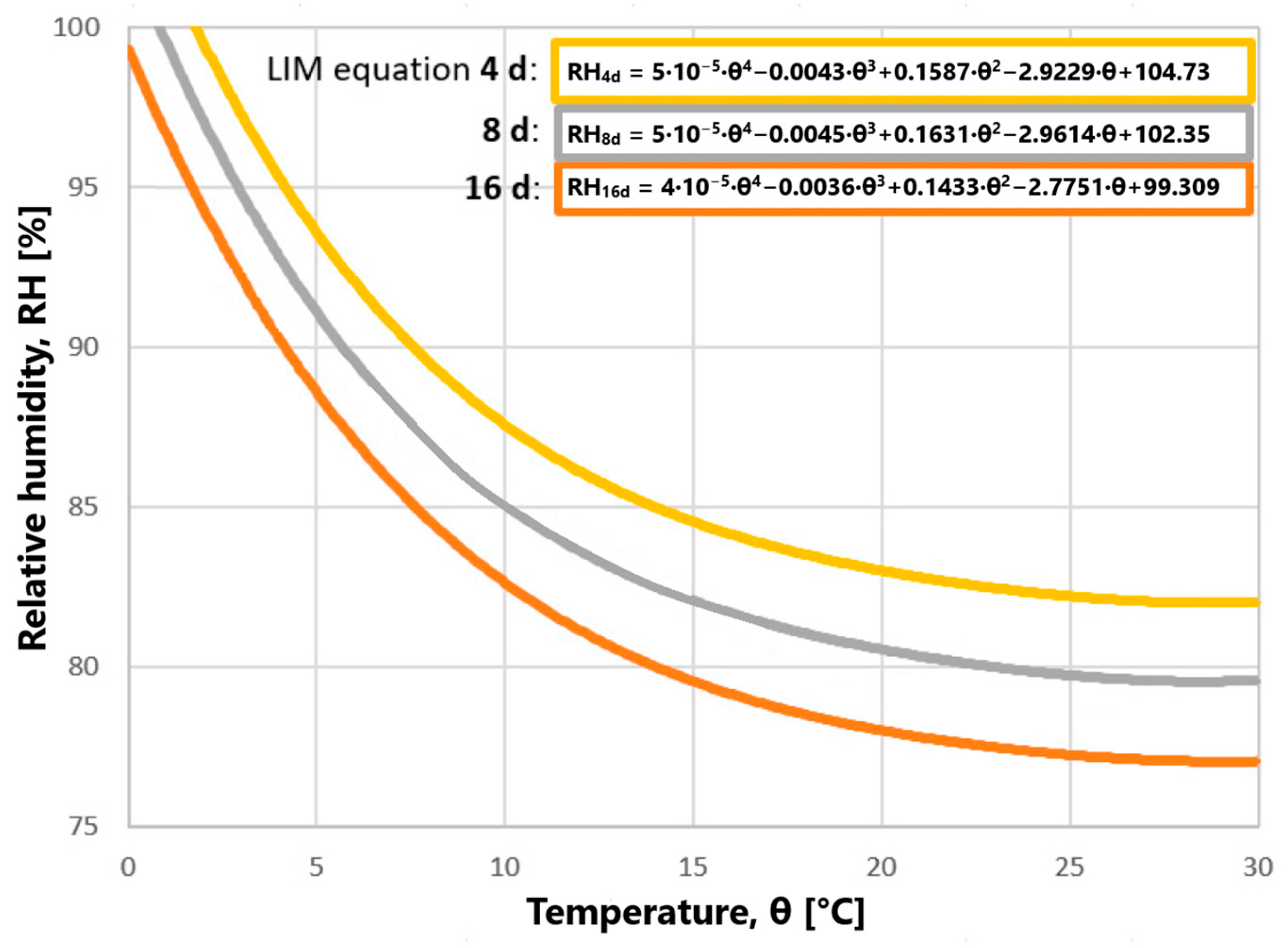

2.3. Boundary Conditions

2.4. Model Configurations

2.5. Mould Growth Evaluation

3. Results

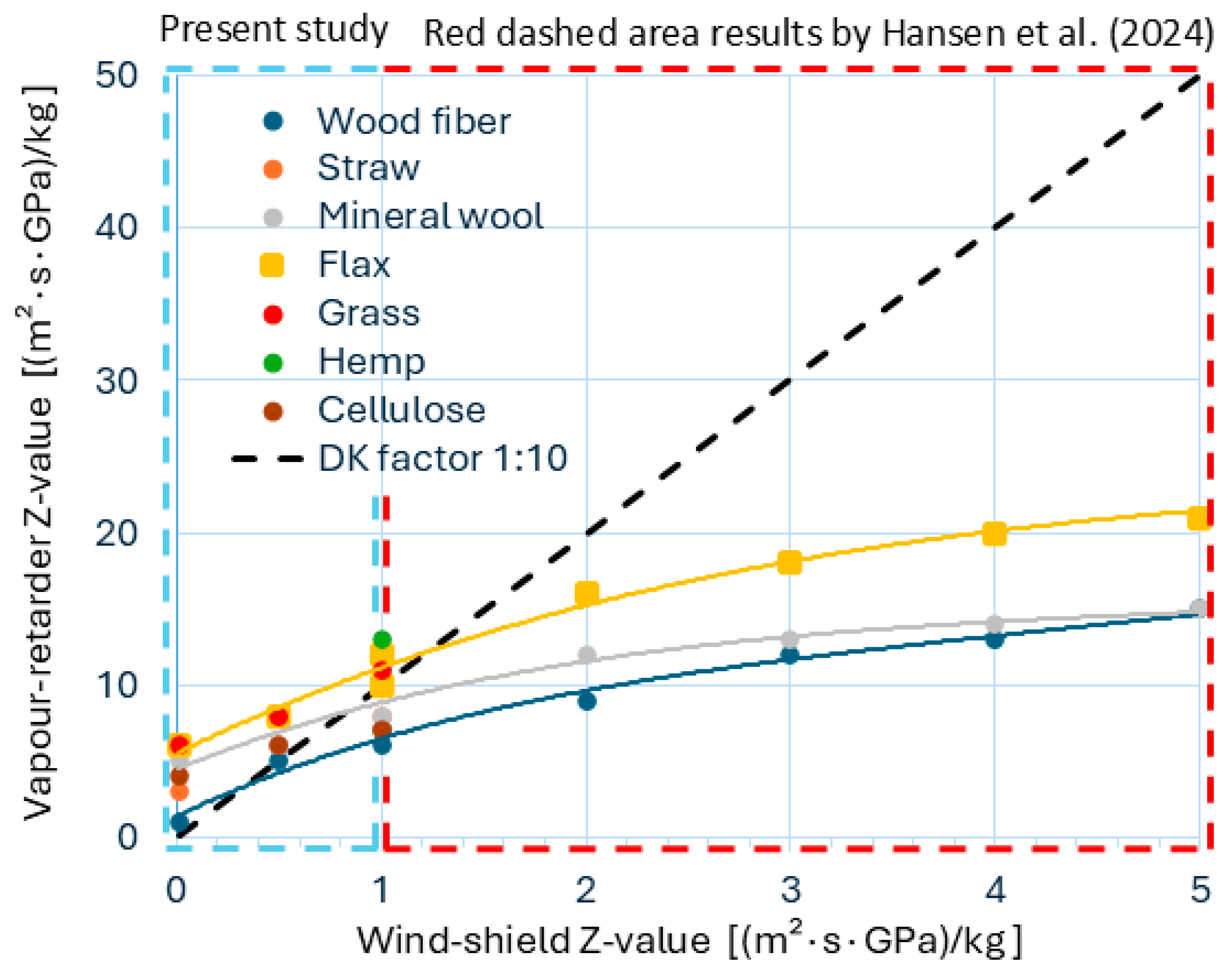

4. Discussion

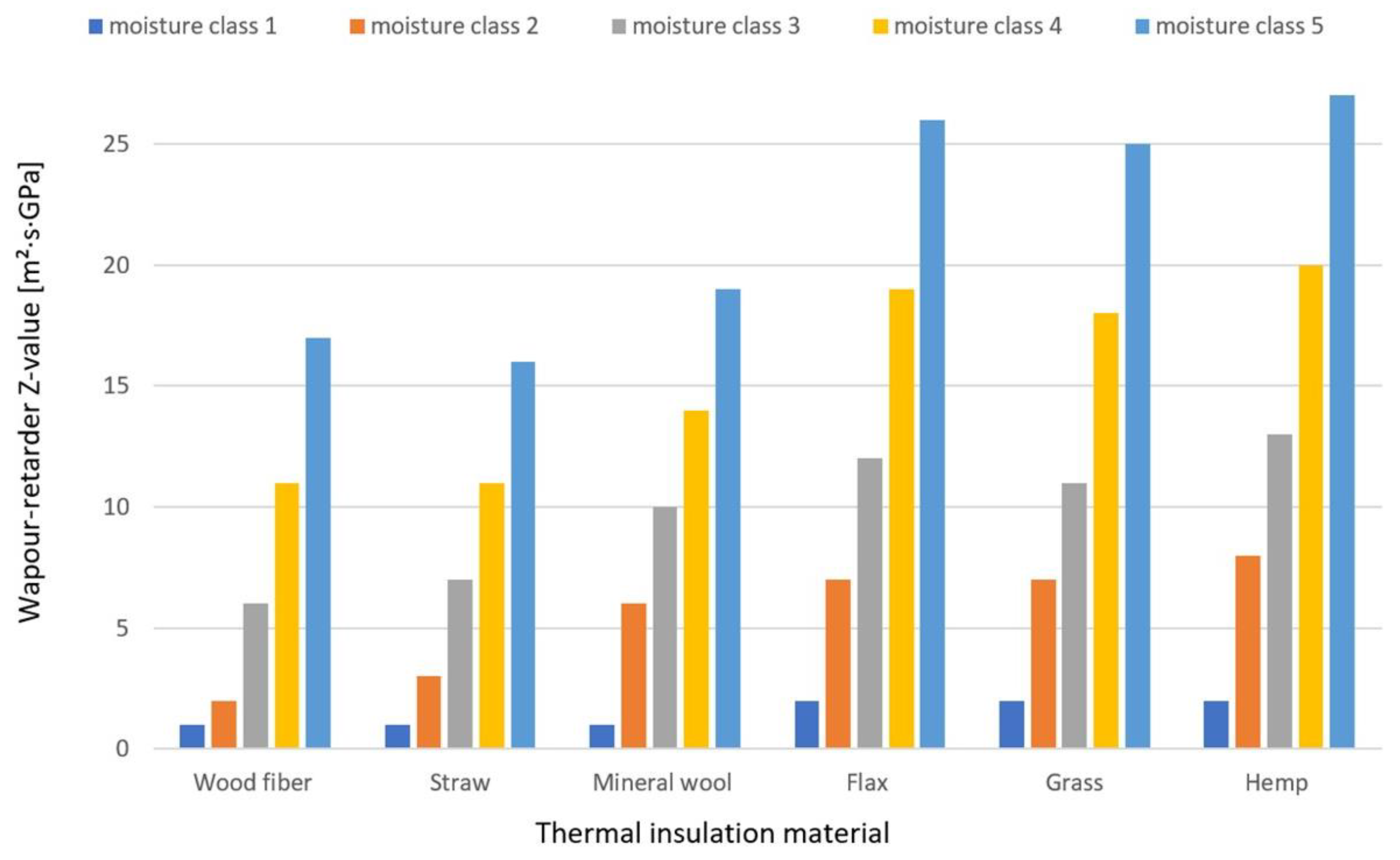

4.1. Water Vapour Diffusion Resistance Ratio vs. Insulation Materials

4.2. Effect of Indoor Moisture Load and Heat Loss Transmission Through the Wall Structure

4.3. Water Vapour Diffusion Resistance Ratio

5. Conclusions

- The necessary vapour-retarder Z-value decreases with a decreasing wind-shield Z-value approaching a fixed value, depending on the thermal insulation material used, the indoor moisture load exposure, and the wall U-value.

- The ratio between the wind-shield Z-value and the vapour-retarder Z-value increases with a decreasing wind-shield Z-value. Moreover, the ratio of 1:10 recommended in Danish best practice guidelines was found to be insufficient for constructions exposed to indoor humidity class 3 using a wind-shield Z-value of 1 (m2·s·GPa)/kg or less, potentially resulting in mould growth.

- The necessary vapour-retarder Z-value increases with an increasing indoor moisture load.

- The necessary vapour-retarder Z-value increases with a decreasing wall U-value.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Dagens Byggeri. Råstofforbruget Skal Ned—Og Udfordringen Skal Løses I Fællesskab. Available online: https://dagensbyggeri.dk/materialer/rastofforbruget-skal-ned-og-udfordringen-skal-loses-i-faellesskab/ (accessed on 13 December 2024).

- Rasmussen, T.V.; Thybring, E.E.; Munch-Andersen, J.; Nord-Larsen, T.; Jørgensen, U.; Gottlieb, S.C.; Bruhn, A.; Rasmussen, B.; Beim, A.; Ramsgaard, T. BUILD Rapport Bind 1 Nr. 2022:09—Biogene Materialers Anvendelse I Byggeriet (Danish). Copenhagen, Denmark, 2022. Available online: https://vbn.aau.dk/ws/portalfiles/portal/467134787/BUILD_Rapport_2022.09.pdf (accessed on 13 December 2024).

- Brandt, E.; Bunch-Nielsen, T.; Hansen, T.K.; Morelli, M.; Nielsen, A. SBi Anvisning 277—Fugt I Bygninger: Teori, Beregning Og Undersøgelse (Danish); Aalborg University: Copenhagen, Denmark, 2023. [Google Scholar]

- DS/EN ISO 13788; Hygrothermal Performance of Building Components and Building Elements—Internal Surface Temperature to Avoid Critical Surface Humidity and Interstitial Condensation—Calculation Methods. Dansk Standard/Danish Standards: Charlottenlund, Denmark, 2013.

- TBST. Bygningsreglementet 2018: Energiforbrug (§ 250–§ 298) (Danish) (Danish Building Regulations 2018: Energy Consumption). Available online: http://bygningsreglementet.dk/Tekniske-bestemmelser/11/Krav/257 (accessed on 12 August 2019).

- Quirouette, R.L. The Difference Between a Vapour Barrier and an Air Barrier; National Research Council Canada: Ottawa, ON, Canada, 1985. [Google Scholar] [CrossRef]

- Rasmussen, T.V.; Hansen, T.K.; Shashoua, Y.; Ottosen, L.M.; Pedersen, L.G.; Nielsen, J.K.; Steenstrup, F.R. Performance of Polyethylene Vapor Barrier Systems in Temperate Climates. Buildings 2022, 12, 1768. [Google Scholar] [CrossRef]

- Rasmussen, T.V.; Hansen, T.K.; Nielsen, J.K.; Steenstrup, F.R.; Ottosen, L.M.; Petersen, L.G.; Shashoua, Y. Long-term Performances of New and Regenerated Polyethylene Membranes Used as Vapor Barriers in Temperate Climates. In Thermal Performance of the Exterior Envelopes of Whole Buildings, Proceedings of the 2022 Thermal Performance of the Exterior Envelopes of Whole Buildings XV International Conference, Clearwater Beach, FL, USA, 5–8 December 2022; American Society of Heating, Refrigeration, and Air-Conditioning Engineers (ASHRAE): Clearwater Beach, FL, USA, 2022; pp. 157–165. Available online: https://vbn.aau.dk/files/504297553/2_1101_Paper_Long_term_performances_of_PE.pdf (accessed on 22 February 2024).

- Rasmussen, T.V.; Thybring, E.E.; Bentsen, N.S.; Nord-Larsen, T.; Jørgensen, U.; Bruhn, A.; Gottlieb, S.C. Negative Emission Potentials Using Biogenic Building Materials—A Case Study from Denmark. In Proceedings of the XVI International Conference on Durability of Building Materials and Components, DBMC 2023, Beijing, China, 10–13 October 2023; Scipedia, S.L.: Beijing, China, 2023; pp. 10–13. [Google Scholar] [CrossRef]

- Rasmussen, T.V.; Nicolajsen, A. Assessment of the performance of organic and mineral-based insulation products used in exterior walls and attics in dwellings. Build. Environ. 2007, 42, 829–839. [Google Scholar] [CrossRef]

- Vinha, J. Hygrothermal Performance of Timber-Framed External Walls in Finnish Climatic Conditions: A Method for Determining the Sufficient Water Vapour Resistance of the Interior Lining of a Wall Assembly. Ph.D. Thesis, Tampere University of Technology, Tampere, Finland, 2007. [Google Scholar]

- Therkelsen, M. MASTER I BYGNINGSFYSIK Dampspaerre i Lette Ydervaegge. 2015. Available online: https://kbdk-aub.primo.exlibrisgroup.com/discovery/fulldisplay?docid=alma9921567361005762&context=L&vid=45KBDK_AUB:DDPB&lang=da&search_scope=Projekter&adaptor=Local%20Search%20Engine&tab=ProjekterSpecialer&query=lds18,exact,Master%20i%20Bygningsfysik,AND&query=any,contains,Therkelsen,AND&sortby=date_d&mode=advanced&offset=0. (accessed on 22 February 2024).

- Morelli, M.; Rasmussen, T.V.; Therkelsen, M. Exterior Wood-Frame Walls—Wind—Vapour Barrier Ratio in Denmark. Buildings 2021, 11, 428. [Google Scholar] [CrossRef]

- Borodinecs, A.; Jacnevs, V.; Ákos, L.; Gendelis, S. Hygrothermal performance of well-insulated wood-frame walls in Baltic climatic conditions. Case Stud. Therm. Eng. 2025, 66, 105772. [Google Scholar] [CrossRef]

- Leszmann, A.E.; Morelli, M.; Rasmussen, T.V. Moisture Performance Requirements for Insulation in Exterior Wood-Frame Walls without a Vapour Barrier. J. Phys. Conf. Ser. 2023, 2654, 012115. [Google Scholar] [CrossRef]

- Bunkholt, N.S.; Rüther, P.; Gullbrekken, L.; Geving, S. Effect of forced convection on the hygrothermal performance of a wood frame wall with wood fibre insulation. Build. Environ. 2021, 195, 107748. [Google Scholar] [CrossRef]

- Pihelo, P.; Kalamees, T. The effect of thermal transmittance of building envelope and material selection of wind barrier on moisture safety of timber frame exterior wall. J. Build. Eng. 2016, 6, 29–38. [Google Scholar] [CrossRef]

- Vanpachtenbeke, M.; Van Den Bulcke, J.; Van Acker, J.; Roels, S. Hygrothermal performance of timber frame walls with brick veneer cladding: A parameter analysis; Hygrothermal performance of timber frame walls with brick veneer cladding: A parameter analysis. E3S Web Conf. 2020, 172, 07002. [Google Scholar] [CrossRef]

- Korsnes, S.; Time, B.; Vågen, M.; Halstedt, H.; Geving, S.; Holme, J. Moisture risk in prefabricated wooden wall elements (TES-elements) with a vapour retarder of OSB/3. In Proceedings of the 6th Passive House Conference in the Nordic Countries, Göteborg, Sweden, 15–17 October 2013; pp. 336–348. [Google Scholar]

- Vanpachtenbeke, M.; Langmans, J.; Van Den Bulcke, J.; Van Acker, J.; Roels, S. On the hygrothermal behaviour of brick veneer cladded timber frame walls: The role of the vapour diffusion resistance of the wind barrier. In Proceedings of the Healthy, Intelligent and Resilient Buildings and Urban Environments 7th International Building Physics Conference, Syracuse, NY, USA, 24 September 2018; pp. 235–240. [Google Scholar] [CrossRef]

- Boverket. Boverkets Byggregler, BBR: BFS 2011:6 Med Ändringar Till Och Med BFS 2020:4 (Swedish); Swedish Building Code; Boverket: Karlskrona, Sweden, 2020. [Google Scholar]

- Simonson, C.J.; Ojanen, T.; Salonvaara, M. Moisture performance of an airtight, vapor-permeable building envelope in a cold climate. J. Therm. Envel. Build. Sci. 2005, 28, 205–226. [Google Scholar] [CrossRef]

- Hansen, S.S.; Thomsen, M.A.; Morelli, M.; Rasmussen, T.V. Requirements of the Vapour Barrier in Wood-Frame Walls. Buildings 2024, 14, 3186. [Google Scholar] [CrossRef]

- DS/EN ISO 12572:2016; Hygrothermal Performance of Building Materials and Products—Determination of Water Vapour Transmission Properties—Cup Method. Dansk Standard/Danish Standards: Charlottenlund, Denmark, 2016.

- Jensen, N.F.; Hansen, T.K.; Morelli, M.; Svane, A.M.; Waagepetersen, R. BUILD Rapport 2023:11 Klimadata Til Fugtsimuleringer Referenceår. 2023. Available online: https://vbn.aau.dk/files/552436442/Klimadata_til_fugtsimuleringer.pdf (accessed on 13 February 2025).

- Jensen, N.F.; Hansen, T.K.; Svane, A.M.; Morelli, M.; Waagepetersen, R. Climate data for moisture simulations: Producing a Danish moisture reference year and comparison with previously used reference year locations. J. Phys. Conf. Ser. 2023, 2654, 012029. [Google Scholar] [CrossRef]

- De Place Hansen, E.J.; Møller, E.B. Moisture supply in Danish single-family houses—The influence of building style. Energy Procedia 2017, 132, 147–152. [Google Scholar] [CrossRef]

- Møller, E.B.; De Place Hansen, E.J. Moisture supply in Danish single-family houses—The influence of occupant behavior and type of room. Energy Procedia 2017, 132, 141–146. [Google Scholar] [CrossRef]

- Mundt-Petersen, S.O. Moisture Safety in Wood Frame Buildings—Blind Evaluation of the Hygrothermal Calculation Tool WUFI Using Field Measurements and Determination of Factors Affecting the Moisture Safety. Ph.D. Thesis, Lund University, Lund, Sweden, 2015. [Google Scholar]

- Sedlbauer, K. Prediction of Mould Fungus Formation on the Surface of and Inside Building Components. Ph.D. Thesis, Stuttgart University, Stuttgart, Germany, 2001. Available online: https://www.ibp.fraunhofer.de/content/dam/ibp/en/documents/ks_dissertation_etcm1021-30729.pdf (accessed on 22 February 2024).

- Johansson, P.; Lång, L.; Capener, C.M. How well do mould models predict mould growth in buildings, considering the end-user perspective? J. Build. Eng. 2021, 40, 102301. [Google Scholar] [CrossRef]

- Stanek, K.; Richter, J.; Pavlickova, N. Measurements of water vapour permeability of oriented strand boards. J. Phys. Conf. Ser. 2022, 2341, 012016. [Google Scholar] [CrossRef]

| Thermal Insulation Material | Thermal Conductivity [W/(m·K)] | Thermal Conductivity and Wooden Frame [W/(m·K)] | Thermal Insulation Thickness, Main Layer [m] | Transmission Coefficient of an Exterior Wall, U-Value [W/(m2·K)] |

|---|---|---|---|---|

| Mineral wool | 0.034 | 0.040 | 0.205/0.330 | 0.15/0.10 |

| Flax | 0.038 | 0.044 | 0.230/0.370 | 0.15/0.10 |

| Grass | 0.040 | 0.046 | 0.240/0.380 | 0.15/0.10 |

| Wood fibre | 0.038 | 0.044 | 0.230/0.360 | 0.15/0.10 |

| Straw | 0.048 | 0.053 | 0.285/0.450 | 0.15/0.10 |

| Cellulose (loose fill) | 0.037 | 0.043 | 0.220/0.350 | 0.15/0.10 |

| Thermal Insulation Material | Density [kg/m3] | Porosity [m3/m3] | Heat Capacity [J/(kg·K)] | Thermal Conductivity [W/(m·K)] | Water Vapour Resistance Factor µ [-] | Moisture Capacity at 100% RH [kg/m3] |

|---|---|---|---|---|---|---|

| Mineral wool | 20 | 0.992 | 850 | 0.034 | 1.3 | 372 |

| Flax | 38 | 0.95 | 1660 | 0.037 | 1.5 | 348 |

| Grass | 40 | 0.95 | 1700 | 0.040 | 1 | 46 |

| Wood fibre | 50 | 0.97 | 2100 | 0.038 | 4 | 300 |

| Straw | 100 | 0.9 | 2000 | 0.048 | 2 | 95.6 |

| Cellulose (loose-fill) | 55 | 0.93 | 2544 | 0.037 | 2 | 494 |

| Air cavity | 1.3 | 0.999 | 1000 | 0.155 | 0.51 | 0.017 |

| Gypsum board * | 625 | 0.706 | 870 | 0.16 | 7.03 | 430.6 |

| Vapour retarder * | 130 | 0.001 | 2300 | 2.3 | 2000 | 0.047 |

| Wind shield * | 1153 | 0.520 | 1200 | 0.32 | 22.2 | 502 |

| Simulation | Thickness [mm] | Z-Value [(m2·s·GPa)/kg] | sd-Value [m] | µ [-] |

|---|---|---|---|---|

| Vapour retarder | 1 | 10 | 2.0 | 2000 |

| Vapour retarder | 1 | 8 | 1.6 | 1600 |

| Vapour retarder | 1 | 7 | 1.4 | 1400 |

| Vapour retarder | 1 | 6 | 1.2 | 1200 |

| Vapour retarder | 1 | 5 | 1.0 | 1000 |

| Vapour retarder | 1 | 4 | 0.8 | 800 |

| Vapour retarder | 1 | 3 | 0.6 | 600 |

| Vapour retarder | 1 | 2 | 0.4 | 400 |

| Vapour retarder | 1 | 1 | 0.2 | 200 |

| Wind shield | 9 | 1 | 0.2 | 22.2 |

| Wind shield | 9 | 0.5 | 0.1 | 11.1 |

| Wind shield | 9 | 0.2 | 0.04 | 4.4 |

| Wind shield | 9 | 0.1 | 0.02 | 2.2 |

| Wind shield | 9 | 0.01 | 0.0003 | 0.02 |

| Thermal Insulation Material | Vapour-Retarders Z-Value [(m2·s·GPa)/kg] | ||||

|---|---|---|---|---|---|

| U-Value 0.15 W/(m2·K) | U-Value 0.10 W/(m2·K) | ||||

| IHC 1 | IHC 2 | IHC 3 | IHC 2 | IHC 3 | |

| Wood fibre | <1/<1/1 | 0.05/<2 **/2 | 1/3/7 | 1/1/3 | 1/4/8 |

| Straw | <0.5/<1/1 | 0.5/2/3 | 3/6/8 | 1/2/4 | 4 */6/10 |

| Mineral wool | <1/<1/1 | 2/4/5 | 5/6/8 | 3/4/5 | 6/8/10 |

| Flax | <1/<1/1 | 2/4/6 | 6/8/10 | 3/5/7 | 8/10/13 |

| Grass | <1/<1/2 | 3/5/6 | 6/8/10 | 4/5/6 | 7/10/12 |

| Cellulose (loose fill) | <1/<1/1 | 1/2/3 | 4/6/7 | 1/3/4 | 4/7/10 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jensen, N.F.; Rasmussen, T.V.; Hofmann, L. Wood Frame Walls Designed with Low Water Vapour Diffusion Resistance Wind Shields. Buildings 2025, 15, 706. https://doi.org/10.3390/buildings15050706

Jensen NF, Rasmussen TV, Hofmann L. Wood Frame Walls Designed with Low Water Vapour Diffusion Resistance Wind Shields. Buildings. 2025; 15(5):706. https://doi.org/10.3390/buildings15050706

Chicago/Turabian StyleJensen, Nickolaj Feldt, Torben Valdbjørn Rasmussen, and Lars Hofmann. 2025. "Wood Frame Walls Designed with Low Water Vapour Diffusion Resistance Wind Shields" Buildings 15, no. 5: 706. https://doi.org/10.3390/buildings15050706

APA StyleJensen, N. F., Rasmussen, T. V., & Hofmann, L. (2025). Wood Frame Walls Designed with Low Water Vapour Diffusion Resistance Wind Shields. Buildings, 15(5), 706. https://doi.org/10.3390/buildings15050706