1. Introduction

The global construction industry is undergoing a significant transformation fueled by rapid technological advancements, urbanization, and the growing demand for sustainable building practices. OSC has emerged as a progressive approach involving designing and producing components in a factory and then installing them in their final positions on construction sites [

1]. OSC is used to build affordable housing, and infrastructure projects like tunnels, bridges, and modular public facilities, addressing social needs for affordable housing and accessible public spaces [

2]. Its precise manufacturing reduces waste, enhances safety, and improves sustainability, offering cost savings over traditional methods through automation and energy efficiency [

3].

Unlike traditional construction practices, OSC demands greater integration and information exchange among stakeholders, encompassing manufacturers, designers, suppliers, transporters, and assembly teams [

4]. Additionally, the decentralized nature of OSC workflows underscores the importance of effective communication and collaboration to ensure projects are delivered on time, within budget, and in accordance with the specified requirements [

5]. Information sharing acts as the backbone of OSC projects, enabling synchronized decision-making, streamlined operations, and reduced risks associated with miscommunication.

Previous studies on OSC in the construction industry have focused on areas like digital technology applications, such as building information modeling (BIM) [

6,

7,

8], supply chain management [

9,

10,

11], and OSC research methodologies [

12]. However, most research treats information sharing as secondary, focusing instead on trends, benefits, and challenges, with limited systematic reviews of stakeholders’ information needs. Consequently, a conspicuous gap exists in our understanding of information sharing within OSC among stakeholders. To address this gap, this study systematically reviews the existing literature, exploring information sharing needs, sources, barriers, and strategies for improvement across various stages of the OSC process. Within this context, the following review questions (RQs) are put forward:

RQ-1: What are the key aspects of information sharing in OSC?

RQ-2: What factors hinder information sharing in OSC?

RQ-3: What are the potential strategies to improve information sharing in the OSC industry?

As a result, this paper has two main objectives: (i) to investigate various aspects of information sharing in OSC, including the factors that hinder its effectiveness and potential ways to improve it; and (ii) to pinpoint future research directions within this field. Consequently, this systematic literature review (SLR) consolidates existing knowledge on information sharing in OSC, laying the foundation for a conceptual framework and offering recommendations for further research. The subsequent sections are organized as follows:

Section 2 provides the background, while

Section 3 details the methodology. Following this,

Section 4 presents the results of descriptive and qualitative analyses. This study’s discussion is covered in

Section 5, the limitations and future directions are discussed in

Section 6, and conclusions are drawn in

Section 7.

2. Background

2.1. Information Sharing in Construction Supply Chains

Information sharing involves exchanging data among various organizations during transactions or collaborations [

13]. It is crucial for supply chain stability and efficiency [

14]. To optimize information sharing, four questions must be addressed: what information to share, who should receive it, how to share it, and when to share it [

15,

16].

Research highlights the benefits of information sharing in supply chains. For example, it can reduce manufacturers’ costs [

17] and inventory costs by 5% to 35%, with no loss in service levels [

18]. However, challenges remain, including confidentiality concerns, incentive alignment, IT reliability and cost, regulatory constraints, and the need for skills to use shared data effectively [

18]. Understanding these benefits and challenges within construction supply chains sets the stage for examining information sharing in specific areas like OSC, which will be discussed next.

2.2. Information Sharing in OSC

Like any supply chain, information sharing is highly significant for the smooth functioning of OSC. However, the industry’s fragmentation, where geographically dispersed participants work towards a common goal, leads to challenges such as inconsistent data communication and accountability issues in sharing project-related information [

19]. Therefore, the development of a robust information sharing platform becomes imperative to facilitate smooth communication without errors and confusion [

20].

Existing studies have identified various stages in the OSC process, with variations in the number and naming of phases. Alfieri et al. 2020 [

21] proposed a comprehensive six-stage framework, which includes project brief, concept design, detailed design, pre-construction, construction, and post-construction. In contrast, Chen et al. 2021 [

22] presented a four-phase model, encompassing design, scheduling, production, and transportation. Sooriyamudalige et al. 2020 [

3] identified six stages: idea generation, design and planning, procurement, manufacturing, transportation, and onsite assembly. For this research, a five-stage framework for OSC will be utilized, based on insights from Jung and Yu 2022 [

23]; it includes design, manufacturing, logistics/transportation, onsite assembly, and handover/completion. This selection provides a clear and structured approach to understanding the OSC process, capturing the sequential flow from design initiation to project handover. These stages reflect a comprehensive view of the OSC lifecycle, highlighting the key interactions among various stakeholders throughout the process [

24,

25]. Categorizing OSC into these five phases aligns with the broader literature and addresses the need for effective information sharing to improve coordination, collaboration, quality assurance, and logistical efficiency in offsite construction projects [

26].

The stakeholders include designers, who specialize in design for manufacture and assembly and who plan and design the offsite components based on the structural and functionality specifications; manufacturers, responsible for producing the building components to be used offsite; transporters, who move the prefabricated components to the construction site; contractors, responsible for the onsite assembly and construction process; and onsite installers, who assemble and install the prefabricated materials [

27]. Each of these stakeholders has unique needs and requirements, including the need to have adequate information needed to perform their tasks. Therefore, there should be efficient collaboration among them to address these needs and ensure the successful completion of the OSC project on time and within budget [

5]. For instance, as manufacturers transport building components to multiple locations, it is essential to coordinate the production process and logistics with the schedules of the construction sites [

28]. Bäckstrand and Fredriksson 2020 [

29] argue that inadequate information sharing can lead to incorrect deliveries, untimely deliveries, material wastage, and the need for rework, all of which can significantly impact construction projects. Luo et al. 2019 [

30] identified issues in OSC due to insufficient information sharing, notably design changes occurring without consulting manufacturers and the main contractor. This results in the production of components based on outdated designs, causing delays [

31]. Exploring diverse information sharing approaches is crucial to addressing this challenge.

2.3. Research Gap

Despite the evident importance of information sharing in OSC, there exists a notable gap in the existing body of research. Previous studies have explored the benefits of OSC but have not delved comprehensively into the nuances of information sharing among stakeholders during the various stages of the OSC process. This research endeavors to bridge this gap by conducting an in-depth examination of information sharing practices among stakeholders. By elucidating the current state of information flow, identifying potential challenges, and proposing effective strategies, this study aims to contribute valuable insights that can inform both academia and industry practitioners.

3. Methodology

This paper conducts an SLR on the OSC and information sharing domain using a typical three-step research methodology. The first step is data collection, which involves identifying keywords and screening articles. The second stage entails descriptive analysis, while the third step involves qualitative discussion and providing recommendations in response to the research questions. This is conducted as per the PRISMA (Preferred Reporting Items for Systematic Reviews and Meta-Analyses) methodology, a widely accepted standard operating procedure for conducting SLRs. The PRISMA methodology involves the following key steps: formulating RQs, selecting relevant databases for article searches, defining inclusion and exclusion criteria, analyzing and synthesizing the selected studies, and presenting the results and discussion [

32]. The RQs are established in

Section 1, while this section outlines the subsequent steps. The final stages, including the results and discussion, are detailed in

Section 4 and

Section 5. Adhering to the PRISMA guidelines ensures accuracy and completeness and minimizes bias in the research process.

3.1. Data Collection

The systematic search starts with the selection of search engines and keywords to find articles. This study used Scopus and Web of Science to search articles relevant to this study. These databases were selected due to their extensive coverage of journals and their inclusion of more recent publications [

33]. Many other studies [

11,

34,

35] have also recommended Scopus and Web of Science in the construction and project management fields. Then, a comprehensive list of relevant and alternative keywords related to OSC and information sharing is used to extract bibliometric data. The research keywords were chosen based on a comprehensive review of prior relevant papers [

10,

12,

25,

36] concerning the definition and concepts of OSC and information sharing. A set of terminology items for OSC and information sharing that are frequently interchanged was identified as the list of keywords. Thus, the following keywords were used in the title, keywords, and abstract search: ((“off-site construction” OR “offsite construction” OR “prefabri*” OR “industriali*ed building” OR “paneli*ed construction” OR “modular construction” OR “tilt up construction” OR “precast” OR “offsite construction” OR “precast construction” OR “tilt-up construction” OR “off-site manufactur*” OR “off site manufactur*” OR “offsite manufactur*”) AND (“information shar*” OR “data shar*” OR “flow of information” OR “information flow*”)).

As of November 2024, the initial search resulted in 228 articles.

Table 1 illustrates the data collection process for the SLR. The next step in this study involves the establishment of inclusion and exclusion criteria to refine the articles obtained and select the relevant ones for analysis. Publications from the preceding decade were considered. This led to the exclusion of 50 articles; thus, the remaining 178 articles were considered for further analysis. Only research from the past decade was considered, as 10 years is commonly used as a standard timeframe for reviewing recent studies [

25,

37]. Moreover, only articles published in the English language were retained. The rationale for choosing studies published in English is based on its dominance in scientific communication and high visibility in the research field [

38]. This led to the exclusion of an additional four articles. Subsequently, strict adherence to peer-reviewed publications was maintained. These studies were chosen for their high credibility, having been reviewed by competent professionals to make them methodologically sound and relevant [

39]. This resulted in the exclusion of 38 papers and a final count of 136 articles.

Within this subset, 51 publications were identified as duplicates and consequently removed. As a result, out of the remaining 85 articles, 2 publications were unretrievable, culminating in a final tally of 83 articles for scrutiny. These articles were further scrutinized, focusing on their abstracts and findings, resulting in 51 papers for comprehensive analysis. Additionally, two articles were included in the sample for full-document review after being identified as relevant to this study through cross-referencing. Accordingly, 53 articles were selected for this study based on the inclusion and exclusion criteria.

3.2. Descriptive Analysis

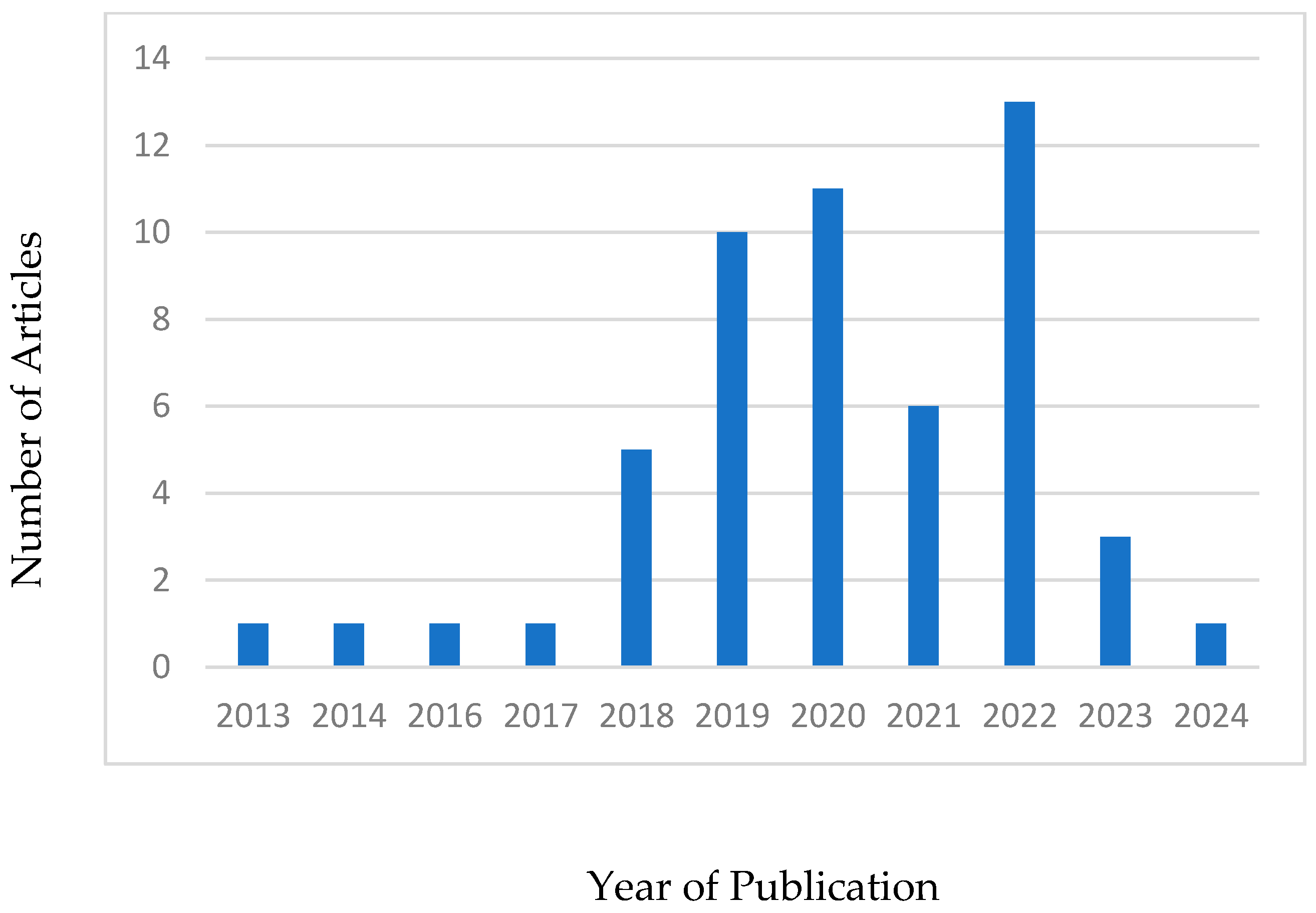

In this stage, the bibliographic statistics of the selected literature were tabulated. It consists of the yearly distribution of publications, article sources, and study locations. This will map the research landscape on this topic, show trends and gaps in the research, and establish the geographical spread of this study.

3.3. Qualitative Analysis

While descriptive analysis offers valuable insights, its capacity for providing an in-depth understanding of the collected data is limited. To gain a more profound comprehension of the data, a qualitative analysis was undertaken to answer the research questions, pinpoint potential research gaps, and ascertain future research requirements. Thematic analysis was used to analyze the publications. Thematic analysis is a way to find patterns and themes in data, helping us understand things better and discover new insights [

40]. Inductive thematic analysis was employed, as this approach is exploratory; it allows the researcher to remain open to new ideas and themes that may emerge from the data [

41].

4. Results

4.1. Results of Descriptive Analysis

Table 2 presents the breakdown of articles based on publication sources. The majority came from journals (92%), with a smaller portion from conference proceedings (8%). Notable journals included

Automation in Construction (eight articles),

Engineering, Construction and Architectural Management (five articles), and

Journal of Cleaner Production (five articles), reflecting a diverse range of perspectives. Additionally, articles were sourced from 22 different journals, highlighting the comprehensive nature of this study. Furthermore, four conference articles were from Proceedings of the Institution of Civil Engineers—Civil Engineering, Management Procurement and Law, International Conference on Computer Supported Cooperative Work in Design, and IOP Conference Series: Earth and Environmental Science. The esteemed reputation of the publication sources instills confidence in the overall quality and credibility of this SLR.

Figure 1 illustrates the trend of articles published between 2013 and 2024, displaying the yearly distribution of publications. The graph demonstrates a steady increase in the number of articles over time, reaching a peak of 13 articles in the year 2022. This indicates a rising interest among researchers in information sharing in OSC, highlighting its growing importance as a research focus. Additionally, the data reveal that 83% (44) of the papers were published within the last 5 years, underscoring the recent surge in scholarly attention to this topic.

Table 3 provides insight into the geographical distribution of the analyzed articles according to their study locations. The data reveal that most articles originate from China (28%), followed by the UK (23%) and the US (11%). Interestingly, most of the publications are from developed countries such as the US, Australia, and the UK. Notably, China contributes the most articles (15), highlighting its substantial presence in the research despite being a developing nation.

4.2. Results of Qualitative Analysis

The selected articles were analyzed using inductive thematic analysis. The process started by reading the selected articles to understand their context to our research on information sharing among the stakeholders in the OSC during different stages. After that, initial codes for sections of the articles that covered key ideas related to the research questions were created. Finally, the themes were reviewed, finalized, and arranged into clear categories representing the different stages of information sharing in the OSC process.

4.2.1. Need for Information Sharing in OSC

OSC presents unique challenges in coordinating dispersed activities and remote stakeholders, which underscores the importance of effective information sharing. Information sharing bridges gaps that arise from conducting these activities at different locations and times, reducing the risk of misalignments, errors, and costly delays [

42,

43]. Unlike traditional construction, where real-time collaboration occurs onsite, OSC demands that remote teams maintain coordination through robust information systems [

4,

44].

Five key reasons justify the need for information sharing in OSC. Firstly, it promotes collaboration and coordination among contractors, designers, and manufacturers, allowing them to streamline processes and work toward shared project goals even from different locations [

6]. Secondly, sharing information acts as a risk mitigation strategy, minimizing errors during crucial stages such as transportation and assembly by ensuring that all stakeholders are aligned [

9]. Thirdly, it facilitates innovation by spreading best practices, emerging technologies, and lessons learned, thus building a foundation for more efficient and effective project execution [

45]. Moreover, optimizing supply chain operations through shared information about lead times, material availability, and logistics enhances resource management and ensures timely deliveries [

9]. Lastly, consistency in information flow supports standardization across design and production phases, leading to higher quality outcomes and adherence to original project specifications [

46].

Effective information sharing throughout the OSC stages ensures that all participants remain fully informed, which is crucial for project coordination and quality assurance. The following section will further explore the specific information needs and sources at each stage of the OSC process.

4.2.2. Information Needs and Its Sources

In OSC, stakeholders need information from various sources to perform effectively. Designers and architects require assembly guidelines, design specifications, and material compatibility [

24]. Builders and contractors need information on project timelines, safety protocols, and construction methods [

47]. Manufacturers require quality standards, production schedules, and component fabrications while suppliers require lead time, pricing, and material availability [

48]. This information is needed at various phases of the project. This section will discuss the information needs and sources within the five stages of OSC projects.

4.2.3. Factors That Act as Barriers to Information Sharing in OSC

In OSC, effective information sharing is paramount for seamless teamwork among all involved [

46]. However, various elements can act as barriers to information sharing making it challenging for stakeholders to share information among them and coordinate multiple processes. Miscommunication is one of the barriers that arise when stakeholders use different types of tools for communication. For example, individuals working on the OSC project come from various cultural and linguistic backgrounds, and this can lead to translation errors or misunderstandings, causing delays further affecting the project’s completion in time [

68].

Secondly, although standards like Industry Foundation Classes exist to streamline digital information sharing, many stakeholders face challenges in adopting them, often preferring traditional methods, leading to data integration issues [

80]. Other barriers include language barriers and cultural disparities. While these barriers may also affect information sharing in onsite construction, their impact is more pronounced in OSC, particularly when working with diverse teams from different geographical locations with varying cultural norms and perceptions of information [

7]. Trust issues among the stakeholders are another factor hindering information sharing. Manufacturing firms often rely on informal channels, this can cause contractual mistrust where other stakeholders doubt the intention of others to meet contractual agreements. For example, suppliers may doubt the manager’s commitment to honor an agreement to pay for the supplies for the offsite construction [

81]. Moreover, when trust is low, various stakeholders may likely hold critical information that could contribute to the success [

74]. Furthermore, OSC involves various stakeholders operating independently utilizing outdated communication methods [

3]. This reduces their ability to communicate transparently.

Addressing the above challenges is pivotal for unlocking the full potential of information sharing in OSC projects.

4.2.4. Strategies to Improve Information Sharing

Adoption of Digital Technologies: The construction industry has generally lagged in adopting digital advancements, critical for improving OSC processes [

82]. Technologies like BIM, cloud platforms, and project management software facilitate data flow and collaboration, centralizing project information to improve transparency and accessibility [

82,

83,

84]. Collaborative contracts further support this by fostering stakeholder trust and encouraging open information sharing [

6]. However, high initial costs and limited technical skills among professionals hinder widespread adoption [

85].

Standardization of Processes and Protocols: Establishing standardized procedures, systems, and documentation will synergize various projects and assist in information sharing between different operations [

86,

87]. This entails developing standard data formats, references, programming protocols, and project management plans. Also, standardization helps present clear and consistent information to the client, reducing the chances of stakeholder mix-ups or misinterpretation [

83]. However, one major challenge of the standardization of protocols and processes is the resistance of stakeholders to changes that would affect their normal way of information sharing [

88].

Collaborative Contracting Practices: Collaborative contracts improve teamwork by establishing shared goals, benefits, and transparent communication among stakeholders [

89,

90]. Despite their advantages, these contracts are not widely adopted, as many stakeholders lack the necessary expertise [

91].

Investment in Training and Education: Offering training and education programs to OSC participants enables them to improve their technical qualifications and communication skills, allowing them to share new information properly [

62,

92]. The training may include BIM workshops, digital collaboration tools training, and effective teamwork among team members [

93,

94]. Organizations can plan for the development of their workforce and provide them with tools to leverage digital technologies and communication strategies to maximize information sharing for OSC projects. However, organizational strategies to build the capacity of various stakeholders may be hit by high costs and limited resources [

92].

Promotion of a Culture of Transparency and Trust: Creating an atmosphere of openness and trust is crucial to presenting information and stimulating communication between OSC members. Facilitating interaction can be achieved through frequent communication channels, with clearly assigned roles and responsibilities, and by providing an atmosphere that creates trust [

4,

95]. Due to trust, stakeholders will not hesitate to exchange information and raise questions whenever necessary [

96]. Achieving trust and transparency in a project may be challenging when leaders who are entitled to implement a culture of trust and transparency are not committed to carrying out the change process and continuous improvement [

95].

5. Discussion

5.1. Discussions on Descriptive Analysis

By analyzing the studies’ publication years, sources, and geographic locations, researchers can identify commonalities, distinctions, and areas for further investigation. The growing number of publications, particularly in the past five years, signifies the increasing recognition of OSC as a critical solution to modern construction challenges.

Despite this upward trend, significant geographic disparities are evident. Research output remains concentrated in developed regions, such as Europe, North America, and parts of Asia, while contributions from developing economies are notably sparse. This lack of representation may be attributed to the limited adoption of OSC technologies, lack of training, and reduced research funding in these regions [

3]. Considering that many emerging economies face pressing infrastructure demands, future research should focus on the unique challenges and opportunities of OSC adoption in these contexts, which could bridge this critical knowledge gap. Furthermore, the diversity of publication sources—spanning construction management, engineering, and supply chain disciplines—reflects a multidisciplinary approach

This study’s findings highlight the need for further exploration of OSC in regions with limited research output. Identifying local challenges and tailoring OSC strategies to these regions can ensure a more globalized adoption of OSC practices. Additionally, the growing focus on multidisciplinary research demonstrates the complexity of OSC projects, requiring collaboration across various expertise areas. These insights guide future research to address the unequal geographic representation and foster an inclusive approach to OSC knowledge development.

5.2. Discussions on Qualitative Analysis

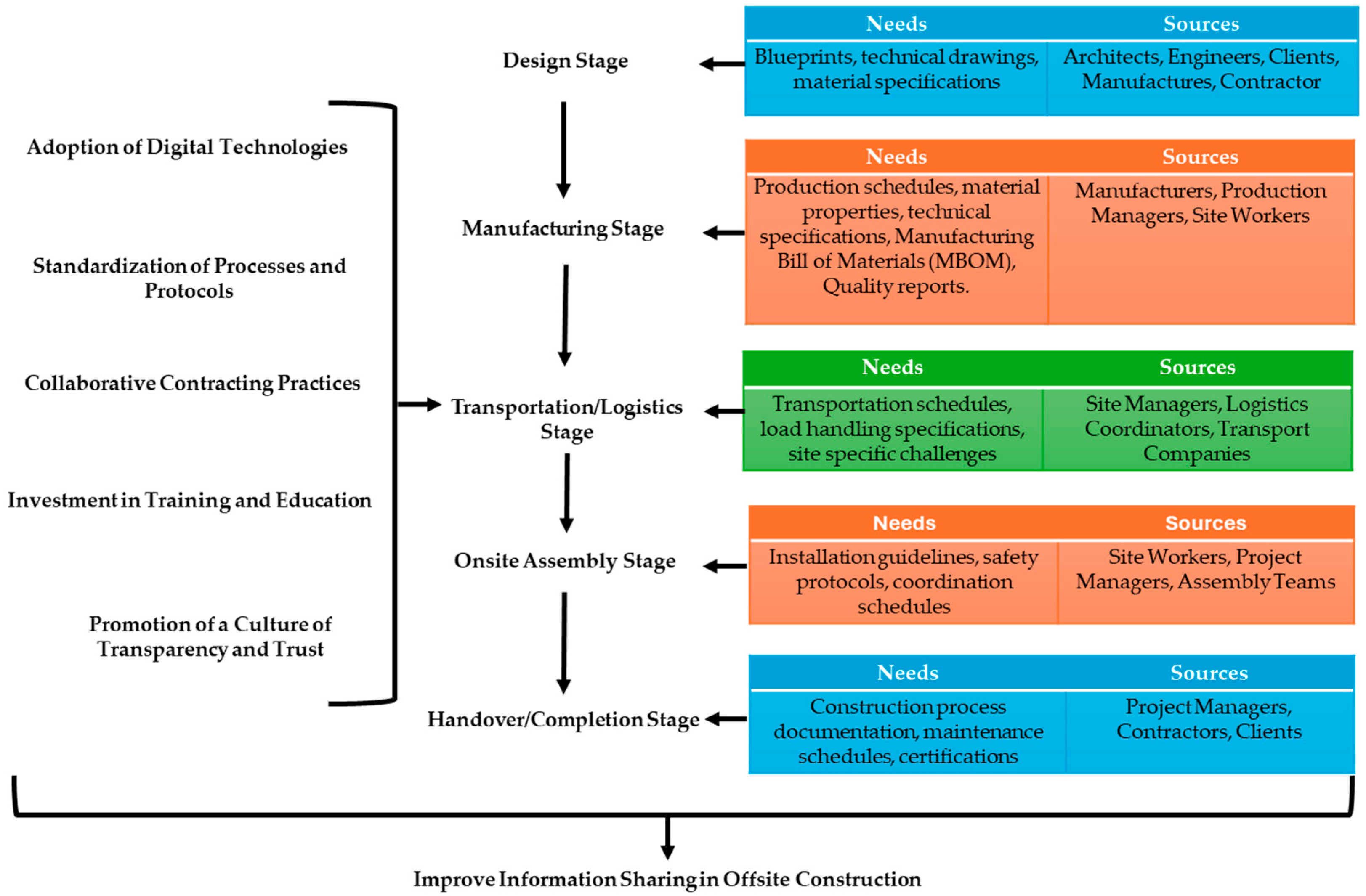

Figure 2 presents a conceptual framework designed to improve information sharing in OSC by incorporating critical factors often overlooked in previous studies. For instance, the inclusion of manufacturer and contractor input during the design stage ensures that practical considerations are embedded early, mitigating downstream inefficiencies [

4]. Similarly, real-time updates to project schedules during manufacturing and detailed site logistics planning—encompassing laydown areas, access points, and transport routes—address logistical bottlenecks that often hinder OSC projects [

5].

The framework also addresses key factors that can improve the information sharing process. Collaborative contracts, such as alliancing and partnering, are included to help align the goals and interests of all parties involved [

97]. Leveraging technology and considering factors like regulatory requirements help to tailor the information sharing process to the needs of the project, making it more efficient and effective [

98].

The findings from this study offer a comprehensive understanding of the importance of information sharing in OSC, highlighting both commonalities and distinctions from existing research on the topic. As highlighted in earlier research [

42,

43], the remote nature of OSC necessitates seamless communication across distributed teams. However, this study goes beyond prior research by identifying specific challenges at each stage of OSC, such as the unique complexities of the logistics and transportation phases. Whereas some studies [

4,

44] discuss the importance of information flow in broader terms, this study provides a nuanced breakdown of information needs at each stage—design, manufacturing, logistics, onsite assembly, and handover/completion—offering a more granular view of the information requirements at each phase. Like previous studies, this research highlights the importance of early-stage collaboration and information flow among stakeholders, to mitigate inefficiencies and delays [

4,

5]. However, the proposed framework introduces new insights by incorporating a broader range of information needs across different project stages.

5.2.1. What Information to Share?

RQ-1 (What are the key aspects of information sharing in OSC?) is addressed by identifying the critical stages and information requirements of OSC projects, including technical specifications during design, quality control measures during manufacturing, logistics details during transportation, and real-time updates during assembly. As highlighted by [

99], the qualitative analysis further explores the nature of information that should be shared with stakeholders at different project stages, as revealed through thematic analysis. This includes market evaluation, feasibility assessments, construction timetables, and safety guidelines. The findings underscore the multifaceted nature of information sharing in OSC, encompassing technical specifications, regulatory requirements, logistics details, and stakeholder feedback, all of which play a crucial role throughout the project lifecycle.

5.2.2. Why Is Information Not Shared?

For RQ-2 (What factors hinder information sharing in OSC?), this study reveals significant barriers, including fragmented supply chains, cultural and linguistic differences, and resistance to adopting digital tools. Miscommunication stemming from these barriers leads to inefficiencies and project delays. Understanding these impediments provides a foundation for developing targeted strategies to enhance collaboration and information exchange among stakeholders.

5.2.3. How to Improve Information Sharing

RQ-3 (What are the potential strategies to improve information sharing in the OSC industry?) is addressed through the proposed strategies in the framework. Recommendations such as adopting digital technologies, standardizing processes, fostering collaborative contractual practices, and investing in training and education are essential to overcoming the identified barriers. Building a culture of transparency and trust further ensures stakeholders are engaged and willing to share critical information.

The conceptual framework developed in this study provides a practical approach for addressing information sharing challenges in OSC. It supports strategic decision-making by enabling stakeholders to determine appropriate technologies and training to improve collaboration. Additionally, it identifies information sharing gaps at each project stage, allowing processes to be adapted to meet unique requirements, thereby enhancing efficiency and effectiveness [

88]. By offering a structured tool for gap analysis and project-specific adaptations, the framework provides valuable insights to ensure that information sharing becomes integral to achieving successful OSC project outcomes.

6. Limitations and Further Research Directions

While this SLT enabled a comprehensive search to cover a wide range of research on the topic of OSC—specifically, studies aligned with the research questions, providing a critical evaluation of their evidence—there were some limitations. First, the publication language was restricted to English. This excluded non-English-language studies that could have valuable evidence for the SLR process [

100]. Secondly, while Scopus and Web of Science contain high-quality journals, restricting the search to these databases could have restricted exposure to other credible papers that cover the topic of study [

33]. Lastly, limiting the search to only peer-reviewed studies ensured the quality of the data collected, this could have also limited exposure to real-case scenarios about information sharing in OSC.

While the conceptual framework provides a foundational basis for advancing research and professional practice in this area, it is derived exclusively from the literature reviewed in this study. As such, it serves as an initial step, necessitating further development to enhance its applicability and effectiveness. Future research should incorporate empirical methods, including interviews, surveys, and case studies, to engage professionals and experts in refining and validating the framework. Such efforts will be critical to ensure its practical relevance and robustness in addressing the complex and dynamic challenges encountered in real-world OSC projects.

Various technologies that support information sharing in OSC projects have emerged. BIM is a technology that helps various stakeholders share information [

69]. It is also valuable in terms of time and cost estimates, which, in turn, help in schedule management to minimize threats of budget and time overruns [

95]. BIM facilitates the efficient production of deliverables, leading to financial gains and enhancing the reputation of construction organizations [

64,

101]. Despite these benefits, these technologies have not been largely implemented in OSC projects. Further comprehensive studies are needed to understand why it has not been largely implemented. Further studies can delve into factors that facilitate and/or hinder seamless collaboration among OSC stakeholders. Future research should also incorporate empirical studies, case analyses, and industry surveys to comprehensively understand information sharing dynamics in real-world construction projects. Additionally, research is needed to focus on emerging technologies like the Internet of Things (IoT) that can further improve information sharing in OSC [

102]. IoT is a network of smart devices that can sense, communicate, and work together [

103]. These devices collect and share data, allowing different applications and services to function smoothly. In the context of OSC, IoT can be utilized to monitor manufacturing processes, track logistics, and ensure quality control.

While information sharing improves OSC project success, it remains underutilized. Future research should explore additional factors contributing to OSC success beyond information sharing, incorporating practical studies, case examples, and organizational data for real-world insights. Understanding stakeholder behavior and attitudes toward information sharing, along with monitoring its long-term impact, will be essential for advancing OSC practices.

7. Conclusions

This systemic literature review has shed light on different aspects of information sharing in OSC projects. The findings of this study show information needs and sources at various stages of the OSC project. At the design stage, stakeholders like architects and engineers need information such as initial design concepts and ensuring compliance with regulatory requirements. Industry reports emerge as a major information source that can be used in analyzing the market implications of OSC and help identify opportunities, threats, and avenues for growth. Having this information guides stakeholders in tailoring construction to meet customer needs and comply with sustainability specifications. Information sources include design software, environmental consultant reports, and supplier catalogs. As the project progresses to the transportation/logistics stage, information needs include logistics details for material transportation and delivery, such information can be accessed from logistics companies and transportation databases. This stage add to the acquisition of various materials, and methods that are used in the OSC project. At the onsite assembly stage, stakeholders need detailed construction schedules, detailed construction schedules and task sequencing, quality control standards and inspection reports, safety protocols and hazard identification as well as real-time progress updates and communication channels from various sources including project management software, and quality control documentation and testing records. Such information enhances the coordination of various processes of construction in the OSC project. Lastly, during the handover stage, various stakeholders including project managers and quality assurance teams, suppliers, manufacturers, warranty providers, facility managers, and maintenance personnel require inspection reports for quality assessment, details for materials and equipment, and operational manuals for facility maintenance. This information can be sourced from inspection reports, quality assurance checklists, supplier and manufacturer documentation, operational manuals from equipment vendors, as well as feedback gathered through stakeholder surveys and discussion sessions.

The findings also highlight that effective collaboration among OSC stakeholders ensures smooth workflows, facilitated by sharing accurate information through appropriate channels. Real-time data integration helps detect issues early and respond proactively, fostering innovation in environmentally sustainable OSC practices. However, challenges like supply chain fragmentation, non-standardization, and communication barriers can hinder information flow, causing inefficiencies and delays. Overcoming these requires strategic use of digital technologies, standardization, collaboration, and a culture of transparency and trust. Future research can further explore these aspects of information management in OSC.

Author Contributions

S.M.: conceptualization, formal analysis, investigation, methodology, visualization, writing—original draft, writing—review and editing. J.J.O.: conceptualization, formal analysis, methodology, supervision, writing—original draft, writing—review and editing. N.G.: conceptualization, formal analysis, supervision, writing—review and editing. R.R.: conceptualization, formal analysis, supervision, writing—review and editing. W.M.: conceptualization, formal analysis, supervision, writing—review and editing. R.M.D.: conceptualization, formal analysis, supervision, writing—review and editing. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The data that support the findings of this study are available within the manuscript.

Acknowledgments

The authors would like to acknowledge the Australian government’s financial support through an Australian Government Research Training Program (RTP) Scholarship for PhD studies and support from the University of South Australia.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Goodier, C.; Gibb, A. Future opportunities for offsite in the UK. Constr. Manag. Econ. 2007, 25, 585–595. [Google Scholar] [CrossRef]

- Sutrisna, M.; Ramnauth, V.; Zaman, A. Towards adopting off-site construction in housing sectors as a potential source of competitive advantage for builders. Archit. Eng. Des. Manag. 2020, 18, 165–183. [Google Scholar] [CrossRef]

- Sooriyamudalige, N.; Domingo, N.; Shahzad, W.; Childerhouse, P. Barriers and enablers for supply chain integration in prefabricated elements manufacturing in New Zealand. Int. J. Constr. Supply Chain. Manag. 2020, 10, 73–91. [Google Scholar] [CrossRef]

- Xue, H.; Zhang, S.; Su, Y.; Wu, Z.; Yang, R.J. Effect of stakeholder collaborative management on off-site construction cost performance. J. Clean. Prod. 2018, 184, 490–502. [Google Scholar] [CrossRef]

- Fathi, M.; Abedi, M.; Rambat, S.; Rawai, S.; Zakiyudin, M. Context-Aware Cloud Computing for Construction Collaboration. J. Cloud Comput. 2012, 2012, 644927. [Google Scholar] [CrossRef]

- Yin, X.; Liu, H.; Chen, Y.; Al-Hussein, M. Building information modelling for off-site construction: Review and future directions. Autom. Constr. 2019, 101, 72–91. [Google Scholar] [CrossRef]

- Wang, M.; Wang, C.C.; Sepasgozar, S.; Zlatanova, S. A Systematic Review of Digital Technology Adoption in Off-Site Construction: Current Status and Future Direction towards Industry 4.0. Buildings 2020, 10, 204. [Google Scholar] [CrossRef]

- Zhang, S.; Li, Z.; Li, T.; Yuan, M. A Holistic Literature Review of Building Information Modeling for Prefabricated Construction. J. Civ. Eng. Manag. 2021, 27, 485–499. [Google Scholar] [CrossRef]

- Hussein, M.; Eltoukhy, A.E.E.; Karam, A.; Shaban, I.A.; Zayed, T. Modelling in off-site construction supply chain management: A review and future directions for sustainable modular integrated construction. J. Clean. Prod. 2021, 310, 127503. [Google Scholar] [CrossRef]

- Han, Y.; Yan, X.; Piroozfar, P. An overall review of research on prefabricated construction supply chain management. Eng. Constr. Archit. Manag. 2022, 30, 5160–5195. [Google Scholar] [CrossRef]

- Masood, R.; Lim, J.; González, V.; Roy, K.; Khan, K. A Systematic Review on Supply Chain Management in Prefabricated House-Building Research. Buildings 2022, 12, 40. [Google Scholar] [CrossRef]

- Ehwi, R.J.; Oti-Sarpong, K.; Shojaei, R.; Burgess, G. Offsite Manufacturing Research: A Systematic Review of Methodologies Used. Constr. Manag. Econ. 2021, 40, 1–24. [Google Scholar] [CrossRef]

- Lee, H.L.; Padmanabhan, V.; Whang, S. Information Distortion in a Supply Chain: The Bullwhip Effect. Manag. Sci. 1997, 50 (Suppl. S12), 1875–1886. [Google Scholar] [CrossRef]

- Zelbst, P.J.; Pelton, L.E.; Green, K.W.; Sower, V.E.; Baker, G. RFID utilization and information sharing: The impact on supply chain performance. J. Bus. Ind. Mark. 2010, 25, 582–589. [Google Scholar] [CrossRef]

- Lotfi, Z.; Mukhtar, M.; Sahran, S.; Zadeh, A.T. Information Sharing in Supply Chain Management. Procedia Technol. 2013, 11, 298–304. [Google Scholar] [CrossRef]

- Sun, S.; Yen, J. Information Supply Chain: A Unified Framework for Information-Sharing. In Lecture Notes in Computer Science, Proceedings of the Intelligence and Security Informatics, Atlanta, GA, USA, 19–20 May; Springer: Berlin/Heidelberg, Germany, 2005; pp. 422–428. [Google Scholar]

- Lee, H.L.; So, K.C.; Tang, C.S. The Value of Information Sharing in a Two-Level Supply Chain. Manag. Sci. 2000, 46, 626–643. [Google Scholar] [CrossRef]

- Zhao, X.; Xie, J.; Zhang, W.J. The impact of information sharing and ordering co-ordination on supply chain performance. Supply Chain. Manag. Int. J. 2002, 7, 24–40. [Google Scholar] [CrossRef]

- Kordestani Ghalenoei, N.; Babaeian Jelodar, M.; Paes, D.; Sutrisna, M. Challenges of offsite construction and BIM implementation: Providing a framework for integration in New Zealand. Smart Sustain. Built Environ. 2022, 13, 780–808. [Google Scholar] [CrossRef]

- Sharma, S.; Sawhney, A.; Arif, M. Parametric Modelling for Designing Offsite Construction. Procedia Eng. 2017, 196, 1114–1121. [Google Scholar] [CrossRef]

- Alfieri, E.; Seghezzi, E.; Sauchelli, M.; Di Giuda, G.M.; Masera, G. A BIM-based approach for DfMA in building construction: Framework and first results on an Italian case study. Archit. Eng. Des. Manag. 2020, 16, 247–269. [Google Scholar] [CrossRef]

- Chen, Q.; Adey, B.T.; Haas, C.T.; Hall, D.M. Exploiting digitalization for the coordination of required changes to improve engineer-to-order materials flow management. Constr. Innov. 2021, 22, 76–100. [Google Scholar] [CrossRef]

- Jung, S.; Yu, J. Design for Manufacturing and Assembly (DfMA) Checklists for Off-Site Construction (OSC) Projects. Sustainability 2022, 14, 11988. [Google Scholar] [CrossRef]

- Sutrisna, M.; Goulding, J. Managing information flow and design processes to reduce design risks in offsite construction projects. Eng. Constr. Archit. Manag. 2019, 26, 267–284. [Google Scholar] [CrossRef]

- Jin, R.; Gao, S.; Cheshmehzangi, A.; Aboagye-Nimo, E. A holistic review of off-site construction literature published between 2008 and 2018. J. Clean. Prod. 2018, 202, 1202–1219. [Google Scholar] [CrossRef]

- Ayinla, K.O.; Cheung, F.; Tawil, A.-R. Demystifying the concept of offsite manufacturing method. Constr. Innov. 2019, 20, 223–246. [Google Scholar] [CrossRef]

- Lee, D.; Wen, L.; Choi, J.O.; Lee, S. Sensor-Integrated Hybrid Blockchain System for Supply Chain Coordination in Volumetric Modular Construction. J. Constr. Eng. Manag. 2023, 149, 04022147. [Google Scholar] [CrossRef]

- Čuš-Babič, N.; Rebolj, D.; Nekrep-Perc, M.; Podbreznik, P. Supply-chain transparency within industrialized construction projects. Comput. Ind. 2014, 65, 345–353. [Google Scholar] [CrossRef]

- Bäckstrand, J.; Fredriksson, A. The role of supplier information availability for construction supply chain performance. Prod. Plan. Control 2020, 33, 863–874. [Google Scholar] [CrossRef]

- Luo, L.; Qiping Shen, G.; Xu, G.; Liu, Y.; Wang, Y. Stakeholder-Associated Supply Chain Risks and Their Interactions in a Prefabricated Building Project in Hong Kong. J. Manag. Eng. 2019, 35, 05018015. [Google Scholar] [CrossRef]

- Durdyev, S.; Hosseini, M.R. Causes of delays on construction projects: A comprehensive list. Int. J. Manag. Proj. Bus. 2019, 13, 20–46. [Google Scholar] [CrossRef]

- Page, M.J.; McKenzie, J.E.; Bossuyt, P.M.; Boutron, I.; Hoffmann, T.C.; Mulrow, C.D.; Shamseer, L.; Tetzlaff, J.M.; Akl, E.A.; Brennan, S.E.; et al. The PRISMA 2020 statement: An updated guideline for reporting systematic reviews. BMJ 2021, 372, n71. [Google Scholar] [CrossRef]

- Pranckutė, R. Web of Science (WoS) and Scopus: The Titans of Bibliographic Information in Today’s Academic World. Publications 2021, 9, 12. [Google Scholar] [CrossRef]

- Rathnayake, I.; Ochoa, J.J.; Gu, N.; Rameezdeen, R.; Statsenko, L.; Sandhu, S. A critical review of the key aspects of sharing economy: A systematic literature review and research framework. J. Clean. Prod. 2024, 434, 140378. [Google Scholar] [CrossRef]

- Wuni, I.Y.; Shen, G.Q.P. Holistic Review and Conceptual Framework for the Drivers of Offsite Construction: A Total Interpretive Structural Modelling Approach. Buildings 2019, 9, 117. [Google Scholar] [CrossRef]

- Hosseini, M.R.; Martek, I.; Zavadskas, E.K.; Aibinu, A.A.; Arashpour, M.; Chileshe, N. Critical evaluation of off-site construction research: A Scientometric analysis. Autom. Constr. 2018, 87, 235–247. [Google Scholar] [CrossRef]

- Ghafoor, S.; Shooshtarian, S.; Udawatta, N.; Gurmu, A.; Karunasena, G.; Maqsood, T. Cost factors affecting the utilisation of secondary materials in the construction sector: A systematic literature review. Resour. Conserv. Recycl. Adv. 2024, 23, 200230. [Google Scholar] [CrossRef]

- Cooper, C.; Booth, A.; Varley-Campbell, J.; Britten, N.; Garside, R. Defining the process to literature searching in systematic reviews: A literature review of guidance and supporting studies. BMC Med. Res. Methodol. 2018, 18, 85. [Google Scholar] [CrossRef] [PubMed]

- Pickering, C.; Byrne, J. The benefits of publishing systematic quantitative literature reviews for PhD candidates and other early-career researchers. High. Educ. Res. Dev. 2014, 33, 534–548. [Google Scholar] [CrossRef]

- Thomas, D.R. A General Inductive Approach for Analyzing Qualitative Evaluation Data. Am. J. Eval. 2016, 27, 237–246. [Google Scholar] [CrossRef]

- Naeem, M.; Ozuem, W.; Howell, K.; Ranfagni, S. A Step-by-Step Process of Thematic Analysis to Develop a Conceptual Model in Qualitative Research. Int. J. Qual. Methods 2023, 22, 16094069231205789. [Google Scholar] [CrossRef]

- Zhang, Z.; Zou, Y.; Guo, B.H.W.; Dimyadi, J.; Davies, R.; Jiang, L. Knowledge management for off-site construction. Autom. Constr. 2024, 166, 105632. [Google Scholar] [CrossRef]

- Ahn, S.; Crouch, L.; Kim, T.W.; Rameezdeen, R. Comparison of Worker Safety Risks between Onsite and Offsite Construction Methods: A Site Management Perspective. J. Constr. Eng. Manag. 2020, 146, 05020010. [Google Scholar] [CrossRef]

- Liu, G.; Nzige, J.H.; Li, K. Trending topics and themes in offsite construction(OSC) research. Constr. Innov. 2019, 19, 343–366. [Google Scholar] [CrossRef]

- Ma, S.; Li, Z.; Li, L.; Yuan, M.; Yin, X. Exploring the Effect of Stakeholder Relationship Quality on Technological Innovation in Off-Site Construction: The Mediating Role of the Knowledge Sharing. J. Civ. Eng. Manag. 2023, 29, 77–92. [Google Scholar] [CrossRef]

- Liu, K.; Su, Y.; Pollack, J.; Liang, H.; Zhang, S. Explaining the Formation Mechanism of Intrateam Knowledge Exchange Network in Offsite Construction Projects: A Social Cognitive Perspective. J. Constr. Eng. Manag. 2022, 148, 04021192. [Google Scholar] [CrossRef]

- Killingsworth, J.; Mehany, M.H.; Ladhari, H. General contractors’ experience using off-site structural framing systems. Constr. Innov. 2020, 21, 40–63. [Google Scholar] [CrossRef]

- Yu, T.; Man, Q.; Wang, Y.; Shen, G.Q.; Hong, J.; Zhang, J.; Zhong, J. Evaluating different stakeholder impacts on the occurrence of quality defects in offsite construction projects: A Bayesian-network-based model. J. Clean. Prod. 2019, 241, 118390. [Google Scholar] [CrossRef]

- Zhang, Z.; Tan, Y.; Shi, L.; Hou, L.; Zhang, G. Current State of Using Prefabricated Construction in Australia. Buildings 2022, 12, 1355. [Google Scholar] [CrossRef]

- Bendi, D.; Rana, M.Q.; Arif, M.; Lamb, S.M.; Sawhney, A.; Kaushik, A.K. Assessing off-site readiness in construction organisations: Cases from India. Constr. Innov. 2021, 22, 320–341. [Google Scholar] [CrossRef]

- Luo, J.; Zhang, H.; Sher, W. Insights into Architects’ Future Roles in Off-Site Construction. Constr. Econ. Build. 2017, 17, 107–120. [Google Scholar] [CrossRef]

- Mao, C.; Xie, F.; Hou, L.; Wu, P.; Wang, J.; Wang, X. Cost analysis for sustainable off-site construction based on a multiple-case study in China. Habitat Int. 2016, 57, 215–222. [Google Scholar] [CrossRef]

- Wang, Y.; Lu, H.; Wang, Y.; Yang, Z.; Wang, Q.; Zhang, H. A hybrid building information modeling and collaboration platform for automation system in smart construction. Alex. Eng. J. 2024, 88, 80–90. [Google Scholar] [CrossRef]

- Gbadamosi, A.-Q.; Oyedele, L.; Mahamadu, A.-M.; Kusimo, H.; Bilal, M.; Davila Delgado, J.M.; Muhammed-Yakubu, N. Big data for Design Options Repository: Towards a DFMA approach for offsite construction. Autom. Constr. 2020, 120, 103388. [Google Scholar] [CrossRef]

- Ginigaddara, B.; Perera, S.; Feng, Y.; Rahnamayiezekavat, P.; Kagioglou, M. Industry 4.0 driven emerging skills of offsite construction: A multi-case study-based analysis. Constr. Innov. 2022, 24, 747–769. [Google Scholar] [CrossRef]

- Lei, Z.; Chen, Q.; Altaf, M.S.; Cao, K. Defining Information Requirements for Off-Site Construction Management: An Industry Case Study from Canada. J. Constr. Eng. Manag. 2024, 150, 05024014. [Google Scholar] [CrossRef]

- Zander, B.; Haasis, H.D.; Lange, K. Designing the Data Supply Chain of a Smart Construction Factory. In Hamburg International Conference of Logistics (HICL); epubli GmbH: Berlin, Germany, 2021. [Google Scholar]

- Ginigaddara, B.; Perera, S.; Feng, Y.; Rahnamayiezekavat, P. Development of an Offsite Construction Typology: A Delphi Study. Buildings 2021, 12, 20. [Google Scholar] [CrossRef]

- Anane, W.; Iordanova, I.; Ouellet-Plamondon, C. Building Information Modeling (BIM) and Robotic Manufacturing Technological Interoperability in Construction—A Cyclic Systematic Literature Review. Digit. Manuf. Technol. 2023, 3, 1–29. [Google Scholar] [CrossRef]

- Hou, L.; Tan, Y.; Luo, W.; Xu, S.; Mao, C.; Moon, S. Towards a more extensive application of off-site construction: A technological review. Int. J. Constr. Manag. 2022, 22, 2154–2165. [Google Scholar] [CrossRef]

- Nesarnobari, S.; Shahzad, W.; Jelodar, M.B.; Sutrisna, M. Investigation of the Effects of Supply Chain Disruptions on Offsite Construction Projects. In Advances in Engineering Management, Innovation, and Sustainability; Lecture Notes in Civil Engineering; Springer: Cham, Switzerland, 2024; pp. 161–172. [Google Scholar]

- Jang, J.; Ahn, S.; Cha, S.H.; Cho, K.; Koo, C.; Kim, T.W. Toward productivity in future construction: Mapping knowledge and finding insights for achieving successful offsite construction projects. J. Comput. Des. Eng. 2021, 8, 1–14. [Google Scholar] [CrossRef]

- Tang, S.; Shelden, D.R.; Eastman, C.M.; Pishdad-Bozorgi, P.; Gao, X. A review of building information modeling (BIM) and the internet of things (IoT) devices integration: Present status and future trends. Autom. Constr. 2019, 101, 127–139. [Google Scholar] [CrossRef]

- Bortolini, R.; Formoso, C.T.; Viana, D.D. Site logistics planning and control for engineer-to-order prefabricated building systems using BIM 4D modeling. Autom. Constr. 2019, 98, 248–264. [Google Scholar] [CrossRef]

- O’Connor, J.T.; O’Brien, W.J.; Choi, J.O. Critical Success Factors and Enablers for Optimum and Maximum Industrial Modularization. J. Constr. Eng. Manag. 2014, 140, 04014012. [Google Scholar] [CrossRef]

- Broadhead, J.P.; Daniel, E.I.; Oshodi, O.; Ahmed, S.I. Exploring offsite construction for the construction sector: A literature review. In Proceedings of the 31st Annual Conference of the International Group for Lean Construction (IGLC31), Lille, France, 26 June–2 July 2023; pp. 735–745. [Google Scholar]

- Khalid, U.; Sagoo, A.; Benachir, M. Safety Management System (SMS) framework development—Mitigating the critical safety factors affecting Health and Safety performance in construction projects. Saf. Sci. 2021, 143, 105402. [Google Scholar] [CrossRef]

- Gan, X.; Chang, R.; Wen, T. Overcoming barriers to off-site construction through engaging stakeholders: A two-mode social network analysis. J. Clean. Prod. 2018, 201, 735–747. [Google Scholar] [CrossRef]

- Raza, M.S.; Tayeh, B.A.; Abu Aisheh, Y.I.; Maglad, A.M. Potential features of building information modeling (BIM) for application of project management knowledge areas in the construction industry. Heliyon 2023, 9, e19697. [Google Scholar] [CrossRef]

- Khalfan, M.M.A.; Maqsood, T. Current State of Off-Site Manufacturing in Australian and Chinese Residential Construction. J. Constr. Eng. 2014, 2014, 164863. [Google Scholar] [CrossRef]

- Goulding, J.S.; Pour Rahimian, F.; Arif, M.; Sharp, M.D. New offsite production and business models in construction: Priorities for the future research agenda. Archit. Eng. Des. Manag. 2014, 11, 163–184. [Google Scholar] [CrossRef]

- Gusmao Brissi, S.; Debs, L. Principles for adopting offsite construction in design and construction companies focused on multifamily projects in the USA. Eng. Constr. Archit. Manag. 2024, 31, 4308–4329. [Google Scholar] [CrossRef]

- Kamali, M.; Hewage, K. Life cycle performance of modular buildings: A critical review. Renew. Sustain. Energy Rev. 2016, 62, 1171–1183. [Google Scholar] [CrossRef]

- Yuan, Y.; Ye, S.; Lin, L. Process Monitoring with Support of IoT in Prefabricated Building Construction. Sens. Mater. 2021, 33, 1167. [Google Scholar] [CrossRef]

- Brandín, R.; Abrishami, S. IoT-BIM and blockchain integration for enhanced data traceability in offsite manufacturing. Autom. Constr. 2024, 159, 105266. [Google Scholar] [CrossRef]

- Saini, M.; Arif, M.; Kulonda, D.J. Challenges to transferring and sharing of tacit knowledge within a construction supply chain. Constr. Innov. 2019, 19, 15–33. [Google Scholar] [CrossRef]

- Fadeyi, M.O. The role of building information modeling (BIM) in delivering the sustainable building value. Int. J. Sustain. Built Environ. 2017, 6, 711–722. [Google Scholar] [CrossRef]

- Said, H.M.; Chalasani, T.; Logan, S. Exterior prefabricated panelized walls platform optimization. Autom. Constr. 2017, 76, 1–13. [Google Scholar] [CrossRef]

- Alencastro, J.; Wilde, P.D. Quality Management in UK Social Housing Projects: Addressing Thermal Performance. In Proceedings of the 36th Annual ARCOM Conference, Online, UK, 7–8 September 2020; Association of Researchers in Construction Management: Leeds, UK, 8 September 2020. [Google Scholar]

- Agapiou, A. Barriers to Offsite Construction Adoption: A Quantitative Study among Housing Associations in England. Buildings 2022, 12, 283. [Google Scholar] [CrossRef]

- Xu, J.; Smyth, H.; Zerjav, V. Towards the dynamics of trust in the relationship between project-based firms and suppliers. Int. J. Proj. Manag. 2021, 39, 32–44. [Google Scholar] [CrossRef]

- Ginigaddara, B.; Perera, S.; Feng, Y.; Rahnamayiezekavat, P. Typologies of offsite construction. In Proceedings of the 8th World Construction Symposium, Colombo, Sri Lanka, 8–10 November 2019; pp. 567–577. [Google Scholar]

- Wu, L.; Li, X.; Zhao, R.; Lu, W.; Xu, J.; Xue, F. A blockchain-based model with an incentive mechanism for cross-border logistics supervision and data sharing in modular construction. J. Clean. Prod. 2022, 375, 133460. [Google Scholar] [CrossRef]

- Darko, A.; Chan, A.P.C.; Yang, Y.; Tetteh, M.O. Building information modeling (BIM)-based modular integrated construction risk management—Critical survey and future needs. Comput. Ind. 2020, 123, 103327. [Google Scholar] [CrossRef]

- Onungwa, I.; Olugu-Uduma, N.; Shelden, D.R. Cloud BIM Technology as a Means of Collaboration and Project Integration in Smart Cities. SAGE Open 2021, 11, 21582440211033250. [Google Scholar] [CrossRef]

- Jang, J.Y.; Ahn, S.; Kim, T.W. Cloud-based information system for automated precast concrete transportation planning. Autom. Constr. 2023, 152, 104942. [Google Scholar] [CrossRef]

- Gupta, S.; Jha, K.N.; Vyas, G. Proposing building information modeling-based theoretical framework for construction and demolition waste management: Strategies and tools. Int. J. Constr. Manag. 2020, 22, 2345–2355. [Google Scholar] [CrossRef]

- Lai, H.; Zhou, C.; Deng, X. Exchange Requirement-Based Delivery Method of Structural Design Information for Collaborative Design Using Industry Foundation Classes. J. Civ. Eng. Manag. 2019, 25, 559–573. [Google Scholar] [CrossRef]

- Wu, Z.; Yang, K.; Xue, H.; Zuo, J.; Li, S. Major barriers to information sharing in reverse logistics of construction and demolition waste. J. Clean. Prod. 2022, 350, 131331. [Google Scholar] [CrossRef]

- Panteli, C.; Kylili, A.; Fokaides, P.A. Building information modelling applications in smart buildings: From design to commissioning and beyond A critical review. J. Clean. Prod. 2020, 265, 121766. [Google Scholar] [CrossRef]

- Akkermans, H.; van Oppen, W.; Wynstra, F.; Voss, C. Contracting outsourced services with collaborative key performance indicators. J. Oper. Manag. 2019, 65, 22–47. [Google Scholar] [CrossRef]

- Moon, S.; Han, S.; Zekavat, P.R.; Bernold, L.E.; Wang, X. Process-waste reduction in the construction supply chain using proactive information network. Concurr. Eng. 2016, 25, 123–135. [Google Scholar] [CrossRef]

- Gusmao Brissi, S.; Wong Chong, O.; Debs, L.; Zhang, J. A review on the interactions of robotic systems and lean principles in offsite construction. Eng. Constr. Archit. Manag. 2021, 29, 383–406. [Google Scholar] [CrossRef]

- Barkokebas, B.; Khalife, S.; Al-Hussein, M.; Hamzeh, F. A BIM-lean framework for digitalisation of premanufacturing phases in offsite construction. Eng. Constr. Archit. Manag. 2021, 28, 2155–2175. [Google Scholar] [CrossRef]

- Lee, D.; Lee, S.H.; Masoud, N.; Krishnan, M.S.; Li, V.C. Integrated digital twin and blockchain framework to support accountable information sharing in construction projects. Autom. Constr. 2021, 127, 103688. [Google Scholar] [CrossRef]

- Razkenari, M.; Fenner, A.; Shojaei, A.; Hakim, H.; Kibert, C. Perceptions of offsite construction in the United States: An investigation of current practices. J. Build. Eng. 2020, 29, 101138. [Google Scholar] [CrossRef]

- Darlow, G.; Rotimi, J.O.B.; Shahzad, W.M. Automation in New Zealand’s offsite construction (OSC): A status update. Built Environ. Proj. Asset Manag. 2021, 12, 38–52. [Google Scholar] [CrossRef]

- Saeed, M.; Yas, H. Building information modelling (BIM) and knowledge management in implementation for con-struction projects. Manag. Sci. Lett. 2023, 13, 277–286. [Google Scholar] [CrossRef]

- Nguyen, B.N.; London, K.; Zhang, P. Stakeholder relationships in off-site construction: A systematic literature review. Smart Sustain. Built Environ. 2021, 11, 765–791. [Google Scholar] [CrossRef]

- Neimann Rasmussen, L.; Montgomery, P. The prevalence of and factors associated with inclusion of non-English language studies in Campbell systematic reviews: A survey and meta-epidemiological study. Syst. Rev. 2018, 7, 129. [Google Scholar] [CrossRef] [PubMed]

- Vernikos, V.K.; Goodier, C.I.; Broyd, T.W.; Robery, P.C.; Gibb, A.G. Building information modelling and its effect on off-site construction in UK civil engineering. Proc. Inst. Civ. Eng. -Manag. Procure. Law 2014, 167, 152–159. [Google Scholar] [CrossRef]

- Kazmi, Z.A.; Sodangi, M. Modeling the Constraints to the Utilization of the Internet of Things in Managing Supply Chains of Off-Site Construction: An Approach toward Sustainable Construction. Buildings 2022, 12, 388. [Google Scholar] [CrossRef]

- Ghosh, A.; Edwards, D.J.; Hosseini, M.R. Patterns and trends in Internet of Things (IoT) research: Future applications in the construction industry. Eng. Constr. Archit. Manag. 2020, 28, 457–481. [Google Scholar] [CrossRef]

| Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).