1. Introduction

Historically, the construction industry has relied on manual drafting and physical models to communicate designs and plans. Shakespeare (referenced as published in [

1] and with a hat tip to the late Jeff Wix) described the construction process almost half a millennia ago:

When we mean to build,

We first survey the plot, then draw the model;

And when we see the figure of the house,

Then we must rate the cost of the erection;

Which if we find outweighs ability,

What do we then but draw anew the model

In fewer offices, or at last desist

To build at all?

At the time, drawing and modeling were synonymous; modeling was not considered something more progressive, as it is in the era of building information modeling (BIM). The introduction of computer-aided design (CAD) in the 1970s offered digital equivalents to manual drafting. CAD systems allowed for greater precision and the ability to easily modify drawings, thus improving productivity and reducing errors [

2,

3].

CAD’s limitations quickly became evident. CAD was largely focused on generating 2D drawings and fell short when it came to handling complex project data. This realization spurred the development of 3D geometric modeling tools. However, it soon became clear that geometry alone was not enough. As Eastman [

4] pointed out, there was a growing need to manage information beyond mere geometry in a more comprehensive way. This led to the evolution of geometric modeling into product modeling, which not only captured the geometric representation of building components but also their properties and relationships.

Process modeling developed in parallel to product modeling and quickly became a focus area in construction research and practice [

5]. Construction projects involve numerous stakeholders, tightly interwoven activities, and a range of resources that need precise coordination. Process modeling emerged to address this complexity by capturing the dynamic and sequential nature of construction operations. Its primary goal was to improve planning, scheduling, and overall coordination. Early tools like the critical path method (CPM) and the program evaluation and review technique (PERT) offered project managers a way to better optimize schedules and allocate resources effectively [

6].

The next logical step was integrating product and process modeling to create a more comprehensive approach. This integration gained traction with initiatives like the European Conference on Product and Process Modelling, as highlighted in the work of Scherer [

7], and the establishment of the European Association of Product and Process Modelling in 1994. These efforts demonstrated the industry’s shift toward viewing construction as a unified system, where product and process considerations work together.

1.1. Building Information Modeling

In 2002, the rather dull and technical term “product and process modeling” was replaced by the catchier acronym BIM [

8]. ISO 19650 defines building information modeling (BIM) as “the use of a shared digital representation of a built object to facilitate design, construction, and operation processes to form a reliable basis for decisions” [

9]. Since then, substantial efforts by researchers, standardization bodies, and software developers have been aimed at creating ever more realistic digital representations of existing or planned construction products

Today, BIM is used across the architecture, engineering, and construction (AEC) industry. Its use is, on the one hand, driven by stakeholder interests, particularly those of owners, who have the most to benefit from better information management. On the other hand, regulatory requirements mandated the use of BIM technology [

10]. The UK and Singapore were the first, in the 2010s, to mandate BIM use for publicly procured or large projects [

11].

At its core, BIM is used for design coordination, enabling architects, engineers, and contractors to collaborate more effectively and reducing design conflicts. It is also extensively employed in cost estimation and scheduling. Construction management benefits from BIM’s ability to track progress, manage resources, and optimize workflows. Facility management leverages asset information models for maintenance and operational efficiency over the life cycle of a building [

12].

Progress in terms of BIM has been gradual but not linear. Borkowski [

13] explored the evolution of BIM through three criteria: idea, approach, and organizational culture. Regarding the “idea”, BIM was first little more than 3D CAD, but then its concepts evolved until it because the de facto only proper way to manage construction information. In terms of “approach”, the progression was from a single building model, via closed proprietary BIM to open BIM. Lastly, in terms of “organizational culture”, Borkowski identified an initial phase of uncoordinated efforts, followed by early federated models, and a more mature era characterized by streamlined collaboration and a shared environment.

An argument for a fourth periodization could be found in this paper. (a) An incubation period when the work was largely theoretical and unburdened by the practical constraints of implementability in software. (b) A growth period when some of the theoretical intricacies had been sacrificed to make the software and standards practically useful. (c) A mature period when the deficiencies of the approach were addressed by methodological developments and wider revisiting of the fundamentals. The milestones from Borkowski [

13] can be used to delimit (a) and (b)—the coining of the BIM acronym and the working version of the IFC standard. The milestone between (b) and (c) could be set at the passing of ISO 19650 [

8], which added a structured process to structured information.

1.2. BIM Challenges

While BIM promises more and better information—potentially driving higher productivity, better quality, and fewer surprises during project delivery—the real-world outcomes often fall short of expectations [

14]. Studies show that the construction industry has yet to see many of the anticipated benefits [

15]. Productivity, for instance, has remained stagnant or even declined in some regions. McKinsey & Company’s report [

16] highlights this, noting that construction productivity has grown by just 1% annually over the past 20 years, compared to 2.8% for the global economy and 3.6% for manufacturing. These figures underscore a gap between BIM’s theoretical potential and its practical impact. Flyvbjerg [

17] finds that about 70% of construction projects continue to suffer cost overruns and delays—a number that has barely shifted, despite widespread digital adoption.

This gap between the promise of BIM and the realities of its implementation in the construction industry throughout the life cycle of a construction product suggests that while digital tools offer significant advantages, systemic issues often stand in the way. Miettinen and Paavola [

18] point out that these challenges highlight the need for a more integrated approach—one that does not just adopt digital tools but also aligns them with organizational and process changes in the sector.

1.3. Hypothesis, Goals and Paper Structure

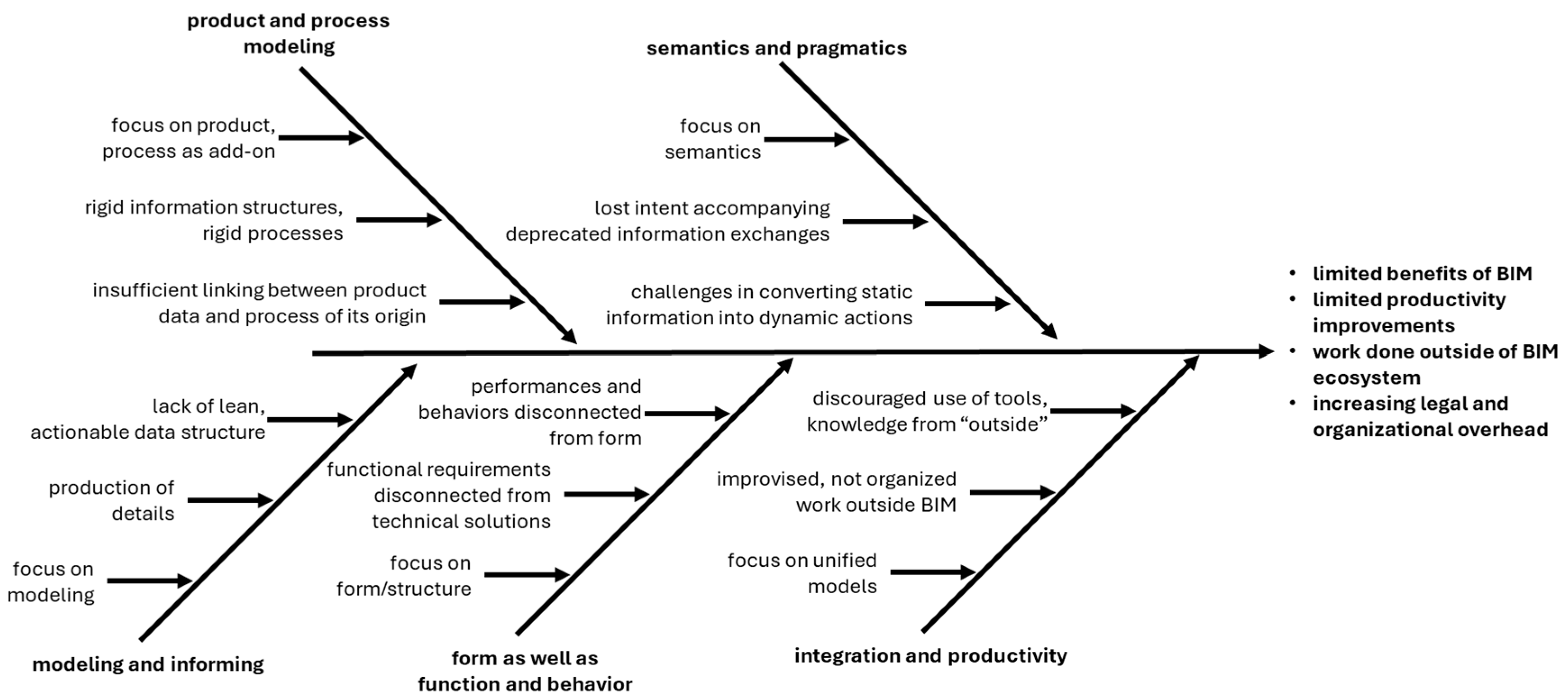

The hypothesis of this paper is that the challenges of BIM might run even deeper: that much of the research and development around BIM has not paid proper attention to the fundamentals that were known during the early research on product and process modeling but have later given way to practically usable results. Many of the current shortcomings of the BIM research, tools, and applications can be traced back to this disconnect (

Figure 1).

This paper presents an analysis that compares the theoretical fundamentals of various aspects of BIM with the mainstream research directions, thus arguing that the hypothesis is true.

The goal of this paper is to motivate the research community to revisit those foundational ideas and, by doing so, realign the discourse and offer a more grounded direction for future work. The goal of this paper is not to introduce the BIM concept, to review BIM usage, to offer a comprehensive literature review or to provide a state-of-the-art summary. The goal is to identify gaps in the BIM research and provide a theoretical argument for why it might make sense to address them better.

In

Section 2,

Section 3,

Section 4,

Section 5 and

Section 6, five BIM-related topics are discussed. The titles themselves introduce pairs of ideas in which the first has plenty of attention while the second has less. The theoretical foundations are introduced first, and against that background, the mainstream approaches are analyzed.

Section 7 summarizes the main points and suggests a few specific topics for further investigation.

2. Product and Process Modeling

Discussing the first principles of human coping with the world, Jordan Peterson [

19] (2002) wrote “The world can be validly construed as a forum for action, or as a place of things. […] No complete world-picture can be generated, without the use of both modes of construal.” Therefore, it is no wonder that early thinking about building digitalization chose to include both product and process modeling, both “place of things” and “forum for action”. However, the majority of research and development activities have been focused on the product, with process elements playing a secondary role.

The duality of product and process, of things and forums, has a long philosophical (this section) and linguistic (next section) tradition.

2.1. Philosophical Foundations

Aristotle’s [

20] approach to knowledge emphasizes that information only becomes valuable when it informs actions and decisions. This idea ties directly to his concept of phronesis—practical wisdom—where knowledge is not pursued for its own sake but is applied to achieve effective action. In construction, for example, product information holds meaning only when it is understood in relation to the processes it supports.

Ludwig von Mises, in

Human Action, states that “human action is purposeful behavior” ([

21], p. 11). For Mises, knowledge acquisition and application are always goal-oriented, a perspective that resonates with the pragmatic view of information. Simply having data is insufficient if it does not drive decisions or help solve problems. In construction projects, actionable insights—rather than mere data accumulation—are what truly enable progress and productivity.

Similarly, Heidegger’s idea of

Zuhandenheit (readiness-to-hand), outlined in

Being and Time [

22], offers a useful framework for understanding the role of information in practice. Heidegger contrasts objects understood theoretically (

Vorhandenheit, or presence-at-hand) with those engaged practically in the world (

Zuhandenheit). In the AEC industry, information must be ready-to-hand: it should be immediately relevant, easy to access, and directly applicable to the tasks being performed.

This practical orientation aligns with the reality of construction workflows, where the integration of information into daily operations can make the difference between efficiency and delay. Heidegger’s philosophy underscores the need for information to be more than theoretical—it must be embedded into tools and processes in a way that drives action.

2.2. Information Science

In the field of information and communication theory, the idea that information must serve a purpose is also present. The father of information theory, Claude Shannon [

23], emphasized that information’s true value lies in its ability to be understood and applied by its recipients.

Building on Shannon’s work, Wiener [

24] argued that information plays a central role in guiding behavior and controlling systems—whether they are biological, mechanical, or social. He claimed that information is not just something to store or transfer. Its real power comes from its ability to drive outcomes and steer systems toward specific goals. This active role of information underscores its practical essence.

In terms of knowledge management, Davenport and Prusak [

25] observed that information’s value is realized and that “information only becomes valuable when it is used to generate action or insight”. This notion ties directly to project execution in engineering, where information is not just there to exist—it must shape decisions, influence behaviors, and drive projects to completion efficiently and effectively.

In communication science, information serves to reduce uncertainty and support decision-making. Simon [

26], in his work on organizational decision-making, explained: “Information is important for decision-making, and the value of information is a function of its ability to change the actions of the decision-maker”. In the context of the AEC industry, this means information is not valuable just because it exists—it matters because of what it does. It needs to guide, influence, and improve the decisions that drive projects forward.

2.3. AEC Information Systems

BIM is supposed to support the decision-making processes across the entire project life cycle. Information in the BIM model is supposed to be needed in the process. The characteristics of the building that can be captured by standardized models are selected, again, with the information requirements in mind.

The creation and extension of Industry Foundation Classes (IFC) standard typically begin with the identification of a need within the industry, often driven by stakeholders such as architects, engineers, other construction professionals, and software vendors. A use-case process is elaborated in the information delivery manual, which documents new product information elements. Once a consensus is reached, the new definition is integrated into the IFC schema through a formal revision process [

27]. The process is there to identify information requirements but later does not receive the same attention as the product itself.

What the BIM approach has achieved to date was an advanced integration of product information and a less detailed integration of processes. It has struggled with the interplay between the two. This connection broke down when the exchange of information—sending around drawings and other documents with partial information—was replaced by contributing to, sharing, and having available the digital model of the whole product.

Process modeling has not received the same attention as product modeling and the relationships between the two could be improved. Another view on the same issue occurs through the optics of semantics and pragmatics.

3. Semantics and Pragmatics

To understand the functional essence of information, it is important to distinguish between semantics and pragmatics. Semantics deals with the meaning of information—what the data represent, its inherent value, and how it connect to other data [

28]. Pragmatics, on the other hand, is about putting that information to use in practical ways—how it informs real-world actions and decisions. This distinction ties closely to the theory of speech acts, which sees information not just as something to be stored or displayed but as something that enables action.

The idea of a speech act was first introduced by Austin [

29] and later expanded by Searle [

30]. It is a concept that shifts the focus from language as a way to describe reality (like products) to its role in performing actions (in a process). Applied to information systems, this theory underscores the need to design data flows that do not just present information but actively drive decisions and actions, ensuring they fulfill objectives [

30]. In the context of construction, this means creating systems where information moves beyond the representation of products and becomes a tool for achieving tangible outcomes of processes.

3.1. Value of Pragmatics

Building information modeling (BIM) has fundamentally transformed the architecture, engineering, and construction (AEC) industry. It introduced digital tools to manage the physical characteristics of buildings and other elements of the built environment. BIM systems are highly effective at creating detailed, multidimensional models that capture the semantics of construction projects. These models meticulously define the geometry, materials, and properties of building components, with ever-increasing precision. However, while this semantic richness is undeniably valuable, it addresses only part of what is needed to make construction processes more efficient and actionable.

As Turk [

31] points out, and as van Leeuwen and Fridqvist [

32] concur, BIM often leans too heavily on representing reality instead of emphasizing the pragmatic use of information to drive action. The models are designed to replicate the “place of things” but frequently fail to inform the “forum for action”. Eastman et al. [

33] similarly criticize BIM for its limited integration into project workflows, arguing that while it excels in design visualization and coordination, its full potential lies in its ability to guide the actions of project teams.

Succar [

34] identifies the industry’s preoccupation with technical capabilities over practical applications. He calls for a more integrated approach to BIM, where the focus shifts to actionable insights that support decision-making throughout a project’s life cycle.

The essence of information, many agree, lies not in simply possessing it but in using it to drive decisions and actions. This aligns with the concept of information as a performative element, akin to a speech act. Yet, BIM information tends to remain static, confined to a repository, waiting passively for someone to retrieve and use it.

Significant progress has been made in repository technologies over the decades: from FTP sites in the 1980s to web-based information sharing in the 1990s, cloud computing in the 2000s, and platforms like Dropbox. More recently, common data environments (CDEs) have also tried to bring order to this chaos. Ultimately, the centralized BIM level-three databases, as envisioned by the Bew and Richards [

35] model, are supposed to be the pinnacle of this evolution, offering a unified system for managing and sharing information. However, a challenge remains: ensuring that the information does not just sit there but actively informs and drives the processes it was meant to serve.

3.2. Improvement in Representation at the Expense of Coordination

These storage technologies replace the mess of sending around files and documents with a neat repository of all the information ever needed. However, the ability to know what information one needs and why the information is there in the first place is lost. Design is increasingly about creating a digital replica of the thing and not about informing others on what they need to know to act.

In contrast, in the traditional way of working, sending information around on paper or as email attachments preserved that important pragmatic aspect. If one received a fax, a letter, or an email, there was always some explicit pragmatics present in the communication explaining why the information was sent and what the recipient was supposed to do with it. Even in the absence of explicit expectations, the pragmatics were implicit in the fact that at some point in time, some information was sent by one project participant who had it to another who was supposed to do something with it. This is lost when information is just uploaded somewhere or when a part of the shared BIM model is updated by one team member.

To fix this problem, it has been believed that process planning needs to improve. Instead of participants self-coordinating through pragmatic information exchanges, structured information calls for rigidly defined processes too. BIM protocols, BIM execution plans, BIM coordination programs, master information delivery plans, project information plans, asset information plans, data exchange definitions, etc., have been introduced to define information needs, data drops, access rights, levels of detail, levels of development, grades of development, depth of detail and many other meta attributes. This has not been needed in the context of paper-based or digital messaging.

3.3. Benefits of Information Scarcity

Simon [

36] claimed that every design problem is due to a lack of information. The digital transformation of construction has created an abundance of information. As economists well know, abundance has its problems as well.

Necessity is the mother of innovation and scarcity is often understood as a motive for growth, innovation, and more effective decision-making because it forces prioritization and efficient use of resources [

37]. Similarly, in construction projects, information scarcity can provide significant benefits by encouraging teams to concentrate on the most essential data rather than drowning in a flood of unnecessary details.

First, the scarcity of information sharpens decision-making by compelling project teams to focus only on the most critical details. This principle aligns with lean construction methods, which aim to eliminate non-value-adding activities and streamline processes. Sacks et al. [

38] argued that when project teams deal with only the essential, actionable data, they can make faster and clearer decisions, avoiding distractions caused by irrelevant details. This clarity fosters smoother workflows and better project outcomes.

Second, Gu and London [

39] claimed that limited information supports more efficient communication. When teams operate under conditions of scarcity, the focus naturally shifts toward sharing only vital updates. This approach reduces the chance of key details being buried under irrelevant or redundant data, ensuring that all stakeholders remain focused on the project’s main tasks. Focused communication minimizes misunderstandings and keeps everyone working toward common goals.

Third, creating, managing, and retrieving volumes of information have their own costs. Overproduction of data wastes not only time but also storage and processing resources. The lessons learned from lean manufacturing and lean construction also apply to information management—producing only what is necessary, when it is necessary. A lean approach to information can save costs and streamline operations, avoiding the inefficiencies associated with managing excessive data.

While semantic information is a foundation, pragmatic information is essential for driving actions. As argued by Turk and Klinc [

40], Gu and London [

40], and Eastman et al. [

34], shifting from information completeness to action-oriented information can cause BIM to evolve from a static repository of information to a dynamic tool for collaboration. By adopting a lean approach, BIM can more efficiently serve construction projects, making information not just accessible but actionable in a collaborative social network.

4. Modeling and Informing

Models are a well-known way of presenting designs in AEC. Architects build models from wood or cardboard. Engineers use mathematical models to predict stresses in the structure. In this context, the term information modeling was introduced to model buildings in information. The term is almost tautological: information about something is always a model of that something. But the choice of term around which research and development has been focused had consequences for the direction and focus of that research.

4.1. Modeling vs. Informing

If we choose to make a distinction between “models” and “information”, then we can identify two fundamentally different approaches to how data are structured and utilized.

Models—as in building (information) models—are primarily concerned with representing the “place of things”. They focus on capturing a detailed, accurate picture of physical reality. This approach emphasizes a high level of detail and fidelity to the real world, with the assumption being that more detail is inherently better for accurately simulating or predicting outcomes. However, this focus on creating an exhaustive digital replica can shift attention away from the practical, action-oriented uses of the information contained within the model.

An information-centric approach—as in building information (model)—aligns more closely with the pragmatics, focusing on the usefulness of data and on informing activities in the “theater of action” rather than just replicating reality. In this view, information is not just about “what is” but about “what is needed to act”. This approach aligns with the speech act theory discussed above.

By asking questions like “How much information suffices to inform action?” and “Does this information inform action?” rather than “What is this thing like?” and “How do we organize all information about this thing?” would prioritize actionable insights over exhaustive detail.

4.2. Turning Chaos into Order

Most of the research and development progress over the decades has concerned the increasingly detailed and unified structuring of information. We started with a pile of data and we wanted to come up with rules and abstractions on how to organize those data so that we could orderly store the data according to the rules.

The evolution of information technology in fields like construction has brought about increasingly sophisticated tools for organizing and classifying data, but the fundamental principles of information management remain largely the same. Initially, data existed in raw, unstructured forms, with minimal organization. Over time, methods such as classification systems and structured document management were introduced, allowing data to be organized in a more systematic way. The development of data structures, object classes, and standards like the Industry Foundation Class (IFC) have added layers of “semantics” to this order, enabling data to be structured in greater detail and interpreted with lesser ambiguity. Ontologies are the next step in this evolution, supposedly encoding “meaning” not just information. However, meaning emerges from action and is not intrinsic.

Despite these advancements in the tools and frameworks for structuring data, the core approach has not changed substantially—we are still focused on categorizing, sorting, and storing information to make it accessible. This incremental progress improves the structure and retrieval of data, yet it does not fundamentally address how information can be made more actionable or relevant for practical decision-making in real-world applications.

All these efforts have been geared toward providing a structure into which anything that the AEC industry deals with would fit and ignoring the fact that the “everything”, the model, is never needed. Instead, just a small chunk of information is needed to inform the next action. It has been taken for granted that an agreement on everything is needed in order for one stakeholder to inform the other.

Turk [

41] argues that BIM should prioritize informing decision-making processes rather than accumulating and organizing information. This emphasis on actionable information supports a lean construction approach, where only relevant and timely data are generated and shared, reducing cognitive overload and enabling more effective project management [

39].

4.3. Lean Information Management

The principles of lean production, originally developed in manufacturing, offer some ideas for improving BIM processes. Lean is about eliminating waste, optimizing workflows, and improving resource use. These concepts can be effectively adapted to manage BIM’s information-heavy environment.

Lean is a well-known concept in construction. Koskela [

42] has been focusing on reducing waste and improving efficiency in construction projects. Lean construction streamlines workflows, reduces redundancies, and enhances collaboration [

43]. The integration of lean construction with BIM has been studied as well. Sacks et al. [

39] demonstrated that BIM’s visualization and coordination capabilities align well with lean principles, minimizing physical and material waste. But in the context of this discussion, the goal is not physical waste—it is information waste. It is about making information processes lean.

Lean BIM has been less explored but is critical. Davies and Harty [

44] identified the risks of overwhelming project teams with excessive data. They recommended applying lean principles to BIM to prioritize and filter data. Similarly, Bortolini et al. [

45] highlighted the need to eliminate non-value-adding activities, such as overproducing detailed models that may not serve project needs.

Tools like value stream mapping (VSM) could be useful. It visualizes the flow of materials and information and could be applied to BIM to identify inefficiencies and focus efforts on value-adding activities [

46].

Another lean concept is just-in-time (JIT) production. It focuses on providing materials and information exactly when and where they are needed. In the BIM context, JIT means delivering specific, relevant data to the right stakeholders at the right time. Rather than storing and sharing all the information in centralized repositories, Womack and Jones [

47] found that targeted messaging can minimize cognitive overload and unnecessary effort.

JIT in BIM would require better search capabilities. While databases are designed for efficient querying, BIM, rarely implemented as a database-proper, often lacks robust search tools. Users typically navigate to objects visually, rather than querying for specific information. Advances in semantic search, as discussed by Molsa et al. [

48] and Pauwels et al. [

49], show promise in addressing this gap by improving the precision and speed of information retrieval.

Focusing BIM on informing rather than modeling leads to leaner BIM strategies and lean BIM or JIT BIM.

5. Form as Well as Function and Behavior

BIM integrates multi-dimensional data, encompassing 3D geometry. The idea of extending BIM beyond its initial 3D capabilities to include additional dimensions—commonly referred to as 4D, 5D, 6D, and nD BIM—was introduced to enhance the utility of BIM by integrating time, cost, sustainability, and other project-related data into the model.

The term “4D BIM” was introduced by Fischer and Kunz [

50], who linked 3D models to the construction schedule, thereby allowing the visualization of the construction sequence over time. Moreover, “5D BIM” emerged to incorporate cost estimation data into the model, thus enabling more accurate budgeting and financial planning [

51]. The progression to “6D BIM” and beyond includes dimensions such as sustainability and life cycle management, where BIM models are used to support energy analysis, facility management, and maintenance throughout the building’s life cycle [

52].

The justification for adding these aspects lies in the desire to create a more holistic and integrated approach to information management, where all the relevant information is embedded within a single, unified model. The justification for calling them dimensions, however, is weak. Dimensions beyond 4D are not dimensions but aspects. One can understand the marketing motives of software companies when increasing the number of dimensions, but not those of researchers.

While those aspects are important, there are core aspects of a conceptual framework for design that have not received proper attention.

5.1. The Framework

In design sciences, the concepts of form, function, and behavior (FFB) are fundamental to understanding and structuring knowledge about artifacts, systems, or processes. These three concepts (sometimes form is called structure) provide a comprehensive framework for analyzing how things are conceived, designed, and realized in the real world [

53].

Form, or structure, refers to the way the components of a system or product or process are arranged—whether physically or conceptually. This includes the geometric layout, material properties, and spatial organization that define how something looks and how it is physically configured. In architecture and engineering, form is what we see in the design: the dimensions, the materials, and the overall arrangement of a building or structure.

Function is about purpose. It answers the following question: what is this thing supposed to do? For buildings, function could mean providing shelter, enabling communication, or facilitating activities like manufacturing, education, or sports.

Behavior is about how the system or object performs under specific conditions and external events. It is what we observe when form and function and external events interact. For example, the behavior of a building might include how well it handles thermal loads, how stable it is under heavy winds or seismic activity, or how effectively it controls sound transmission.

These three—form, function, and behavior—are deeply interconnected. The form affects the behavior, the behavior reflects the function, and the function sets the requirements for the form. In design sciences, these elements are often examined through different phases of a project’s life cycle: “as required”, which outlines initial goals; “as designed”, which captures the intent of the engineers and architects; “as built,” reflecting the actual construction; and “as measured”, showing the real-world performance of the constructed facility.

5.2. FFB and BIM

Current BIM approaches predominantly focus on the representation of form, with significantly less emphasis on function and behavior. This imbalance limits the ability of BIM to fully capture and communicate the complexity of construction projects.

Objectively, the vast majority of megabytes in BIM models are about form. BIM excels at capturing the geometric, spatial, and material characteristics of buildings, including detailed 3D representations of structural elements, architectural layouts, and material specifications. The emphasis on form is driven by the need for accurate and detailed design documentation.

Function is addressed in BIM to a lesser extent. While BIM can include data related to the intended use of spaces or systems (such as the function of a room, occupancy levels, or equipment requirements), this information is an exception. Neither standards nor software support functional attributes such as “the load bearing capacity here should be this is this many Newtons”. The end user’s functional requirements are typically captured in the early stages of design through programmatic documents or design briefs, and not even these are always fully and explicitly integrated into the BIM model itself.

The separation between functional units and technical solutions—a concept recognized in systems engineering [

54] and present in early “BIM” research [

55]—is nonexistent and even less so the staging of attributes into “as required”, “as designed” and “as built”.

Behavior is the least represented aspect in current BIM practices. While BIM includes the information needed to simulate certain behaviors—such as energy performance, structural analysis, or daylighting—these capabilities are often treated as add-ons rather than integral parts of the BIM models and processes. Behavioral data are typically generated through specialized simulations or analysis tools that, as a rule, have one one-way interface to the core BIM model: data can be exported from BIM into analysis tools and only rarely can the results be pushed back into BIM. As a result, behavior is not consistently captured or updated within the BIM environment.

5.3. Function and Behavior in a Forum for Action

In

Section 2, a perspective has been presented to view the world both as a “place of things” and as a “forum for action”. There, this metaphor has been used to argue for more attention on what goes on in the construction process rather than on what we are constructing. However, the same duality can help to refocus our thinking about “things” as well. The facilities that we are constructing will not only be “things” in the “place of things” but they will also be part of a “forum” where the action takes place. For the facility to exist in a “place of things”, it needs form. For the facility to take part in a “forum for action”, it needs to perform: perform its function and behave as a response to external events.

In brief, objects from “the place of things” take part in “action in the forum”—they are affected and changed by the ongoing “play”. This is another area where the support in the BIM ontology (as in BuildingSmart) and BIM tools could be stronger.

6. Computer-Integrated Construction and Productivity

The idea of BIM as a comprehensive, unified digital representation of a building—an idealized, Cartesian model capturing every possible detail—is an ambitious vision. However, as Turk [

42] points out, this goal is ultimately an incorrect one. The construction industry is interested in efficiency and productivity. Integration and interoperability are tools to achieve that but not goals in themselves. In addition, it is an impossible and impractical goal.

6.1. Computer-Integrated Construction

BIM’s promise is to create a model that serves as a “single source of truth”, facilitating seamless integration across all the phases of the construction life cycle—from design and engineering to construction and operation. However, this goal presupposes that all the relevant data and processes can be neatly codified within a predefined framework. The belief is that it is only a matter of time before all the information fits this framework and that only more work needs to be put toward it.

The construction industry involves a wide range of stakeholders, each using specialized tools and workflows tailored to their own information needs. While BIM aims to bring these disparate elements together, it often falls short in addressing the unique requirements of different disciplines [

35].

The push for a unified model can also lead to an overemphasis on certain types of data, sidelining other critical information or knowledge [

56]. Such knowledge is vital for project success but difficult to codify in a digital model. BIM models, designed with rigid structures, struggle to adapt as new methods or materials emerge during a project, making the integration of such innovations cumbersome or even impractical [

45].

Construction projects are inherently dynamic. Changing site conditions, regulations, and stakeholder needs introduce new constraints that a BIM model, no matter how detailed, cannot fully predict or accommodate. The flexibility required to address these evolving needs often lies outside the scope of predefined models.

Although research, standards, and software development have aimed for seamless interoperability and computer-integrated construction, the industry’s primary goal remains practical: delivering projects on time, within budget, and of high quality for the lowest cost. Integration and interoperability are tools to improve productivity, but when enforced too rigidly, they can hinder it. Also, focusing on integration may ignore supporting non-yet-integrated information and processes that are always bound to exist.

6.2. Productivity

Adam Smith, in

The Wealth of Nations [

57], pointed out that “the greatest improvements in the productive powers of labor […] seem to have been the effects of the division of labor”. He observed that specialization and the breaking down of tasks into focused roles allow workers to develop expertise, save time by avoiding constant task-switching, and make use of tools and machinery optimized for specific functions—all of which drive higher productivity. Building on this, Friedrich Hayek, in

The Use of Knowledge in Society [

58], underscored the importance of specialization in leveraging dispersed knowledge. Hayek argued that in a specialized economy, individuals can focus on areas where they hold unique, localized expertise, and when this specialized knowledge is combined across society, it leads to efficient resource allocation and innovative problem-solving. Construction is an excellent example of this.

To be more productive and more creative, construction needs to allow further and further specialization. As projects grew in history, so did the body of knowledge required to execute them. In ancient times, when communication was limited mostly to oral means, the expertise of only a small group of individuals could be utilized. The advent of paper-based communication expanded this substantially, enabling drawn blueprints and correspondence to connect specialized professionals, each focused on distinct aspects of a project. Today, with digital technology, this trend is accelerating. Modern tools and platforms make it easier than ever to make use of the collective expertise of teams, allowing specialists in engineering, architecture, and construction to collaborate efficiently.

BIM is an enabler of this trend. It simplifies the collaboration of specialists, integration of information, and management of processes that are already covered by the standards and tools. However, by doing so, it also opens the door to new specialists, new knowledge, and their information not yet part of the grand schema.

To date, the term open BIM is understood as a collaborative approach that enhances the accessibility, usability, management, and sustainability of digital data in the built asset industry. It is based on open standards and workflows that allow different stakeholders to share their data with any BIM-compatible software [

59].

Another kind of open BIM is such that it encourages and supports the non-standardized, not-(yet)-integrated elements at its margins.

6.3. BIM at the Margins

The work in the AEC industry is thus condemned to an environment where some information and processes are integrated and some are not, because the goal of the industry is productivity and it is facilitated by specialization that is happening at the margins.

Given these challenges, Turk [

42] argues that rather than striving for an unattainable ideal of a unified, all-encompassing model, the focus should be on developing BIM systems that are inherently open, flexible, and adaptable. Such systems would allow for the inclusion of new specialists, data, and processes as they emerge, rather than attempting to anticipate every possibility at the outset. This approach recognizes that the construction process is not a linear, deterministic sequence but a complex, adaptive system where unforeseen changes and innovations are not only inevitable but also desirable.

By embracing the fact that a BIM model can never be complete, research and development can address systems that serve as dynamic tools for managing complexity and facilitating collaboration, enabling collaborations at the margins and managing roles, information, and knowledge outside the BIM framework—yet loosely associated with it. This shift in perspective aligns with the ideas of modular and decentralized approaches in digital construction, where the ability to quickly integrate and adapt to new information is more valuable than the pursuit of a perfect model.

7. Conclusions

The progress that BIM research, development, and standardization has achieved over the decades has been immense and provided value to the AEC industry. However, some aspects that have profound theoretical foundations could use more attention. The practical difficulties and ad hoc solutions are an argument for this as well.

Modeling products is important, but models are used in a process. Information only receives meaning in processes. Combining the dual nature of reality—as a place of things and a forum for action—should be acknowledged. Potential research topics include methods for formally linking product models with process workflows; frameworks for integrating process-oriented semantics with BIM tools; ontologies that supersede the product and process branches; techniques for dynamic process adaptation with product changes; sparsely structured information and thinly organized and improvised processes; social media types of collaborations; and the development of real-time decision-support systems that rely on process-integrated modeling.

Semantics is interesting and associated with meaning and intelligence, but what is actually needed is pragmatics to support decision-making. Potential research topics include parsimonious data structures for actionable information in construction; applications of speech act theory in construction communication; collaboration-support systems emphasizing pragmatics and improvisation in multi-disciplinary teams; the role of real-time data feedback loops in enhancing project outcomes; studies on how pragmatics-driven systems improve construction project efficiency and safety; and the use of AI to work with less structured or unstructured yet practically useful information.

The goal is not to have models but to inform those who have some work to do. Research topics include strategies for translating BIM data into task-specific instructions; human-centered design principles for construction information interfaces; systems for automating actionable insights from BIM repositories; evaluation of communication protocols that prioritize actionable over descriptive data; impact studies on task-specific information delivery in terms of field productivity and error rates; abstract meta-model toolboxes allowing for the rapid creation of specific models that have standardized, machine readable descriptions yet non-standard content; and kaizen approaches to the continuous improvement of BIM processes.

Form is what we see and can touch and like to visualize about a project, but we are building facilities to achieve the desired function and proper behavior. Potential research topics include methods for aligning form-centric BIM models with functional performance analysis; integration of tools simulating behavioral outcomes (e.g., energy use, structural performance) and extending BIM data structures to store related data; data structures and process steps for the modeling of functional specifications in early design phases; predictive analytics for ensuring functional performance over a facility’s life cycle; and frameworks for balancing aesthetic, functional, and behavioral objectives in construction projects.

Interoperability and computer-integrated construction are not the goals but the means to higher productivity and technological progress. Productivity is a result of specialization, which happens at the margins that are not yet integrated in BIM. BIM should be systematically open to unforeseen specialists, information, and processes. Potential research topics include methods for making BIM interoperable with non-standardized data sources; studies on the impact of modularity and adaptability in BIM systems on project outcomes; the role of APIs and middleware in enhancing BIM flexibility; methodologies for integrating new domains of expertise and processes dynamically into ongoing projects; and truly open BIM frameworks to accommodate emerging specialists and tools that are not supported by open BIM.

Taking into account the fundamental theories that underpin BIM both opens up new research directions and leads to more efficient implementation tools for the industry.