Evaluating the Performance of Fixed 3D-Printed and Dynamic Fabric Modules in a Second-Skin Façade System: A Residential Case Study in Southern Italy at Building and District Scales

Abstract

1. Introduction

1.1. Literature Review

1.1.1. Textile Solutions

1.1.2. 3D-Printed Solutions

1.2. Research Novelty and Goals

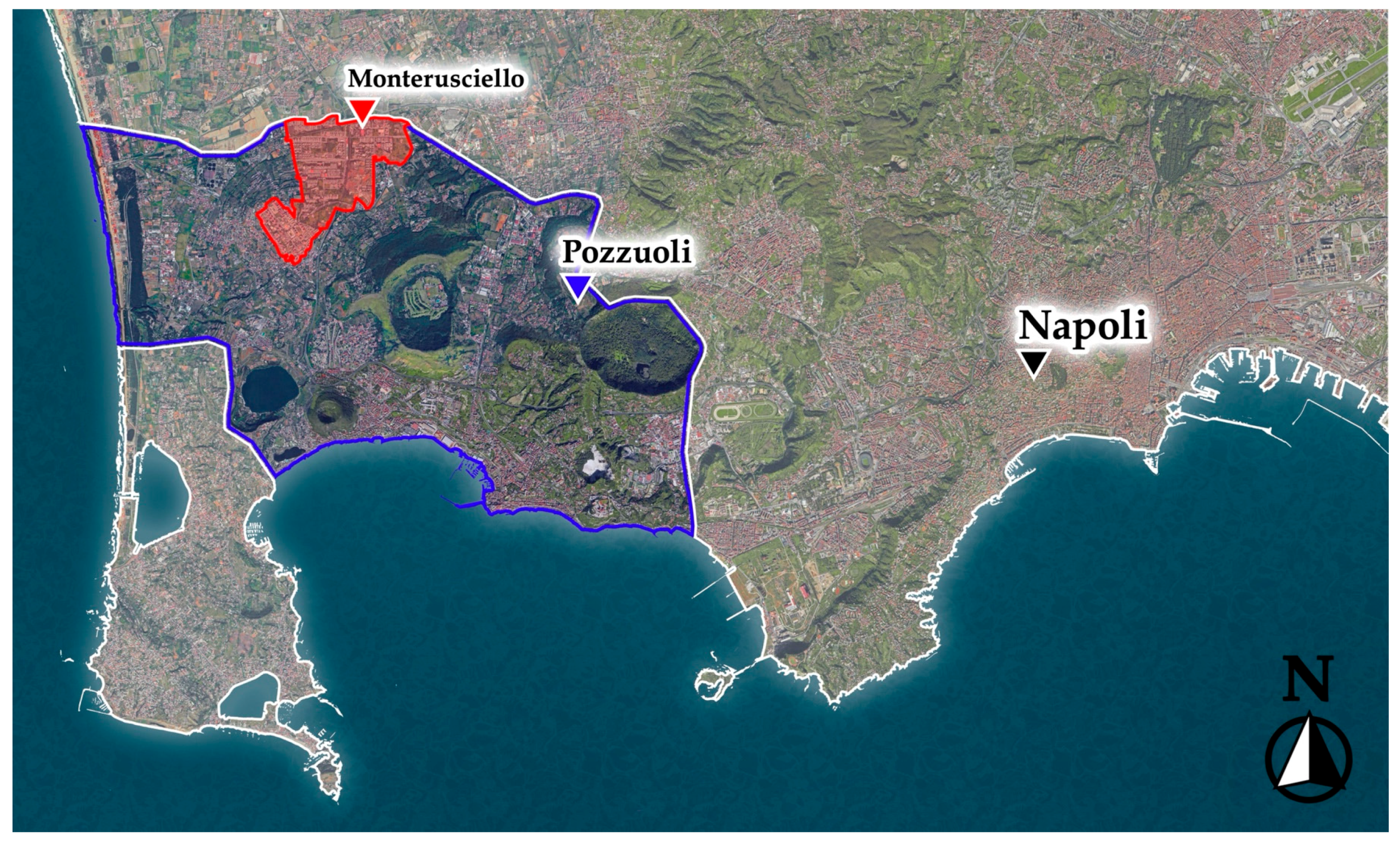

- To assess the potential energy saving and CO2 reduction achievable in residential building refurbishment using a combination of 3D-printed and fabric-based modules as an SSF system by means of dynamic numerical simulation;

- To evaluate the impacts on an extended residential area, taking into account the interrelations between buildings and urban morphology;

- To explore and discuss the potential economic and social effects on the involved communities and provide suggestions and solutions for strengthening existing policies and implementing new ones.

2. Materials and Methods

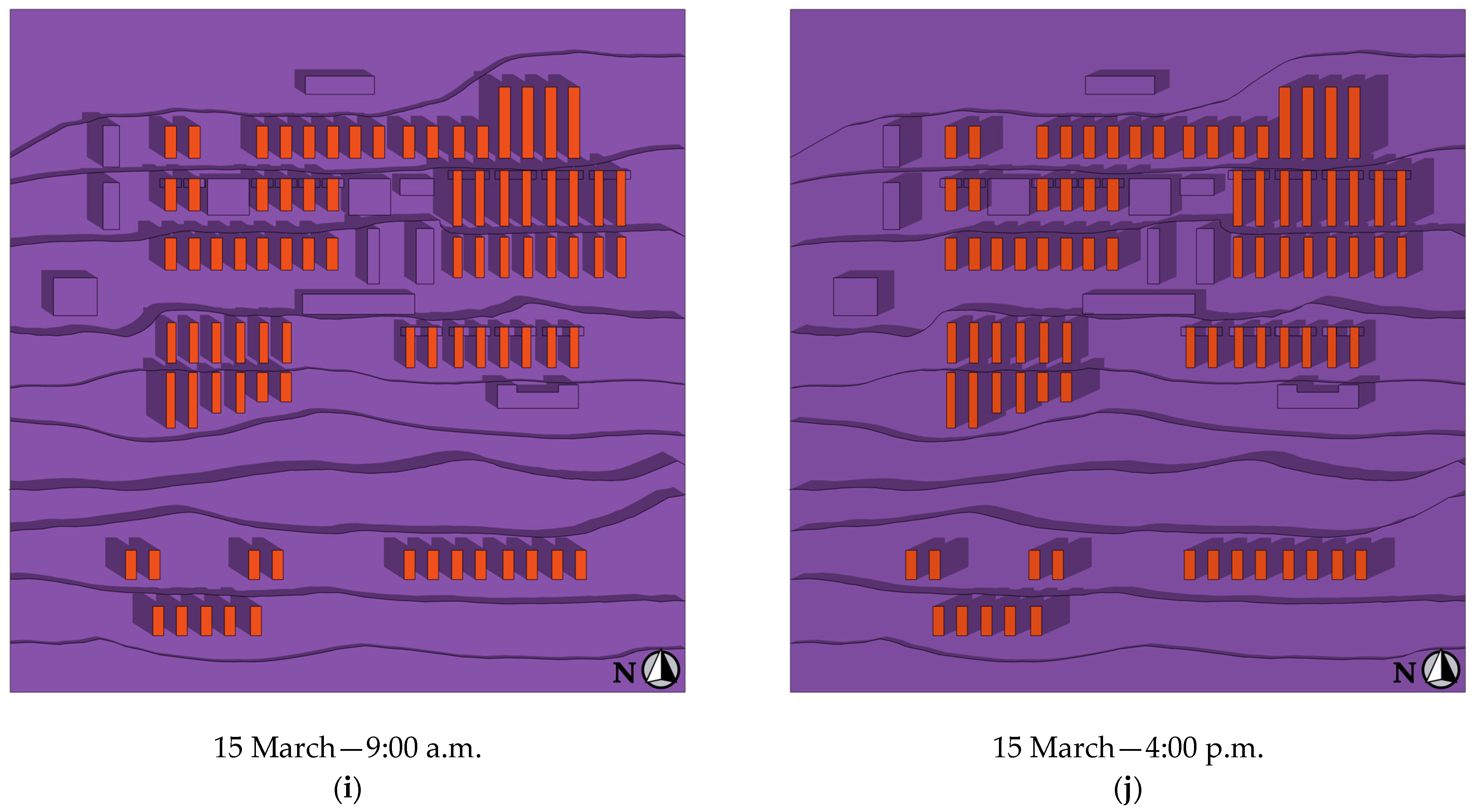

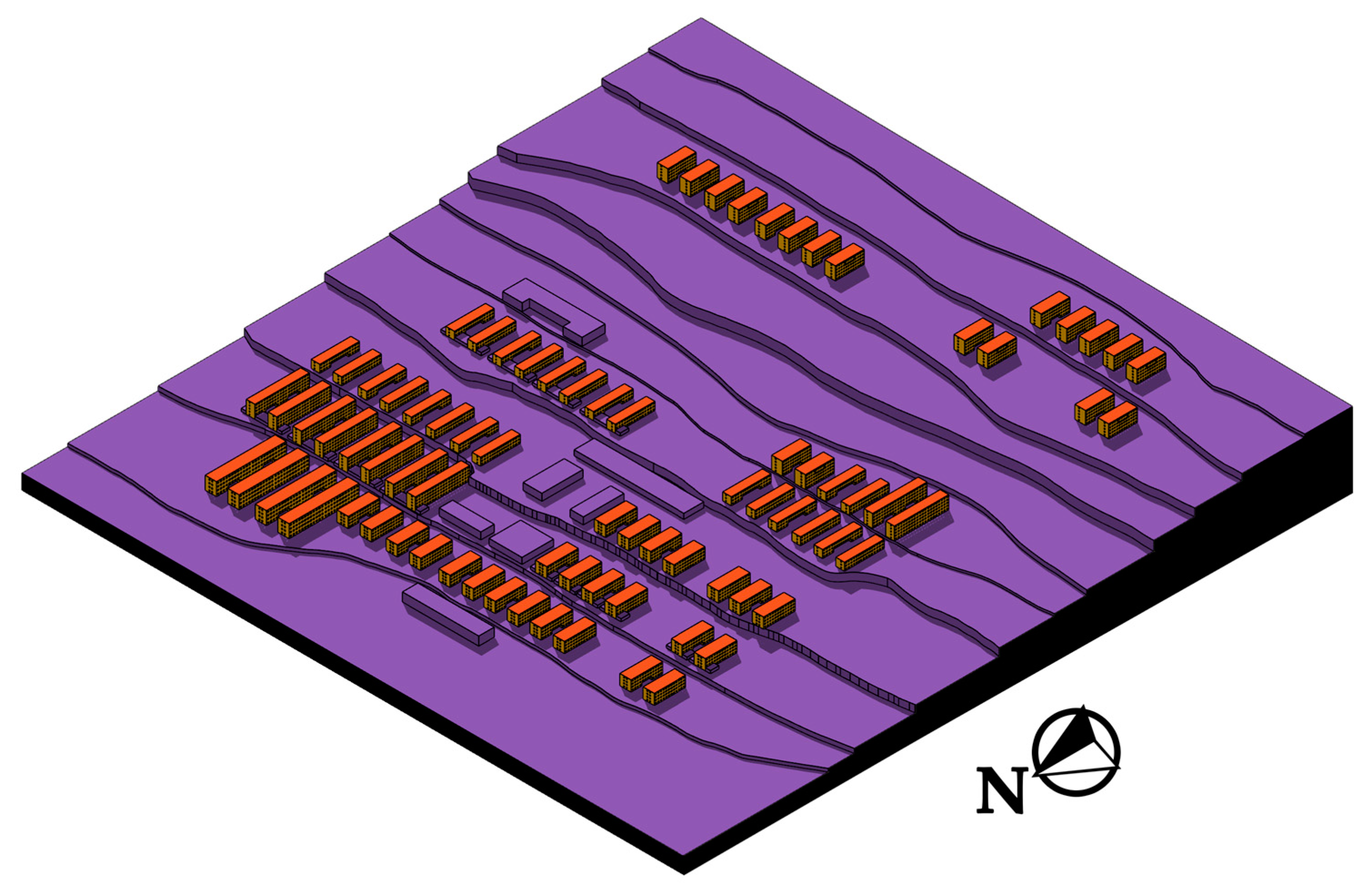

2.1. Description of the Monterusciello District

2.2. Modelling of the Numerical Case Studies

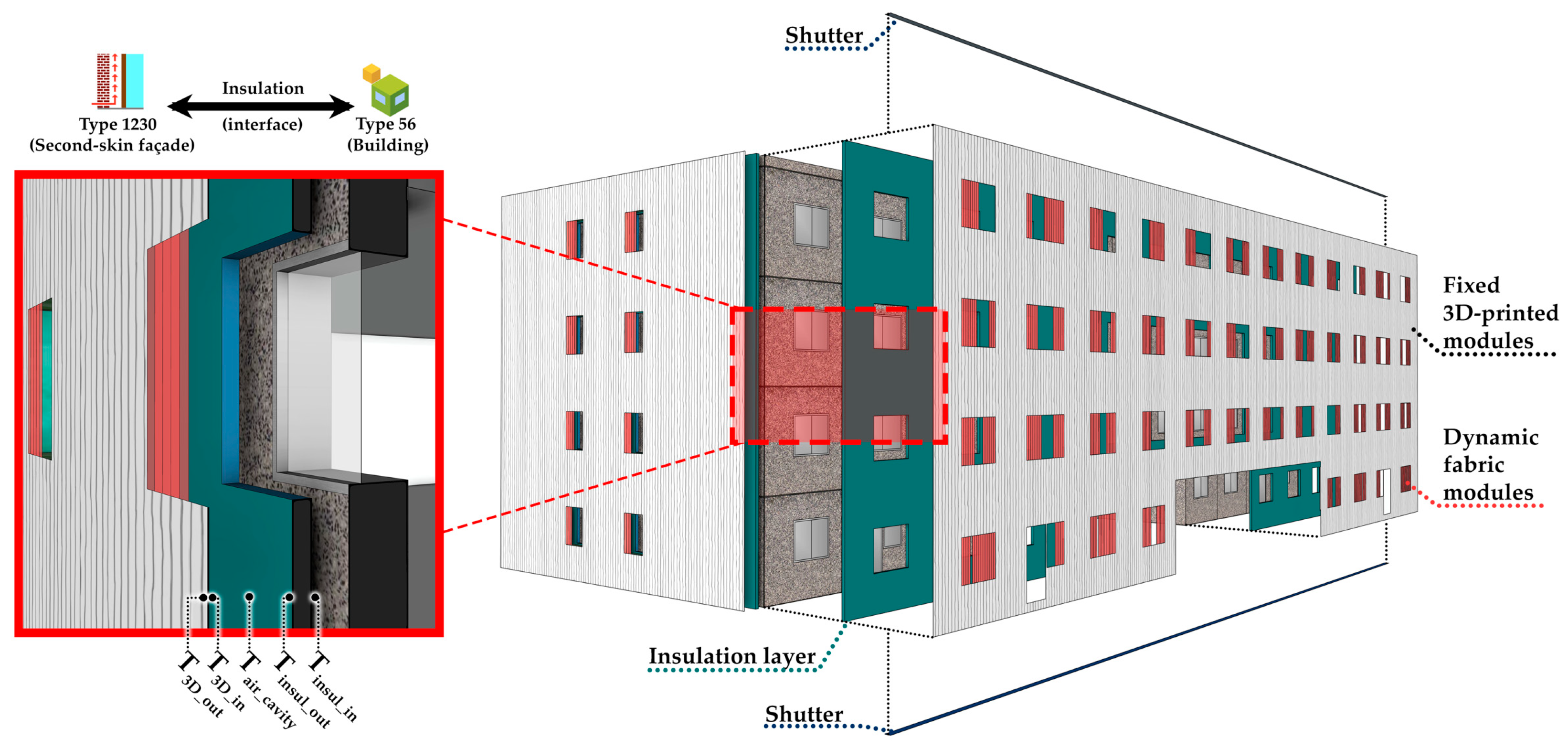

2.2.1. Numerical Model at the Individual Building Level

- The installation of an insulation layer on all of the external walls;

- The installation of a fixed shading system on the windows.

- Fixed modules installed on the opaque envelope by installing the insulation layer, leaving an air cavity of 10 cm, and adding an opaque cladding realised by using 3D-printed modules;

- Dynamic modules installed in front of the windows, leaving a cavity of 10 cm, and realised by using the PVC fabric.

- ASA (Acrylonitrile Styrene Acrylate), which offers strong resistance to weather, chemical, and mechanical stress while being non-biodegradable and hardly recyclable; the cost per kilogram of this filament ranges between USD 25 and USD 50 [60].

- NYLON PA66, which offers very high mechanical and thermal properties, even at extreme temperatures, thanks to the infusion of fibreglass into the polymer, thus making it non-biodegradable and complex to recycle; the cost per kilogram of this filament ranges between USD 40 and USD 80 [61].

- PETG (PolyEthylene Terephthalate Glycol-modified), which offers good resilience and printability, as well as high recyclability despite being non-biodegradable; the cost per kilogram of this filament ranges between USD 20 and USD 40 [62].

- PLA pro HT (PolyLactic Acid), which offers good printability and resistance while also being produced from renewable resources, thus biodegradable under industrial composting conditions; the cost per kilogram of this filament ranges between USD 30 and USD 50 [63].

- PMMA (PolyMethyl MethAcrylate), which offers excellent chemical and weather resistance, as well as excellent optical properties, while being non-biodegradable and complex to recycle; the cost per kilogram of this filament ranges between USD 20 and USD 50 [64].

2.2.2. Numerical Model at the District–Area Level

2.3. Methodology: Energy and Environmental Assessments

3. Simulation Results

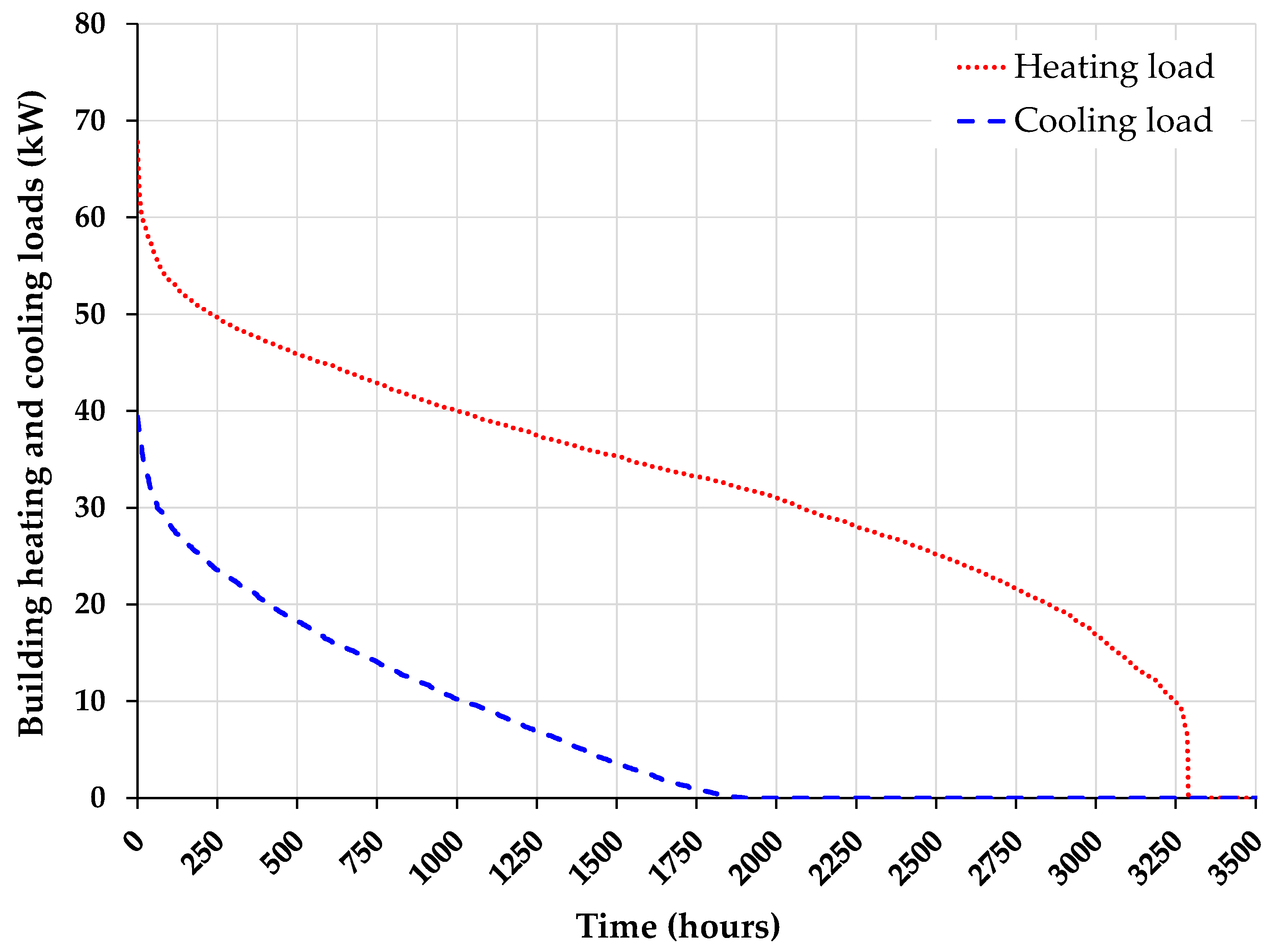

3.1. Energy and Environmental Impacts of the Retrofit on the Individual Building Level

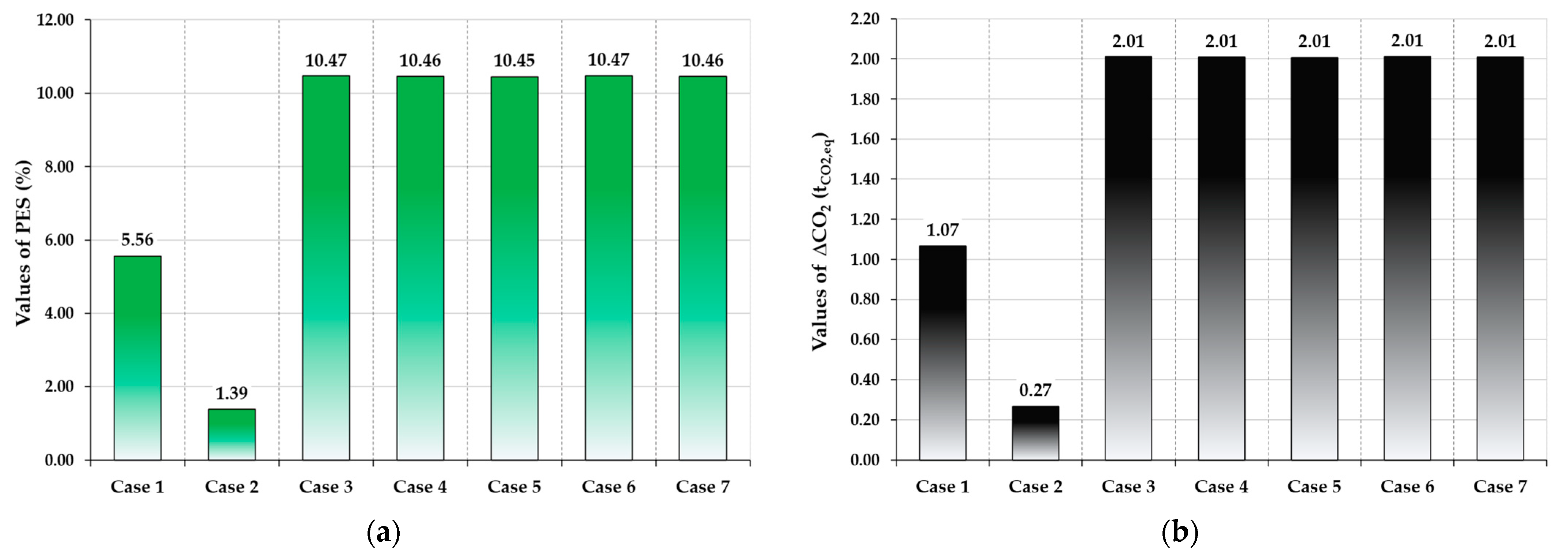

- In Case 1, the PES showed a positive value of 5.56%, and the reduction in CO2 emissions (ΔCO2) was 1.07 tonCO2,eq; these positive values are mainly due to the best result in terms of thermal energy demand reduction compared to Case 0 (equal to 10.8%), despite a non-negligible increase in cooling energy demand (about 10.0%); these results are in line with those reported in [17,18].

- In Case 2, the simulation results returned a value of PES equal to 1.39% and a ΔCO2 value equal to 0.27 tonCO2,eq; these results were achieved thanks to a 21.5% reduction in cooling energy demand despite a 5.4% increase in energy demand during the heating period compared to the reference case (Case 0); these findings are consistent with those documented in [19].

- All the case studies with the proposed SSF systems (Cases 3–7) always return positive values of both PES (~10.5% in all cases) and ΔCO2 (~2.0 tonCO2,eq in all cases) when compared to the reference case; this means that all the proposed materials used for refurbishment cases allow for the reduction of both primary energy consumption and carbon dioxide equivalent emissions for the current building status; these findings align with those previously reported in [20,21,28,33].

- Comparing the proposed SSF system (Cases 3–7) to a conventional insulation system (Case 1) and a case study (Case 2) featuring fixed window shading, the SSF system demonstrates its ability to enhance primary energy savings further, positively impacting both the cooling and thermal energy demands; this translates in an upgrade in PES ranges from an additional 4.9% to 9.0%, respectively. At the same time, the SSF system reduces environmental impact more effectively, and the reduction in CO2 emissions varies from an additional 0.94 to 1.74 tonCO2,eq, respectively;

- Among the SSF retrofit cases, no significant differences can be highlighted by considering different 3D-printed materials for the fixed module installed in the SSF: indeed, Cases 3 and 6 (with 3D-printed ASA and PLA modules, respectively) returned better results in terms of PES (10.47%), while no differences can be highlighted in terms of ΔCO2 (Cases 3–7 allow to save 2.01 tonCO2,eq per year);

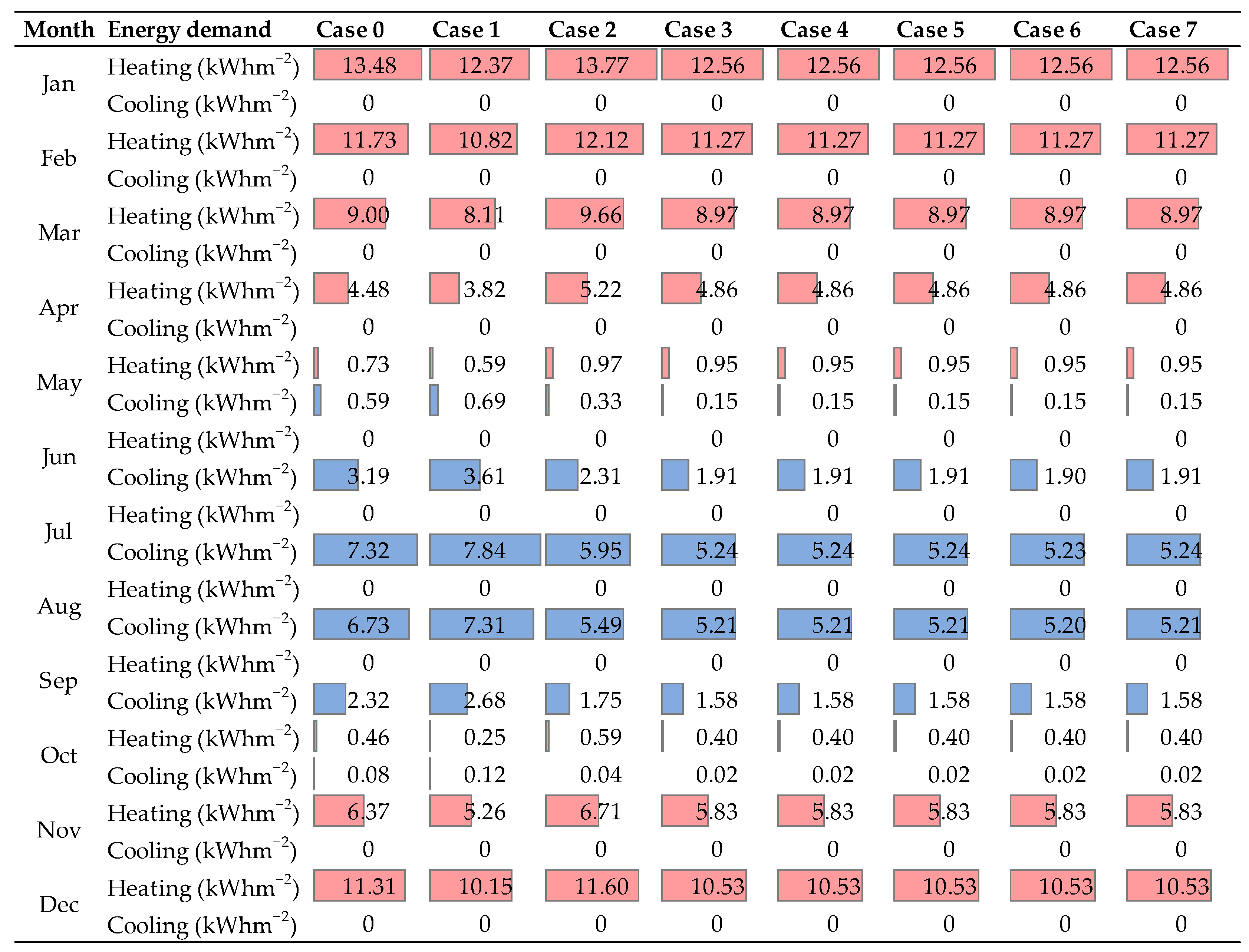

- The trends of thermal and cooling energy flows (Figure 11), as well as the annual specific cooling and thermal energy demands (Table 5), justify the values of PES and ΔCO2, showing how the SSF (Cases 3–7) struggled to perform well during the milder months (April, May, October), while, in harsher conditions, the SSF characteristics (dynamic cavity ventilation, insulation, dynamic shading) allowed for the best yearly performance; indeed, the SSF cases returned the best results among all the retrofit cases in terms of cooling energy demand reduction while performing worse than Case 1 in terms of thermal energy demand reduction.

- In terms of cooling energy demand, all the simulation case studies using the proposed SSF system (Cases 3–7) returned similar monthly trends with a yearly reduction of about 30.2%, which amounts to a reduction in the annual specific cooling energy demand of about 6.1 kWh m−2 year−1 in comparison to the Case 0; the best month in terms of cooling energy demand reduction is July, with a decrease in the monthly specific cooling energy demand of about 2.1 kWh m−2 year−1 if compared with the reference case;

- In terms of thermal energy demand, all the simulation case studies with the SSF system (Cases 3–7) returned a yearly reduction of about 3.8%, which amounts to a reduction in the annual specific thermal energy demand of about 2.2 kWh m−2 year−1 in comparison to the Case 0; the best month in terms of thermal energy demand reduction was January, with a decrease in the monthly specific thermal energy demand of about 0.9 kWh m−2 year−1 if compared with the reference case;

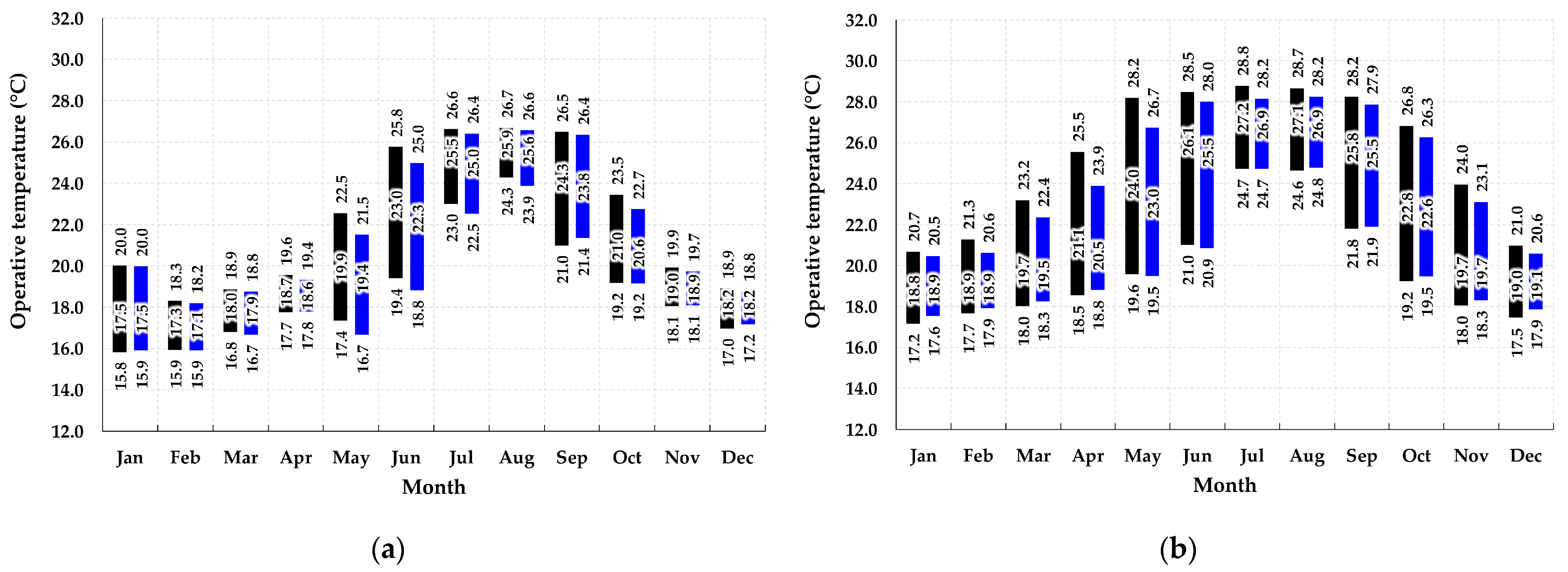

- The comparison of the monthly minimum, average, and maximum values of the operative temperatures (Figure 12) between the two cases, Case 0 (black) and Case 6 (blue), demonstrated that the use of the SSF system (Case 6) leads to lower maximum temperature values across the whole year while returning, in terms of minimum temperatures, slightly higher values during the heating months and slightly lower values during the cooling months, resulting in a slightly more comfortable indoor environment overall; a similar trend can be observed in both TZ_3 and TZ_5. The operative temperature values also confirm that the SSF does not perform as well during milder months, as already highlighted by the energy flows’ results (Figure 11).

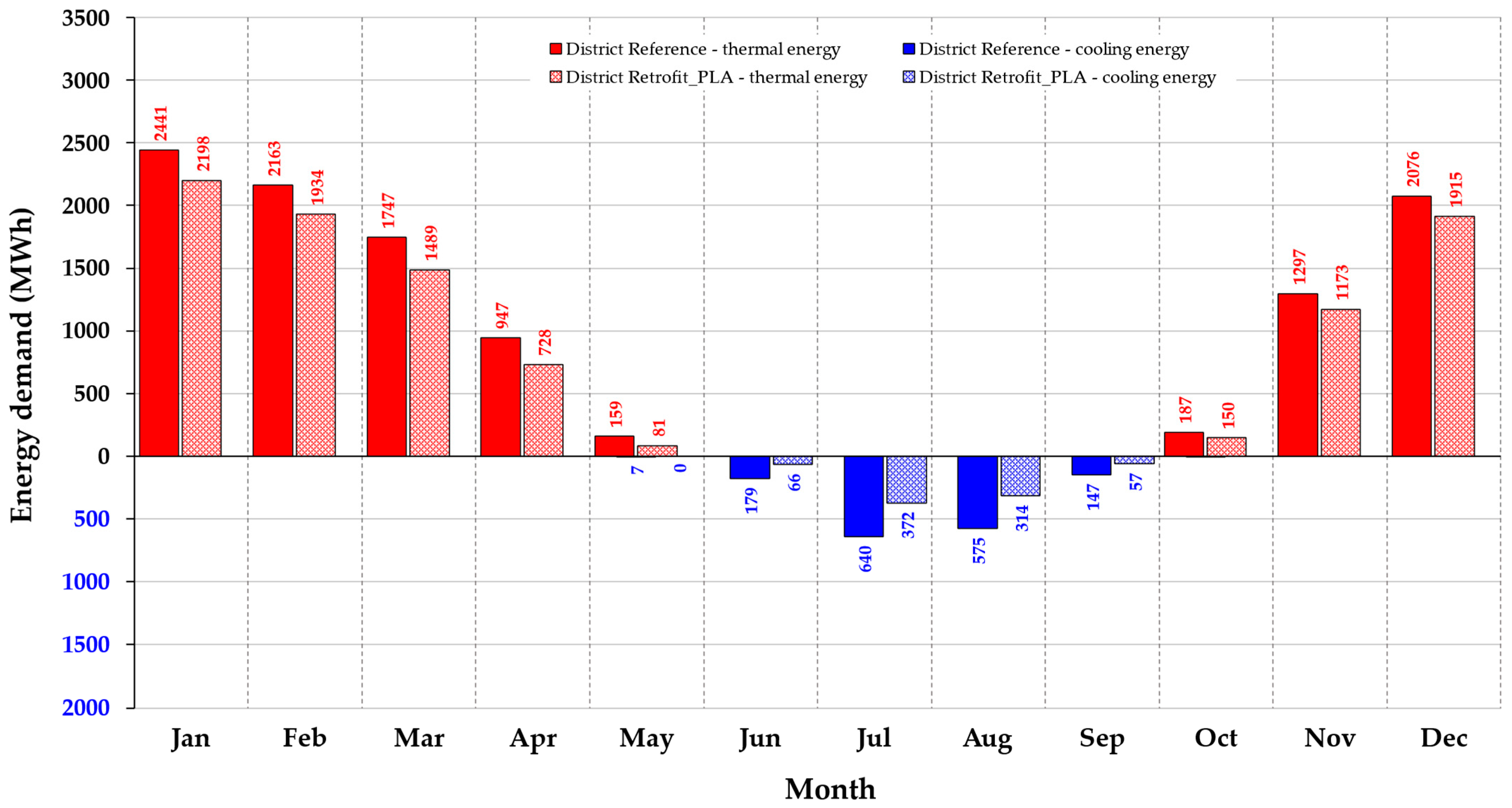

3.2. Energy and Environmental Impacts of the Retrofit on the District–Area Level

4. Discussion

- The simulations were conducted using climate data specific to southern Italy (Monterusciello), limiting the generalizability of the findings to other regions;

- The energy and environmental impact assessments relied on numerical simulations in TRNSYS, which simplified variables such as occupant behaviour, actual solar gains, and thermal bridges. These simplifications may lead to discrepancies between simulated and actual energy savings;

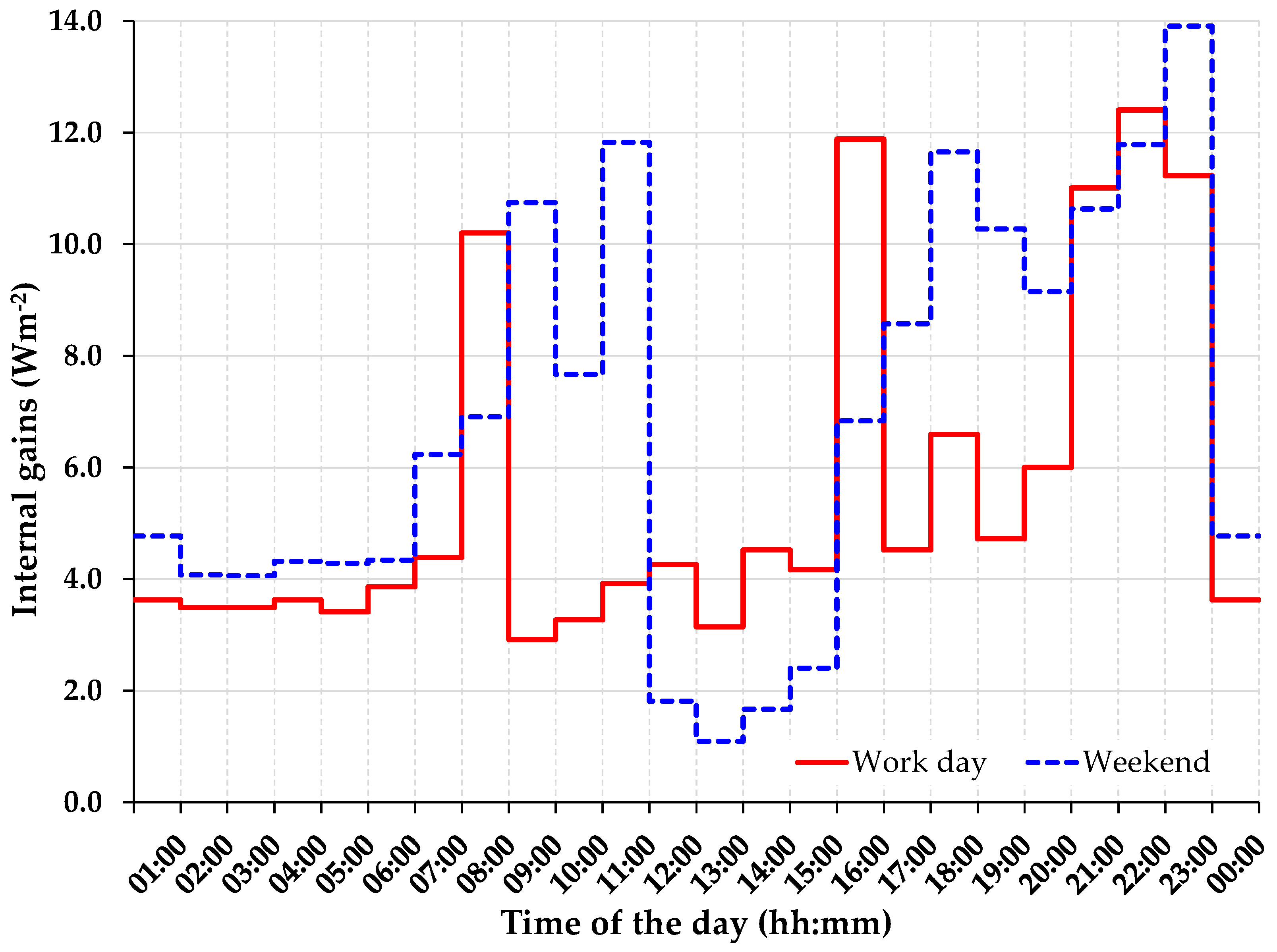

- No real data on occupant behaviour were available at the time of this study; demand and gain profiles were simplified using references from scientific literature, local legislation, interviews, or archival data;

- This study focused solely on the energy and environmental performance of the passive retrofit without addressing interventions on active systems;

- The economic and social benefits of retrofitting, particularly in public housing contexts, were only briefly addressed, with no in-depth analysis of how large-scale retrofits could be implemented from a policy or regulatory standpoint. The proposed solutions may face challenges related to policy frameworks, financing mechanisms, or homeowner adoption, especially in areas with fewer incentives for energy-efficient retrofits.

5. Conclusions

- The proposed dynamic SSF system (Cases 3–7) returned better performance in terms of primary energy saving (PES) and reduction in carbon dioxide equivalent emissions (ΔCO2) in comparison to traditional passive retrofit actions (Cases 1 and 2);

- Cases 3–7 demonstrated reductions in terms of PES (up to 10.5%) and ΔCO2 (up to 2.01 tonCO2,eq per year), thanks to a reduction of both the cooling energy demand of about 6.1 kWh m−2 year−1 and the thermal energy demand of about 2.2 kWh m−2 year−1 in comparison to the reference case (Case 0);

- Considering the refurbishment of the whole Area_A of the Monterusciello district using the SSF integrating fixed 3D-printed PLA and dynamic fabric modules, the analyses returned a PES value of 16.4% and a ΔCO2 value equal to 285 tonCO2,eq.

- Explore the performance of the SSF system in different climates (e.g., colder or more humid regions) and in urban contexts with varying morphologies or denser city centers;

- Conduct real-world pilot projects to validate the efficacy of the simulations and identify unforeseen challenges related to installation, maintenance, or user adoption;

- Develop more dynamic models that include occupant behaviour or varying internal gains based on human activity patterns to improve the representation of energy use;

- Investigate the long-term durability and economic feasibility of different SSF materials and designs to provide more comprehensive guidance for stakeholders and policymakers;

- Carry out field surveys, including interviews and audits with occupants, to also assess indoor comfort parameters, such as thermal and visual comfort, and optimize the dynamic control logics of the SSF system for energy savings, operative temperatures, and daylight distribution.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A

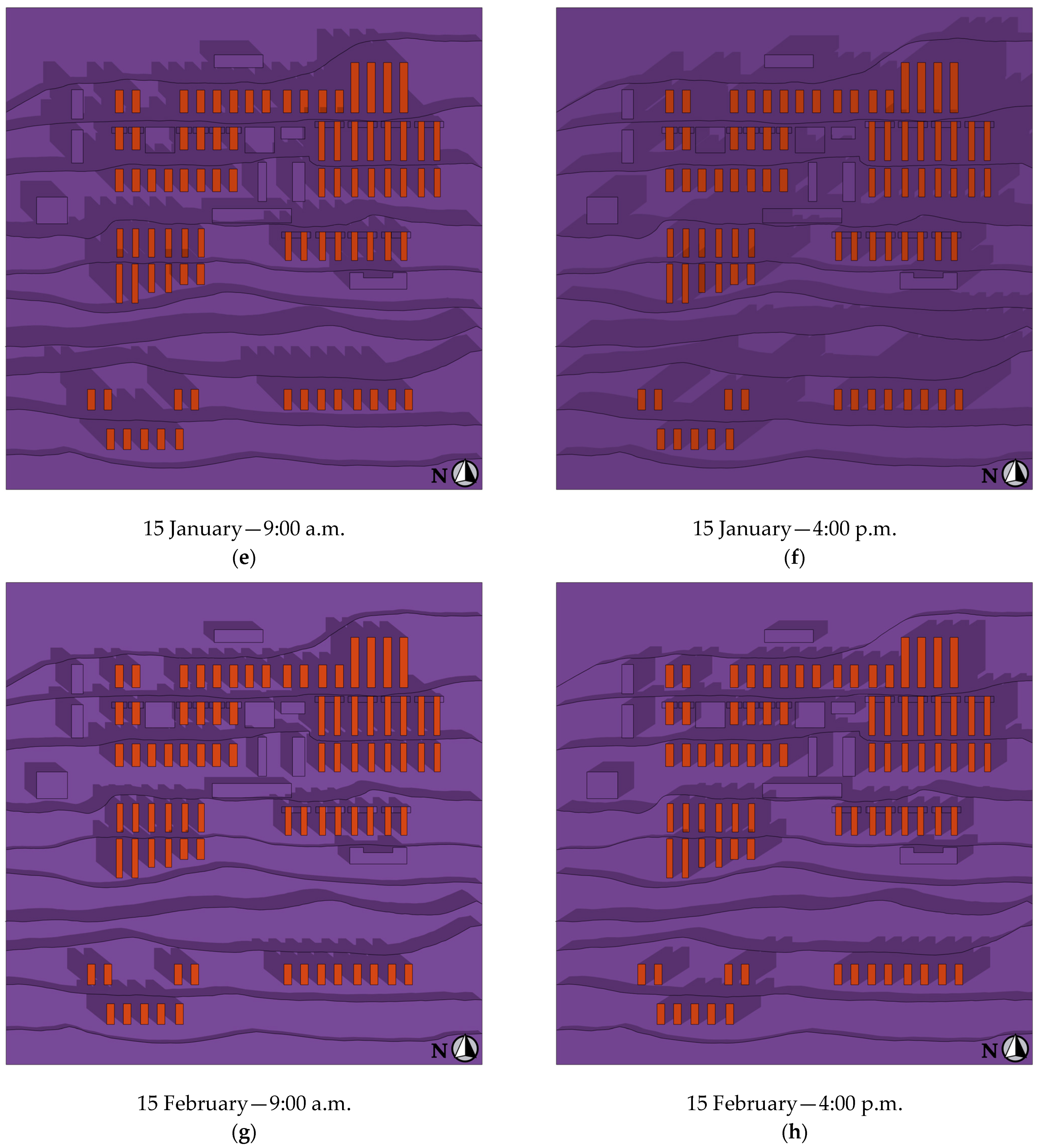

- In November and December, shadows are longer in both the morning and afternoon, consistent with the sun being at a lower altitude during winter months. The shading pattern indicates that the sun is rising and setting closer to the horizon, which means that the buildings block more sunlight and create deeper, more extended shadows;

- In January, the length of the shadows remains substantial, though slightly shorter than in December due to the sun’s position being higher in the sky as the days start lengthening;

- In February and March, the shadows become noticeably shorter compared to the previous months, especially at 9:00 a.m. This is due to the higher sun’s position in the sky as spring approaches, reducing the overall shadow length and modifying the shading pattern.

References

- Energy Statistics Data Browser—Data Tools—IEA. Available online: https://www.iea.org/data-and-statistics/data-tools/energy-statistics-data-browser?country=WEOEUR&fuel=Energy%20consumption&indicator=TFCShareBySector (accessed on 22 July 2024).

- Kitsopoulou, A.; Ziozas, N.; Iliadis, P.; Bellos, E.; Tzivanidis, C.; Nikolopoulos, N. Energy Performance Analysis of Alternative Building Retrofit Interventions for the Four Climatic Zones of Greece. J. Build. Eng. 2024, 87, 109015. [Google Scholar] [CrossRef]

- Buildings—Energy System—IEA. Available online: https://www.iea.org/energy-system/buildings (accessed on 19 September 2024).

- European Commission. Energy Performance of Buildings Directive. Available online: https://energy.ec.europa.eu/topics/energy-efficiency/energy-efficient-buildings/energy-performance-buildings-directive_en (accessed on 22 July 2024).

- Wu, S.; Sun, K.; Bi, Y.; Shi, M.; Yu, L. Carbon Reduction Potential of Housing Retrofits: Evidence from China. Renew. Sustain. Energy Rev. 2024, 200, 114580. [Google Scholar] [CrossRef]

- Nikdel, L.; Agee, P.; Reichard, G.; McCoy, A. Net Zero Energy Housing: An Empirical Analysis from Measured Data. Energy Build. 2022, 270, 112275. [Google Scholar] [CrossRef]

- Yilmaz, D.G.; Cesur, F. A Study for the Improvement of the Energy Performance Certificate (EPC) System in Turkey. Sustainability 2023, 15, 14074. [Google Scholar] [CrossRef]

- Kirme, S.K.; Kapse, V.S. A comprehensive Review of Residential Building Energy Efficiency Measures in India. Energy Build. 2024, 319, 114537. [Google Scholar] [CrossRef]

- Panjaitan, T.W.S.; Pandyaswargo, A.H.; Atmaja, T.D.; Firman, F.A.; Al Irsyad, M.I. Drawing Insights from Japan’s Energy Efficiency Policies for Indonesia’s Progress. Indones. J. Energy 2024, 7, 107–123. [Google Scholar] [CrossRef]

- Berry, S.; Moore, T.; Ambrose, M. Australia’s Experience of Combining Building Energy Standards and Disclosure Regulation. Front. Sustain. Cities 2022, 4, 801460. [Google Scholar] [CrossRef]

- Moskaleva, A.; Safonov, A.; Hernández-Montes, E. Fiber-Reinforced Polymers in Freeform Structures: A Review. Buildings 2021, 11, 481. [Google Scholar] [CrossRef]

- Li, Q.; Zanelli, A. A Review on Fabrication and Applications of Textile Envelope Integrated Flexible Photovoltaic Systems. Renew. Sustain. Energy Rev. 2021, 139, 110678. [Google Scholar] [CrossRef]

- Ahmed, G.H. A Review of “3D Concrete Printing”: Materials and Process Characterization, Economic Considerations and Environmental Sustainability. J. Build. Eng. 2023, 66, 105863. [Google Scholar] [CrossRef]

- Bedarf, P.; Dutto, A.; Zanini, M.; Dillenburger, B. Foam 3D Printing for Construction: A Review of Applications, Materials, and processes. Autom. Constr. 2021, 130, 103861. [Google Scholar] [CrossRef]

- Craveiro, F.; Duarte, J.P.; Bártolo, H.; Bártolo, P. Moving Forward to 3D/4D Printed Building Facades. In Proceedings of the Progress in Digital and Physical Manufacturing. ProDPM 2019. Lecture Notes in Mechanical Engineering; Springer: Leiria, Portugal, 2019; pp. 277–282. [Google Scholar]

- Spanodimitriou, Y.; Ciampi, G.; Tufano, L.; Scorpio, M. Flexible and Lightweight Solutions for Energy Improvement in Construction: A Literature Review. Energies 2023, 16, 6637. [Google Scholar] [CrossRef]

- Ciampi, G.; Spanodimitriou, Y.; Scorpio, M.; Rosato, A.; Sibilio, S. Integration of a Flexible Tensile Material in a Second Skin Façade System: A Passive Method to Enhance the Energy Performances of the Italian Building Scenario. In Proceedings of the 2021 Building Simulation Conference, Bruges, Belgium, 1–3 September 2021; pp. 2821–2828. [Google Scholar]

- Basińska, M.; Kaczorek, D.; Koczyk, H. Economic and Energy Analysis of Building Retrofitting Using Internal Insulations. Energies 2021, 14, 2446. [Google Scholar] [CrossRef]

- Elzeyadi, I. The Impacts of Dynamic Façade Shading Typologies on Building Energy Performance and Occupant’s Multi-Comfort. Arch. Sci. Rev. 2017, 60, 316–324. [Google Scholar] [CrossRef]

- Ibañez-Puy, M.; Vidaurre-Arbizu, M.; Sacristán-Fernández, J.A.; Martín-Gómez, C. Opaque Ventilated Façades: Thermal and Energy Performance Review. Renew. Sustain. Energy Rev. 2017, 79, 180–191. [Google Scholar] [CrossRef]

- Saroglou, T.; Theodosiou, T.; Givoni, B.; Meir, I.A. Studies on the Optimum Double-Skin Curtain Wall Design for High-Rise Buildings in the Mediterranean Climate. Energy Build. 2020, 208, 109641. [Google Scholar] [CrossRef]

- Building Envelopes—IEA. Available online: https://www.iea.org/energy-system/buildings/building-envelopes#tracking (accessed on 19 September 2024).

- Funding Energiesprong Global Alliance Energiesprong Project. Available online: https://energiesprong.org/ (accessed on 22 July 2024).

- Santarsiero, G.; Misceo, M.; Aversa, P.; Candigliota, E.; Di Micco, A.; Hugony, F.; Manfredi, V.; Marghella, G.; Marzo, A.; Masi, A.; et al. Holistic Assessment for Social Housing Retrofitting: Integrating Seismic, Energy, and Social Aspects in the REHOUSE Project. Buildings 2024, 14, 3659. [Google Scholar] [CrossRef]

- Hu, X.; Xiang, Y.; Zhang, H.; Lin, Q.; Wang, W.; Wang, H. Active–Passive Combined Energy-Efficient Retrofit of Rural Residence with Non-Benchmarked Construction: A Case Study in Shandong Province, China. Energy Rep. 2021, 7, 1360–1373. [Google Scholar] [CrossRef]

- Brito-Coimbra, S.; Aelenei, D.; Gomes, M.G.; Rodrigues, A.M. Building Façade Retrofit with Solar Passive Technologies: A Literature Review. Energies 2021, 14, 1774. [Google Scholar] [CrossRef]

- Balali, A.; Hakimelahi, A.; Valipour, A. Identification and Prioritization of Passive Energy Consumption Optimization Measures in the Building Industry: An Iranian Case Study. J. Build. Eng. 2020, 30, 101239. [Google Scholar] [CrossRef]

- Ciampi, G.; Spanodimitriou, Y.; Scorpio, M.; Rosato, A.; Sibilio, S. Energy Performance of PVC-Coated Polyester Fabric as Novel Material for the Building Envelope: Model Validation and a Refurbishment Case Study. J. Build. Eng. 2021, 41, 102437. [Google Scholar] [CrossRef]

- Zhao, Z.; Liu, H.; Chen, Z. Thermal Behavior of Large-Span Reticulated Domes Covered by ETFE Membrane Roofs under Solar radiation. Thin-Walled Struct. 2017, 115, 1–11. [Google Scholar] [CrossRef]

- Flor, J.-F.; Liu, D.; Sun, Y.; Beccarelli, P.; Chilton, J.; Wu, Y. Optical Aspects and Energy Performance of Switchable Ethylene-tetrafluoroethylene (ETFE) Foil Cushions. Appl. Energy 2018, 229, 335–351. [Google Scholar] [CrossRef]

- Karimi, F.; Soltani, P.; Zarrebini, M.; Hassanpour, A. Acoustic and Thermal Performance of Polypropylene Nonwoven Fabrics for Insulation in Buildings. J. Build. Eng. 2022, 50, 104125. [Google Scholar] [CrossRef]

- Scorpio, M.; Ciampi, G.; Spanodimitriou, Y.; Laffi, R.; Rosato, A.; Sibilio, S. Double-Skin Facades With Semi-Transparent Modules For Building Retrofit Actions: Energy And Visual Performances. In Proceedings of the Building Simulation 2019, Rome, Italy, 2–4 September 2019. [Google Scholar]

- Spanodimitriou, Y.; Ciampi, G.; Scorpio, M.; Mokhtari, N.; Teimoorzadeh, A.; Laffi, R.; Sibilio, S. Passive Strategies for Building Retrofitting: Performances Analysis and Incentive Policies for the Iranian Scenario. Energies 2022, 15, 1628. [Google Scholar] [CrossRef]

- Ciampi, G.; Spanodimitriou, Y.; Nocente, A.; Scorpio, M.; Sibilio, S. Energy Performances of Tensile Material in Building Renovation in the Nordic Region. E3S Web Conf. 2022, 362, 05003. [Google Scholar] [CrossRef]

- Kamel, E.; Kazemian, A. BIM-Integrated Thermal Analysis and Building Energy Modeling in 3D-Printed Residential Buildings. Energy Build. 2023, 279, 112670. [Google Scholar] [CrossRef]

- Na, S.; Kim, S.; Moon, S. Additive Manufacturing (3D Printing)-Applied Construction: Smart Node System for an Irregular Building Façade. J. Build. Eng. 2022, 56, 104743. [Google Scholar] [CrossRef]

- Sarakinioti, M.V.; Konstantinou, T.; Turrin, M.; Tenpierik, M.; Loonen, R.; De Klijn-Chevalerias, M.L.; Knaack, U. Development and Prototyping of an Integrated 3D-Printed Façade for Thermal Regulation in Complex Geometries. J. Facade Des. Eng. 2018, 6, 29–40. [Google Scholar] [CrossRef]

- Ciampi, G.; Spanodimitriou, Y.; Scorpio, M.; Rosato, A.; Sibilio, S. Energy Performances Assessment of Extruded and 3D Printed Polymers Integrated into Building Envelopes for a South Italian Case Study. Buildings 2021, 11, 141. [Google Scholar] [CrossRef]

- Mortarotti, G.; Morganti, M.; Cecere, C. Thermal Analysis and Energy-Efficient Solutions to Preserve Listed Building Façades: The INA-Casa Building Heritage. Buildings 2017, 7, 56. [Google Scholar] [CrossRef]

- Mokhtari, N.; Ciampi, G.; Spanodimitriou, Y.; Nocente, A.; Manni, M.; Lobaccaro, G.; Scorpio, M.; Sibilio, S. Textile as Second-Skin Façade for Building Envelope Retrofitting: A Numerical Analysis on the Comfort, Energy and Environmental Impacts in Different European Climates. In Proceedings of the Building Simulation 2023: 18th Conference of IBPSA, Shanghai, China, 4–6 September 2023; pp. 1901–1908. [Google Scholar]

- TRNSYS. Transient System Simulation Tool. Available online: http://www.trnsys.com (accessed on 22 July 2024).

- DPR 412/93 and DPR 551/99 Decree of the President of the Italian Republic. Available online: https://www.gazzettaufficiale.it/eli/id/2000/04/06/000G0118/sg (accessed on 19 September 2024).

- Solano, V. Monterusciello: The New Town. Available online: https://www.valentinasolano.it/monterusciello-the-new-town/ (accessed on 19 September 2024).

- Discetti, E.; Discetti, P.; Masturzo, A. Progetto Esecutivo Intervento di “Rigenerazione Eco-Energetica Degli Edifici Erp del Quartiere di Monterusciello”; Pozzuoli. 2020. Available online: https://halleyweb.com/c063060/zf/index.php/atti-amministrativi/delibere/dettaglio/atto/G5WpBMETUTT0-A (accessed on 19 September 2024).

- Trimble Inc. SketchUp. Available online: https://www.sketchup.com/en (accessed on 22 July 2024).

- Energyplus Energyplus_Weather_Naples.162890_IWEC. Available online: https://energyplus.net/weather-location/europe_wmo_region_6/ITA/ITA_Naples.162890_IWEC (accessed on 22 April 2024).

- CEN/TC 228—Heating Systems in Buildings; CEN/TC 228/WG 4—Calculation Methods and System Performance and Evaluation EN 12831:2003—Heating Systems in Buildings—Method for Calculation of the Design Heat Load. 2003. Available online: https://standards.iteh.ai/catalog/standards/cen/5a4acdae-ff13-4411-8b0b-b54c65c4f91c/en-12831-2003?srsltid=AfmBOoojYgMeuCkBaPak05TkrGlD8bPFY7-i5boCuMBaWJY8BDR4vibn (accessed on 19 September 2024).

- CTI UNI TS 11300-1:2014; Energy Performance of Buildings—Part 1: Evaluation of Energy Need for Space Heating and Cooling. UNI: Milan, Italy, 2014.

- Angrisani, G.; Canelli, M.; Roselli, C.; Sasso, M. Microcogeneration in Buildings with Low Energy Demand in Load Sharing Application. Energy Convers. Manag. 2015, 100, 78–89. [Google Scholar] [CrossRef]

- Barton, J.; Thomson, M. CREST Demand Model v2.3.3—A High-Resolution Stochastic Integrated Ther-mal-Electrical Domestic Demand Simulation Tool 2020. Available online: https://repository.lboro.ac.uk/articles/dataset/CREST_Demand_Model_v2_0/2001129 (accessed on 19 September 2024).

- Zarrella, A.; De Carli, M.; Peretti, C. Radiant Floor Cooling Coupled with Dehumidification Systems in Residential Buildings: A Simulation-Based Analysis. Energy Convers. Manag. 2014, 85, 254–263. [Google Scholar] [CrossRef]

- Clint Technical Data Sheet Model CRA/K 15÷131. Available online: https://clint.it/en/products/watercooled-condenserless-liquid-chillers-and-heat-pumps-for-commercial-industrial-application-remote-condensers-3/watercooled-water-chillers-and-heat-pumps/cwwkwp-15151/ (accessed on 19 September 2024).

- Plastifab Plastispan-Insulation. Available online: https://www.plastifab.com/products/plastispan-insulation/plastispan-20.html (accessed on 10 September 2024).

- Settino, J.; Carpino, C.; Perrella, S.; Arcuri, N. Multi-Objective Analysis of a Fixed Solar Shading System in Different Climatic Areas. Energies 2020, 13, 3249. [Google Scholar] [CrossRef]

- Mandalaki Maria and Tsoutsos, T. Shading Systems: Their Relation to Thermal Conditions. In Solar Shading Systems: Design, Performance, and Integrated Photovoltaics; Springer International Publishing: Cham, Switzerland, 2020; pp. 23–66. ISBN 978-3-030-11617-0. [Google Scholar]

- TRNSYS Thermal Energy System Specialists, TESS Individual Components—TYPE 1230: Ventilated Air Cavity Wall (Ventilated Facade). Available online: https://www.trnsys.com/tess-libraries/individual-components.php.html (accessed on 19 September 2024).

- Shemelya, C.; De La Rosa, A.; Torrado, A.R.; Yu, K.; Domanowski, J.; Bonacuse, P.J.; Martin, R.E.; Juhasz, M.; Hurwitz, F.; Wicker, R.B.; et al. Anisotropy of Thermal Conductivity in 3D Printed Polymer Matrix Composites for Space Based Cube Satellites. Addit. Manuf. 2017, 16, 186–196. [Google Scholar] [CrossRef]

- Hasselman, D.; Johnson, L.F. Effective Thermal Conductivity of Composites with Interfacial Thermal Barrier Resistance. J. Compos. Mater. 1987, 21, 508–515. [Google Scholar] [CrossRef]

- Sarvestani, H.Y.; Akbarzadeh, A.; Niknam, H.; Hermenean, K. 3D Printed Architected Polymeric Sandwich Panels: Energy Absorption and Structural Performance. Compos. Struct. 2018, 200, 886–909. [Google Scholar] [CrossRef]

- Acrylonitrile Styrene Acrylate (ASA) Filament. Available online: https://www.makeitfrom.com/material-properties/Acrylonitrile-Styrene-Acrylate-ASA (accessed on 4 July 2024).

- Polyamide (PA, Nylon) 6/6 (66, Nylon 101) Filament. Available online: https://www.makeitfrom.com/material-properties/Polyamide-PA-Nylon-6-6-66-Nylon-101 (accessed on 4 July 2024).

- Glycol-Modified Polyethylene Terephthalate (PETG, PET-G) Filament. Available online: https://www.makeitfrom.com/material-properties/Glycol-Modified-Polyethylene-Terephthalate-PETG-PET-G (accessed on 4 July 2024).

- Polylactic Acid (PLA, Polylactide) Filament. Available online: https://www.makeitfrom.com/material-properties/Polylactic-Acid-PLA-Polylactide (accessed on 4 July 2024).

- Polymethylmethacrylate (PMMA, Acrylic) Filament. Available online: https://www.makeitfrom.com/material-properties/Polymethylmethacrylate-PMMA-Acrylic (accessed on 4 July 2024).

- Stephan, K.; Laesecke, A. The Thermal Conductivity of Fluid Air. J. Phys. Chem. Ref. Data 1985, 14, 227–234. [Google Scholar] [CrossRef]

- Gregor-Svetec, D. Polymers in Printing Filaments. In Polymers for 3D Printing: Methods, Properties, and Characteristics; William Andrew Publishing: Norwich, NY, USA, 2022; pp. 155–269. [Google Scholar] [CrossRef]

- Oladapo, B.I.; Bowoto, O.K.; Adebiyi, V.A.; Ikumapayi, O.M. Net Zero on 3D Printing Filament Recycling: A Sustainable Analysis. Sci. Total Environ. 2023, 894, 165046. [Google Scholar] [CrossRef]

- Serge Ferrari Frontside View 381. Available online: https://www.sergeferrari.com/productsfrontside-range/frontside-view-381 (accessed on 22 July 2024).

- Cortiços, N.D. Improving Residential Building Efficiency with Membranes Over Façades: The Mediterranean Context. J. Build. Eng. 2020, 32, 101421. [Google Scholar] [CrossRef]

- Ascione, F.; Bianco, N.; Iovane, T.; Mastellone, M.; Mauro, G.M. The Evolution of Building Energy Retrofit Via Double-Skin and Responsive Façades: A Review. Sol. Energy 2021, 224, 703–717. [Google Scholar] [CrossRef]

- DM 26 Giugno 2015 Italian Minister Decree. Available online: https://www.mimit.gov.it/index.php/it/normativa/decreti-interministeriali/decreto-interministeriale-26-giugno-2015-adeguamento-linee-guida-nazionali-per-la-certificazione-energetica-degli-edifici (accessed on 19 September 2024).

- Marrasso, E.; Roselli, C.; Sasso, M. Electric Efficiency Indicators and Carbon Dioxide Emission Factors for Power Generation by Fossil and Renewable Energy Sources on Hourly Basis. Energy Convers. Manag. 2019, 196, 1369–1384. [Google Scholar] [CrossRef]

| Parameter | Typology A | Typology B | Typology C | Typology D | Typology E |

|---|---|---|---|---|---|

| Length (m) | 36.60 | 81.00 | 46.00 | 33.30 | 63.10 |

| Width (m) | 13.00 | 13.00 | 10.00 | 12.40 | 10.00 |

| Height (m) | 12.00 | 15.00 | 9.00 | 15.00 | 15.00 |

| Covered ground area (m2) | 475.80 | 1053.00 | 460.00 | 412.92 | 631.00 |

| N. of floors (-) | 4 | 5 | 3 | 5 | 5 |

| N. of buildings per typology (-) | 25 | 4 | 24 | 19 | 10 |

| WWR North façade (%) | 8 | 8 | 5 | 9 | 5 |

| Opaque area (m2) | 143.07 | 178.84 | 85.15 | 169.84 | 141.92 |

| Transparent area (m2) | 12.93 | 16.26 | 4.85 | 16.15 | 8.08 |

| WWR South façade (%) | 5 | 6 | 4 | 6 | 4 |

| Opaque area (m2) | 147.36 | 184.2 | 86.76 | 175.00 | 144.60 |

| Transparent area (m2) | 8.54 | 10.80 | 3.24 | 10.80 | 5.40 |

| WWR West façade (%) | 21 | 21 | 19 | 21 | 21 |

| Opaque area (m2) | 345.92 | 969.93 | 335.53 | 395.94 | 751.48 |

| Transparent area (m2) | 93.28 | 251.52 | 78.46 | 103.56 | 195.02 |

| WWR East façade (%) | 20 | 22 | 21 | 22 | 21 |

| Opaque area (m2) | 350.58 | 955.61 | 327.04 | 392.06 | 746.21 |

| Transparent area (m2) | 88.62 | 268.84 | 86.96 | 107.44 | 200.29 |

| Component | Layers (Inside to Outside) | Thickness (mm) | Density (kg m−3) | Thermal Conductivity (W m−1 K−1) | Thermal Capacity (kJ kg−1 K−1) | Thermal Transmittance (W m−2 K−1) |

|---|---|---|---|---|---|---|

| External walls | Plaster | 15.0 | 1400 | 0.700 | 1.01 | 0.85 |

| Concrete panel | 80.0 | 1400 | 1.565 | 1.00 | ||

| Polystyrene panel | 37.0 | 30 | 0.045 | 1.22 | ||

| Vapor barrier | 3.0 | 1100 | 0.100 | 0.90 | ||

| Concrete panel | 120.0 | 1400 | 1.565 | 1.00 | ||

| Roof | Concrete panel | 180.0 | 1400 | 1.565 | 1.00 | 2.69 |

| Screed | 30.0 | 2000 | 1.060 | 1.00 | ||

| Bitumen | 10.0 | 1200 | 0.170 | 1.00 | ||

| Ground floor | Ceramic tiles | 10.0 | 1700 | 1.470 | 1.00 | 2.23 |

| Screed | 30.0 | 2000 | 1.060 | 1.00 | ||

| Concrete panel | 380.0 | 1400 | 1.565 | 1.00 | ||

| Internal walls | Plaster | 10.0 | 1400 | 0.700 | 1.01 | 2.38 |

| Bricks | 80.0 | 600 | 0.360 | 0.84 | ||

| Plaster | 10.0 | 1400 | 0.700 | 1.01 | ||

| Internal floors | Ceramic tiles | 10.0 | 1700 | 1.470 | 1.00 | 3.12 |

| Screed | 30.0 | 2000 | 1.060 | 1.00 | ||

| Concrete panel | 180.0 | 1400 | 1.565 | 1.00 | ||

| Windows | Single glass glazing | 4 | - | - | - | 6.12 |

| Filament | Density (kg m−3) | Specific Heat (kJ kg−1 K−1) | Thermal Conductivity (W m−1 K−1) | Cost Range ($ m−2) |

|---|---|---|---|---|

| ASA | 340 | 1.096 | 0.053 | 85–170 |

| NYLON PA66 | 493 | 1.096 | 0.077 | 197–395 |

| PETG | 411 | 1.065 | 0.082 | 82–164 |

| PLA pro HT | 401 | 1.220 | 0.045 | 120–200 |

| PMMA | 350 | 1.151 | 0.059 | 70–175 |

| Case Study | Retrofit Action and Material | Insulation Thickness (m) | Façades Thermal Transmittance (W m−2 K−1) |

|---|---|---|---|

| Case 0 | - | - | 0.85 |

| Case 1 | Insulation | 0.065 | 0.36 |

| Case 2 | Opaque fixed shading (no insulation) | - | 0.85 |

| Case 3 | SSF made of fixed 3D-printed ASA and dynamic fabric modules | 0.052 | 0.36 |

| Case 4 | SSF made of fixed 3D-printed NYLON and dynamic fabric modules | 0.054 | |

| Case 5 | SSF made of fixed 3D-printed PETG and dynamic fabric modules | 0.055 | |

| Case 6 | SSF made of fixed 3D-printed PLA and dynamic fabric modules | 0.051 | |

| Case 7 | SSF made of fixed 3D-printed PMMA and dynamic fabric modules | 0.053 |

| Simulation Case | Cooling Energy for Space Cooling Demand Associated with the Whole Building (kWh m−2 Year−1) | Thermal Energy for Space Thermal Demand Associated with the Whole Building (kWh m−2 Year−1) |

|---|---|---|

| Case 0 | 20.2 | 57.6 |

| Case 1 | 22.2 | 51.4 |

| Case 2 | 15.9 | 60.6 |

| Case 3 | 14.1 | 55.4 |

| Case 4 | 14.1 | 55.4 |

| Case 5 | 14.1 | 55.4 |

| Case 6 | 14.1 | 55.4 |

| Case 7 | 14.1 | 55.4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Spanodimitriou, Y.; Ciampi, G.; Tufano, L.; Scorpio, M.; Sibilio, S. Evaluating the Performance of Fixed 3D-Printed and Dynamic Fabric Modules in a Second-Skin Façade System: A Residential Case Study in Southern Italy at Building and District Scales. Buildings 2025, 15, 189. https://doi.org/10.3390/buildings15020189

Spanodimitriou Y, Ciampi G, Tufano L, Scorpio M, Sibilio S. Evaluating the Performance of Fixed 3D-Printed and Dynamic Fabric Modules in a Second-Skin Façade System: A Residential Case Study in Southern Italy at Building and District Scales. Buildings. 2025; 15(2):189. https://doi.org/10.3390/buildings15020189

Chicago/Turabian StyleSpanodimitriou, Yorgos, Giovanni Ciampi, Luigi Tufano, Michelangelo Scorpio, and Sergio Sibilio. 2025. "Evaluating the Performance of Fixed 3D-Printed and Dynamic Fabric Modules in a Second-Skin Façade System: A Residential Case Study in Southern Italy at Building and District Scales" Buildings 15, no. 2: 189. https://doi.org/10.3390/buildings15020189

APA StyleSpanodimitriou, Y., Ciampi, G., Tufano, L., Scorpio, M., & Sibilio, S. (2025). Evaluating the Performance of Fixed 3D-Printed and Dynamic Fabric Modules in a Second-Skin Façade System: A Residential Case Study in Southern Italy at Building and District Scales. Buildings, 15(2), 189. https://doi.org/10.3390/buildings15020189