Comprehensive Design Process of CEB-Reinforced Masonry Panels for Earthquake and Hurricane-Resilient Houses

Abstract

1. Introduction

2. General Aspects of Proposed Housing Solution

2.1. The Constructive Technology

2.2. Real Applications in Communitary Works

2.3. SHS-Multirisk Project Timeline

- Phase 1: UFRJ. In 2018 and 2019, studies of threats from strong winds [41] and earthquakes [42] took place at UFRJ, when a first detailed experimental phase was carried out and enabled the first design of the SHS-Multirisk 1.0 model. From mid-2019 to March 2020, immediately before the first lockdown due to the COVID-19 pandemic, the second experimental phase took place at the UFRJ Campus Fundão facilities, when shear tests were carried out on 16 wallets aiming to understand the contribution of the following factors in shear strength: arrangement of reinforcing joists along the height, percentage of reinforced vertically holes, and the existence of rough coating with plaster. Authors from UFRJ participated in this phase.

- Phase 2: UFRJ-UA Partnership. In April 2021, the partnership between UFRJ and UA began though a postdoctoral internship of the first author at UA, under the supervision of the second author and in collaboration with other authors from UA. The first phase results were used as inputs to the second phase. The aim was to define types of reinforced masonry panels and carry out a broad experimental program [43], intending to understand the cyclical behavior of full-scale panels for in-plane and out-of-plane bending shear and determine the mechanical properties of the masonry and its components through static tests. Based on these results, the residential model SHS-Multirisk 2.0 was proposed.

2.4. Overall Multi-Risk House Conception

2.4.1. The SHS-Multirisk 1.0 House Model

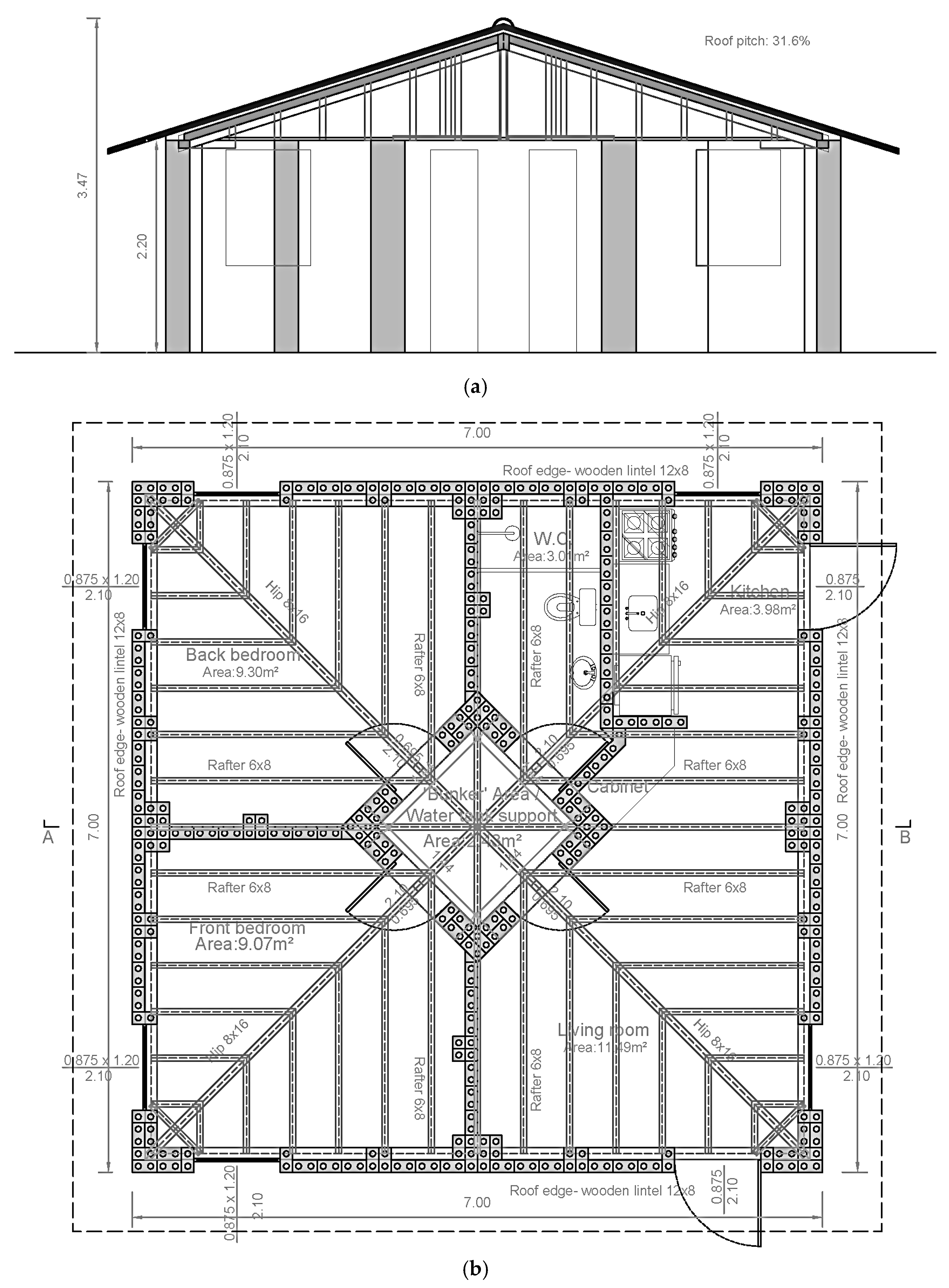

2.4.2. The SHS-Multirisk 2.0 Preliminary House Model

- House with just one floor and low ceiling height on the borders (next to 220 cm), which reduces bending moments at the base and wind pressures on the masonry panels, in addition to simplifying the work.

- Absence of a slab, which reduces bending moments at the bottom of the panels and simplifies the construction process.

- Roofs with semi-loose tiles, aiming at the formation of openings in the roof during strong winds and the consequent reduction in the pressure difference in the masonry panels (fuse effect).

- Maximization of symmetry in masonry and openings, which increases predictability and symmetry in the house’s response to different angles of horizontal force incidences.

- The adoption of the walls’ design as a combination of individualized patterned panels rather than panels with varying dimensions. By using a set of panels with similar stiffness, it is possible to conceive a resistant scheme that favors global torsional behavior and allows for flexible architectural options, within certain limits that are currently being studied. It also favors better distribution of loads and damage, increasing the predictability even in more advanced stages of damage. In addition, it is possible to recover the elements in isolation, reducing costs.

- To simplify the construction process, only two panel geometries were adopted, C and L, which are integrated into the preliminary model of Figure 2, along with the other elements mentioned above. Roof options are under study.

- Opening of external doors to the outside of the house, making it easier for residents to leave in the event of a disaster occurrence. Opening doors to the outside, as well as opening internal doors towards outside the ‘bunker’ area, also makes it easier for residents to break down doors if these elements are jammed after the adverse event.

- The use of timber to brace the panels against their out-of-plane behavior, allowing the transfer of forces/displacements to the panels with in-plane behavior (bracing system and tensioned timber lines).

- Masonry lintel’s elimination and use of the wooden beam on the roof edge as a slight lintel.

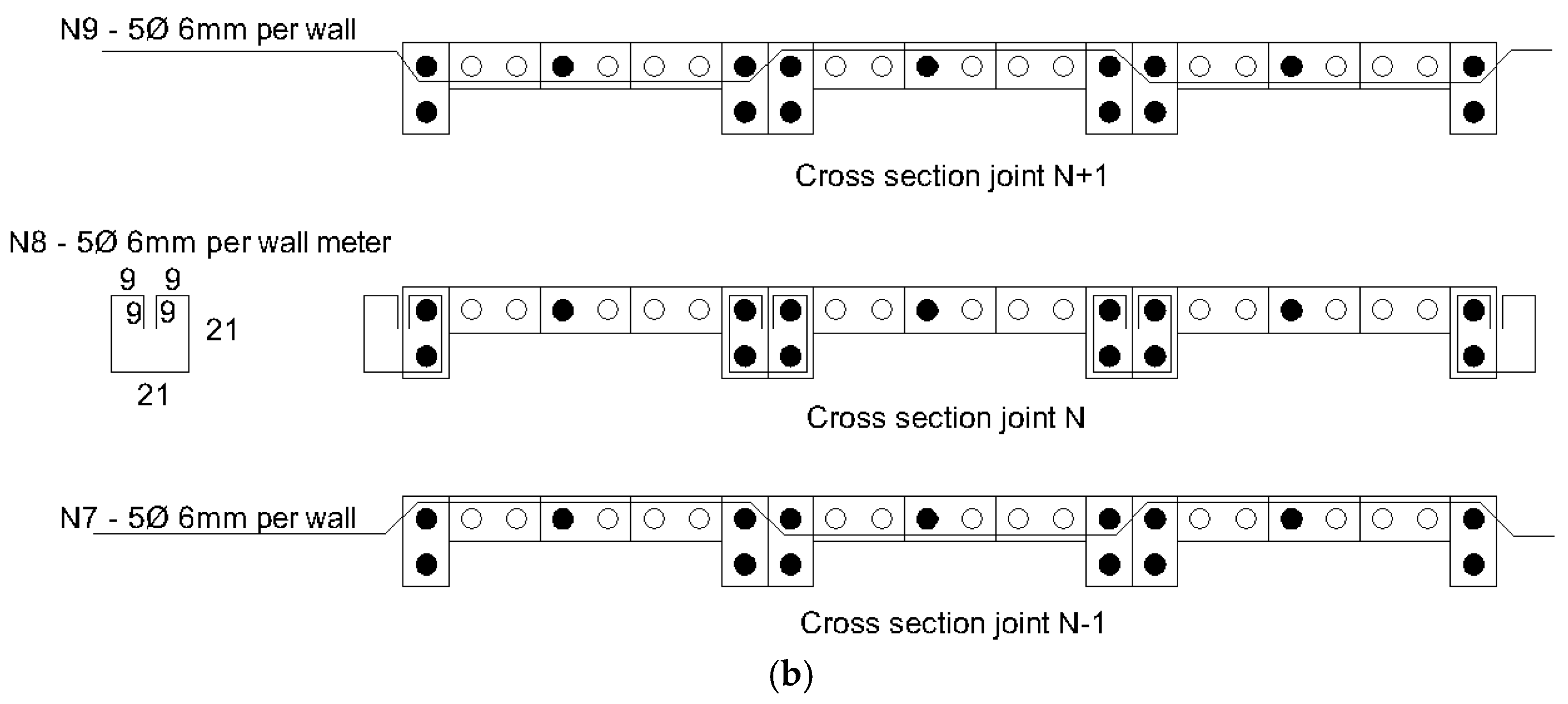

- Presence of stiffeners at each meter of masonry on the sides of door and window openings.

- Presence of a central core of L-shaped panels to function as a ‘bunker’ for emergency shelter for up to six people during hurricanes and as an isolated support structure for the water tank.

- Overall cost limitation for a house of smaller than 50 m2, considering that the project’s target audience is composed of vulnerable communities and larger houses could make the project economically unfeasible.

2.5. Novel Contribution and Advantages of House 2.0’s Panels

- Panels’ geometry allows for the creation of a bunker region inside the house, what differentiates SHS 2.0 concept and design.

- Panels’ typologies and geometry allow for symmetric distribution of loads and resistances, contributing to house’s predictable behavior in different directions.

- The construction technology adopted in the panels makes it easy to carry out maintenance and recovery of damaged panels.

- The panels’ design was integrated into a special multi- and interdisciplinary design, making it possible to face hurricane and earthquake hazards.

- The adopted technology allows for self-construction and has low environmental impacts.

- The findings have practical implications for vulnerable communities in disaster-prone regions, offering a viable solution for housing reconstruction and risk mitigation.

3. Materials and Methods

- (a)

- Preliminary architectural design (Section 2.4.1);

- (b)

- Preliminary structural panels’ design (Section 3.1);

- (c)

- Panels’ introductory experimental study (Section 3.2);

- (d)

- New panels’ design (Section 3.3);

- (e)

- New architectural design (Section 2.4.2);

- (f)

- Panels’ main experimental study (Section 3.4);

- (g)

- Panels’ design improvement (Section 3.5);

- (h)

- Architectural design improvement;

- (i)

- House 2.0 computer modeling;

- (j)

- House 2.0 structural behavior analysis under different load scenarios;

- (k)

- Adjustments and obtaining the final residence model.

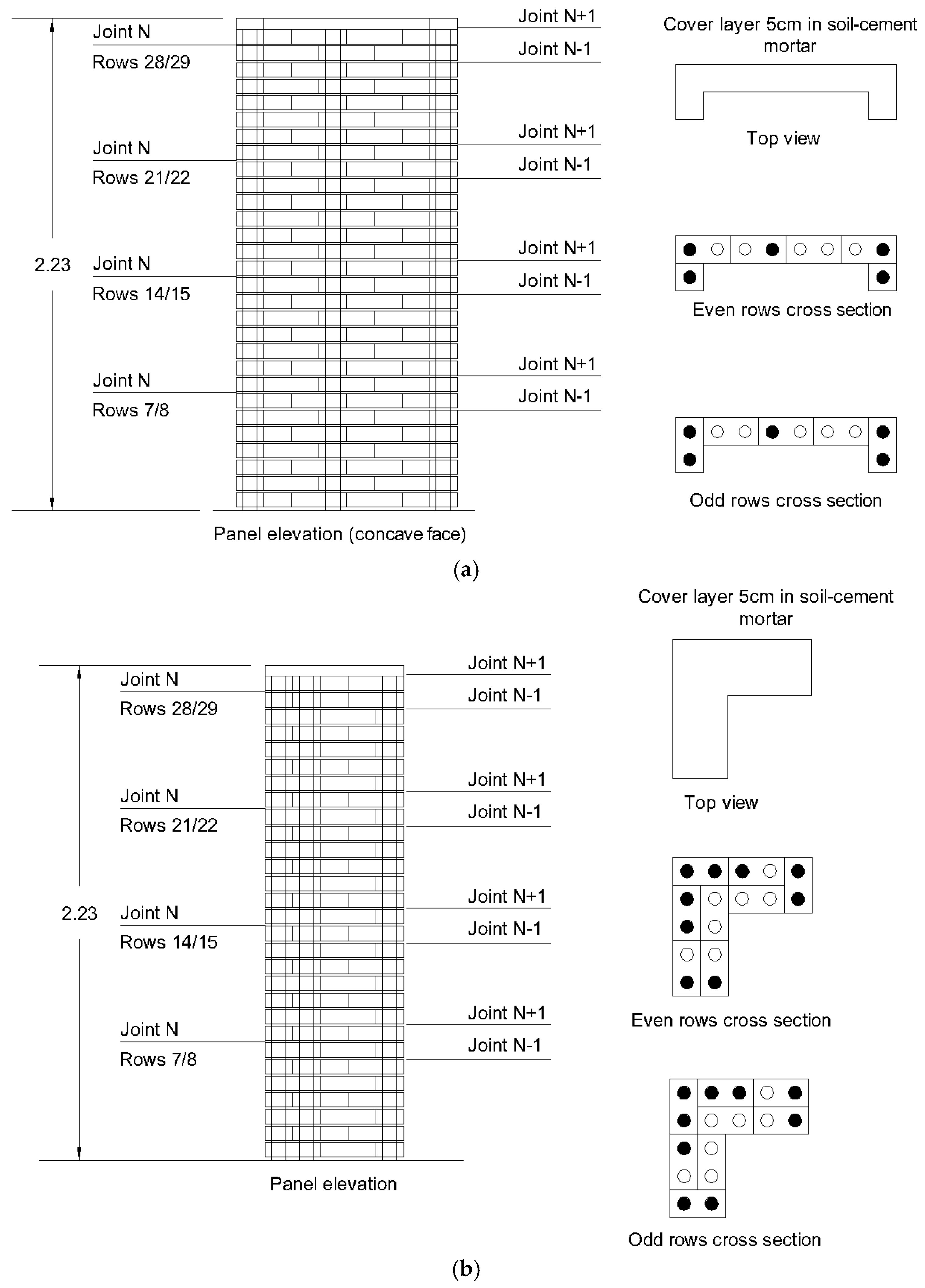

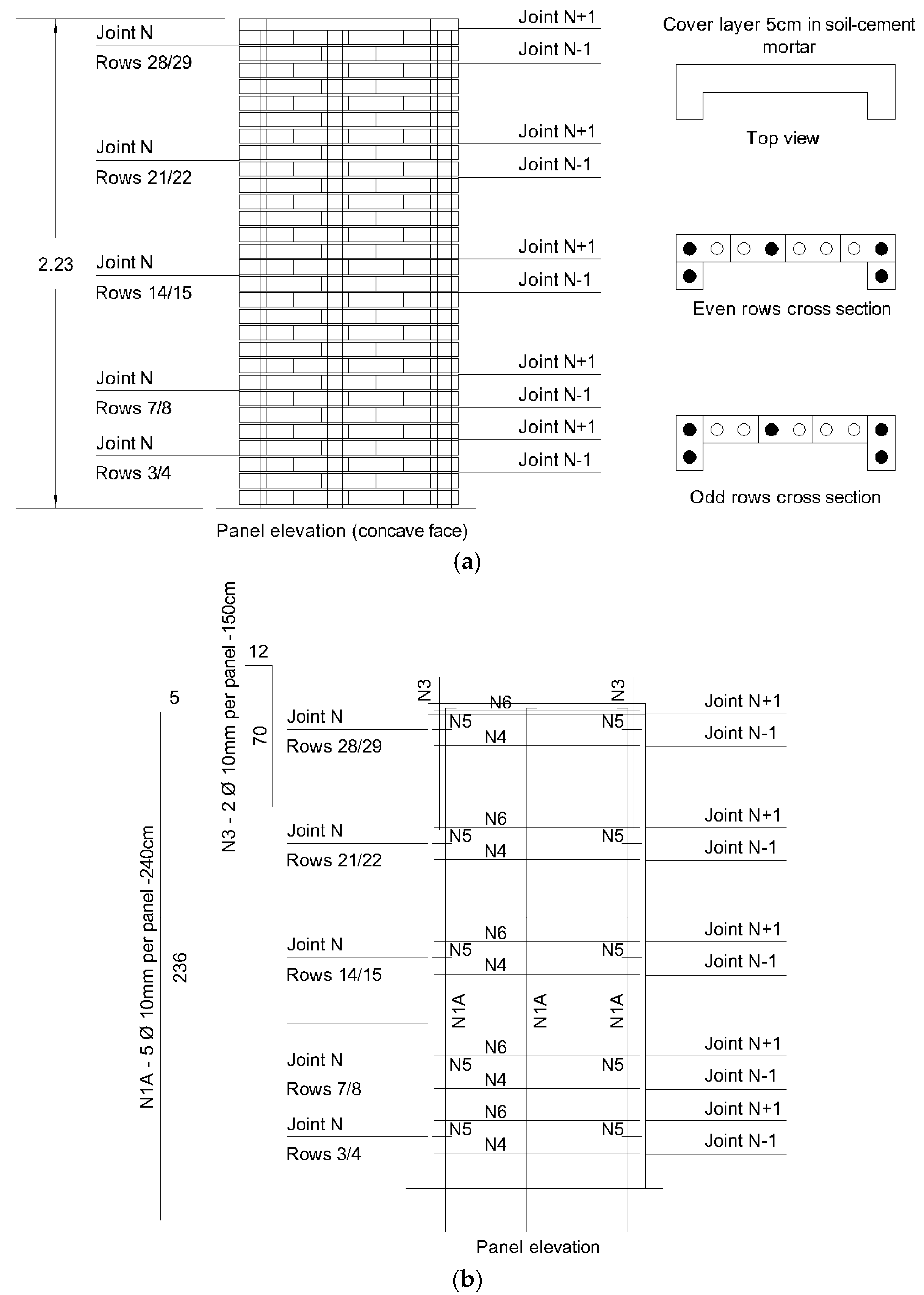

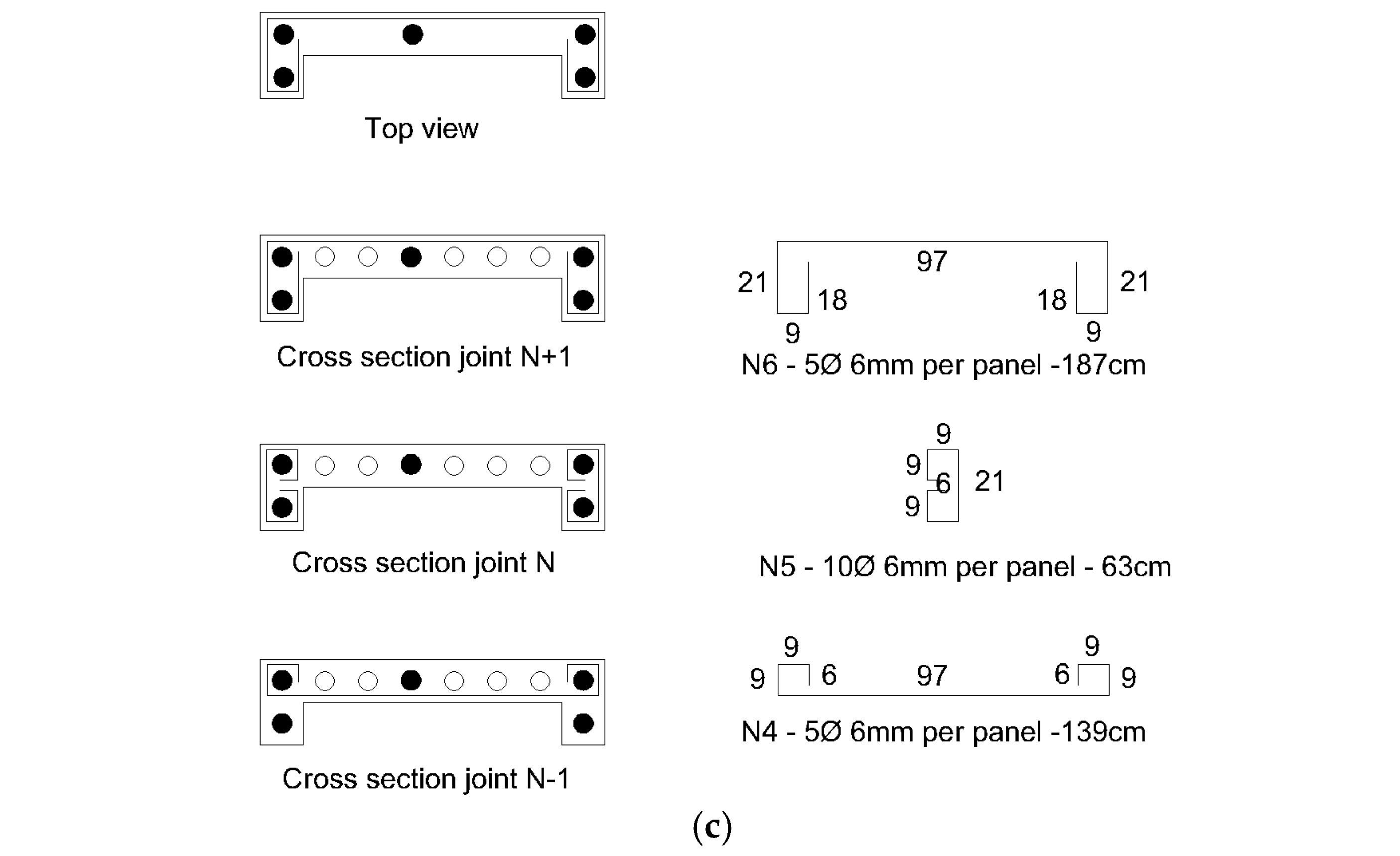

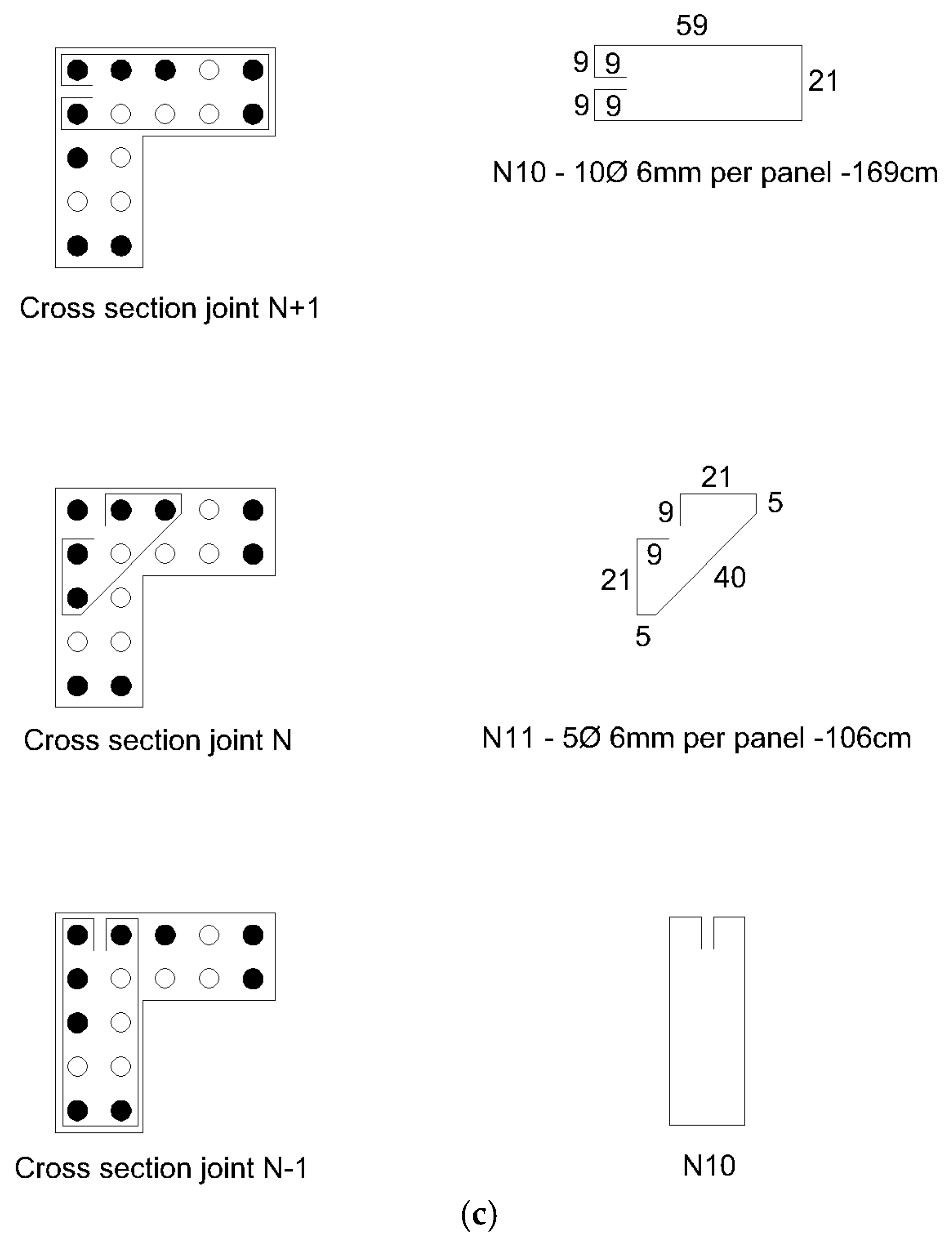

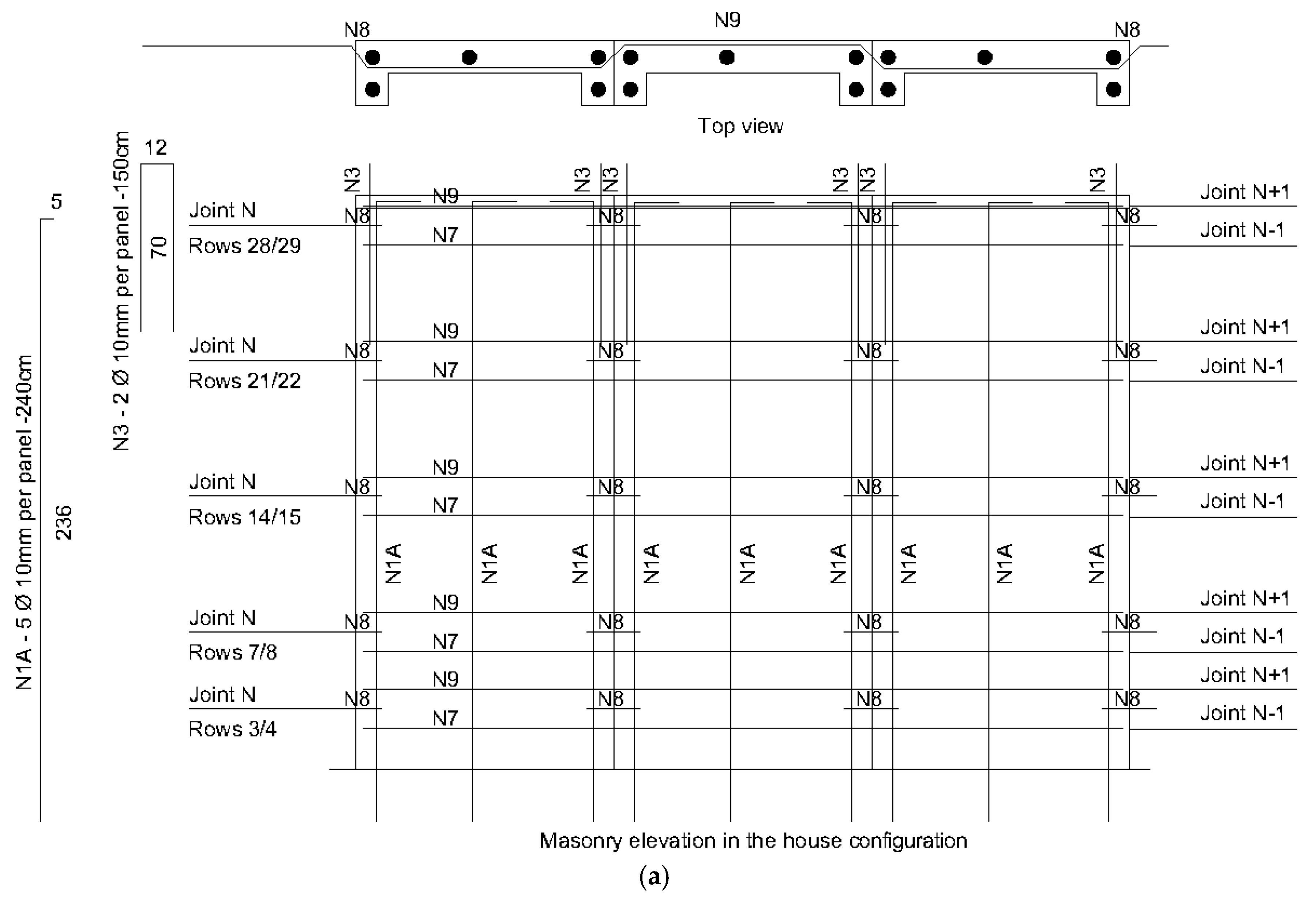

3.1. Strucutural Panels’ Preliminary Design

3.2. Panels’ Introductory Experimental Study

- Multifactorial experiment in wallets. Since the ability to withstand horizontal forces depends on compression and tensile elements, it was necessary to improve the understanding of how these elements could be modified, aiming to obtain better panel performance. Thus, an experimental program was developed in Brazil, from 2019 to 2020, consisting of a multifactorial experiment with 16 wallets, with the objective of understanding the influence of the following factors on the panels’ shear strength: arrangement of reinforcing joists along the height, percentage of holes reinforced vertically, and the existence of rough coating with plaster.

- Experiments to select components. In 2021, at the University of Aveiro, experiments were carried out to select the mix that would be used in the mortars for manufacturing the blocks, in the coating, and in the filling of the joints and holes in the blocks. Furthermore, tests were carried out to verify the adhesion between the soil/cement mortar and reinforcement, aiming to provide assertive choices for the experimental campaign performed in phase 2. These results can be found in [43].

3.2.1. Multifactorial Shear Experiment on Wallets

- 1V.GP.SE: One joist, 50% of the holes grouted and without plaster.

- 1V.GT.SE: One joist, 100% of the holes grouted and without plaster.

- 1V.GP.CE: One joist, 50% of holes grouted and plastered.

- 1V.GT.CE: One joist, 100% of holes grouted and plastered.

- 2V.GP.SE: One joist at the top and one in the middle, 50% of the holes grouted and without plaster.

- 2V.GT.SE: One top joist and one intermediate, 100% of the holes grouted and without plaster.

- 2V.GP.CE: One joist at the top and another in the middle, 50% of the holes grouted and plastered.

- 2V.GT.CE: One joist at the top and one in the middle, 100% of the holes grouted and plastered.

Multifactorial Experiment Analysis

3.2.2. Tests for Choosing New Panels’ Components

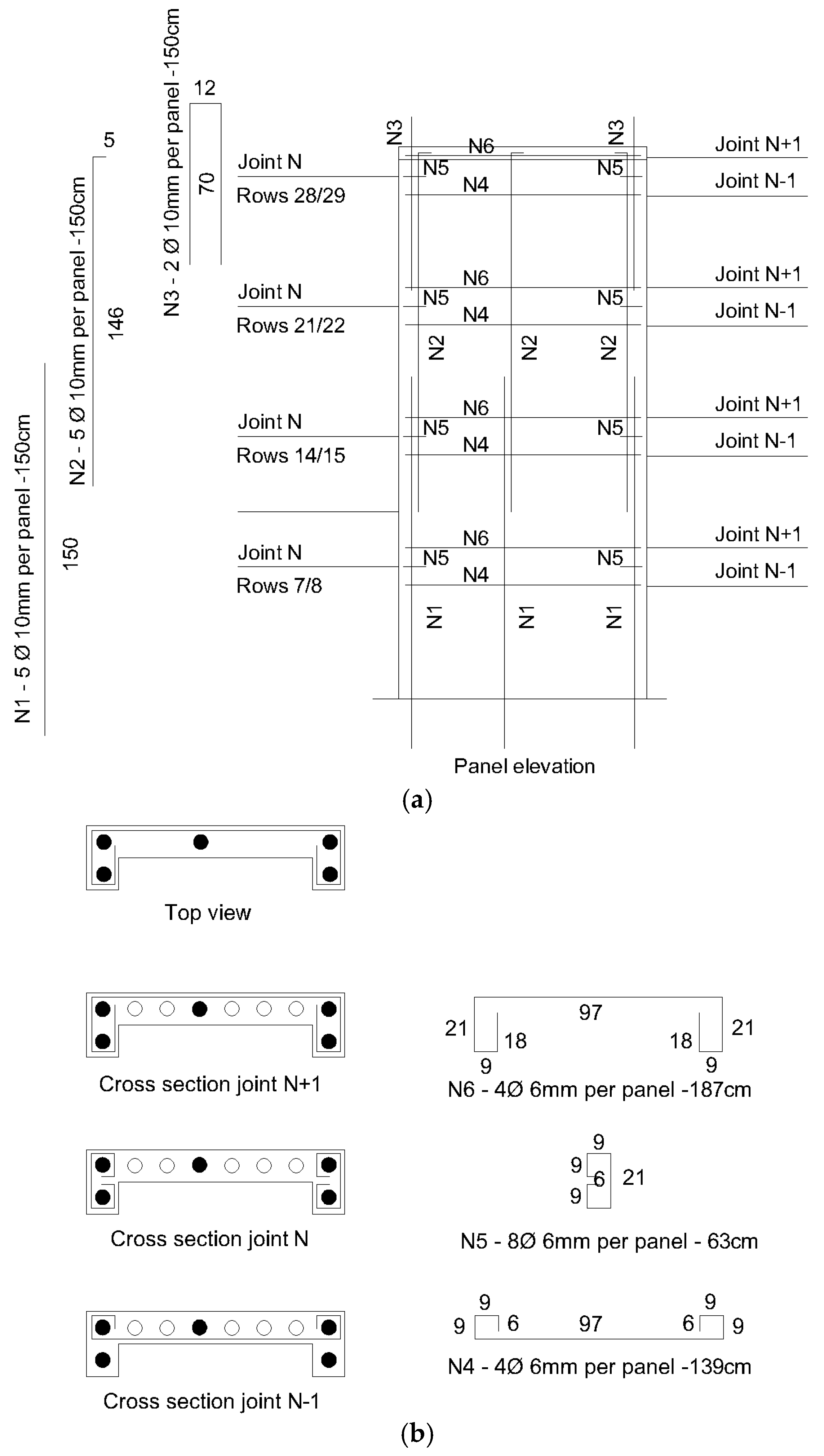

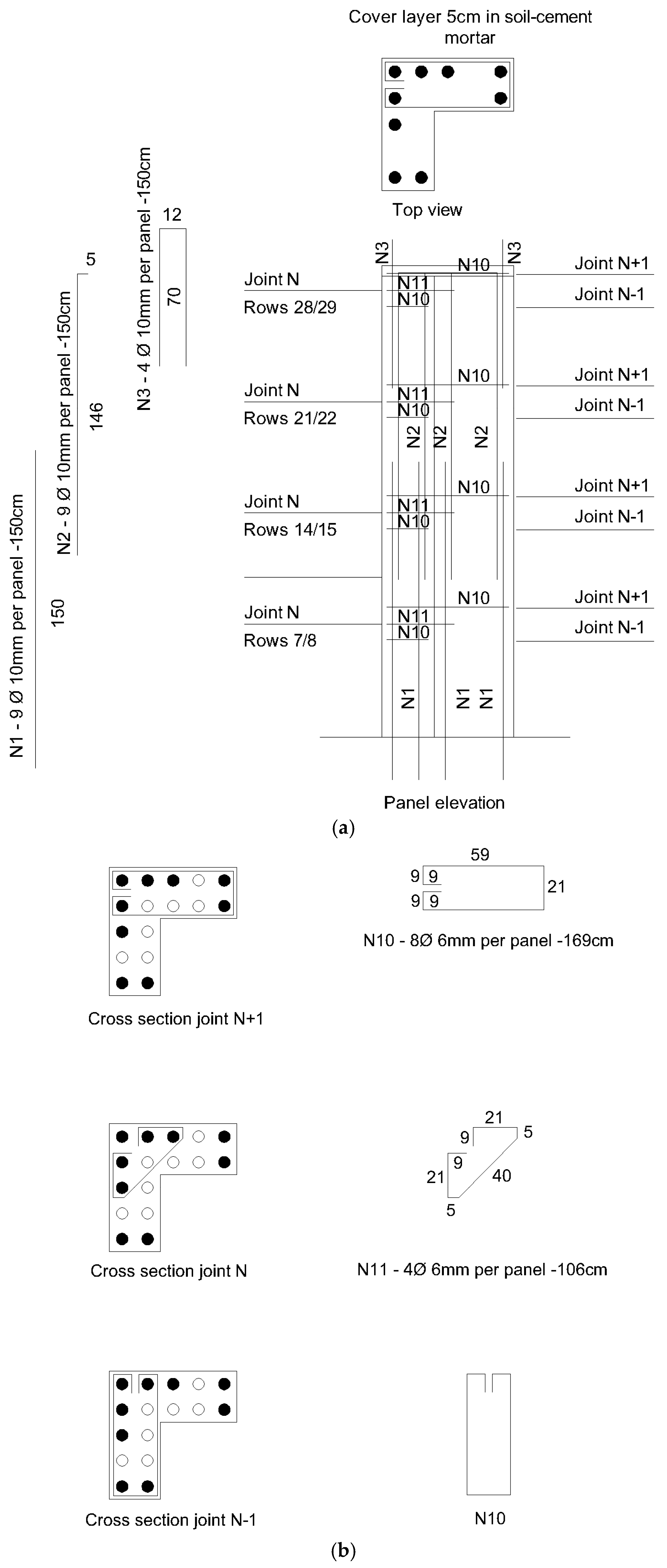

3.3. New Panels’ Design

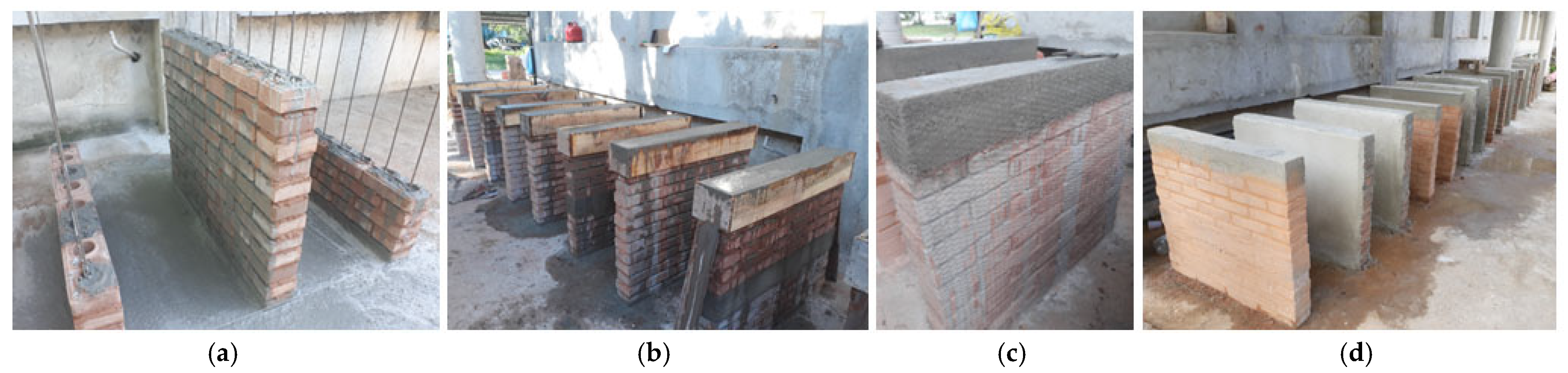

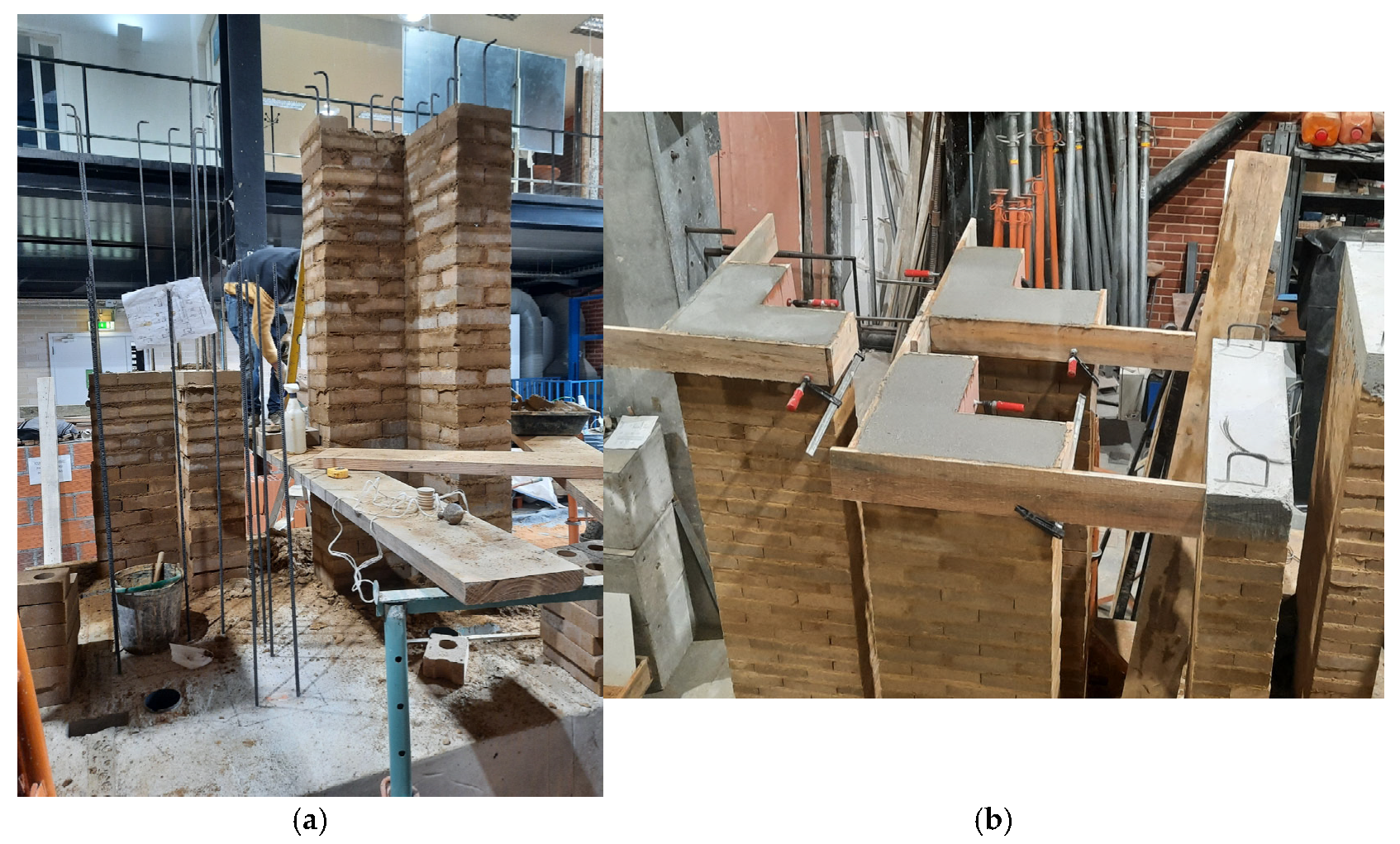

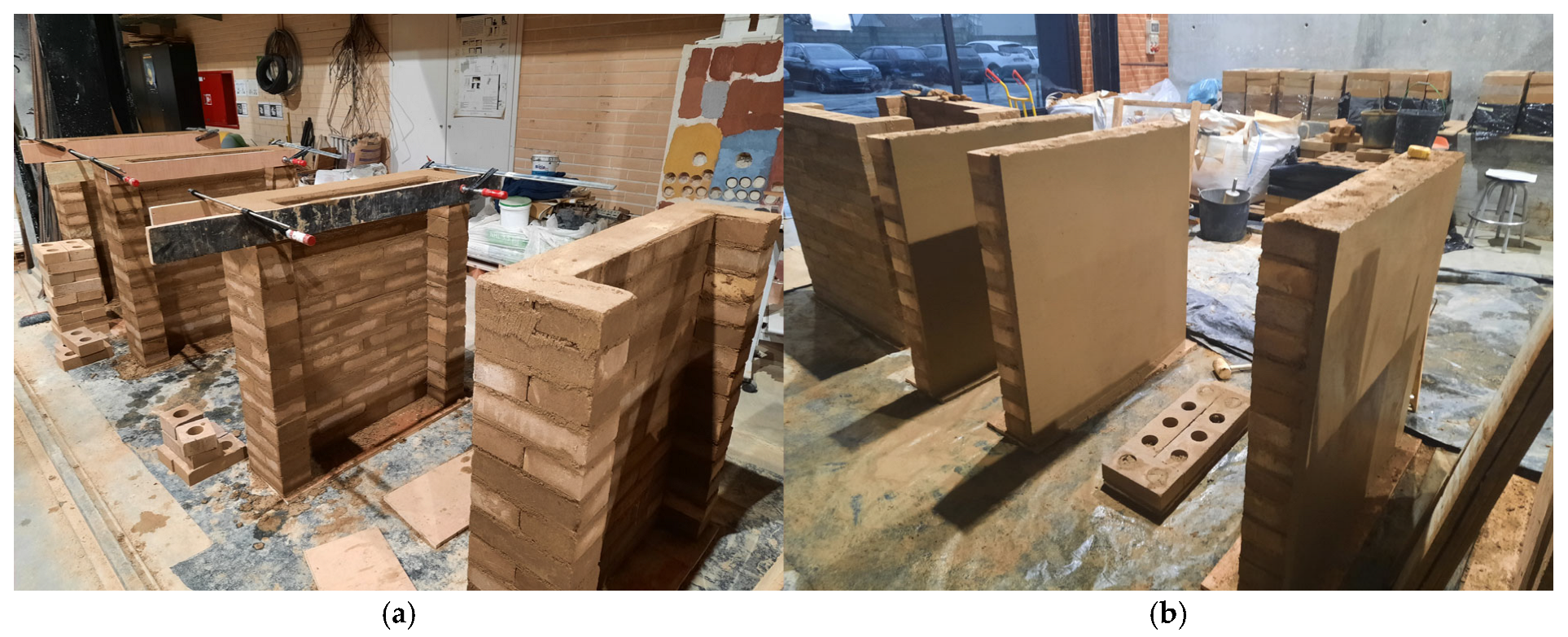

3.4. New Panels’ Main Experimental Study

- Main experiment planning;

- Block manufacturing;

- Specimens’ construction;

- Test systems design and assembly;

- Carrying out the experiments and data analysis.

3.4.1. Main Experiments Planning

- Group 1: Experiments on full-scale panels.

- Group 2: Experiments on wallets and components.

Group 1 Experiments

Group 2 Experiments

3.4.2. Block Manufacturing

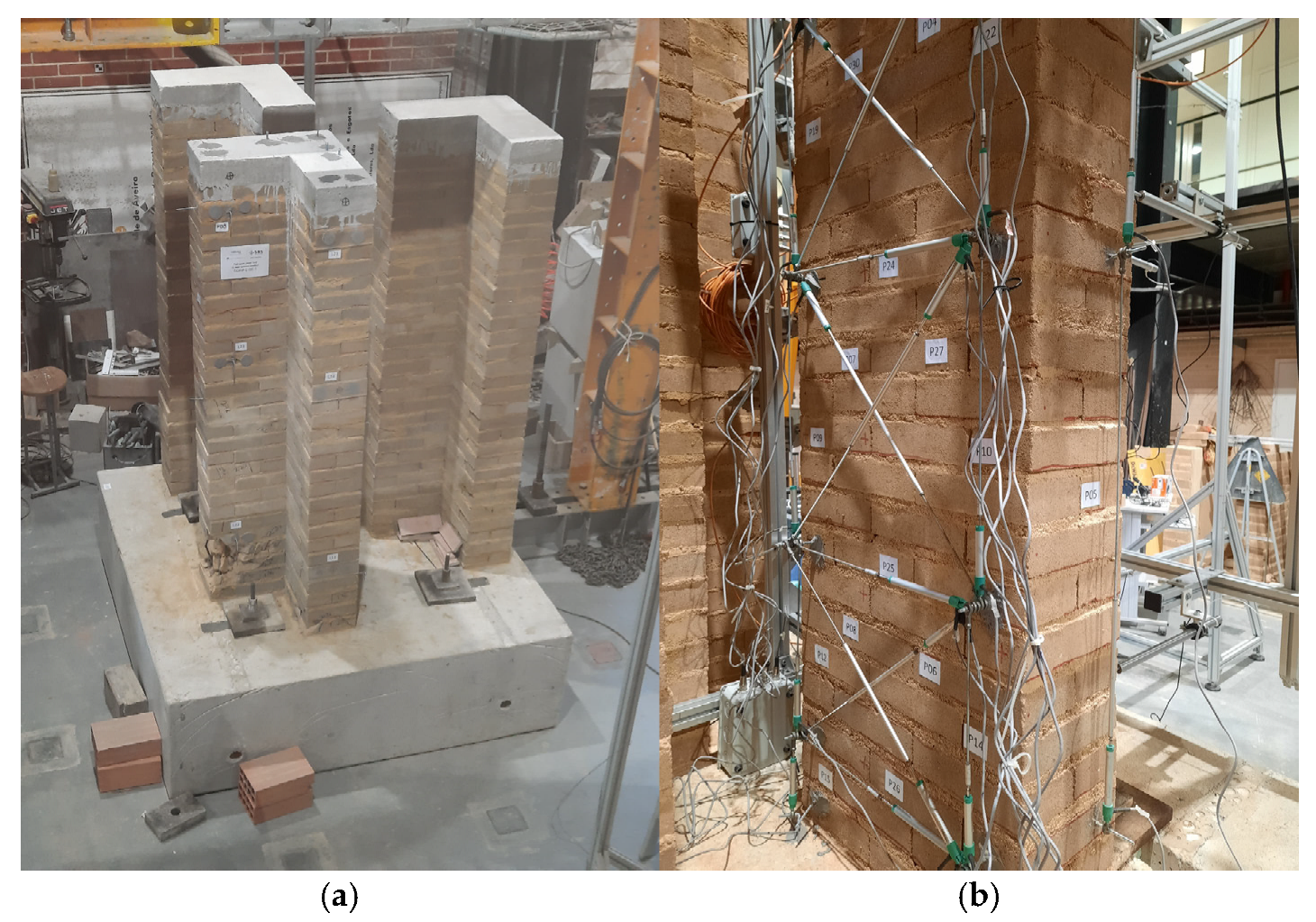

3.4.3. Construction of Test Specimens

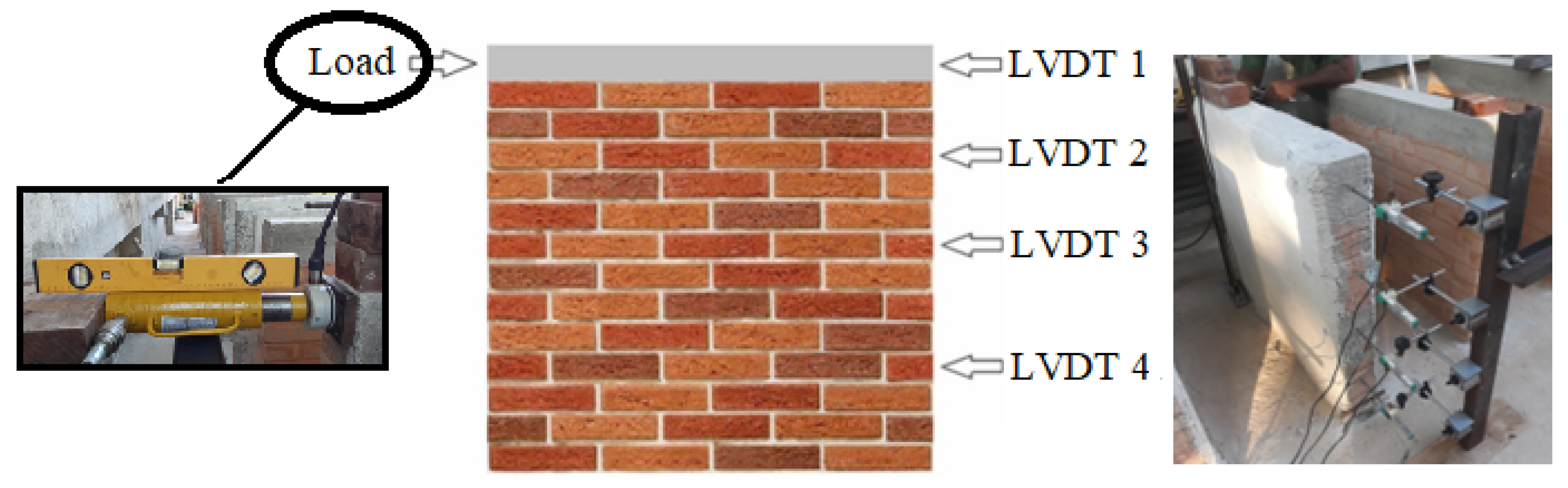

3.4.4. Test Systems’ Design and Assembly

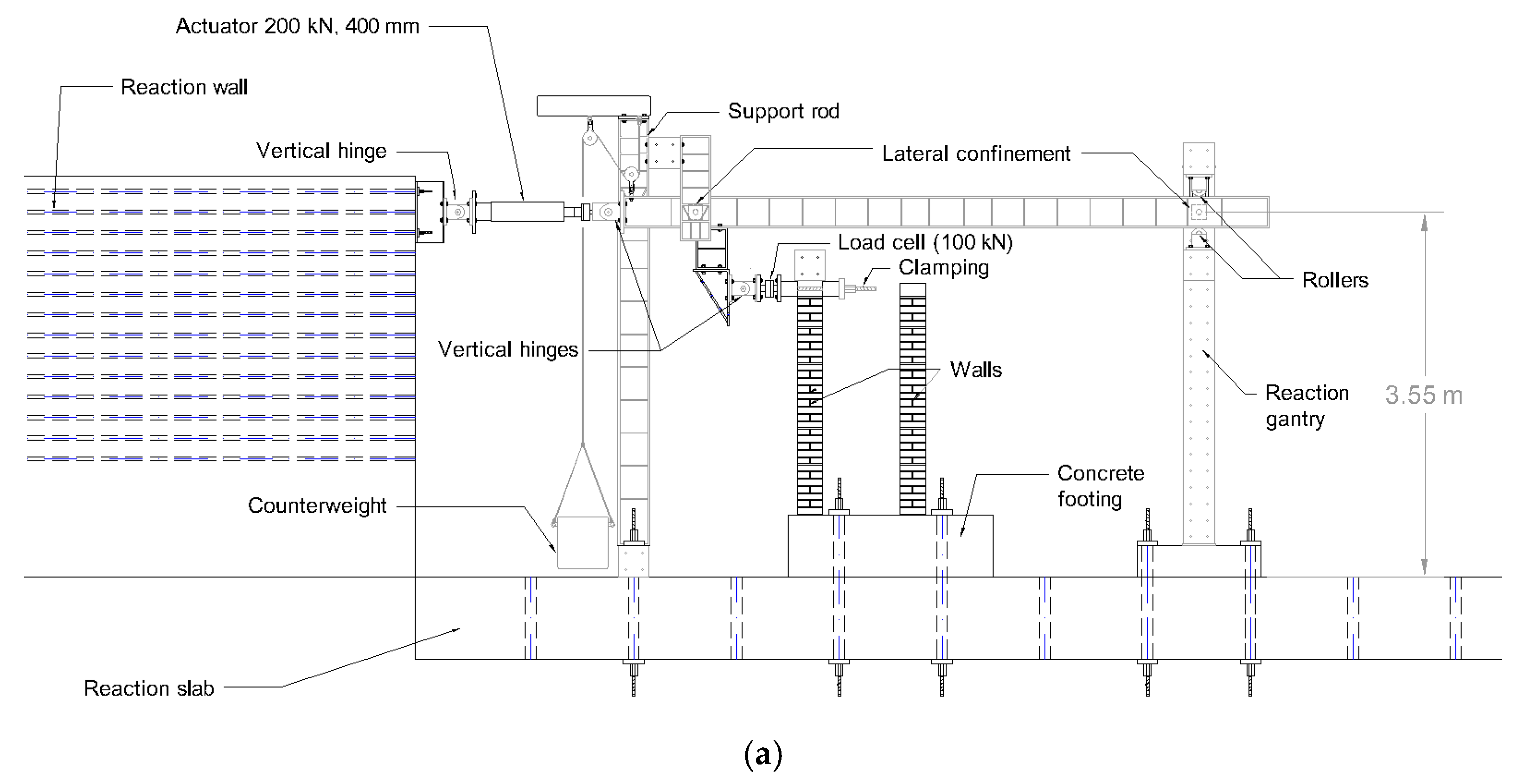

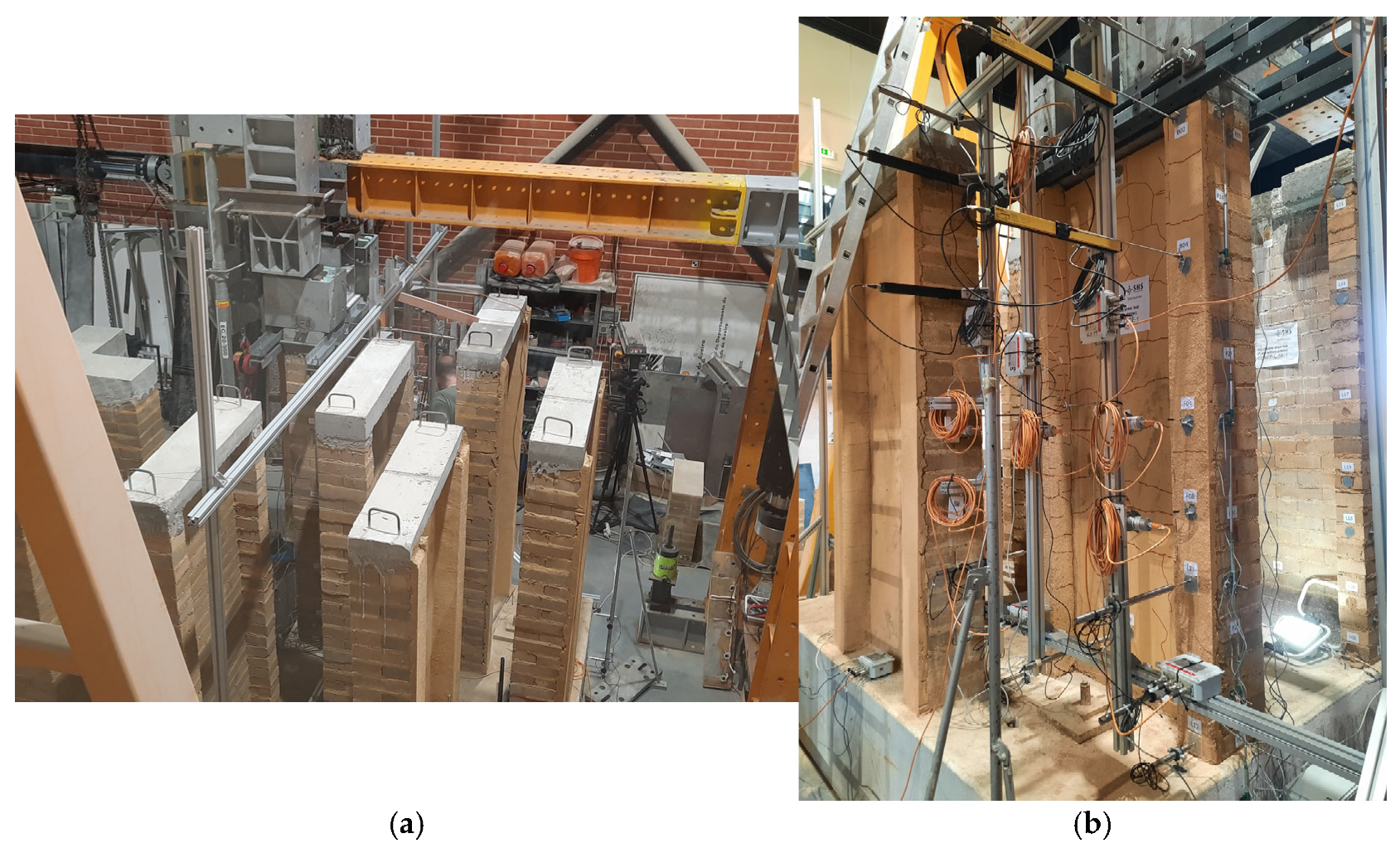

- System for Cyclic Bending Shear Tests on Full-Scale Walls.

- System for Static Characterization Tests.

Development of System for Cyclic Bending Shear Tests on Full-Scale Walls

- Push configuration, phase 1/4 (positive displacements are increasing), and phase 2/4 (positive displacements are decreasing).

- Pull configuration, phase 3/4 (negative displacements are increasing in absolute values), and phase 4/4 (negative displacements are decreasing in absolute values).

Development of System for Static Characterization Tests

3.4.5. Carrying Out Experiments and Data Analysis

3.5. Panels’ Design Improvement

4. Results and Discussion

4.1. Panels’ Introductory Experimental Study

4.1.1. Multifactorial Shear Experiment on Wallets

4.1.2. Implications of Using Different Panel Types in SHS-Multirisk 1.0 House Model

4.2. Panels’ Design Review

4.3. Panels’ Main Experimental Study

4.3.1. Key Experiment Outputs

Results from Static Diagonal Compression Tests at UA

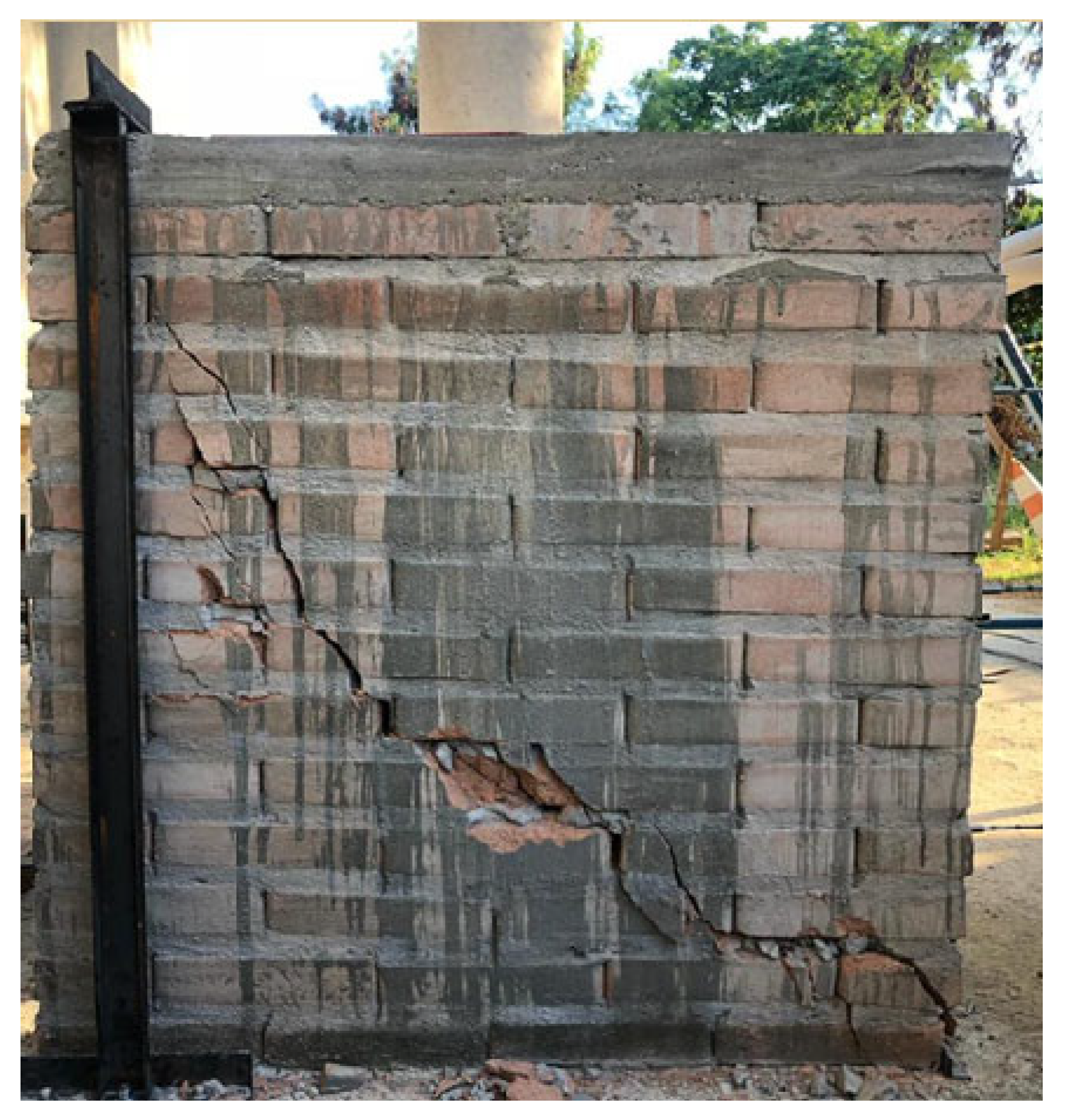

Results from Full-Scale Panels’ In-Plane Bending Shear Tests

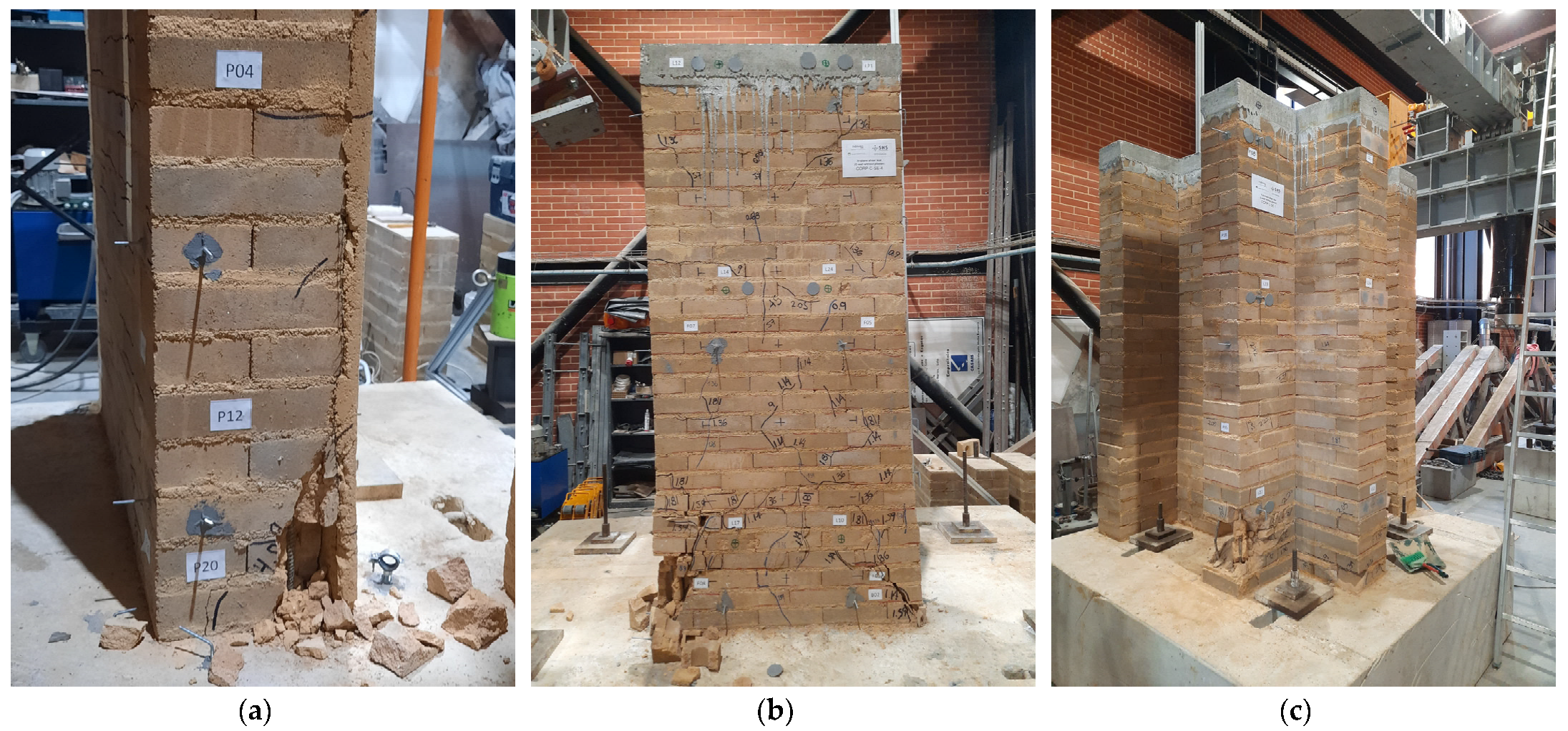

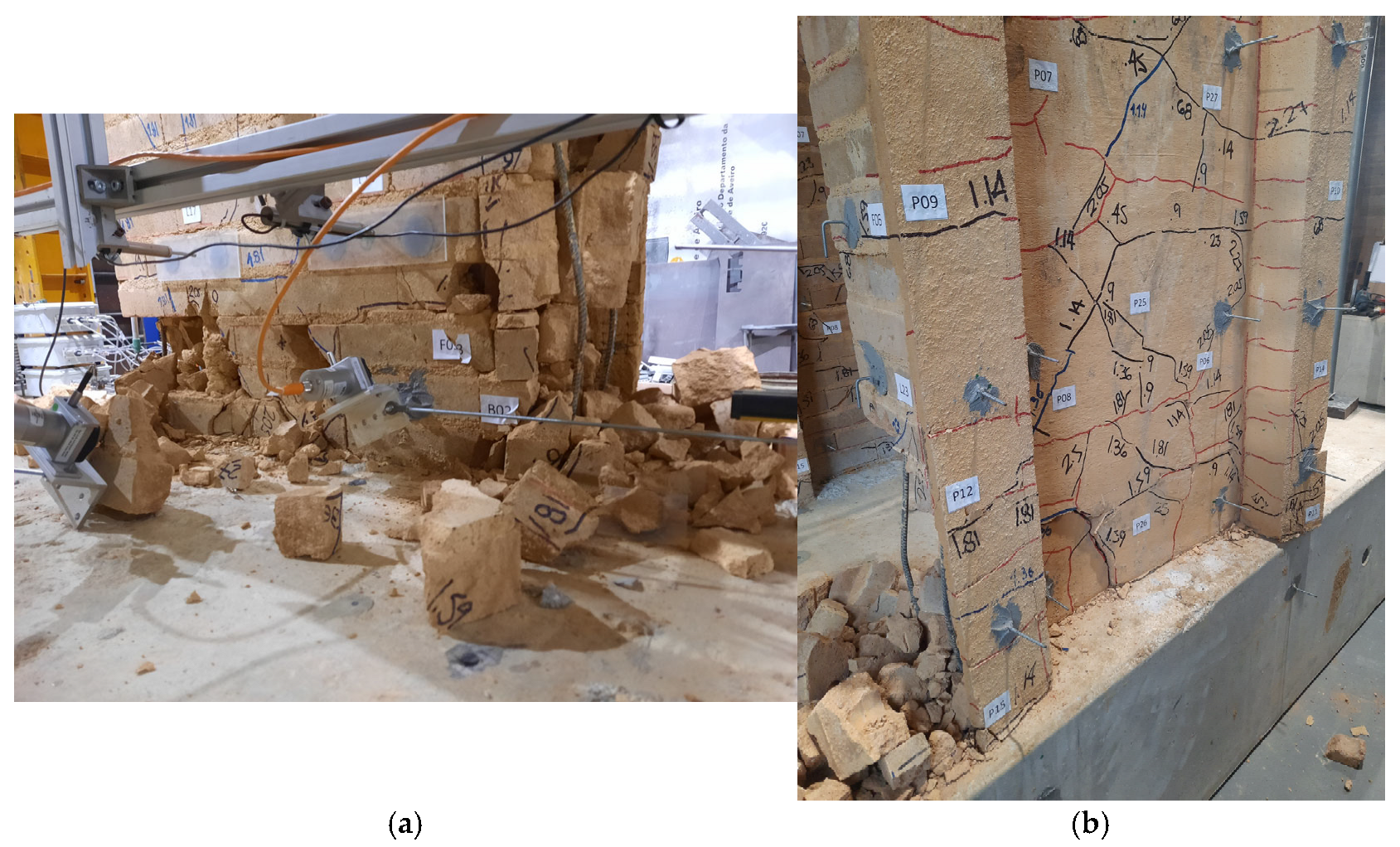

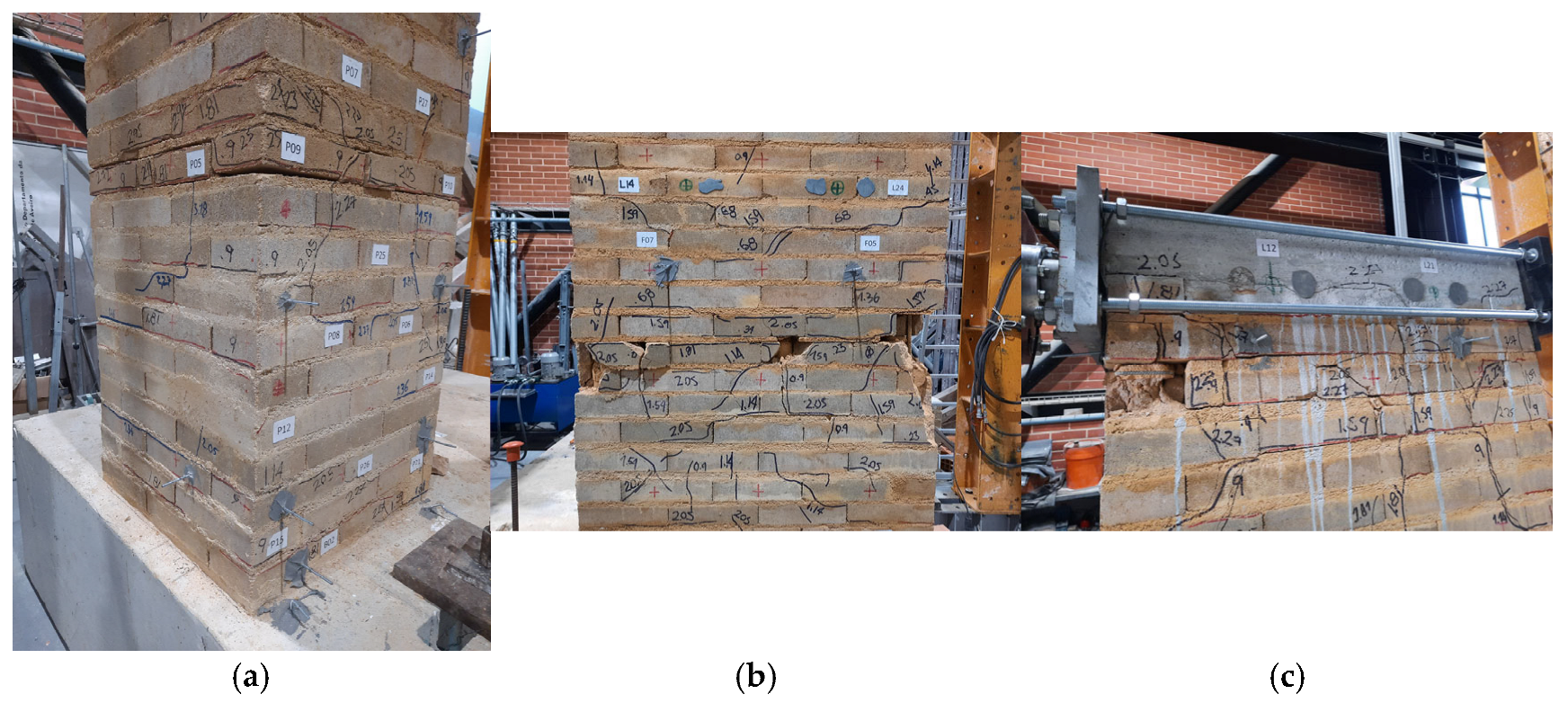

- In all panels that kept vertical reinforcement active, collapsing occurred by the blocks’ compression at the base, revealing that the bending effect is critical to the structural panels’ performance under cyclic loads (Figure 19).

- In addition to the blocks’ compressive collapse, it was observed that the high plastic stretching at the base bars increased buckling when compressed, contributing to the base blocks’ damage (Figure 20). This observation led to the decision to reinforce the horizontal bars at the panel’s low quarter, shortening the spaces between the steel stirrups.

- When vertical reinforcement remained active, the arrangement between the vertically grouted holes and the steel stirrups were successful in keeping the panel’s integrity during the cyclic tests, even if some mortar layers slightly slipped.

- In 2/3 of the L-panels, the lap splices did not work effectively, while this happened in apparently 3/8 of the C-panels tested under cyclic in-plane shear with bending (Figure 21). This was attributed to the more prominent torsional behavior and to the shorter distance between the reinforcements and the compressed section in the L-panels, what increases the forces at the bars under bending stress, when compared to the C-panels. This observation led to the decision to adopt vertical entire bars, instead of using lap splices.

4.3.2. Implications of Using Proposed Panel Types in SHS-Multirisk 2.0 House Model

- M1 (based on the resistance factors calculated in Section Results from Static Diagonal Compression Tests at UA): For similar situations where the components’ strengths are 2.51× lower than the ones obtained at UA, it is expected that the bending shear behavior will be 2.19× lower for plastered panels and 2.86× lower for non-plastered ones.

- M2 (based on the bending shear efficiency factors calculated in Section Results from Full-Scale Panels’ In-Plane Bending Shear Tests): In this option, the hypothesis is that the efficiency factors (0.451 for C-panels without plaster, 0.275 for plastered C-panels, and 0.360 for non-plastered L-panels) may be similar independently of the components’ resistances, so that applying these factors to the average shear forces obtained in UFRJ wallet tests would allow for obtaining bending shear estimations for full-scale panels with minimum resistance components.

4.3.3. Aspects Regarding Panels’ Deformation Capacity

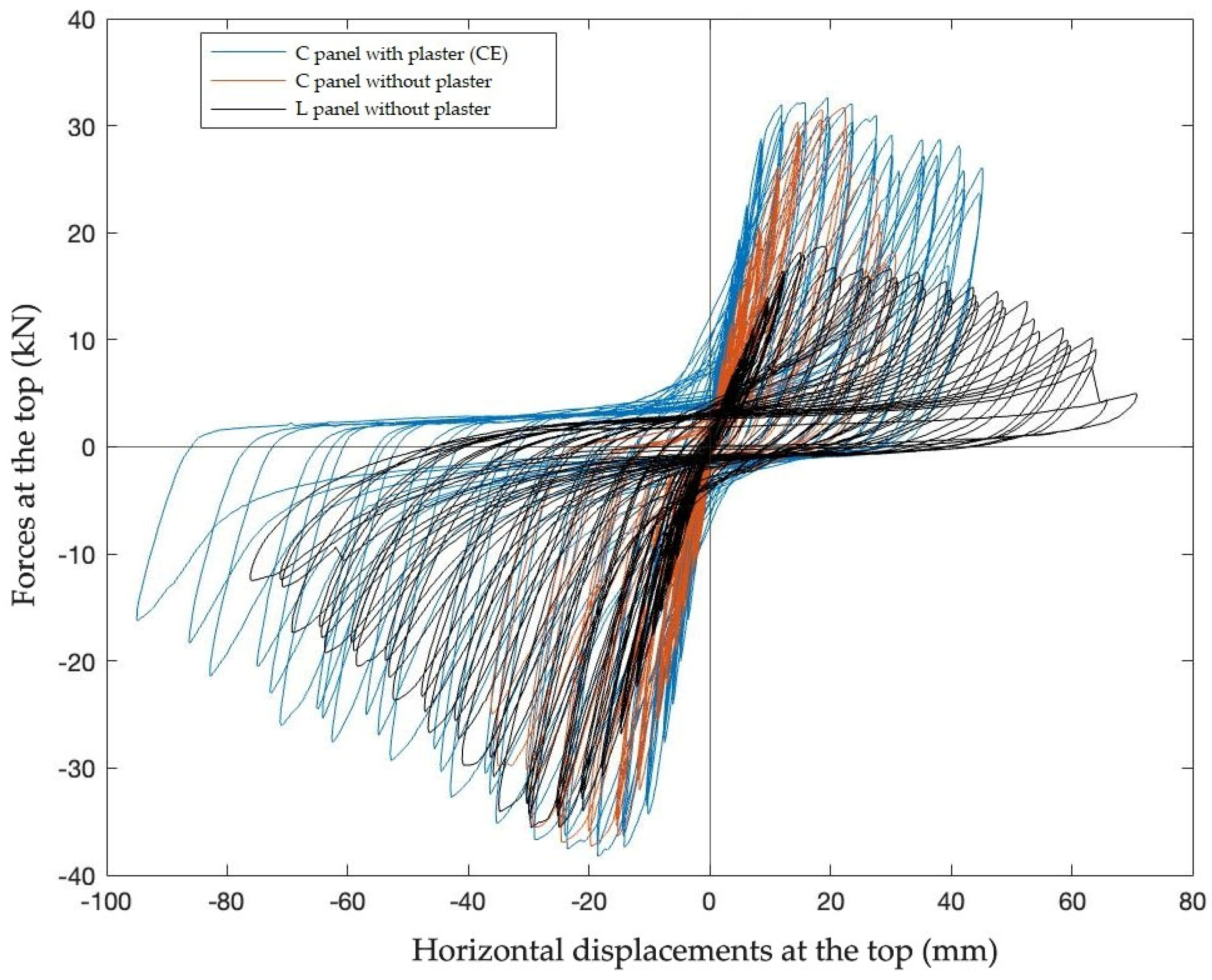

- Despite the maximum forces are similar, C plastered panels allow for greater displacements than non-plastered ones, revealing more ductility and better stability in critical damage conditions. This characteristic is very useful in seismic contexts, what confirms C plastered panels as a resilient option.

- L-panels also presented good deformation capacity, but due to their asymmetric geometry, the force behavior in pulling is very different from pushing. However, as they act in opposite pairs within the panel lines, the load asymmetry effect may be reduced. These panels presented a more prominent stiffness degradation rate when the tensioned region was within the panel’s width (and the compressed region was within the panel’s length).

- For all panels in which the steel bars remained working, high displacements were achieved.

4.4. Panels’ Design Improvement

4.5. Panels’ Recovery Process

- Pre-shoring of walls;

- Wall’s horizontal alignment at the base;

- Wall’s vertical alignment;

- Locking struts in the wall right position;

- Replacing/welding of broken bars;

- Adding new steel bars where buckling occurred;

- Wooden formwork to cast mortar;

- Pouring soil/cement mortar into the forms;

- Mortar wet curing for 3 days;

- Removal of forms after 7 days;

- Removal of metal props after 28 days.

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Centre for Research on the Epidemiology of Disasters (CRED). 2023: Disasters in Numbers, 1st ed.; UCLouvain: Brussels, Belgium, 2024. [Google Scholar]

- Cutter, S.L.; Boruff, B.J.; Shirley, W.L. Social vulnerability to environmental hazards. Soc. Sci. Q. 2023, 84, 242–261. [Google Scholar] [CrossRef]

- UN-Habitat. World Cities Report 2020: The Value of Sustainable Urbanization, 1st ed.; United Nations Human Settlements Programme: Nairóbi, Kenya, 2020. [Google Scholar]

- Tierney, K. The Social Roots of Risk: Producing Disasters, Promoting Resilience, 1st ed.; Stanford University Press: Redwood City, CA, USA, 2014. [Google Scholar]

- Okuyama, Y. Disaster impact and input–output analysis. Econ. Syst. Res. 2019, 31, 178–193. [Google Scholar] [CrossRef]

- Norris, F.H.; Stevens, S.P.; Pfefferbaum, B.; Wyche, K.F.; Pfefferbaum, R.L. Community resilience as a metaphor, theory, set of capacities, and strategy for disaster readiness. Am. J. Community Psychol. 2008, 41, 127–150. [Google Scholar] [CrossRef] [PubMed]

- Aldrich, D.P. Building Resilience: Social Capital in Post-Disaster Recovery, 1st ed.; University of Chicago Press: Chicago, IL, USA, 2012. [Google Scholar]

- Aydin, M.C.; Işık, E.; Büyüksaraç, A.; Ulu, A.E.; Avcil, F. Technical and Socio-Economic Perspective on the Disaster of the Century (6 February 2023 Earthquake) in Türkiye on the Second Anniversary. Geol. J. 2025, 1–18. [Google Scholar] [CrossRef]

- Di Gregorio, L.; Guimarães, G.; Tenório, M.; Lima, D.; Haddad, A.; Danziger, F.; Jannuzzi, G.; Santos, S.; Lima, S. The Potential of CEB Reinforced Masonry Technology for (Re)construction in the Context of Disasters. Materials 2020, 13, 3861. [Google Scholar] [CrossRef]

- Houben, H.; Guillaud, H. Earth Construction: A Comprehensive Guide, 1st ed.; Intermediate Technology Publications: Rugby, UK, 1994. [Google Scholar]

- Vintzileou, E. Testing Historic Masonry Elements and/or Building Models. In Perspectives on European Earthquake Engineering and Seismology; ANSAL, A., Ed.; University Istanbul: Istanbul, Türkiye, 2014; Volume 1, pp. 267–307. [Google Scholar]

- Magenes, G.; Calvi, G.M. In-plane seismic response of brick masonry walls. Earthq. Eng. Struct. Dyn. 1997, 26, 1091–1112. [Google Scholar] [CrossRef]

- Di Gregorio, L.; Guimarães, G.; Danziger, F.; Jannuzzi, G.; Qualharini, E.; Veról, A.; Haddad, A.; Miguez, M.; Cruz, V.; Bianchessi, D. Simple Housing Solution Project: (Re) Building in Critical Situations. In Natural Hazards—Impacts, Adjustments, and Resilience, 1st ed.; Farsangi, E.N., Ed.; IntechOpen: London, UK, 2021; Volume 1, pp. 1–22. [Google Scholar] [CrossRef]

- SHS—Solução Habitacional Simples/Simple Housing Solution. Available online: https://shs.poli.ufrj.br/ (accessed on 29 August 2025).

- UNDRR—United Nations Office for Disaster Risk Reduction. Sendai Framework for Disaster Risk Reduction 2015–2030, 1st ed.; UNISDR: Geneva, Switzerland, 2015. [Google Scholar]

- Village Marie Haiti. Available online: https://villagemarie.com/ (accessed on 29 August 2025).

- Kamalizad, M.; Morshed, R. Seismic performance of compressed earth block walls reinforced with common reeds. Case Stud. Constr. Mater. 2024, 21, e03388. [Google Scholar] [CrossRef]

- Tello, J.; Cabrera, M.; Rodríguez, J.; Eyzaguirre, C. Compressed earth blocks for rural housing in seismic zones using bagasse fibers from sugarcane. Key Eng. Mater. 2022, 922, 177–184. [Google Scholar] [CrossRef]

- Elmaatoufi, S.; Kheltent, M.; Na Sla, S.; El Maatoufi, Y.; Gueraoui, A.; Cherraj, M. Numerical study of the mechanical behavior of compressed earth block walls under uniaxial compression: Influence of sisal fibers and mortar composition through finite element simulation. JP J. Heat Mass Transf. 2025, 38, 651–662. [Google Scholar] [CrossRef]

- Bailly, G.C.; El Mendili, Y.; Konin, A.; Khoury, E. Advancing earth-based construction: A comprehensive review of stabilization and reinforcement techniques for adobe and compressed earth blocks. Engineering 2024, 5, 750–783. [Google Scholar] [CrossRef]

- Zarzour, N.; Santisi d’Avila, M.P.; Mercerat, E.D.; Lenti, L.; Oggero, M. Seismic design of a low-carbon building constructed with in-situ produced compressed earth blocks. Soil Dyn. Earthq. Eng. 2024, 187, 108990. [Google Scholar] [CrossRef]

- Jouhar, A.; Moussaoui, R.; Cherraj, M.; Nchiti, E.M.; Takarli, M.; Allou, F.; Hachmi, D.E. Ultrasonic characterization of compressed earth blocks in post-seismic reconstruction in the Al Haouz region, Tayidrin Village, Morocco. Sustain. Mediterr. Constr. 2024, 20, 89–93. [Google Scholar]

- Kahya, V.; Genç, A.F.; Sunca, F.; Roudane, B.; Altunişik, A.C.; Yilmaz, S.; Günaydin, M.; Dok, G.; Kirtel, O.; Demir, A.; et al. Evaluation of earthquake-related damages on masonry structures due to the 6 February 2023 Kahramanmaras¸-Türkiye earthquakes: A case study for Hatay Governorship Building. Eng. Fail. Anal. 2024, 156, 107855. [Google Scholar] [CrossRef]

- Sorrentino, L.; Cattari, S.; da Porto, F.; Magenes, G.; Penna, A. Seismic behaviour of ordinary masonry buildings during the 2016 central Italy earthquakes. Bull Earthq. Eng. 2019, 17, 5583–5607. [Google Scholar] [CrossRef]

- Bruneau, M. State-of-the-Art Report on Seismic Performance of Unreinforced Masonry Buildings. J. Struct. Eng. 1994, 120, 230–251. [Google Scholar] [CrossRef]

- Ferreira, T.M.; Costa, A.A.; Costa, A. Analysis of the Out-Of-Plane Seismic Behavior of Unreinforced Masonry: A Literature Review. Int. J. Archit. Herit. 2015, 9, 949–972. [Google Scholar] [CrossRef]

- Leitão, D.; Barbosa, J.; Soares, E.; Miranda, T.; Cristelo, N.; Briga-Sá, A. Thermal performance assessment of masonry made of ICEB’s stabilized with alkali activated fly ash. Energy Build. 2017, 139, 44–52. [Google Scholar] [CrossRef]

- Arrigoni, A.; Beckett, C.; Ciancio, D.; Dotelli, G. Life cycle analysis of environmental impact vs. durability of stabilised rammed earth. Constr. Build. Mater. 2017, 142, 128–136. [Google Scholar] [CrossRef]

- Jaquin, P.A.; Augarde, C.E.; Gerrard, C.M. Chronological description of the spatial development of rammed earth techniques. Int. J. Archit. Herit. 2008, 2, 377–400. [Google Scholar] [CrossRef]

- Pacheco-Torgal, F.; Eires, R.; Jalali, S. Construção em Terra, 1st ed.; University of Minho TecMinho: Guimarães, Portugal, 2009. [Google Scholar]

- Pitta, M.R. Estabilização com solo-cimento. Techne 1995, 17. [Google Scholar]

- Nambatya, M. Investigating the Rationale for Material Selection in Tropical Housing Projects in Uganda—A Case for Interlocking Stabilised Soil Blocks (ISSB) Technology. Master’s Thesis, University of Cambridge, Cambridge, UK, 2015. [Google Scholar]

- HYT Uganda. Haileybury Youth Trust Project’s in Uganda. Available online: https://hytuganda.com/our-projects/ (accessed on 22 August 2025).

- Moreira, T.S. Experimental Characterization of Dry-Stack Interlocking Compressed Earth Block Masonry. Ph.D. Thesis, University of Minho, Guimarães, Portugal, 2015. [Google Scholar]

- Auroville Earth Institute. Auroville Case Study. Available online: https://dev.earth-auroville.com/auroville-case-study/ (accessed on 29 August 2025).

- World Habitat. Eco-Brick Technology and Enterprises Transforming Communities in Nepal–World Habitat Awards Silver Winner. Available online: https://world-habitat.org/news/press-releases/eco-brick-technology-and-enterprises-transforming-communities-in-nepal-world-habitat-awards-silver-winner-2020/ (accessed on 29 August 2025).

- Build-up-Nepal. Interlocking Eco-Bricks. Available online: https://www.buildupnepal.com/interlocking-bricks/ (accessed on 22 August 2025).

- Ecología y Desarrollo (Organization). Study of Social Entrepreneurship and Innovation Ecosystems in the Latin American Pacific Alliance Countries: Case Study: Echale a tu casa, Mexico, 1st ed.; Interamerican Development Bank: Washington, DC, USA, 2016. [Google Scholar]

- Planeta Coppe. Village Marie: Os Primeiros Tijolos de um Sonho Nascido na UFRJ. 2021. Available online: https://coppe.ufrj.br/planeta-coppe/village-marie-os-primeiros-tijolos-de-um-sonho-nascido-na-ufrj/ (accessed on 29 August 2025).

- Techo Haiti. Sustainable Homes in Haiti with Village Marie. 2025. Available online: https://www.youtube.com/watch?v=FO9SbmpIQvM (accessed on 29 August 2025).

- Gonçalves, F.S. Aspectos Construtivos Para Residências de Baixo Custo Sob a Ação de Ventos Fortes. Bachelor’s Thesis, Universidade Federal do Rio de Janeiro, Rio de Janeiro, Brazil, 2018. [Google Scholar]

- Tenório, M.C.U. Análise da Viabilidade Técnica da Alvenaria Estrutural em Tijolos de Solo-Cimento Para Situações com Cargas Sísmicas: Práticas Construtivas e Análise Estrutural do Projeto de Solução Habitacional Simples. Bachelor’s Thesis, Federal University of Rio de Janeiro, Rio de Janeiro, Brazil, 2019. [Google Scholar]

- Di Gregorio, L.T.; Costa, A.; Tavares, A.; Rodrigues, H.; Fonseca, J. SHS-Multirisco: Solução Habitacional Simples para (re)construção resistente a sismos e furacões. In 8º Fórum Internacional do Património Arquitetónico Portugal Brasil; Tavares, A., Costa, A., Eds.; Universidade de Aveiro: Aveiro, Portugal, 2022; Volume 1, pp. 41–51. [Google Scholar]

- Di Gregorio, L.T.; Costa, A.; Tavares, A.; Rodrigues, H.; Fonseca, J. SHS-Multirisk Internal Project Report #3. Unpublished. 2022. [Google Scholar]

- Arkan, E.; Işık, E.; Avcil, F.; İzol, R.; Büyüksaraç, A. Seismic Damages in Masonry Structural Walls and Solution Suggestions. Acad. Platf. J. Nat. Hazards Disaster Manag. 2023, 4, 49–64. [Google Scholar] [CrossRef]

- NBR 8492; Tijolo de Solo-Cimento—Análise Dimensional, Determinação da Resistência à Compressão e da Absorção de água—Método de ensaio. Associação Brasileira De Normas Técnicas: Rio de Janeiro, Brazil, 2012.

- Santos, R.L.R. Orçamento, Planejamento e Gerenciamento de Obras de Residências de Baixo Custo em Regime de Mutirão: Caso de Estudo do Projeto Solução Habitacional Simples. Bachelor’s Thesis, Federal University of Rio de Janeiro, Rio de Janeiro, Brazil, 2019. [Google Scholar]

- NBR 8491; Tijolo de Solo-Cimento—Requisitos. Associação Brasileira De Normas Técnicas: Rio de Janeiro, Brazil, 2012.

- EN 1015-11; Methods of Test for Mortar for Masonry—Part 11: Determination of Flexural and Compressive Strength of Hardened Mortar. CEN—Comité Européen de Normalisation: Brussels, Belgium, 1999.

- BS 1052-3; Methods of Test for Masonry—Part 3: Determination of Initial Shear Strength. BSI—British Standards Institution: London, UK, 2002.

- BS EN 10080; Stell for the Reinforcement Of Concrete—Weldable Reinforcing Steel—General. BSI—British Standards Institution: London, UK, 2005.

- Lanese, I.; Pavese, A.; Furinghetti, M. Hybrid testing of Seismic Isolated Structures: Facing time and Geometry Scaling Issues. In Proceedings of the 16th European Conference on Earthquake Engineering, Thessaloniki, Greece, 18–21 June 2018. [Google Scholar]

- Mucciarelli, M. The Role of Site Effects at the Boundary Between Seismology and Engineering: Lessons from Recent Earthquakes. In Perspectives on European Earthquake Engineering and Seismology, 1st ed.; Ansal, A., Ed.; School of Engineering Ozyeğin, University Istanbul: Istanbul, Türkiye, 2014; Volume 1, Chapter 5. [Google Scholar]

- Di Gregorio, L.; Costa, A.; Rodrigues, H.; Fonseca, J.; Tavares Costa, A. Development of a System for Cyclic Shear Tests on Full-Scale Walls. Appl. Sci. 2023, 13, 7498. [Google Scholar] [CrossRef]

- NBR 15421; Projeto de estruturas resistentes a sismos—Procedimento. Associação Brasileira De Normas Técnicas: Rio de janeiro, Brazil, 2006.

- BS 5628-2; Code of Practice for the Use of Masonry—Part 2: Structural Use of Reinforced and Prestressed Masonry. BSI—British Standards Institution: London, UK, 2005.

- Bourgeois, I.; Di Gregorio, L.T.; Rodrigues, H.; Fonseca, J.; Tavares, A.; Costa, A. Application of Sonic Tests and Modal Identification in the Characterization of Masonry Walls. Appl. Sci. 2023, 13, 3762. [Google Scholar] [CrossRef]

- Di Gregorio, L.T.; Costa, A.; Tavares, A.; Rodrigues, H.; Fonseca, J. SHS-Multirisk UFRJ-UA: Simple Housing Solution for (re)construction resilient to earthquakes and hurricanes. In 9º Fórum Internacional do Património Arquitetônico Portugal Brasil, 1st ed.; Amoroso, M.R., Bogéa, K., Fonseca, H., Beso, M., Eds.; Edutira UEMA: São Luís, Brasil, 2023; Volume 1, pp. 424–433. [Google Scholar]

- Long, X.; Li, H.; Iyela, P.M.; Kang, S.-B. Predicting the bond stress–slip behavior of steel reinforcement in concrete under static and dynamic loadings by finite element, deep learning and analytical methods. Eng. Fail. Anal. 2024, 161, 108312. [Google Scholar] [CrossRef]

- Zhang, W.; Lin, J.; Huang, Y.; Lin, B.; Liu, X. Experimental and numerical studies on flexural performance of composite beams under cyclic loading. Structures 2024, 70, 107728. [Google Scholar] [CrossRef]

- Kennedy, N.E. Seismic Design Manual for Interlocking Compressed Earth Blocks. Ph.D. Thesis, California Polytechnic State University, San Luis Obispo, CA, USA, 2013. [Google Scholar] [CrossRef]

| Main Causes of Damage to Load-Bearing Walls in Masonry Structures [45] | SHS-Multirisk 2.0 House Panels’ Resilient Characteristics |

|---|---|

| Lack of professional engineering input during construction. | SHS 2.0 house panels are engineered. |

| Ignoring earthquake-resistant design principles. | The panels’ design was driven by earthquake-resistant design principles and were tested in cyclic conditions. |

| Weak corner connections between walls. | Panels have a near-independent in-plane bending shear performance and corner panels are in reinforced L-shape. Against out-of-plane bending, shear panels have stiffeners, horizontal steel stirrups, and a light timber lintel. |

| Absence of reinforcing bond beams. | Panels have vertical and horizontal steel reinforcements. |

| Heavy roofs made of earthen materials. | SHS-Multirisk 2.0 house model is light, symmetrical, and designed to lower wind pressures. |

| Poor construction quality and workmanship. | SHS uses simple construction techniques with local materials, establishes clear construction patterns, and addresses educational aspects that allow people’s training for self/owner-driven construction. |

| Large openings for doors and windows weakening walls. | Openings for doors and windows are patterned and less than 90 cm large, providing sufficient comfort and necessary multi-hazard safety. |

| Use of low-quality or weak materials. | SHS adopts local engineered materials with minimum strength parameters allowed by technical standards. |

| Improperly formed joints. | Vertical joints between panels reduce stiffness and allow damage contention. |

| Mixing materials with incompatible properties. | Panels’ materials are essentially the same: soil/cement mortars and rough steel bars, which are compatible and adherent within the mixes tested. |

| Irregularly shaped wall materials. | Components are regular and allow regular shape panels. |

| Incorrect placement of wall components. | SHS panels executive design details the placement of all panels’ components. |

| Poor-quality mortar for connections. | Pre-defined mortar mixes used in blocks, joints, and plaster are compatible and tested. |

| Decline in skilled masonry construction practices. | Content of SHS project strengthens skilled masonry construction practices. |

| Unregulated use of local building materials. | The use of local materials is controlled in a simple and effective way. |

| Type | Wallet Number | Maximum Shear Force (kn) |

|---|---|---|

| 1V.GP.SE | W5 | 17.46 |

| W14 | 18.45 | |

| 1V.GT.SE | W4 | 34.54 |

| W9 | 29.12 | |

| 1V.GP.CE | W2 | 50.60 |

| W10 | 48.36 | |

| 1V.GT.CE | W7 | 60.71 |

| W15 | 67.88 | |

| 2V.GP.SE | W1 | 20.87 |

| W11 | 28.24 | |

| 2V.GT.SE | W8 | 49.59 |

| W13 | 44.32 | |

| 2V.GP.CE | W6 | 59.65 |

| W16 | 54.08 | |

| 2V.GT.CE | W3 | 57.22 |

| W12 | 59.22 |

| Types of Panels and Their Properties | Effective Shear Force Factor | House Cost Factor | ||||||

|---|---|---|---|---|---|---|---|---|

| Type | Average Shear Force (kn) | Var. Coef. | Mass per Area (kg/m2) | Force /Mass (m/s2) | Seismic Loads | Non Seismic Loads | Usual System | Joint Working System |

| 1V.GP.SE | 17.96 | 3.9% | 220 | 81.54 | 1.00 | 1.00 | 1.00 | 1.00 |

| 1V.GT.SE | 31.83 | 12.0% | 265 | 120.01 | 1.47 | 1.77 | 1.18 | 1.18 |

| 1V.GP.CE | 49.48 | 3.2% | 320 | 154.50 | 1.89 | 2.76 | 1.32 | 1.29 |

| 1V.GT.CE | 64.30 | 7.9% | 365 | 176.03 | 2.16 | 3.58 | 1.50 | 1.46 |

| 2V.GP.SE | 24.55 | 21.2% | 231 | 106.51 | 1.31 | 1.37 | 1.02 | 1.03 |

| 2V.GT.SE | 46.96 | 7.9% | 271 | 173.61 | 2.13 | 2.61 | 1.20 | 1.20 |

| 2V.GP.CE | 56.87 | 6.9% | 331 | 172.06 | 2.11 | 3.17 | 1.34 | 1.32 |

| 2V.GT.CE | 58.22 | 2.4% | 371 | 157.14 | 1.93 | 3.24 | 1.52 | 1.49 |

| PGA | Class of Foundation Soil | Scenario | Type of Basic Panel | H—Equivalent Horizontal Force (kN) | Approved Masonry for In-Plane Shear | Approved Masonry for Different Bending Types | ||

|---|---|---|---|---|---|---|---|---|

| 0.20 g e.g., Haiti 2018 | A | 1 | 0.40 g | 0.133 | 1V.GP.SE | 41.29 | 100% | 100% |

| B | 2 | 0.50 g | 0.167 | 1V.GP.SE | 51.62 | 100% | 100% | |

| C | 3 | 0.60 g | 0.200 | 1V.GP.SE | 61.94 | 100% | 100% | |

| D | 4 | 0.80 g | 0.267 | 1V.GP.SE | 82.58 | 100% | 100% | |

| E | 5 | 1.25 g | 0.417 | 2V.GP.SE | 134.15 | 100% | 96% | |

| 0.50 g e.g., Haiti 2010 | A | 6 | 1.00 g | 0.333 | 2V.GP.SE | 107.32 | 100% | 96% |

| B | 7 | 1.25 g | 0.417 | 2V.GP.SE | 134.15 | 100% | 96% | |

| C | 8 | 1.50 g | 0.500 | 2V.GP.CE | 216.71 | 100% | 83% | |

| D | 9 | 1.75 g | 0.583 | 2V.GP.CE | 252.82 | 100% | 78% |

| Wallet ID | Diagonal Force (kN) | Horizontal Equiv. Pushover Force (kN) | Average Horiz. Equiv. Pushover Force (kN) | Variation Coefficient |

|---|---|---|---|---|

| CE1 | 187.16 | 128.63 | 124.55 | 12.24% |

| CE2 | 199.80 | 137.34 | ||

| CE3 | 156.62 | 107.68 | ||

| SE1 | 104.03 | 71.28 | 70.30 | 5.46% |

| SE2 | 107.18 | 73.55 | ||

| SE3 | 96.28 | 66.07 |

| Pannel Type—ID | Maximum Pushing Force (kN) | Maximum Pulling Force (kN) | Average Maximum Panels’ Load (kN) |

|---|---|---|---|

| L-1 | 18.72 | 35.55 | 25.29 |

| L-2 | 29.68 | 25.63 | |

| L-3 | 19.57 | 22.56 | |

| C-1 | 28.83 | 33.00 | 31.73 |

| C-2 | 28.76 | 35.77 | |

| C-3 | 28.67 | 29.88 | |

| C-4 | 31.67 | 37.28 | |

| CE-1 | 31.86 | 36.44 | 34.28 |

| CE-2 | 31.46 | 37.83 | |

| CE-3 | 29.24 | 36.56 | |

| CE-4 | 32.63 | 38.21 |

| Panels’ Typologies | In-Plane Moment of Inertia (cm4) | Average In-Plane Bending Shear Capacity (kN) | Self-Weight (kN) | Loads from Near Panels (kN) |

|---|---|---|---|---|

| L—without plaster | 1,095,000 | 25.29 | 10.07 | 3.72 |

| C—without plaster | 1,600,000 | 31.73 | 6.21 | 3.10 |

| CE—with plaster | 1,915,000 | 34.28 | 7.45 | 3.72 |

| Number of Panels Within the Line | % Roof Load Distribution Within the Line | Roof Load Distribution (kN) | Panels’ Self-Weight (kN) | Near Panels’ Loads (kN) | Wline (kN) | LSC (kN) |

|---|---|---|---|---|---|---|

| LINE TYPE 1: 2 L- + 4 C-PANELS | ||||||

| 2-L | 25.49% | 4.11 | 20.13 | 7.45 | 31.69 | 50.57 |

| 4-C | 74.51% | 12.01 | 24.85 | 12.42 | 49.28 | 126.93 |

| TOTAL | 100.00% | 16.12 | 44.98 | 19.87 | 80.97 | 177.50 |

| LINE TYPE 2: 2 L- + 4 CE-PANELS | ||||||

| 2-L | 22.23% | 3.58 | 20.13 | 7.45 | 31.16 | 50.57 |

| 4-CE | 77.77% | 12.53 | 29.79 | 14.89 | 57.22 | 137.11 |

| TOTAL | 100.00% | 16.12 | 49.92 | 22.34 | 88.38 | 187.69 |

| PGA | Class of Foundation Soil | Scenario | Hline_type1 (kN) | LSCtype1 (kN) | GSFline_type1 | |||

|---|---|---|---|---|---|---|---|---|

| 0.20 g e.g., Haiti 2018 | A | 1 | 0.40 g | 0.133 | 0.160 | 12.95 | 177.50 | 13.70 |

| B | 2 | 0.50 g | 0.167 | 0.200 | 16.19 | 177.50 | 10.96 | |

| C | 3 | 0.60 g | 0.200 | 0.240 | 19.43 | 177.50 | 9.13 | |

| D | 4 | 0.80 g | 0.267 | 0.320 | 25.91 | 177.50 | 6.85 | |

| E | 5 | 1.25 g | 0.417 | 0.500 | 40.48 | 177.50 | 4.38 | |

| 0.50 g e.g., Haiti 2010 | A | 6 | 1.00 g | 0.333 | 0.400 | 32.39 | 177.50 | 5.48 |

| B | 7 | 1.25 g | 0.417 | 0.500 | 40.48 | 177.50 | 4.38 | |

| C | 8 | 1.50 g | 0.500 | 0.600 | 48.58 | 177.50 | 3.65 | |

| D | 9 | 1.75 g | 0.583 | 0.700 | 56.68 | 177.50 | 3.13 |

| PGA | Class of Foundation Soil | Scenario | Hline_type2 (kN) | LSCtype2 (kN) | GSFline_type2 | |||

|---|---|---|---|---|---|---|---|---|

| 0.20 g e.g., Haiti 2018 | A | 1 | 0.40 g | 0.133 | 0.160 | 14.14 | 187.69 | 13.27 |

| B | 2 | 0.50 g | 0.167 | 0.200 | 17.68 | 187.69 | 10.62 | |

| C | 3 | 0.60 g | 0.200 | 0.240 | 21.21 | 187.69 | 8.85 | |

| D | 4 | 0.80 g | 0.267 | 0.320 | 28.28 | 187.69 | 6.64 | |

| E | 5 | 1.25 g | 0.417 | 0.500 | 44.19 | 187.69 | 4.25 | |

| 0.50 g e.g., Haiti 2010 | A | 6 | 1.00 g | 0.333 | 0.400 | 35.35 | 187.69 | 5.31 |

| B | 7 | 1.25 g | 0.417 | 0.500 | 44.19 | 187.69 | 4.25 | |

| C | 8 | 1.50 g | 0.500 | 0.600 | 53.03 | 187.69 | 3.54 | |

| D | 9 | 1.75 g | 0.583 | 0.700 | 61.87 | 187.69 | 3.03 |

| Panels’ Typologies | In-Plane Moment of Inertia (cm4) | Estimation for In-Plane Bending Shear Capacity (kN) | Self-Weight (kN) | Loads from Near Panels (kN) |

|---|---|---|---|---|

| L—without plaster | 1,095,000 | 8.83 | 10.07 | 3.72 |

| C—without plaster | 1,600,000 | 11.08 | 6.21 | 3.10 |

| CE—with plaster | 1,915,000 | 15.65 | 7.45 | 3.72 |

| Number of Panels Within the Line | % Roof Load Distribution Within the Line | Roof Load Distribution (kN) | Panels’ Self-Weight (kN) | Near Panels’ Loads (kN) | Wline (kN) | LSC (kN) |

|---|---|---|---|---|---|---|

| LINE TYPE 1: 2 L- + 4 C-PANELS | ||||||

| 2-L | 25.49% | 4.11 | 20.13 | 7.45 | 31.69 | 17.66 |

| 4-C | 74.51% | 12.01 | 24.85 | 12.42 | 49.28 | 44.33 |

| TOTAL | 100.00% | 16.12 | 44.98 | 19.87 | 80.97 | 61.99 |

| LINE TYPE 2: 2 L- + 4 CE-PANELS | ||||||

| 2-L | 22.23% | 3.58 | 20.13 | 7.45 | 31.16 | 17.66 |

| 4-CE | 77.77% | 12.53 | 29.79 | 14.89 | 57.22 | 62.61 |

| TOTAL | 100.00% | 16.12 | 49.92 | 22.34 | 88.38 | 80.27 |

| PGA | Class of Foundation Soil | Scenario | Hline_type1 (kN) | LSCtype1 (kN) | GSFline_type1 | |||

|---|---|---|---|---|---|---|---|---|

| 0.20 g e.g., Haiti 2018 | A | 1 | 0.40 g | 0.133 | 0.160 | 12.95 | 61.99 | 4.78 |

| B | 2 | 0.50 g | 0.167 | 0.200 | 16.19 | 61.99 | 3.83 | |

| C | 3 | 0.60 g | 0.200 | 0.240 | 19.43 | 61.99 | 3.19 | |

| D | 4 | 0.80 g | 0.267 | 0.320 | 25.91 | 61.99 | 2.39 | |

| E | 5 | 1.25 g | 0.417 | 0.500 | 40.48 | 61.99 | 1.53 | |

| 0.50 g e.g., Haiti 2010 | A | 6 | 1.00 g | 0.333 | 0.400 | 32.39 | 61.99 | 1.91 |

| B | 7 | 1.25 g | 0.417 | 0.500 | 40.48 | 61.99 | 1.53 | |

| C | 8 | 1.50 g | 0.500 | 0.600 | 48.58 | 61.99 | 1.28 | |

| D | 9 | 1.75 g | 0.583 | 0.700 | 56.68 | 61.99 | 1.09 |

| PGA | Class of Foundation Soil | Scenario | Hline_type2 (kN) | LSCtype2 (kN) | GSFline_type2 | |||

|---|---|---|---|---|---|---|---|---|

| 0.20 g e.g., Haiti 2018 | A | 1 | 0.40 g | 0.133 | 0.160 | 14.14 | 80.27 | 5.68 |

| B | 2 | 0.50 g | 0.167 | 0.200 | 17.68 | 80.27 | 4.54 | |

| C | 3 | 0.60 g | 0.200 | 0.240 | 21.21 | 80.27 | 3.78 | |

| D | 4 | 0.80 g | 0.267 | 0.320 | 28.28 | 80.27 | 2.84 | |

| E | 5 | 1.25 g | 0.417 | 0.500 | 44.19 | 80.27 | 1.82 | |

| 0.50 g e.g., Haiti 2010 | A | 6 | 1.00 g | 0.333 | 0.400 | 35.35 | 80.27 | 2.27 |

| B | 7 | 1.25 g | 0.417 | 0.500 | 44.19 | 80.27 | 1.82 | |

| C | 8 | 1.50 g | 0.500 | 0.600 | 53.03 | 80.27 | 1.51 | |

| D | 9 | 1.75 g | 0.583 | 0.700 | 61.87 | 80.27 | 1.30 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Di Gregorio, L.; Costa, A.; Tavares, A.; Rodrigues, H.; Fonseca, J.; Guimarães, G.; Haddad, A.; Danziger, F.; Jannuzzi, G. Comprehensive Design Process of CEB-Reinforced Masonry Panels for Earthquake and Hurricane-Resilient Houses. Buildings 2025, 15, 3242. https://doi.org/10.3390/buildings15173242

Di Gregorio L, Costa A, Tavares A, Rodrigues H, Fonseca J, Guimarães G, Haddad A, Danziger F, Jannuzzi G. Comprehensive Design Process of CEB-Reinforced Masonry Panels for Earthquake and Hurricane-Resilient Houses. Buildings. 2025; 15(17):3242. https://doi.org/10.3390/buildings15173242

Chicago/Turabian StyleDi Gregorio, Leandro, Aníbal Costa, Alice Tavares, Hugo Rodrigues, Jorge Fonseca, Gustavo Guimarães, Assed Haddad, Fernando Danziger, and Graziella Jannuzzi. 2025. "Comprehensive Design Process of CEB-Reinforced Masonry Panels for Earthquake and Hurricane-Resilient Houses" Buildings 15, no. 17: 3242. https://doi.org/10.3390/buildings15173242

APA StyleDi Gregorio, L., Costa, A., Tavares, A., Rodrigues, H., Fonseca, J., Guimarães, G., Haddad, A., Danziger, F., & Jannuzzi, G. (2025). Comprehensive Design Process of CEB-Reinforced Masonry Panels for Earthquake and Hurricane-Resilient Houses. Buildings, 15(17), 3242. https://doi.org/10.3390/buildings15173242