Automated Screw-Fastened Assembly of Layered Timber Arch-Shells: Construction-Phase LCA and Performance Validation

Abstract

1. Introduction

1.1. Research Progress in Robotic Automation in Construction

1.2. Research Aim

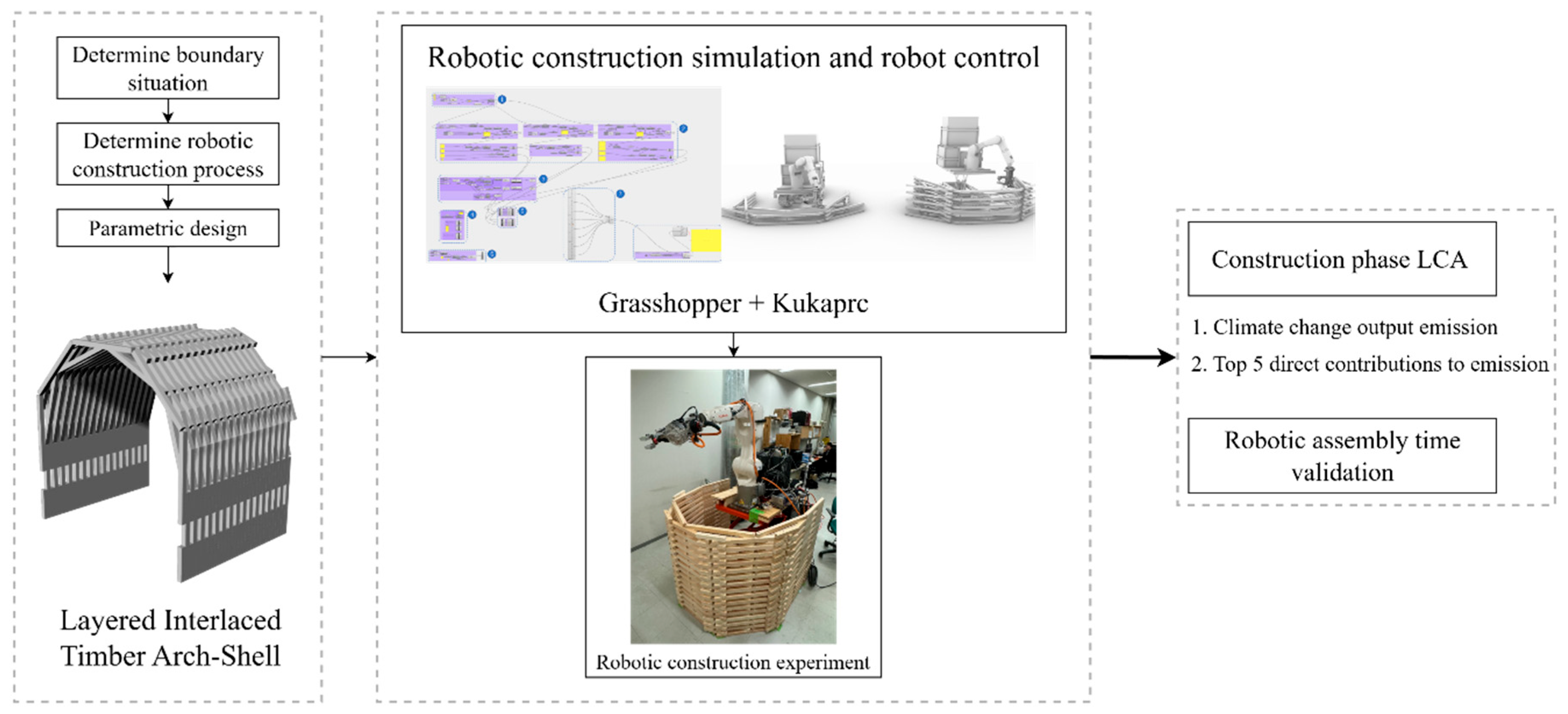

2. Methodology

2.1. Workflow

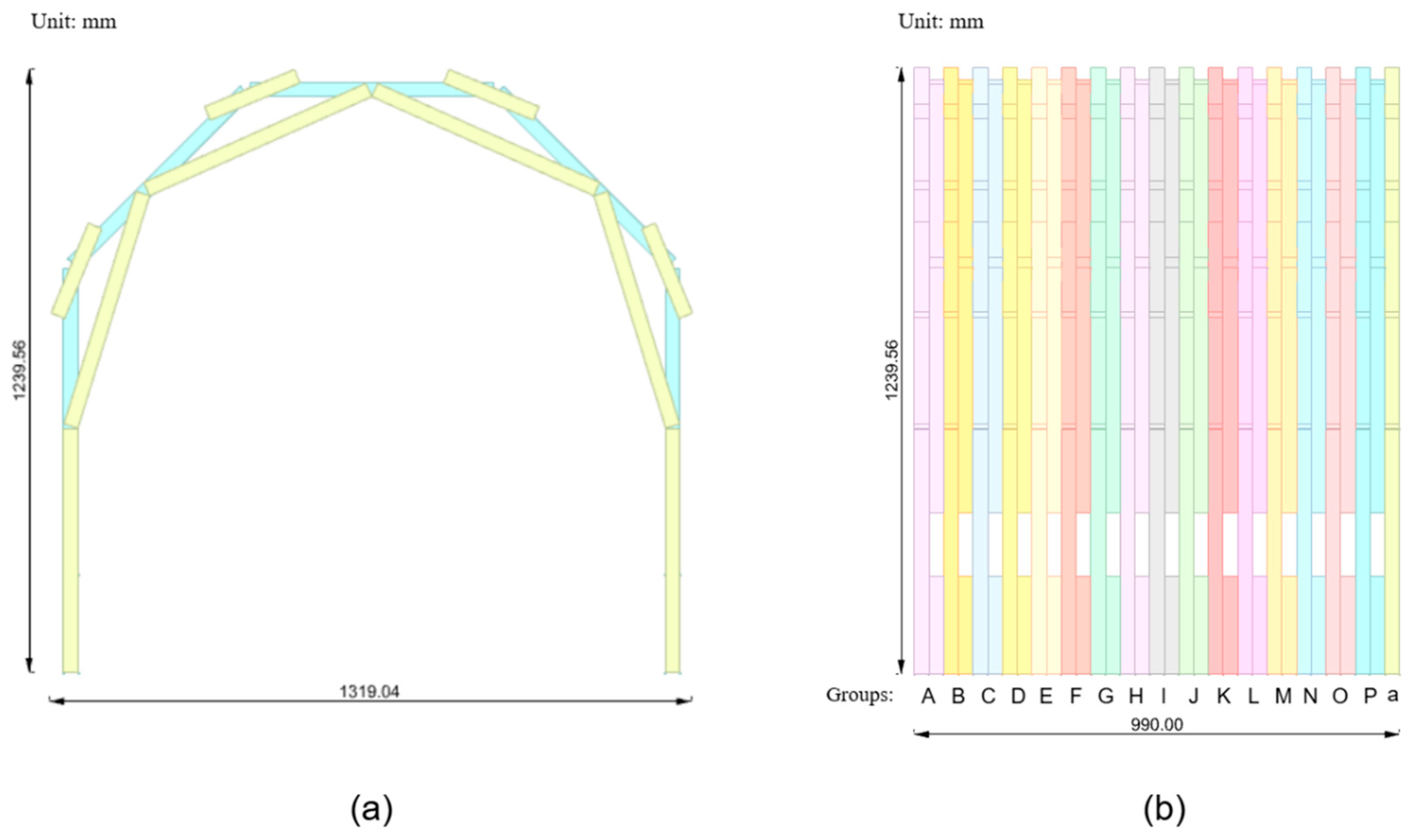

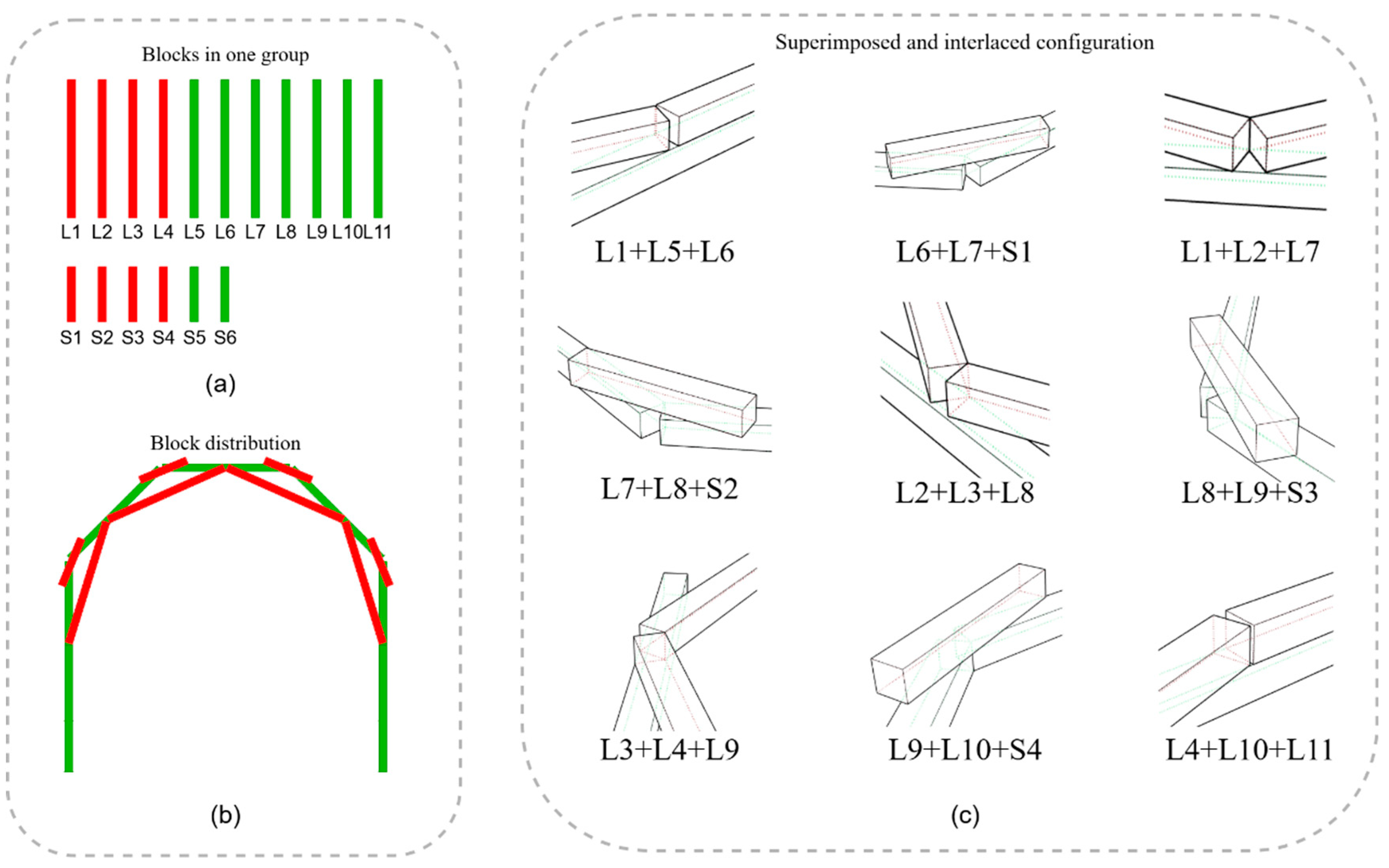

2.2. Objective Timber Structure Design

2.3. Life-Cycle Assessment Method

2.3.1. Functional Unit Definition

2.3.2. Boundary System

2.3.3. Construction-Phase Life-Cycle Inventory

3. Robotic Automation Construction

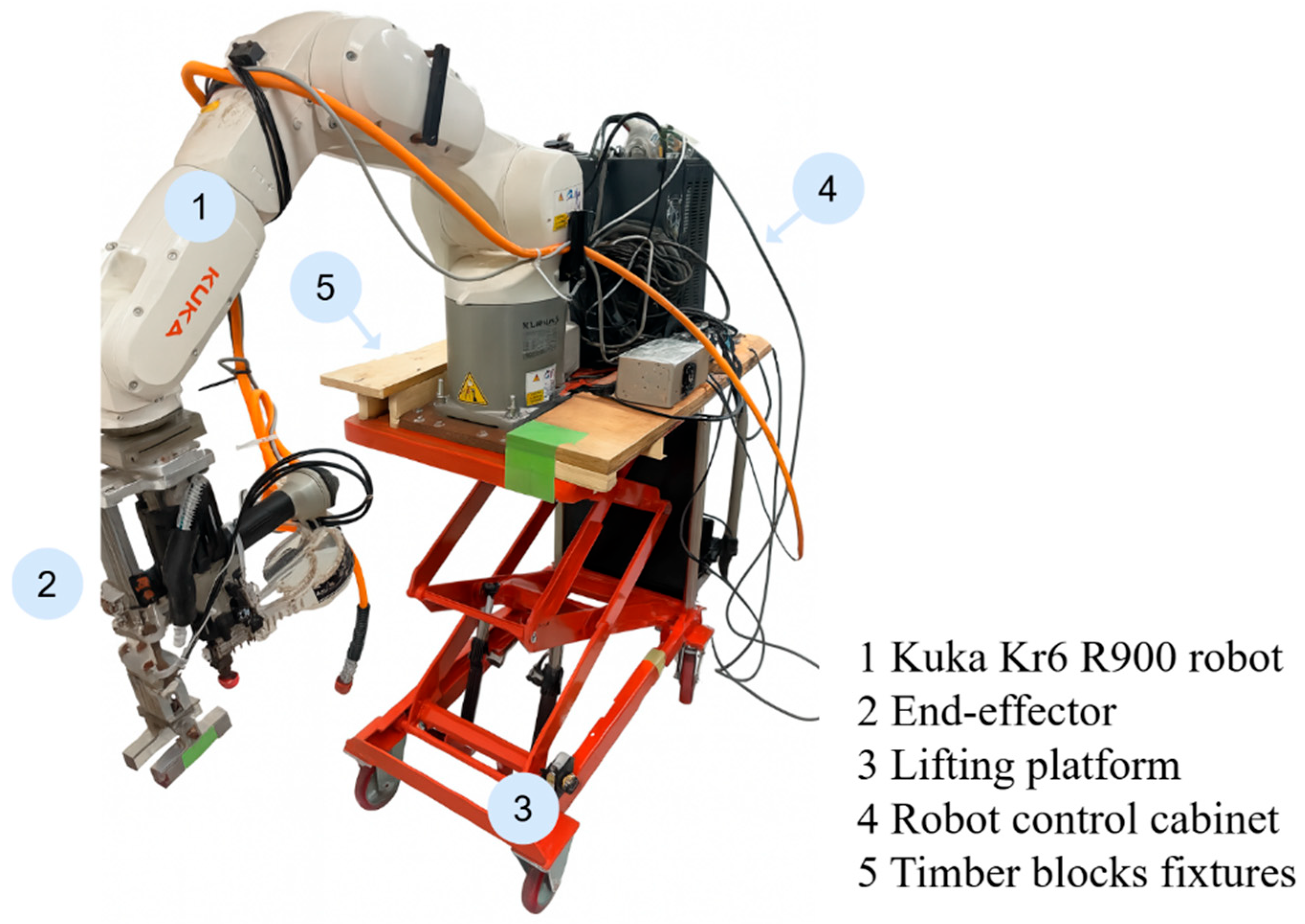

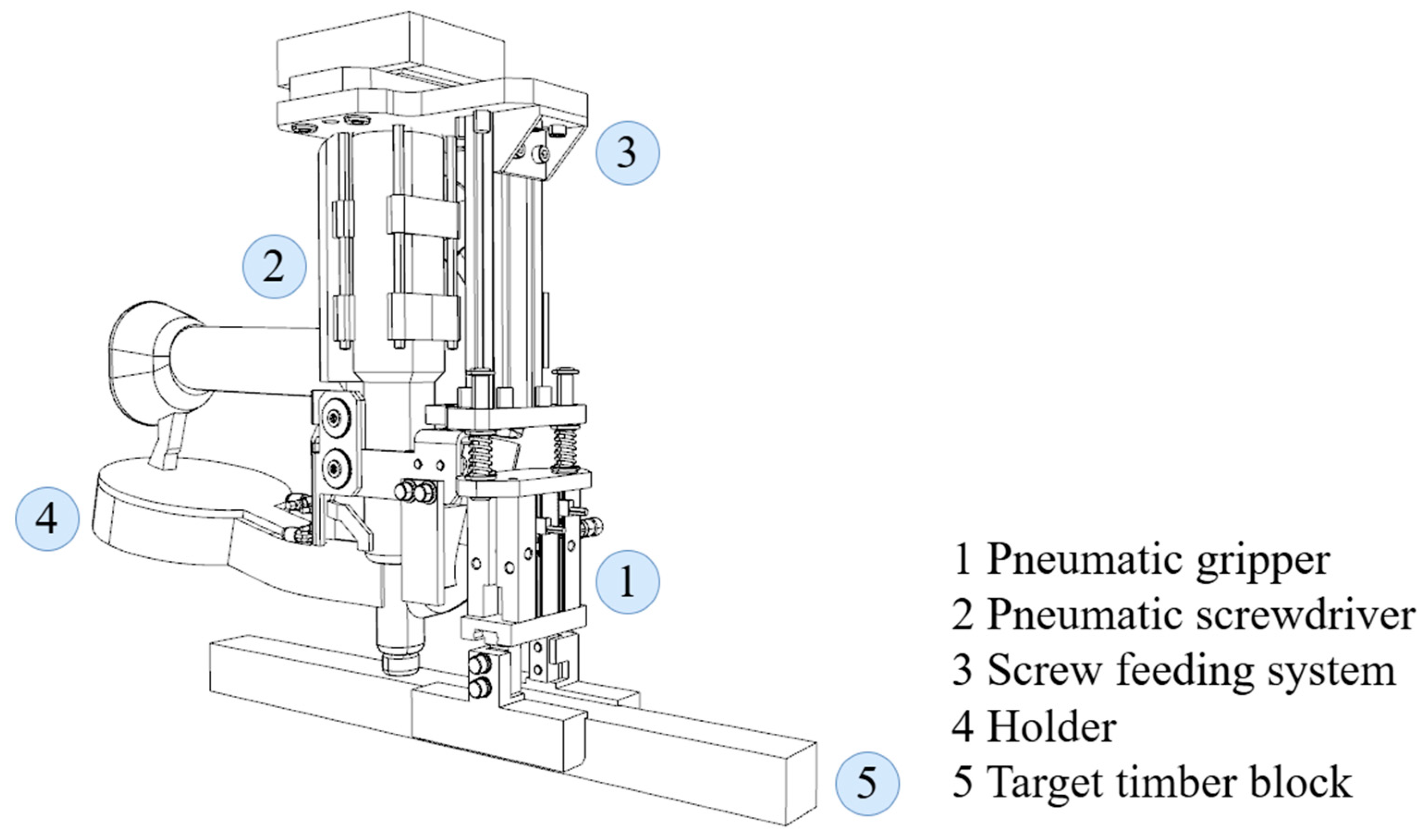

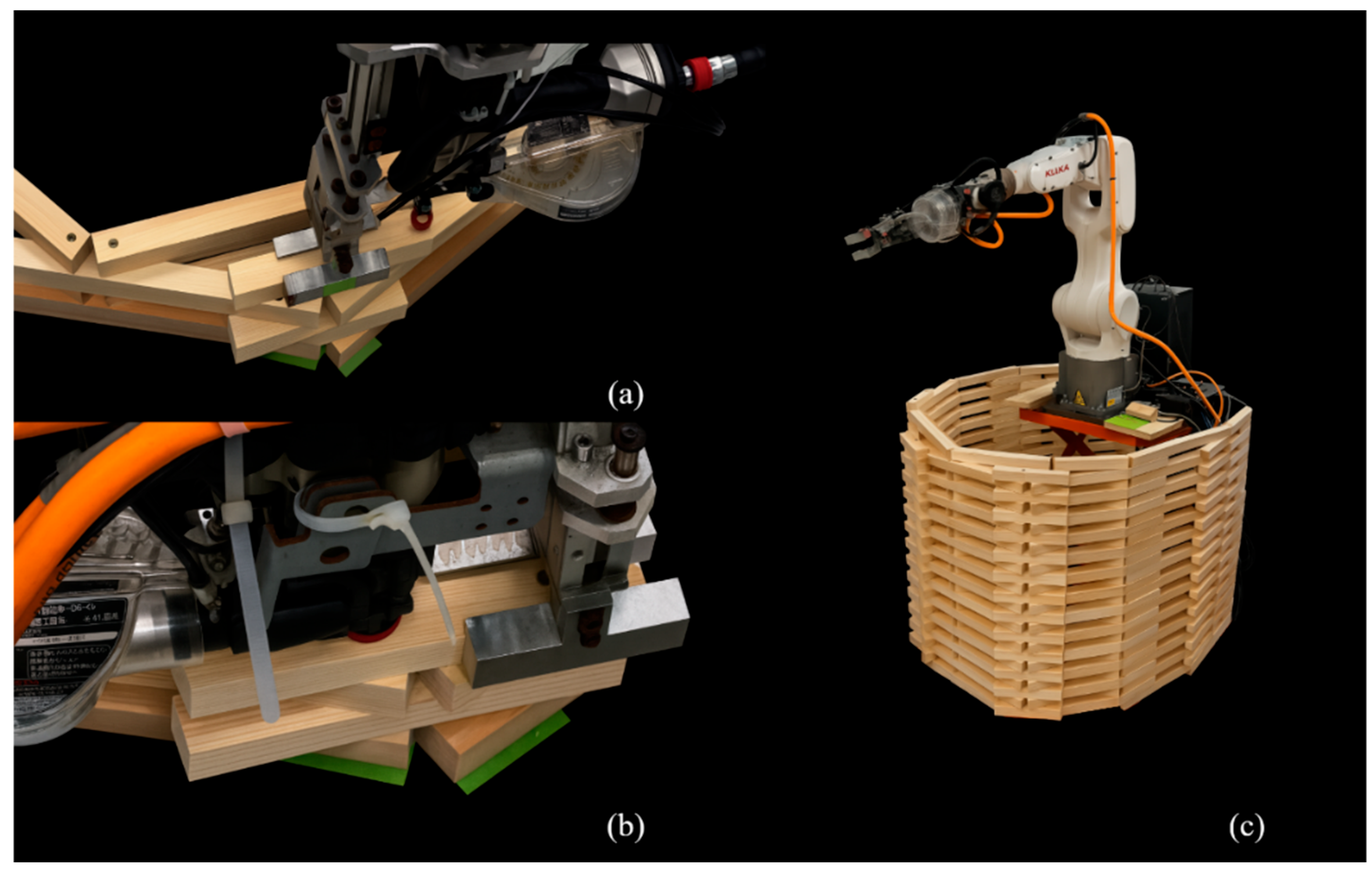

3.1. Robot Setup

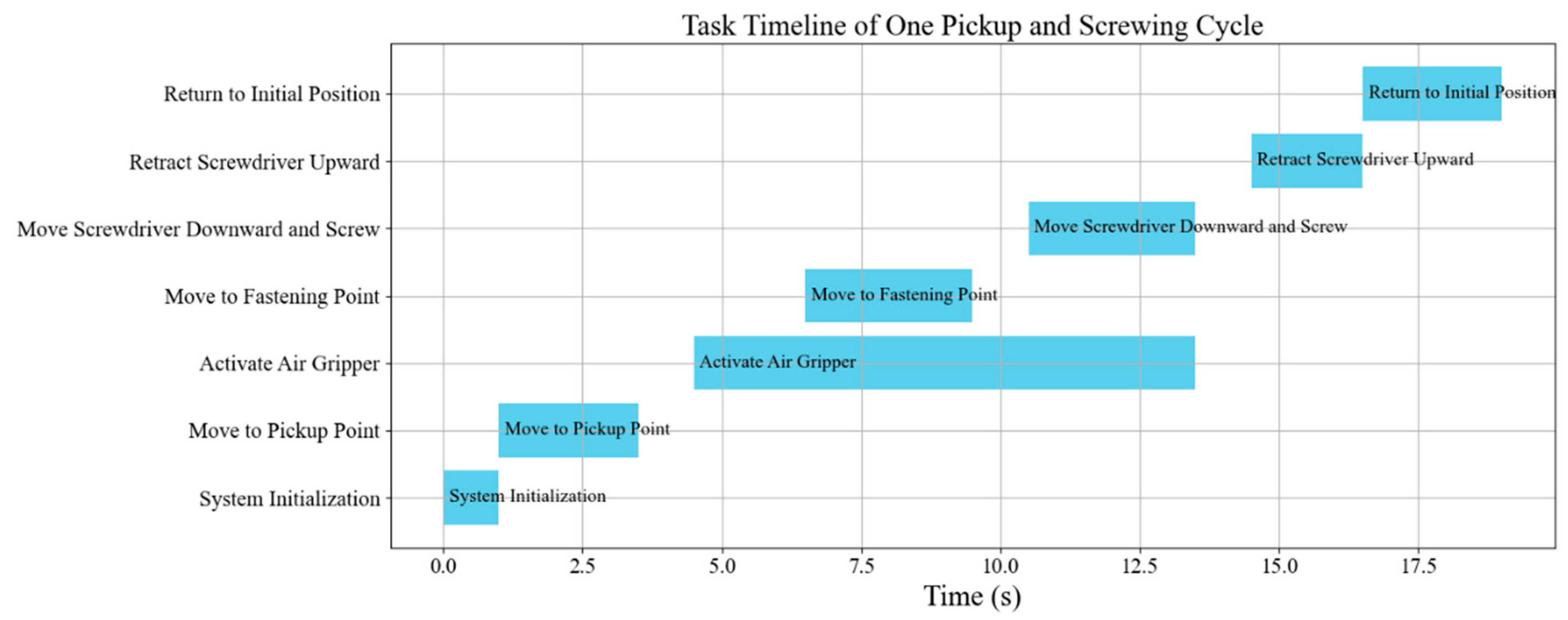

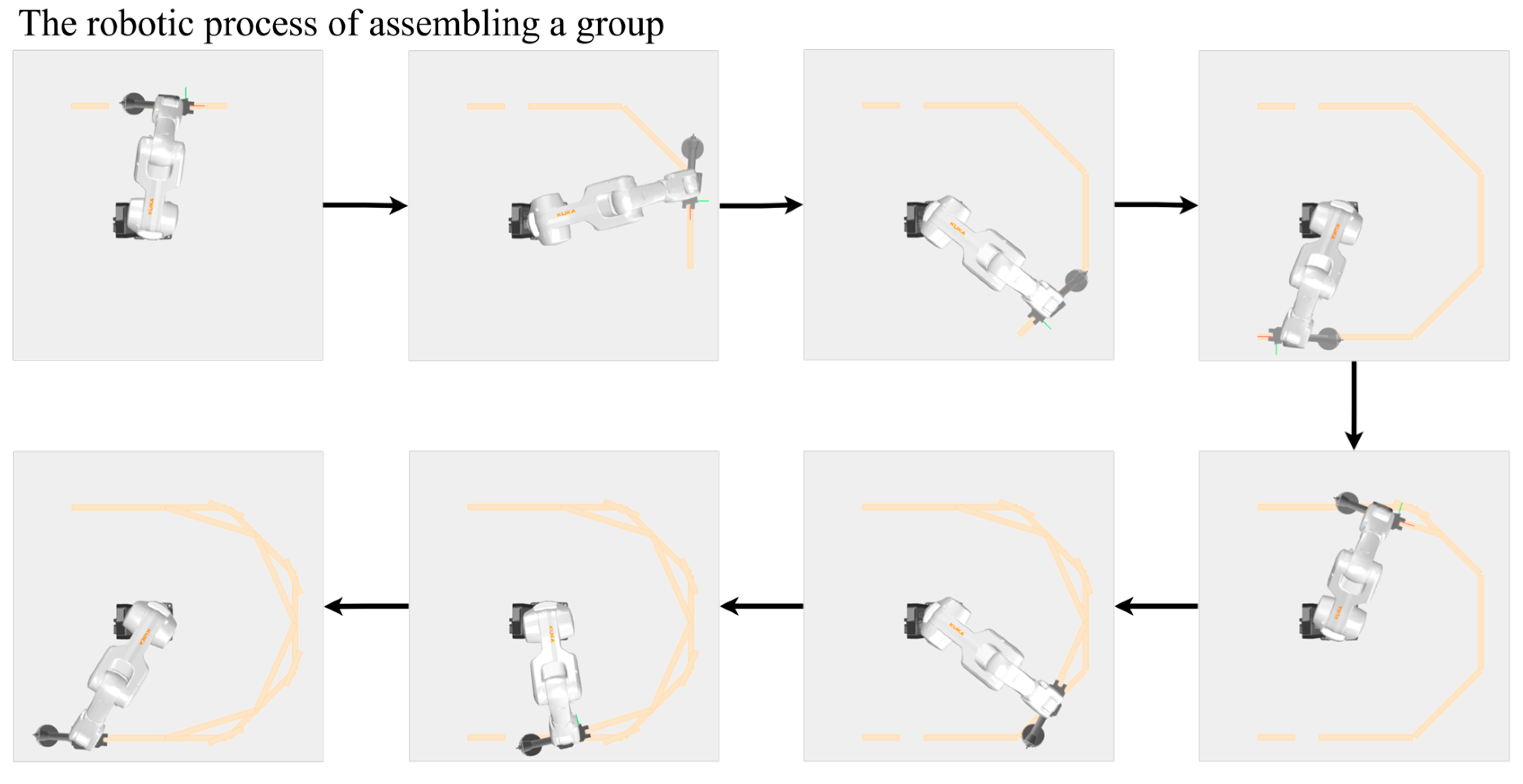

3.2. Robotic Construction Simulation and Robot Control

- (1)

- Gripping: A robot-recognizable reference plane is generated on each timber block’s top surface. The calibrated offset between the screwdriver axis and gripper center enables single-step gripping pose determination. This approach eliminates frequent realignment during subsequent screwing operations caused by pose errors.

- (2)

- Placing: To prevent collisions between the target block and assembled components, the timber block is first positioned 100 mm above location, then lowered vertically to its final coordinate. This ensures a safe and linear trajectory.

- (3)

- Screw-driving: Experimental validation established an optimal insertion time of 0.5 s per self-tapping screw, balancing sufficient torque with maximum cycle efficiency.

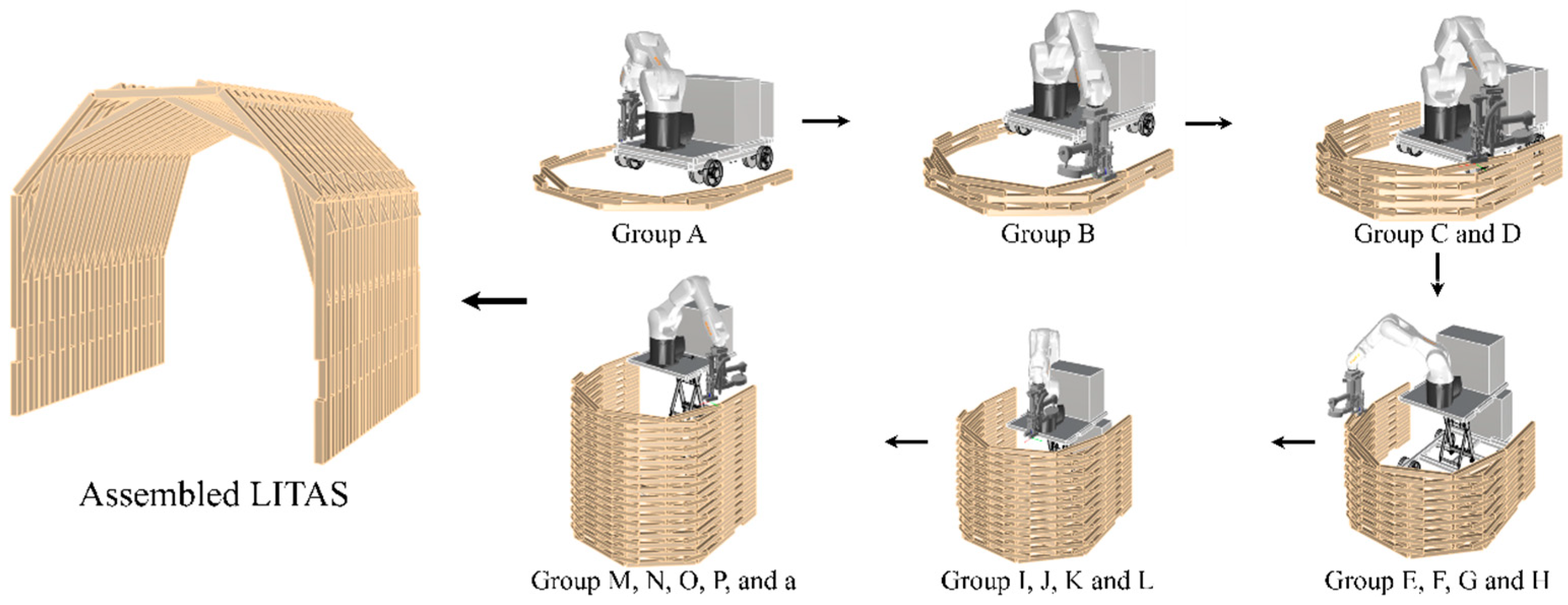

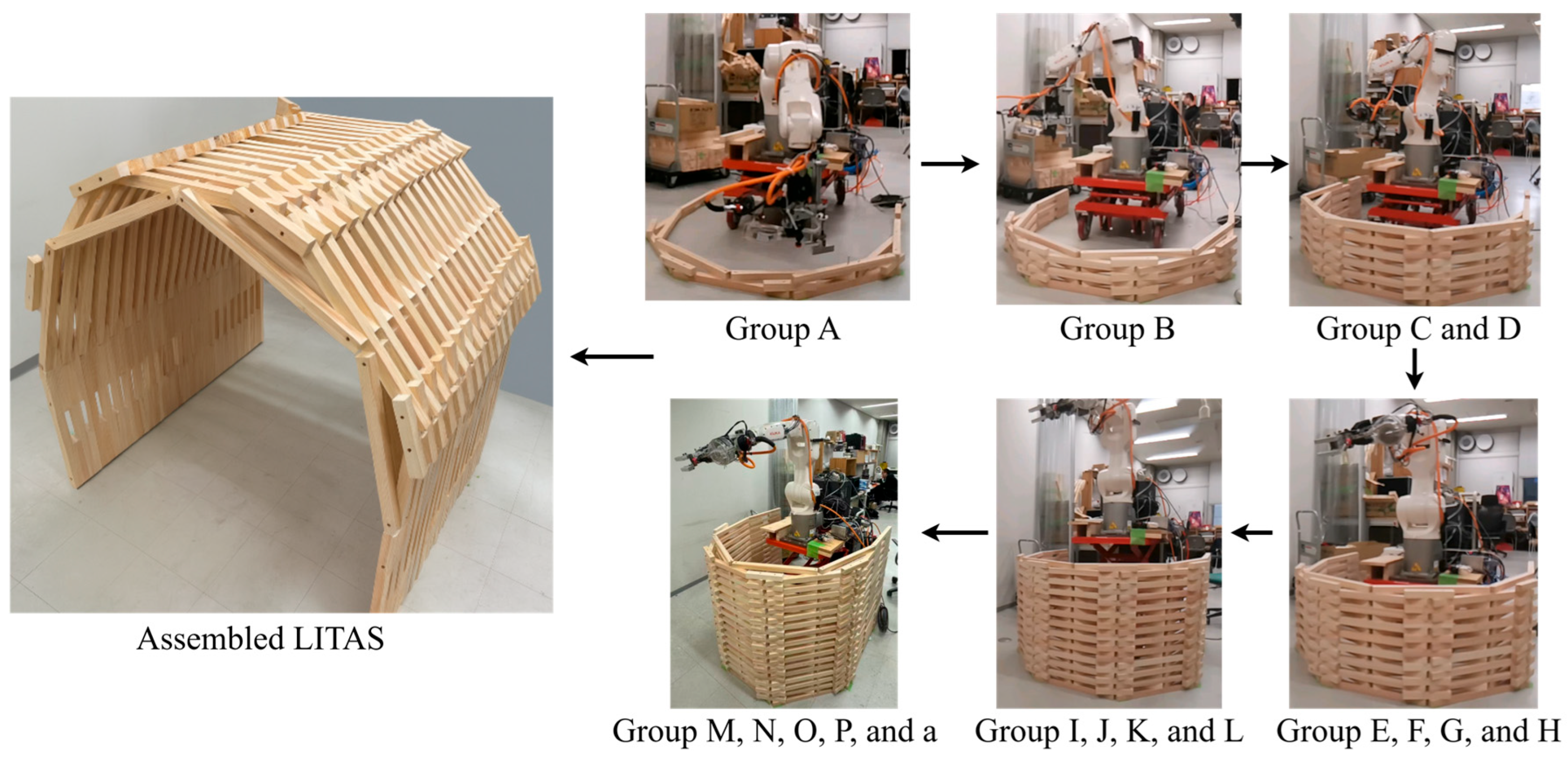

3.3. Robotic Construction System Assembly

4. Results

4.1. Robotic Construction Assembly Results

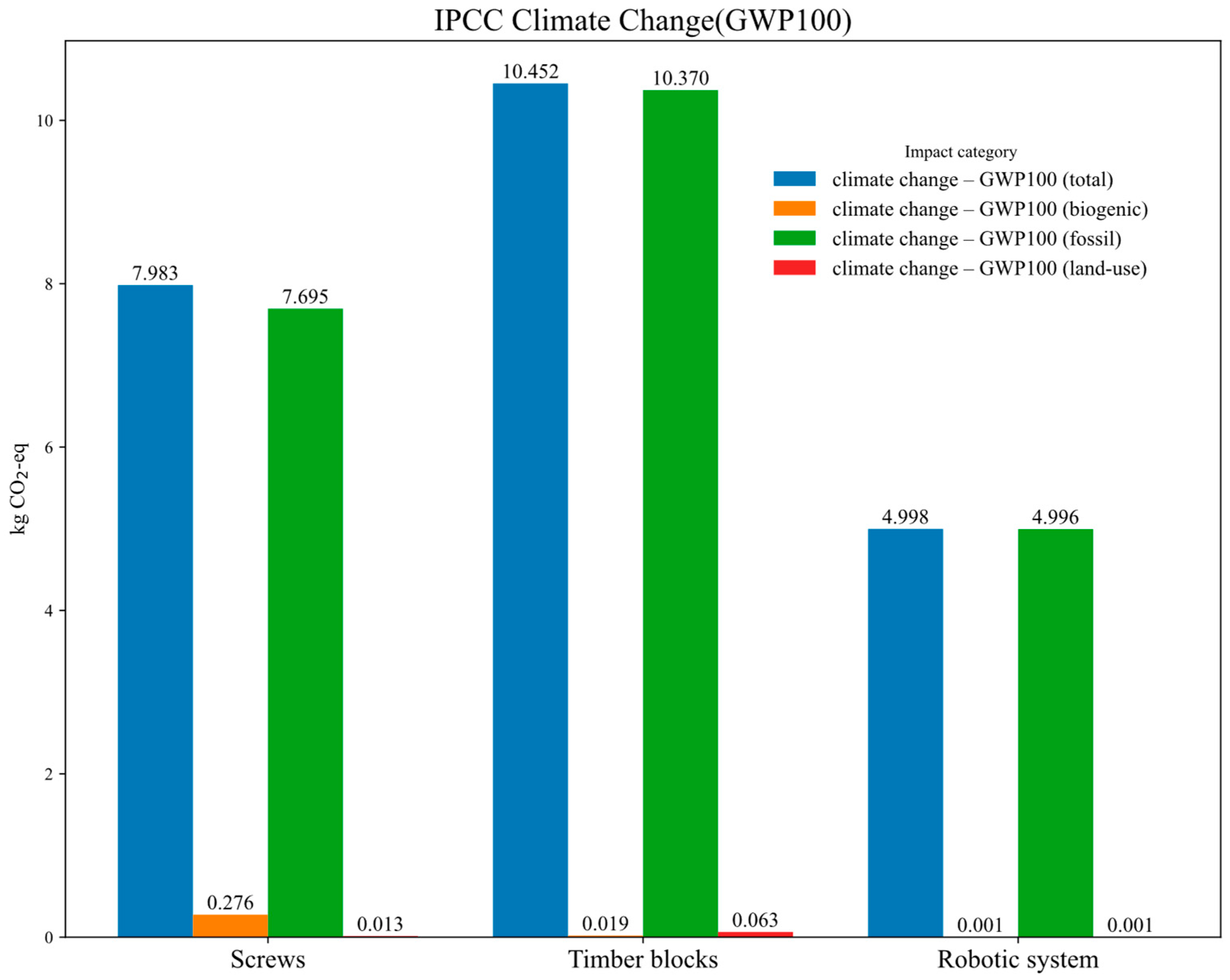

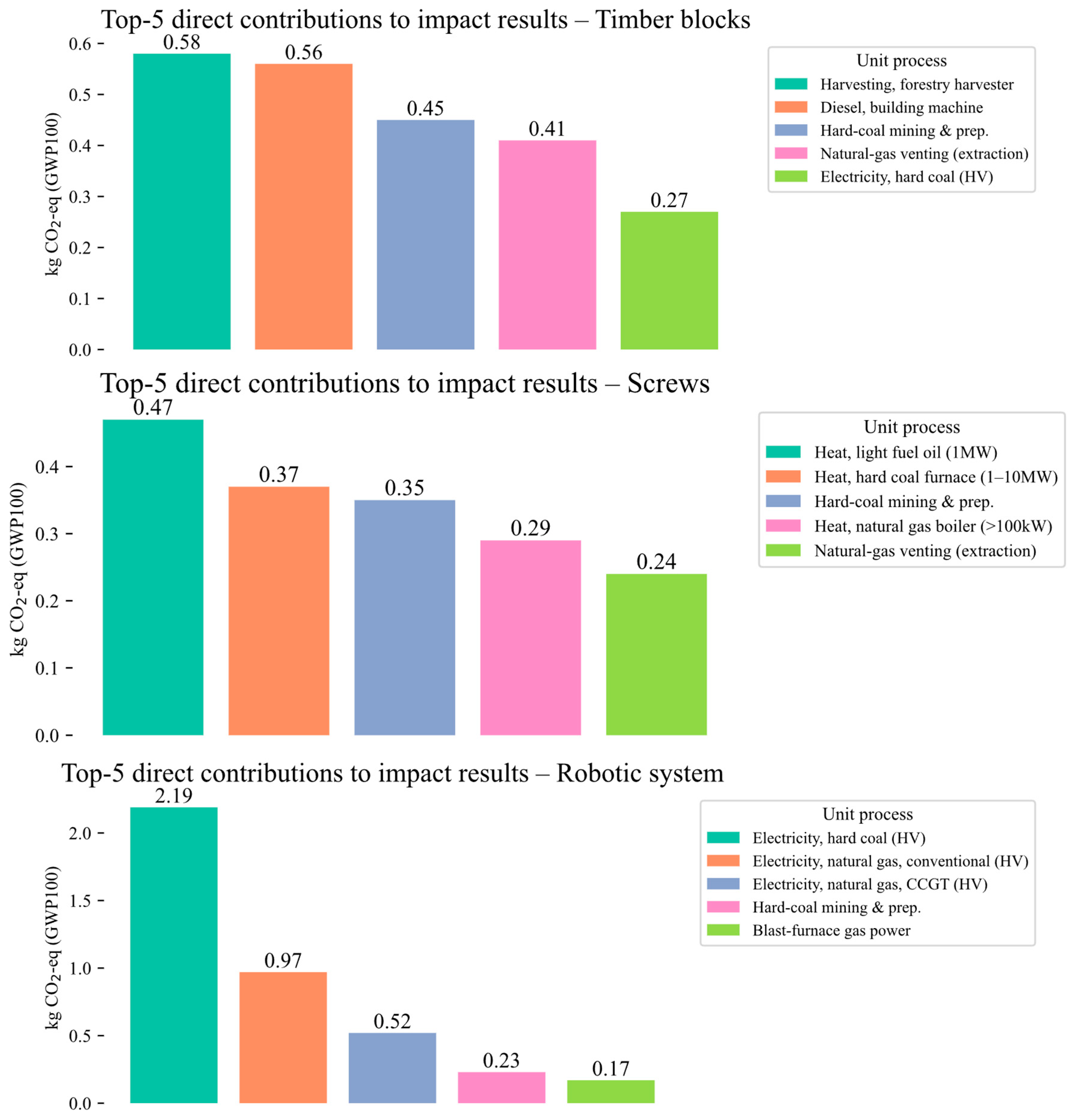

4.2. Life-Cycle Impact Assessment (LCIA)

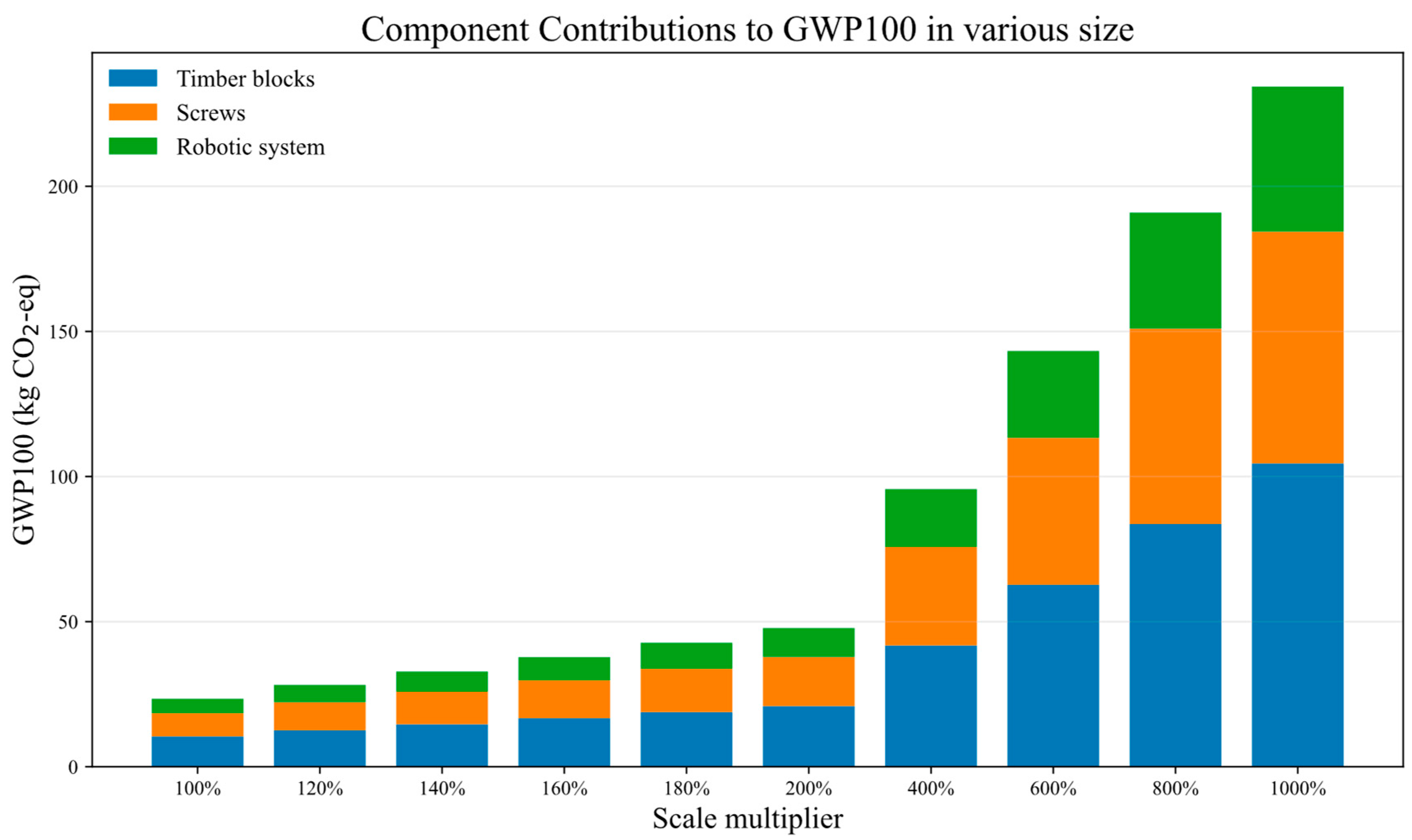

4.3. Elasticity Analysis of Environmental Impact

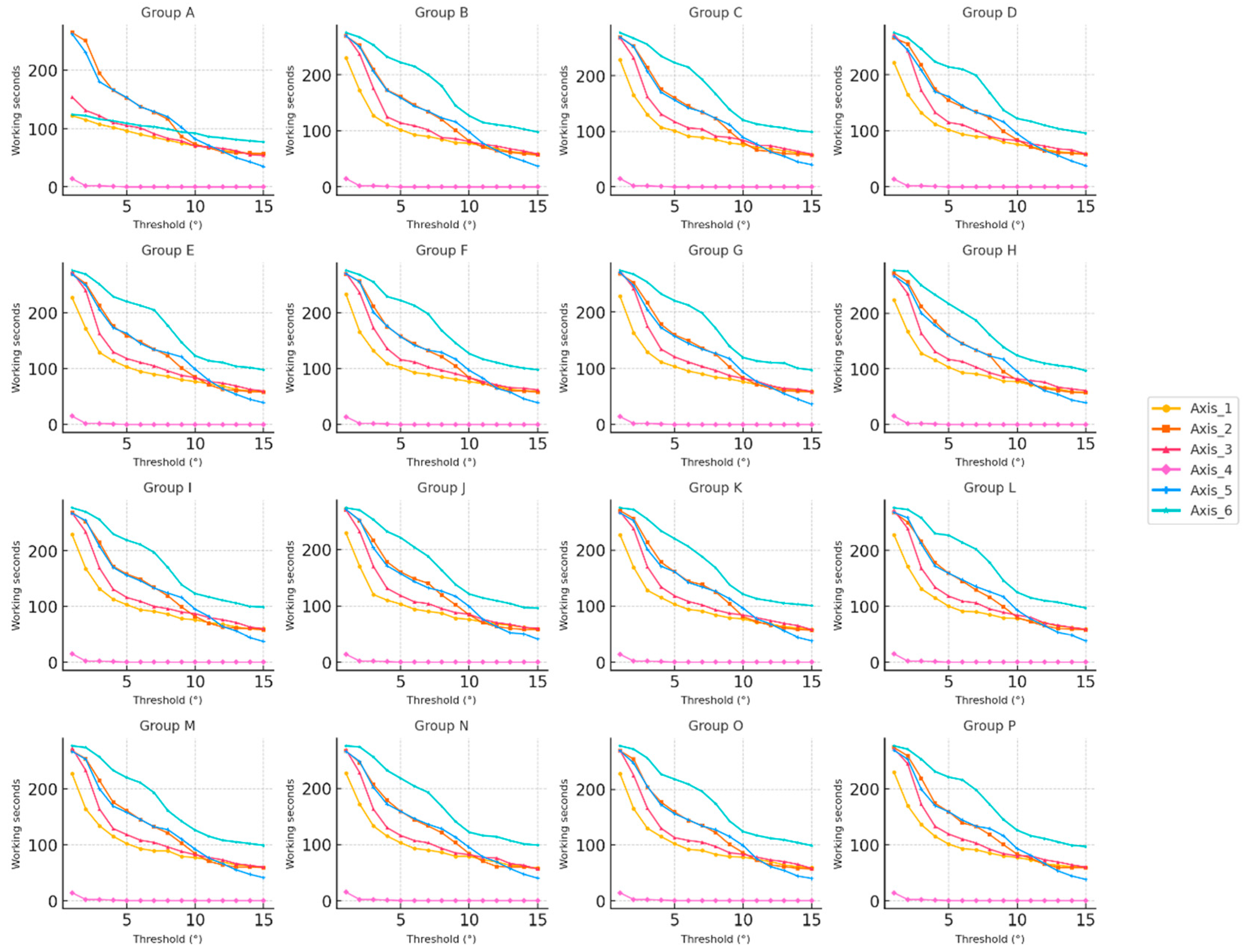

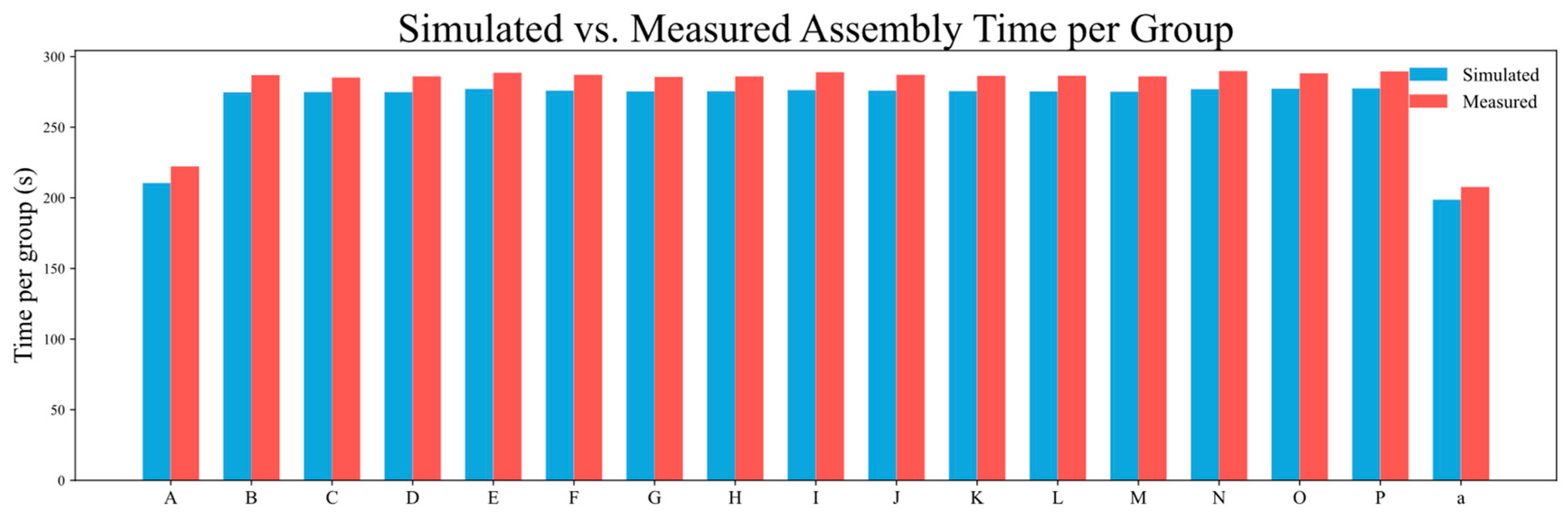

4.4. Robotic Assembly Time Validation

5. Discussion

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- United Nations Environment Programme. Building Materials and the Climate: Constructing a New Future; United Nations: Nairobi, Kenya, 2023; ISBN 978-92-807-4064-6. [Google Scholar]

- Sizirici, B.; Fseha, Y.; Cho, C.-S.; Yildiz, I.; Byon, Y.-J. A Review of Carbon Footprint Reduction in Construction Industry, from Design to Operation. Materials 2021, 14, 6094. [Google Scholar] [CrossRef] [PubMed]

- Howard, C.; Dymond, C.C.; Griess, V.C.; Tolkien-Spurr, D.; Van Kooten, G.C. Wood Product Carbon Substitution Benefits: A Critical Review of Assumptions. Carbon Balance Manag. 2021, 16, 9. [Google Scholar] [CrossRef]

- Winchester, N.; Reilly, J.M. The Economic and Emissions Benefits of Engineered Wood Products in a Low-Carbon Future. Energy Econ. 2020, 85, 104596. [Google Scholar] [CrossRef]

- Leskinen, P.; Cardellini, G.; González-García, S.; Hurmekoski, E.; Sathre, R.; Seppälä, J.; Smyth, C.; Stern, T.; Verkerk, P.J. Substitution Effects of Wood-Based Products in Climate Change Mitigation; From Science to Policy; European Forest Institute: Joensuu, Finland, 2018. [Google Scholar]

- Falk, R. Wood as a Sustainable Building Material. In Wood Handbook: Wood as an Engineering Material: Chapter 1; U.S. Department of Agriculture, Forest Service, Forest Products Laboratory: Madison, WI, USA, 2010. [Google Scholar]

- Brozovsky, J.; Labonnote, N.; Vigren, O. Digital Technologies in Architecture, Engineering, and Construction. Autom. Constr. 2024, 158, 105212. [Google Scholar] [CrossRef]

- Biswas, H.K.; Sim, T.Y.; Lau, S.L. Impact of Building Information Modelling and Advanced Technologies in the AEC Industry: A Contemporary Review and Future Directions. J. Build. Eng. 2024, 82, 108165. [Google Scholar] [CrossRef]

- Nguyen, T.D.; Adhikari, S. The Role of BIM in Integrating Digital Twin in Building Construction: A Literature Review. Sustainability 2023, 15, 10462. [Google Scholar] [CrossRef]

- García De Soto, B.; Agustí-Juan, I.; Hunhevicz, J.; Joss, S.; Graser, K.; Habert, G.; Adey, B.T. Productivity of Digital Fabrication in Construction: Cost and Time Analysis of a Robotically Built Wall. Autom. Constr. 2018, 92, 297–311. [Google Scholar] [CrossRef]

- Pajonk, A.; Prieto, A.; Blum, U.; Knaack, U. Multi-Material Additive Manufacturing in Architecture and Construction: A Review. J. Build. Eng. 2022, 45, 103603. [Google Scholar] [CrossRef]

- Takva, Ç.; Top, S.M.; Gökgöz, B.İ.; Gebel, Ş.; İlerisoy, Z.Y.; İlcan, H.; Şahmaran, M. Applicability of 3D Concrete Printing Technology in Building Construction with Different Architectural Design Decisions in Housing. J. Build. Eng. 2024, 98, 111257. [Google Scholar] [CrossRef]

- Chea, C.P.; Bai, Y.; Pan, X.; Arashpour, M.; Xie, Y. An Integrated Review of Automation and Robotic Technologies for Structural Prefabrication and Construction. Transp. Saf. Environ. 2020, 2, 81–96. [Google Scholar] [CrossRef]

- Adekunle, P.; Aigbavboa, C.; Otasowie, O.K.; Adekunle, S. Benefits of Robotic Utilization in the Prefabricated Construction Industry. In Proceedings of the 31st Annual Conference of the International Group for Lean Construction, Lille, France, 26 June–2 July 2023; pp. 746–754. [Google Scholar]

- Li, Y.; Zhang, Y.; Pan, A.; Han, M.; Veglianti, E. Carbon Emission Reduction Effects of Industrial Robot Applications: Heterogeneity Characteristics and Influencing Mechanisms. Technol. Soc. 2022, 70, 102034. [Google Scholar] [CrossRef]

- Willmann, J.; Knauss, M.; Bonwetsch, T.; Apolinarska, A.A.; Gramazio, F.; Kohler, M. Robotic Timber Construction—Expanding Additive Fabrication to New Dimensions. Autom. Constr. 2016, 61, 16–23. [Google Scholar] [CrossRef]

- Liu, Y.; Alias, A.H.; Haron, N.A.; Bakar, N.A.; Wang, H. Robotics in the Construction Sector: Trends, Advances, and Challenges. J. Intell. Robot. Syst. 2024, 110, 72. [Google Scholar] [CrossRef]

- Wagner, H.J.; Alvarez, M.; Groenewolt, A.; Menges, A. Towards Digital Automation Flexibility in Large-Scale Timber Construction: Integrative Robotic Prefabrication and Co-Design of the BUGA Wood Pavilion. Constr. Robot. 2020, 4, 187–204. [Google Scholar] [CrossRef]

- Wagner, H.J.; Alvarez, M.; Kyjanek, O.; Bhiri, Z.; Buck, M.; Menges, A. Flexible and Transportable Robotic Timber Construction Platform—TIM. Autom. Constr. 2020, 120, 103400. [Google Scholar] [CrossRef]

- Lai, Z.; Xiao, Y.; Chen, Z.; Li, H.; Huang, L. Preserving Woodcraft in the Digital Age: A Meta-Model-Based Robotic Approach for Sustainable Timber Construction. Buildings 2024, 14, 2900. [Google Scholar] [CrossRef]

- Kramberger, A.; Kunic, A.; Iturrate, I.; Sloth, C.; Naboni, R.; Schlette, C. Robotic Assembly of Timber Structures in a Human-Robot Collaboration Setup. Front. Robot. AI 2022, 8, 768038. [Google Scholar] [CrossRef] [PubMed]

- Yang, X.; Amtsberg, F.; Sedlmair, M.; Menges, A. Challenges and Potential for Human–Robot Collaboration in Timber Prefabrication. Autom. Constr. 2024, 160, 105333. [Google Scholar] [CrossRef]

- Apolinarska, A.A.; Pacher, M.; Li, H.; Cote, N.; Pastrana, R.; Gramazio, F.; Kohler, M. Robotic Assembly of Timber Joints Using Reinforcement Learning. Autom. Constr. 2021, 125, 103569. [Google Scholar] [CrossRef]

- Naboni, R.; Kunic, A.; Kramberger, A.; Schlette, C. Design, Simulation and Robotic Assembly of Reversible Timber Structures. Constr. Robot. 2021, 5, 13–22. [Google Scholar] [CrossRef]

- Kunic, A.; Naboni, R.; Kramberger, A.; Schlette, C. Design and Assembly Automation of the Robotic Reversible Timber Beam. Autom. Constr. 2021, 123, 103531. [Google Scholar] [CrossRef]

- Chai, H.; So, C.; Yuan, P.F. Manufacturing Double-Curved Glulam with Robotic Band Saw Cutting Technique. Autom. Constr. 2021, 124, 103571. [Google Scholar] [CrossRef]

- Leng, Y.; Shi, X.; Fukuda, H.; Kalachev, A.; Wan, D. Automated Construction for Human–Robot Interaction in Wooden Buildings: Integrated Robotic Construction and Digital Design of iSMART Wooden Arches. J. Field Robot. 2023, 40, 810–827. [Google Scholar] [CrossRef]

- Reisach, D.; Schütz, S.; Willman, J.; Schneider, S. Digital Fabrication for Circular Timber Construction: A Case Study. J. Circ. Econ. 2024, 1, 1–18. [Google Scholar] [CrossRef]

- Zhao, S.; Guo, F.; Zhao, J.; Yang, S.; He, F.; Liu, H.; Chen, Z. Investigation of the In-Plane Mechanical Behavior of Timber and Steel–Timber Composite Arches. Structures 2023, 57, 105267. [Google Scholar] [CrossRef]

- Yokoyama, M.; Gril, J.; Matsuo, M.; Yano, H.; Sugiyama, J.; Clair, B.; Kubodera, S.; Mistutani, T.; Sakamoto, M.; Ozaki, H.; et al. Mechanical Characteristics of Aged Hinoki Wood from Japanese Historical Buildings. Comptes Rendus Phys. 2009, 10, 601–611. [Google Scholar] [CrossRef]

- ISO 14040:2006; Environmental Management—Life Cycle Assessment—Principles and Framework. International Organization for Standardization: Geneva, Switzerland, 2006.

- ISO 14044:2006; Environmental Management—Life Cycle Assessment—Requirements and Guidelines. International Organization for Standardization: Geneva, Switzerland, 2006.

- EN 15804:2012+A2:2019; Sustainability of Construction Works—Environmental Product Declarations—Core Rules for the Product Category of Construction Products. European Committee for Standardization: Brussels, Belgium, 2019.

- Rassolkin, A.; Hoimoja, H.; Teemets, R. Energy Saving Possibilities in the Industrial Robot IRB 1600 Control. In Proceedings of the 2011 7th International Conference-Workshop Compatibility and Power Electronics (CPE), Tallinn, Estonia, 1–3 June 2011; pp. 226–229. [Google Scholar]

- Paryanto; Brossog, M.; Kohl, J.; Merhof, J.; Spreng, S.; Franke, J. Energy Consumption and Dynamic Behavior Analysis of a Six-Axis Industrial Robot in an Assembly System. Procedia CIRP 2014, 23, 131–136. [Google Scholar] [CrossRef]

- IPCC. Climate Change 2021: The Physical Science Basis. Contribution of Working Group I to the Sixth Assessment Report of the Intergovernmental Panel on Climate Change; Masson-Delmotte, V., Zhai, P., Pirani, A., Connors, S.L., Péan, C., Berger, S., Caud, N., Chen, Y., Goldfarb, L., Gomis, M.I., et al., Eds.; Cambridge University Press: Cambridge, UK; New York, NY, USA, 2021. [Google Scholar] [CrossRef]

| Materials | Item | Weight (kg) |

|---|---|---|

| Cypress blocks (500 mm) | 182 | 33.58 |

| Cypress blocks (200 mm) | 100 | 7.38 |

| M4 self-tapping screws | 512 | 2.43 |

| Group | Robot (kWh) | Compressor (kWh) | Lift-Platform (kWh) | Total (kWh) |

|---|---|---|---|---|

| A | 0.36 | 0.008 | 0.02 | 0.391 |

| B | 0.44 | 0.011 | 0.451 | |

| C | 0.44 | 0.011 | 0.451 | |

| D | 0.43 | 0.011 | 0.441 | |

| E | 0.44 | 0.011 | 0.02 | 0.471 |

| F | 0.45 | 0.011 | 0.461 | |

| G | 0.44 | 0.011 | 0.451 | |

| H | 0.45 | 0.011 | 0.461 | |

| I | 0.43 | 0.011 | 0.02 | 0.461 |

| J | 0.44 | 0.011 | 0.451 | |

| K | 0.45 | 0.011 | 0.461 | |

| L | 0.44 | 0.011 | 0.451 | |

| M | 0.45 | 0.011 | 0.02 | 0.481 |

| N | 0.43 | 0.011 | 0.441 | |

| O | 0.44 | 0.011 | 0.451 | |

| P | 0.45 | 0.011 | 0.461 | |

| a | 0.21 | 0.008 | 0.02 | 0.238 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Y.; Bi, K.; Fukuda, H. Automated Screw-Fastened Assembly of Layered Timber Arch-Shells: Construction-Phase LCA and Performance Validation. Buildings 2025, 15, 3186. https://doi.org/10.3390/buildings15173186

Li Y, Bi K, Fukuda H. Automated Screw-Fastened Assembly of Layered Timber Arch-Shells: Construction-Phase LCA and Performance Validation. Buildings. 2025; 15(17):3186. https://doi.org/10.3390/buildings15173186

Chicago/Turabian StyleLi, Yanfu, Kang Bi, and Hiroatsu Fukuda. 2025. "Automated Screw-Fastened Assembly of Layered Timber Arch-Shells: Construction-Phase LCA and Performance Validation" Buildings 15, no. 17: 3186. https://doi.org/10.3390/buildings15173186

APA StyleLi, Y., Bi, K., & Fukuda, H. (2025). Automated Screw-Fastened Assembly of Layered Timber Arch-Shells: Construction-Phase LCA and Performance Validation. Buildings, 15(17), 3186. https://doi.org/10.3390/buildings15173186