An Assessment of the Energy Performance and Initial Investment Cost of SDHW Systems: A Case Study of University Dormitory in Northern Cyprus

Abstract

1. Introduction

1.1. SDHW Systems in the Context of the Global Energy Crisis and Current Status of Northern Cyprus

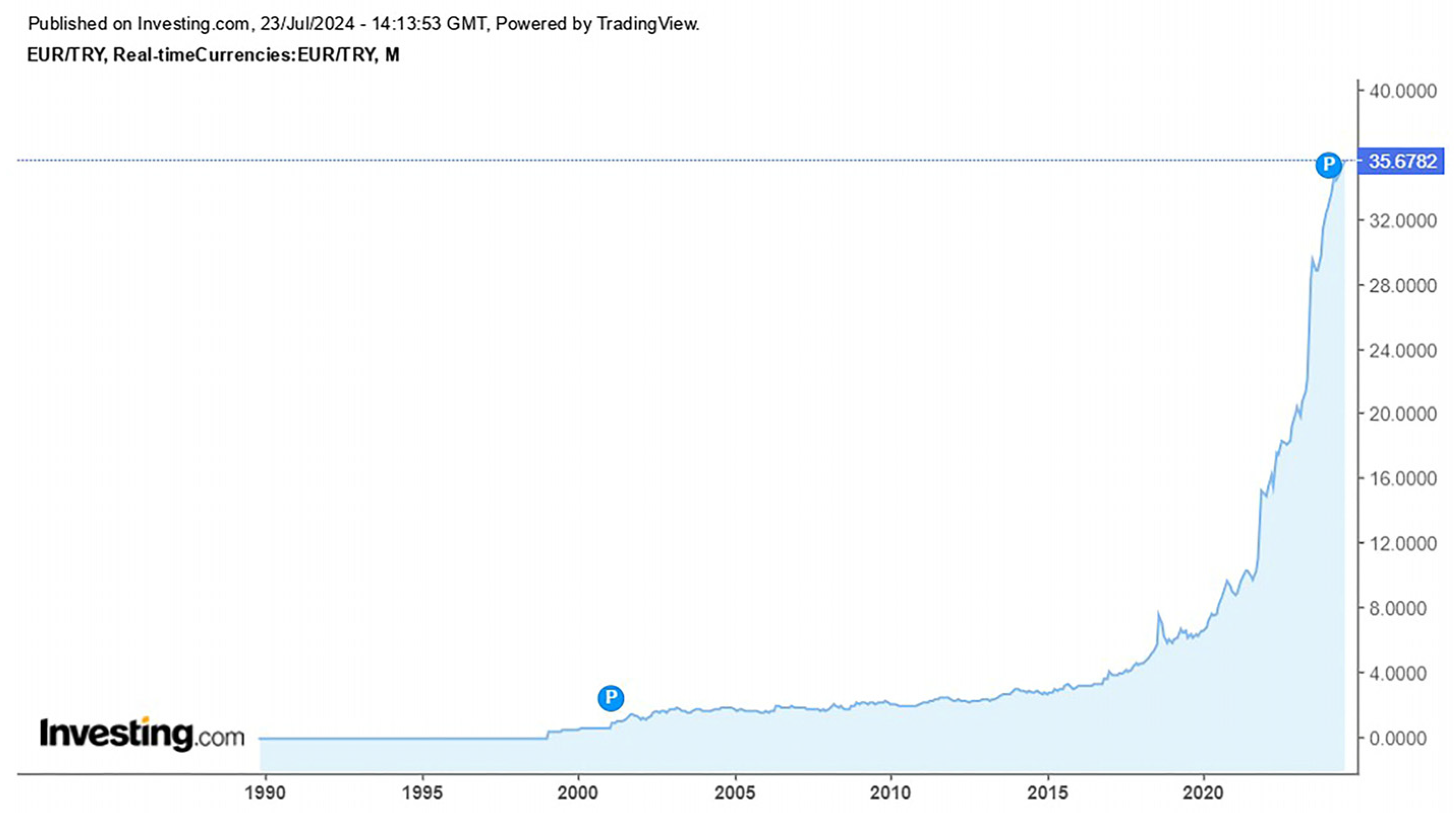

1.2. The Current Economic Situation of Türkiye and North Cyprus

2. Method of the Study

2.1. Research Approach and Design

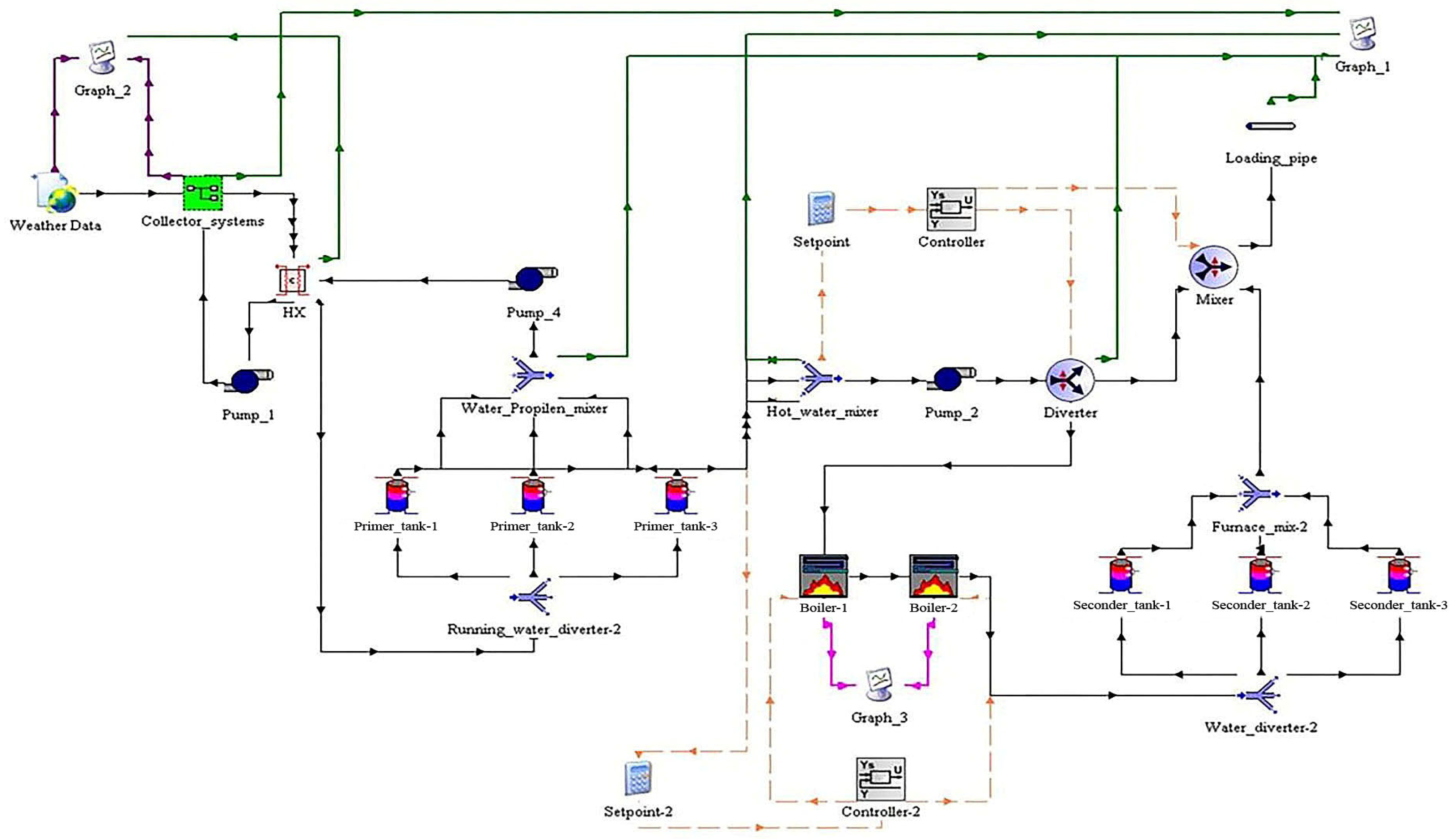

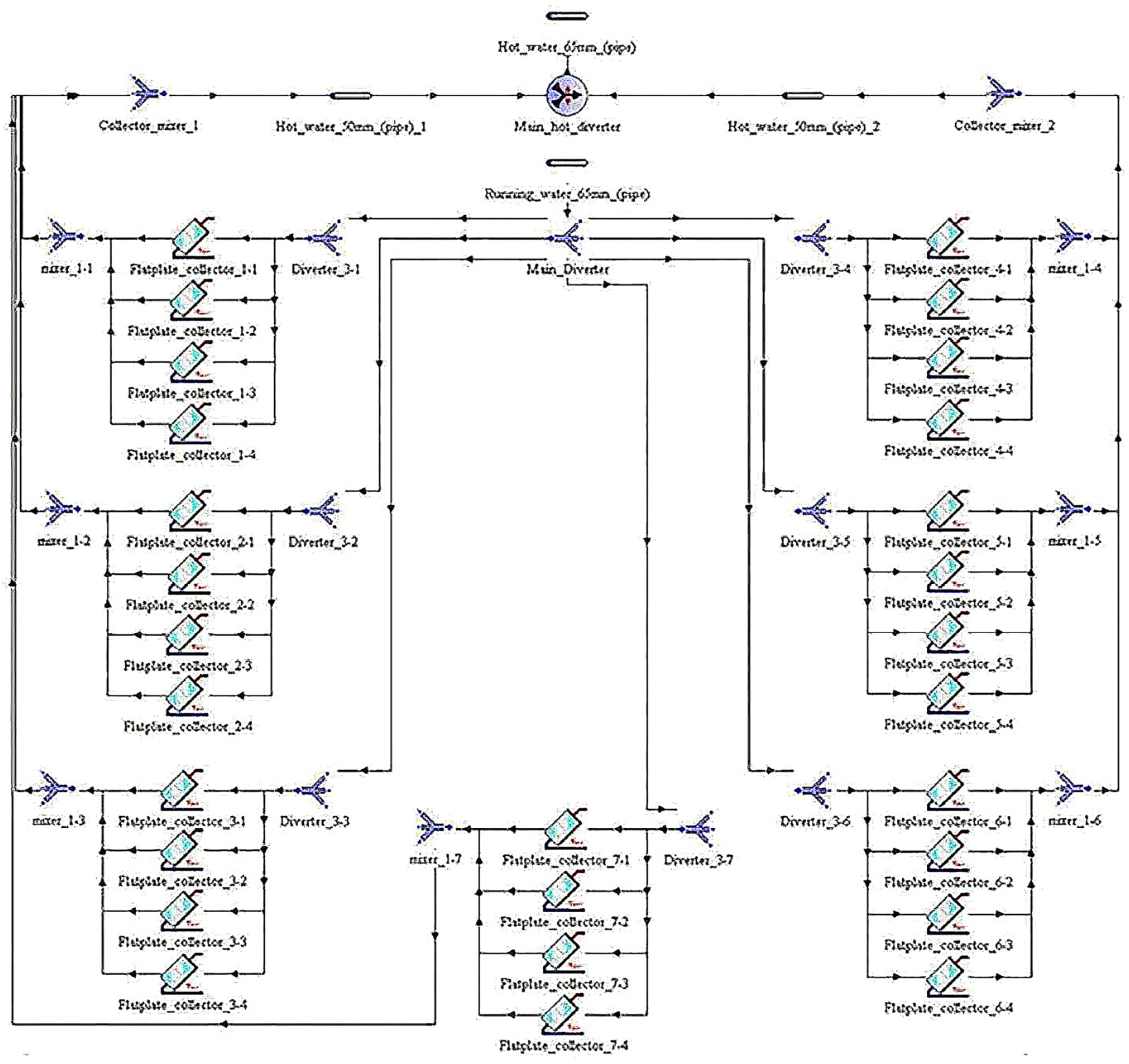

2.2. Simulation Process and Energy Performance Analysis

2.3. Usage Scenario and Domestic Hot Water Consumption Profile

2.4. Economic Analysis and Cost Variation Model

2.5. Validity and Limitations

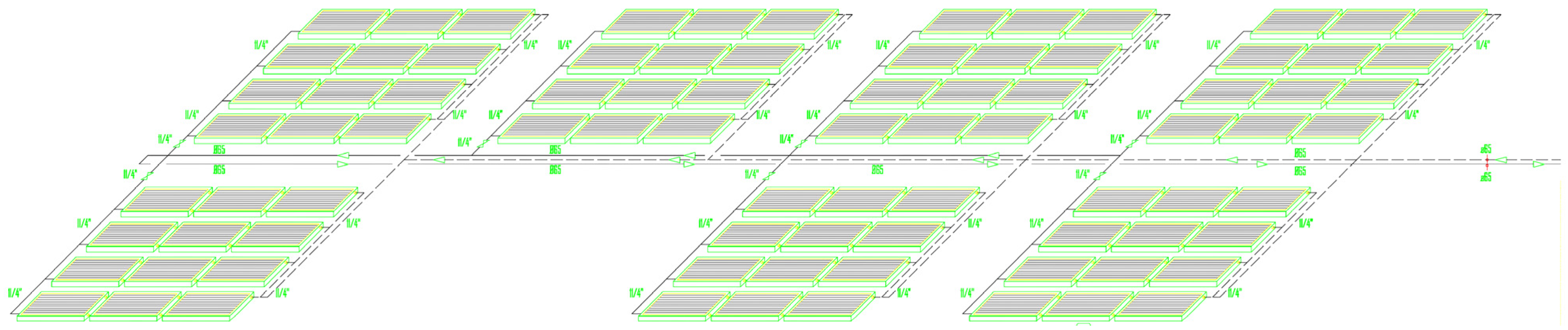

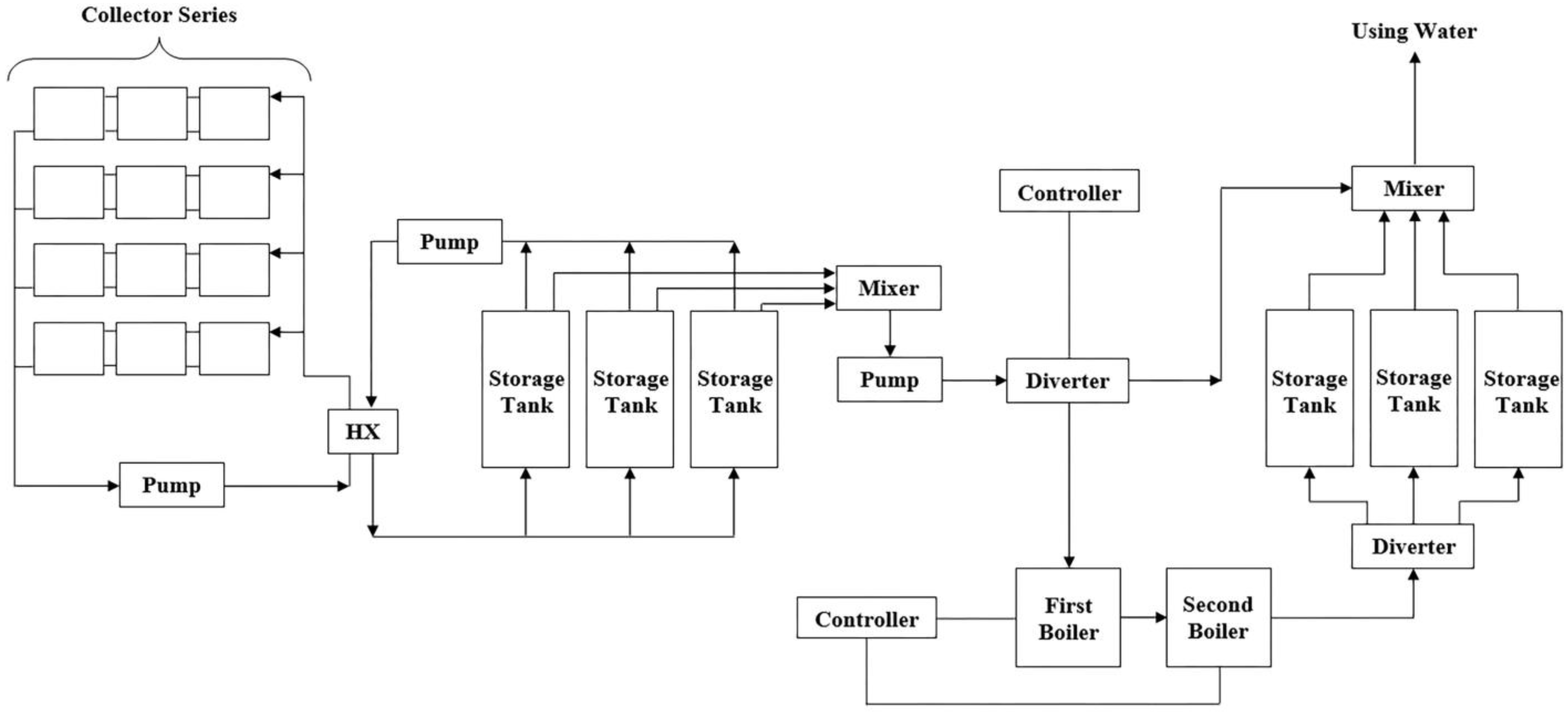

3. SDHW System Description

- Primary solar side: The primary line includes three storage tanks, each with a capacity of 5000 lt, designed to store DHW heated by the solar collectors via the heat-transfer fluid circulating through the plate heat exchanger. This configuration yields a total primary storage capacity of 15,000 lt, ensuring that the high hot-water flow rate demand (14,790 lt/h) can be buffered and managed effectively.

- Secondary boiler-assisted side: On the auxiliary line, which is backed up by boilers, an additional three storage tanks are employed, each again with a 5000 lt capacity. This provides a further 15,000 lt of storage, enabling a continuous hot-water supply during periods of insufficient solar radiation.

4. Description of the SDHW System Energy Model

5. Results and Analysis

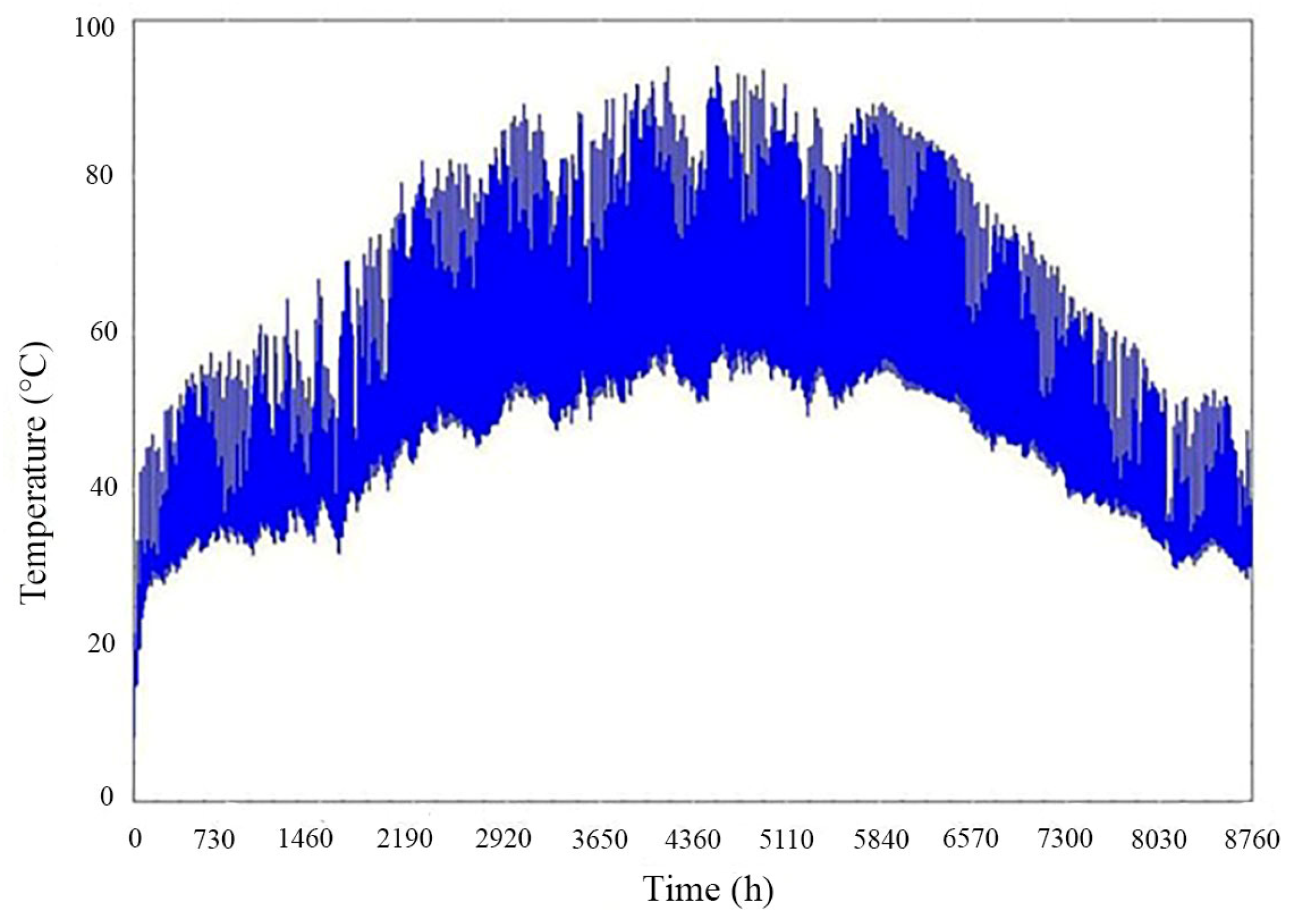

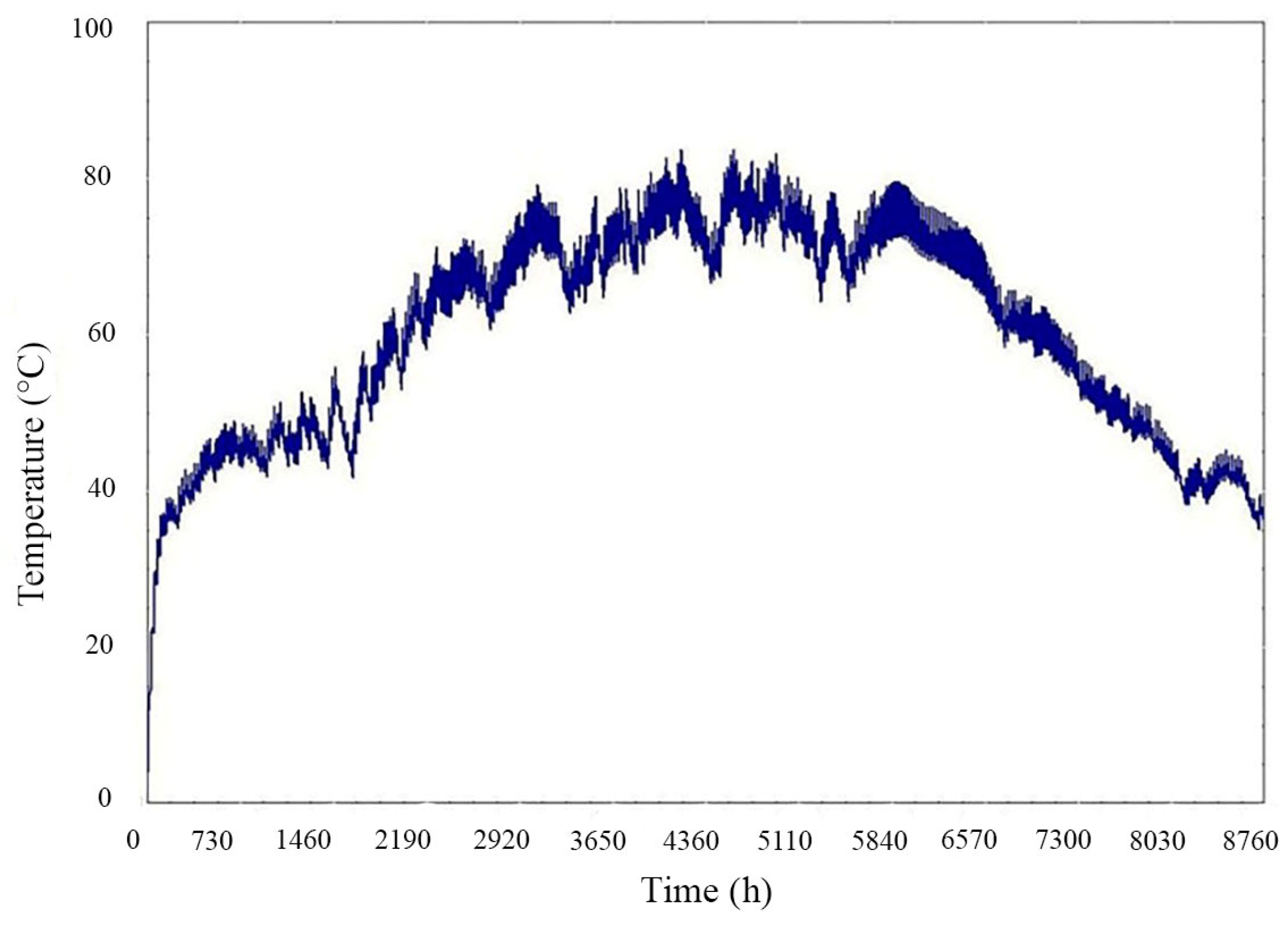

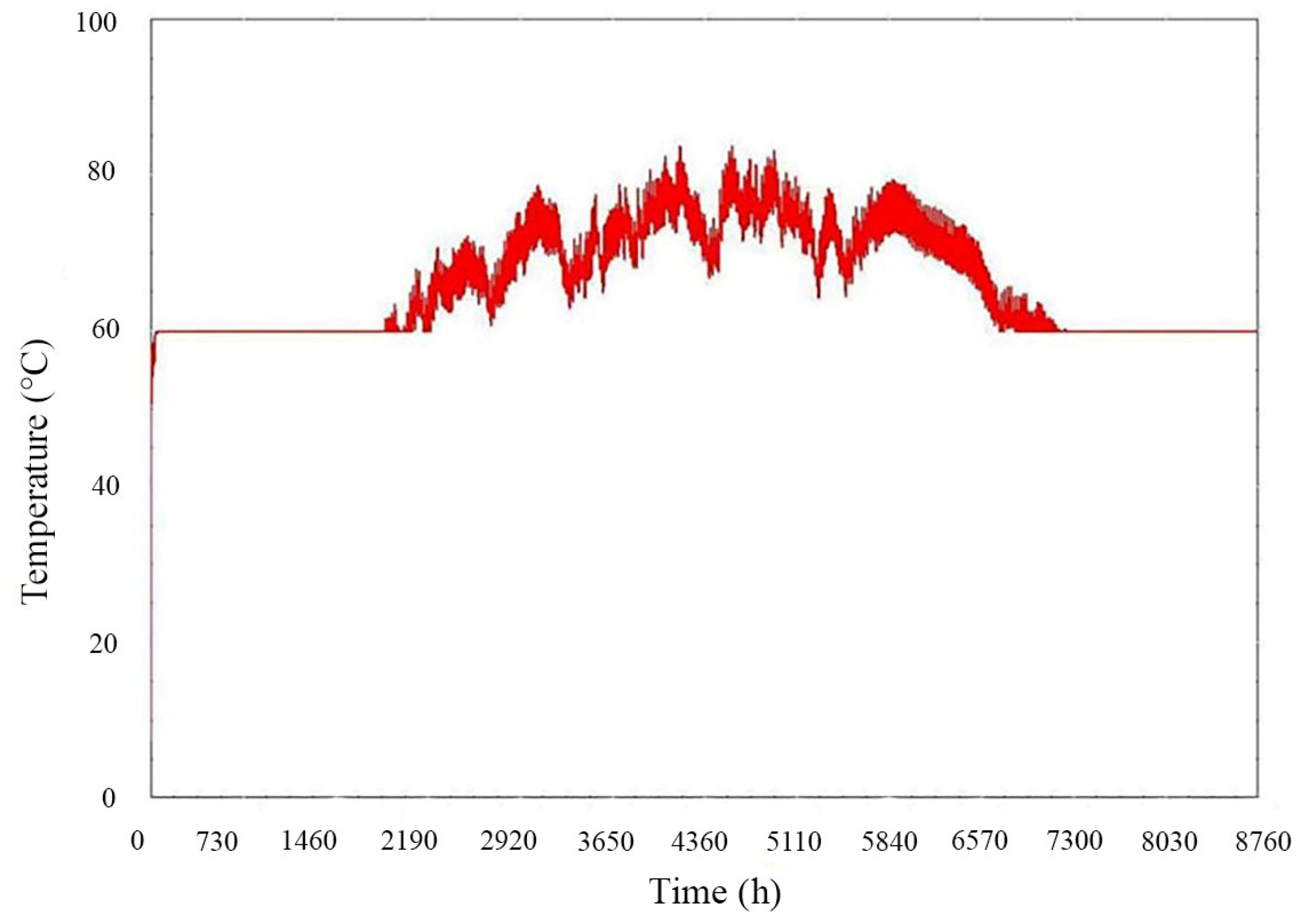

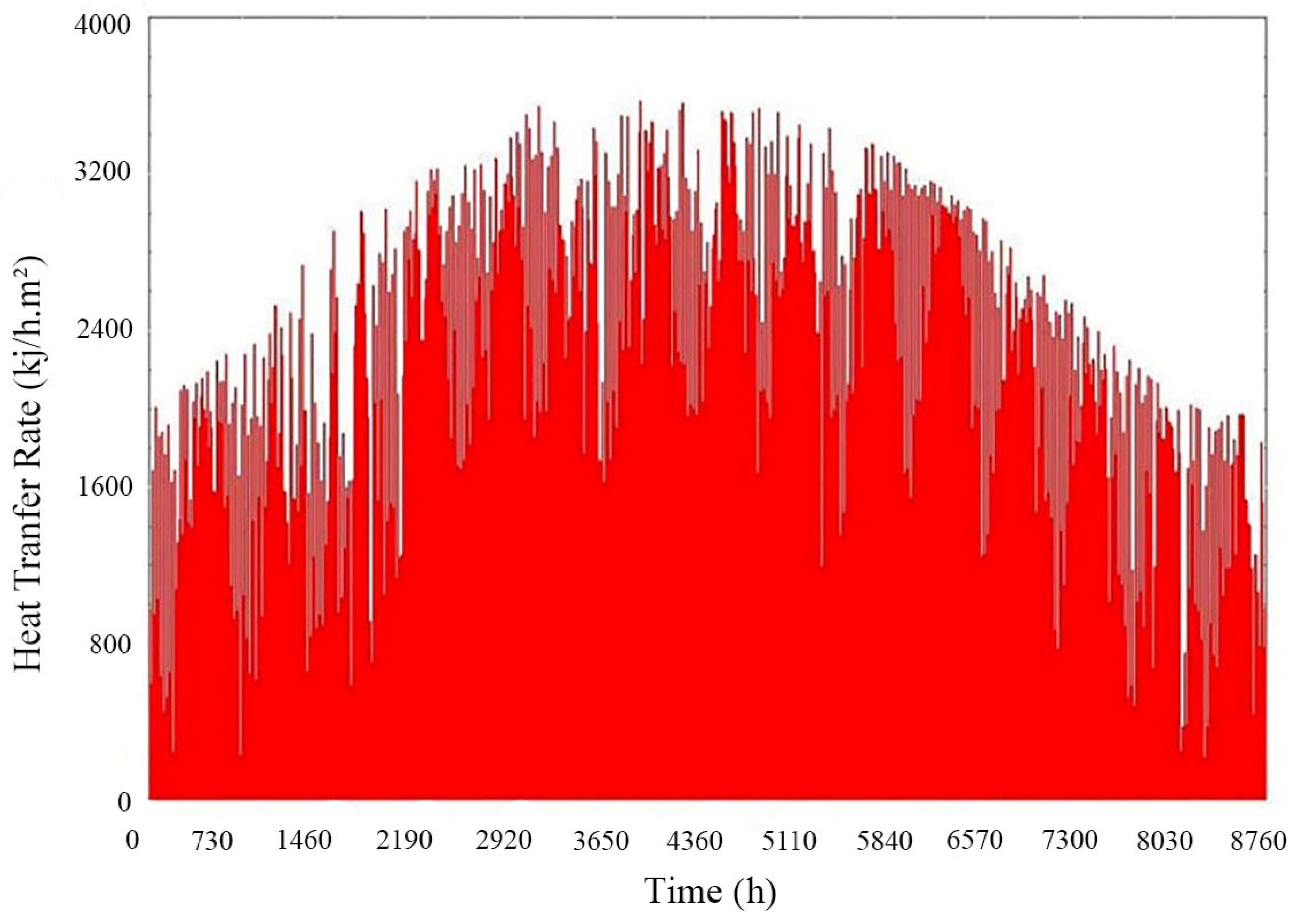

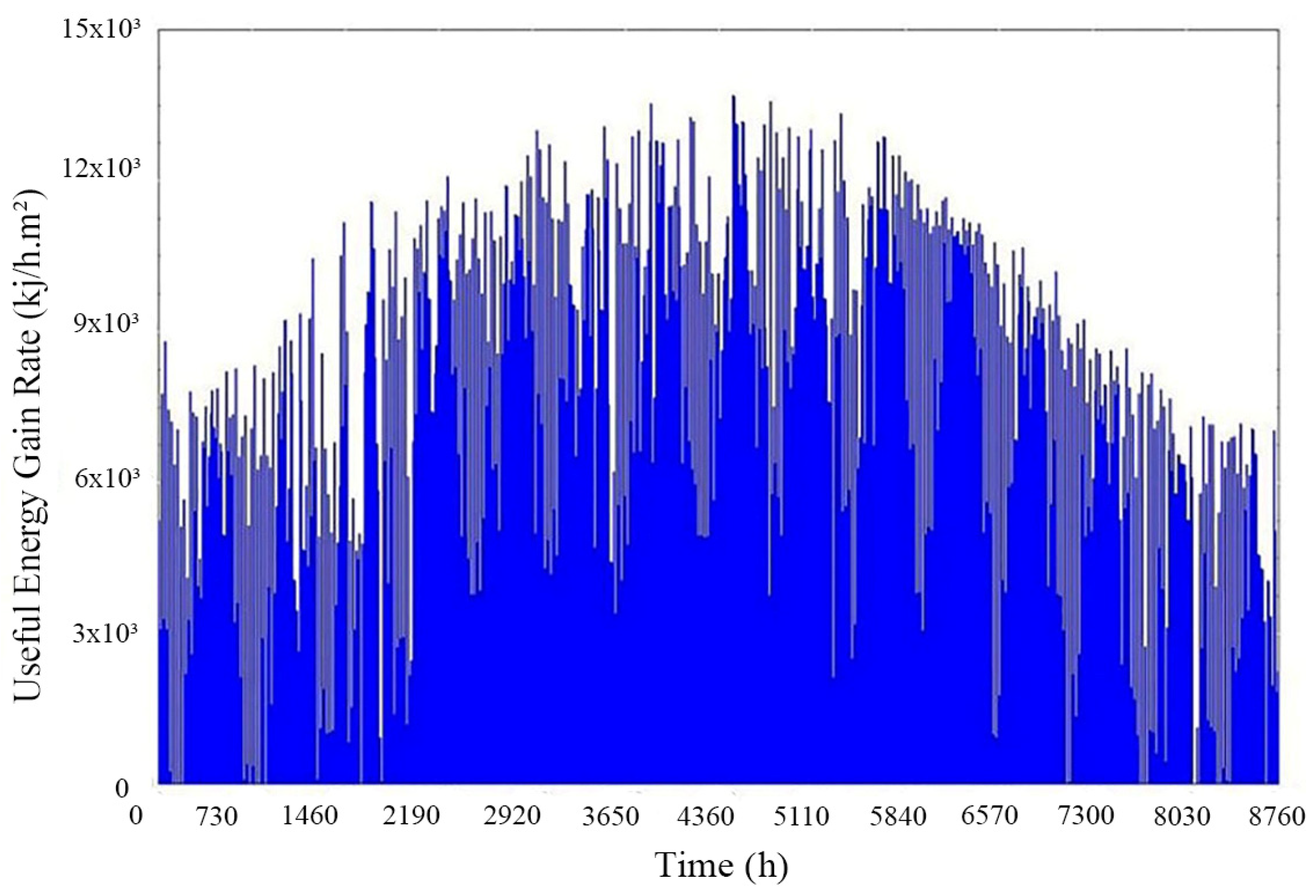

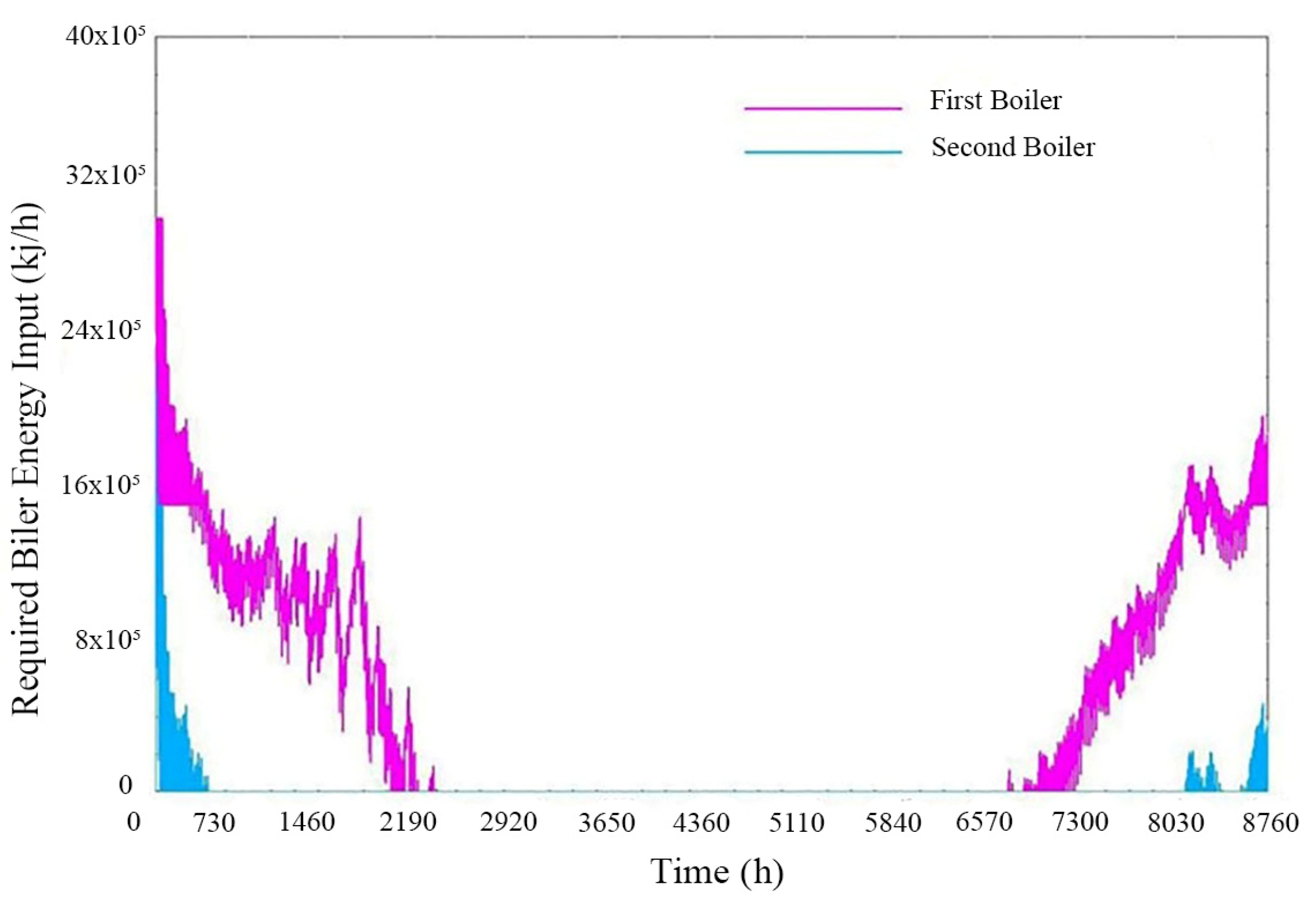

5.1. Analyzing Energy Performance of SDHW System

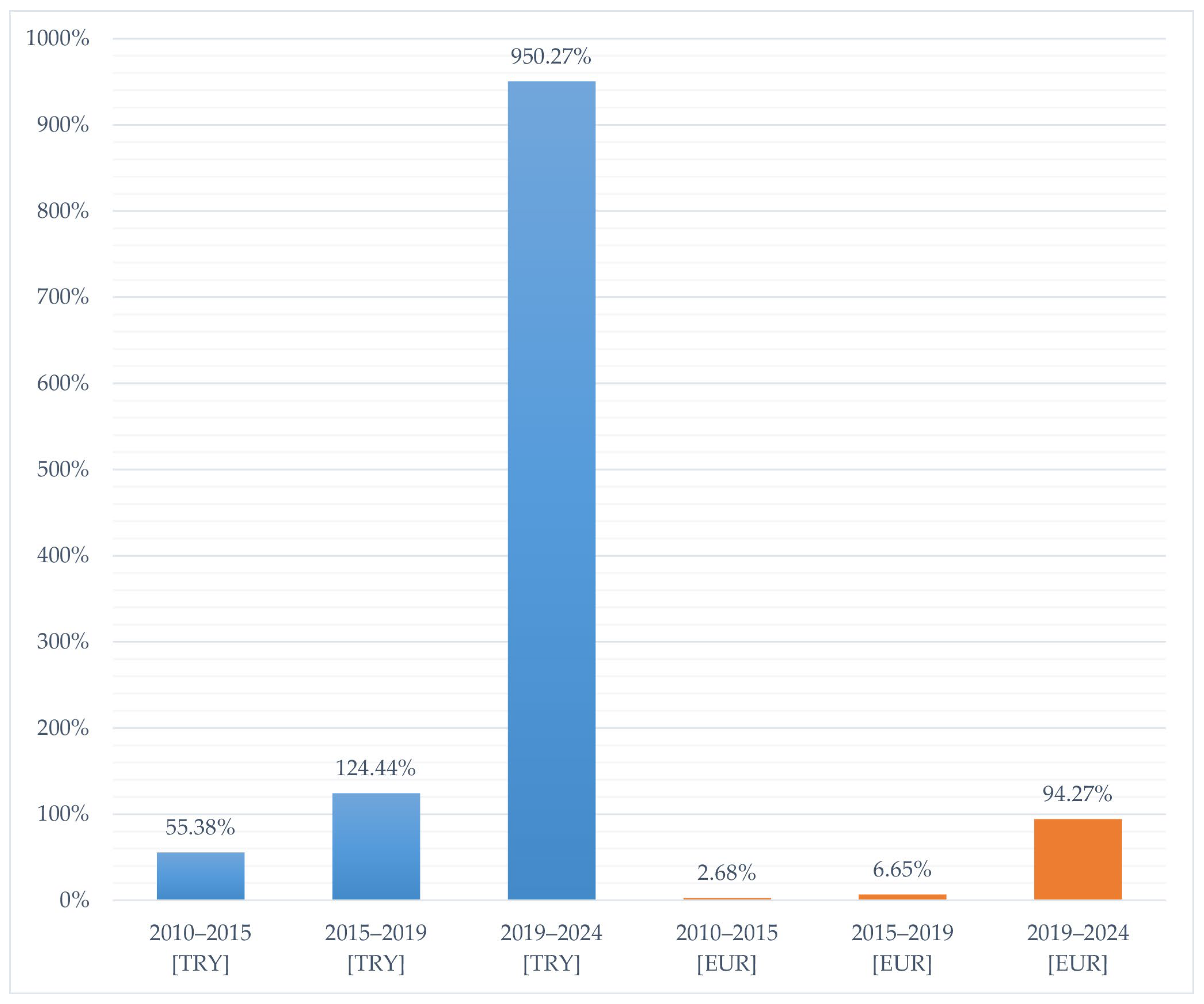

5.2. Analyzing Initial Investment Cost of SDHW System

- Certain components—such as the boiler, solar collector, boiler-supported hot water tank, and circulation pump—constitute the largest share of the total system cost.

- Other components—such as the thermometer, manometer, and safety valve—account for the smallest share of the total system cost.

- As a result of the study, the primary factors contributing to the increase in construction costs between 2010 and 2024 included rising fuel and material prices, higher taxes and customs duties, and increased labor costs associated with the economic policies of the Turkish government—particularly the significant devaluation of the Turkish lira against the euro following the COVID-19 pandemic. Figure 16 illustrates the change in the total initial investment cost of the SDHW system designed for the dormitory building, expressed in both Turkish lira and euro, over the years. The most pronounced cost increase occurred between 2019 and 2024, largely due to the inability to control price escalations within Türkiye’s recent free-market conditions. Furthermore, the lack of adequate support for domestic producers has increased foreign dependency, causing materials purchased in foreign currency to impose an excessive financial burden on investors.

- The increase in construction costs in Northern Cyprus has become inevitable due to shipping expenses for transporting materials, combined with the aforementioned dependency of the region. The appreciation of the euro may have discouraged investors from pursuing solar energy projects, especially given that such systems are generally imported. The rise in costs in euro terms can extend the payback period of solar energy investments in Northern Cyprus. Nevertheless, this situation could be reversed through government support aimed at strengthening domestic production.

6. Discussion

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Pillai, I.R.; Banerjee, R. Methodology for estimation of potential for solar water heating in a target area. Sol. Energy 2007, 81, 162–172. [Google Scholar] [CrossRef]

- Kannan, N.; Vakeesan, D. Solar energy for future world: A review. Renew. Sustain. Energy Rev. 2016, 62, 1092–1105. [Google Scholar] [CrossRef]

- Kusakana, K.; Hohne, P.A. A survey of domestic water heating technologies. In Proceedings of the 25th Southern African Universities Power Engineering Conference, Stellenbosch, South Africa, 30 January–1 February 2017; pp. 1–5. [Google Scholar]

- Kicsiny, R. Transfer functions of solar heating systems for dynamic analysis and control design. Renew. Energy 2015, 77, 64–78. [Google Scholar] [CrossRef]

- Soriga, I.; Badescu, V. Performance of SDHW systems with fully mixed and stratified tank operation under radiative regimes with different degree of stability. Energy 2017, 118, 1018–1034. [Google Scholar] [CrossRef]

- Ma, S.; Lu, S.; Ma, D.; Li, C.; Liu, C.; Wu, L.; Ma, H. Investigation on the thermal performance and economy of a solar assisted air source heat pump domestic hot water system. Appl. Therm. Eng. 2023, 232, 121007. [Google Scholar] [CrossRef]

- Ghorab, M.; Entchev, E.; Yang, L. Inclusive analysis and performance evaluation of solar domestic hot water system (a case study). Alex. Eng. J. 2017, 56, 201–212. [Google Scholar] [CrossRef]

- Dudkiewicz, E.; Fidorów-Kaprawy, N. Hybrid domestic hot water system performance in industrial hall. Resources 2020, 9, 65. [Google Scholar] [CrossRef]

- Obalanlege, M.A.; Xu, J.; Markides, C.N.; Mahmoudi, Y. Techno-economic analysis of a hybrid photovoltaic-thermal solar-assisted heat pump system for domestic hot water and power generation. Renew. Energy 2022, 196, 720–736. [Google Scholar] [CrossRef]

- Andrés, A.C.; Cejudo López, J.M. TRNSYS model of a thermosiphon solar domestic water heater with a horizontal store and mantle heat exchanger. Sol. Energy 2002, 72, 89–98. [Google Scholar] [CrossRef]

- Klein, S.A. TRNSYS—A Transient System Simulation Program; Engineering Experiment Station Report 38-12; University of Wisconsin-Madison: Madison, WI, USA, 1988. [Google Scholar]

- Hobbi, A.; Siddiqui, K. Optimal design of a forced circulation solar water heating system for a residential unit in cold climate using TRNSYS. Sol. Energy 2009, 83, 700–714. [Google Scholar] [CrossRef]

- Ayompe, L.M.; Duffy, A.; McCormack, S.J.; Conlon, M. Validated TRNSYS model for forced circulation solar water heating systems with flat plate and heat pipe evacuated tube collectors. Appl. Therm. Eng. 2011, 31, 1536–1542. [Google Scholar] [CrossRef]

- Belmonte, J.F.; Ramírez, F.J.; Almendros-Ibáñez, J.A. A stochastic thermo-economic analysis of solar domestic hot-water systems in compliance with building energy code requirements: The case of Spain. Sustain. Energy Technol. Assess. 2022, 52, 102007. [Google Scholar] [CrossRef]

- Cadafalch, J.; Carbonell, D.; Consul, R.; Ruiz, R. Modelling of storage tanks with immersed heat exchangers. Sol. Energy 2015, 112, 154–162. [Google Scholar] [CrossRef]

- Celador, A.C.; Odriozola, M.; Sala, J.M. Implications of the modelling of stratified hot water storage tanks in the simulation of CHP plants. Energy Convers. Manag. 2011, 52, 3018–3026. [Google Scholar] [CrossRef]

- Colle, S.; Koller, T. Simulation and performance analysis of a solar domestic hot water system controlled by weather forecast information. Energy Procedia 2014, 57, 2496–2505. [Google Scholar] [CrossRef]

- Dannemand, M.; Sifnaios, I.; Tian, Z.; Furbo, S. Simulation and optimization of a hybrid unglazed solar photovoltaic-thermal collector and heat pump system with two storage tanks. Energy Convers. Manag. 2020, 206, 112429. [Google Scholar] [CrossRef]

- Joubert, E.C.; Hess, S.; Van Niekerk, J.L. Large-scale solar water heating in South Africa: Status, barriers and recommendations. Renew. Energy 2016, 97, 809–822. [Google Scholar] [CrossRef]

- U.S. Department of Energy. EnergyPlus Essentials; EnergyPlus™ Is a Whole-Building Energy Simulation Program; Successor to DOE-2.1E; U.S. Department of Energy: Washington, DC, USA, 2023; Available online: https://energyplus.net/assets/nrel_custom/pdfs/pdfs_v23.2.0/EnergyPlusEssentials.pdf (accessed on 12 August 2025).

- U.S. Department of Energy. EnergyPlus Official Website. Available online: https://energyplus.net/ (accessed on 12 August 2025).

- Vela Solaris, A.G. Polysun User Manual. 2022. Available online: https://www.velasolaris.com/en/user-manual/ (accessed on 12 August 2025).

- Berger, M. Assessment of residential scale renewable heating solutions with thermal energy storages. Energy 2022, 244, 122618. [Google Scholar] [CrossRef]

- National Renewable Energy Laboratory (NREL). System Advisor Model (SAM) Official Website. Available online: https://sam.nrel.gov/ (accessed on 12 August 2025).

- Hamilton, W.; Neises, T. Dispatch optimization of electric thermal energy storage within System Advisor Model. J. Energy Storage 2023, 61, 106805. [Google Scholar] [CrossRef]

- Hayibo, K.S.; Pearce, J.M. Vertical free-swinging photovoltaic racking energy modeling using SAM. Renew. Energy 2023, 211, 1370–1383. [Google Scholar]

- Gomariz, F.P.; López, J.M.C.; Munoz, F.D. An analysis of low flow for solar thermal system for water heating. Sol. Energy 2019, 179, 67–73. [Google Scholar] [CrossRef]

- Rodriguez-Pastor, D.A.; Becerra, J.A.; Chacartegui, R. Adaptation of residential solar systems for domestic hot water (DHW) to hybrid organic Rankine Cycle (ORC) distributed generation. Energy 2023, 263, 125901. [Google Scholar] [CrossRef]

- Harkouss, F.; Fardoun, F.; Biwole, P.H. Multi-objective optimization methodology for net zero energy buildings. J. Build. Eng. 2018, 16, 57–71. [Google Scholar] [CrossRef]

- Maxoulis, C.N.; Charalampous, H.P.; Kalogirou, S.A. Cyprus solar water heating cluster: A missed opportunity? Energy Policy 2007, 35, 3302–3315. [Google Scholar] [CrossRef]

- Kalogirou, S.A.; Papamarcou, C. Modelling of a thermosyphon solar water heating system and simple model validation. Renew. Energy 2000, 21, 471–493. [Google Scholar] [CrossRef]

- Michopoulos, A.; Ziogou, I.; Kerimis, M.; Zachariadis, T. A study on hot-water production of hotels in Cyprus: Energy and environmental considerations. Energy Build. 2017, 150, 1–12. [Google Scholar] [CrossRef]

- Soylu, R. Turkish Lira: What is Erdogan’s New Economic Model for Turkey? Middle East Eye. 18 December 2021. Available online: https://www.middleeasteye.net/news/turkey-lira-erdogan-new-economic-model-what (accessed on 20 June 2024).

- Thorbecke, W.; Sengonul, A. The impact of exchange rates on Turkish imports and exports. Int. Econ. 2023, 174, 231–249. [Google Scholar] [CrossRef]

- World Bank. Türkiye Ekonomik Izleme Raporu, Şubat 2022: Akıntıya Karşı Kürek Çekmek; World Bank: Washington, DC, USA, 2022; Available online: https://www.worldbank.org/tr/country/turkey/publication/economic-monitor (accessed on 20 June 2024).

- World Bank: Washington, DC, USA. 2023. Overview. Available online: https://www.worldbank.org/tr/country/turkey/overview (accessed on 20 June 2024).

- Investing. Euro/Try Chart. Available online: https://www.investing.com/currencies/eur-try-chart (accessed on 1 July 2024).

- Ministry of Commerce of the Republic of Turkey. Uluslararası Anlaşmalar ve Avrupa Birliği Genel Müdürlüğü, KKTC Ülke Profili; Ministry of Commerce: Ankara, Turkey, 2022. [Google Scholar]

- Kuzey Kıbrıs Türk Ticaret Odası. Northern Cyprus in Figures and Investment Climate 2023; KKTC: Lefkoşa, Cyprus, 2023; Available online: https://www.ktto.net/wp-content/uploads/2024/05/Northern-Cyprus-in-Figures-and-Investment-Climate-2023.pdf (accessed on 12 August 2025).

- KKTC İstatistik Kurumu. Gayri Safi Millî Hasıla (2015–2020); KKTC: Lefkoşa, Cyprus, 2020. Available online: https://istatistik.gov.ct.tr/TEMEL-%C4%B0STAT%C4%B0ST%C4%B0KLER/GAYR%C4%B0-SAF%C4%B0-M%C4%B0LL%C4%B0-HASILA/GAYR%C4%B0-SAF%C4%B0-M%C4%B0LL%C4%B0-HASILA-2015-2020 (accessed on 12 August 2025).

- Court of Justice of the European Union. Case C-432/92, The Queen v. Minister of Agriculture, Fisheries and Food, Ex Parte S. P. Anastasiou (Pissouri) Ltd. and Others (Judgment of 5 July 1994); Luxembourg. 1994. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX%3A61992CJ0432 (accessed on 12 August 2025).

- OFX. Yearly Average Rates. Available online: https://www.ofx.com/en-au/forex-news/historical-exchange-rates/yearly-average-rates/ (accessed on 1 July 2024).

- Parmaksızoğlu, İ.C.; Kürekci, N.A. Technical Principles for Preparing Sanitary Installation Projects, 8th ed.; TMMOB Chamber of Mechanical Engineers, Istanbul Branch: Istanbul, Turkey, 2018; ISBN 978-605-01-1256-6. [Google Scholar]

- Crawley, D.B.; Lawrie, L.K. Rethinking the TMY: Is the “Typical” Meteorological Year best for building performance simulation? In Proceedings of the 14th Conference of International Building Performance Simulation Association, Hyderabad, India, 7–9 December 2015; pp. 2707–2714. Available online: https://publications.ibpsa.org/proceedings/bs/2015/papers/bs2015_2707.pdf (accessed on 13 August 2025).

- University of Wisconsin–Madison, Solar Energy Laboratory. TRNSYS 17: Transient System Simulation Program; Volume 4: Mathematical Reference; University of Wisconsin–Madison: Madison, WI, USA, 2012. [Google Scholar]

- Obalanlege, K.; Smith, J.; Brown, L. Economic and energy performance comparison between SDHW and PV-T heat pump hybrid systems. Renew. Energy J. 2020, 145, 1345–1356. [Google Scholar]

- Xie, Y.; Zhao, H.; Li, M. Comparative cost-benefit analysis of solar water heating and hybrid PV-T systems in Mediterranean climates. Sol. Energy 2022, 230, 123–134. [Google Scholar]

- Lee, A.; Wang, P. Lifecycle assessment of SDHW vs. hybrid solar-heat-pump systems in small-scale buildings. Energy Build. 2023, 297, 113510. [Google Scholar]

- Çakır, Ö.; Demir, F.; Yıldız, S. Feasibility of solar domestic hot water systems in energy-import-dependent areas: A case study in Northern Cyprus. Appl. Energy 2024, 365, 120000. [Google Scholar]

- Fernández-González, M.; López, A.; Pérez, J. Long-term investment analysis of PV-T heat pump hybrid systems under renewable energy incentives. J. Sustain. Energy 2023, 19, 95–110. [Google Scholar]

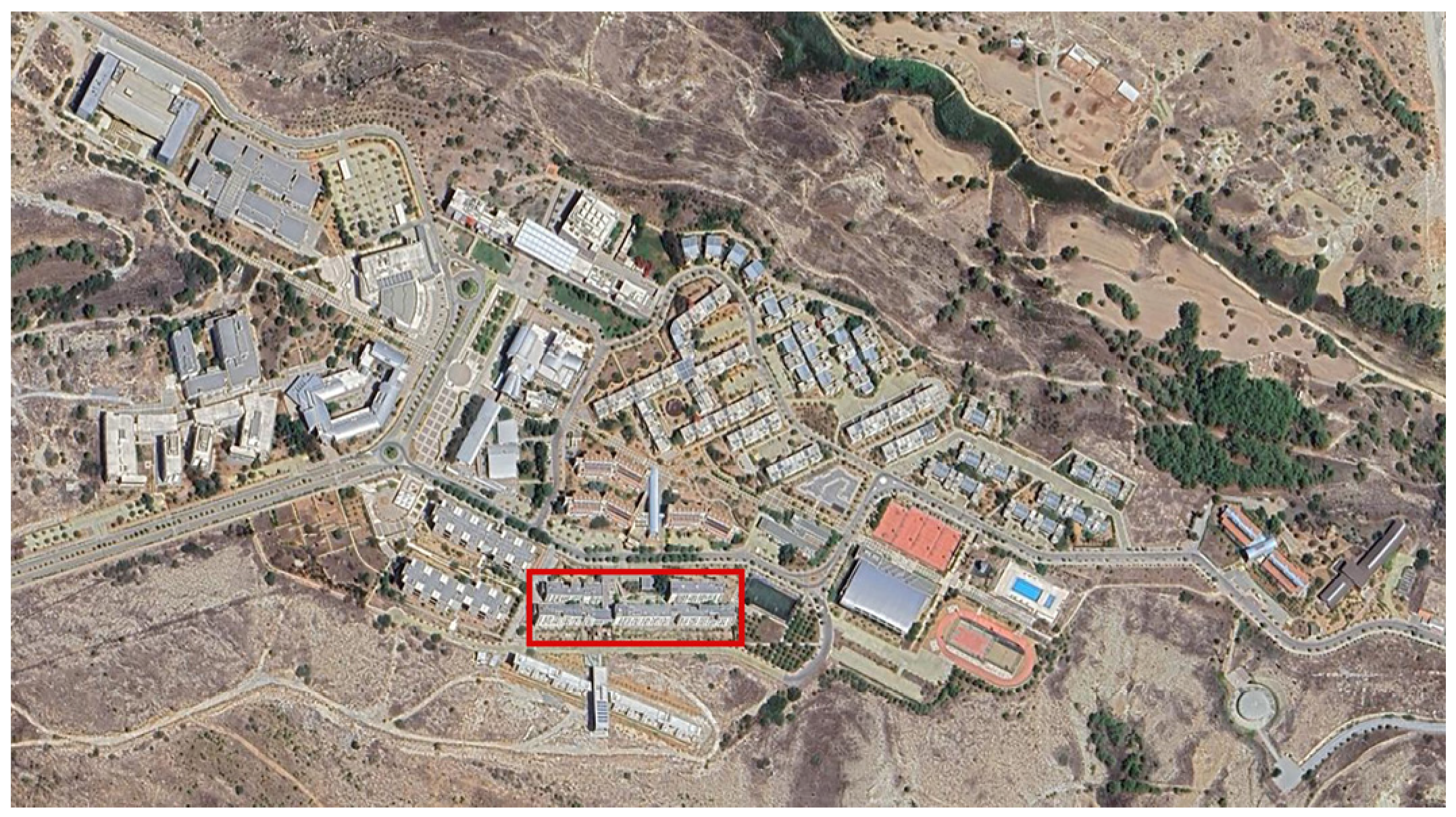

- Google. [Metu Northern Cyprus Campus, Satellite Image]. Google Earth. 2025. Available online: https://earth.google.com/ (accessed on 20 August 2025).

- Middle East Technical University (METU). Available online: https://ncc.metu.edu.tr/accommodation/dorm-and-room-options (accessed on 20 March 2024).

- TS-1258; Rules for Calculation for Installation Water Supply in Buildings. Turkish Standards Institution: Ankara, Turkey, 1983.

- TS EN 12056; Gravity Drainage Systems Inside Buildings. Turkish Standards Institution: Ankara, Türkiye, 2000.

- Huld, T. Typical Meteorological Data Access Service; [Dataset] PID; European Commission, Joint Research Centre (JRC): Brussels, Belgium, 2017; Available online: http://data.europa.eu/89h/jrc-tmy-tmy-download-service (accessed on 20 August 2025).

- Türkyılmaz, O. Enerji Fiyatları Artıyor, Enerji Yoksulluğu Yaygınlaşıyor. In Türkiye’nin Enerji Görünümü 2022; TMMOB: Ankara, Turkey, 2022; pp. 58–62. [Google Scholar]

- International Renewable Energy Agency (IRENA); Climate Policy Initiative (CPI). Global Landscape of Renewable Energy Finance 2023; International Renewable Energy Agency (IRENA): Abu Dhabi, United Arab Emirates, 2023; Available online: https://www.irena.org/-/media/Files/IRENA/Agency/Publication/2023/Feb/IRENA_CPI_Global_RE_finance_2023.pdf (accessed on 26 July 2025).

- U.S. Department of Energy. Estimating the cost and energy efficiency of a solar water heater. In Energy Saver 2025; U.S. Department of Energy: Washington, DC, USA, 2025. Available online: https://www.energy.gov/energysaver/estimating-cost-and-energy-efficiency-solar-water-heater (accessed on 13 August 2025).

- California Solar & Storage Association. New study documents superior performance of solar water heating. In CALSSA Press Release; California Solar & Storage Association: Sacramento, CA, USA, 2020; Available online: https://calssa.org/press-releases/2020/12/1/new-study-documents-superior-performance-of-solar-water-heating (accessed on 13 August 2025).

| Türkiye—Northern Cyprus | Exports of Türkiye | Imports of Türkiye |

|---|---|---|

| 2016 | $906 million | $64.5 million |

| 2017 | $1.09 billion | $66.7 million |

| 2018 | $1.22 billion | $67.8 million |

| 2018 | $1.27 billion | $57.5 million |

| Exchange Rate Averages | 2010 | 2015 | 2019 | 2024 |

|---|---|---|---|---|

| EUR/TRY | 1.9983 | 3.0238 | 6.3634 | 34.4146 |

| Technical Features | Bath Sink | Shower | Kitchen Sink |

|---|---|---|---|

| Number of fixtures | 130 | 96 | 48 |

| DHW demand of fixture in an hour [lt/h] | 30 | 250 | 35 |

| Total amount of DHW demand in an hour [lt/h] | 3900 | 24,000 | 1680 |

| Total DHW demand [lt/h] | 29,580 | ||

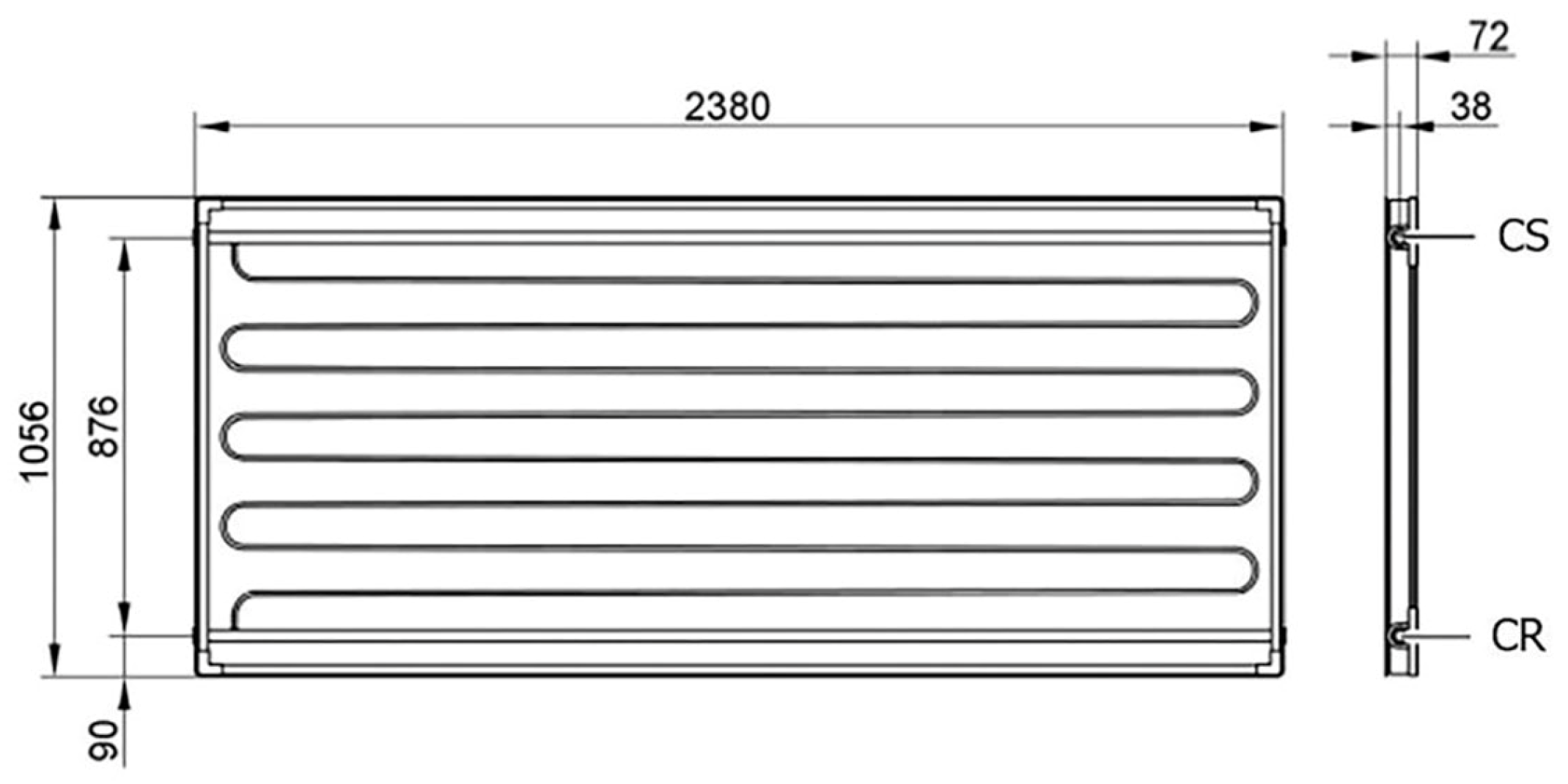

| Technical Features | Values | |

|---|---|---|

| Total surface area [m2] | 2.51 | |

| Absorber surface area [m2] | 2.32 | |

| Aperture area [m2] | 2.33 | |

| Optical efficiency [%] | 74.3 | |

| Heat loss coefficient | U1 [W/m2.K] | 4.16 |

| U2 [W/m2.K2] | 0.0124 | |

| Thermal capacity [kJ/m2.K] | 6.4 | |

| Fluid capacity (heat-transfer medium) [lt] | 2.33 | |

| Maximum stagnation temperature [°C] | 221 | |

| Maximum working pressure [bar] | 6 | |

| Technical Features | Values |

|---|---|

| Water content [%] | 50 |

| Density (38 °C) [kg/m3] | 1025 |

| Viscosity (38 °C) [kg/m.s] | 0.0031 |

| Specific heat (38 °C) [kJ/kg.K] | 3.64 |

| Heat-transfer rate [W/m.K] | 0.39 |

| Boiling point [°C] | 110 |

| Frost protection [°C] | −33 |

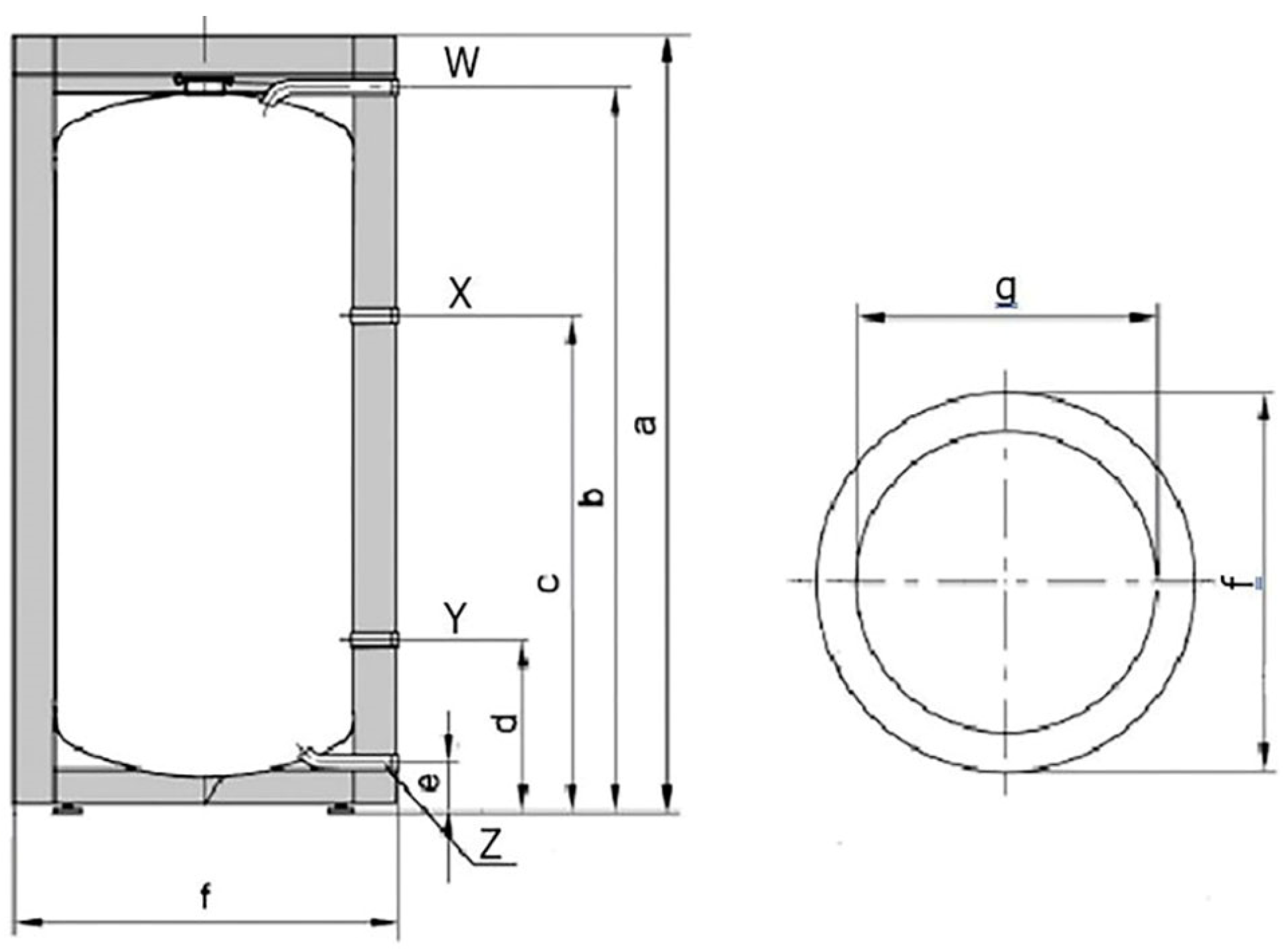

| Technical Features | Letter | Values |

|---|---|---|

| Volume [lt] | - | 5000 |

| Diameter [mm] | f | 1890 |

| Total height [mm] | a | 2200 |

| Height of exiting hot water [mm] | b | 2100 |

| Height of exiting circulation water [mm] | c | 1373 |

| Height of returning heated water [mm] | d | 332 |

| Height of entering running water [mm] | e | 104 |

| Except thermal isolation [mm] | g | 1750 |

| System Components | |||

|---|---|---|---|

| Flat-plate solar collector |  | Fluid diverting valve |

| Boiler |  | Fluid mixing valve |

| Storage tank |  | Pipe |

| Single-speed pump |  | Weather data processor |

| Heat exchanger |  | Iterative feedback controller |

| Controlled flow mixer |  | Calculator |

| Controlled flow diverter |  | Printer |

| Month | DHW Load | Solar Useful Heat | Boiler Status (B1/B2) | Remarks |

|---|---|---|---|---|

| Jan | 872 kWh | Low | B1 On/B2 Off | Solar partial coverage |

| Feb | 872 kWh | Low | B1 On/B2 Off | Solar partial coverage |

| Mar | 872 kWh | Medium | B1 On/B2 Off | Solar gains increasing |

| Apr | 872 kWh | High | B1 Off/B2 Off | Full solar coverage |

| May | 872 kWh | High | B1 Off/B2 Off | Full solar coverage |

| Jun | 872 kWh | High | B1 Off/B2 Off | Full solar coverage |

| Jul | 872 kWh | High | B1 Off/B2 Off | Full solar coverage |

| Aug | 872 kWh | High | B1 Off/B2 Off | Full solar coverage |

| Sep | 872 kWh | High | B1 Off/B2 Off | Full solar coverage |

| Oct | 872 kWh | Medium | B1 On/B2 Off | Solar gains decreasing |

| Nov | 872 kWh | Low | B1 On/B2 Off | Solar partial coverage |

| Dec | 872 kWh | Low | B1 On/B2 Off | Solar partial coverage |

| System No | System Component | Capacity | Pressure | Flow Rate | Temperature | Power | Number | Size |

|---|---|---|---|---|---|---|---|---|

| 1 | Solar collector | 2.3 m2 | - | - | - | - | 84 | - |

| 2 | Solar-assisted HW tank | 5000 lt | 16 Atu | - | - | - | 3 | - |

| 3 | 3-Speed circulation pump | - | 6 mwc | 5 m3/h | - | - | 2 | - |

| 4 | Expansion tank for solar-assisted HW tank | 1500 lt | 10 Atu | - | - | - | 1 | - |

| 5 | Boiler | 800,000 kcal/h | 6 Atu | - | 90/70 °C | - | 2 | - |

| 6 | Boiler-assisted HW tank | 5000 lt | 16 Atu | 60/10 °C | - | 3 | - | |

| 7 | 3-Speed circulation pump | - | 5 mwc | 3 m3/h | - | - | 4 | - |

| 8 | Fuel preheater tank | 50 lt | - | - | - | 2000 Watt | 2 | - |

| 9 | Two-stage fuel-oil burner | - | - | 110 kg/h | - | - | 2 | - |

| 10 | 3-Speed circulation pump | - | 10 mwc | 10 m3/h | - | - | 2 | - |

| 11 | 3-Speed circulation pump | - | 10 mwc | 11 m3/h | - | - | 2 | - |

| 12 | 3-Speed circulation pump | - | 10 mwc | 11.5 m3/h | - | - | 2 | - |

| 13 | 3-Speed circulation pump | - | 10 mwc | 27.5 m3/h | - | - | 2 | - |

| 14 | Daily heating fuel-oil storage | 1000 lt | - | - | - | - | 1 | - |

| 15 | Main heating fuel-oil storage | 40,000 lt | - | - | - | - | 1 | - |

| 16 | Fuel-oil pump | - | 3 bar | 1000 kg/h | - | - | 2 | - |

| 17 | Expansion tank | 5 lt | - | - | - | - | 18 | - |

| 18 | Supply manifold | - | - | - | - | - | 1 | 2 m |

| 19 | Return manifold | - | - | - | - | - | 1 | 2 m |

| 20 | Ball valve | - | - | - | - | - | 160 | - |

| 21 | Pressure holding valve | - | - | - | - | - | 18 | - |

| 22 | Strainer | - | - | - | - | - | 9 | - |

| 23 | Fuel-oil filter | - | - | - | - | - | 2 | - |

| 24 | Thermometer | - | - | - | - | - | 24 | - |

| 25 | Manometer | - | - | - | - | - | 26 | - |

| 26 | Safety valve | - | - | - | - | - | 10 | - |

| 27 | Outlet air temperature sensor | - | - | - | - | - | 4 | - |

| 28 | Pipe (1/2″) | - | - | - | - | - | - | 169.66 m |

| 29 | Pipe (3/4″) | - | - | - | - | - | - | 24.07 m |

| 30 | Pipe (1″) | - | - | - | - | - | - | 42.88 m |

| 31 | Pipe (11/4″) | - | - | - | - | - | - | 121.48 m |

| 32 | Pipe (11/2″) | - | - | - | - | - | - | 75.04 m |

| 33 | Pipe (2″) | - | - | - | - | - | - | 194.87 m |

| 34 | Pipe (Ø65) | - | - | - | - | - | - | 139.96 m |

| 35 | Pipe (Ø80) | - | - | - | - | - | - | 520.89 m |

| 36 | Pipe (Ø100) | - | - | - | - | - | - | 20.63 m |

| 37 | Pipe (Ø125) | - | - | - | - | - | - | 229.17 m |

| 38 | Pipe (Ø150) | - | - | - | - | - | - | 18.88 m |

| System No | (2010) [TRY] | (2015) [TRY] | (2019) [TRY] | (2024) [TRY] | (2010) [EUR] | (2015) [EUR] | (2019) [EUR] | (2024) [EUR] |

|---|---|---|---|---|---|---|---|---|

| 1 | 12,768.00 | 39,900.00 | 86,683.80 | 776,055.00 | 6389.39 | 13,195.25 | 13,622.20 | 22,558.06 |

| 2 | 14,726.25 | 28,500.00 | 53,888.28 | 764,601.99 | 7369.34 | 9425.18 | 8468.44 | 22,225.15 |

| 3 | 1206.60 | 2160.00 | 6939.56 | 47,235.00 | 603.81 | 714.33 | 1090.54 | 1373.01 |

| 4 | 2885.75 | 2960.00 | 4138.33 | 38,552.41 | 1444.09 | 978.90 | 650.33 | 1120.63 |

| 5 | 46,113.10 | 50,200.00 | 126,137.78 | 1,223,414.40 | 23,076.01 | 16,601.54 | 19,822.32 | 35,561.73 |

| 6 | 14,726.25 | 28,500.00 | 53,888.28 | 764,601.99 | 7369.34 | 9425.18 | 8468.44 | 22,225.15 |

| 7 | 2256.60 | 4040.00 | 13,247.96 | 90,220.00 | 1129.25 | 1336.06 | 2081.89 | 2622.48 |

| 8 | 141.30 | 212.00 | 472.98 | 5940.50 | 70.71 | 70.11 | 74.33 | 172.68 |

| 9 | 5963.10 | 7580.00 | 22,124.90 | 198,727.32 | 2984.07 | 2506.77 | 3476.89 | 5776.53 |

| 10 | 1255.20 | 2240.00 | 13,451.18 | 94,677.00 | 628.13 | 740.79 | 2113.83 | 2752.03 |

| 11 | 1255.20 | 2240.00 | 13,451.18 | 94,677.00 | 628.13 | 740.79 | 2113.83 | 2752.03 |

| 12 | 1255.20 | 2240.00 | 13,451.18 | 94,677.00 | 628.13 | 740.79 | 2113.83 | 2752.03 |

| 13 | 3114.70 | 3940.00 | 14,818.10 | 117,552.00 | 1558.66 | 1302.99 | 2328.64 | 3416.96 |

| 14 | 1388.65 | 2110.00 | 3479.53 | 48,307.15 | 694.91 | 697.79 | 546.80 | 1404.17 |

| 15 | 15,123.95 | 22,620.00 | 34,352.79 | 387,384.80 | 7568.36 | 7480.62 | 5398.48 | 11,260.35 |

| 16 | 662.00 | 1140.00 | 3066.22 | 38,792.50 | 331.28 | 377.01 | 481.85 | 1127.61 |

| 17 | 144.00 | 356.40 | 683.82 | 6783.84 | 72.06 | 117.86 | 107.46 | 197.19 |

| 18 | 21.95 | 49.90 | 125.26 | 1237.50 | 10.98 | 16.50 | 19.68 | 35.97 |

| 19 | 21.95 | 49.90 | 125.26 | 1237.50 | 10.98 | 16.50 | 19.68 | 35.97 |

| 20 | 9488.00 | 9920.00 | 22,305.60 | 257,400.00 | 4748.00 | 3280.62 | 3505.28 | 7482.00 |

| 21 | 1982.70 | 2916.00 | 4771.44 | 86,823.00 | 992.19 | 964.34 | 749.82 | 2523.74 |

| 22 | 8781.30 | 7623.00 | 9912.42 | 108,211.50 | 4394.36 | 2520.99 | 1557.72 | 3145.45 |

| 23 | 51.50 | 103.00 | 257.18 | 2864.50 | 25.77 | 34.06 | 40.42 | 83.26 |

| 24 | 832.80 | 916.80 | 1347.84 | 8025.12 | 416.75 | 303.19 | 211.81 | 233.27 |

| 25 | 782.60 | 824.20 | 1224.60 | 8531.38 | 391.63 | 272.57 | 192.44 | 247.99 |

| 26 | 520.00 | 925.00 | 2368.40 | 43,012.50 | 260.22 | 305.90 | 372.19 | 1250.27 |

| 27 | 453.00 | 528.00 | 556.00 | 7885.00 | 226.69 | 174.61 | 87.37 | 229.20 |

| 28 | 475.05 | 941.61 | 2020.65 | 21,144.73 | 237.72 | 311.40 | 317.54 | 614.63 |

| 29 | 75.82 | 156.46 | 349.74 | 3622.54 | 37.94 | 51.74 | 54.96 | 105.30 |

| 30 | 184.38 | 377.34 | 842.59 | 8726.08 | 92.27 | 124.79 | 132.41 | 253.65 |

| 31 | 649.92 | 1311.98 | 2911.88 | 34,226.99 | 325.23 | 433.88 | 457.60 | 994.90 |

| 32 | 469.00 | 900.48 | 2004.32 | 23,693.88 | 234.70 | 297.80 | 314.97 | 688.72 |

| 33 | 1578.45 | 3078.95 | 6668.45 | 76,511.81 | 789.89 | 1018.23 | 1047.93 | 2224.02 |

| 34 | 1497.57 | 2645.24 | 5780.35 | 67,059.03 | 749.42 | 874.80 | 908.37 | 1949.25 |

| 35 | 7136.19 | 12,761.81 | 27,904.08 | 302,637.09 | 3571.11 | 4220.43 | 4385.07 | 8796.94 |

| 36 | 389.91 | 722.05 | 1557.36 | 15,549.86 | 195.12 | 238.79 | 244.74 | 452.00 |

| 37 | 5901.13 | 10,541.82 | 22,355.53 | 219,001.73 | 2953.05 | 3486.26 | 3513.13 | 6365.86 |

| 38 | 570.18 | 1010.08 | 2176.11 | 21,289.65 | 285.33 | 334.04 | 341.97 | 618.84 |

| Total Investment cost | 166,849.24 | 259,242.02 | 581,840.92 | 6,110,891.29 | 83,495.05 | 85,733.43 | 91,435.21 | 177,629.00 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Akgüç, A.; Yasar, D. An Assessment of the Energy Performance and Initial Investment Cost of SDHW Systems: A Case Study of University Dormitory in Northern Cyprus. Buildings 2025, 15, 3042. https://doi.org/10.3390/buildings15173042

Akgüç A, Yasar D. An Assessment of the Energy Performance and Initial Investment Cost of SDHW Systems: A Case Study of University Dormitory in Northern Cyprus. Buildings. 2025; 15(17):3042. https://doi.org/10.3390/buildings15173042

Chicago/Turabian StyleAkgüç, Alpay, and Dilek Yasar. 2025. "An Assessment of the Energy Performance and Initial Investment Cost of SDHW Systems: A Case Study of University Dormitory in Northern Cyprus" Buildings 15, no. 17: 3042. https://doi.org/10.3390/buildings15173042

APA StyleAkgüç, A., & Yasar, D. (2025). An Assessment of the Energy Performance and Initial Investment Cost of SDHW Systems: A Case Study of University Dormitory in Northern Cyprus. Buildings, 15(17), 3042. https://doi.org/10.3390/buildings15173042