Abstract

In this study, glass fiber-reinforced polymer (GFRP) rebars were fabricated using epoxy resin matrix filled with 5 wt.% of hemp and bamboo powder fillers, both untreated and dielectric barrier discharge (DBD) plasma treated. The tensile, flexural, transverse shear, and pull-out bond strengths were evaluated to investigate the effects of filler type and surface modification. The results show that the incorporation of untreated fillers decreased tensile strength from 706.4 MPa for hemp to 682.3 MPa for bamboo. The plasma-treated hemp formulation demonstrated a higher recovery (762.1 MPa), approaching the control value (804.2 MPa). Transverse shear strength increased from 117.0 MPa (untreated hemp) to 128.3 MPa (plasma-treated hemp). The bond strength with concrete remained unaffected across all groups. Scanning electron microscopy (SEM) revealed improved filler dispersion, reduced voids, and enhanced resin wetting in the plasma-treated specimens. Fourier-transform infrared spectroscopy (FTIR) confirmed the introduction of polar functional groups such as hydroxyl and carbonyl groups onto the fiber surfaces following plasma exposure. These modifications contributed to improved interfacial adhesion and mechanical integrity. Overall, the DBD plasma treatment effectively enhanced the performance and interfacial characteristics of natural fiber-filled GFRP rebars, supporting their potential as sustainable reinforcements in structural applications.

1. Introduction

Glass fiber-reinforced polymer (GFRP) composites have emerged as a promising alternative to traditional steel reinforcement, particularly in environments where corrosion resistance and long-term durability are critical, such as marine structures and chemically aggressive settings [1]. Furthermore, for structural applications in seismically active areas, torsional performance is another critical design consideration [2]. With their superior strength-to-weight ratio and ease of fabrication, GFRP rebars offer compelling advantages in modern infrastructure applications. Nevertheless, challenges persist, especially in terms of environmental impact, filler dispersion, and matrix-fiber interfacial bonding quality [3]. Previous research has explored the integration of bio-based fillers, particularly natural fibers, as a sustainable means of reducing petroleum-based constituents in polymer composites [4,5]. Fibers such as hemp, flax, jute, and bamboo are not only renewable and biodegradable but are also widely available as agricultural by-products [6,7]. Unlike short fibers or woven fabrics, which primarily provide directional reinforcement, powdered fillers are investigated here for their potential to modify the bulk matrix properties and act as a sustainable, low-cost volume substitute for the polymer matrix. However, their inherently hydrophilic surfaces tend to exhibit poor compatibility with hydrophobic thermoset matrices, often leading to insufficient stress transfer and premature interfacial failure [8].

Among the various surface treatment methods developed to overcome this incompatibility, plasma treatment has attracted considerable attention due to its dry, non-destructive, and environmentally friendly nature. Dielectric barrier discharge (DBD) plasma is known to introduce oxygen-containing functional groups onto fiber surfaces, which improves their wettability and chemical affinity toward polymer matrices [9,10]. Several studies [11,12,13] have reported enhanced mechanical properties and interfacial adhesion following plasma treatment of natural fiber composites. In addition to chemical modification, plasma exposure also induces surface roughening, which promotes mechanical interlocking and anchoring at the micro-scale [14,15]. These physical and chemical enhancements have been shown to reduce interfacial voids, limit fiber pull-out, and improve overall mechanical integrity [16]. For instance, mild plasma exposure on jute or flax fibers has resulted in measurable improvements in interfacial strength and durability.

Parallel research has investigated the use of micro- and nano-sized fillers, particularly ceramic and carbon-based materials, to improve the performance of GFRP composites [17,18]. Hybrid systems that combine natural and synthetic fillers have demonstrated synergistic effects, allowing for a balance between mechanical performance and sustainability [19,20,21]. When carefully selected and dispersed, bio-based powder fillers derived from agricultural waste, such as hemp or bamboo, have been found to enhance impact resistance and reduce microstructural defects [22]. Beyond performance improvements, these natural fillers contribute to sustainability by reducing embodied carbon and promoting the circular use of biomass resources. Despite the increasing interest in natural fiber-reinforced composites, few studies have explored the use of powdered natural fibers in pultruded GFRP rebars. Pultrusion is a continuous manufacturing process that is particularly suited to structural applications, yet the incorporation of low-cost bio-based powders remains underutilized [5,22]. Narayanan et al. [23] demonstrated that when hybrid fillers are carefully selected and dispersed, they can significantly boost impact strength and reduce microstructural defects. In such crashworthiness applications, performance is often evaluated not just by strength, but by key energy absorption metrics like Specific Energy Absorption [24]. This represents an opportunity to improve both the mechanical and environmental performance of GFRP composites.

In this context, the present study investigates the effects of incorporating 5 wt.% of untreated and DBD plasma-treated hemp and bamboo powder fillers into the epoxy matrix of pultruded GFRP rebars. The objective is to evaluate how filler type and surface modification influence tensile, flexural, shear, and bond strength properties. These findings are further supported by microstructural and chemical analyses using SEM and FTIR. The study aims to establish a practical route for producing sustainable and high-performance GFRP rebars suitable for durable infrastructure.

2. Experimental Program

2.1. Specimens and Materials

This study utilized continuous E-glass fibers (grade EC17-2400) as the primary reinforcement. These fibers were sourced from Hebei Yuniu Fiberglass Manufacturing Co., Ltd., Xingtai, China. The matrix system was composed of a two-component epoxy resin: Part A consisted of YD 515, a bisphenol-A epoxy resin modified with a reactive diluent, and Part B was TH 7301, a cycloaliphatic polyamine hardener. Both components were supplied by J.N. Transos Co., Ltd., Samut Sakhon, Thailand.

Hemp and bamboo fibers were selected as sustainable fillers. The hemp fiber was derived from the bark of Cannabis sativa L. sourced from Fang District, Chiang Mai Province, Thailand, while the bamboo fiber was obtained from South Samoeng, Chiang Mai, Thailand. As these materials were sourced as post-agricultural waste, they were first thoroughly cleaned and washed to remove any surface impurities, minimizing the risk of residual contaminants. Following this initial cleaning, the materials were subjected to mechanical preprocessing, which included cutting, peeling, and coarse grinding to reduce the bulk size and separate the fibrous components. Following this, the fibers underwent a chemical purification process to remove lignin and hemicellulose, thereby improving compatibility with the epoxy matrix. The purified fibers were subsequently dried, ground into powder form, and sieved through a 76 µm mesh, resulting in a fine powder with a maximum particle size of 76 µm. The typical mechanical properties of the constituent materials are summarized in Table 1 for reference.

Table 1.

Typical mechanical properties of the constituent materials.

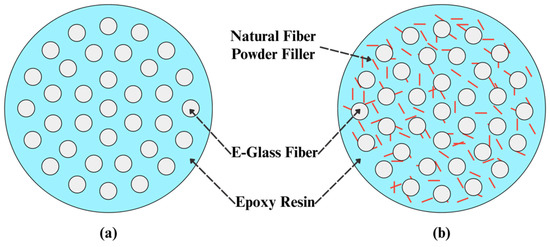

Four types of natural fiber fillers were used: untreated hemp (HU), plasma-treated hemp (HT), untreated bamboo (BU), and plasma-treated bamboo (BT). In addition to the control group (C), which contained no filler, a total of five GFRP rebar groups were fabricated. For the experimental groups, 5 wt.% of the corresponding fiber powder was mixed into the epoxy resin prior to fabrication. All specimens were produced using the same pultrusion method, as detailed in Section 2.3. A summary of the rebar groups is presented in Table 2, and Figure 1 schematically compares the internal structure of the control rebar and those containing natural fiber powder fillers.

Table 2.

Description of GFRP Rebar Groups.

Figure 1.

Cross-sectional schematic of GFRP rebars: (a) Control group (C) with E-glass fibers embedded in epoxy resin, and (b) experimental groups (HU, HT, BU, BT) incorporating natural fiber powder fillers in the epoxy matrix.

2.2. Plasma Surface Treatment

Dielectric barrier discharge (DBD) plasma treatment was used to improve the interfacial adhesion of the fiber surfaces. The treatment was performed under atmospheric pressure using a gas mixture of argon and oxygen (Ar + O2) at a steady flow rate of 10 L/min. Plasma was generated between parallel electrodes driven by a 13.56 MHz RF source, delivering 180 W of power across a 1 mm gap. During the process, fiber powders were continuously transported beneath the grounded electrode at a speed of 30 cm/s to ensure uniform exposure to the plasma field. Each batch was treated for 30 min. As reported by Rachtanapun et al. [28], this type of plasma treatment modifies lignocellulosic fiber surfaces by introducing oxygenated functional groups, which enhance their polarity and wettability. These surface changes contribute to improved bonding with epoxy matrices in composite systems. While the 30 min duration was chosen to ensure sufficient surface activation, it is recognized that treatment time is a critical parameter, as excessive exposure can lead to fiber degradation and embrittlement [29]. All plasma treatment procedures were conducted following university laboratory safety guidelines; specifically, the system operates within a shielded enclosure with safety interlocks to prevent operator exposure to RF emissions.

2.3. Fabrication of GFRP Rebars

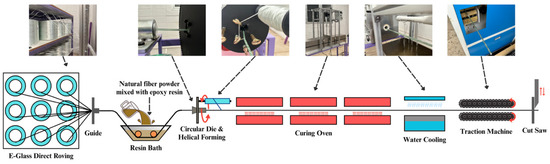

Glass fiber-reinforced polymer (GFRP) rebars with a circular cross-section of 9 mm were fabricated using a semi-industrial laboratory-scale pultrusion apparatus designed for continuous operation, as shown in Figure 2. The resin formulation began with the gradual incorporation of natural fiber powder into the epoxy resin, followed by mechanical stirring until a homogeneous mixture was achieved. The curing agent was then added to complete the resin system. Continuous E-glass roving was pulled through the resin bath via a motorized traction system, enabling complete impregnation with the resin-filler blend. The saturated fibers were subsequently passed through a circular die to define the rebar geometry and remove excess resin, then immediately routed through a helical forming unit to create a spring-pattern surface texture that enhances mechanical interlocking. The formed profiles underwent thermal curing in a 120 °C oven, with the pulling speed synchronized to ensure proper crosslinking and dimensional stability. Based on the pultrusion line speed and the length of the curing oven, the residence time for thermal curing was approximately 7 min per meter. Resin exotherm was not monitored during this process. After curing, the rebars were cooled, cut to length, and prepared for mechanical testing. As illustrated in Figure 3, the fabricated rebars exhibited distinct differences in surface texture and coloration depending on the type and treatment of the incorporated natural fiber fillers.

Figure 2.

Schematic and photographic views of the semi-industrial pultrusion process used to fabricate GFRP rebars containing natural fiber powder fillers.

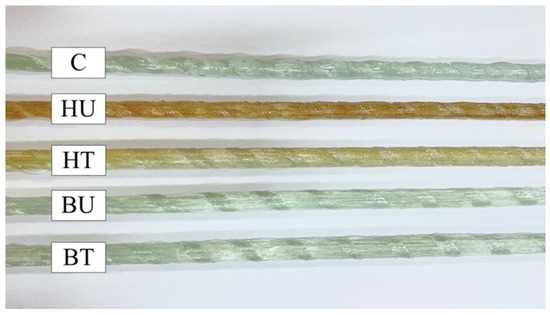

Figure 3.

GFRP rebars fabricated via pultrusion, illustrating surface texture and color differences among the five groups: control (C), untreated hemp (HU), plasma-treated hemp (HT), untreated bamboo (BU), and plasma-treated bamboo (BT).

2.4. Mechanical Testing

Mechanical testing was performed to assess the structural performance of the fabricated GFRP rebars. Four types of tests were conducted: tensile strength, transverse shear strength, flexural strength, and pull-out bond strength. For each test, three specimens per group (n = 3) were evaluated, and the results are reported as mean ± standard deviation (SD). Testing procedures followed the respective international standards, with detailed conditions outlined below.

2.4.1. Tensile Strength Testing

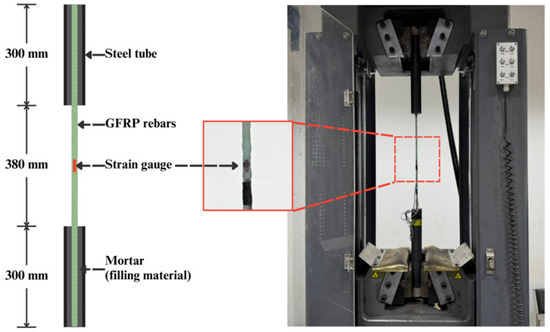

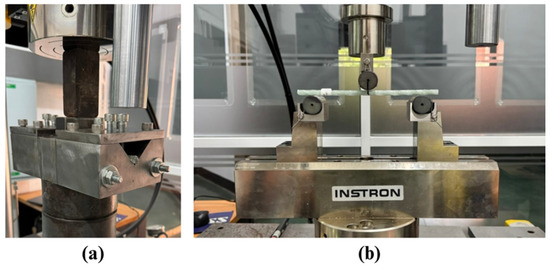

Tensile tests were conducted in accordance with ASTM D7205/D7205M [30] using a 1000 kN universal testing machine supplied by Soil Testing Siam Co., Ltd., Bangkok, Thailand. Each GFRP rebar specimen was prepared with a 380 mm gauge length. To prevent premature failure at the grips and end-brooming, each end was anchored within a 300 mm long steel tube filled with high-strength mortar, as shown in Figure 4. The crosshead moved at a constant rate of 3.8 mm/min during testing. To capture strain during loading, a strain gauge (FLAB-5-11-1LJC-F, Tokyo Measuring Instruments Laboratory Co., Ltd., Tokyo, Japan) was attached at the center of the gauge length. The collected strain data were used to construct stress–strain curves and evaluate elastic behavior. Ultimate tensile strengths were recorded and are shown in Figure 4.

Figure 4.

Tensile test setup for GFRP rebars with a strain gauge positioned at mid-gauge. Specimens were anchored using mortar-filled steel tubes and tested using a 1000 kN universal testing machine.

2.4.2. Transverse Shear Strength Testing

Transverse shear strength was evaluated following ASTM D7617/D7617M [31]. Rebar specimens were cut to a standard length of 225 mm and tested using a 100 kN Instron universal testing machine (8800 Series). A crosshead speed of 1 mm/min was applied, and the maximum load at failure was used to calculate the shear strength. Figure 5a shows the test configuration.

Figure 5.

Experimental setups for mechanical testing of GFRP rebars: (a) transverse shear test according to ASTM D7617/D7617M, and (b) three-point flexural test according to ASTM D790.

2.4.3. Flexural Strength Testing

Flexural behavior was assessed using a three-point bending setup in accordance with ASTM D790 [32]. The specimens, each 194 mm in length, were tested over a support span of 144 mm, corresponding to a span-to-depth ratio of 16:1 (based on the 9 mm bar diameter), as recommended by the standard. Tests were conducted using the same 100 kN Instron UTM, with a crosshead speed of 1.44 mm/min. The testing arrangement is displayed in Figure 5b.

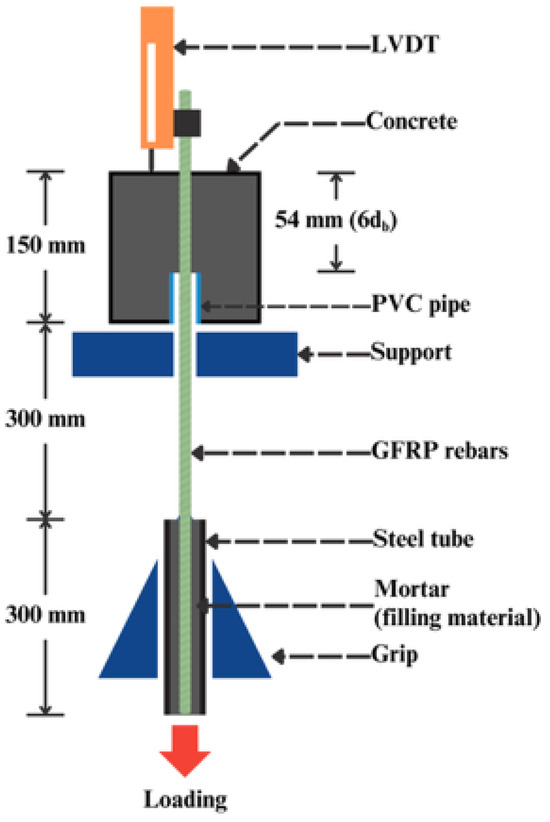

2.4.4. Pull-Out Bond Strength Testing

The bond between GFRP rebars and concrete were tested by pull-out tests following Annex H of CSA S806-02 [33]. Each rebar was embedded to a length equal to six times its nominal diameter (6db) into a concrete block. The anchoring concrete had a 28-day compressive strength of 30 ± 3 MPa. Testing was performed using a Baldwin hydraulic universal testing machine (Model 200HVL-200000LB) (SATEC Systems, Inc., Grove City, PA, USA) at a loading rate of 1.27 mm/min. A linear variable differential transformer (LVDT) (Tokyo Measuring Instruments Laboratory Co., Ltd., Tokyo, Japan) was used to measure the slip between the rebar and the surrounding concrete during loading. Bond strength was calculated from the peak pull-out force, and the experimental setup is illustrated in Figure 6.

Figure 6.

Pull-out bond test setup of GFRP rebar following CSA S806-02, showing 6db embedment length and LVDT-based slip measurement.

2.5. Morphology

The morphology of the GFRP fabricated rebars were observed by scanning electron microscopy (SEM; JSM-IT300LV, JEOL Ltd., Tokyo, Japan). Specimens were sectioned into two orientations, including cross-sectional cuts perpendicular to the fiber axis and longitudinal cuts along the fiber axis, to examine filler dispersion and fiber-matrix bonding behavior. Before imaging, a thin layer of gold was applied using a sputter coater (108 Auto/SE, Cressington Co., Ltd., Watford, UK) to minimize surface charging, and SEM observations were conducted at an accelerating voltage of 10 kV.

2.6. Reaction Mechanism

Fourier transform infrared spectroscopy (FTIR) was conducted to examine plasma treatment alters the chemical structure of natural fiber powder fillers. Untreated and plasma-treated samples were analyzed using a Nicolet 6700 FTIR spectrometer (Thermo Fisher Scientific, Waltham, MA, USA) equipped with an attenuated total reflectance (ATR) accessory. This technique was selected as highly sensitive to the surface chemistry of the samples, which is the primary location of modification by the plasma treatment. Spectral data were collected in the range of 500 to 4000 cm−1, using 16 scans per spectrum at a resolution of 4 cm−1.

2.7. Statistical Analyses

All mechanical test data were analyzed using one-way analysis of variance (ANOVA) to determine significant differences among groups. Tukey’s post hoc test was then applied for pairwise comparisons to identify which specific groups were different from each other. In the results presented in figures and tables, groups that do not share a common letter (e.g., A vs. B) are considered statistically different at a 95% confidence level (p < 0.05).

3. Results and Discussion

The following sections present the experimental results for the GFRP rebars with 5 wt.% filler content. It is important to note that this specific filler percentage was chosen as a representative value for this initial investigation. A full optimization to determine the ideal content would require a multi-criteria benefit evaluation, balancing mechanical, environmental, and economic factors, as outlined in established frameworks [34].

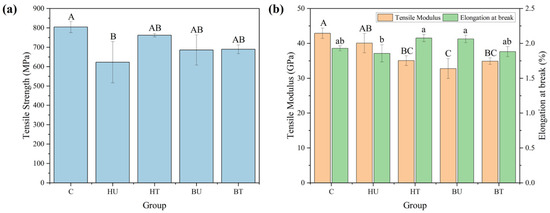

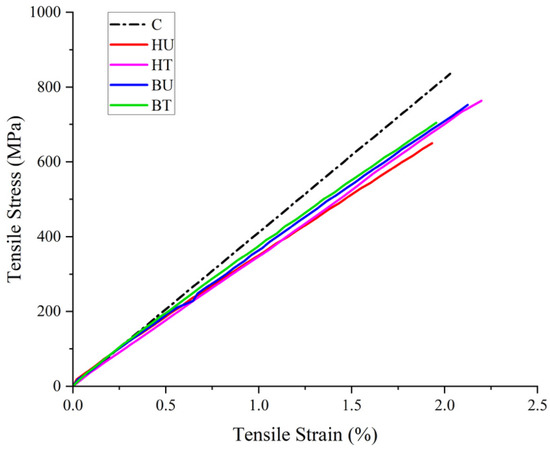

3.1. Tensile Properties

Figure 7 and Table 3 show the mechanical properties of the fabricated GFRP rebars. The control group (C) achieved the highest tensile strength at 804.2 MPa, reflecting efficient load transfer within the epoxy and glass fiber composite system. However, the addition of 5 wt.% untreated natural fiber powder caused a significant reduction in performance. The hemp-filled group (HU) recorded the tensile strength at 623.0 MPa, a value significantly lower than the control group as per Tukey’s test (p < 0.05). while the bamboo-filled group (BU) achieved a slightly better result at 686.0 MPa. These reductions are mainly due to poor interfacial adhesion between the hydrophilic fillers and the hydrophobic epoxy matrix, which tends to cause localized stress concentrations and early failure. Plasma treatment helped to recover the mechanical performance. The hemp-treated group (HT) reached 762.1 MPa, approaching a level that was not statistically different from the control value. which is nearly 95 percent of the control. The bamboo-treated group (BT) showed a moderate improvement to 689.6 MPa with less variation, indicating more consistent bonding. These outcomes suggest that plasma surface treatment significantly improves compatibility between fillers and matrix, especially in the hemp-filled system. The representative tensile stress–strain curves for all GFRP rebar groups are displayed in Figure 8. All specimens exhibited nearly linear-elastic behavior up to the point of brittle failure, which is characteristic of FRP composites. The slope of these curves corresponds to the tensile modulus reported in Figure 7b, with the control group (C) showing the steepest slope. The plasma-treated groups (HT and BT) demonstrate failure points at higher stress levels compared to their untreated counterparts (HU and BU), confirming the positive effect of the surface treatment. Tensile modulus and elongation at break, as shown in Figure 7b, further support these observations. The control group had the highest modulus at 42.9 GPa, followed by HU at 40.1 GPa. BU recorded the lowest stiffness at 32.8 GPa. Plasma-treated groups HT and BT partially recovered the modulus to 35.1 GPa and 34.9 GPa, respectively. This suggests improved stress transfer through a better filler and matrix interface. Regarding ductility, elongation values ranged narrowly from 1.9 to 2.1 percent. HT showed a slightly higher elongation at 2.1 percent compared to the control at 1.9 percent, which may be due to better mechanical interlocking and energy dissipation. BU also showed higher elongation, likely due to debonding and matrix-driven deformation, while BT was similar to the control and had low variability, suggesting more stable failure behavior.

Figure 7.

Tensile properties of GFRP rebars with natural fiber powder fillers: (a) Tensile strength; (b) Tensile modulus (left axis) and elongation at break (right axis). Different letters indicate statistically significant differences (p < 0.05) within each property.

Table 3.

Summary of tensile properties of GFRP rebars. Different superscript letters indicate statistically significant differences (p < 0.05) within each column.

Figure 8.

Representative tensile stress–strain curves of GFRP rebars.

The mechanical improvements observed in HT and BT are attributed to dielectric barrier discharge (DBD) plasma treatment. This method introduces oxygen-containing polar groups such as hydroxyl and carboxyl onto the fiber surface, which increases polarity and enhances bonding with the epoxy matrix [35]. Additional support comes from SEM results in Section 3.5, where treated samples showed fewer voids and better filler-matrix bonding [29]. In summary, plasma-treated natural fiber fillers, especially hemp, can effectively address the strength loss commonly seen with bio-based additives, helping to retain stiffness and ductility in GFRP rebars and making them suitable for structural applications.

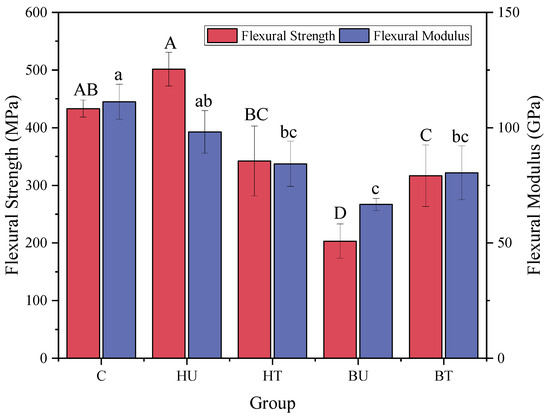

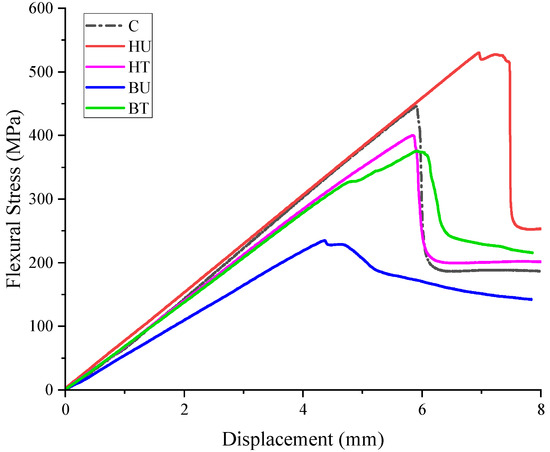

3.2. Flexural Properties

The flexural behavior of the GFRP rebars was presented in Table 4, Figure 9 and Figure 10. Notably, the hemp-filled group (HU) exhibited the highest average flexural strength at 501.5 MPa, which was statistically higher than all other groups except the control group, surpassing even the control group at 433.2 MPa. This enhancement may stem from the physical reinforcement provided by the hemp powder near the rebar surface, contributing to resistance against tensile and compressive stresses during bending. This unusual result, where flexural strength surpasses the control while tensile strength is significantly lower, may also be attributed to a “skin effect” caused by filler segregation. It is hypothesized that during pultrusion, some hemp powder migrated towards the rebar’s surface. This powder-rich outer layer might act as a reinforcing shell that effectively resists bending stresses, while the core of the rebar, potentially weakened by poor filler-matrix adhesion, governs the lower overall tensile strength. Similar mechanisms have been reported in natural fiber composites, where filler morphology and frictional interaction improve stress transfer and bending stiffness [36]. In contrast, the bamboo-filled group (BU) showed a markedly lower flexural strength of 203.4 MPa, the lowest among all groups (p < 0.05). This performance reduction is likely due to poor dispersion and weak bonding between untreated bamboo fillers and the matrix, which can lead to stress concentration and premature cracking. Plasma treatment provided moderate improvements in both filler types. The hemp-treated group (HT) achieved 342.5 MPa, while the bamboo-treated group (BT) reached 316.7 MPa. Statistically, these two treated groups were not different from each other. Although these values did not exceed HU, they significantly outperformed BU, indicating that plasma modification improved interfacial bonding and overall composite integrity. Flexural modulus values followed a consistent trend. The control group retained the highest stiffness at 111.2 GPa, followed by HU at 98.1 GPa, while BU remained the lowest at 66.7 GPa. HT and BT demonstrated partial recovery, recording 84.4 GPa and 80.4 GPa, respectively.

Table 4.

Flexural strength and modulus of GFRP rebars. Different uppercase letters in the same column indicate significant differences (p < 0.05) for strength, while lowercase letters indicate differences for modulus.

Figure 9.

Flexural strength (left axis) and flexural modulus (right axis) of GFRP rebars filled with natural fiber powders. Different letters indicate significant differences (p < 0.05).

Figure 10.

Representative flexural stress-displacement curves of GFRP rebars with natural fiber powder fillers. Each curve demonstrates bending behavior and post-peak deformation of each group.

These outcomes suggest that plasma surface activation strengthens the filler-matrix interface, contributing to the recovery of flexural stiffness despite the inherent softness of natural fillers. Figure 10 presents representative stress-displacement curves. The control and HU groups displayed linear-elastic responses with brittle fracture behavior, whereas BU failed abruptly with minimal deformation, consistent with weak bonding. In comparison, HT and BT exhibited extended post-peak displacements, reflecting improved toughness and energy absorption. These results support the effectiveness of dielectric barrier discharge (DBD) plasma treatment in improving interfacial adhesion, which helps stabilize composite performance under bending loads [36,37].

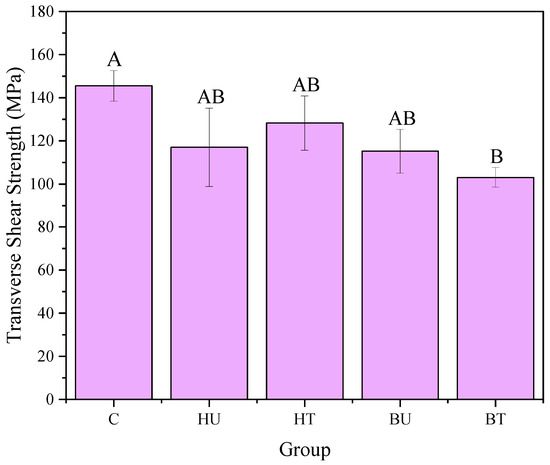

3.3. Shear Properties

Figure 11 presents the transverse shear strength (TSS) of the fabricated GFRP rebars. The control group (C) exhibited the highest strength at 145.5 ± 7.1 MPa, indicating robust internal cohesion and effective matrix-fiber bonding. In contrast, the groups filled with untreated natural fiber powders, HU (117.0 ± 18.1 MPa) and BU (115.2 ± 10.2 MPa), showed lower average strengths. However, these reductions were not statistically significant compared to the control group. Following plasma treatment, the hemp-filled group (HT) achieved a TSS of 128.3 ± 12.6 MPa, a value that also showed no statistical difference from the control. Conversely, the treated bamboo group (BT) yielded a strength of 103.0 ± 4.5 MPa, which was statistically lower than the control group (p < 0.05). This indicates that the plasma treatment had a detrimental effect on the shear performance of the bamboo-filled composites, a finding consistent with the hypothesis of fiber embrittlement discussed in Section 3.5. These results support that while DBD plasma is a viable surface modification technique, its effects are highly material-dependent and require optimization for each specific filler type [38,39].

Figure 11.

Transverse shear strength (MPa) of GFRP rebars with natural fiber powder fillers. Different letters indicate significant differences (p < 0.05).

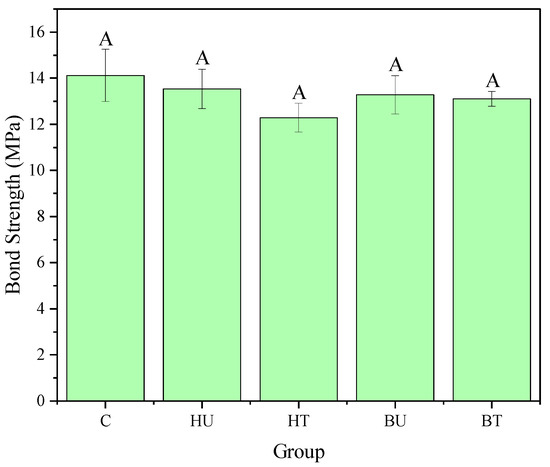

3.4. Bond Strength with Concrete

Figure 12 presents the bond strength results of GFRP rebars embedded in concrete blocks. The control group (C) achieved the highest average value at 14.12 ± 0.8 MPa, followed by HU at 13.88 ± 0.9 MPa, BT at 13.35 ± 0.4 MPa, BU at 13.17 ± 0.6 MPa, and HT at 12.29 ± 0.8 MPa. Despite these numerical variations, statistical analysis revealed no significant differences among the groups (p > 0.05). This suggests that the incorporation of 5 wt.% untreated or plasma-treated natural fiber powder fillers had no meaningful effect on the bond performance between GFRP rebars and concrete. The results support the conclusion that bond strength in FRP-concrete systems is primarily governed by surface features such as texture, roughness, and mechanical interlocking rather than by internal matrix formulation or filler modifications [40,41]. Even though plasma-treated fillers improved the internal matrix-fiber bonding and mechanical performance under tensile, flexural, and shear loading, their influence on the rebar-concrete interface was negligible. This may be attributed to the dominant role of frictional resistance and surface texture in pull-out behavior, which overshadows subtle chemical or microstructural changes within the composite core [42,43].

Figure 12.

Bond strength (MPa) of GFRP rebars incorporating natural fiber powder fillers. The same letter (A) above the bars indicates no significant difference among the groups (p > 0.05).

3.5. Morphological Observations via SEM

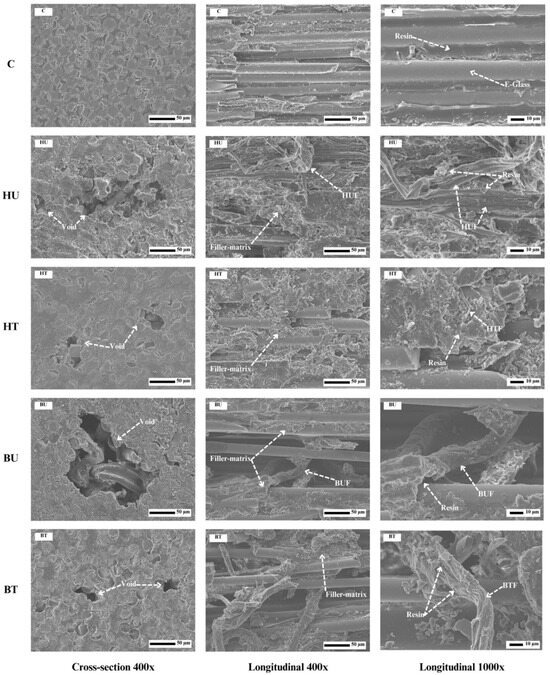

The microstructural differences arising from the addition of natural fiber powder fillers and plasma surface treatment were observed by scanning electron microscopy (SEM), as shown in Figure 13. The micrographs are organized into three views: cross-sectional (400×), longitudinal (400×), and high-magnification longitudinal (1000×) for all five groups (C, HU, HT, BU, BT). The control group (C) displayed a well-consolidated structure with tightly packed E-glass fibers embedded in a continuous epoxy matrix. No significant defects or interfacial gaps were visible, reflecting the good mechanical performance observed across all test methods. This morphology is typical of conventional GFRP composites with optimal resin wetting and consolidation, consistent with previous literature [44]. In contrast, the HU and BU groups showed clear signs of interfacial defects and voids. The cross-sectional views revealed irregularly distributed voids surrounding the filler particles, while longitudinal images displayed fiber pull-out and discontinuities at the filler-matrix interface. These features indicate inadequate resin infiltration and poor interfacial bonding between untreated fillers and the hydrophobic matrix. Similar effects have been reported in other studies on natural-fiber-filled epoxy systems, where untreated lignocellulosic particles were shown to cause matrix discontinuities and interfacial debonding [45]. The plasma-treated groups (HT and BT) demonstrated marked morphological improvements. In both cross-sectional and longitudinal views, voids were less pronounced, and filler particles appeared more intimately integrated with the surrounding matrix. High-magnification SEM images revealed resin encapsulation around the treated fillers, suggesting improved interfacial wetting.

Figure 13.

SEM images of GFRP rebars: cross-sectional views (400×, left), longitudinal views (400×, center), and high-magnification longitudinal views (1000×, right).

These observations support the hypothesis that plasma treatment introduces polar functional groups such as hydroxyl and carboxyl groups and increases surface roughness, thereby enhancing filler-resin compatibility. This aligns with findings from flax- and hemp-based composites, where dielectric barrier discharge (DBD) plasma treatment led to the formation of well-bonded interfaces and reduced pull-out zones in SEM micrographs.

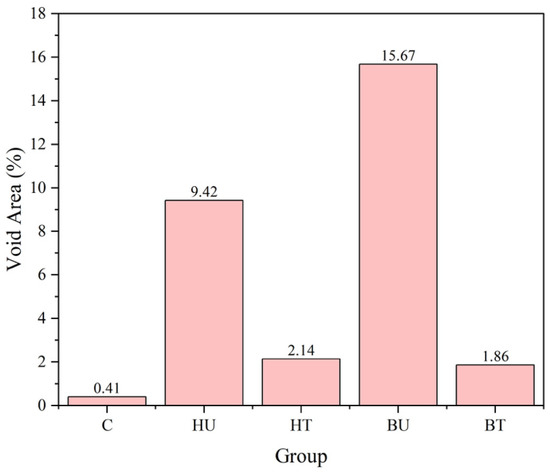

To provide quantitative support for these morphological observations, a preliminary analysis was conducted on a representative SEM cross-section from each group using ImageJ (Version 1.54p, National Institutes of Health, Bethesda, MD, USA) software (Figure 14). While this analysis from a single location is illustrative, it clearly corroborates the qualitative findings. The results show a significant reduction in void area after plasma treatment for both hemp (from 9.42% in HU to 2.14% in HT) and bamboo (from 15.67% in BU to 1.86% in BT). This densification of the microstructure is a key factor in the improved mechanical performance. Specifically, the reduction in voids provides a more effective path for stress transfer and helps explain the observed increase in transverse shear strength from 117.0 MPa in the HU group to 128.3 MPa in the HT group. Interestingly, the opposite trend was observed for the bamboo-filled composites; despite the significant reduction in voids, the transverse shear strength decreased from 115.2 MPa in BU to 103.0 MPa in BT. This suggests a more complex mechanism is at play, where it is hypothesized that the plasma treatment, while improving the interfacial bond, may have also inadvertently caused surface degradation or embrittlement of the bamboo powder itself. Indeed, previous studies have shown that prolonged plasma treatment can lead to the embrittlement and thinning of bamboo fibers, which negatively impacts mechanical properties [29]. This potential degradation could have made the bamboo fibers more prone to fracture under shear, offsetting the benefits gained from a denser microstructure. This highlights that optimal plasma treatment conditions are highly dependent on the specific fiber type used, as overtreatment can also lead to degradation in other natural fibers [28].

Figure 14.

Illustrative void area percentage from a single SEM cross-section for each group, showing a clear trend of void reduction after plasma treatment.

3.6. FTIR Analysis

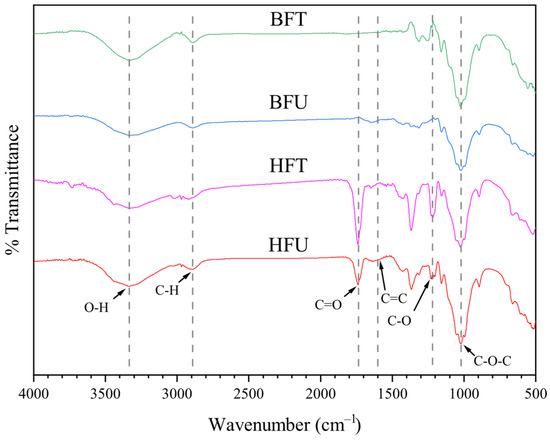

Fourier Transform Infrared (FTIR) spectroscopy was performed to investigate chemical changes on the surfaces of hemp and bamboo fillers before and after plasma treatment. Figure 15 shows the FTIR spectra for untreated (HFU, BFU) and plasma-treated (HFT, BFT) powders within the 4000–500 cm−1 range. The broad absorption near 3335 cm−1 corresponds to O-H stretching vibrations, with increased intensity observed in HFT and BFT, suggesting enhanced surface polarity due to plasma-induced oxidation. Peaks around 1732 cm−1, associated with C=O stretching in carbonyl or carboxylic groups, also became more prominent after treatment, indicating the formation of oxygen-containing functionalities. Furthermore, stronger bands near 1240 and 1030 cm−1, attributed to C-O and C-O-C stretching of lignin, cellulose, and hemicellulose, imply that plasma treatment removed amorphous surface contaminants and exposed underlying cellulose. These shifts are consistent with prior studies on plasma-treated flax, kapok, and Arundo donax fibers, which reported similar enhancements in surface chemistry and polarity [28,45,46]. Overall, the FTIR results confirm that dielectric barrier discharge (DBD) plasma effectively introduced polar groups and improved chemical reactivity at the filler surface, supporting the enhanced interfacial bonding and mechanical performance of HFT and BFT composites [47,48].

Figure 15.

FTIR spectra of untreated and plasma-treated natural fiber powders. HFU: hemp filler untreated; HFT: hemp filler plasma-treated; BFU: bamboo filler untreated; BFT: bamboo filler plasma-treated.

4. Conclusions

This study systematically investigated the influence of untreated and plasma-treated natural fiber powder fillers of hemp and bamboo on the mechanical performance, interfacial morphology, and chemical surface characteristics of glass fiber-reinforced polymer (GFRP) rebars. The principal conclusions are as follows:

- Mechanical Performance: The incorporation of 5 wt.% untreated hemp (HU) and bamboo (BU) powders generally resulted in reduced tensile, flexural, and shear strengths due to poor interfacial bonding between the hydrophilic fillers and the hydrophobic epoxy matrix. In contrast, plasma-treated fillers (HT and BT) significantly enhanced mechanical properties, with HT achieving approximately 95% of the control’s tensile strength and showing notable improvement in transverse shear strength. These results highlight the effectiveness of plasma surface treatment in restoring and reinforcing mechanical performance.

- Bond Behavior with Concrete: Pull-out tests demonstrated that neither the filler type nor surface treatment significantly affected the bond strength between GFRP rebars and concrete. This indicates that external surface roughness and mechanical interlocking mechanisms, rather than internal resin chemistry, primarily govern bond performance at the rebar-concrete interface.

- Morphological Characteristics: SEM analysis revealed improved filler dispersion, reduced voids, and enhanced matrix wetting in the plasma-treated groups. Evidence of resin encapsulation and limited fiber pull-out in HT and BT rebars supports the observed improvements in mechanical integrity and stress transfer efficiency.

- Chemical Surface Modification: FTIR analysis confirmed the formation of polar functional groups (-OH, -COOH, C=O) on the surface of plasma-treated fillers. These chemical modifications enhanced the filler-matrix interfacial adhesion, promoting better mechanical interlocking and reducing microstructural defects. This finding aligns with previous studies on plasma-treated natural fibers such as flax, Arundo donax, and kapok.

In conclusion, dielectric barrier discharge (DBD) plasma treatment offers a practical and scalable approach to surface-modify natural fiber powders, enabling their effective use in high-performance GFRP composites. The improvement in interfacial bonding and reduction in filler-induced defects affirm the potential of plasma-treated bio-based fillers to serve as sustainable reinforcements in structural applications.

Author Contributions

Conceptualization, P.R., K.J., C.S. and P.W.; Methodology, T.K. (Thaloengsak Keereemasthong), T.K. (Thidarat Kanthiya), K.K., S.C. and P.W.; Validation, P.R., K.J., C.S. and P.W.; Formal analysis, P.R., K.J., C.S. and P.W.; Investigation, T.K. (Thaloengsak Keereemasthong), T.K. (Thidarat Kanthiya), K.K. and S.C.; Resources, P.R., K.J., J.S., C.S. and P.W.; Writing—original draft, T.K. (Thaloengsak Keereemasthong); Writing—review & editing, T.K. (Thidarat Kanthiya) and K.K.; Visualization, T.K. (Thaloengsak Keereemasthong) and P.W.; Supervision, P.W.; Project administration, T.K. (Thaloengsak Keereemasthong) and P.W.; Funding acquisition, P.W. All authors have read and agreed to the published version of the manuscript.

Funding

This research has received funding support from the National Science, Research and Innovation Fund (NSRF) via the Program Management Unit for Human Resources & Institutional Development, Research and Innovation (PMU-B) [Grant No. B16F640206].

Data Availability Statement

The data presented in this study are available upon request from the corresponding author.

Acknowledgments

The authors gratefully acknowledge the Agriculture and Bio Plasma Technology Center (ABPlas), Science and Technology Park (STeP), Chiang Mai University for access to plasma surface modification facilities. We also thank the Faculty of Engineering and the Faculty of Agro-Industry, Chiang Mai University, for providing laboratory equipment and infrastructure support.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Nugraha, A.D.; Nuryanta, M.I.; Sean, L.; Budiman, K.; Kusni, M.; Muflikhun, M.A. Recent Progress on Natural Fibers Mixed with CFRP and GFRP: Properties, Characteristics, and Failure Behaviour. Polymers 2022, 14, 5138. [Google Scholar] [CrossRef]

- Zhang, W.; Yang, X.; Lin, J.; Lin, B.; Huang, Y. Experimental and numerical study on the torsional behavior of rectangular hollow reinforced concrete columns strengthened By CFRP. Structures 2024, 70, 107690. [Google Scholar] [CrossRef]

- Liu, J.L.; Pham, V.N.H.; Mencattelli, L.; Chew, E.; Chua, P.Y.; Shen, J.; Tian, K.; Zhi, J.; Jiang, D.; Tay, T.E.; et al. Improving the impact performance of natural fiber reinforced laminate through hybridization and layup design. Compos. Sci. Technol. 2024, 251, 110585. [Google Scholar] [CrossRef]

- Fiore, V.; Scalici, T.; Nicoletti, F.; Vitale, G.; Prestipino, M.; Valenza, A. A new eco-friendly chemical treatment of natural fibres: Effect of sodium bicarbonate on properties of sisal fibre and its epoxy composites. Compos. Part B Eng. 2016, 85, 150–160. [Google Scholar] [CrossRef]

- Naguib, H.M. Evaluation of filler activation for sustainable FRP composite by studying properties, mechanism, and stability. Sci. Rep. 2024, 14, 18256. [Google Scholar] [CrossRef] [PubMed]

- Nyssanbek, M.; Kuzina, N.; Kondrashchenko, V.; Azimov, A. Effects of plasma treatment on biodegradation of natural and synthetic fibers. npj Mater. Degrad. 2024, 8, 23. [Google Scholar] [CrossRef]

- John, M.J.; Thomas, S. Biofibres and biocomposites. Carbohydr. Polym. 2008, 71, 343–364. [Google Scholar] [CrossRef]

- Sun, D. Surface Modification of Natural Fibers Using Plasma Treatment. In Biodegradable Green Composites; John Wiley & Sons: Hoboken, NJ, USA, 2016; pp. 18–39. [Google Scholar]

- Dimic-Misic, K.; Bratislav, O.; Milorad, K.; Mirjana, K.; Quang, L.H.; Matea, K.; Monireh, I.; Gane, P. Production of Micro Nanofibrillated Cellulose from Prerefined Fiber via a Dry Dielectric Barrier Discharge (DBD) Oxygen Plasma-Treated Powder Precursor. J. Nat. Fibers 2024, 21, 2394146. [Google Scholar] [CrossRef]

- Saleem, M.; Naz, M.Y.; Shukrullah, S.; Shujah, M.A.; Ullah, S.; Al-Sehemi, A.G. Statistical optimization of open air dielectric barrier discharge plasma effect on self-cleaning activity of ultrasonically Cu2O/TiO2-coated cotton fabric. Appl. Phys. A 2021, 127, 776. [Google Scholar] [CrossRef]

- Rachtanapun, P.; Sawangrat, C.; Kanthiya, T.; Thipchai, P.; Kaewapai, K.; Suhr, J.; Worajittiphon, P.; Tanadchangsaeng, N.; Wattanachai, P.; Jantanasakulwong, K. Effect of Plasma Treatment on Bamboo Fiber-Reinforced Epoxy Composites. Polymers 2024, 16, 938. [Google Scholar] [CrossRef]

- Sawangrat, C.; Jantanasakulwong, K.; Suhr, J.; Kaewapai, K.; Kanthiya, T.; Thipchai, P.; Rachtanapun, P.; Wattanachai, P. Synergistic Effects of Dielectric Barrier Discharge Plasma Treatment on Hemp Fiber Surface Modification and Mechanical Properties of Hemp-Fiber-Reinforced Epoxy Composites. Appl. Sci. 2025, 15, 2818. [Google Scholar] [CrossRef]

- Yuan, X.; Jayaraman, K.; Bhattacharyya, D. Effects of plasma treatment in enhancing the performance of woodfibre-polypropylene composites. Compos. Part A Appl. Sci. Manuf. 2004, 35, 1363–1374. [Google Scholar] [CrossRef]

- Sinha, E.; Panigrahi, S. Effect of Plasma Treatment on Structure, Wettability of Jute Fiber and Flexural Strength of its Composite. J. Compos. Mater. 2009, 43, 1791–1802. [Google Scholar] [CrossRef]

- Morent, R.; De Geyter, N.; Verschuren, J.; De Clerck, K.; Kiekens, P.; Leys, C. Non-thermal plasma treatment of textiles. Surf. Coat. Technol. 2008, 202, 3427–3449. [Google Scholar] [CrossRef]

- Sever, K.; Erden, S.; Gülec, H.A.; Seki, Y.; Sarikanat, M. Oxygen plasma treatments of jute fibers in improving the mechanical properties of jute/HDPE composites. Mater. Chem. Phys. 2011, 129, 275–280. [Google Scholar] [CrossRef]

- Harsha Vardhan, D.; Ramesh, A.; Chandra Mohana Reddy, B. Effect of ceramic fillers on flexural strength of the GFRP composite material. Mater. Today Proc. 2021, 37, 1739–1742. [Google Scholar] [CrossRef]

- Sravanthi, K.; Mahesh, V.; Nageswara Rao, B. Influence of micro and nano carbon fillers on impact behavior of GFRP composite materials. Mater. Today Proc. 2021, 37, 1075–1078. [Google Scholar] [CrossRef]

- Sharma, M.; Sharma, R.; Chandra Sharma, S. A review on fibres and fillers on improving the mechanical behaviour of fibre reinforced polymer composites. Mater. Today Proc. 2021, 46, 6482–6489. [Google Scholar] [CrossRef]

- Jawaid, M.; Abdul Khalil, H.P.S. Cellulosic/synthetic fibre reinforced polymer hybrid composites: A review. Carbohydr. Polym. 2011, 86, 1–18. [Google Scholar] [CrossRef]

- Dhawan, V.; Singh, S.; Singh, I. Effect of natural fillers on mechanical properties of GFRP composites. J. Compos. 2013, 2013, 792620. [Google Scholar] [CrossRef]

- Kabir, M.M.; Mustak, R.; Hasan Sadik, M.M. Effect of bio-filler on various properties of glass fiber reinforced epoxy composites. Hybrid Adv. 2025, 10, 100448. [Google Scholar] [CrossRef]

- Sathiya Narayanan, N.; Sai Venkat Mohan, D.; Abhinay, J.; Dinesh, T.; Satya Sai Surya Teja, V.; Praneeth, R. Effects on microhardness, tensile strength, deflection, and drop weight impact resistance with the addition of hybrid filler materials for enhancing GFRP composites. Sci. Rep. 2024, 14, 27524. [Google Scholar] [CrossRef]

- Yang, C.; Nan, Z.; Huo, Y.; Yang, Y.; Xu, P.; Xiao, Y.; Fang, Y.; Meng, K. Design, characterisation, and crushing performance of hexagonal-quadrilateral lattice-filled steel/CFRP hybrid structures. Compos. Part B Eng. 2025, 304, 112631. [Google Scholar] [CrossRef]

- Graupner, N.; Poonsawat, T.; Narkpiban, K.; Müssig, J. Potential of Thai Bast Fibers for Injection Molded PLA Composites. J. Renew. Mater. 2023, 11, 2279–2300. [Google Scholar] [CrossRef]

- Limpitipanich, P.; Promwungkwa, A. Axial Response of Hemp-Fiber Composite Tube under Quasi-Static Compression and Impact Crushing. CMU J. Nat. Sci. 2019, 18, 285–304. [Google Scholar] [CrossRef]

- Kaima, J.; Preechawuttipong, I.; Jongchansitto, P.; Charoenloe, N. Effect of chemical solution on tensile strength of bamboo fiber. Proc. IOP Conf. Ser. Mater. Sci. Eng. 2020, 886, 012061. [Google Scholar] [CrossRef]

- Rachtanapun, P.; Sawangrat, C.; Kanthiya, T.; Kaewpai, K.; Thipchai, P.; Tanadchangsaeng, N.; Worajittiphon, P.; Suhr, J.; Wattanachai, P.; Jantanasakulwong, K. Comparison of Effects of Plasma Surface Modifications of Bamboo and Hemp Fibers on Mechanical Properties of Fiber-Reinforced Epoxy Composites. Polymers 2024, 16, 3394. [Google Scholar] [CrossRef]

- Sawangrat, C.; Thipchai, P.; Kaewapai, K.; Jantanasakulwong, K.; Suhr, J.; Wattanachai, P.; Rachtanapun, P. Surface Modification and Mechanical Properties Improvement of Bamboo Fibers Using Dielectric Barrier Discharge Plasma Treatment. Polymers 2023, 15, 1711. [Google Scholar] [CrossRef]

- ASTM D7205/D7205M-06; Standard Test Method for Tensile Properties of Fiber Reinforced Polymer Matrix Composite Bars. ASTM International: West Conshohocken, PA, USA, 2016.

- ASTM D7617/D7617M-11; Test Method for Transverse Shear Strength of Fiber-Reinforced Polymer Matrix Composite Bars. ASTM International: West Conshohocken, PA, USA, 2017.

- ASTM D790-17; Standard Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials. American Society for Testing Materials: Filadelfia, PA, USA, 2017.

- S806-02; Design and Construction of Building Components with Fibre-Reinforced Polymers. Canadian Standards Association: Toronto, ON, USA, 2002.

- Li, K.; Wang, X.; Wang, X.; Tu, S.; Song, Y.; Shi, T.; Wang, L.; Zhou, H. A comprehensive benefit evaluation of recycled carbon fiber reinforced cement mortar based on combined weighting. Constr. Build. Mater. 2025, 489, 142196. [Google Scholar] [CrossRef]

- Ricciardi, M.R.; Papa, I.; Coppola, G.; Lopresto, V.; Sansone, L.; Antonucci, V. Effect of Plasma Treatment on the Impact Behavior of Epoxy/Basalt Fiber-Reinforced Composites: A Preliminary Study. Polymers 2021, 13, 1293. [Google Scholar] [CrossRef]

- Attia, M.M.; Olwan, M.M.; Amoush, E.; Aamer, S.R.R.H.; Eita, M.A. Behavior of hybrid natural fiber reinforced polymers bars under uniaxial tensile strength and pull-out loads with UHPC. Case Stud. Constr. Mater. 2024, 21, e03442. [Google Scholar] [CrossRef]

- Scalici, T.; Fiore, V.; Valenza, A. Effect of plasma treatment on the properties of Arundo Donax L. leaf fibres and its bio-based epoxy composites: A preliminary study. Compos. Part B Eng. 2016, 94, 167–175. [Google Scholar] [CrossRef]

- Pejić, B.M.; Kramar, A.D.; Obradović, B.M.; Kuraica, M.M.; Žekić, A.A.; Kostić, M.M. Effect of plasma treatment on chemical composition, structure and sorption properties of lignocellulosic hemp fibers (Cannabis sativa L.). Carbohydr. Polym. 2020, 236, 116000. [Google Scholar] [CrossRef] [PubMed]

- Bozaci, E.; Sever, K.; Sarikanat, M.; Seki, Y.; Demir, A.; Ozdogan, E.; Tavman, I. Effects of the atmospheric plasma treatments on surface and mechanical properties of flax fiber and adhesion between fiber–matrix for composite materials. Compos. Part B Eng. 2013, 45, 565–572. [Google Scholar] [CrossRef]

- Nepomuceno, E.; Sena-Cruz, J.; Correia, L.; D′Antino, T. Review on the bond behavior and durability of FRP bars to concrete. Constr. Build. Mater. 2021, 287, 123042. [Google Scholar] [CrossRef]

- Ahmad Sawpan, M. Shear properties and durability of GFRP reinforcement bar aged in seawater. Polym. Test. 2019, 75, 312–320. [Google Scholar] [CrossRef]

- Parvizi, M.; Noël, M.; Vasquez, J.; Rios, A.; González, M. Assessing the bond strength of Glass Fiber Reinforced Polymer (GFRP) bars in Portland Cement Concrete fabricated with seawater through pullout tests. Constr. Build. Mater. 2020, 263, 120952. [Google Scholar] [CrossRef]

- Sakcalı, G.B.; Yüksel, İ.; Sağıroğlu, S. Experimental investigation of flexural bond behavior of sand-coated GFRP rebar embedded in concrete. J. Build. Eng. 2024, 87, 109113. [Google Scholar] [CrossRef]

- Pickering, K.L.; Efendy, M.G.A.; Le, T.M. A review of recent developments in natural fibre composites and their mechanical performance. Compos. Part A Appl. Sci. Manuf. 2016, 83, 98–112. [Google Scholar] [CrossRef]

- Sienkiewicz, N.; Dominic, M.; Parameswaranpillai, J. Natural Fillers as Potential Modifying Agents for Epoxy Composition: A Review. Polymers 2022, 14, 265. [Google Scholar] [CrossRef]

- Macedo, M.J.P.; Silva, G.S.; Feitor, M.C.; Costa, T.H.C.; Ito, E.N.; Melo, J.D.D. Surface modification of kapok fibers by cold plasma surface treatment. J. Mater. Res. Technol. 2020, 9, 2467–2476. [Google Scholar] [CrossRef]

- Kidangayil Sali, A.; Keerthiveettil Ramakrishnan, S.; Keloth Paduvilan, J.; Vackova, T.; Král, R.; Zemenova, P.; Thomas, S.; Spatenka, P. Natural fiber thermoplastic composites: Exploring the impact of plasma surface treatment on viscoelastic and thermal behavior. Mater. Chem. Phys. 2025, 338, 130599. [Google Scholar] [CrossRef]

- da Silva, C.C.; de Faria Lima, A.; Moreto, J.A.; Dantas, S.; Alves Henrique, M.; Pasquini, D.; Cipriano Rangel, E.; Scarmínio, J.; Gelamo, R.V. Influence of plasma treatment on the physical and chemical properties of sisal fibers and environmental application in adsorption of methylene blue. Mater. Today Commun. 2020, 23, 101140. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).