Numerical Simulation of Surrounding Rock Vibration and Damage Characteristics Induced by Blasting Construction in Bifurcated Small-Spacing Tunnels

Abstract

1. Introduction

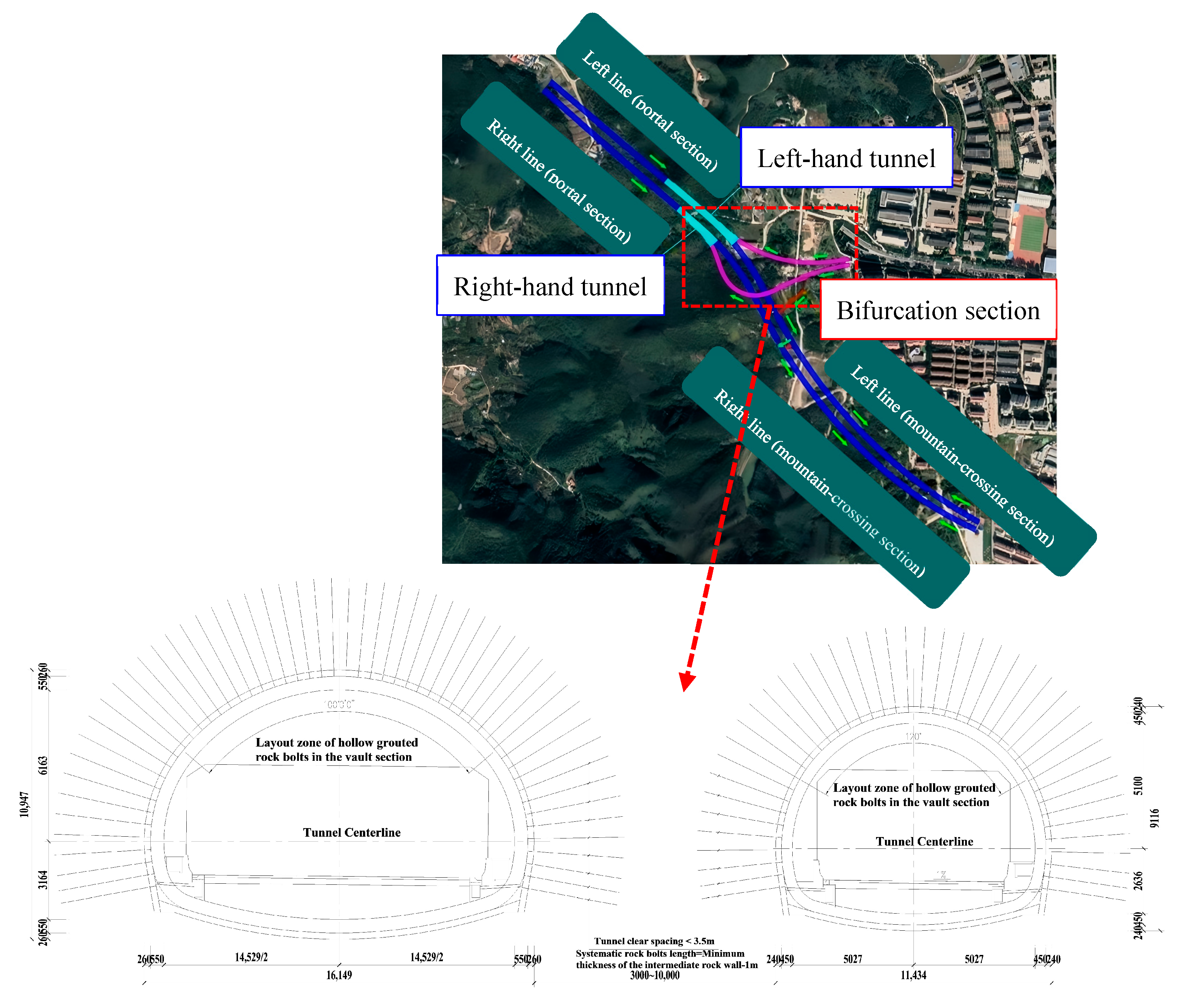

2. Engineering Prototype

2.1. Engineering Project Overview

2.2. Geological Conditions

3. Determination of Blasting Load and Damage Criterion for Surrounding Rock

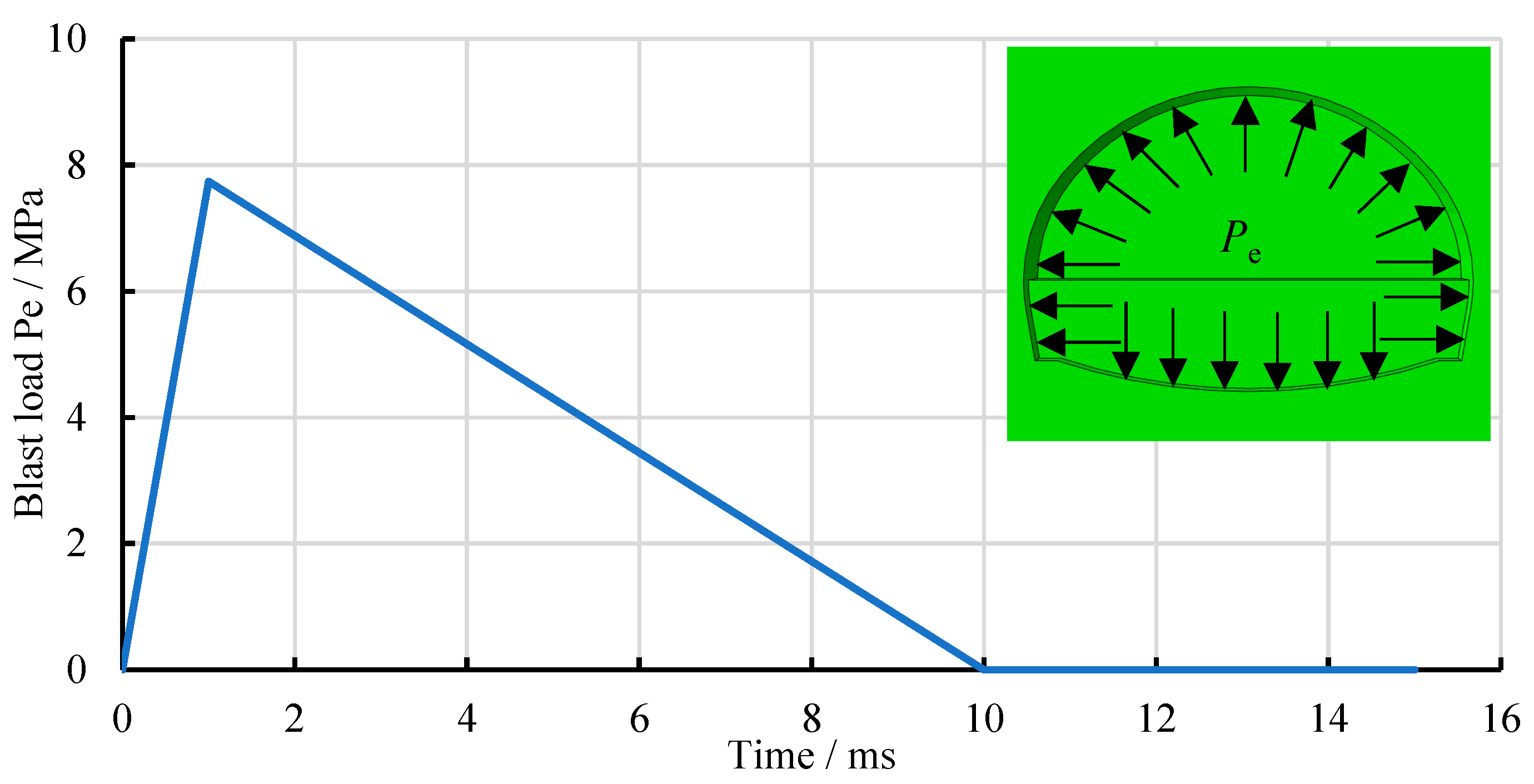

3.1. Application Method of the Blasting Load

- (1)

- Application of blasting loads on the blast hole surface. This approach primarily simulates the detonation process of explosives by employing the Jones–Wilkins–Lee (JWL) equation of state for explosive materials or by applying pressure loads on the blast hole wall to investigate the damage to surrounding rock and the propagation of vibrations within the near-field zone of the blast hole. For example, Li et al. [29] developed the blasting load time–history curve using the JWL equation of state and conducted investigations on rock damage. Guan et al. [30] investigated the vibration damage characteristics of tunnel middle partitions by employing the JWL equation of state. Meanwhile, Cho et al. [31] utilized the blast hole wall pressure time–history curve to examine the cracking mechanisms of surrounding rock during single-hole blasting. Hu et al. [32] compared tensile-compressive damage models with several widely used blasting damage models using the blast hole wall pressure time–history curve and introduced a novel model for simulating blasting vibration damage. This approach effectively simulates the blasting vibration response of rock masses within the near-field zone of the blast hole for scenarios involving single or a limited number of blast holes. However, when applied to large-scale blasting problems in practical engineering contexts, this method demands excessive computational resources, significantly compromising computational efficiency.

- (2)

- Application of blasting loads on the excavation contour surface. This method involves scaling down the load acting on the blast hole wall and subsequently applying it across a broader area of the tunnel excavation contour surface to investigate the blasting vibration response in the medium- and far-field zones from the blast hole. For example, Yan et al. [13] employed this method to apply equivalent loads to the excavation contour and investigated the excavation damage zone of the tunnel under transient in situ stress unloading conditions. Lu et al. [9] applied the equivalent load to the elastic boundary and derived the load history to simulate vibrations in the medium- and far-field zones. Shin et al. [33] scaled down the load on the blast hole wall and applied it to the outer boundary of the blasting plastic zone. This approach eliminates the need for establishing a blast hole model and is particularly suitable for simulating the vibration response of surrounding rock in the medium- and far-field zones under multi-hole blasting conditions. However, it has limitations in addressing issues such as rock fragmentation and blasting damage in the near-field zone of the blast hole.

3.2. Form and Magnitude of Blasting Load

3.3. Damage Criterion for Surrounding Rock

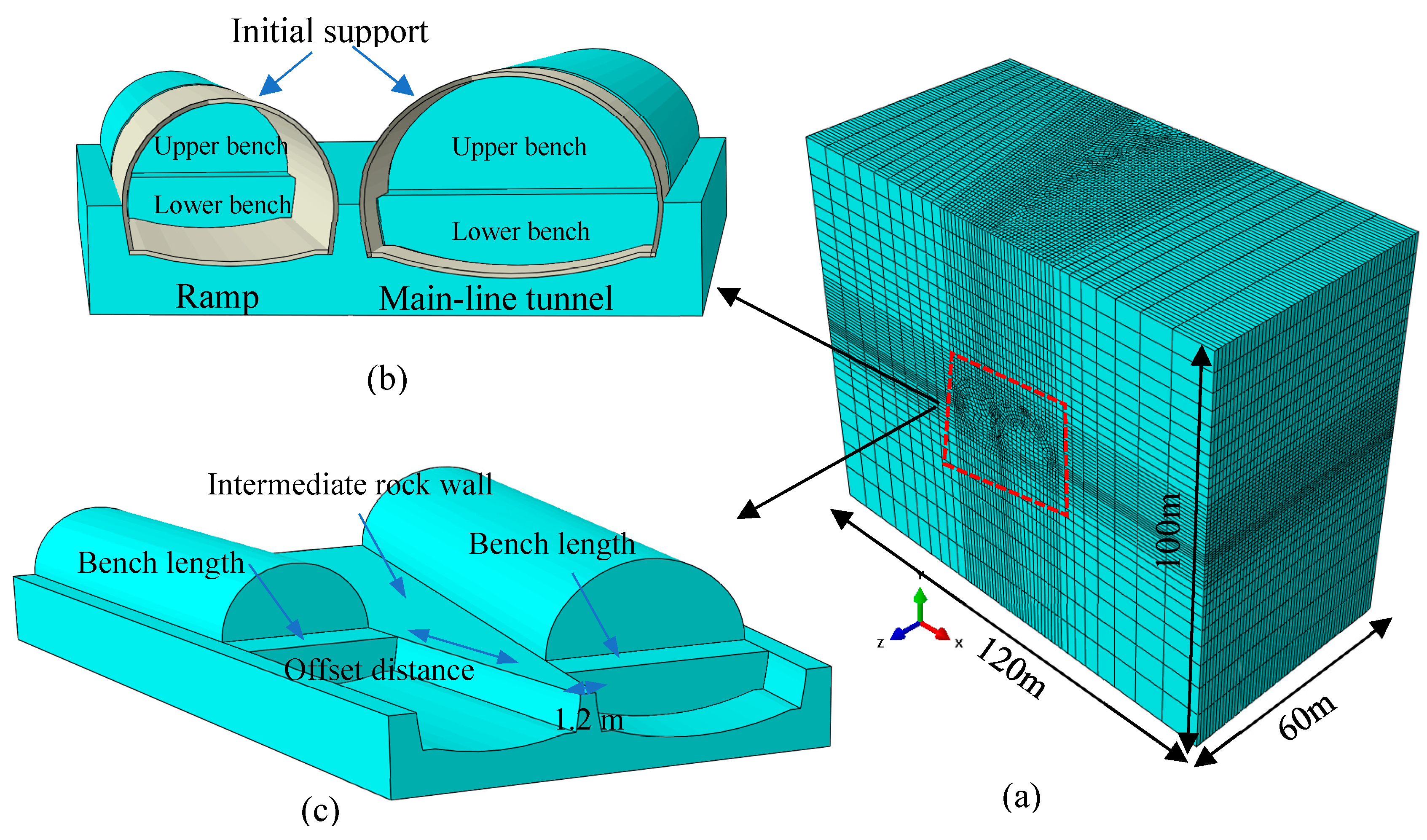

4. Numerical Analysis of Blasting Construction in Bifurcated Tunnels

4.1. Numerical Calculation Model

4.2. Parameters of Numerical Calculation

4.2.1. Calculation Parameters of Surrounding Rock and Support

4.2.2. Calculation Parameters of Blasting Load

4.3. Results and Analysis of Numerical Calculation

- (1)

- First, the upper bench of the ramp tunnel is excavated with an advance of 2 m per cycle. After completing 4 m of upper bench excavation, the lower bench is excavated, followed by sequential cyclic excavation of the ramp tunnel.

- (2)

- Following the excavation of 8 m of the lower bench in the ramp tunnel, the upper bench of the main-line tunnel is excavated with an advance of 2 m per cycle. After completing 4 m of upper bench excavation in the main-line tunnel, the lower bench is excavated.

- (3)

- A face offset distance of 8 m is maintained between the ramp and main-line tunnels, and both tunnels are advanced simultaneously until the lower bench excavation of the main-line tunnel reaches 20 m, marking the completion of the excavation process.

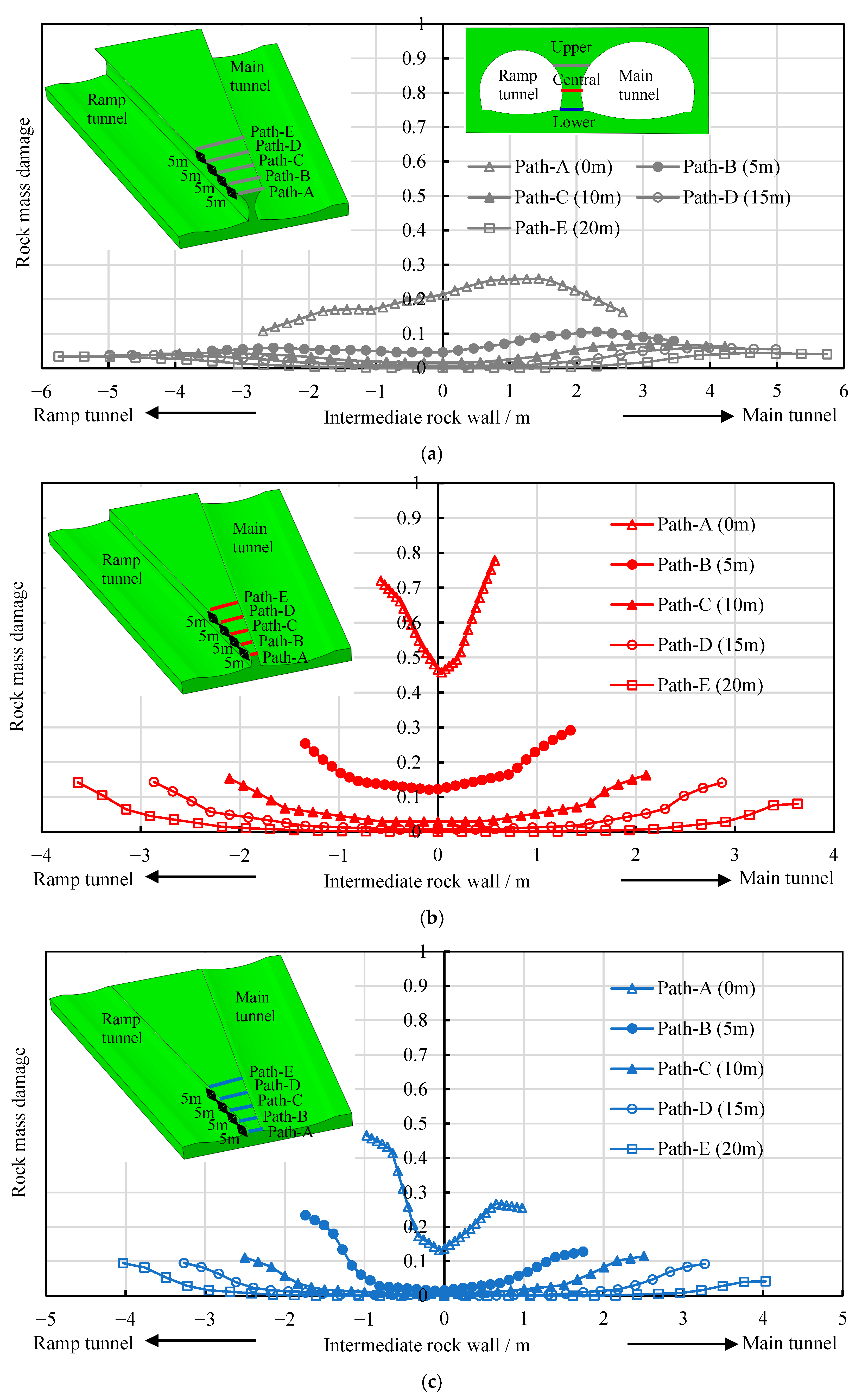

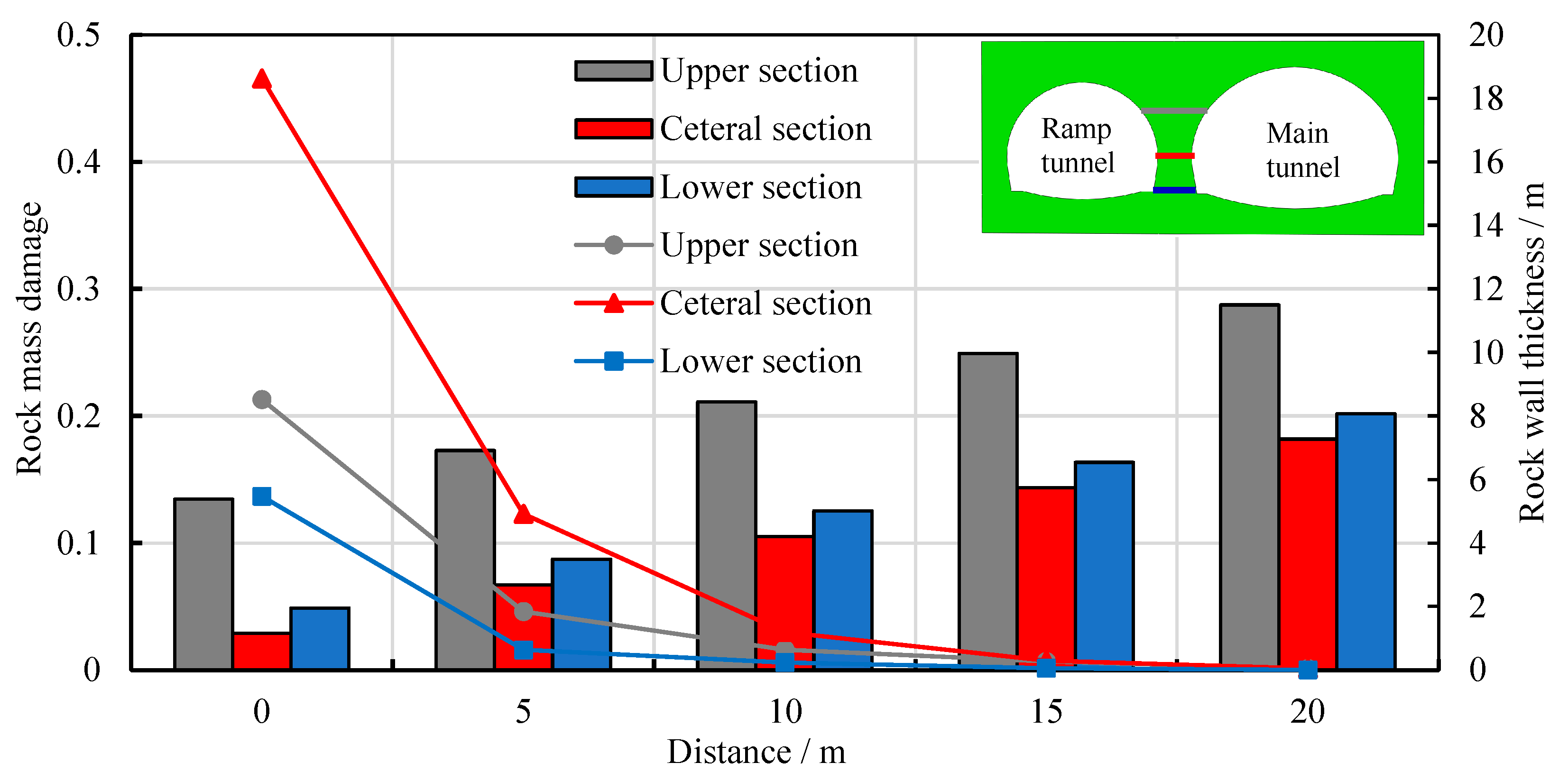

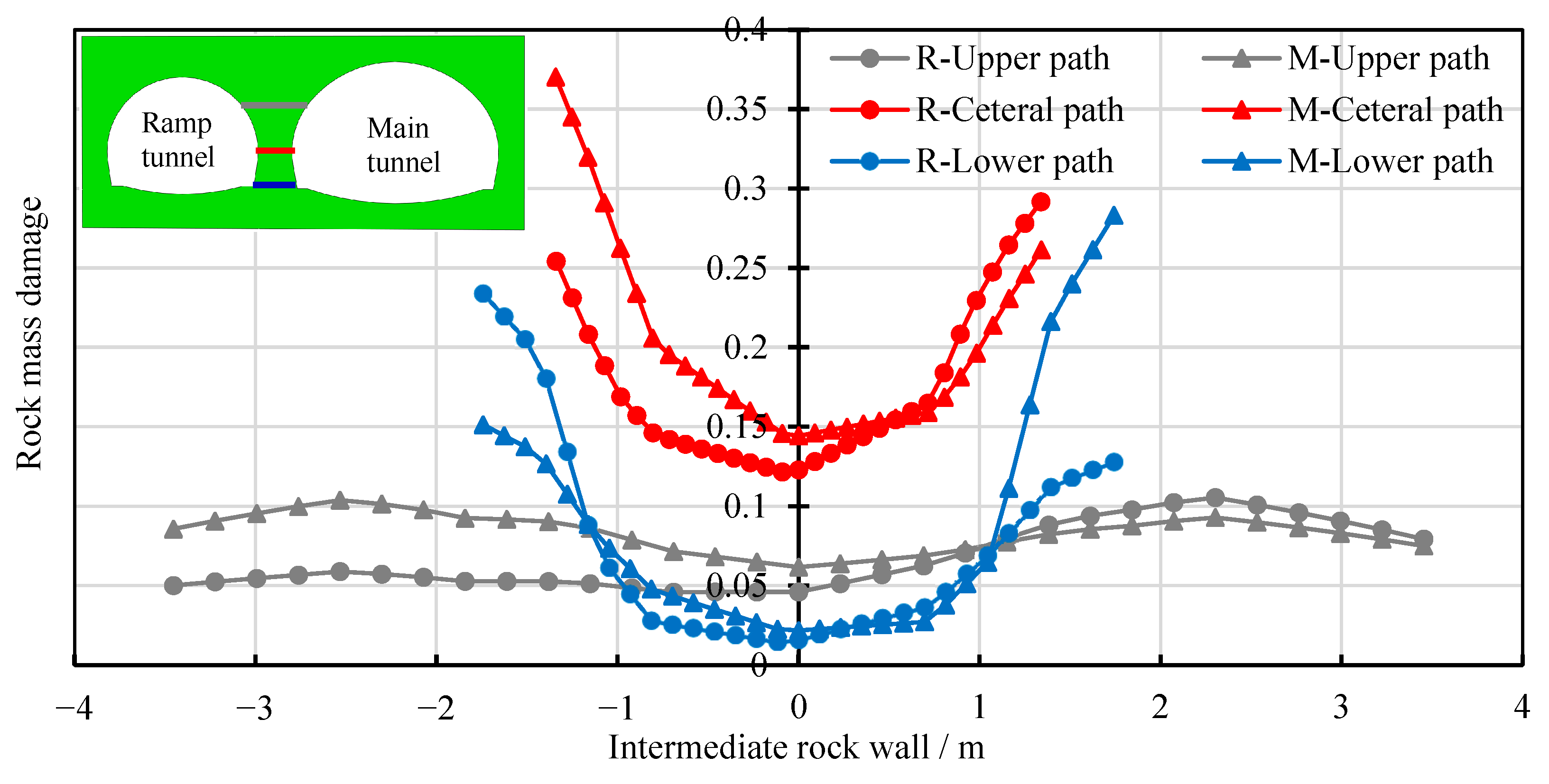

4.3.1. Analysis of the Damage to Intermediate Rock Wall After the Completion of Construction

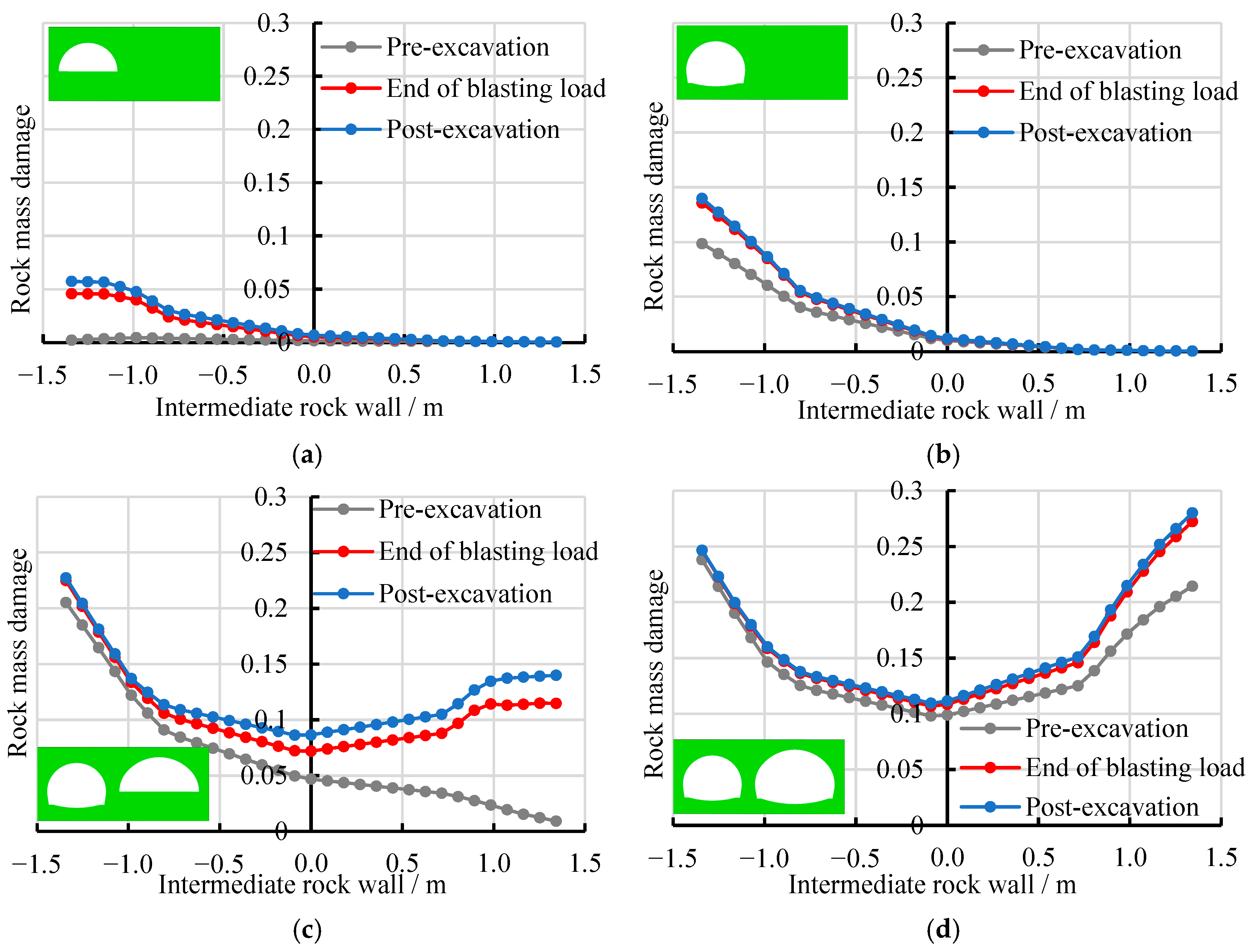

4.3.2. Analysis of the Damage to the Intermediate Rock Wall During the Construction Process

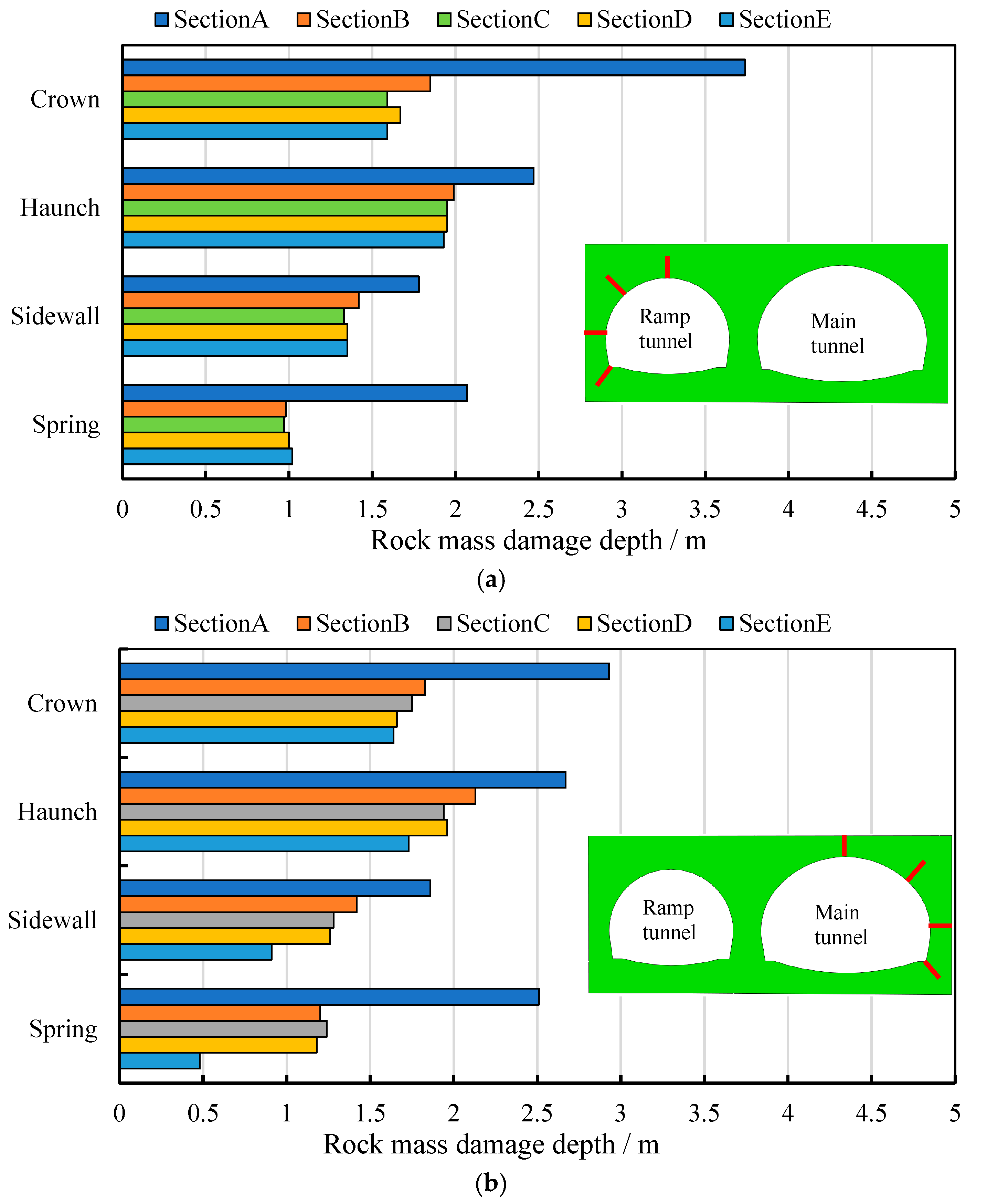

4.3.3. Analysis of the Damage to Surrounding Rock on the Outer Side of Ramp and Main-Line Tunnels

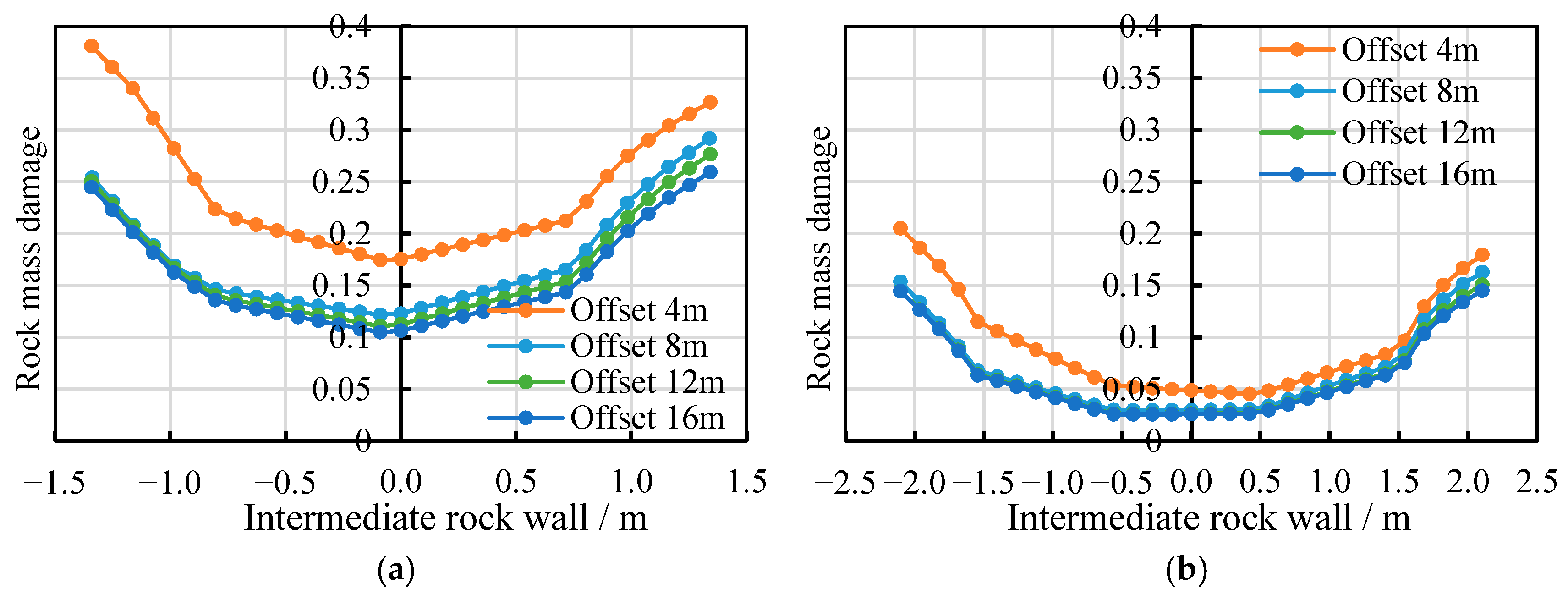

4.4. Discussion on Factors Influencing Intermediate Rock Wall Damage

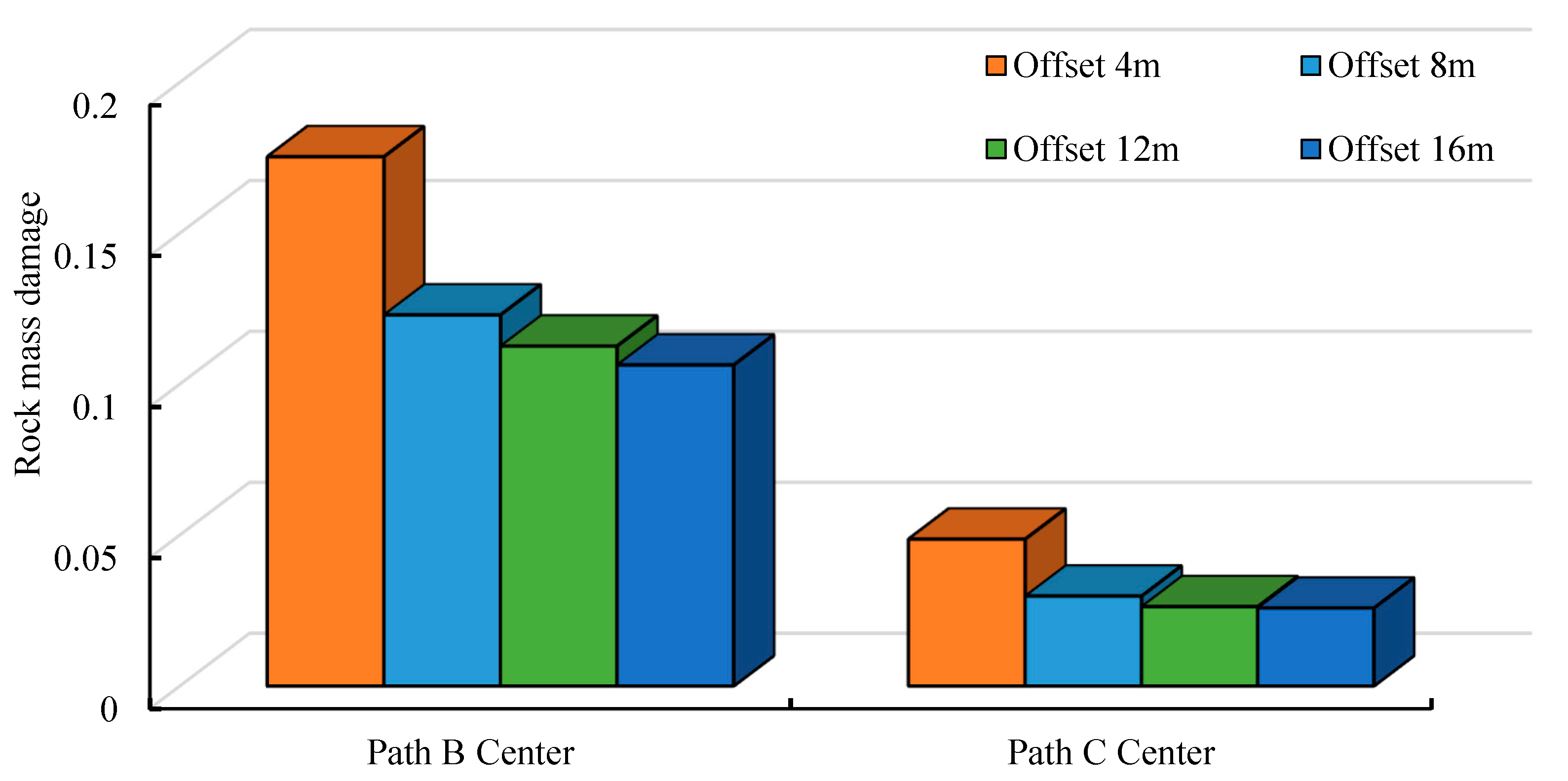

4.4.1. Offset Distance Between Leading and Trailing Tunnel Faces

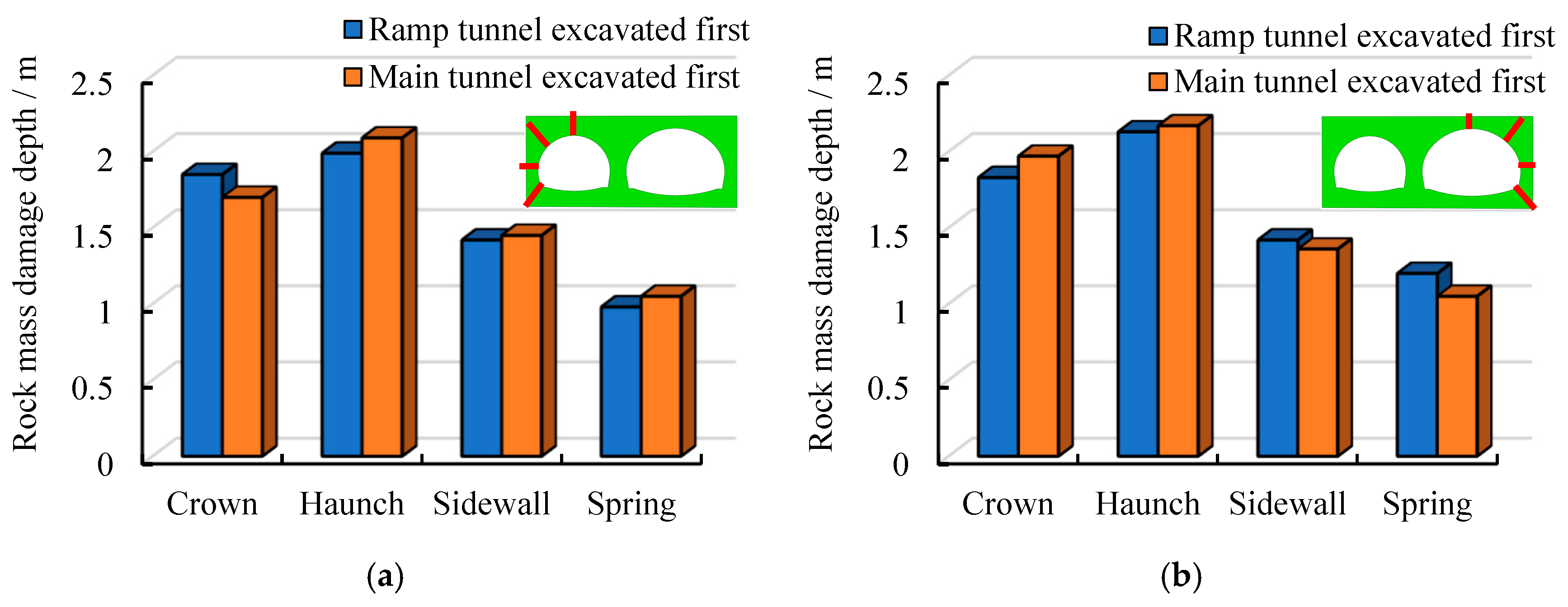

4.4.2. Construction Sequence of Leading and Trailing Tunnels

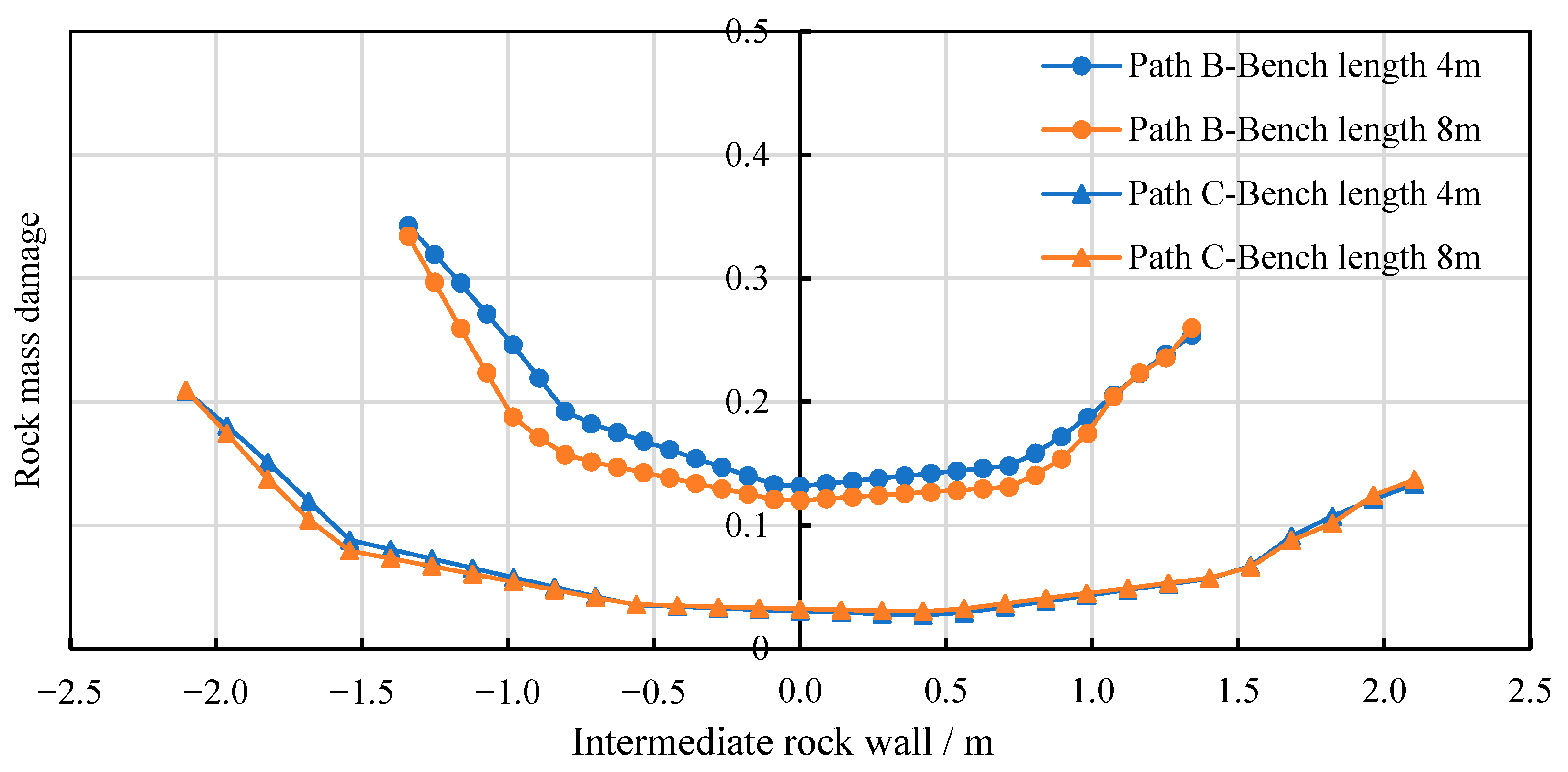

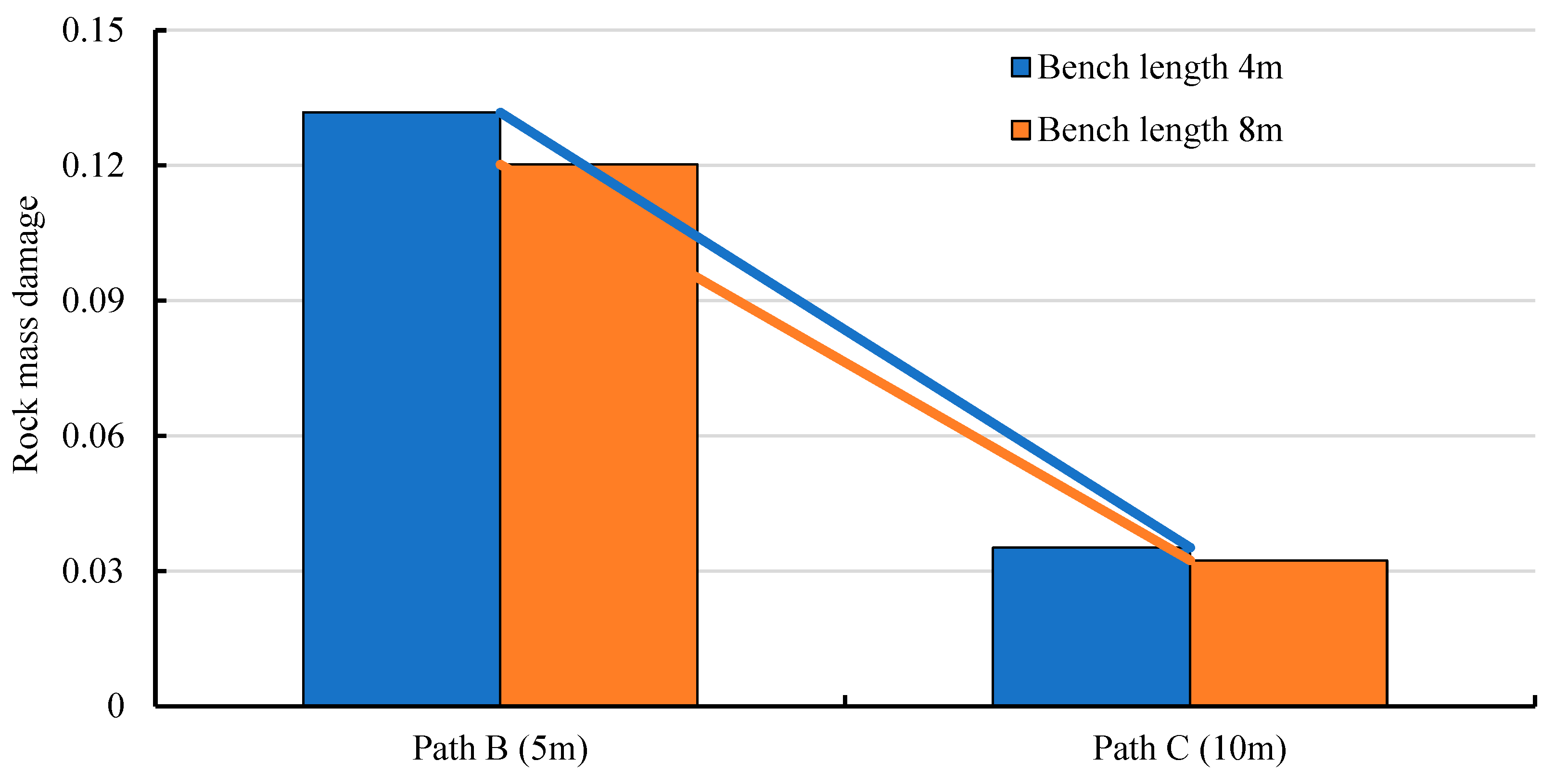

4.4.3. Length of Construction Benches

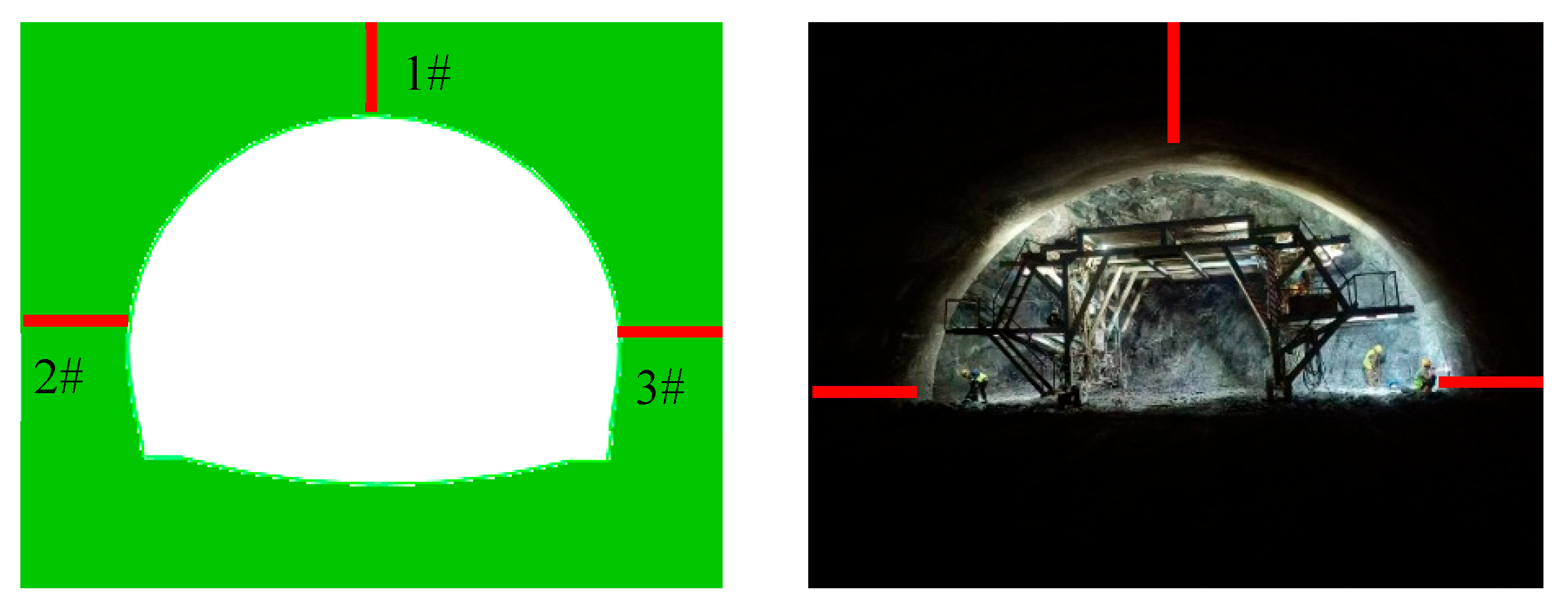

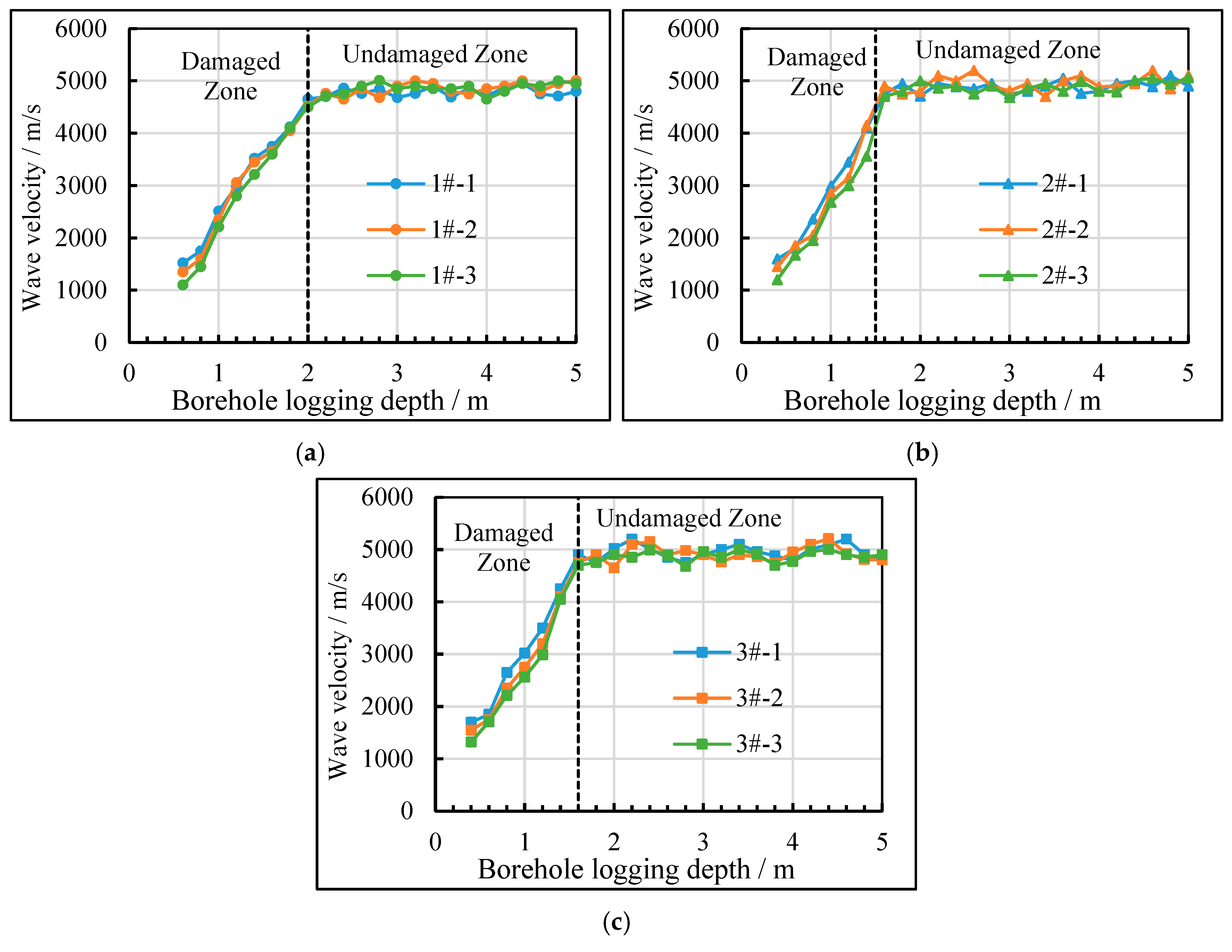

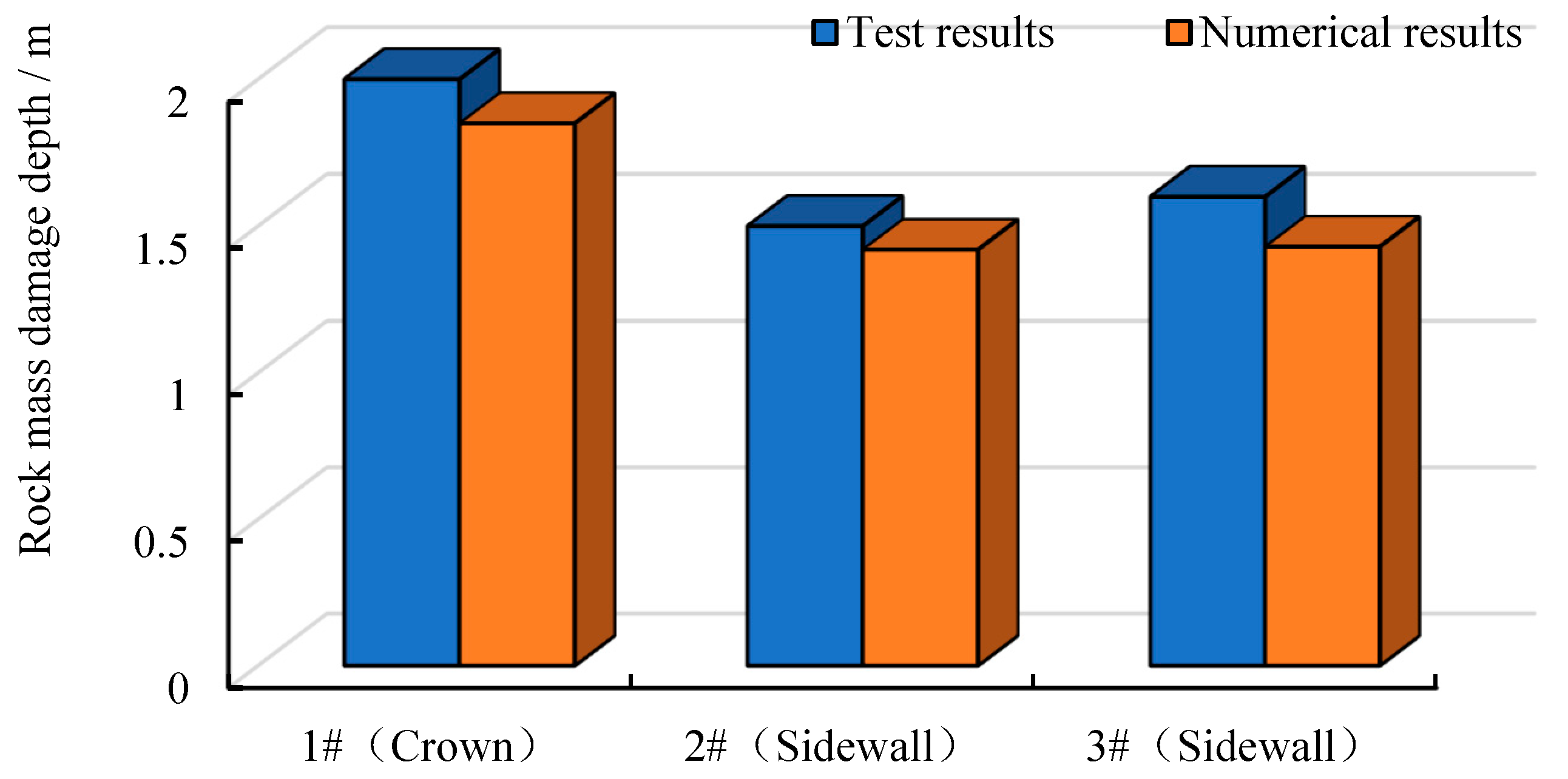

5. In Situ Testing and Analysis

6. Conclusions

- The damage to the surrounding rock of the bifurcated tunnel caused by blasting construction is mainly concentrated on the side of the intermediate rock wall. The damage zone gradually decreases from the excavation contour surface toward the center of the intermediate rock wall thickness, exhibiting an asymmetric “U”-shaped distribution. At the haunch and sidewall sections of the intermediate rock wall, the damage to the surrounding rock is greater on the side closer to the trailing tunnel. In contrast, at the springing section, the damage is more significant on the side closer to the leading tunnel. Along the height direction of the intermediate rock wall, the damage is more pronounced at the sidewall section, followed by the springing section and the haunch section. Along the tunnel axis direction, the closer the location is to the starting position of the bifurcated tunnel, the thinner the intermediate rock wall and the greater the damage to the surrounding rock. Within a range of 5 m from the starting position of the bifurcated tunnel, the damaged zones of the intermediate rock wall are interconnected, necessitating safety measures during construction. For tunnel construction within 10 m of the bifurcation starting point, pre-grouting (e.g., pipe roof grouting) and radial bolt reinforcement in the intermediate rock wall are recommended to enhance its integrity and strength.

- During the blasting construction process, the construction of the trailing main-line tunnel significantly impacts the damage to the intermediate rock wall. The damage to the surrounding rock is relatively minor after the excavation of the upper bench of the leading ramp tunnel but increases after the excavation of the lower bench. The damage to the intermediate rock wall significantly increases after the construction of the trailing main-line tunnel, especially following the excavation of its lower bench. During each excavation step of the ramp and main-line tunnels, the damage to the intermediate rock wall is primarily caused by the blasting load. As tunnel excavation progresses, the damage to the rock wall gradually increases under the combined effects of the blasting load and the excavation-induced space effects. During tunnel excavation, immediate protection measures should be implemented for the intermediate rock wall after its formation, including the prompt installation of initial support near the rock wall excavation faces to minimize exposure time.

- During the construction of bifurcated tunnels, the smaller the offset distance between the leading and trailing tunnel faces is, the earlier the intermediate rock wall forms, and the greater the damage to the surrounding rock. As the offset distance between the leading and trailing tunnel faces increases, the damage to the intermediate rock wall gradually decreases. Constructing the tunnel with a larger cross-sectional area first will cause more damage to the intermediate rock wall. Therefore, it is safer and more rational to construct the tunnel with a smaller cross-sectional area first. When using the bench method, the damage to the intermediate rock wall decreases as the bench length increases. Thus, the bench length should be increased as much as possible to ensure the safety of the rock wall. When in situ conditions permit, priority should be given to constructing the ramp tunnel first, with a bench length maintained at 8 m and a face offset distance exceeding 16 m.

- These research findings provide a valuable reference for determining a safe and rational blasting schemes for this bifurcated small-spacing tunnel. However, it should be noted that the numerical simulation of construction schemes assumes homogeneous and isotropic material properties for the surrounding rock vibration-damage analysis, while insufficiently accounting for practical engineering factors such as geological discontinuities, delayed blasting, and actual blast hole arrangements. These aspects warrant further investigation in subsequent research.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhang, Y.W.; Zhang, Y.D.; Song, Z.P.; Pan, H.W. A LFPP-FAHP based evaluation model of blasting scheme for tunnel undercrossing existing buildings. Tunn. Undergr. Space Technol. 2024, 153, 105937. [Google Scholar] [CrossRef]

- Wang, F.; Xue, Y.H.; Zhang, Y.Y.; Pan, Y.D.; Luo, C. Response of existing lining subjected to closed blasting in zero-spacing twin tunnels and its damping measures. Eng. Fail. Anal. 2024, 166, 108847. [Google Scholar] [CrossRef]

- Wang, X.; Li, J.C.; Zhao, X.B.; Liang, Y. Propagation characteristics and prediction of blast-induced vibration on closely spaced rock tunnels. Tunn. Undergr. Space Technol. 2023, 123, 104416. [Google Scholar] [CrossRef]

- He, B.; Armaghani, D.J.; Lai, S.H.; He, X.Z.; Asteris, P.G.; Sheng, D.C. A deep dive into tunnel blasting studies between 2000 and 2023-Asystematic review. Tunn. Undergr. Space Technol. 2024, 147, 105727. [Google Scholar] [CrossRef]

- Guan, X.M.; Xu, H.W.; Fu, H.X.; Zhang, W.J.; Li, P.F.; Ding, H.; Yu, K.; Zhang, S.L. Vibration characteristics, attenuation law and prediction method in the near field of tunnel blasting. Case Stud. Constr. Mater. 2023, 19, e02662. [Google Scholar] [CrossRef]

- Guan, X.M.; Yao, Y.K.; Yang, N.; Xu, H.W.; Xin, B.C.; Li, B.Y. Analysis of factors influencing vibration reduction and design optimization of damping holes in adjacent tunnel blasting. Case Stud. Constr. Mater. 2023, 19, e02448. [Google Scholar] [CrossRef]

- Wang, X.; Hou, X.F.; Yuan, W.; He, C.D.; Sarfarazi, V.S.; Fan, H. Attenuation of blast-induced vibration on tunnel structures. Geohazard Mech. 2024, 2, 153–163. [Google Scholar] [CrossRef]

- Xu, M.N.; Li, X.P.; Xu, K.; Liu, T.T.; Zhang, Y.; Yang, T. Influence of the spatial distribution of underground tunnel group on its blasting vibration response. Undergr. Space 2023, 10, 248–268. [Google Scholar] [CrossRef]

- Lu, W.B.; Yang, J.H.; Yan, P.; Chen, M.; Zhou, C.B.; Luo, Y.; Jin, L. Dynamic response of rock mass induced by the transient release of in-situ stress. Int. J. Rock Mech. Min. Sci. 2012, 53, 129–141. [Google Scholar] [CrossRef]

- Xu, S.X.; Wu, B.; Zhang, H.L.; Qi, S.X.; Bian, H.B.; Wang, J.J. Directional crack propagation and optimization strategies for multi-hole shaped charge blasting in tunnel construction. Structures 2025, 72, 108268. [Google Scholar] [CrossRef]

- Ding, J.J.; Yang, J.H.; Ye, Z.W.; Leng, Z.D.; Zhou, C.B. Numerical study on rock blasting assisted by in-situ stress redistribution. Tunn. Undergr. Space Technol. 2024, 153, 106022. [Google Scholar] [CrossRef]

- Li, X.D.; Liu, K.W.; Sha, Y.Y.; Yang, J.C.; Hong, Z.X. Experimental and numerical investigation on rock fracturing in tunnel contour blasting under initial stress. Int. J. Impact Eng. 2024, 185, 104844. [Google Scholar] [CrossRef]

- Yan, P.; Lu, W.B.; Chen, M.; Hu, Y.G.; Zhou, C.B.; Wu, X.X. Contributions of in-situ stress transient redistribution to blasting excavation damage zone of deep tunnels. Rock Mech. Rock Eng. 2015, 48, 715–726. [Google Scholar] [CrossRef]

- Chen, M.; Lu, W.B.; Yan, P.; Hu, Y.G. Blasting Excavation induced damage of surrounding rock masses in deep-buried tunnels. KSCE J. Civ. Eng. 2016, 20, 933–942. [Google Scholar] [CrossRef]

- Verma, H.K.; Samadhiya, N.K.; Singh, M.; Goel, R.K.; Singh, P.K. Blast induced rock mass damage around tunnels. Tunn. Undergr. Space Technol. 2018, 71, 149–158. [Google Scholar] [CrossRef]

- Li, Q.; Li, H.B.; Fu, S.Y.; Li, X.F. The effect of in-situ stress on blast-induced rock fracture and damage zone. Tunn. Undergr. Space Technol. 2024, 154, 106091. [Google Scholar] [CrossRef]

- Wang, Y.Q.; Chen, Y.Q.; Li, C.H.; He, Y.S.; Wang, Q.R.; Xu, J.M.; Fan, J.Q.; Dai, M.N. Model test study on the dynamic failure process of tunnel surrounding rocks in jointed rock mass under explosive load. Eng. Fail. Anal. 2025, 167, 108996. [Google Scholar] [CrossRef]

- Ji, L.; Zhou, C.B.; Lu, S.W.; Jiang, N.; Li, H.B. Modeling study of cumulative damage effects and safety criterion of surrounding rock under multiple full-face blasting of a large cross-section tunnel. Int. J. Rock Mech. Min. Sci. 2021, 147, 104882. [Google Scholar] [CrossRef]

- Li, Z.; Hu, Y.; Wang, G.Z.; Zhou, M.; Hu, W.J.; Zhang, X.J.; Gao, W.X. Study on cyclic blasting failure characteristics and cumulative damage evolution law of tunnel rock mass under initial in-situ stress. Eng. Fail. Anal. 2023, 150, 107310. [Google Scholar] [CrossRef]

- Zhao, R.; Tao, M.; Karakus, M. Damage zone around underground opening caused by combined blast loading and initial stress unloading. Int. J. Rock Mech. Min. Sci. 2025, 186, 106018. [Google Scholar] [CrossRef]

- Zhu, Y.M.; Tang, Y.L.; Wang, H.C.; Zhang, Q.B. Development of a dynamic cumulative damage model and its application to underground hydropower caverns under multiple blasting. Int. J. Rock Mech. Min. Sci. 2024, 184, 105948. [Google Scholar] [CrossRef]

- Fu, S.Y.; Li, H.B.; Liu, L.W.; Li, Q.; Li, X.F. Study on the characteristics of blast-induced damage zone by using the wave velocity field inversion technique. Comput. Geotech. 2024, 176, 106808. [Google Scholar] [CrossRef]

- Wang, Q.R.; Xie, L.X.; Song, E.X.; Kong, F.L.; Fan, J.Q.; Yu, L.Y.; Xu, J.M.; Shi, X.Y. Model tests on dynamic responses of surrounding rock and support structure on underground tunnel under combined dynamic and static loading. Int. J. Rock Mech. Min. Sci. 2023, 171, 105572. [Google Scholar] [CrossRef]

- Song, Z.G.; Zou, S.M.; Zhou, W.X.; Huang, Y.; Shao, L.W.; Yuan, J. Clinically applicable histopathological diagnosis system for gastric cancer detection using deep learning. Nat. Commun. 2020, 11, 4294. [Google Scholar] [CrossRef]

- Kabir, H.; Wu, J.; Dahal, S.; Joo, T.; Garg, N. Automated estimation of cementitious sorptivity via computer vision. Nat. Commun. 2024, 15, 9935. [Google Scholar] [CrossRef]

- Wu, X.D.; Gong, M.; Wu, H.J.; Hu, G.F.; Wang, S.J. Vibration reduction technology and the mechanisms of surrounding rock damage from blasting in neighborhood tunnels with small clearance. Int. J. Min. Sci. Technol. 2023, 33, 625–637. [Google Scholar] [CrossRef]

- Ling, T.L.; Li, S.L.; Liu, D.S.; Liang, S.F. Blasting damage of tunnel rock mass based on cumulative effect. Rock Mech. Rock Eng. 2023, 56, 1679–1695. [Google Scholar] [CrossRef]

- Yang, H.P.; Yu, J.; Fu, X.Q.; Yao, W.; Lin, C.B.; Chang, F.Q. Damage characteristics of intercalary rock in bifurcated tunnel under alternate blasting excavation. J. Vib. Shock 2023, 42, 46–53. [Google Scholar] [CrossRef]

- Li, H.B.; Xiang, X.; Li, J.C.; Zhao, J.; Liu, B.; Liu, Y.Q. Rock damage control in bedrock blasting excavation for a nuclear power plant. Int. J. Rock Mech. Min. Sci. 2011, 48, 210–218. [Google Scholar] [CrossRef]

- Guan, X.M.; Yang, N.; Zhang, W.J.; Li, M.G.; Liu, Z.L.; Wang, X.H.; Zhang, S.L. Vibration response and failure modes analysis of the temporary support structure under blasting excavation of tunnels. Eng. Fail. Anal. 2022, 136, 106188. [Google Scholar] [CrossRef]

- Cho, S.H.; Kaneko, K. Influence of the applied pressure waveform on the dynamic fracture processes in rock. Int. J. Rock Mech. Min. Sci. 2004, 41, 771–784. [Google Scholar] [CrossRef]

- Hu, Y.G.; Lu, W.B.; Jin, X.H.; Chen, M.; Yan, P. Numerical simulation for excavation blasting dynamic damage of rock high slope. Chin. J. Rock Mech. Eng. 2012, 31, 2204–2213. [Google Scholar]

- Shin, J.H.; Moon, H.G.; Chae, S.E. Effect of blast-induced vibration on existing tunnels in soft rocks. Tunn. Undergr. Space Technol. 2011, 26, 51–56. [Google Scholar] [CrossRef]

- Sun, P.C.; Yang, G.D.; Lu, W.B.; Fan, Y.; Meng, H.L.; Xue, L. A study on explosion load history of rock blasting considering rock failure zones. Explos. Shock Waves 2024, 44, 171–186. [Google Scholar] [CrossRef]

- Jiang, N.; Lyu, G.P.; Wu, T.Y.; Zhou, C.B.; Li, H.B.; Yang, F. Vibration effect and ocean environmental impact of blasting excavation in a subsea tunnel. Tunn. Undergr. Space Technol. 2023, 131, 104855. [Google Scholar] [CrossRef]

- Deng, J. Analytical and numerical investigations on pillar rockbursts induced by triangular blasting waves. Int. J. Rock Mech. Min. Sci. 2021, 138, 104518. [Google Scholar] [CrossRef]

- Henrych, J. The Dynamics of Explosion and Its Use: Developments in Civil Engineering; Elsevier: Amsterdam, The Netherlands, 1979; pp. 59–64. [Google Scholar]

- Esen, S.; Onederra, I.; Bilgin, H.A. Modelling the size of the crushed zone around a blasthole. Int. J. Rock Mech. Min. Sci. 2003, 40, 485–495. [Google Scholar] [CrossRef]

- Luo, S.; Yan, P.; Lu, W.B.; Chen, M.; Wang, G.H. Research on the simulation of blasting damage and its mechanism of deep tunnel excavation. Chin. J. Rock Mech. Eng. 2021, 40 (Suppl. S1), 2760–2772. [Google Scholar]

| Influencing Factors | Ramp Tunnel | Main-Line Tunnel |

|---|---|---|

| Offset distance of working faces | 4 m, 8 m, 12 m, 16 m | - |

| Construction sequence | Ramp tunnel excavated first | Main-line tunnel excavated first |

| Bench length | - | 4 m, 8 m |

| Items | Density ρ (kg/m3) | Elastic Modulus E (GPa) | Poisson’s Ratio μ | Cohesion c (kPa) | Internal Friction Angle φ (°) | Tensile Strength (MPa) | Compressive Strength (MPa) | |

|---|---|---|---|---|---|---|---|---|

| Materials | ||||||||

| Rock | 2450 | 5 | 0.32 | 80 kpa | 38 | 2.5 | 80 | |

| Support | 2650 | 22.5 | 0.25 | - | - | - | - | |

| Test Holes | Test Results | Numerical Calculation Results |

|---|---|---|

| 1# | 2.00 | 1.85 |

| 2# | 1.50 | 1.42 |

| 3# | 1.60 | 1.43 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, M.; Wang, Y.; Dai, G.; Song, K.; Xie, X.; Yu, K. Numerical Simulation of Surrounding Rock Vibration and Damage Characteristics Induced by Blasting Construction in Bifurcated Small-Spacing Tunnels. Buildings 2025, 15, 2737. https://doi.org/10.3390/buildings15152737

Sun M, Wang Y, Dai G, Song K, Xie X, Yu K. Numerical Simulation of Surrounding Rock Vibration and Damage Characteristics Induced by Blasting Construction in Bifurcated Small-Spacing Tunnels. Buildings. 2025; 15(15):2737. https://doi.org/10.3390/buildings15152737

Chicago/Turabian StyleSun, Mingshe, Yantao Wang, Guangwei Dai, Kezhi Song, Xuyang Xie, and Kejia Yu. 2025. "Numerical Simulation of Surrounding Rock Vibration and Damage Characteristics Induced by Blasting Construction in Bifurcated Small-Spacing Tunnels" Buildings 15, no. 15: 2737. https://doi.org/10.3390/buildings15152737

APA StyleSun, M., Wang, Y., Dai, G., Song, K., Xie, X., & Yu, K. (2025). Numerical Simulation of Surrounding Rock Vibration and Damage Characteristics Induced by Blasting Construction in Bifurcated Small-Spacing Tunnels. Buildings, 15(15), 2737. https://doi.org/10.3390/buildings15152737