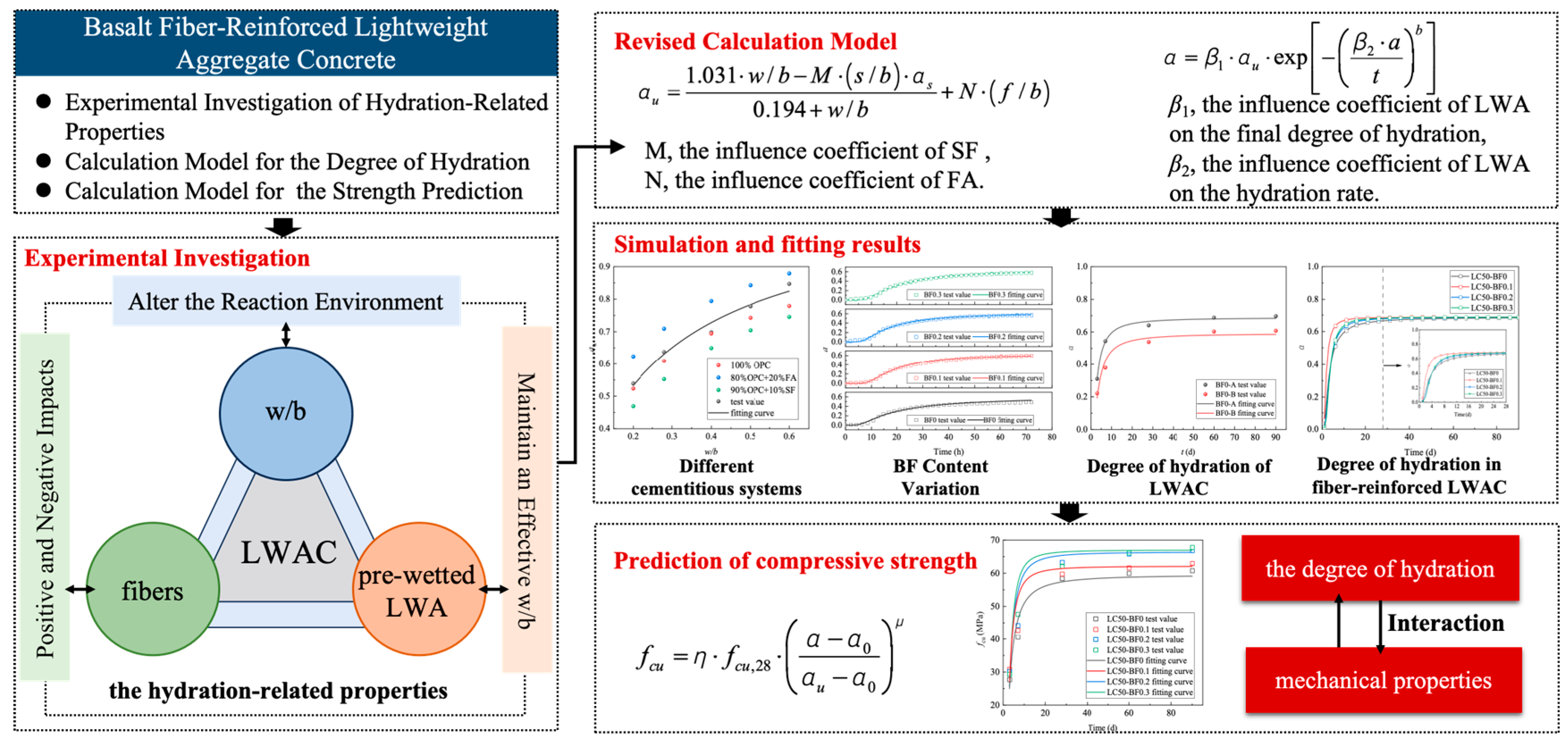

Calculation Model for the Degree of Hydration and Strength Prediction in Basalt Fiber-Reinforced Lightweight Aggregate Concrete

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Mix Proportions and Test Methods

2.2.1. Mechanical Properties Test

2.2.2. Isothermal Calorimetry Test

2.2.3. High-Temperature Calcination Test

3. Results and Discussion

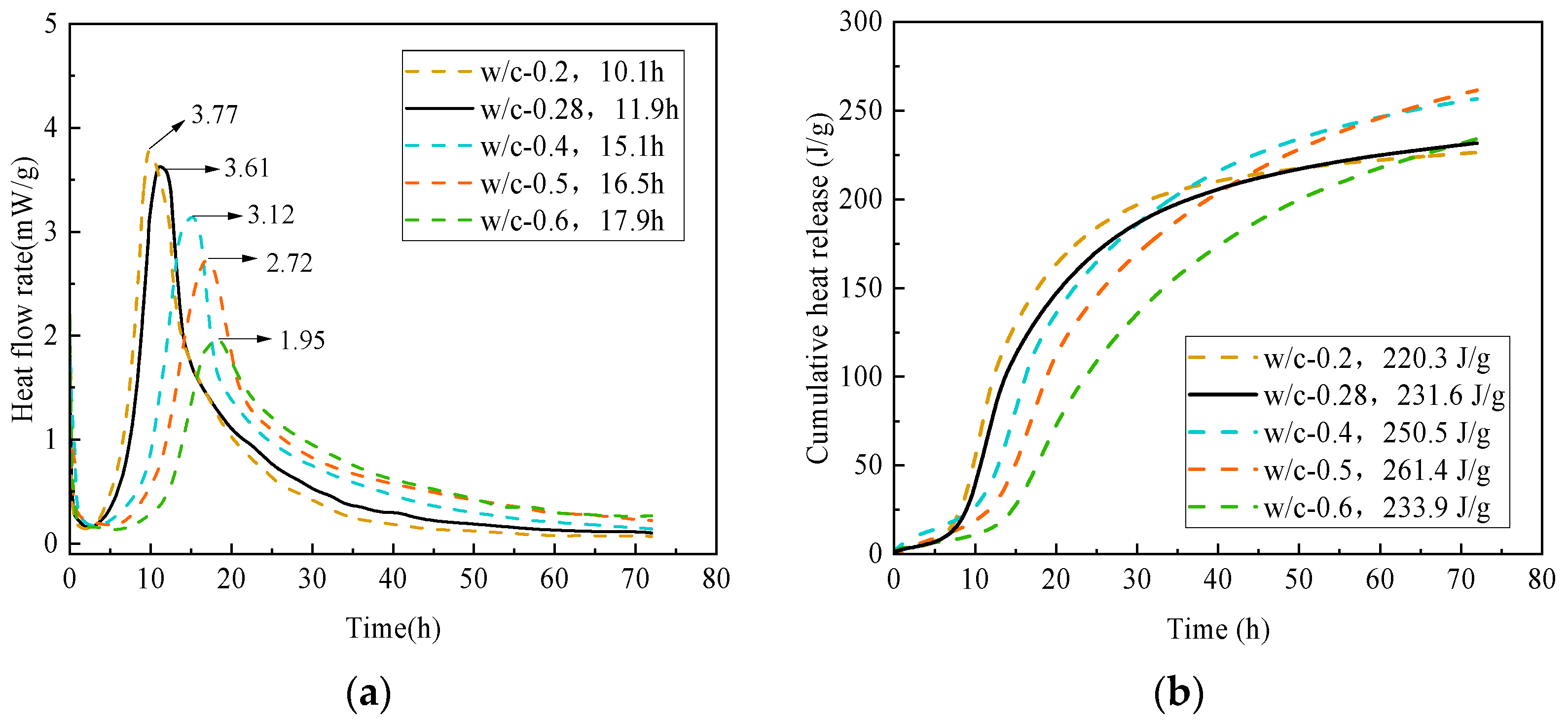

3.1. The Effect of w/b on Hydration Heat

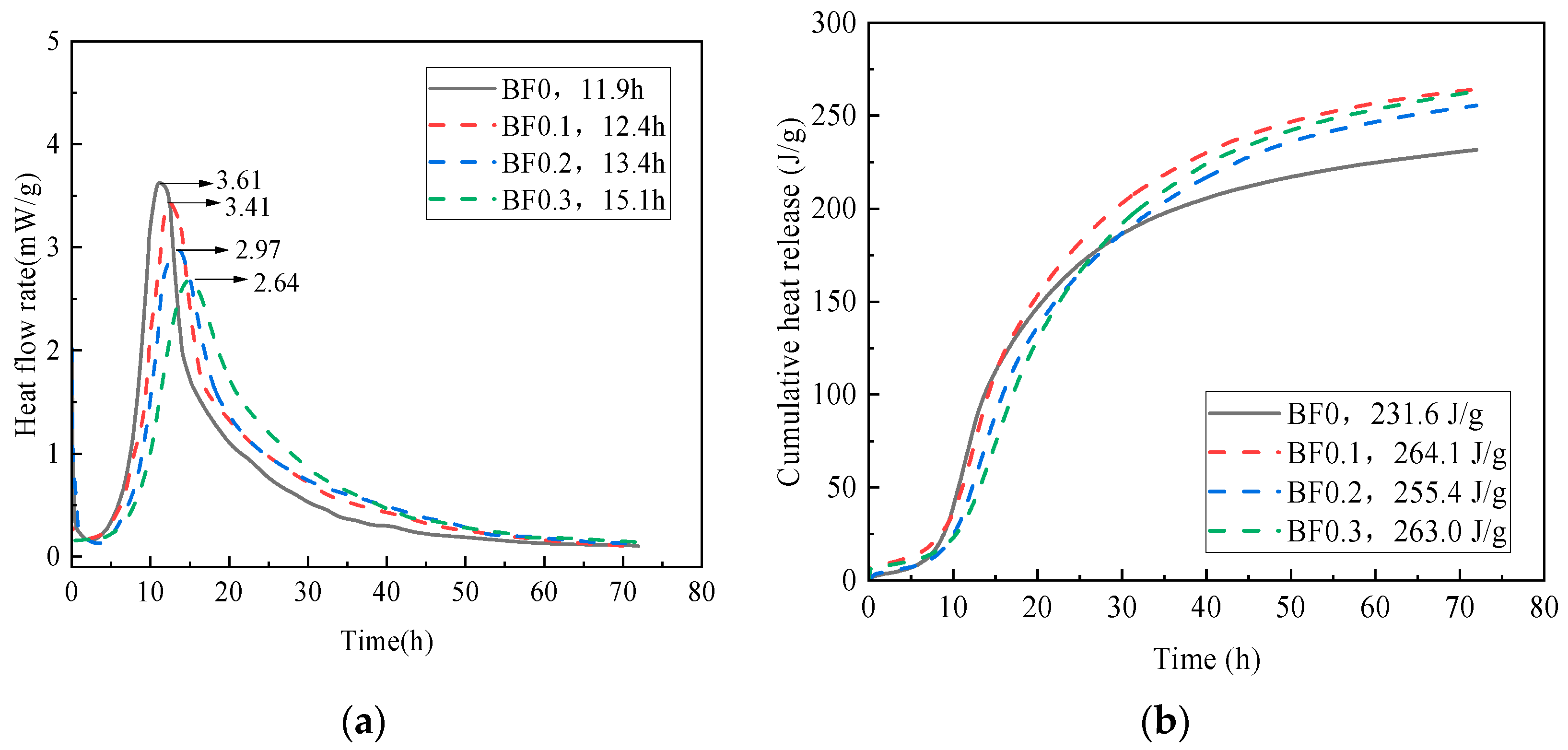

3.2. The Effect of Fibers on Hydration Heat

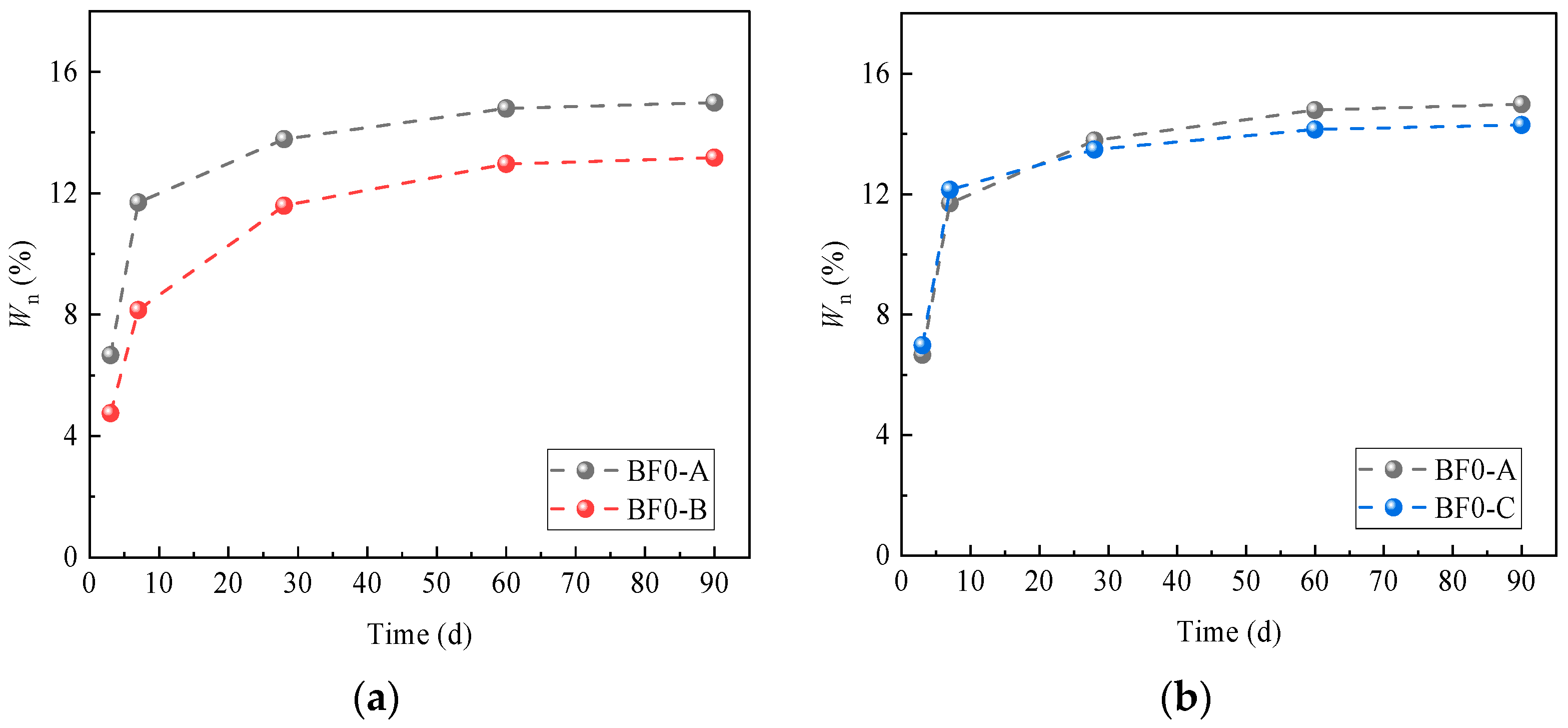

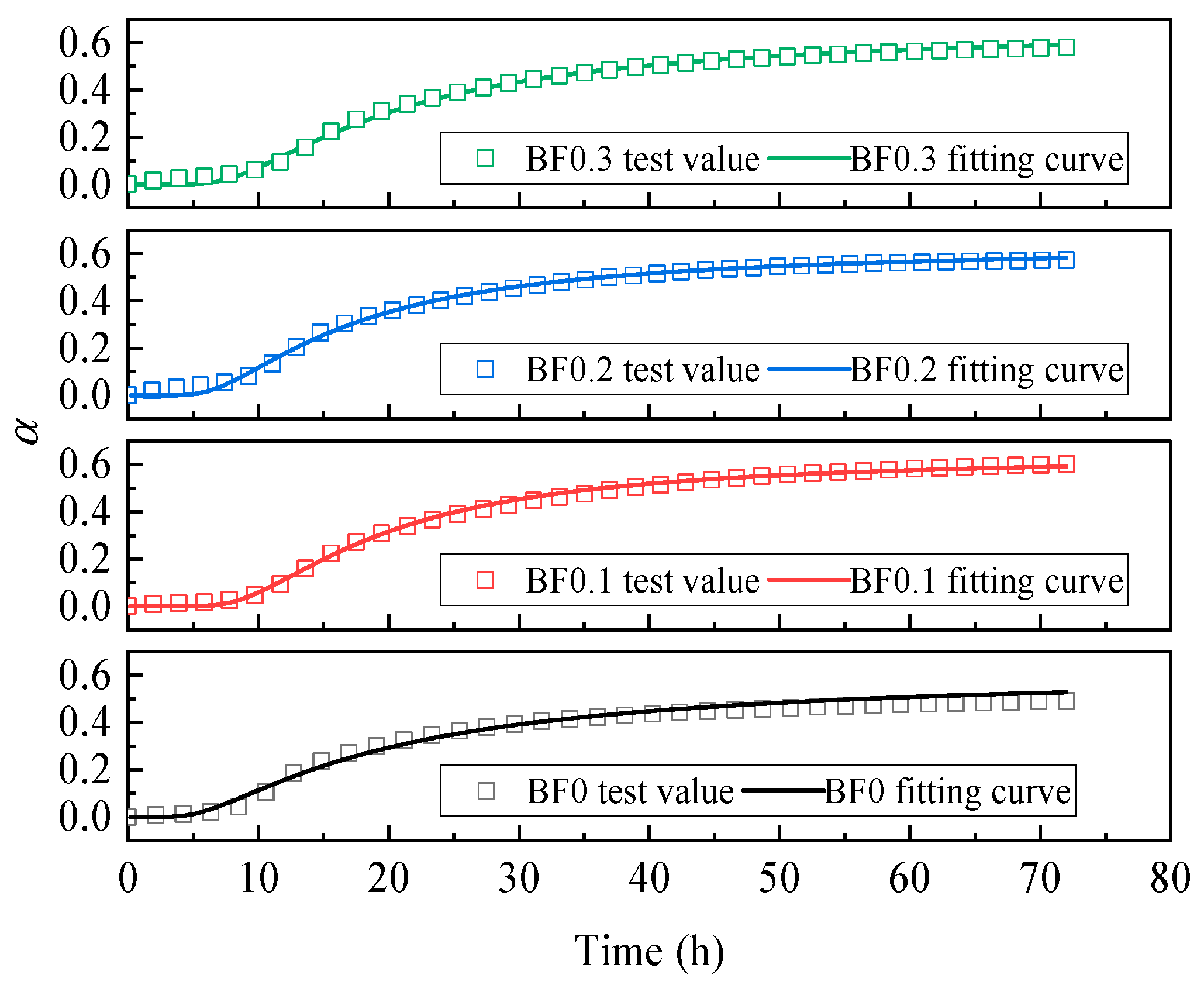

3.3. The Effect of Pre-Wetted LWA on Chemically Bound Water Content

4. Calculation Model for the Degree of Hydration

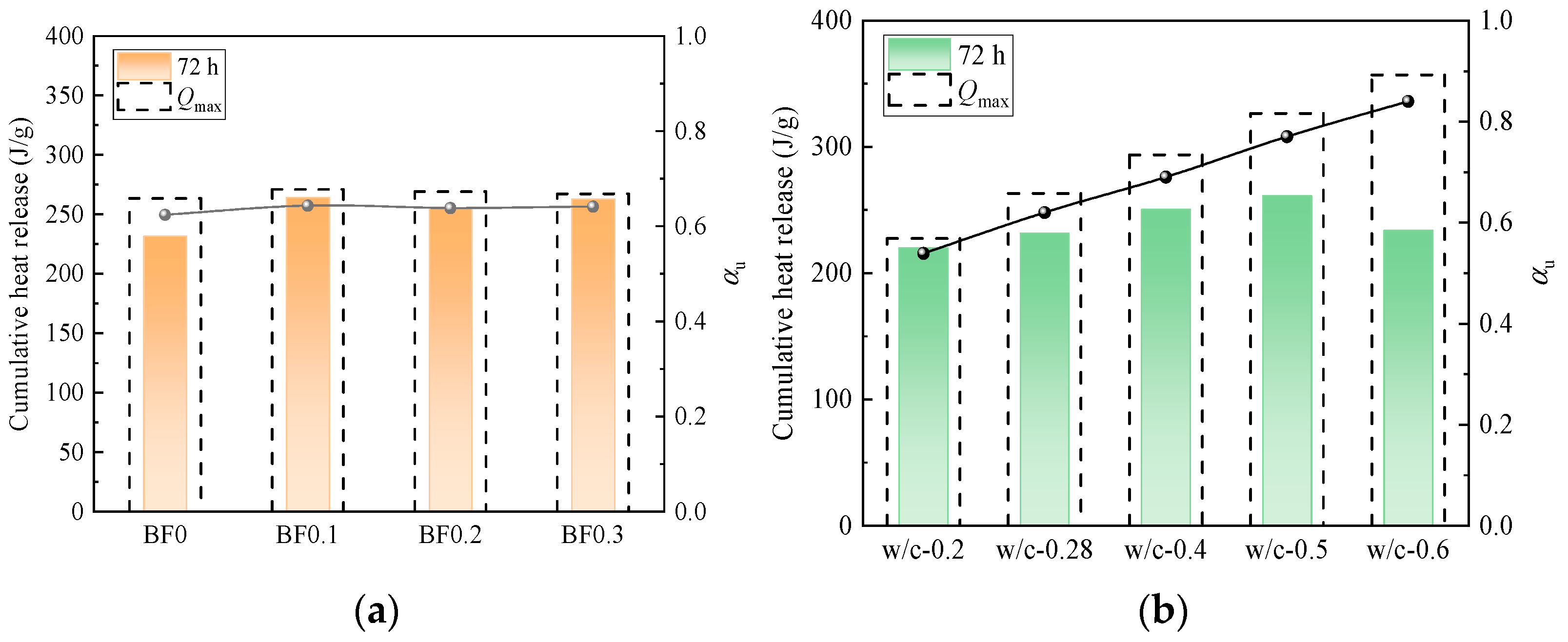

4.1. The Final Degree of Hydration

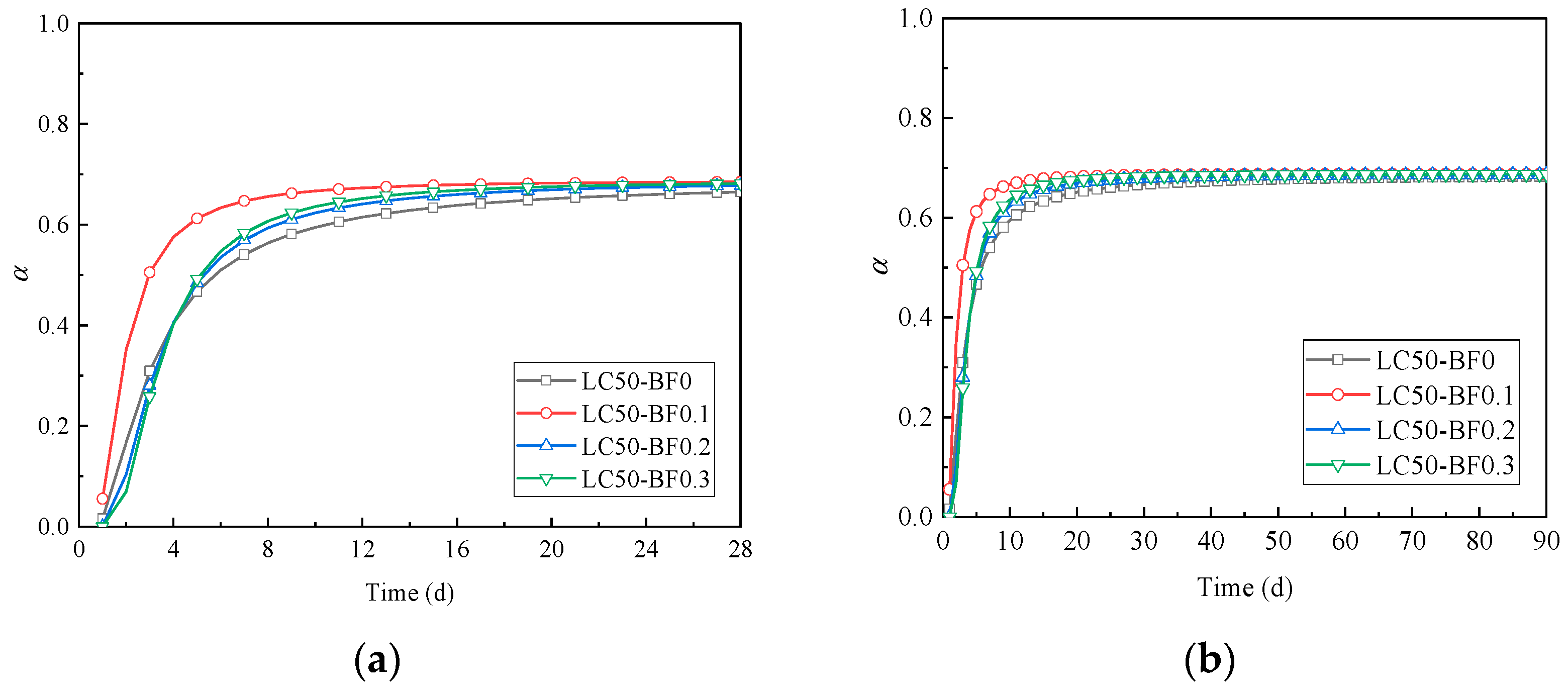

4.2. The Influence Coefficient of Pre-Wetted LWA

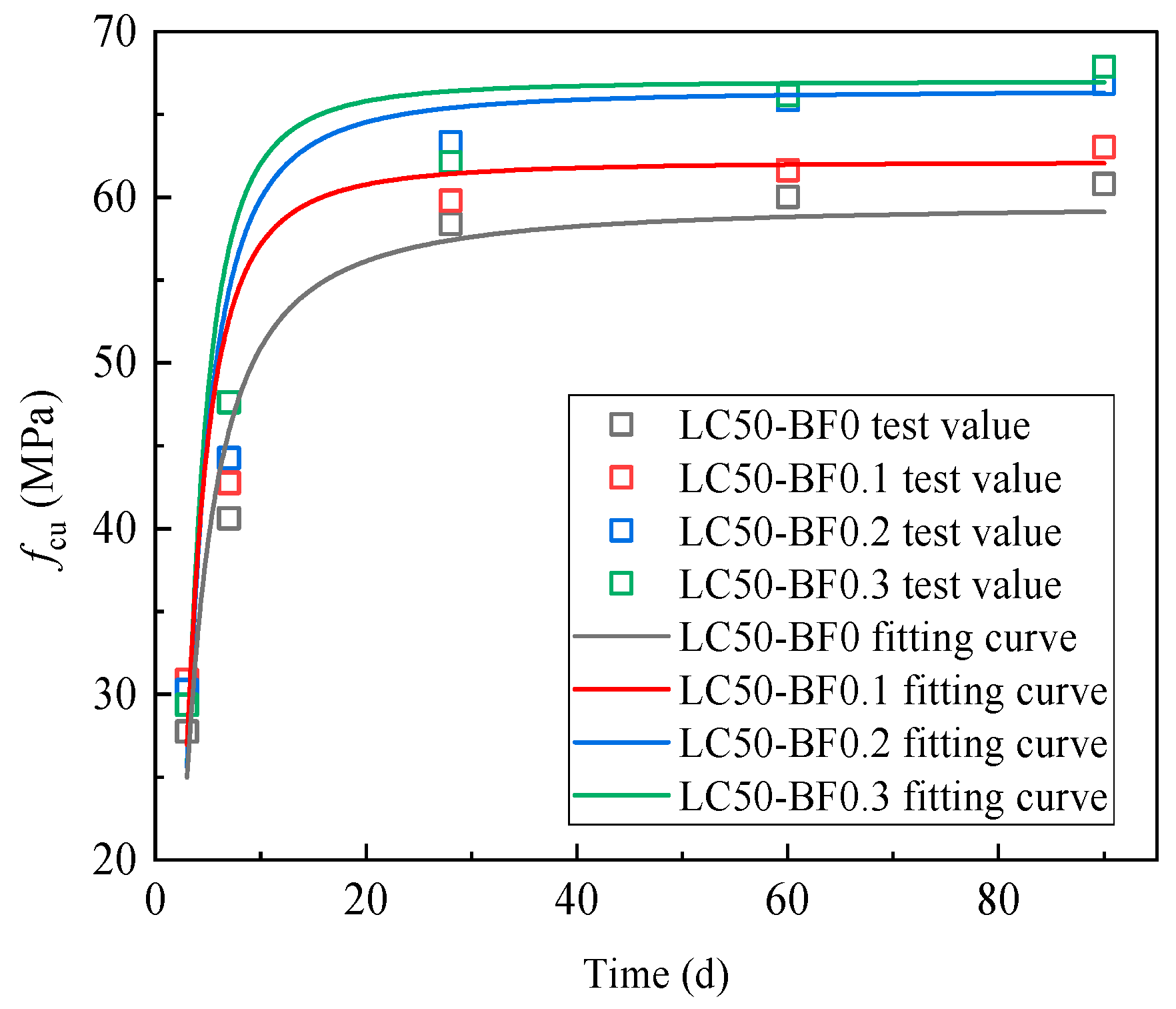

4.3. Prediction of Compressive Strength

5. Conclusions

- (1)

- The results of isothermal calorimetry tests indicated that specimens containing BF exhibited a delayed heat release peak and a lower rate of heat release peak compared to the reference group. This suggests that during the early hydration stage, the mechanical obstruction of fibers to pore connectivity significantly affects the rate of heat release in the cementitious system. However, the fitting results of the Knudsen hydration kinetics model revealed that the effect of fibers on the maximum heat release was minimal, as the maximum heat release values of the BF0–BF0.3 cementitious systems varied by no more than 3%.

- (2)

- The results of chemically bound water content tests indicated that, under identical net water content conditions, the specimens with pre-wetted LWAs were consistently higher than those of non-pre-wetted LWAs at all ages. Under identical total water content conditions, the long-term hydration performance of non-pre-wetted specimens was inferior to that of pre-wetted specimens. This suggests that pre-wetting treatment of low-water-absorption LWAs can contribute to maintaining an effective water-to-binder ratio and sustaining the progression of long-term hydration.

- (3)

- Based on the cumulative heat release data of the ternary cementitious system comprising cement, FA, and SF under different w/b, the final degree of hydration was deduced in conjunction with the Knudsen hydration kinetics model. This enabled the adjustment of the calculation model for the final degree of hydration in the ternary cementitious system. Through fitting, the influence coefficients M and N of SF and FA on the final degree of hydration were determined to be 0.312 and 0.407, respectively.

- (4)

- Two influence coefficients related to LWAs, namely the final degree of hydration influence coefficient β1 and the hydration rate influence coefficient β2, were introduced to establish the calculation model for the degree of hydration in fiber-reinforced LWAC. Based on this calculation model, a compressive strength prediction model was developed, and the fitting results showed good agreement with the experimental values, with all determination coefficients exceeding 0.85.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Liao, Q.; Lu, S.Y.; Zhang, C.P.; Lu, J.X.; Li, B.X.; Duan, Z.H.; Pang, C.M.; Poon, C.S. Improving expansion and mechanical properties of sustainable high-strength lightweight concrete incorporating cold-bonded lightweight core-shell aggregates. Constr. Build. Mater. 2025, 474, 141095. [Google Scholar] [CrossRef]

- Meng, L.Q.; Zhang, C.X.; Wei, J.Q.; Li, L.; Liu, J.B.; Wang, S.H.; Ding, Y.H. Mechanical properties and microstructure of ultra-high strength concrete with lightweight aggregate. Case Stud. Constr. Mater. 2023, 18, e01745. [Google Scholar] [CrossRef]

- Sifan, M.; Nagaratnam, B.; Thamboo, J.; Poologanathan, K.; Corradi, M. Development and prospectives of lightweight high strength concrete using lightweight aggregates. Constr. Build. Mater. 2023, 362, 129628. [Google Scholar] [CrossRef]

- Gao, Y.; Han, X.; Su, X.C. Analysis of applicability and influencing factors of elastic modulus prediction model of lightweight aggregate concrete. Constr. Build. Mater. 2025, 462, 140022. [Google Scholar] [CrossRef]

- Wu, T.; Yang, X.; Wei, H.; Liu, X. Mechanical properties and microstructure of lightweight aggregate concrete with and without fibers. Constr. Build. Mater. 2019, 199, 526–539. [Google Scholar] [CrossRef]

- Zhao, C.G.; Wang, Z.Y.; Zhu, Z.Y.; Guo, Q.Y.; Wu, X.R.; Zhao, R.D. Research on different types of fiber reinforced concrete in recent years: An overview. Constr. Build. Mater. 2023, 365, 130075. [Google Scholar] [CrossRef]

- Wu, R.D.; Gu, Q.; Gao, X.; Luo, Y.; Zhang, H.L.; Tian, S.; Ruan, Z.X.; Huang, J. Effect of basalt fibers and silica fume on the mechanical properties, stress-strain behavior, and durability of alkali-activated slag-fly ash concrete. Constr. Build. Mater. 2024, 418, 135440. [Google Scholar] [CrossRef]

- Yu, W.X.; Jin, L.; Du, X.L. Experimental investigation on splitting-tension failures of basalt fiber-reinforced lightweight aggregate concrete: Effects of strain rate and structure size. J. Build. Eng. 2023, 68, 105853. [Google Scholar] [CrossRef]

- Saradar, A.; Nemati, P.; Paskiabi, A.S.; Moein, M.M.; Moez, H.; Vishki, E.H. Prediction of mechanical properties of lightweight basalt fiber reinforced concrete containing silica fume and fly ash: Experimental and numerical assessment. J. Build. Eng. 2020, 32, 101732. [Google Scholar] [CrossRef]

- Li, S.P.; Sun, Y.; Qian, Y.; Chen, W.J.; Hu, J.H. Flexural behaviour of post-tensioned precast beams manufactured with basalt-fibre-reinforced recycled concrete-conventional concrete. J. Build. Eng. 2024, 89, 109154. [Google Scholar] [CrossRef]

- Yu, W.X.; Jin, L.; Du, X.L. Experimental study on compression failure characteristics of basalt fiber-reinforced lightweight aggregate concrete: Influences of strain rate and structural size. Cem. Concr. Compos. 2023, 138, 104985. [Google Scholar] [CrossRef]

- Zhang, B.; Zhang, X.; Wang, M.; Zhang, D.; Wang, D.; Ma, X. Improvement in the Recycled Aggregate Replacement Ratio in Concrete Pavement Bricks by Incorporating Nano-Calcium Carbonate and Basalt Fibre: Model Experiment Investigation. Buildings 2025, 15, 2070. [Google Scholar] [CrossRef]

- Chidiac, S.E.; Shafikhani, M. Cement degree of hydration in mortar and concrete. J. Therm. Anal. Calorim. 2019, 138, 2305–2313. [Google Scholar] [CrossRef]

- Kim, H.K.; Lee, H.K. Hydration kinetics of high-strength concrete with untreated coal bottom ash for internal curing. Cem. Concr. Compos. 2018, 91, 67–75. [Google Scholar] [CrossRef]

- Thongsanitgarn, P.; Wongkeo, W.; Chaipanich, A. Hydration and Compressive Strength of Blended Cement Containing Fly Ash and Limestone as Cement Replacement. J. Mater. Civ. Eng. 2014, 26, 04014088. [Google Scholar] [CrossRef]

- Abouelnour, M.A.; Fathy, I.N.; Mahmoud, A.A.; Alturki, M.; Abdelaziz, M.M.; Mostafa, S.A.; Mahmoud, K.A.; Dahish, H.A.; Nabil, I.M.; Fattouh, M.S. Valorization of nano additives effects on the physical, mechanical and radiation shielding properties of high strength concrete. Sci. Rep. 2025, 15, 14440. [Google Scholar] [CrossRef]

- Chen, X.D.; Wu, S.X. Influence of water-to-cement ratio and curing period on pore structure of cement mortar. Constr. Build. Mater. 2013, 38, 804–812. [Google Scholar] [CrossRef]

- Abriak, Y.; Chu, D.C.; Maherzi, W.; Benzerzour, M.; Rivard, P. Influence of fine recycled concrete aggregates use on the hydration kinetics and mechanical-microstructural properties of hydrated cement: Experimental and numerical approaches. Constr. Build. Mater. 2023, 408, 133769. [Google Scholar] [CrossRef]

- Phung, Q.T.; Ferreira, E.; Seetharam, S.; Nguyen, V.T.; Govaerts, J.; Valcke, E. Understanding hydration heat of mortars containing supplementary cementitious materials with potential to immobilize heavy metal containing waste. Cem. Concr. Compos. 2021, 115, 103859. [Google Scholar] [CrossRef]

- Lei, D.Y.; Yu, L.; Wang, S.J.; Li, Y.; Jia, H.X.; Wu, Z.Y.; Bao, J.W.; Liu, J.P.; Xi, X.; Su, L. A state-of-the-art on electromagnetic and mechanical properties of electromagnetic waves absorbing cementitious composites. Cem. Concr. Compos. 2025, 157, 105889. [Google Scholar] [CrossRef]

- Lothenbach, B.; Scrivener, K.; Hooton, R.D. Supplementary cementitious materials. Cem. Concr. Res. 2011, 41, 1244–1256. [Google Scholar] [CrossRef]

- Jones, C.; Goad, D.; Hale, W.M. Examining soaking duration of coarse clay and shale lightweight aggregates for internal curing in conventional concrete. Constr. Build. Mater. 2020, 249, 118754. [Google Scholar] [CrossRef]

- Feng, Z.Z.; Shen, D.J.; Wen, C.Y.; Tang, X.J.; Jiang, G.Q. Effect of Water-to-Cement Ratios on Performance of Concrete with Prewetted Lightweight Aggregates. J. Mater. Civ. Eng. 2023, 35, 14923. [Google Scholar] [CrossRef]

- Wang, X.X.; Wang, W.J.; Li, Y.X.; Wang, L.; Duan, P.F.; Liu, Y.Z. Water absorption and desorption behavior of lightweight aggregate for internal curing in cement-based materials: A critical review. J. Build. Eng. 2025, 106, 112624. [Google Scholar] [CrossRef]

- Paul, A.; Murgadas, S.; Delpiano, J.; Moreno-Casas, P.A.; Walczak, M.; Lopez, M. The role of moisture transport mechanisms on the performance of lightweight aggregates in internal curing. Constr. Build. Mater. 2021, 268, 121191. [Google Scholar] [CrossRef]

- Lyu, Z.H.; Shen, A.Q.; Meng, W.N. Properties, mechanism, and optimization of superabsorbent polymers and basalt fibers modified cementitious composite. Constr. Build. Mater. 2021, 276, 122212. [Google Scholar] [CrossRef]

- Ja’e, I.A.; Sazrin, R.A.N.B.; Syamsir, A.; Bheel, N.; Amaechi, C.V.; Min, T.H.; Anggraini, V. Optimisation of mechanical properties and impact resistance of basalt fibre reinforced concrete containing silica fume: Experimental and response surface assessment. Dev. Built Environ. 2024, 17, 100368. [Google Scholar] [CrossRef]

- GB/T 17431.1; Lightweight Aggregates and Its Test Methods-Part 1: Lightweight Aggregates. Standardization Administration of the People’s Republic of China: Beijing, China, 2010.

- JGJ/T 12-2019; Technical Standard for Application of Lightweight Aggregate Concrete. Ministry of Housing and Urban-Rural Development of the People’s Republic of China: Beijing, China, 2019.

- GB/T 50080-2016; Standard for Test Method of Performanceon Ordinary Fresh Concrete. Ministry of Housing and Urban-Rural Development of China: Beijing, China, 2016.

- GB/T 50081-2019; Standard for Test Methods of Concrete Physical and Mechanical Properties. Ministry of Housing and Urban-Rural Development of the People’s Republic of China: Beijing, China, 2019.

- Snellings, R.; Machner, A.; Bolte, G.; Kamyab, H.; Durdzinski, P.; Teck, P.; Zajac, M.; Muller, A.; de Weerdt, K.; Ben Haha, M. Hydration kinetics of ternary slag-limestone cements: Impact of water to binder ratio and curing temperature. Cem. Concr. Res. 2022, 151, 106647. [Google Scholar] [CrossRef]

- Li, D.Z.; Du, C.B.; Yi, F.; Li, F.; Li, S. Performance and microstructural characterization of fiber-reinforced cement-based grout incorporating waste tailing sand and fly ash. Mater. Today Commun. 2024, 41, 110289. [Google Scholar] [CrossRef]

- Hruby, P.; Kalina, L.; Másilko, J.; Porizka, J.; Soukal, F.; Nevrly, V.; Kimm, M.; Gries, T. Stability of Basalt-Fibres Reinforcement in Alkali-Activated Systems. Mater. Technol. 2020, 54, 203–210. [Google Scholar] [CrossRef]

- Wang, D.X.; Wang, H.W.; Larsson, S.; Benzerzour, M.; Maherzi, W.; Amar, M. Effect of basalt fiber inclusion on the mechanical properties and microstructure of cement-solidified kaolinite. Constr. Build. Mater. 2020, 241, 118085. [Google Scholar] [CrossRef]

- Zhang, J.L.; Zhang, N.; Wang, Y.D.; Lu, P.; Wu, N.J.; Li, C.; Zhang, Y.H. Superior reinforcement efficiency of basalt fibers in geopolymers: Hydration interaction and embodied carbon advantage over carbon fibers. Sustain. Mater. Technol. 2025, 43, e01203. [Google Scholar] [CrossRef]

- Bello, L.; Garcia-Diaz, E.; Rougeau, P. An original test method to assess water absorption/desorption of lightweight aggregates in presence of cement paste. Constr. Build. Mater. 2017, 154, 752–762. [Google Scholar] [CrossRef]

- Schindler, A.K.; Folliard, K.J. Heat of hydration models for cementitious materials. ACI Mater. J. 2005, 102, 24–33. [Google Scholar] [CrossRef] [PubMed]

- Langan, B.W.; Weng, K.; Ward, M.A. Effect of silica fume and fly ash on heat of hydration of Portland cement. Cem. Concr. Res. 2002, 32, 1045–1051. [Google Scholar] [CrossRef]

- Knudsen, T. On particle size distribution in cement hydration. In Proceedings of the 7th International Congress on the Chemistry of Cements, Paris, France, 30 June–4 July 1980; pp. 170–175. [Google Scholar]

- Mills R, H. Factors influencing cessation of hydration in water-cured cement pastes. In Proceedings of the Symposium on the Structure of Portland Cement Paste and Concrete, Washington, DC, USA, 13–14 June 1966; pp. 406–424. [Google Scholar]

- Luzio, G.D.; Cusatis, G. Hygro-thermo-chemical modeling of high performance concrete. I: Theory. Cem. Concr. Compos. 2009, 31, 301–308. [Google Scholar] [CrossRef]

- Marsh, B.K.; Day, R.L. Pozzolanic and cementitious reactions of fly ash blended cement pastes. Cem. Concr. Res. 1998, 18, 301–310. [Google Scholar] [CrossRef]

- Bonen, D.; Khayat, K.H. Characterization and pozzolanic properties of silica fume stored in an open pond. Cem. Concr. Res. 1995, 25, 395–407. [Google Scholar] [CrossRef]

- Fei, X.P.; Guo, L.P.; Lu, J.T.; Shen, H.R.; Chen, H.T.; Rui, Z.Q. Modeling and analysis of hydration in cementitious composites with ultra-high dosage of fly ash: Hydrates and microstructure evolutions. Constr. Build. Mater. 2025, 470, 140557. [Google Scholar] [CrossRef]

- Kurylowicz-Cudowska, A. Correlation between Compressive Strength and Heat of Hydration of Cement Mortars with Siliceous Fly Ash. Minerals 2022, 12, 1471. [Google Scholar] [CrossRef]

- De Schutter, G.; Taerwe, L. Degree of hydration-based description of mechanical propertiesof early age concrete. Mater. Struct. 1996, 29, 335–344. [Google Scholar] [CrossRef]

| Type | Chemical Composition/% | Specific Gravity/kg/m3 | Specific Surface/m2/kg | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| CaO | SiO2 | Al2O3 | Fe2O3 | SO3 | MgO | Other | LOI | |||

| OPC | 63.38 | 20.87 | 5.43 | 2.76 | 2.56 | 1.53 | 1.31 | 2.16 | 3100 | 350 |

| FA | 3.67 | 52.08 | 25.17 | 7.26 | 1.36 | 2.73 | 5.49 | 2.24 | 2200 | 540 |

| SF | 0.41 | 95.11 | 0.82 | 0.48 | 0.18 | 0.72 | 0.41 | 1.87 | 2110 | 20,000 |

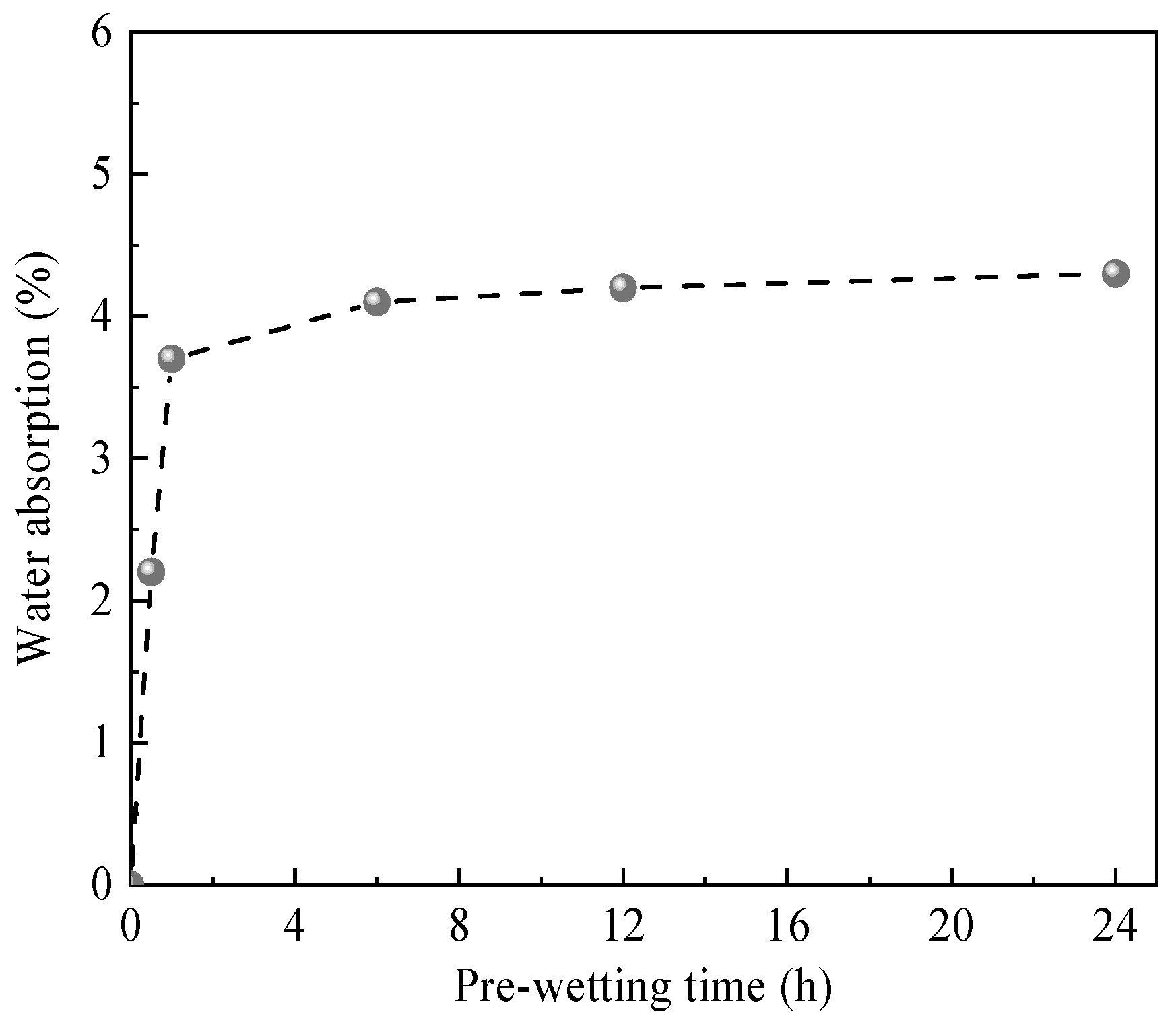

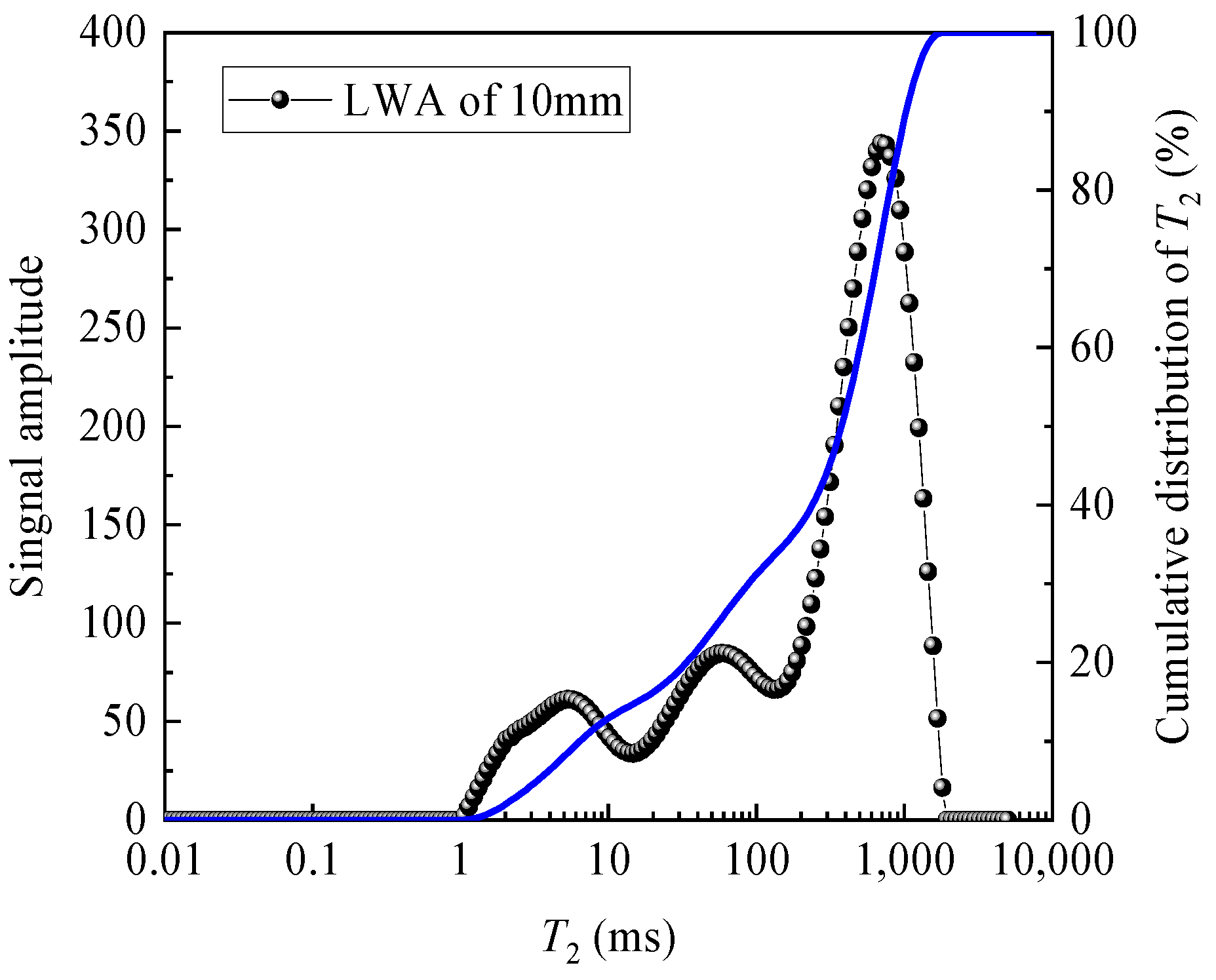

| Grain Size/mm | Bulk Density/kg/m3 | Apparent Density/kg/m3 | Moisture Content/% | Water Absorption/% | Cylinder Compressive Strength/MPa | |

|---|---|---|---|---|---|---|

| 1 h | 24 h | |||||

| 5–16 | 869 | 1460 | 0.3 | 3.7 | 4.2 | 6.9 |

| Grain Size/mm | Bulk Density/kg/m3 | Apparent Density/kg/m3 | Fineness Modulus |

|---|---|---|---|

| 0–4.75 | 1520 | 2640 | 2.6 |

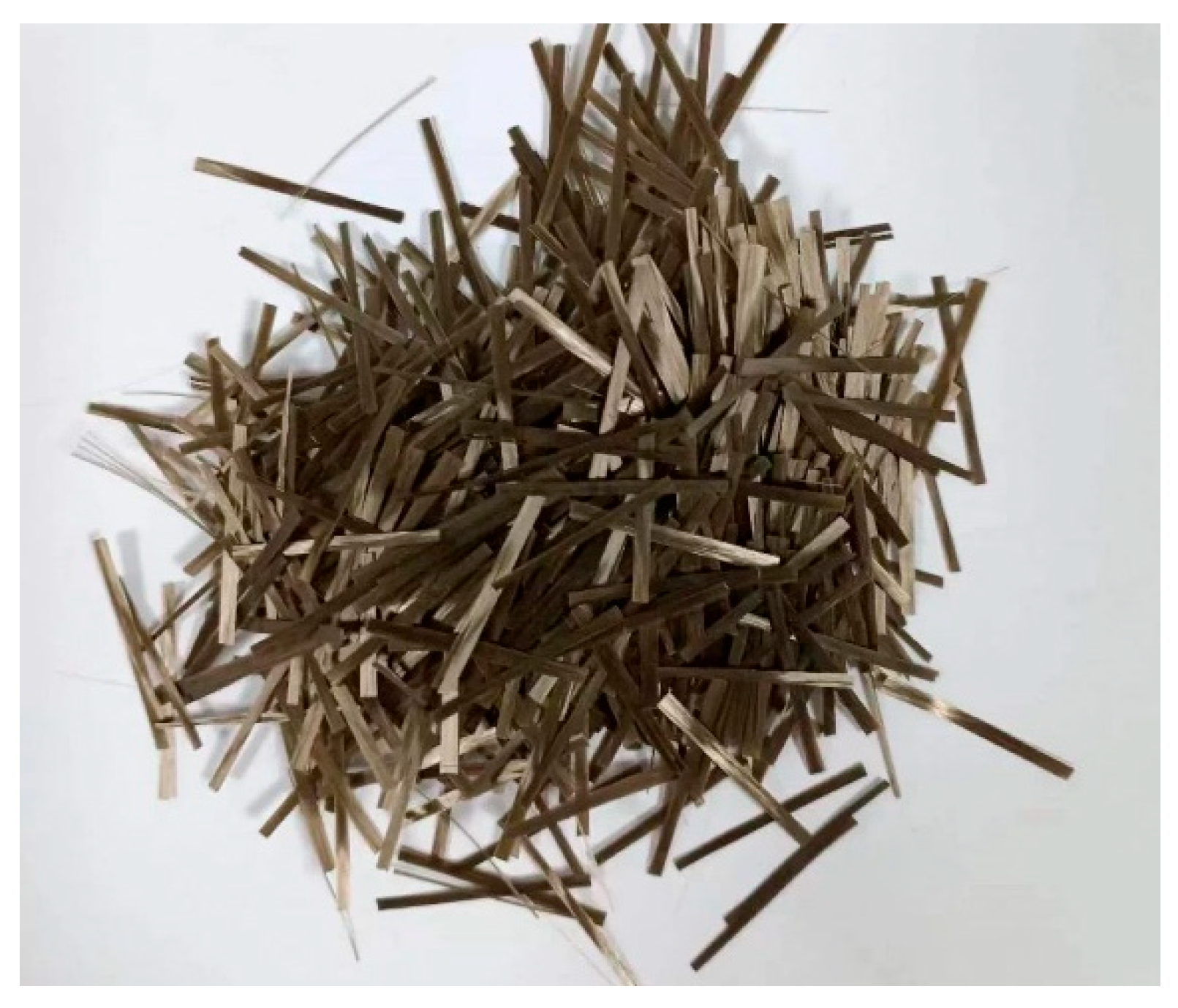

| Density/kg/m3 | Length/mm | Diameter/mm | Tensile Strength/MPa | Elastic Modulus/GPa | Ultimate Elongation/% |

|---|---|---|---|---|---|

| 2650 | 18 | 0.013 | 3000–4800 | 91–110 | 3.0–3.2 |

| No. | Materials (kg/m3) | BF (%) | fcu,28 (MPa) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| OPC | FA | SF | LWAs | Fine Aggregate | Water * | SP | |||

| LC50-BF0 | 385 | 110 | 55 | 568 | 684 | 154 | 2.2 | 0 | 58.4 |

| LC50-BF0.1 | 385 | 110 | 55 | 568 | 684 | 154 | 4.3 | 0.1 | 59.8 |

| LC50-BF0.2 | 385 | 110 | 55 | 568 | 684 | 154 | 4.6 | 0.2 | 63.3 |

| LC50-BF0.3 | 385 | 110 | 55 | 568 | 684 | 154 | 4.9 | 0.3 | 62.1 |

| No. | w/b | OPC (%) | FA (%) | SF (%) | BF (%) |

|---|---|---|---|---|---|

| BF0 (w/b-0.28) | 0.28 | 70 | 20 | 10 | 0 |

| BF0.1 | 0.28 | 70 | 20 | 10 | 0.1 |

| BF0.2 | 0.28 | 70 | 20 | 10 | 0.2 |

| BF0.3 | 0.28 | 70 | 20 | 10 | 0.3 |

| w/b-0.2 | 0.2 | 70 | 20 | 10 | 0 |

| w/b-0.4 | 0.4 | 70 | 20 | 10 | 0 |

| w/b-0.5 | 0.5 | 70 | 20 | 10 | 0 |

| w/b-0.6 | 0.6 | 70 | 20 | 10 | 0 |

| No. | Materials (kg/m3) | BF (%) | fcu,28 (MPa) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| OPC | FA | SF | LWAs | Fine Aggregate | Water * | SP | |||

| BF0-A | 385 | 110 | 55 | 568 | 684 | 154 | 2.2 | 0 | 58.4 |

| BF0-B | 385 | 110 | 55 | 568 | 684 | 154 | 2.8 | 0 | 55.1 |

| BF0-C | 385 | 110 | 55 | 568 | 684 | 175 | 2.0 | 0 | 53.6 |

| No. | Knudsen Equation | Qmax | R2 |

|---|---|---|---|

| BF0 (w/c-0.28) | 1/Q = 0.03123/(t − t0) + 0.00379 | 263.24 | 0.994 |

| BF0.1 | 1/Q = 0.03391/(t − t0) + 0.00369 | 270.83 | 0.986 |

| BF0.2 | 1/Q = 0.03306/(t − t0) + 0.00372 | 269.15 | 0.989 |

| BF0.3 | 1/Q = 0.04162/(t − t0) + 0.00376 | 266.19 | 0.992 |

| w/c-0.2 | 1/Q = 0.03111/(t − t0) + 0.00439 | 227.38 | 0.992 |

| w/c-0.4 | 1/Q = 0.03837/(t − t0) + 0.00341 | 293.61 | 0.995 |

| w/c-0.5 | 1/Q = 0.04296/(t − t0) + 0.00306 | 326.52 | 0.993 |

| w/c-0.6 | 1/Q = 0.04561/(t − t0) + 0.00280 | 356.89 | 0.997 |

| No. | a | b | R2 |

|---|---|---|---|

| BF0 | 14.45 | 1.41 | 0.995 |

| BF0.1 | 14.22 | 1.91 | 0.996 |

| BF0.2 | 15.99 | 1.84 | 0.998 |

| BF0.3 | 16.78 | 2.09 | 0.996 |

| No. | αu | β1 | β2 | R2 |

|---|---|---|---|---|

| BF0-A | 0.630 | 1.092 | 4.25 | 0.989 |

| BF0-B | 0.630 | 0.938 | 5.42 | 0.951 |

| No. | η | μ | R2 |

|---|---|---|---|

| LC50-BF0 | 1.02 | 6.15 | 0.95 |

| LC50-BF0.1 | 1.04 | 16.04 | 0.85 |

| LC50-BF0.2 | 1.05 | 11.85 | 0.87 |

| LC50-BF0.3 | 1.08 | 16.64 | 0.88 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, Y.; Jia, H.; Wang, J.; Ding, Y.; Guan, Y.; Lei, D.; Li, Y. Calculation Model for the Degree of Hydration and Strength Prediction in Basalt Fiber-Reinforced Lightweight Aggregate Concrete. Buildings 2025, 15, 2699. https://doi.org/10.3390/buildings15152699

Sun Y, Jia H, Wang J, Ding Y, Guan Y, Lei D, Li Y. Calculation Model for the Degree of Hydration and Strength Prediction in Basalt Fiber-Reinforced Lightweight Aggregate Concrete. Buildings. 2025; 15(15):2699. https://doi.org/10.3390/buildings15152699

Chicago/Turabian StyleSun, Yanqun, Haoxuan Jia, Jianxin Wang, Yanfei Ding, Yanfeng Guan, Dongyi Lei, and Ying Li. 2025. "Calculation Model for the Degree of Hydration and Strength Prediction in Basalt Fiber-Reinforced Lightweight Aggregate Concrete" Buildings 15, no. 15: 2699. https://doi.org/10.3390/buildings15152699

APA StyleSun, Y., Jia, H., Wang, J., Ding, Y., Guan, Y., Lei, D., & Li, Y. (2025). Calculation Model for the Degree of Hydration and Strength Prediction in Basalt Fiber-Reinforced Lightweight Aggregate Concrete. Buildings, 15(15), 2699. https://doi.org/10.3390/buildings15152699