1. Introduction and Background: Traditional Timber Structures

Traditional timber structures have played a vital role in the architectural heritage of many regions worldwide, especially in areas prone to seismic activity. Examples like the Chuan-dou timber frames in China, Japanese pagodas, and European half-timbered houses demonstrate remarkable resilience to seismic forces. Understanding their seismic performance is essential not only for preserving these historical structures but also for integrating their resilient design features into modern construction practices [

1,

2].

Timber’s flexibility, lightweightness, and energy dissipation make it ideal for seismic resistance, along with its structural configuration and connections. Some joinery techniques found in traditional timber structures further enhance their seismic resilience, as mentioned in [

3]. Timber’s anisotropy, damping capacity, and ability to deform without failing are key to its seismic behavior [

4,

5]. Additionally, timber’s flexibility and energy-dissipating capacity help reduce the impact of seismic forces [

4,

6].

The structural configuration of timber buildings plays a critical role in their seismic performance. The arrangement of beams, columns, and infill materials enhances the structure’s ability to resist seismic forces. For instance, ref. [

7] demonstrated that masonry infill in traditional Chinese timber frames significantly improves load capacity and energy dissipation, highlighting its importance in seismic resilience. Similarly, studies like [

8,

9] on Taiwanese timber shear walls revealed that traditional design elements, such as the friction between board units and beams, along with embedment resistance, are key factors in resisting lateral forces.

Likewise, joints between timber elements are crucial to a structure’s seismic resilience. Traditional joinery, such as mortise–tenon and dovetail joints, allows for flexibility and energy dissipation. However, these joints can degrade under repeated seismic loading if not properly maintained. Reinforcing joints with modern materials, like steel plates or advanced adhesives, could significantly improve seismic performance while preserving the historical integrity of the structures.

Historical records and experiments show timber structures’ resilience, as seen in the Great Kanto (Japan) and Sichuan (China) earthquakes, due to their flexible frameworks and energy-dissipating joints. Studies [

1,

2,

7,

10] highlight how these buildings have withstood significant seismic forces due to the effective combination of the inherent properties of wood and traditional construction techniques; for example, these traditional wood structures have shown outstanding earthquake performance due to their excellent deformation capacity and energy dissipation properties.

Experimental research has provided further evidence of the seismic resilience of traditional timber structures. For instance, ref. [

11] demonstrated through shake table tests that proper structural configuration is critical, with column-and-tie timber frames showing excellent resistance to collapse under maximum earthquake scenarios. Similarly, ref. [

12] performed pseudo-static cyclic tests on Chuan-dou timber frames with varying infill configurations, analyzing key parameters such as force deformation behavior, failure mechanisms, stiffness, and energy dissipation capacity using 1:2 scale models. More recently, ref. [

13], inspired by traditional Romanian architecture, conducted pseudo-static tests on the TRAROM lightweight timber frame system, further validating the seismic performance of timber-based designs.

Detailed case studies provide further insight into the seismic performance of specific traditional wood structures around the world. For example, ref. [

8] studied Taiwanese timber shear walls, while [

14] analyzed European timber frames (a timber frame structure called “gaiola pombalina” used in downtown Lisbon after the 1755 earthquake), emphasizing how design details—such as the use of bamboo nails in Taiwanese structures and the integration of masonry infill in European designs—affect seismic performance. Ref. [

15] further investigated the seismic behavior (strength, stiffness, ductility, and energy dissipation) of traditional Mediterranean infilled timber frame walls subjected to pseudo-static tests. The infill consists of masonry lath and plaster. The authors also tested a timber frame without infill for comparison. The tests showed how the infill was able to guarantee greater stiffness, ductility, and the ultimate capacity of the wall. Ref. [

16] performed static cyclic tests on timber frame specimens, which were constructed based on findings from field investigations of traditional Romanian buildings. Some of the specimens tested exhibited excellent deformation capacity, with drifts greater than 5%. Similarly, ref. [

17] tested double-span traditional timber structure models, highlighting that the experimental pseudo-static tests had stable hysteretic loops and that the P–Δ effect could affect the response of timber frames.

Shaking table tests and cyclic loading experiments confirm timber-framed walls with infill materials like adobe or fired bricks can withstand lateral displacements and ground accelerations without collapsing [

18]. The results indicated that walls with bamboo or timber frameworks provided superior seismic performance, particularly in terms of energy dissipation and the reduced likelihood of catastrophic failure.

Computational modeling has become an essential tool for predicting the seismic response of traditional timber structures. For example, ref. [

19] developed a hysteretic model for “frontal” walls in Pombalino buildings, providing valuable insights into their seismic behavior. Finite element analysis (FEA) has also been widely applied to simulate the performance of timber frames with various infill materials, demonstrating how different configurations influence structural response. Similarly, ref. [

20] created numerical models calibrated with the experimental results of timber frames, both with and without masonry infill, incorporating key effects such as flexural behavior, pinching, and strength degradation. Advancements in modeling techniques include shear spring models proposed in [

21], which accurately replicate initial stiffness and peak strength, effectively capturing the complex interactions between structural elements during seismic events. Various software tools have facilitated these analyses, with OpenSees employed in [

19] and ABAQUS utilized in [

22] to assess the dynamic properties of timber frame masonry systems.

While the technical literature and several reports from Colombia (northern South America) have studied the behavior of cemented bahareque (a type of timber-framed structure) with bolted connections (actually included in the Colombian earthquake-resistant code) or contemporary systems such as prefabricated wattle and daub [

23], there are few studies in the scientific literature focused on the structural behavior of traditional timber-framed bahareque modules used in the rural areas of northern South America.

The novelty of this research lies in providing the first scientific report on the structural behavior of traditional bahareque walls subjected to in-plane horizontal loads, as constructed in the Valle del Cauca and Cauca regions of Colombia. This study highlights the potential of bahareque as a safe and resilient construction system, particularly for seismically vulnerable areas. Furthermore, it offers a unique experimental comparison, under controlled and identical loading conditions, of the seismic performance of bahareque walls constructed with guadua (a bamboo-like material) versus wooden frameworks, incorporating insights into their distinct mechanical behaviors, emphasizing the role of soil infill and guadua strips in structural performance.

The primary objective of this study is to experimentally evaluate the seismic performance of traditional bahareque walls, focusing on the influence of material configurations (guadua, wood, and soil infill) on their ductility, stiffness, and failure mechanisms. Addressing a critical gap in the literature, this research provides much needed empirical data on the seismic behavior of bahareque systems, which have received limited attention despite their widespread use in rural South America. By grounding its findings in robust experimental analysis, this study not only preserves traditional construction knowledge but also lays the foundation for enhancing the seismic resilience of bahareque walls, aligning them with modern performance standards and sustainable building practices.

3. Characteristics of Bahareque-Framed Earthen Walls and Field Visits

A typology of traditional wooden structures, used for centuries in South America, Central America, and Asia [

26,

27,

28,

29]), is known as bahareque in Colombia and Ecuador (quincha in Peru, taipa de mão in Brazil). This system is renowned for its use of natural materials such as bamboo, wood, and earth, making it not only sustainable but also highly resilient in seismic zones [

30]. In recent years, these construction techniques have seen renewed interest due to their low environmental impact and inherent seismic resistance. The basic characteristic of the bahareque system (native from the Andean region of South America) is the reliance on a bamboo or wooden framework (braced and with sill beams), infilled with a mixture of soil and fibers (organic). According to [

31], this framework is usually plastered or coated with mortar to protect it from the weather.

In reference [

32], the authors mention that bamboo is a natural construction material found in tropical, sub-tropical, and mild temperate regions of at least four continents (America, Oceania, Asia, Africa). This natural material is particularly widespread in Colombia (Northern Andean region of South America), where it serves as the primary structural element of some rural and urban dwellings due to its abundance and favorable mechanical properties [

33]. As indicated in [

34], modern adaptations often use engineered bamboo products, such as laminated bamboo, which provide enhanced strength and uniformity by bonding layers of bamboo strips, making them stronger and more durable than traditional bamboo. Bamboo’s rapid growth also makes it a highly renewable resource [

35].

Bahareque is a traditional construction technique that weaves bamboo or wooden strips with mud or clay, creating walls that are both thermally efficient and highly durable. As reported in [

36], these walls can endure harsh environmental conditions and remain functional for decades with minimal maintenance. A key advantage of bahareque systems lies in their capacity to absorb and dissipate seismic energy, a result of the materials’ flexibility and lightweight nature. Bamboo-framed structures, in particular, demonstrate exceptional seismic performance due to their ability to undergo large deformations without failure. Research in [

37] highlights the critical role of joint design, such as bolted steel-to-bamboo connections, in ensuring structural strength. Similarly, ref. [

38] showed that adding diagonal bamboo strips to the walls significantly enhances seismic performance, improving both lateral load capacity and stiffness.

Field studies conducted after the 1999 Armenia earthquake in Colombia revealed that bahareque structures performed remarkably well compared to modern construction technologies. Ref. [

33] reported that houses constructed with well-maintained bahareque walls suffered minimal damage, whereas those with poorly maintained walls experienced significant failures. This underscores the importance of maintenance and the use of high-quality materials to ensure the longevity and seismic resilience of these structures.

Additionally, several studies have highlighted the potential of combining traditional materials with modern construction techniques. For instance, ref. [

23,

39] explored bahareque in contemporary construction, demonstrating its viability as an alternative to conventional materials, especially for low-income housing projects in seismic regions. Combining traditional bahareque techniques with modern materials, such as reinforced concrete for foundations, can further enhance the seismic performance of these structures.

Hybrid wood–soil systems (HWSs), particularly those integrating bamboo, wood, and soil, have gained attention for their potential to meet global housing demands sustainably. Traditional systems like bahareque, prevalent in Latin America, utilize natural materials such as bamboo, soil, and mortar, providing low-cost and environmentally friendly solutions [

31]. Modern iterations of HWSs have adapted these techniques to incorporate engineered materials, improving performance under seismic and environmental conditions [

34]. Studies demonstrate that combining traditional materials with engineered components enhances durability, resilience, and adaptability, making HWSs a promising solution in addressing housing deficits while reducing environmental impacts.

Comparative evaluations of traditional and modern HWSs reveal significant advantages for engineered systems in terms of environmental impact and scalability. Ref. [

40] conducted a comprehensive life cycle assessment of bamboo-based construction systems, showing that engineered bamboo, particularly glue-laminated bamboo, significantly reduces CO

2 emissions compared to traditional systems. The environmental savings result from reduced material weight and lower energy consumption during processing and transport, allowing for its use in multi-story construction. Similarly, ref. [

35] highlighted the superior renewability of bamboo as a resource, noting its rapid growth and carbon sequestration capabilities, which further enhance the sustainability of HWSs.

The bahareque construction system stands out as a highly sustainable solution due to its reliance on locally available and renewable materials, such as guadua (a bamboo-like material) and soil. Studies have shown that guadua angustifolia, a species widely used in Colombia, captures significant amounts of CO

2 during its growth cycle, contributing to carbon sequestration and reducing the overall environmental footprint of the material. According to [

40], bamboo-based construction systems, including traditional bahareque-cemented systems (bahareque coated with a thin layer of cement mortar), exhibit lower carbon emissions compared to conventional materials like concrete and brick, particularly when transportation distances are minimized. The minimal energy required to process bamboo or guadua and the use of soil further reduce the embodied energy of bahareque walls, making them an eco-friendly choice for construction in rural and low-income regions. Additionally, promoting the use of the local and decentralized production of materials (as suggested by [

40]) can significantly lower transportation impacts, making the system even more viable for remote regions. However, challenges remain regarding the optimization of the bahareque system to enhance its environmental benefits. Traditional bahareque-cemented systems use mortar or cement plaster for weather protection, which can increase its carbon footprint. Efforts to reduce this dependency through natural coatings or alternative binders could further improve sustainability.

Structural performance is another key advantage of HWSs. Ref. [

28] analyzed cemented bahareque systems under seismic loads, concluding that their structural behavior meets earthquake resistance criteria. These findings align with the work presented in [

34], which demonstrated that multi-story bamboo frames achieve high levels of seismic resilience through improved joint design and dynamic load management. Furthermore, ref. [

41] emphasized that hybrid construction systems like engineered bahareque housing maintain affordability while offering enhanced strength and durability, making them particularly suited for low-income housing in seismically active regions.

Despite these advancements, challenges remain in expanding the adoption of HWSs. Traditional bahareque systems are labor-intensive, requiring significant manual effort for construction [

31], while engineered systems depend on centralized production and advanced manufacturing, increasing costs [

40]. Optimizing transport logistics and decentralizing production centers, as suggested in [

40], can mitigate these challenges. Moreover, integrating sustainable design principles, as outlined in [

35], and leveraging bamboo’s environmental benefits can further strengthen the role of HWSs in promoting sustainable development. These systems exemplify how traditional knowledge and modern engineering can converge to provide affordable, resilient, and sustainable housing solutions.

In addition, studies such as [

42] emphasize the importance of preserving and adapting traditional construction methods (in response to modern challenges), such as timber framing like frontal real in Portugal or bahareque in Colombia. These traditional techniques not only provide a connection to cultural heritage but also offer practical solutions for building in seismic zones. The application of these methods in contemporary contexts is further supported by environmental and sustainability considerations.

Globally, traditional seismic-resistant systems have developed to address earthquake challenges, sharing commonalities with bahareque walls in their use of natural materials and energy-dissipating features. For instance, Japanese timber pagodas rely on mortise and tenon joinery to dissipate seismic energy, while Chuan-dou timber frames in China use diagonal bracing and infill panels for lateral stiffness and ductility. Similarly, gaiola pombalina structures in Portugal integrate timber frames with masonry infill, combining flexibility and strength, and bamboo-based construction in South Asia demonstrates the importance of lightweight, flexible materials for seismic resilience.

These global examples highlight the universality of traditional systems in prioritizing resilience and sustainability. Bahareque walls, like these practices, provide a heritage-based yet innovative approach to seismic-resistant construction. This study builds on these global lessons by experimentally analyzing bahareque walls under controlled conditions, emphasizing their potential as a sustainable and seismic-resistant solution.

Furthermore, contemporary research has begun to formalize traditional practices into hybrid approaches. Engineered bamboo frames and advanced joinery techniques, for example, combine traditional materials with modern performance standards. This aligns with the objectives of this study, bridging traditional bahareque methods with experimental validation to strengthen their integration into global practices for resilient construction.

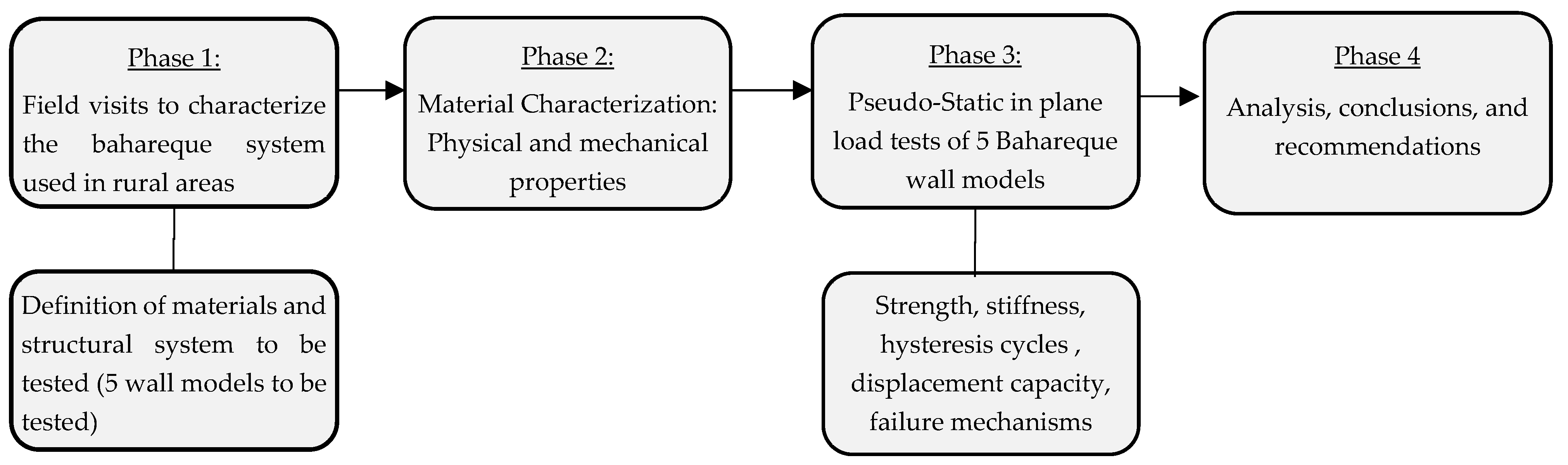

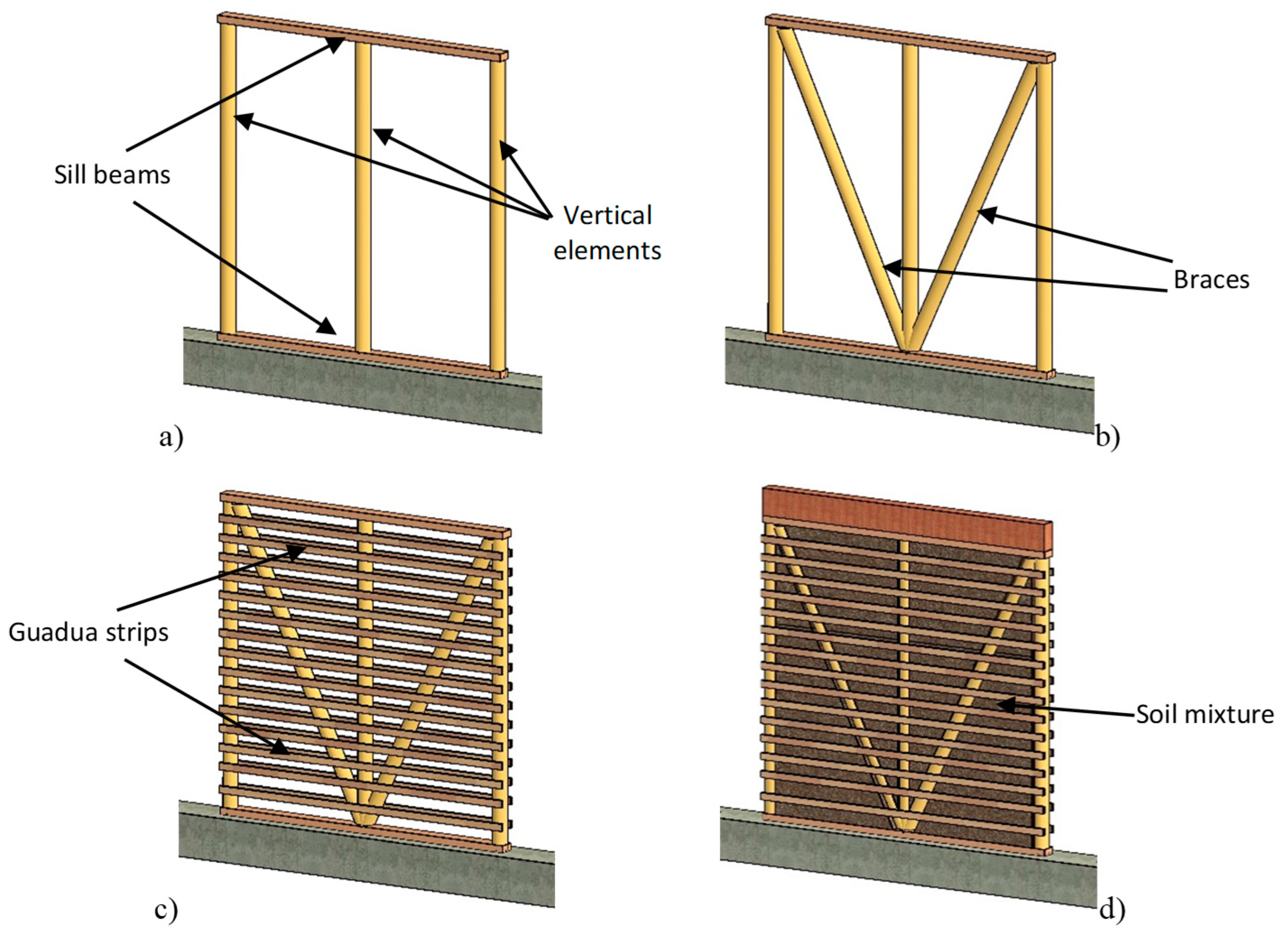

In Colombia, the bahareque construction system is characterized by a structural framework made of sawn wood or guadua bamboo (guadua). The Colombian bahareque consists of upper and lower sill beams, vertical elements, and braces (inclined diagonal members). The infill bahareque walls are built using strips of guadua, approximately 4 to 5 cm wide, placed lengthwise to secure the filler (an earth mixture). These strips are nailed horizontally on both sides of the frame, leaving a gap of about 10 cm between them to facilitate the hand application of the mixture. The mixture itself consists of clay with high moisture content, combined with natural fibers such as ficus, straw, and grass. Additionally, a protective coating of manure or a mixture of cement and sand is applied, with lime used in some cases. These characteristics were documented during technical visits, which enabled the observation and analysis of construction techniques used in bahareque structures in rural areas of southern Colombia (northern South America). During these visits, specimens were collected from existing houses, facilitating the analysis of materials, soil properties, and natural fibers. Various construction styles were observed, ranging from houses built 50 years ago to those constructed within the past two years. Examples of these buildings are shown in

Figure 2. In many cases, these structures are owned by individuals with low socio-economic status.

During field visits to rural areas, several site-specific challenges were observed that highlight the complexities of traditional bahareque construction. One major issue was the variability in construction techniques and materials across different communities, leading to significant differences in structural configurations and joint integrity. Additionally, many existing bahareque structures exhibited signs of aging and poor maintenance, inadequate connections, high humidity and exposure to rainfall, and loss of soil infill cohesion. Another challenge was the limited use of standardized practices for soil mixture preparation, resulting in variations in mechanical properties of the infill material.

The use of bahareque walls in rural South America is deeply rooted in local traditions, which have shaped their construction techniques, material selection, and cultural significance over generations. These practices are informed by the availability of natural materials like guadua and soil, as well as by the collective knowledge passed down through communities. For instance, the incorporation of natural fibers in the soil mixture or the specific arrangement of guadua strips reflects adaptations to regional climatic conditions and seismic risks. Additionally, bahareque construction is often carried out collaboratively within communities, reinforcing its role as a sustainable and affordable solution for low-income families. Understanding these traditional influences is essential for preserving the cultural heritage associated with bahareque while promoting its adaptation to modern seismic standards.

However, based on the collected information, models were designed for the construction of prototypes, which were experimentally evaluated under in-plane pseudo-static loads in the Structures Laboratory at the Pontificia Universidad Javeriana.

Figure 3 illustrates the construction process of a Colombian bahareque module in four phases as follows: placing the sill beams and vertical elements (

Figure 3a), installing the braces (

Figure 3b), attaching horizontal strips (

Figure 3c), and filling the wall with the soil mixture (

Figure 3d). Steel nails were used to secure all joints and connections between the various elements (vertical members, sill beams, braces, and strips).

4. Material Characterization

The soil specimen studied is classified as elastic silt with sand (MH) based on the Unified Soil Classification System (USCS). According to the classification, gravels are defined as particles with diameters greater than 4.75 mm, sands range from 0.075 mm to 4.75 mm, silts from 0.002 mm to 0.075 mm, and clays consist of particles smaller than 0.002 mm. Following the ASTM D422 [

43], the grain size distribution of the soil revealed a gravel content of 1%, sand content ranging from 17.4% to 21.1%, silt content between 61.6% and 64.7%, and clay content between 13.1% and 20%. The soil behavior is primarily influenced by its fine-grained fraction, particularly silt. Additionally, the compaction characteristics were determined using the ASTM D698 test method [

44], resulting in a maximum dry density of 14.1 kN/m

3 with an optimum water content of 23.5%.

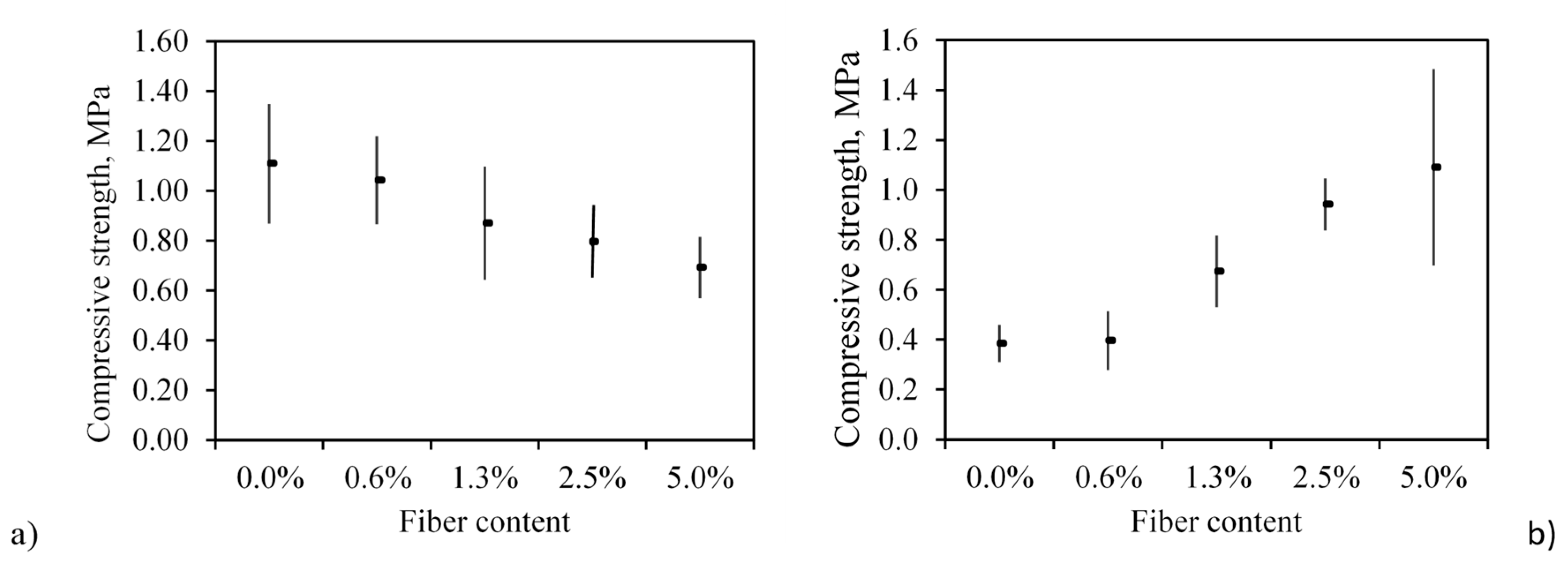

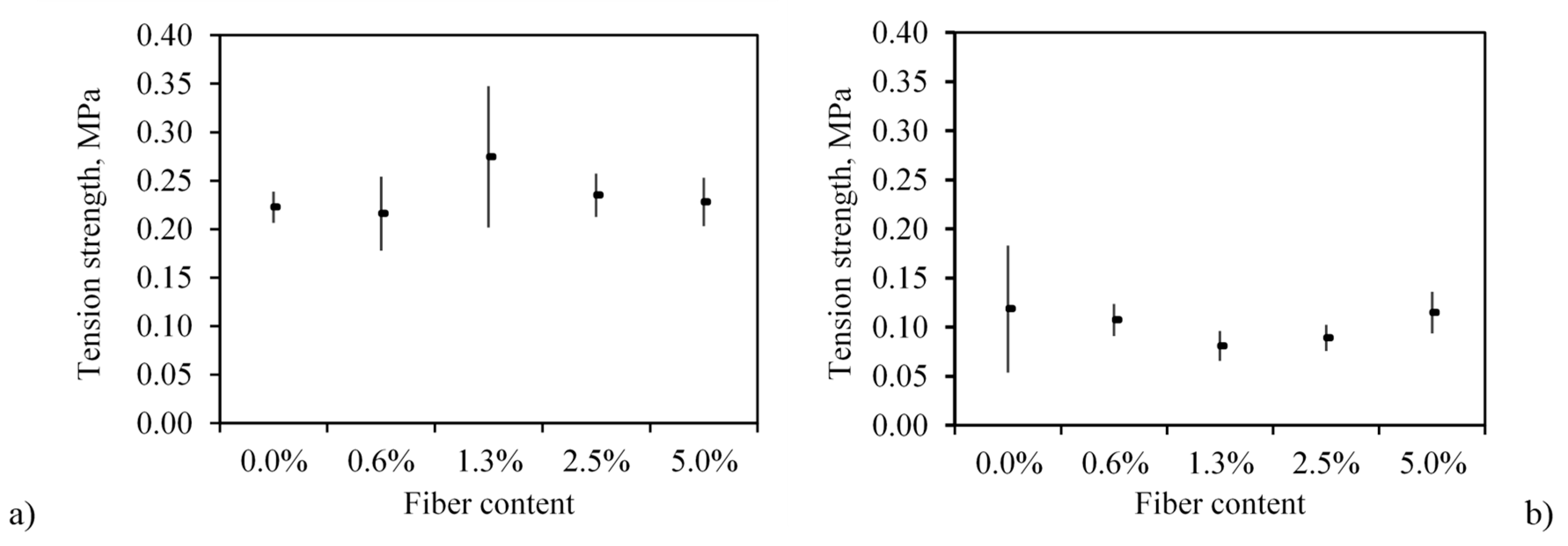

A natural fiber native to the study region (Valle del Cauca, municipality of Jamundí), identified as Andropogon glomeratus of the Poaceae family, was incorporated into the soil mixtures following local construction practices. The production process did not adhere to standardized methods; instead, the community manually mixed the soil with pre-cut fibers and placed the mixture within the bahareque walls without compaction. The fibers were cut to two lengths—2.5 cm and 5 cm—based on traditional techniques, and fiber content ranged from 0% to 5% across ten mixtures for each length. Cylindrical specimens were subsequently prepared to estimate the material’s compressive and indirect tensile strengths. The results for compressive strength are presented in

Figure 4, while the indirect tensile strength results are shown in

Figure 5.

Compression test results after 28 days of drying indicated strengths from 0.3 MPa to 1.5 MPa. However, due to the high variability in the results, no clear relationship could be established between fiber content, length, and compressive strength. In contrast, the indirect tensile strength results indicated better performance for the soil mixture with 2.5 cm long fibers, achieving tensile strengths of up to 0.35 MPa. The soil mixture with 5 cm long fibers exhibited lower tensile strength, with a maximum value of 0.18 MPa.

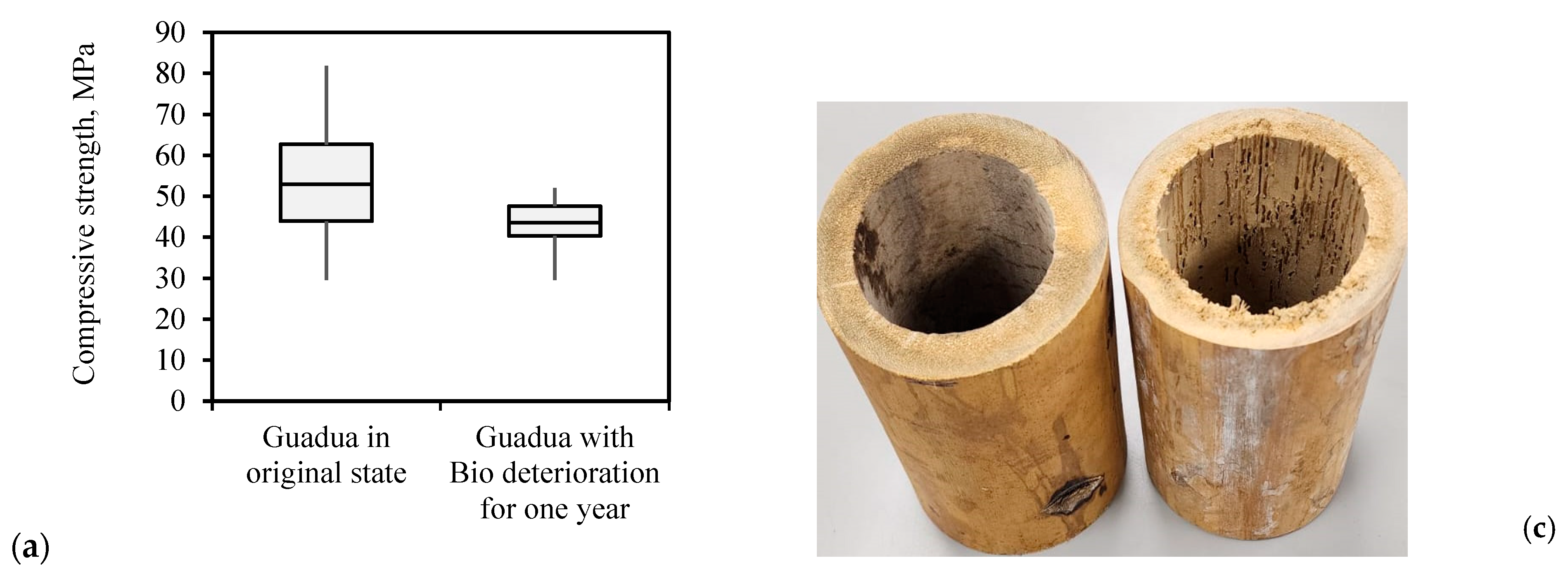

Compression tests on guadua specimens were performed according to the ISO standard [

45]. Both specimens, with and without biodeterioration, (

Figure 6c) were evaluated one year after the materials were obtained. It is important to note that biodeterioration, as referred to in this study, is defined as the degradation or damage of the guadua material caused by biological agents such as insects, fungi, or microorganisms, which can compromise the structural integrity of untreated specimens. In all cases presented in

Figure 6, the slenderness ratio was 2:1, with specimens measuring approximately 10 cm in diameter.

The mean compressive strength of the guadua specimens without biodeterioration was 54.9 MPa, with a coefficient of variation of 25.6% (

Figure 6a), while biodeteriorated specimens averaged 43 MPa. Compressive Young’s modulus tests revealed an average modulus of 9.3 GPa for the guadua without biodeterioration (

Figure 6b). Additionally, the average density of the guadua without biodeterioration was 508.3 kg/m

3 (standard deviation of 55.78 kg/m

3). The wet wood density was 691.0 kg/m

3 (standard deviation of 73.7 kg/m

3). After drying, the density of the wood decreased to 613.6 kg/m

3 (standard deviation of 67.0 kg/m

3). The maximum compressive strength of the tested wood elements was 54.1 MPa, the average of the results was 34.5 MPa, and the standard deviation was 14 MPa (

Figure 6d).

Figure 6e shows the stress–strain curves of the 20 wood specimens tested in compression. The variability in strength (which is consistent with the data in

Figure 6d) is evident, as is the variability in maximum strain. Nevertheless, it can be seen that the material has a good inelastic deformation capacity.

5. Pseudo-Static In-Plane Load Tests of Bahareque Walls

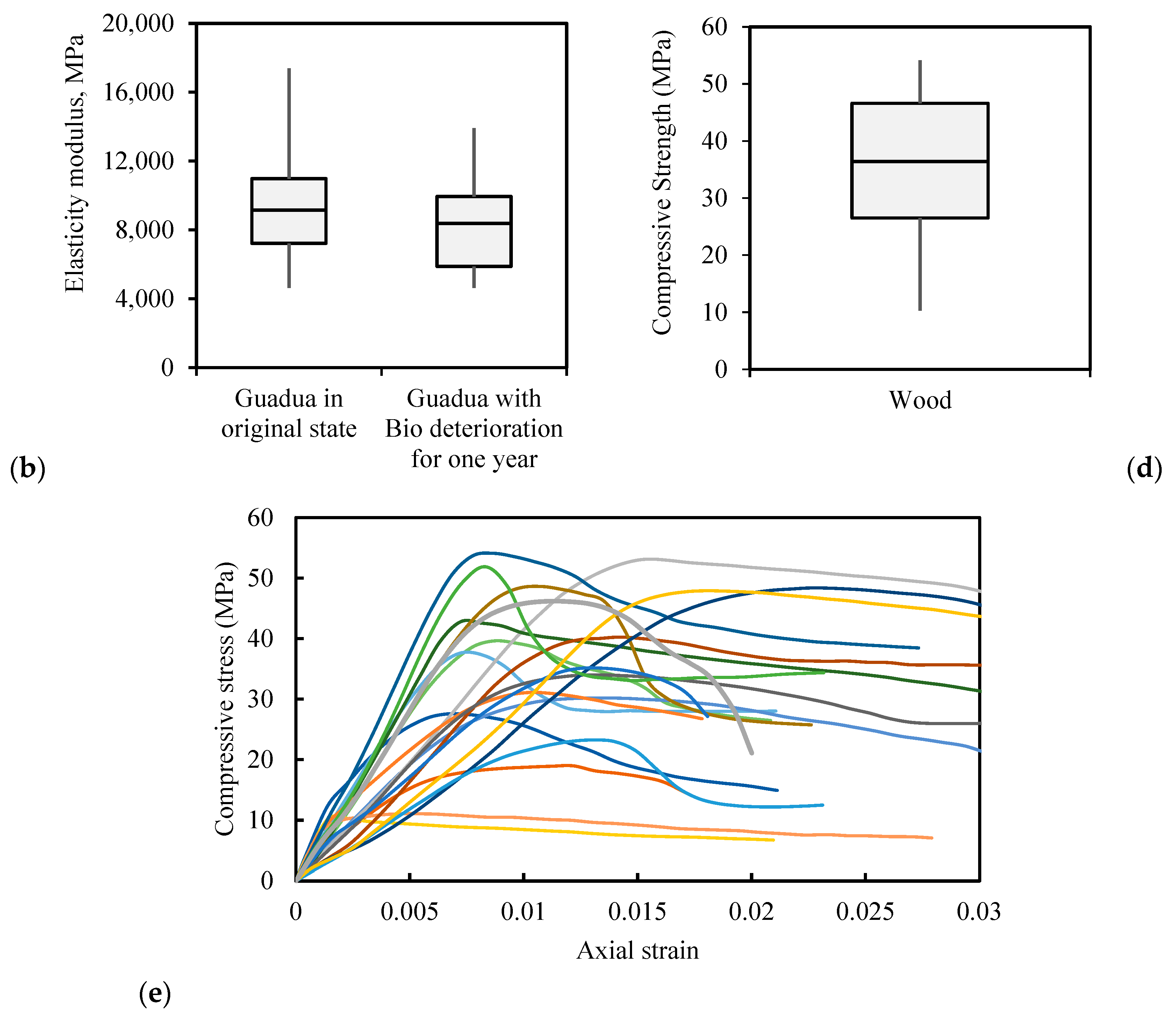

Pseudo-static in-plane load tests of bahareque walls were conducted on the five following prototypes, designed and constructed based on field observations and the technical literature: (a) guadua skeleton (GS), (b) timber skeleton with horizontal strips (TSH), (c) guadua skeleton with horizontal guadua strips (GSH), (d) guadua skeleton with horizontal guadua strips and soil mixture filling (GSHS), and (e) timber skeleton with horizontal guadua strips and soil mixture filling (TSHS).

Figure 7 illustrates these prototypes. Each measured 2.2 m in both height and base width, with two 1.1 m panels and lower sill beams made of wood with cross-sectional dimensions of 10 cm wide by 5 cm high. Detailed descriptions of each prototype are provided as follows:

GS: Constructed of two panels made entirely of guadua (approximately 10 cm in diameter), joined by three vertical elements and two diagonal braces, with sawn wooden sill beams. This prototype did not include guadua strips or soil mix infill (

Figure 7a).

TSH: Featured vertical sawn timber elements with a square cross-section of 10 cm by 10 cm and incorporated horizontal guadua strips spaced 9–10 cm. The strips had an average width of 4–5 cm and thickness of 1 to 2 cm (

Figure 7b).

GSH: included three vertical elements and two diagonal braces, all made of guadua (approximately 10 cm in diameter), with horizontal guadua strips installed similarly to the TSH prototype (

Figure 7c).

GSHS: Comprised three vertical guadua elements and two diagonal braces, with horizontal guadua strips spaced 9–10 cm apart. The strips were 4–5 cm wide and 1–2 cm thick, with the wall filled using a mixture of soil and natural fibers, as described in the Methodology section (

Figure 7d).

TSHS: Consisted of vertical sawn timber elements and two diagonal braces with a 10 cm by 10 cm cross-section. Like the TSH, GSH, and GSHS prototypes, guadua strips were installed and the wall was infilled with a mixture of soil and fibers (

Figure 7e).

Field observations revealed foundations made of cyclopean concrete, stone, or standard concrete. To replicate these foundations, the lower sill beam of each prototype was anchored to a concrete beam, secured to the reaction plate in the Structures Laboratory at Pontificia Universidad Javeriana. The connections between the structural elements (vertical members, braces, and sill beams) were based on typical field practices using 3-inch steel nails.

Figure 8 illustrates examples of these connections for both wood and guadua elements.

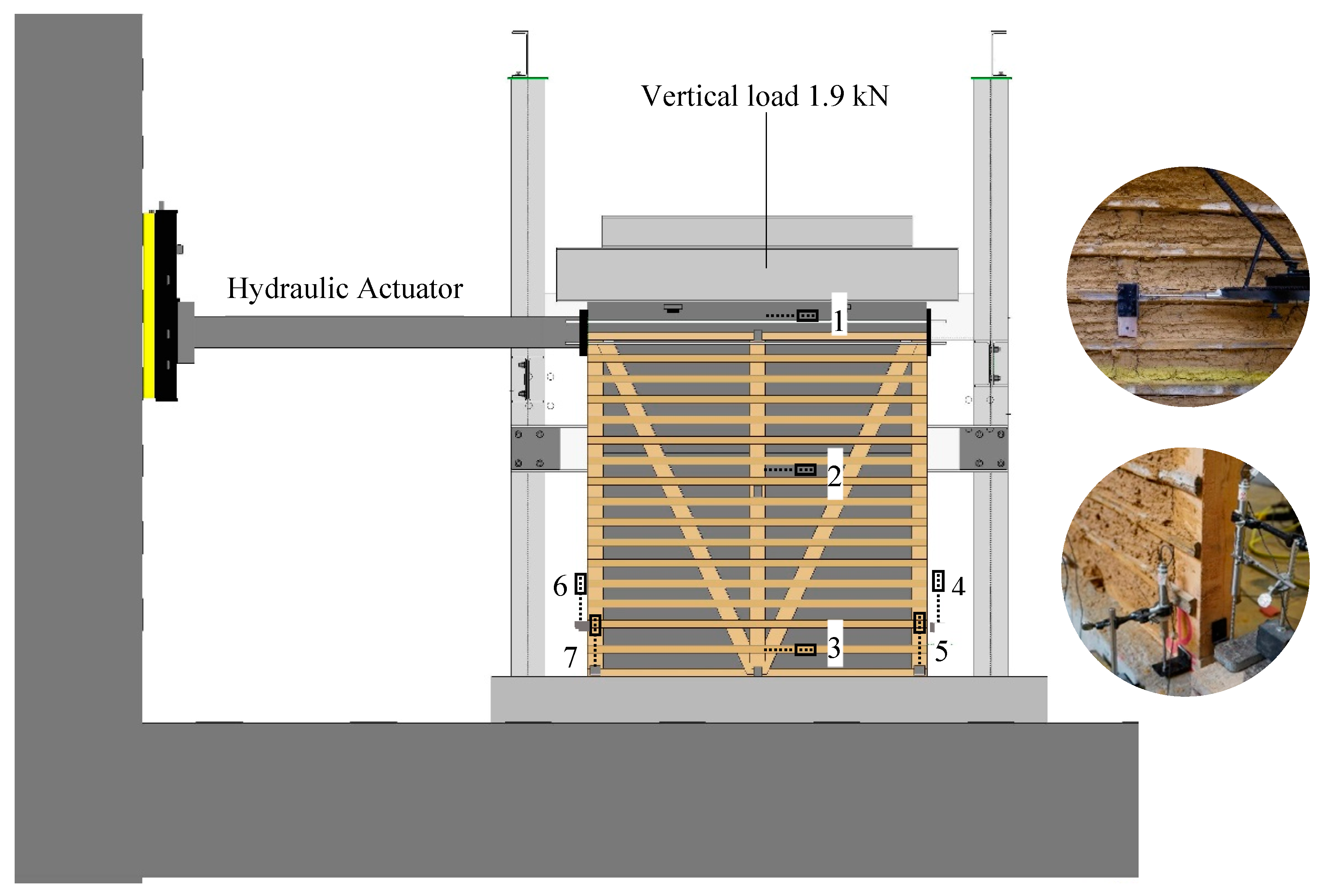

The test setup included an MTS hydraulic actuator used to apply in-plane shear loads to the specimens.

Figure 9 illustrates the test setup with the actuator attached to the reaction wall, with QR codes in

Figure 9b,c providing 360° views of the test setup. To simulate the weight of a typical building roof, a vertical load of 1.9 kN was applied to all specimens, as determined during the site visits. The dynamic actuator was connected to the bahareque wall using two steel components and four rods, allowing for reversible displacement in accordance with the test protocol.

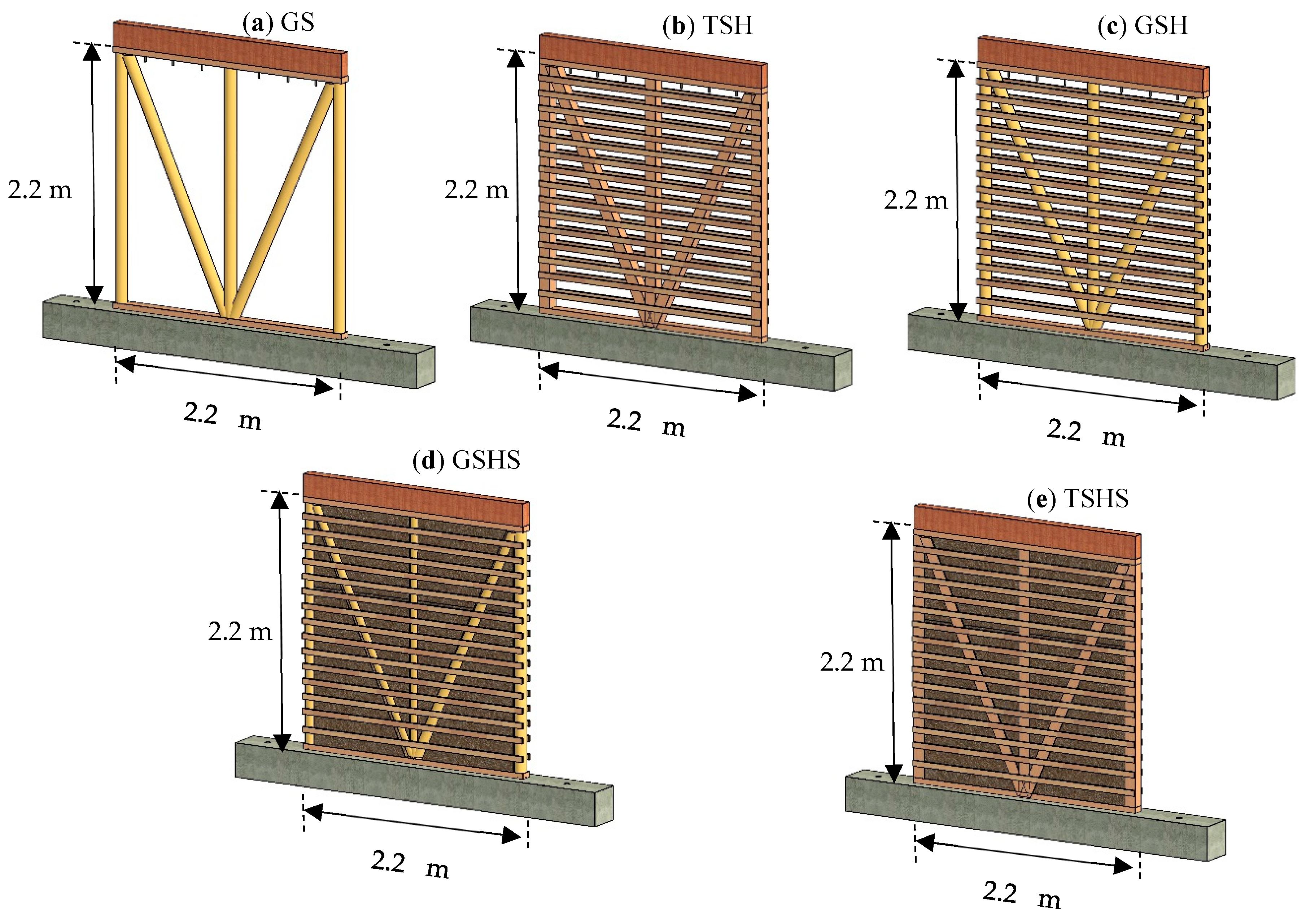

Figure 10 presents the displacement protocol (pseudo-static).

The loading procedure followed the provisions of ref [

46] and Test Method B of ref. [

47], and it was displacement-controlled, with displacement cycles grouped into phases of increasing levels at a frequency of f = 0.01 Hz. The protocol was designed for a target maximum drift of 6% based on the consulted references but allowed for drifts up to 10%.

A servo-controlled dynamic hydraulic actuator was used to apply the in-plane cyclic loads to the bahareque walls. All walls were instrumented with displacement sensors using LVDT technology, with ranges of ±25 mm, ±50 mm, ±100 mm, and ±150 mm and a sampling rate of 10 Hz. The LVDTs were distributed as follows (

Figure 11): LVDT 1 (±150 mm) on the upper sill beam; LVDT 2 (±100 mm) at wall center height; LVDT 3 (±50 mm) for the wall–foundation relative displacement; LVDTs 4 and 6 (±50 mm) for vertical displacements of the vertical (side) elements of the bahareque walls; and LVDTs 5 and 7 for the relative vertical displacement of the sill beam anchored to the foundation. It is important to note that the control sensor for the test was LVDT 1. Finally, the hydraulic actuator was also equipped with an LVDT with a range of ±250 mm.

Figure 12 illustrates the failure mechanisms for each of the five bahareque wall specimens. In the GS wall, failure initiated with a crack in the lower zone of the wooden sill beam. Subsequently, joint failures occurred between the wood and guadua, leading to the detachment of the vertical elements (

Figure 12a—1). This was primarily due to the steel nails becoming dislodged and unanchored (

Figure 12a—3). During loading, the connection of the central vertical member to the braces failed as steel nails loosened and were reinserted repeatedly, eventually causing misalignment. Notably, neither the wood nor the guadua elements fractured. In the TSH specimen, detachment of the steel nails was observed at the joints between the bottom sill and the vertical elements (

Figure 12b—1), causing the central vertical member became separated from the bottom sill, along with the diagonals at the joint. Similarly to the GS wall, the steel nails repeatedly detached during loading cycles and reattached during unloading until some were crushed. Minor detachment also occurred in the upper region, though less significant than in the lower region. It is important to note that despite these issues, no fractures were detected in the wood, although a crack appeared in the guadua strips (

Figure 12b—2). In addition, the vertical members completely detached from the lower sill beam joint (

Figure 12b—3). For the GSH specimen, steel nails were pulled out at the joint of the central vertical member and the top sill beam (

Figure 12c—1), resulting in the separation of the elements. During the final loading cycles, the left vertical member completely detached from the lower sill beam joint (

Figure 12c—2). By the test’s end, a crack appeared in the bottom sill beam near a vertical member connection (

Figure 12c—3), but the guadua strips and their connections remained intact. Prior to the pseudo-static testing of the GSHS wall, a one-month drying process was conducted in the structures laboratory to assess the impact of the infill soil on structural performance. The drying process took place in the structures laboratory, with the wall exposed to solar radiation. The moisture content was measured at two stages, namely during wall construction and at the end of the drying period. Initially, when the soil mix was prepared, the moisture content was set at 26.3%, corresponding to the optimum value determined through compaction tests. After one month of drying, by the time the pseudo-static test was conducted, the moisture content had reduced to a range of 5.2% to 8.2%. Upon applying the loading protocol, the failure mechanism was found to be similar to those observed in the previous walls tested (

Figure 12d). The failure mechanism included lifting of the vertical elements with respect to the bottom sill beam (

Figure 12d—1), the removal of steel nails at the connection of the central vertical element, and cycles of removal and insertion of steel nails in the vertical elements, which resulted in a loss of alignment in the lower zone of the wall. Additionally, fissures and cracks developed in the infill soil (

Figure 12d—2,3), along with a noticeable separation between the infill and the skeleton formed by the guadua strips. The soil fill exhibited loss and spalling during the loading and unloading cycles applied to the wall.

Similarly, to the previous wall, the TSHS bahareque wall was constructed with soil mix filler between the guadua strips, which was applied in three layers. Prior to the pseudo-static test, a drying period of one month was allowed. After drying, the filler soil shrank without delamination. Testing of the TSHS wall revealed steel nail detachment in some joints and lifting of vertical elements at the wall’s ends (

Figure 12e—1) and fractures in some guadua strips at the steel nail joints with the wooden elements (

Figure 12e—2). Although noise was noted during the failure of the bahareque walls in all tests, the TSHS wall exhibited particularly pronounced noise during the failure of the guadua strips, which showed multiple fractures. Additionally, the infill soil demonstrated a significant degree of delamination and separation from the wooden skeleton at the lower and upper sill beams, vertical members, and bracing (

Figure 12e—3). Evidence of spalling and loss of soil fill was also observed at the conclusion of the experimental test.

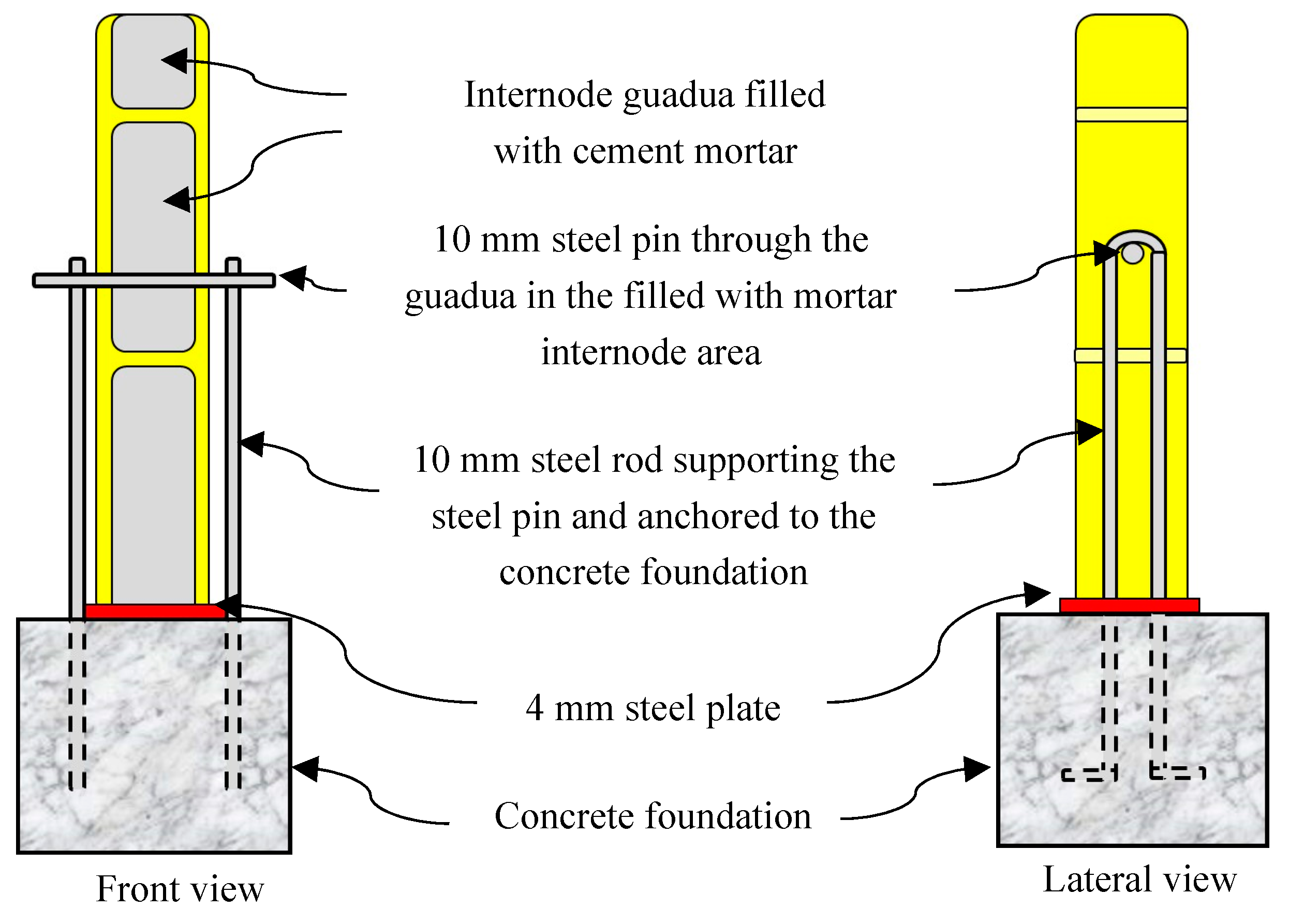

In order to avoid the connection failures found in the tested bahareque models, reference [

48] proposed a connection system that resists tensile and compressive forces. For walls made of guadua, the elements must be connected to the foundations according to the scheme shown in

Figure 13. The system is based on a mortar–bahareque, where the internode elements of the guadua are filled with mortar. The guadua must not be in direct contact with the soil, masonry, or concrete; therefore, the guadua elements must be supported on a steel plate or other impermeable material separator. Compressive forces are transmitted through the separator, which must always rest on the foundation. Tensile forces are transmitted through pin connections. A pin passes through the first or second internode of the guadua element (filled with mortar), and this pin is anchored to the foundation with steel rods. This type of connection resists tensile forces but is not suitable for resisting bending moments. Reference [

48] also includes examples of improved connections for wooden bahareque.

The enhanced connection design illustrated in

Figure 13 provides a feasible solution to improve the performance of traditional bahareque systems. However, implementing such enhancements in rural and low-income areas faces significant logistical and economic challenges. The reliance on materials like mortar, cement, and steel introduces barriers due to their high cost and limited availability in remote regions. Transporting these materials to isolated areas, where infrastructure is often lacking, adds to the complexity and expense of adopting these improvements. Moreover, traditional construction practices in these communities are deeply rooted in locally sourced materials and techniques, making it challenging to introduce new methods without comprehensive training and support.

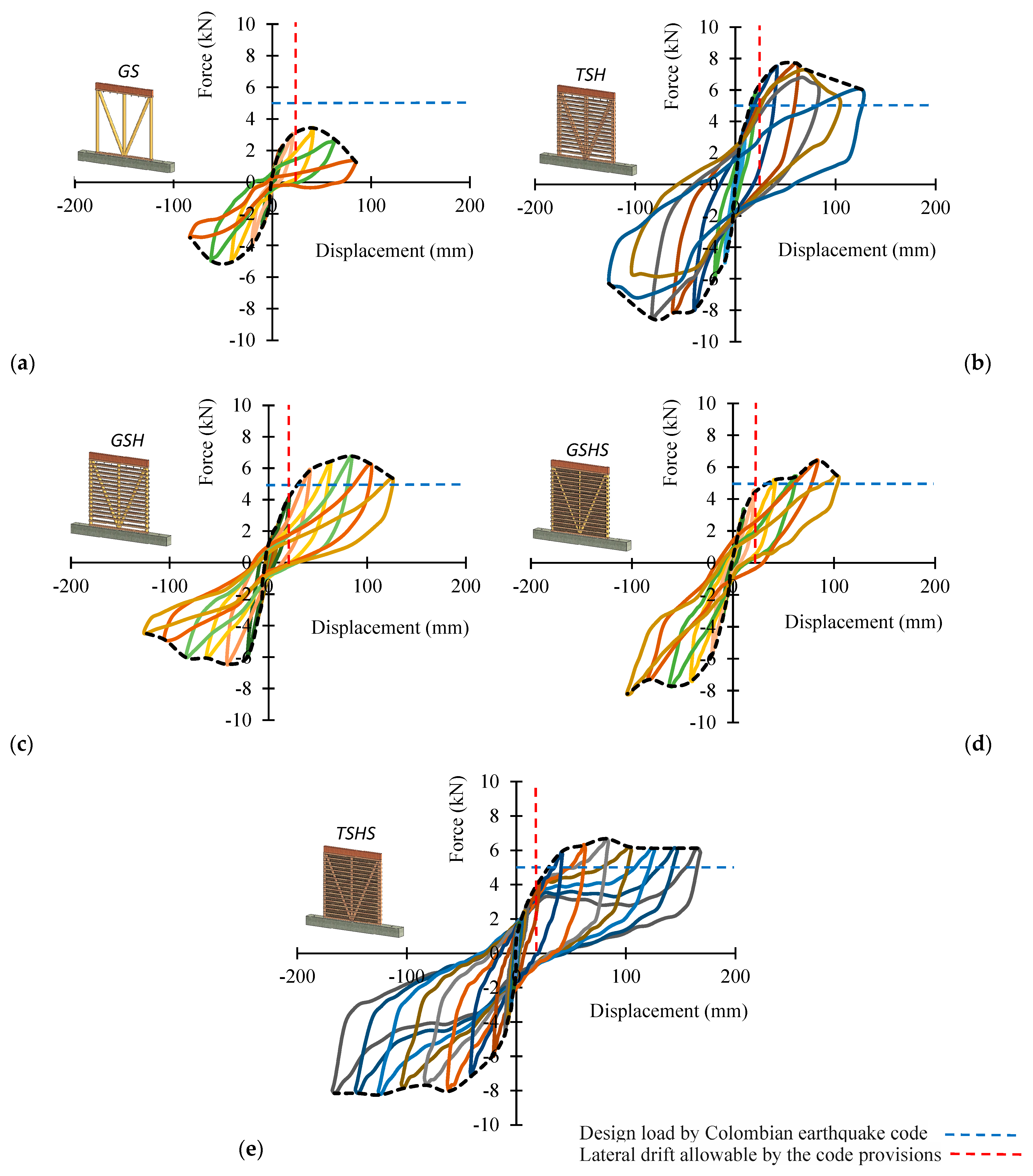

Figure 14 presents the in-plane hysteresis loops for the bahareque prototypes tested. The guadua skeleton (GS) wall exhibits narrow loops, indicating limited energy dissipation. Its force–displacement curve indicates relatively linear behavior during the initial loading cycles, with slight stiffness degradation as displacement increases.

The loops do not significantly expand, suggesting low energy absorption and moderate deformation capacity. Overall, the wall exhibits a stiff response with minimal nonlinear behavior. In contrast, the timber skeleton with horizontal guadua strips (TSH) shows more pronounced pinching effects in its hysteresis loops, indicative of reduced stiffness as displacement increases. The force–displacement curve reveals moderate energy dissipation, with wider loops suggesting greater ductility and a higher capacity for larger displacements and effective energy absorption compared to the GS wall.

The hysteresis cycles for the guadua skeleton with horizontal guadua strips (GSH) demonstrate a more stable cyclic behavior, with larger hysteresis loops compared to both the GS and TSH walls. Enhanced energy dissipation reflects a better balance between stiffness and ductility. The wider loops illustrate an improved capacity to absorb energy under cyclic loading, accompanied by a noticeable increase in displacement capacity.

The GSHS wall’s wider hysteresis loops indicate greater ductility and better energy dissipation than previous wall types. The incorporation of the soil mixture improves structural performance under cyclic loading, enabling larger displacements with a gradual reduction in stiffness. This response demonstrates strong energy absorption characteristics, making the GSHS wall more suitable for seismic applications. Overall, this wall type exhibits excellent cyclic performance, with a superior ability to absorb energy and sustain larger displacements, rendering it the most resilient among the tested configurations.

The TSHS wall exhibited the best performance in terms of hysteresis cycles, establishing itself as the most effective bahareque wall type tested. The TSHS wall demonstrated remarkable ductility and resilience under load. The enhanced energy absorption capabilities of this wall are clearly reflected in its wide hysteresis loops, which indicate a higher capacity for energy dissipation during cyclic loading. Moreover, the hysteresis loops for the TSHS wall illustrate a significant ability to recover after unloading, suggesting effective energy absorption and dissipation mechanisms. The favorable hysteresis response of the TSHS wall underscores the importance of combining timber elements with soil mixture infill to enhance the seismic performance of traditional bahareque construction methods. It is important to note that

Figure 14 includes the design load and lateral drift allowed by the code as horizontal (blue) and vertical (red) dotted lines. According to the results, all models except the GS specimen would be able to withstand the seismic forces and drift limit specified in the earthquake resistance code.

Finally,

Table 1 summarizes the results of each tested bahareque wall, considering the following variables: maximum displacement achieved (both positive maximum and negative minimum), yield displacement (both positive and negative), strength, and yield force (both positive and negative). The GS wall has the lowest load and displacement capacity, with forces of 3.4–5.1 kN and 85 mm displacement. The TSH and GSH walls (timber skeleton and guadua skeleton with horizontal strips) demonstrate intermediate performance, achieving forces of 8.1 kN and 6.8 kN, respectively, and displacement capacities of 126 mm. In contrast, the GSHS and TSHS walls (those with soil mixture filling) exhibit the highest capacities, achieving maximum forces of about 8.4 kN and displacement capacities up to 166 mm.

The stiffness degradation curves are presented in

Figure 15 to complement the analysis of the hysteresis loops by highlighting the differences in stiffness behavior among the five tested bahareque wall models. The GS wall exhibits the most rapid degradation, becoming the least stiff at larger displacements. In contrast, the GSHS and TSHS walls, which demonstrate the widest hysteresis loops and highest energy dissipation, exhibit more stable stiffness degradation at larger displacements. This underscores the significance of the soil mixture infill and guadua strips in enhancing the seismic in-plane performance. Overall, the walls with wooden skeletons (TSH and TSHS) provide superior performance, combining good initial stiffness with gradual degradation. Based on the data of

Figure 15, it was found that the walls with guadua skeletons (GSH and GSHS) had an average initial stiffness of about 0.6 kN/mm, while the walls with wooden skeletons (TSH and TSHS) had an average initial stiffness of about 0.9 kN/mm, which is 50% higher. At a drift level of 1% (0.01), the stiffness degradation observed in the GSHS and TSHS walls from the present study aligns with trends reported in similar traditional seismic wall systems. For example, the TSHS specimen shows improved stiffness retention compared to findings in [

49] and [

15], where walls without infill exhibited a sharper reduction in stiffness. Similarly, the GSHS model, with its soil infill and guadua strips, demonstrates a more gradual stiffness degradation than the results presented in [

14] for timber walls with masonry infill. However, the stiffness degradation in the present study is comparable to results reported in [

38]. On the other hand, the results in [

16] emphasize the role of structural connections, which appear to be a limiting factor in the GSHS model due to the influence of nail pullout and joint behavior under cyclic loading.

Finally, the comparison between bahareque walls with and without soil infill highlights significant differences in seismic performance, which can be attributed not only to the presence of the soil infill but also to the role of the horizontal guadua strips installed to contain it. Walls with soil infill, such as the GSHS and TSHS prototypes, demonstrated good energy dissipation and ductility. The soil infill acted as an energy-absorbing buffer during cyclic loading, while the horizontal guadua strips provided additional lateral confinement, enhancing structural stability. These walls showed a delayed onset of failure, higher displacement capacities (up to 166 mm), and improved stiffness retention compared to walls without infill (e.g., GS), which reached a maximum displacement of only 85 mm. In contrast, non-infill walls had premature joint failure due to nail pullout and limited load distribution. This combination of soil infill and guadua strips not only increased the walls’ energy dissipation capacity but also reduced the risk of brittle failures by enhancing the ductility and integrity of the overall system.

Several studies have reported the energy dissipation of bahareque or wooden frames under pseudo-static loading, as observed in experimental hysteresis loops. The amount of energy dissipated depends on factors such as the specimen’s size, resistance, and system flexibility. Consequently, this energy (measured in joules or kilojoules) is not directly comparable across models from different studies due to variations in these geometric and mechanical parameters. To address this, researchers often report the evolution of equivalent hysteretic damping as a function of drift, which provides a standardized metric. Equivalent damping relates the energy dissipated through hysteresis to the elastic energy, offering a consistent basis for comparison. Based on the above,

Table 2 presents a comparison of equivalent damping values reported by various authors. These values, measured at a 1% drift, are contrasted with the results obtained for the GSHS and TSHS models.

According to

Table 2, TSHS and GSHS models exhibit equivalent viscous damping ratios of 14.7% and 11.3%, respectively. When compared with the data from previous studies, these values align closely with those reported for timber frame walls with masonry or panel infills. Notably, the TSHS model demonstrates comparable performance to systems such as timber frames with brick masonry infills and composite mortar bamboo walls, highlighting its superior energy dissipation capacity. In contrast, the GSHS model shows slightly lower damping values but still outperforms some timber walls without masonry infill. These findings suggest that the incorporation of soil infill and guadua strips significantly enhances the energy dissipation performance of bahareque walls.

6. Conclusions

This study provides a comprehensive evaluation of the seismic performance of bahareque walls constructed with guadua and timber frames. Key conclusions from this study are summarized below.

Displacement capacity was a key finding of the study and prototype TSHS (timber skeleton with horizontal guadua strips and soil mixture infill) exhibited an enhanced displacement capacity with recorded maximum displacements up to 166 mm (and wider hysteresis loops indicating higher energy dissipation). This displacement capacity is important for dissipating seismic energy without compromising overall structural integrity. The hysteresis loop analysis showed that wooden skeletons with guadua strips infilled with soil mix exhibited notably wider loops, an indication of superior energy dissipation during cyclic loading. In contrast, the GS wall had the worst displacement capacity, with a maximum reached displacement of 83 mm. However, it is important to note that the results are based on laboratory-controlled conditions, which may not fully represent the variability of traditional construction practices in the field.

The strength of the system showed differences between configurations; for instance, the results indicate that the strength of the bahareque system with a wood skeleton is on average 23% higher than that of the guadua skeleton (when comparing TSH and GSH). In addition, the soil-infilled walls showed improvements in load-bearing capacity, achieving maximum in-plane shear strengths of up to 8.4 kN (TSHS wall). This fact highlights the importance of infill materials and guadua strips in seismic design, which can improve structural performance under lateral forces. While these results highlight the importance of material combinations, the influence of long-term environmental factors, such as moisture or soil degradation, was not evaluated and could affect performance over time.

The horizontal guadua strips affect the performance of the structural system, and an example of this fact is the notable difference between the GSH and the GS walls, where the guadua strips contribute significantly to the strength, displacement capacity, and ductility of the structure by allowing for energy absorption and reducing the risk of brittle failure under load reversals. While the average strength of the GS wall was 4.2 kN (average between maximum positive force and maximum negative force in absolute value), the strength of the GSH wall was 6.4 kN (51% higher). The same observation applies to the displacement capacity, since the wall without guadua strips (GS) had an average displacement capacity of 84 mm (average between maximum positive displacement and maximum negative displacement in absolute value), while the GSH wall (with guadua strips) had an average maximum displacement of 126 mm (50% higher). Nevertheless, the variability in guadua properties and the nail connections introduces uncertainties, which should be explored in subsequent investigations.

Failure mechanisms differed between models with and without infill; for example, infill models generally retained structural integrity longer, with cracks occurring in the soil infill rather than in the primary load-bearing members, suggesting that the infill acted as an energy-dissipating buffer. In contrast, the non-infill models exhibited early failure at the joints, primarily due to the detachment of vertical members from the lower sill beams as a result of nail pullout. This behavior indicates that without the added stability of the infill, structural weaknesses at the joints become critical failure points. Among the materials tested, the wood skeleton models generally demonstrated superior performance compared to the guadua-based structures, highlighting the role of material selection in joint performance.

The stiffness of the structures also varied by design and materials; according to the stiffness analysis, it was found that the wood-framed walls (TSH and TSHS) had an average initial stiffness 50% higher than the guadua-framed walls (GSH and GSHS). In addition, the soil infill and the guadua strips not only increase the energy absorption capacity but also contribute to maintaining the structural stiffness throughout the loading cycle.

The seismic suitability of the models was evident in the results, as the soil-infilled, guadua strip, wood frame model improved load-bearing and energy-dissipating capacity, along with improved structural stability over repeated load cycles, making it preferable for applications in seismically active areas. However, the results are limited to the tested prototypes, and additional dynamic testing under simulated earthquake conditions is required to confirm their performance in real scenarios. To promote the adoption of these systems in seismically active regions, public policies should focus on providing technical guidance, financial incentives, and training programs for rural communities. These measures can facilitate the integration of improved bahareque techniques into local construction practices, enhancing safety and sustainability.