Petrological Characteristics and Physico-Mechanical Properties of Dokhan Volcanics for Decorative Stones and Building Material Applications

Abstract

1. Introduction

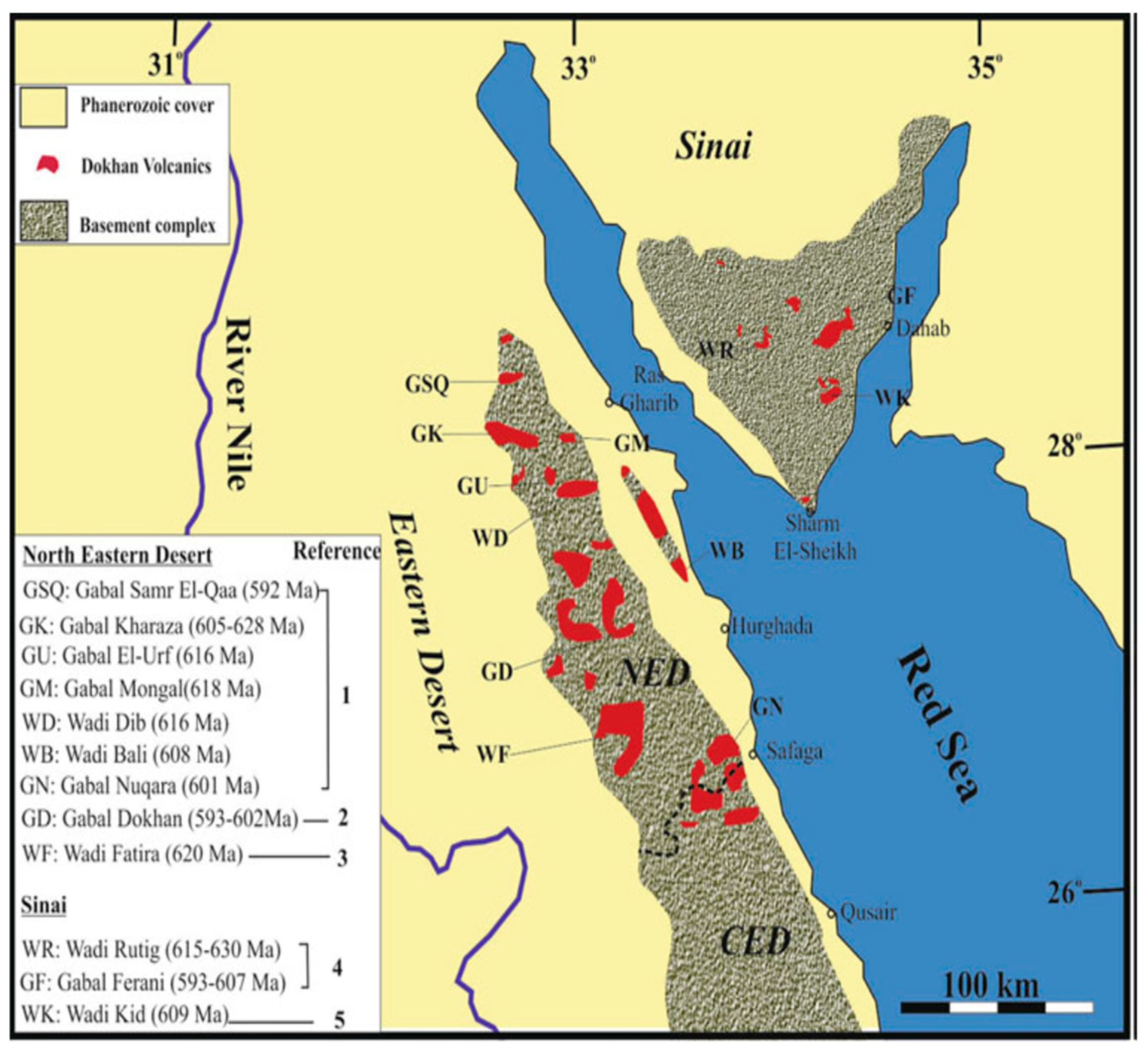

2. Study Significance

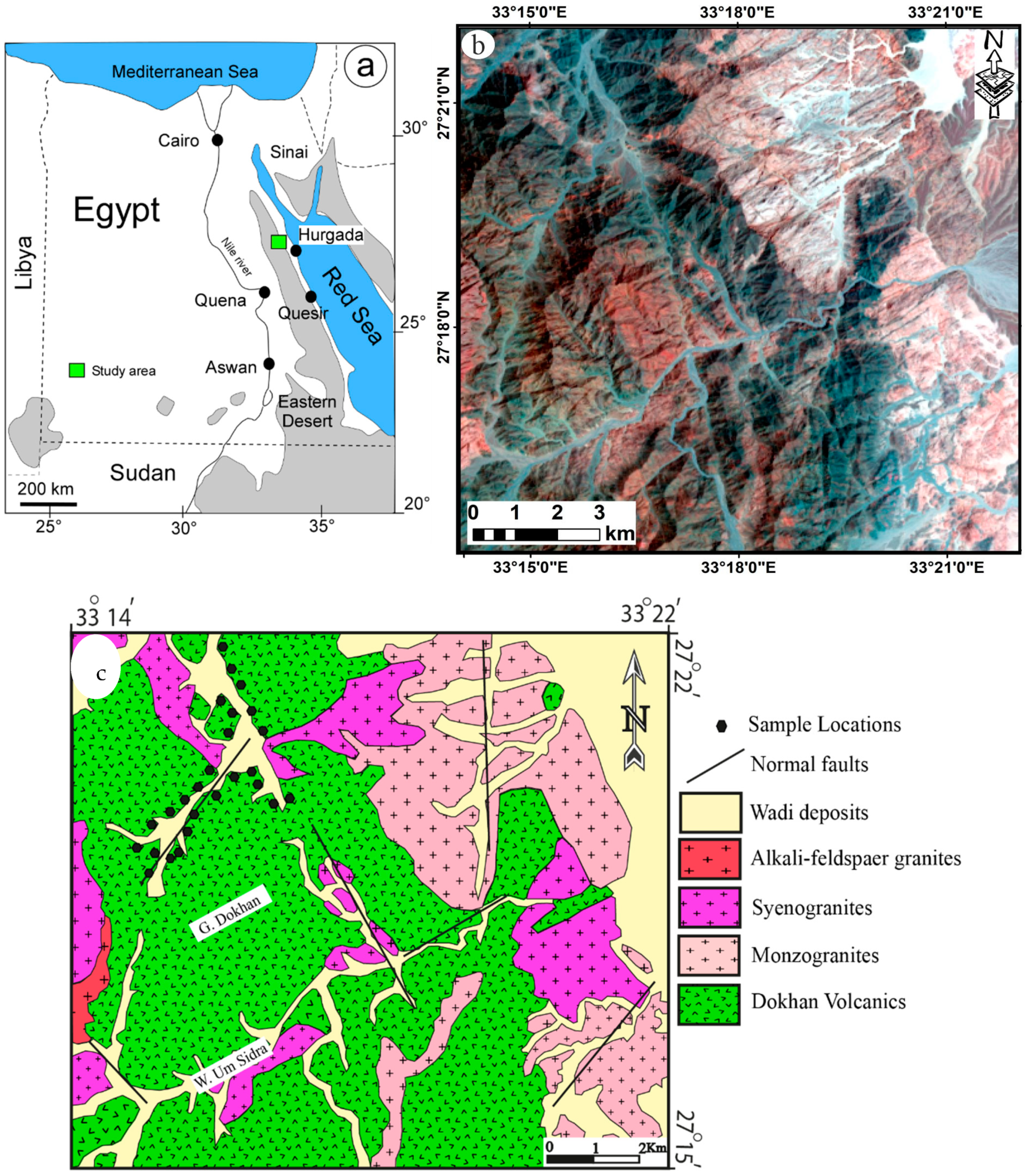

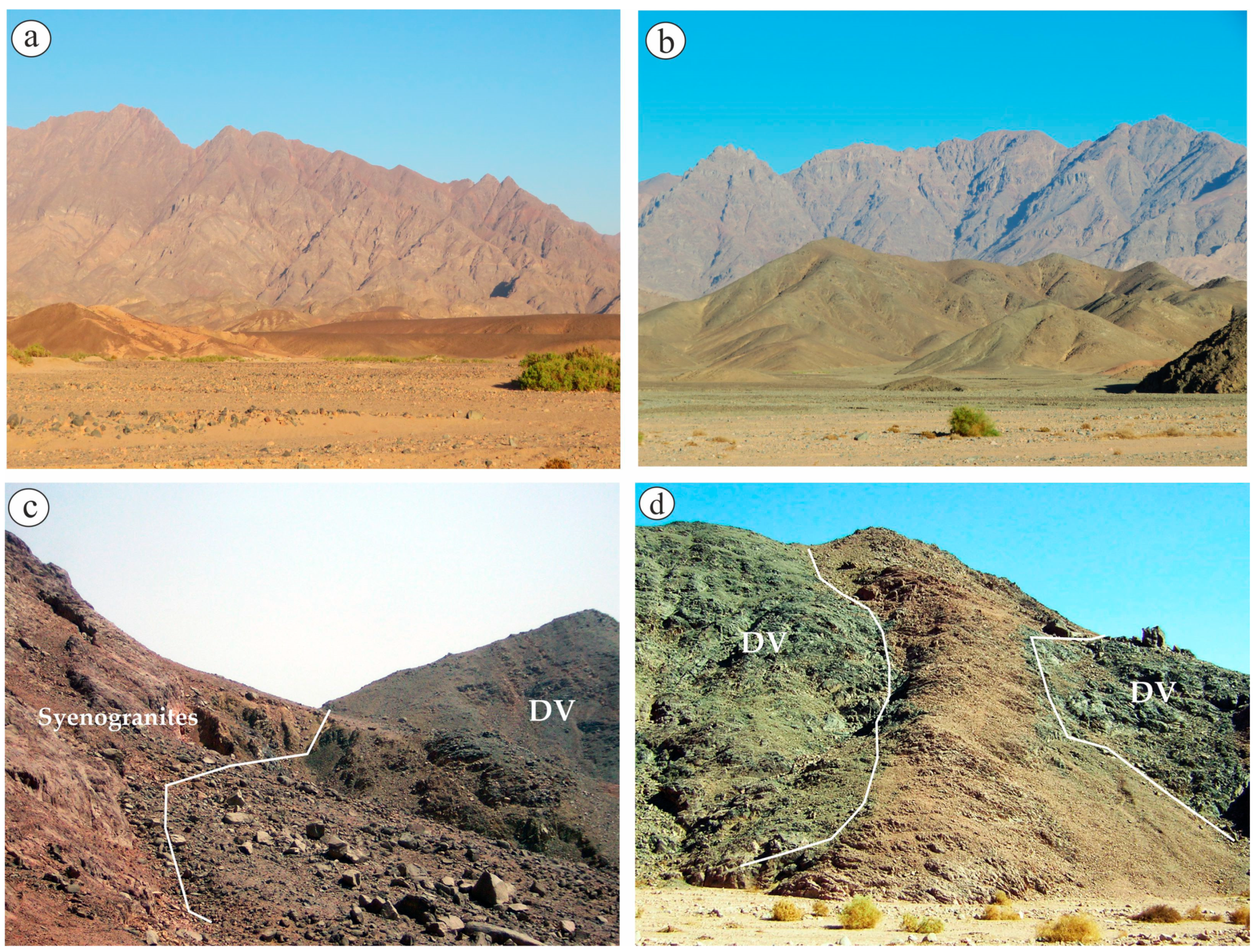

3. Field Geology

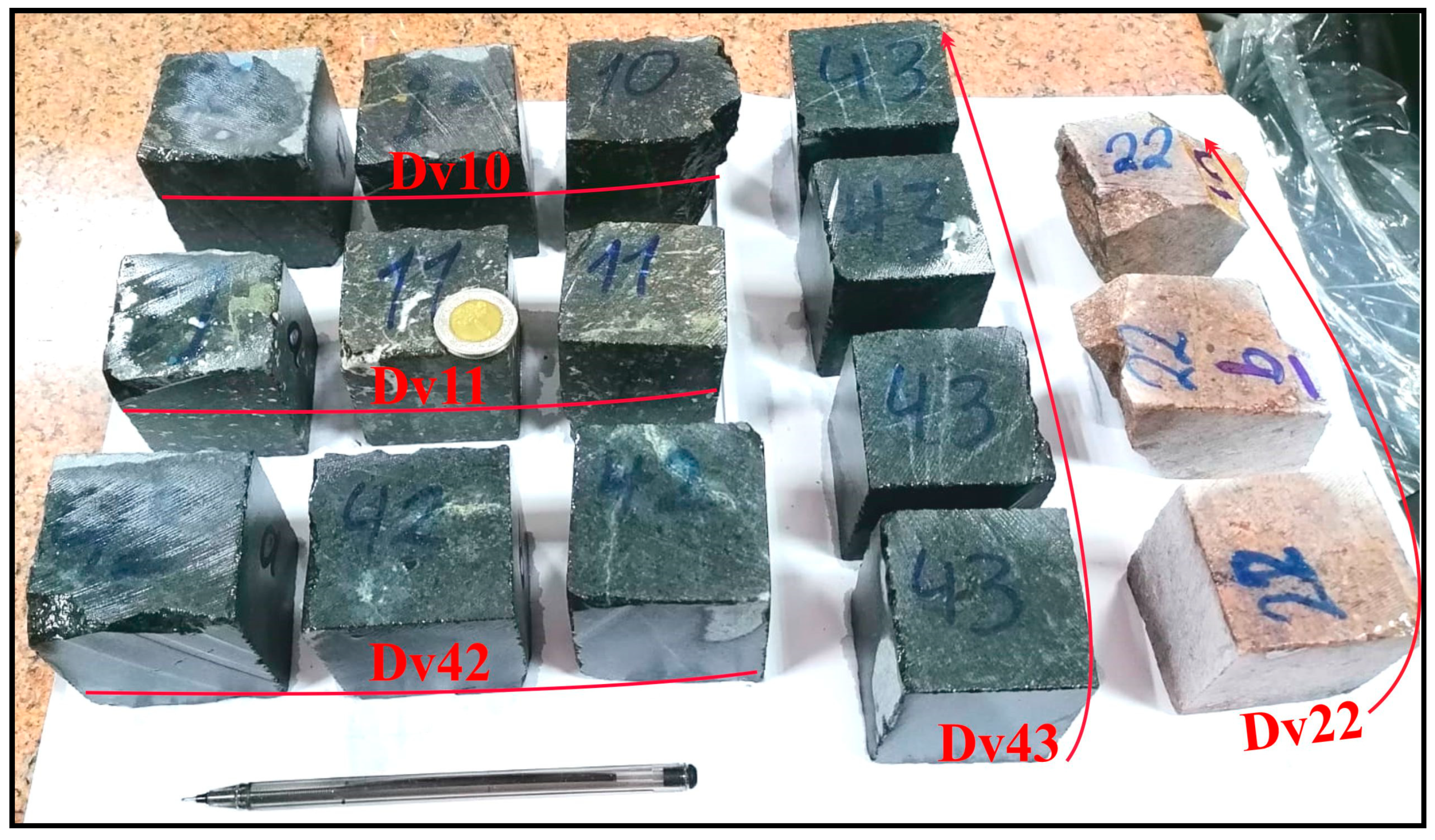

4. Methodology

4.1. Petrological Study

4.2. Physico-Mechanical Tests

4.3. Pozzolanic Activity Assessment

5. Results and Discussion

5.1. Petrography

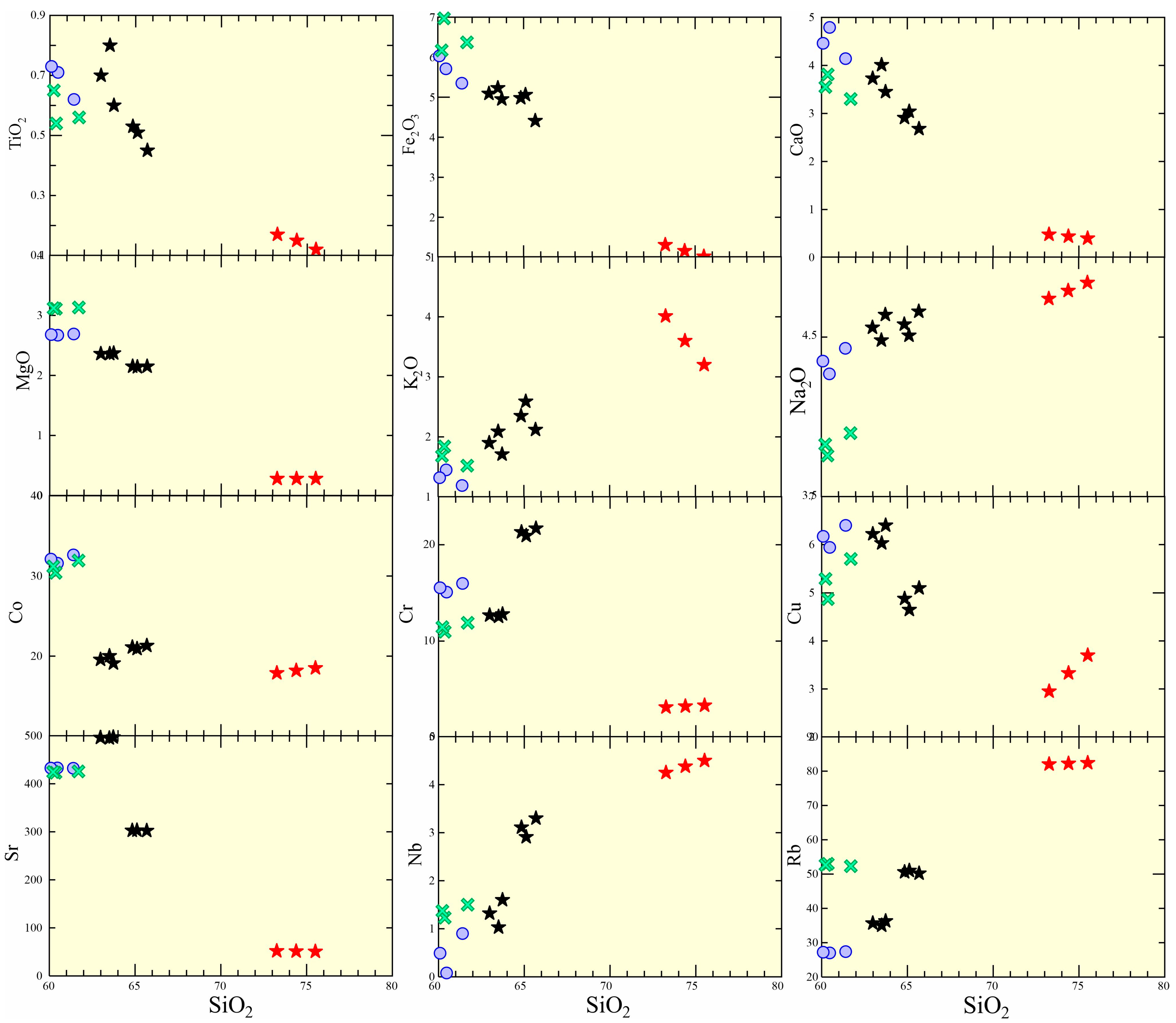

5.2. Petrochemistry

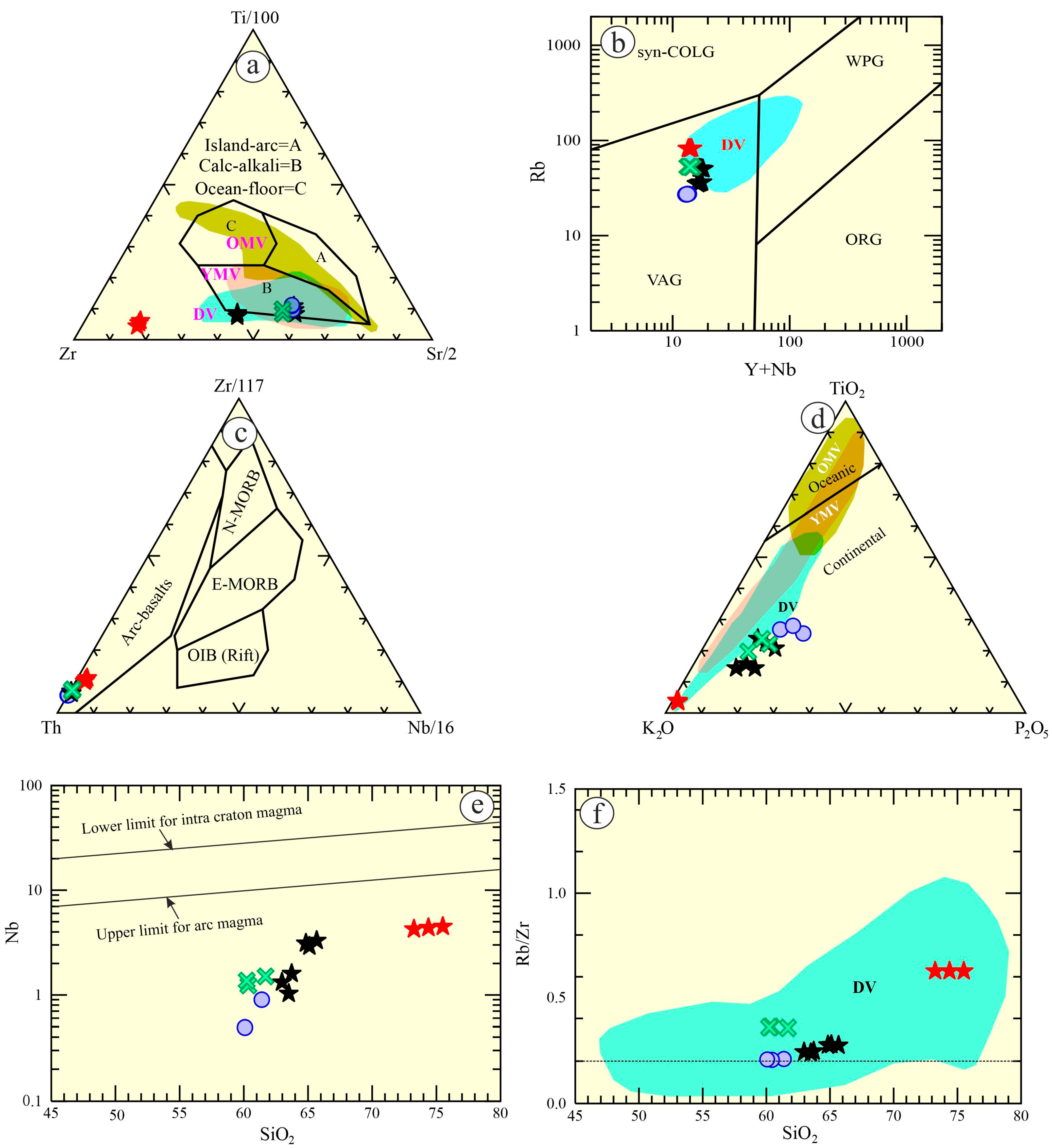

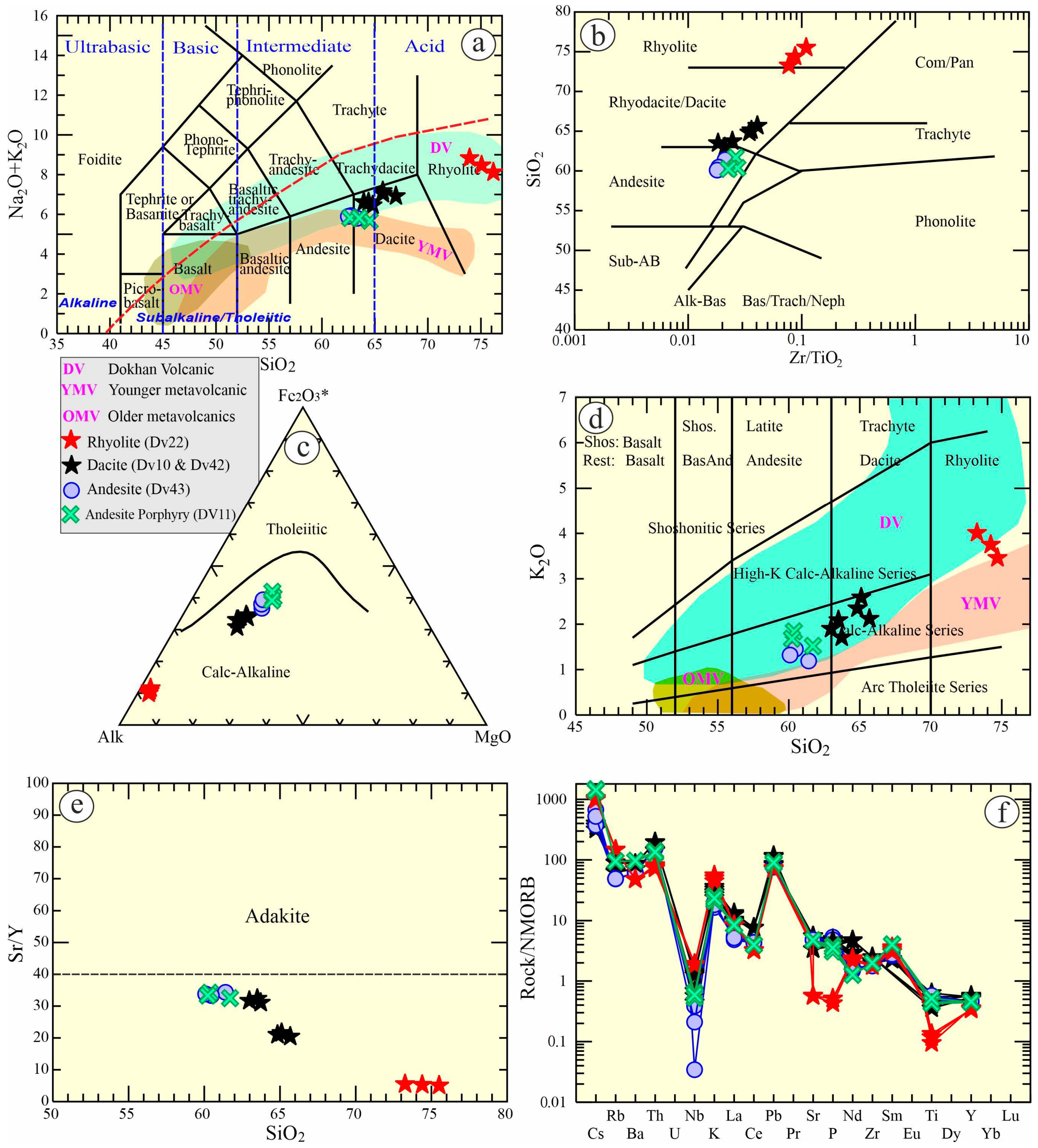

5.2.1. Classification and Lava Variations

5.2.2. Tectonic Emplacement

5.2.3. Petrogenesis

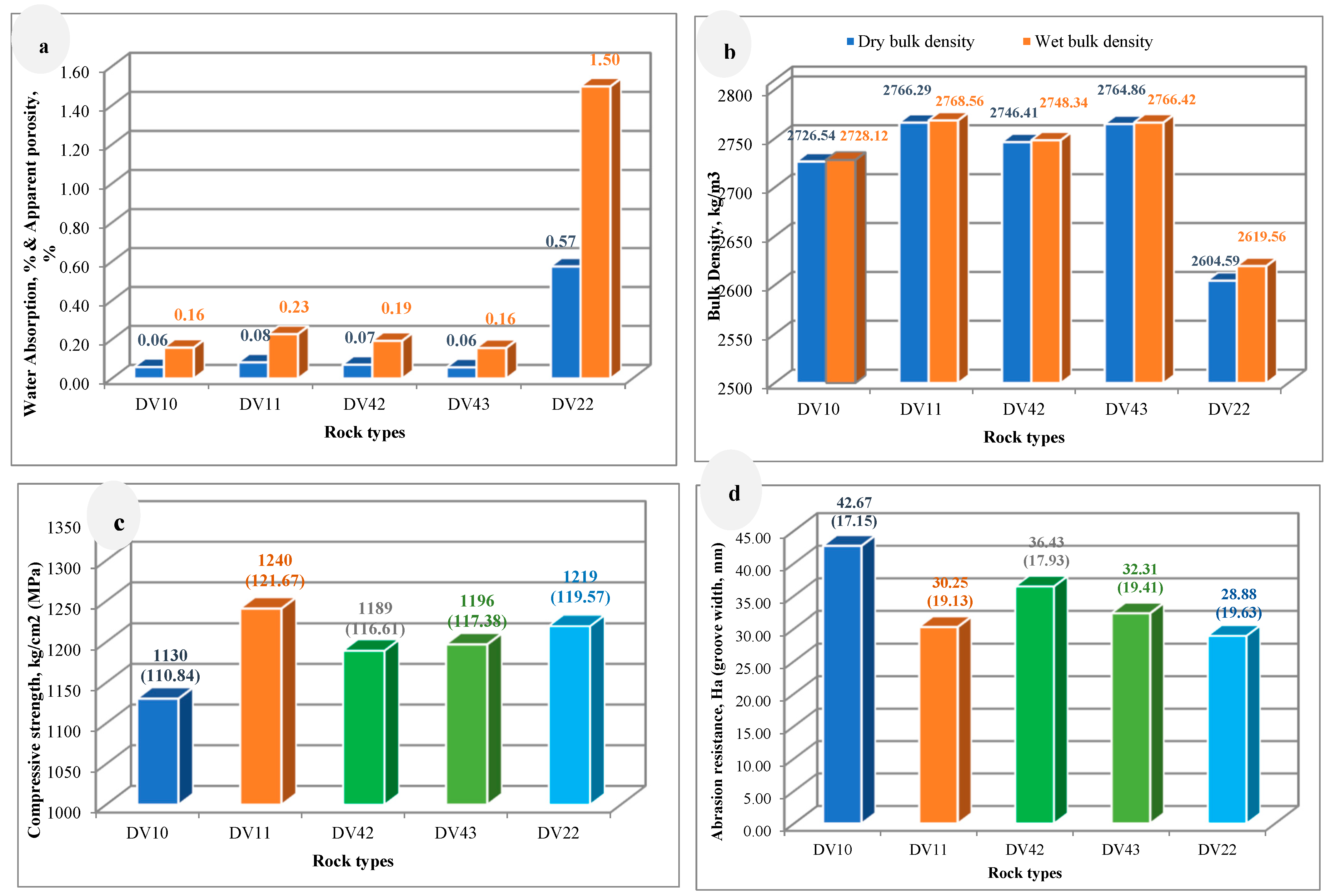

5.3. Decorative Applications of Dokhan Volcanics

5.4. Pozzolanic Activity of Dokhan Volcanics

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Sami, M.; Faisal, M.; Leybourne, M.; Sanislav, I.V.; Ahmed, M.S.; Lasheen, E.S.R. Unravelling the Genesis and Depositional Setting of Neoproterozoic Banded Iron Formation from Central Eastern Desert, Egypt. Front. Earth Sci. 2024, 12, 1359617. [Google Scholar] [CrossRef]

- Moghazi, A.M. Geochemistry and Petrogenesis of a High-K Calc-Alkaline Dokhan Volcanic Suite, South Safaga Area, Egypt: The Role of Late Neoproterozoic Crustal Extension. Precambrian Res. 2003, 125, 161–178. [Google Scholar] [CrossRef]

- Khaleal, F.M.; Lentz, D.R.; Kamar, M.S.; Saleh, G.M.; Lasheen, E.S.R. Critical Raw Material Resources in Nugrus-Sikait Area, South Eastern Desert, Egypt: Geological and Geochemical Aspects. J. Afr. Earth Sci. 2023, 197, 104782. [Google Scholar] [CrossRef]

- Stern, R.J. Neoproterozoic Formation and Evolution of Eastern Desert Continental Crust—The Importance of the Infrastructure-Superstructure Transition. J. Afr. Earth Sci. 2018, 146, 15–27. [Google Scholar] [CrossRef]

- Khaleal, F.M.; Lentz, D.R.; Kamh, S.Z.; Saleh, G.M.; Abdalla, F.; Lasheen, E.S.R. Remote Sensing Analysis and Geodynamic Setting of Magmatic Spessartine-Almandine-Bearing Leucogranites, Um Addebaa Area, Southeastern Desert, Egypt: Bulk Rock and Mineral Chemistry. Phys. Chem. Earth Parts ABC 2024, 136, 103749. [Google Scholar] [CrossRef]

- Saleh, G.M.; Kamh, S.Z.; Abdalla, F.; Kilias, A.; Lasheen, E.S.R. A New Occurrence of Rift-Related Damtjernite (Ultramafic) Lamprophyre, Gebel Anweiyib Area, Arabian Nubian Shield: Insights from Bulk Rock Geochemistry and Remote Sensing Data Analysis. Phys. Chem. Earth Parts ABC 2024, 133, 103530. [Google Scholar] [CrossRef]

- Abdel-Rahman, A.-F.M. Pan-African Volcanism: Petrology and Geochemistry of the Dokhan Volcanic Suite in the Northern Nubian Shield. Geol. Mag. 1996, 133, 17–31. [Google Scholar] [CrossRef]

- Abuamarah, B.A.; Azer, M.K.; Asimow, P.D.; Shi, Q. Post-Collisional Volcanism with Adakitic Signatures in the Arabian-Nubian Shield: A Case Study of Calc-Alkaline Dokhan Volcanics in the Eastern Desert of Egypt. Lithos 2021, 388–389, 106051. [Google Scholar] [CrossRef]

- Eliwa, H.A.; Kimura, J.-I.; Itaya, T. Late Neoproterozoic Dokhan Volcanics, North Eastern Desert, Egypt: Geochemistry and Petrogenesis. Precambrian Res. 2006, 151, 31–52. [Google Scholar] [CrossRef]

- Obeid, M.A.; Azer, M.K. Pan-African Adakitic Rocks of the North Arabian–Nubian Shield: Petrological and Geochemical Constraints on the Evolution of the Dokhan Volcanics in the North Eastern Desert of Egypt. Int. J. Earth Sci. 2015, 104, 541–563. [Google Scholar] [CrossRef]

- Seddiek, S.H.; El Afandy, A.H.; El Kaliouby, B.A.; Eliwa, H.A.; Khamis, H.A. Petrological and Geochemical Investigations on Dokhan Volcanics at Wadi Um Sidra-Wadi Um Asmer Area, North Eastern Desert, Egypt. Egypt J. Geol. 2020, 64, 237–254. [Google Scholar]

- Wilde, S.A.; Youssef, K. Significance of SHRIMP U-Pb Dating of the Imperial Porphyry and Associated Dokhan Volcanics, Gebel Dokhan, North Eastern Desert, Egypt. J. Afr. Earth Sci. 2000, 31, 403–413. [Google Scholar] [CrossRef]

- Hassan, M.A.; Hashad, A.H. Precambrian Egypt. In Geology of Egypt; Said, R., Ed.; Balkema: Rotterdam, The Netherlands, 1990. [Google Scholar]

- Fritz, H.; Wallbrecher, E.; Khudeir, A.A.; Abu El Ela, F.; Dallmeyer, D.R. Formation of Neoproterozoic Metamorphic Complex during Oblique Convergence (Eastern Desert, Egypt). J. Afr. Earth Sci. 1996, 23, 311–329. [Google Scholar] [CrossRef]

- Sami, M.; Azer, M.; Abdel-Karim, A.A. Postcollisional Ferani volcanics from north Arabian–Nubian Shield (south Sinai, Egypt): Petrogenesis and implication for Ediacaran (607–593 Ma) geodynamic evolution. J. Geo. 2022, 130, 475–498. [Google Scholar] [CrossRef]

- Mohamed, F.H.; Moghazi, A.M.; Hassanen, M.A. Geochemistry, Petrogenesis and Tectonic Setting of Late Neoproterozoic Dokhan-Type Volcanic Rocks in the Fatira Area, Eastern Egypt. Int. J. Earth Sci. 2000, 88, 764–777. [Google Scholar] [CrossRef]

- Wahab, G.M.A.; Gouda, M.; Ibrahim, G. Study of Physical and Mechanical Properties for Some of Eastern Desert Dimension Marble and Granite Utilized in Building Decoration. Ain Shams Eng. J. 2019, 10, 907–915. [Google Scholar] [CrossRef]

- ASTM C119; Standard Terminology Relating to Dimension Stone American Society for Testing and Materials. ASTM International: West Conshohocken, PA, USA, 2014.

- Careddu, N. Dimension Stones in the Circular Economy World. Resour. Policy 2019, 60, 243–245. [Google Scholar] [CrossRef]

- Freire-Lista, D.M. The Forerunners on Heritage Stones Investigation: Historical Synthesis and Evolution. Heritage 2021, 4, 1228–1268. [Google Scholar] [CrossRef]

- Mosch, S.; Siegesmund, S. Petrophysical and Technical Properties of Dimensional Stones: A Statistical Approach. Zeitschrift der Deutschen Gesellschaft für Geowissenschaften 2007, 158, 821–868. [Google Scholar] [CrossRef]

- Sitzia, F.; Lisci, C.; Mirão, J. Accelerate Ageing on Building Stone Materials by Simulating Daily, Seasonal Thermo-Hygrometric Conditions and Solar Radiation of Csa Mediterranean Climate. Constr. Build. Mater. 2021, 266, 121009. [Google Scholar] [CrossRef]

- Vigroux, M.; Eslami, J.; Beaucour, A.-L.; Bourgès, A.; Noumowé, A. High Temperature Behaviour of Various Natural Building Stones. Constr. Build. Mater. 2021, 272, 121629. [Google Scholar] [CrossRef]

- Marble Institute of America Geology of Stone. 2011. Available online: www.Marble-Institute.Com (accessed on 1 January 2024).

- Ciccu, R.; Cosentino, R.; Montani, C.; El Kotb, A.; Hamdy, H. Strategic Study on the Egyptian Marble and Granite Sector; Industrial Modernization Centre: Cairo, Egypt, 2005. [Google Scholar]

- Gomes, V.R.; Babisk, M.P.; Vieira, C.M.F.; Sampaio, J.A.; Vidal, F.W.H.; Gadioli, M.C.B. Ornamental Stone Wastes as an Alternate Raw Material for Soda-Lime Glass Manufacturing. Mater. Lett. 2020, 269, 127579. [Google Scholar] [CrossRef]

- Lasheen, E.S.R.; Elyaseer, M.H.; Mohamed, W.H.; Azer, M.K.; Rashwan, M.A.; Thabet, I.A. Economic Feasibility of Gabal Um Takha Leucogranitic Intrusion, South Sinai, Egypt: Integrated Remote Sensing, Geochemical, Aeromagnetic, and Geotechnical Approach. Phys. Chem. Earth Parts A/B/C 2024, 133, 103531. [Google Scholar] [CrossRef]

- Rashwan, M.A.; Lasheen, E.S.R.; Azer, M.K. Thermal and Physico-Mechanical Evaluation of Some Magmatic Rocks at Homrit Waggat Area, Eastern Desert, Egypt: Petrography and Geochemistry. Bull. Eng. Geol. Environ. 2023, 82, 199. [Google Scholar] [CrossRef]

- Mashaly, A.O.; El-Kaliouby, B.A.; Shalaby, B.N.; El-Gohary, A.M.; Rashwan, M.A. Effects of Marble Sludge Incorporation on the Properties of Cement Composites and Concrete Paving Blocks. J. Clean. Prod. 2016, 112, 731–741. [Google Scholar] [CrossRef]

- Rashwan, M.A.; Lasheen, E.S.R.; Abdelwahab, W.; Azer, M.K.; Zakaly, H.M.H.; Alarifi, S.S.; Ene, A.; Thabet, I.A. Physico-Mechanical Properties and Shielding Efficiency in Relation to Mineralogical and Geochemical Compositions of Um Had Granitoid, Central Eastern Desert, Egypt. Front. Earth Sci. 2023, 11, 1228489. [Google Scholar] [CrossRef]

- Ericsson, M. XXIX World Marble and Stones Report 2018 by Carlo Montani: Aldus Casa Di Edizioni, Carrara Italy 2018 E-Mail: Aldus.Danielecanal@alice.It. Miner. Econ. 2019, 32, 255–256. [Google Scholar] [CrossRef]

- Rana, A.; Kalla, P.; Verma, H.K.; Mohnot, J.K. Recycling of Dimensional Stone Waste in Concrete: A Review. J. Clean. Prod. 2016, 135, 312–331. [Google Scholar] [CrossRef]

- Singh Chouhan, H.; Kalla, P.; Nagar, R.; Kumar Gautam, P. Influence of Dimensional Stone Waste on Mechanical and Durability Properties of Mortar: A Review. Constr. Build. Mater. 2019, 227, 116662. [Google Scholar] [CrossRef]

- Alzahrani, A.M.; Lasheen, E.S.R.; Rashwan, M.A. Relationship of Mineralogical Composition to Thermal Expansion, Spectral Reflectance, and Physico-Mechanical Aspects of Commercial Ornamental Granitic Rocks. Materials 2022, 15, 2041. [Google Scholar] [CrossRef]

- Rashwan, M.A.; Abd El-Shakour, Z.A. Low-Cost, Highly-Performance Fired Clay Bodies Incorporating Natural Stone Sludge: Microstructure and Engineering Properties. Clean. Waste Syst. 2022, 3, 100041. [Google Scholar] [CrossRef]

- Lasheen, E.S.R.; Rashwan, M.A.; Azer, M.K. Effect of Mineralogical Variations on Physico-Mechanical and Thermal Properties of Granitic Rocks. Sci. Rep. 2023, 13, 10320. [Google Scholar] [CrossRef] [PubMed]

- Freire-Lista, D.M.; Gonçalves, G.V.; Vazquez, P. Weathering Detection of Granite from Three Asynchronous Historical Quarries of Sabrosa Municipally (North Portugal). J. Cult. Herit. 2022, 58, 199–208. [Google Scholar] [CrossRef]

- Heuze, F.E. High-Temperature Mechanical, Physical and Thermal Properties of Granitic Rocks—A Review. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1983, 20, 3–10. [Google Scholar] [CrossRef]

- Huotari, T.K.; Kukkonen, I. Thermal Expansion Properties of Rocks: Literature Survey and Fstimation of Thermal Expansion Coefficient for Olkiluoto Mica Gneiss; Geological Survey of Finland: Espoo, Finland, 2004. [Google Scholar]

- Siegesmund, S.; Sousa, L.; Knell, C. Thermal Expansion of Granitoids. Environ. Earth Sci. 2018, 77, 41. [Google Scholar] [CrossRef]

- Agasnalli, C.; Hema, H.C.; Lakkundi, T.; Chandrappa, K.D. Integrated Assessment of Granite and Basalt Rocks as Building Materials. Mater. Today Proc. 2022, 62, 5388–5391. [Google Scholar] [CrossRef]

- Sivanandhini, K.; Subasree, S.; Preethika, R.; Meenakshi, M. Experimental Study on Using Basalt as a Construction Material. Int. J. Civ. Eng. 2019, 6, 11–12. [Google Scholar] [CrossRef]

- Dobiszewska, M.; Schindler, A.K.; Pichór, W. Mechanical Properties and Interfacial Transition Zone Microstructure of Concrete with Waste Basalt Powder Addition. Constr. Build. Mater. 2018, 177, 222–229. [Google Scholar] [CrossRef]

- Ingrao, C.; Lo Giudice, A.; Tricase, C.; Mbohwa, C.; Rana, R. The Use of Basalt Aggregates in the Production of Concrete for the Prefabrication Industry: Environmental Impact Assessment, Interpretation and Improvement. J. Clean. Prod. 2014, 75, 195–204. [Google Scholar] [CrossRef]

- Kılıç, A.; Atiş, C.D.; Teymen, A.; Karahan, O.; Özcan, F.; Bilim, C.; Özdemir, M. The Influence of Aggregate Type on the Strength and Abrasion Resistance of High Strength Concrete. Cem. Concr. Compos. 2008, 30, 290–296. [Google Scholar] [CrossRef]

- Korkanç, M.; Tuğrul, A. Evaluation of Selected Basalts from Niğde, Turkey, as Source of Concrete Aggregate. Eng. Geol. 2004, 75, 291–307. [Google Scholar] [CrossRef]

- Li, P.P.; Yu, Q.L.; Brouwers, H.J.H. Effect of Coarse Basalt Aggregates on the Properties of Ultra-High Performance Concrete (UHPC). Constr. Build. Mater. 2018, 170, 649–659. [Google Scholar] [CrossRef]

- Piasta, W.; Góra, J.; Turkiewicz, T. Properties and Durability of Coarse Igneous Rock Aggregates and Concretes. Constr. Build. Mater. 2016, 126, 119–129. [Google Scholar] [CrossRef]

- Davraz, M.; Ceylan, H.; Topçu, İ.B.; Uygunoğlu, T. Pozzolanic Effect of Andesite Waste Powder on Mechanical Properties of High Strength Concrete. Constr. Build. Mater. 2018, 165, 494–503. [Google Scholar] [CrossRef]

- Ghorbani, S.; Taji, I.; De Brito, J.; Negahban, M.; Ghorbani, S.; Tavakkolizadeh, M.; Davoodi, A. Mechanical and Durability Behaviour of Concrete with Granite Waste Dust as Partial Cement Replacement under Adverse Exposure Conditions. Constr. Build. Mater. 2019, 194, 143–152. [Google Scholar] [CrossRef]

- Labbaci, Y.; Abdelaziz, Y.; Mekkaoui, A.; Alouani, A.; Labbaci, B. The Use of the Volcanic Powders as Supplementary Cementitious Materials for Environmental-Friendly Durable Concrete. Constr. Build. Mater. 2017, 133, 468–481. [Google Scholar] [CrossRef]

- Laibao, L.; Yunsheng, Z.; Wenhua, Z.; Zhiyong, L.; Lihua, Z. Investigating the Influence of Basalt as Mineral Admixture on Hydration and Microstructure Formation Mechanism of Cement. Constr. Build. Mater. 2013, 48, 434–440. [Google Scholar] [CrossRef]

- Mashaly, A.O.; Shalaby, B.N.; Rashwan, M.A. Performance of Mortar and Concrete Incorporating Granite Sludge as Cement Replacement. Constr. Build. Mater. 2018, 169, 800–818. [Google Scholar] [CrossRef]

- Rashwan, M.A.; Lasheen, E.S.R.; Hegazy, A.A. Tracking the Pozzolanic Activity of Mafic Rock Powder on Durability Performance of Cement Pastes under Adverse Conditions: Physico-Mechanical, Mineralogy, Microstructure, and Heat of Hydration. J. Build. Eng. 2023, 71, 106485. [Google Scholar] [CrossRef]

- Rashwan, M.A.; Al-Basiony, T.M.; Mashaly, A.O.; Khalil, M.M. Behaviour of Fresh and Hardened Concrete Incorporating Marble and Granite Sludge as Cement Replacement. J. Build. Eng. 2020, 32, 101697. [Google Scholar] [CrossRef]

- Rashwan, M.A.; Lasheen, E.S.R.; Shalaby, B.N. Incorporation of Metagabbro as Cement Replacement in Cement-Based Materials: A Role of Mafic Minerals on the Physico-Mechanical and Durability Properties. Constr. Build. Mater. 2019, 210, 256–268. [Google Scholar] [CrossRef]

- Saraya, M.E.-S.I. Study Physico-Chemical Properties of Blended Cements Containing Fixed Amount of Silica Fume, Blast Furnace Slag, Basalt and Limestone, a Comparative Study. Constr. Build. Mater. 2014, 72, 104–112. [Google Scholar] [CrossRef]

- Singh, S.; Anshumantiwari; Nagar, R.; Agrawal, V. Feasibility as a Potential Substitute for Natural Sand: A Comparative Study between Granite Cutting Waste and Marble Slurry. Procedia Environ. Sci. 2016, 35, 571–582. [Google Scholar] [CrossRef]

- Hegazy, A.; Khalil, A.; El-Alfi, E.; El-Shahat, M. Durability of Supersulphated Cement Pastes Activated with Portland Cement in Magnesium Chloride Solution. Egypt J. Chem. 2019, 62, 1145–1155. [Google Scholar] [CrossRef]

- ASTM C125; Standard Terminology Relating to Concrete and Concrete Aggregates American Society for Testing and Materials. ASTM International: West Conshohocken, PA, USA, 2015.

- Massazza, F. Pozzolana and Pozzolanic Cements. In Lea’s Chemistry of Cement and Concrete; Hewlett, P., Ed.; Elsevier Science: Amsterdam, The Netherlands, 2004. [Google Scholar]

- Scherer, C.; Felippi De Lima, L.; Eunice Zorzi, J. Effect of Partial Replacement of Cement by Fine Powders on the Corrosion Resistance of Concrete. Constr. Build. Mater. 2023, 401, 132982. [Google Scholar] [CrossRef]

- Yang, R.; Yu, R.; Shui, Z.; Gao, X.; Han, J.; Lin, G.; Qian, D.; Liu, Z.; He, Y. Environmental and Economical Friendly Ultra-High Performance-Concrete Incorporating Appropriate Quarry-Stone Powders. J. Clean. Prod. 2020, 260, 121112. [Google Scholar] [CrossRef]

- Scheinherrová, L.; Keppert, M.; Černý, R. Chemical Aspects of the Application of Basalt in Cement Composites. Constr. Build. Mater. 2022, 350, 128873. [Google Scholar] [CrossRef]

- Türk, E.; Karataş, M.; Dener, M. Rheological, Mechanical and Durability Properties of Self-Compacting Mortars Containing Basalt Powder and Silica Fume. Constr. Build. Mater. 2022, 356, 129229. [Google Scholar] [CrossRef]

- Baki, V.A.; Nayir, S.; Erdogdu, S.; Ustabas, I. Pozzolanic Properties of Trachyte and Rhyolite and Their Effects on Alkali-Silica Reaction. Adv. Concr. Constr. 2021, 11, 299–306. [Google Scholar] [CrossRef]

- Çullu, M.; Bolat, H.; Vural, A.; Tuncer, E. Investigation of Pozzolanic Activity of Volcanic Rocks from the Northeast of the Black Sea. Sci. Eng. Compos. Mater. 2016, 23, 315–323. [Google Scholar] [CrossRef]

- ASTM E1621; Standard Guide for Elemental Analysis by Wavelength Dispersive X-Ray Fluorescence Spectrometry. American Society for Testing and Materials: West Conshohocken, PA, USA, 2013.

- ASTM D7348; Standard Test Methods for Loss on Ignition (LOI) of Solid Combustion Residues. American Society for Testing and Materials: West Conshohocken, PA, USA, 2013.

- ASTM C97/C97M; Standard Test Method for Absorption and Bulk Specific Gravity of Dimension Stone. American Society for Testing and Materials: West Conshohocken, PA, USA, 2015.

- EN 1936; Natural Stone Test Methods—Determination of Real Density and Apparent Density, and of Total and Open Porosity. European Committee for Standardization (CEN): Brussels, Belgium, 1999.

- ASTM C170/C170M; Standard Test Method for Compressive Strength of Dimension Stone. American Society for Testing and Materials: West Conshohocken, PA, USA, 2015.

- ASTM C241/C241M; Standard Test Method for Abrasion Resistance of Stone Subjected to Foot Traffic. American Society for Testing and Materials: West Conshohocken, PA, USA, 2015.

- EN 14157; Natural Stone Test Methods—Determination of the Abrasion Resistance. European Committee for Standardization: Brussels, Belgium, 2017.

- BS EN 196-5; Methods of Testing Cement—Part 5: Pozzolanicity Test for Pozzolanic Cement. European Committee for Standardization: Brussels, Belgium, 2011.

- ASTM C618; Standard Specification for Coal Fly Ash and Raw or Calcined Natural Pozzolan for Use in Concrete. American Society for Testing and Materials: West Conshohocken, PA, USA, 2003.

- ASTM C311/C311M; Standard Test Methods for Sampling and Testing Fly Ash or Natural Pozzolans for Use in Portland-Cement Concrete. American Society for Testing and Materials: West Conshohocken, PA, USA, 2013.

- Le Bas, M.J.L.; Maitre, R.W.L.; Streckeisen, A.; Zanettin, B.; IUGS Subcommission on the Systematics of Igneous Rocks. A Chemical Classification of Volcanic Rocks Based on the Total Alkali-Silica Diagram. J. Petrol. 1986, 27, 745–750. [Google Scholar] [CrossRef]

- Winchester, J.A.; Floyd, P.A. Geochemical Discrimination of Different Magma Series and Their Differentiation Products Using Immobile Elements. Chem. Geol. 1977, 20, 325–343. [Google Scholar] [CrossRef]

- Irvine, T.N.; Baragar, W.R.A. A Guide to the Chemical Classification of the Common Volcanic Rocks. Can. J. Earth Sci. 1971, 8, 523–548. [Google Scholar] [CrossRef]

- Le Maitre, R.W. A Classification of Igneous Rocks and Glossary of Terms; Blackwell: Oxford, UK, 1989. [Google Scholar]

- Defant, M.J.; Drummond, M.S. Derivation of Some Modern Arc Magmas by Melting of Young Subducted Lithosphere. Nature 1990, 347, 662–665. [Google Scholar] [CrossRef]

- Woodhead, J.; Eggins, S.; Gamble, J. High Field Strength and Transition Element Systematics in Island Arc and Back-Arc Basin Basalts: Evidence for Multi-Phase Melt Extraction and a Depleted Mantle Wedge. Earth Planet. Sci. Lett. 1993, 114, 491–504. [Google Scholar] [CrossRef]

- Stern, R.J.; Gottfried, D.; Hedge, C.E. Late Precambrian Rifting and Crustal Evolution in the Northeastern Desert of Egypt. Geology 1984, 12, 168. [Google Scholar] [CrossRef]

- Pearce, J.A.; Cann, J.R. Tectonic Setting of Basic Volcanic Rocks Determined Using Trace Element Analyses. Earth Planet. Sci. Lett. 1973, 19, 290–300. [Google Scholar] [CrossRef]

- Pearce, J.A.; Harris, N.B.W.; Tindle, A.G. Trace Element Discrimination Diagrams for the Tectonic Interpretation of Granitic Rocks. J. Petrol. 1984, 25, 956–983. [Google Scholar] [CrossRef]

- Wood, D.A. The Application of a ThHfTa Diagram to Problems of Tectonomagmatic Classification and to Establishing the Nature of Crustal Contamination of Basaltic Lavas of the British Tertiary Volcanic Province. Earth Planet. Sci. Lett. 1980, 50, 11–30. [Google Scholar] [CrossRef]

- Pearce, T.H.; Gorman, B.E.; Birkett, T.C. The TiO2–K2O–P2O5 Diagram: A Method of Discriminating between Oceanic and Non-Oceanic Basalts. Earth Planet. Sci. Lett. 1975, 24, 419–426. [Google Scholar] [CrossRef]

- Pearce, J.A.; Gale, G.H. Identification of Ore-Deposition Environment from Trace-Element Geochemistry of Associated Igneous Host Rocks. Geol. Soc. Lond. Spec. Publ. 1977, 7, 14–24. [Google Scholar] [CrossRef]

- Sun, S.-S.; McDonough, W.F. Chemical and Isotopic Systematics of Oceanic Basalts: Implications for Mantle Composition and Processes. Geol. Soc. Lond. Spec. Publ. 1989, 42, 313–345. [Google Scholar] [CrossRef]

- Stern, R.J. Petrogenesis and Tectonic Setting of Late Precambrian Ensimatic Volcanic Rocks, Central Eastern Desert of Egypt. Precambrian Res. 1981, 16, 195–230. [Google Scholar] [CrossRef]

- Stern, R.J.; Gottfried, D. Petrogenesis of a Late Precambrian (575–600 Ma) Bimodal Suite in Northeast Africa. Contrib. Mineral. Petrol. 1986, 92, 492–501. [Google Scholar] [CrossRef]

- Hawkesworth, C.J.; Gallagher, K.; Hergt, J.M.; McDermott, F. Mantle and Slab Contributions in ARC Magmas. Annu. Rev. Earth Planet. Sci. 1993, 21, 175–204. [Google Scholar] [CrossRef]

- Eby, G.N. Chemical Subdivision of the A-Type Granitoids: Petrogenetic and Tectonic Implications. Geology 1992, 20, 641. [Google Scholar] [CrossRef]

- Eyal, M.; Litvinovsky, B.; Jahn, B.M.; Zanvilevich, A.; Katzir, Y. Origin and Evolution of Post-Collisional Magmatism: Coeval Neoproterozoic Calc-Alkaline and Alkaline Suites of the Sinai Peninsula. Chem. Geol. 2010, 269, 153–179. [Google Scholar] [CrossRef]

- Davidson, J.P.; Ferguson, K.M.; Colucci, M.T.; Dungan, M.A. The Origin and Evolution of Magmas from the San Pedro-Pellado Volcanic Complex, S. Chile: Multicomponent Sources and Open System Evolution. Contrib. Mineral. Petrol. 1988, 100, 429–445. [Google Scholar] [CrossRef]

- ASTM C615/C615M; Standard Specification for Granite Dimension Stone. American society for testing and materials: West Conshohocken, PA, USA, 2011.

- Török, A.; Török, Á. The Effect of Temperature on the Strength of Two Different Granites. Cent. Eur. Geol. 2015, 58, 356–369. [Google Scholar] [CrossRef]

- Siegesmund, S.; Dürrast, H. Physical and Mechanical Properties of Rocks. In Stone in Architecture; Siegesmund, S., Snethlage, R., Eds.; Springer: Berlin/Heidelberg, Germany, 2011; pp. 97–225. ISBN 978-3-642-14474-5. [Google Scholar]

- Jain, N. Effect of Nonpozzolanic and Pozzolanic Mineral Admixtures on the Hydration Behavior of Ordinary Portland Cement. Constr. Build. Mater. 2012, 27, 39–44. [Google Scholar] [CrossRef]

| Dv No. | 42a | 42b | 42c | 43a | 43b | 43c | 10a | 10b | 10c | 22a | 22b | 22c | 11a | 11b | 11c |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| SiO2 | 63.73 | 63.50 | 62.98 | 61.40 | 60.47 | 60.09 | 65.68 | 65.11 | 64.84 | 75.51 | 73.26 | 74.39 | 61.70 | 60.36 | 60.23 |

| TiO2 | 0.60 | 0.80 | 0.70 | 0.62 | 0.71 | 0.73 | 0.45 | 0.51 | 0.53 | 0.12 | 0.17 | 0.15 | 0.56 | 0.54 | 0.65 |

| Al2O3 | 16.73 | 16.78 | 16.36 | 16.94 | 16.26 | 16.45 | 15.70 | 16.04 | 16.17 | 13.71 | 14.82 | 14.26 | 15.12 | 16.03 | 15.58 |

| Fe2O3 | 4.95 | 5.23 | 5.09 | 5.35 | 5.71 | 6.03 | 4.41 | 5.06 | 4.98 | 1.02 | 1.31 | 1.16 | 6.37 | 6.97 | 6.17 |

| MnO | 0.09 | 0.11 | 0.10 | 0.10 | 0.12 | 0.11 | 0.09 | 0.10 | 0.09 | 0.07 | 0.09 | 0.08 | 0.20 | 0.24 | 0.22 |

| CaO | 3.45 | 4.01 | 3.73 | 4.14 | 4.79 | 4.46 | 2.68 | 3.04 | 2.91 | 0.40 | 0.48 | 0.44 | 3.30 | 3.81 | 3.55 |

| MgO | 2.37 | 2.36 | 2.36 | 2.69 | 2.67 | 2.68 | 2.15 | 2.14 | 2.15 | 0.28 | 0.28 | 0.28 | 3.13 | 3.11 | 3.12 |

| K2O | 1.71 | 2.09 | 1.90 | 1.19 | 1.45 | 1.32 | 2.12 | 2.59 | 2.35 | 3.20 | 4.01 | 3.60 | 1.52 | 1.84 | 1.68 |

| Na2O | 4.64 | 4.48 | 4.56 | 4.43 | 4.27 | 4.35 | 4.66 | 4.51 | 4.58 | 4.84 | 4.74 | 4.79 | 3.90 | 3.76 | 3.83 |

| P2O5 | 0.58 | 0.46 | 0.52 | 0.62 | 0.49 | 0.56 | 0.55 | 0.44 | 0.49 | 0.06 | 0.05 | 0.06 | 0.45 | 0.36 | 0.41 |

| LOI | 0.76 | 0.76 | 0.76 | 1.70 | 1.70 | 1.70 | 1.10 | 1.10 | 1.10 | 0.40 | 0.40 | 0.40 | 3.33 | 3.33 | 3.33 |

| Normative values | |||||||||||||||

| Qz | 20.87 | 18.63 | 19.11 | 19.97 | 17.27 | 17.77 | 23.09 | 20.49 | 21.13 | 34.06 | 29.06 | 31.56 | 22.74 | 19.70 | 20.42 |

| C | 2.34 | 0.94 | 1.24 | 2.33 | 0.15 | 1.09 | 2.18 | 1.33 | 1.96 | 1.72 | 1.94 | 1.83 | 2.15 | 1.79 | 1.97 |

| Or | 10.12 | 12.32 | 11.22 | 7.03 | 8.54 | 7.79 | 12.50 | 15.30 | 13.90 | 18.89 | 23.72 | 21.30 | 8.97 | 10.86 | 9.91 |

| Ab | 39.29 | 37.93 | 38.61 | 37.48 | 36.12 | 36.80 | 39.41 | 38.17 | 38.79 | 40.94 | 40.08 | 40.51 | 33.02 | 31.78 | 32.40 |

| An | 13.36 | 16.92 | 15.14 | 16.46 | 20.53 | 18.50 | 9.74 | 12.24 | 11.23 | 1.55 | 2.03 | 1.79 | 13.41 | 16.57 | 14.99 |

| Hy | 5.91 | 5.87 | 5.89 | 6.70 | 6.65 | 6.68 | 5.36 | 5.34 | 5.35 | 0.70 | 0.71 | 0.70 | 7.80 | 7.75 | 7.77 |

| Il | 0.20 | 0.24 | 0.22 | 0.22 | 0.26 | 0.24 | 0.18 | 0.22 | 0.20 | 0.16 | 0.19 | 0.17 | 0.43 | 0.51 | 0.47 |

| Hm | 4.95 | 5.23 | 5.09 | 5.35 | 5.71 | 6.03 | 4.41 | 5.06 | 4.98 | 1.02 | 1.31 | 1.17 | 6.38 | 6.97 | 6.17 |

| Ru | 0.50 | 0.68 | 0.59 | 0.51 | 0.58 | 0.60 | 0.36 | 0.39 | 0.43 | 0.04 | 0.07 | 0.06 | 0.34 | 0.28 | 0.41 |

| Ap | 1.37 | 1.08 | 1.23 | 1.48 | 1.17 | 1.32 | 1.30 | 1.04 | 1.17 | 0.15 | 0.12 | 0.14 | 1.07 | 0.85 | 0.96 |

| Sum | 98.91 | 99.85 | 98.34 | 97.53 | 96.98 | 96.81 | 98.51 | 99.57 | 99.14 | 99.23 | 99.22 | 99.23 | 96.30 | 97.04 | 95.47 |

| Trace elements (ppm) | |||||||||||||||

| As | 18.50 | 18.00 | 18.25 | 5.70 | 5.80 | 5.75 | 13.10 | 13.00 | 13.05 | 45.40 | 45.87 | 45.64 | 3.30 | 3.56 | 3.43 |

| Ba | 443.00 | 441.00 | 442.00 | 384.20 | 382.00 | 383.10 | 542.10 | 540.60 | 541.35 | 298.20 | 301.00 | 299.60 | 606.10 | 605.00 | 605.55 |

| Cd | 8.80 | 8.22 | 8.51 | 6.20 | 5.98 | 6.09 | 7.80 | 7.91 | 7.86 | 4.00 | 3.99 | 4.00 | 5.80 | 5.21 | 5.51 |

| Ce | 57.30 | 57.22 | 57.26 | 32.90 | 31.98 | 32.44 | 57.10 | 56.91 | 57.01 | 24.50 | 23.99 | 24.25 | 29.50 | 30.01 | 29.76 |

| Co | 19.10 | 20.01 | 19.56 | 32.60 | 31.56 | 32.08 | 21.30 | 20.91 | 21.11 | 18.50 | 17.88 | 18.19 | 31.90 | 30.41 | 31.16 |

| Cr | 12.80 | 12.55 | 12.68 | 16.00 | 15.09 | 15.55 | 21.70 | 20.93 | 21.32 | 3.30 | 3.11 | 3.21 | 11.90 | 10.97 | 11.44 |

| Cs | 2.80 | 2.22 | 2.51 | 4.70 | 2.61 | 3.66 | ND | ND | ND | 7.40 | 6.87 | 7.14 | 10.30 | 9.55 | 9.93 |

| Cu | 6.40 | 6.03 | 6.22 | 6.40 | 5.94 | 6.17 | 5.10 | 4.65 | 4.88 | 3.70 | 2.95 | 3.33 | 5.70 | 4.87 | 5.29 |

| Ga | 23.00 | 23.06 | 23.03 | 24.10 | 24.05 | 24.08 | 21.90 | 21.09 | 21.50 | 15.50 | 14.76 | 15.13 | 20.90 | 21.01 | 20.96 |

| Hf | 3.20 | 2.83 | 3.02 | 12.30 | 11.05 | 11.68 | 19.80 | 18.99 | 19.40 | ND | ND | ND | 12.10 | 11.43 | 11.77 |

| La | 25.90 | 24.06 | 24.98 | 13.80 | 12.03 | 12.92 | 33.30 | 31.22 | 32.26 | 21.10 | 20.89 | 21.00 | 21.20 | 20.85 | 21.03 |

| Nb | 1.60 | 1.03 | 1.32 | 0.90 | 0.08 | 0.49 | 3.30 | 2.91 | 3.11 | 4.50 | 4.25 | 4.38 | 1.50 | 1.23 | 1.37 |

| Nd | 21.60 | 20.75 | 21.18 | 12.30 | 10.86 | 11.58 | 34.60 | 34.11 | 34.36 | 17.40 | 15.88 | 16.64 | 9.40 | 9.21 | 9.31 |

| Ni | 5.90 | 4.87 | 5.39 | 8.00 | 7.54 | 7.77 | 10.30 | 9.88 | 10.09 | 1.10 | 1.02 | 1.06 | 8.70 | 7.93 | 8.32 |

| Pb | 25.70 | 24.54 | 25.12 | 23.70 | 22.64 | 23.17 | 34.90 | 33.74 | 34.32 | 22.00 | 21.07 | 21.54 | 27.70 | 26.04 | 26.87 |

| Rb | 36.30 | 35.02 | 35.66 | 27.40 | 27.01 | 27.21 | 50.20 | 51.00 | 50.60 | 82.40 | 82.02 | 82.21 | 52.30 | 53.00 | 52.65 |

| Sc | 11.10 | 10.54 | 10.82 | 13.50 | 12.05 | 12.78 | 8.30 | 7.88 | 8.09 | 2.20 | 2.02 | 2.11 | 12.30 | 11.29 | 11.80 |

| m | 5.90 | 6.11 | 6.01 | 7.60 | 6.98 | 7.29 | ND | ND | ND | 8.00 | 9.52 | 8.76 | 10.60 | 10.41 | 10.51 |

| Sn | 50.30 | 50.82 | 50.56 | 51.00 | 50.67 | 50.84 | 61.40 | 60.82 | 61.11 | 10.90 | 11.52 | 11.21 | 50.90 | 51.03 | 50.97 |

| Sr | 496.80 | 495.00 | 495.90 | 432.20 | 433.00 | 432.60 | 302.30 | 303.00 | 302.65 | 50.70 | 51.77 | 51.24 | 425.60 | 423.00 | 424.30 |

| Th | 17.50 | 17.01 | 17.26 | 18.60 | 19.00 | 18.80 | 23.30 | 23.53 | 23.42 | 9.80 | 8.67 | 9.24 | 16.80 | 15.32 | 16.06 |

| V | 33.40 | 32.43 | 32.92 | 37.00 | 38.00 | 37.50 | 35.50 | 35.22 | 35.36 | ND | ND | ND | 69.70 | 68.54 | 69.12 |

| Y | 16.00 | 15.32 | 15.66 | 12.60 | 13.00 | 12.80 | 14.80 | 14.06 | 14.43 | 10.00 | 9.45 | 9.73 | 13.10 | 12.38 | 12.74 |

| Zn | 54.30 | 55.01 | 54.66 | 65.80 | 66.01 | 65.91 | 50.10 | 51.01 | 50.56 | 29.80 | 30.40 | 30.10 | 241.80 | 244.00 | 242.90 |

| Zr | 147.10 | 146.87 | 146.99 | 131.20 | 132.00 | 131.60 | 183.10 | 184.00 | 183.55 | 131.50 | 130.80 | 131.15 | 147.10 | 146.70 | 146.90 |

| Geochemical Parameters | |||||||||||||||

| Agpaitic | 0.57 | 0.57 | 0.59 | 0.51 | 0.53 | 0.52 | 0.63 | 0.64 | 0.62 | 0.83 | 0.82 | 0.83 | 0.53 | 0.51 | 0.52 |

| Sr/Y | 31.05 | 32.31 | 31.67 | 34.30 | 33.31 | 33.80 | 20.43 | 21.55 | 20.97 | 5.07 | 5.48 | 5.27 | 32.49 | 34.17 | 33.30 |

| Th/Zr | 0.12 | 0.12 | 0.12 | 0.14 | 0.14 | 0.14 | 0.13 | 0.13 | 0.13 | 0.07 | 0.07 | 0.07 | 0.11 | 0.10 | 0.11 |

| Rb/Zr | 0.25 | 0.24 | 0.24 | 0.21 | 0.20 | 0.21 | 0.27 | 0.28 | 0.28 | 0.63 | 0.63 | 0.63 | 0.36 | 0.36 | 0.36 |

| La/Sm | 4.39 | 3.94 | 4.16 | 1.82 | 1.72 | 1.77 | ND | ND | ND | 2.64 | 2.19 | 2.40 | 2.00 | 2.00 | 2.00 |

| Y/Nb | 10.00 | 14.87 | 11.91 | 14.00 | 162.50 | 26.12 | 4.48 | 4.83 | 4.65 | 2.22 | 2.22 | 2.22 | 8.73 | 10.07 | 9.33 |

| Ba/Nb | 276.88 | 428.16 | 336.12 | 426.89 | 4775.00 | 781.84 | 164.27 | 185.77 | 174.35 | 66.27 | 70.82 | 68.48 | 404.07 | 491.87 | 443.63 |

| K/Rb | 471.90 | 595.37 | 532.53 | 434.31 | 534.99 | 484.29 | 421.31 | 507.65 | 464.82 | 387.86 | 489.27 | 438.45 | 290.25 | 346.60 | 318.61 |

| Mg# | 32.37 | 31.07 | 31.71 | 33.46 | 31.87 | 30.78 | 32.80 | 29.76 | 30.12 | 21.55 | 17.86 | 19.52 | 32.95 | 30.84 | 33.58 |

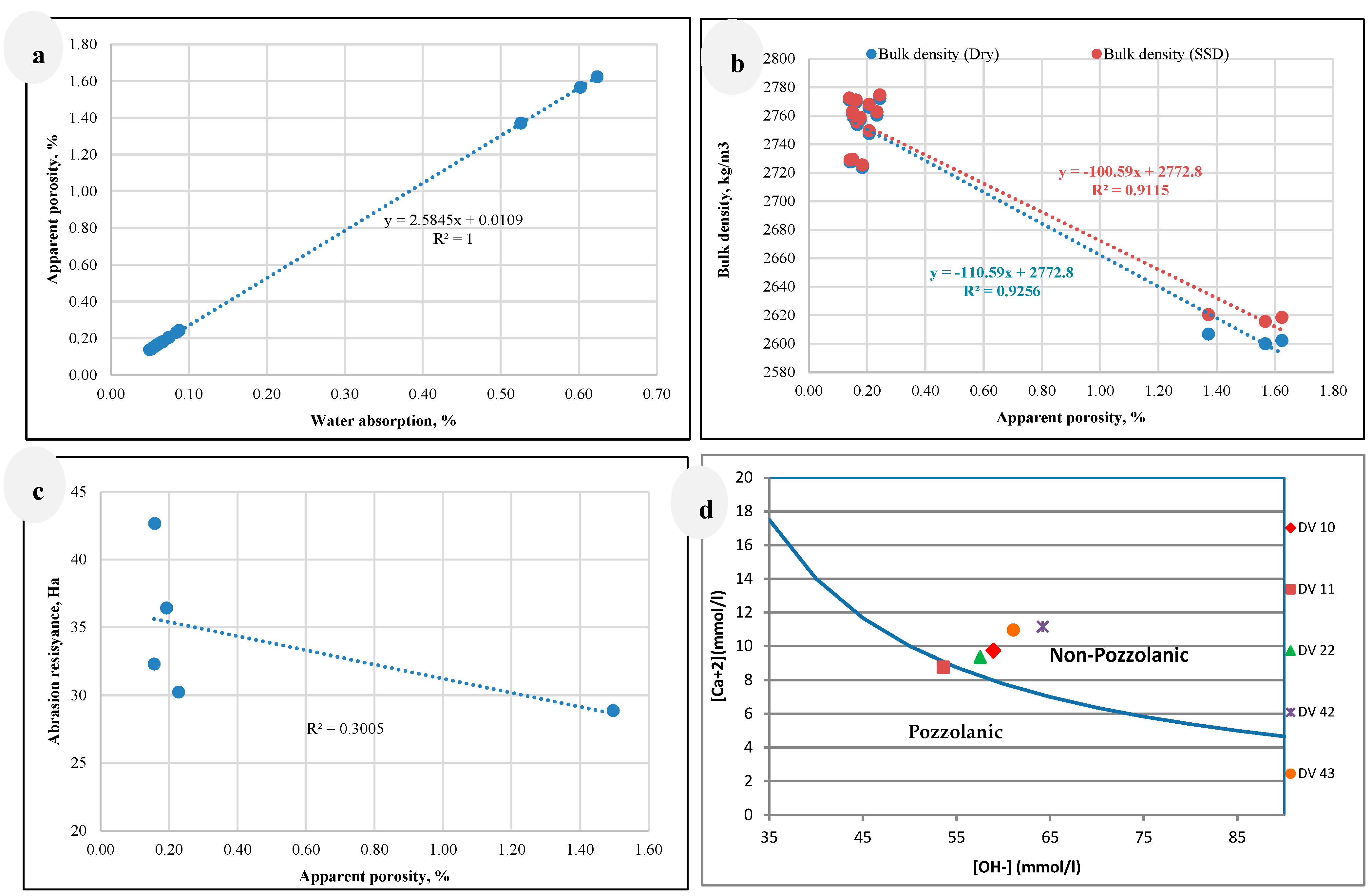

| Measured Parameters | Statistical Parameters | Studied Rock Specimens | Reference Standard, ASTM C615 [97] | ||||

|---|---|---|---|---|---|---|---|

| DV 10 | DV 11 | DV 42 | DV 43 | DV 22 | |||

| Water absorption, % | Max. | 0.07 | 0.09 | 0.08 | 0.06 | 0.62 | 0.4% max. |

| Min. | 0.05 | 0.07 | 0.06 | 0.05 | 0.53 | ||

| Av. | 0.06 | 0.08 | 0.06 | 0.06 | 0.58 | ||

| Apparent porosity, % | Max. | 0.18 | 0.24 | 0.21 | 0.18 | 1.62 | N/A |

| Min. | 0.14 | 0.21 | 0.16 | 0.14 | 1.37 | ||

| Av. | 0.16 | 0.23 | 0.18 | 0.16 | 1.52 | ||

| Dry bulk density, kg/m3 | Max. | 2728.08 | 2772.23 | 2756.81 | 2771.11 | 2606.82 | 2560 kg/m3 min. |

| Min. | 2723.81 | 2760.56 | 2747.59 | 2757.32 | 2600.03 | ||

| Av. | 2726.54 | 2766.29 | 2752.77 | 2764.86 | 2603.07 | ||

| Wet bulk density, kg/m3 | Max. | 2729.58 | 2772.66 | 2758.41 | 2772.50 | 2620.52 | N/A |

| Min. | 2725.64 | 2762.88 | 2749.66 | 2759.07 | 2615.69 | ||

| Av. | 2728.12 | 2768.56 | 2754.54 | 2766.42 | 2618.27 | ||

| Compressive strength, kg/cm2 (MPa) | Max. | 1634.38 (160.28) | 1625.54 (159.41) | 1234.58 (121.07) | 1360.92 (133.46) | 1515.05 (148.58) | 131 MPa min. |

| Min. | 690.59 (67.72) | 802.83 (78.73) | 1141.22 (111.92) | 817.89 (80.21) | 798.25 (78.28) | ||

| Av. | 1130.21 (110.84) | 1240.69 (121.67) | 1189.10 (116.61) | 1196.98 (117.38) | 1219.30 (119.57) | ||

| Abrasion resistance, Ha (Groove width) | Max. | 58.63 (15.04) | 34.14 (18.28) | 43.16 (16.81) | 33.73 (18.36) | 37.82 (17.62) | 25 Ha min. |

| Min. | 32.07 (18.69) | 26.52 (19.99) | 32.08 (18.69) | 21.01 (21.69) | 21.79 (21.41) | ||

| Av. | 42.67 (17.15) | 30.25 (19.13) | 36.43 (17.93) | 29.49 (19.41) | 28.88 (19.63) | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lasheen, E.S.R.; Sami, M.; Hegazy, A.A.; Arman, H.; Sanislav, I.V.; Ahmed, M.S.; Rashwan, M.A. Petrological Characteristics and Physico-Mechanical Properties of Dokhan Volcanics for Decorative Stones and Building Material Applications. Buildings 2024, 14, 3418. https://doi.org/10.3390/buildings14113418

Lasheen ESR, Sami M, Hegazy AA, Arman H, Sanislav IV, Ahmed MS, Rashwan MA. Petrological Characteristics and Physico-Mechanical Properties of Dokhan Volcanics for Decorative Stones and Building Material Applications. Buildings. 2024; 14(11):3418. https://doi.org/10.3390/buildings14113418

Chicago/Turabian StyleLasheen, El Saeed R., Mabrouk Sami, Ahmed A. Hegazy, Hasan Arman, Ioan V. Sanislav, Mohamed S. Ahmed, and Mohammed A. Rashwan. 2024. "Petrological Characteristics and Physico-Mechanical Properties of Dokhan Volcanics for Decorative Stones and Building Material Applications" Buildings 14, no. 11: 3418. https://doi.org/10.3390/buildings14113418

APA StyleLasheen, E. S. R., Sami, M., Hegazy, A. A., Arman, H., Sanislav, I. V., Ahmed, M. S., & Rashwan, M. A. (2024). Petrological Characteristics and Physico-Mechanical Properties of Dokhan Volcanics for Decorative Stones and Building Material Applications. Buildings, 14(11), 3418. https://doi.org/10.3390/buildings14113418