Experimental Study on the Mechanical Properties of Squat RC Shear Walls with Corrosion Along the Base

Abstract

1. Introduction

2. Experimental Program

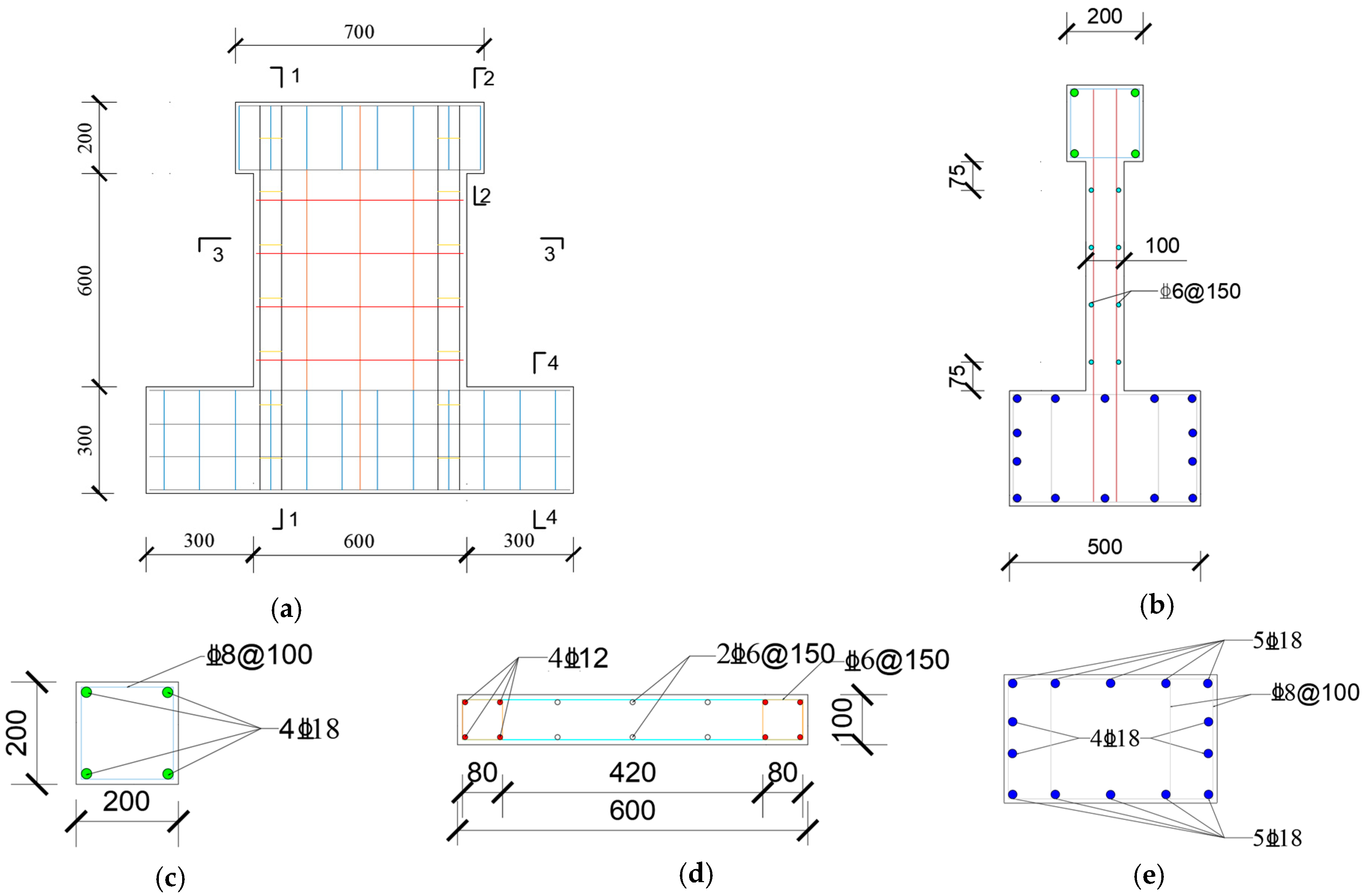

2.1. Design of SRCSWs

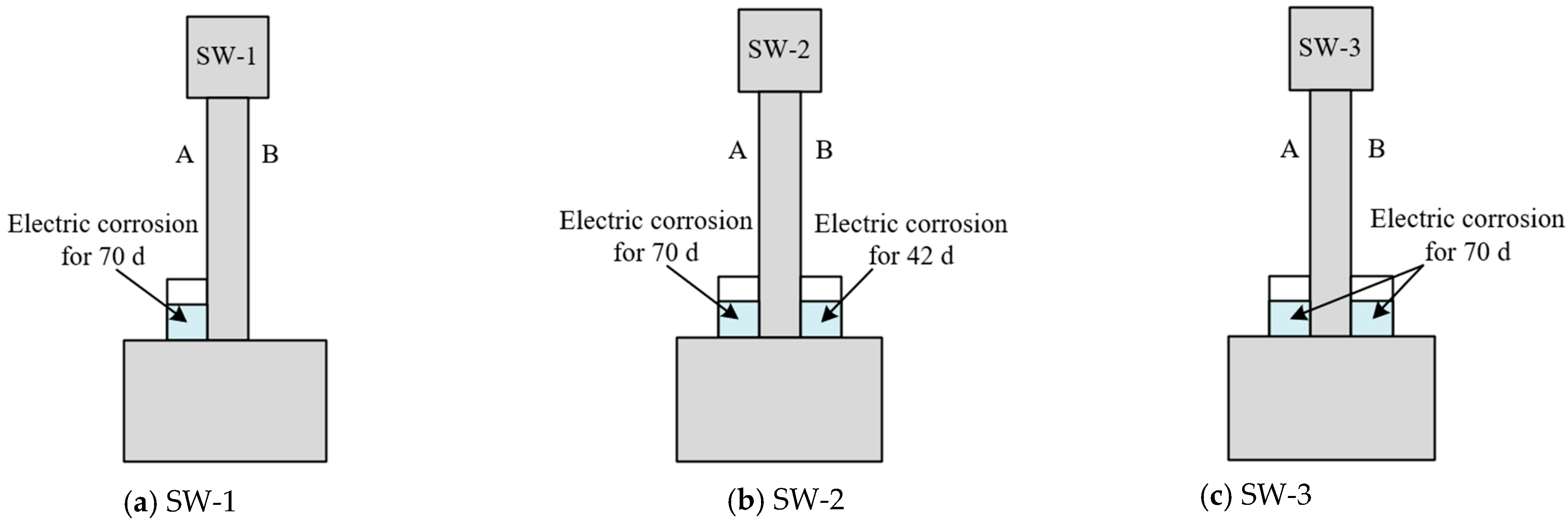

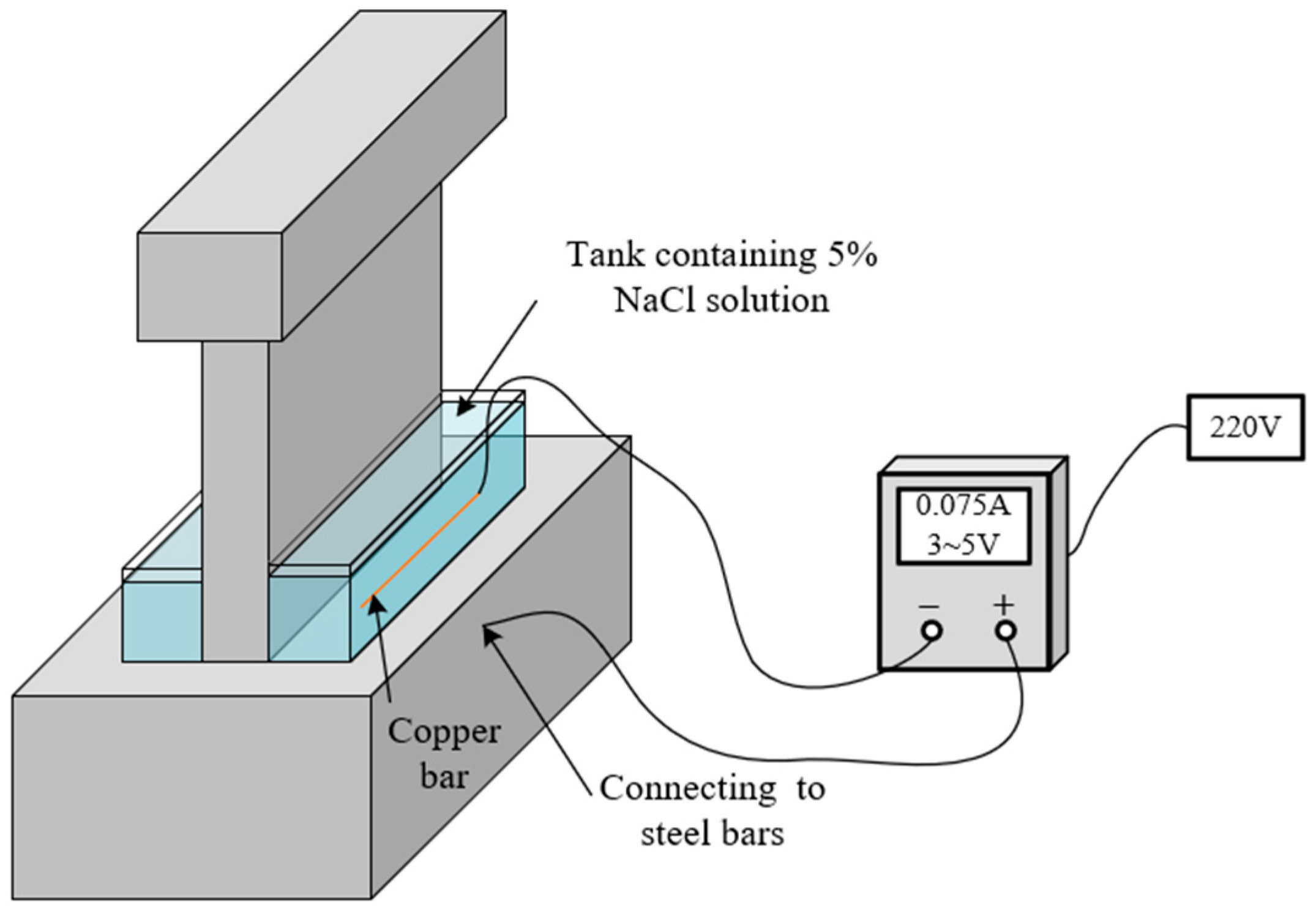

2.2. Accelerated Corrosion Test

2.3. Loading Failure Test

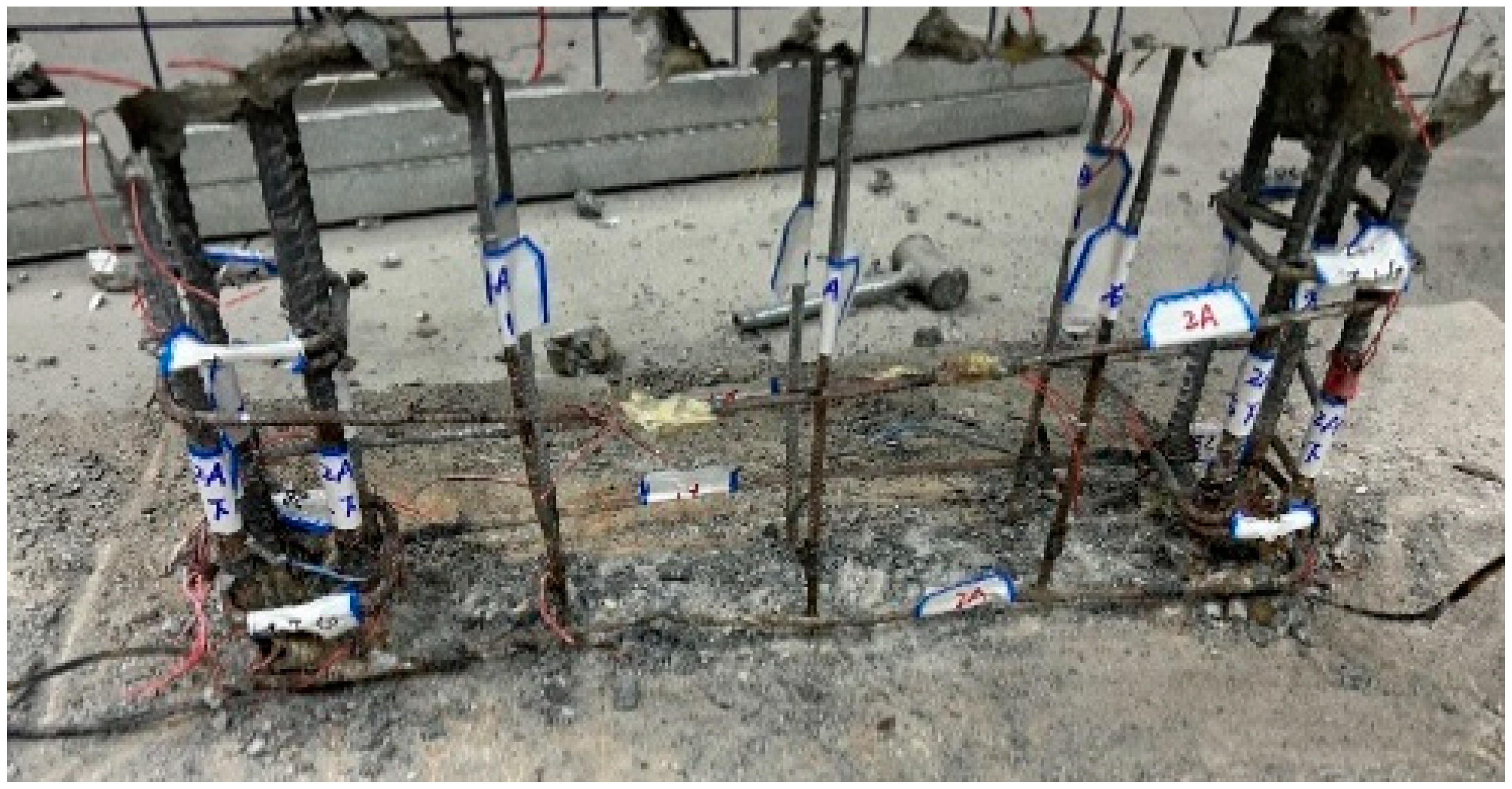

2.4. Measurement of Mass Loss of Steel Bars

3. Results and Discussion

3.1. Corrosion Phenomenon of SRCSWs

3.2. Analysis of the Loading Failure

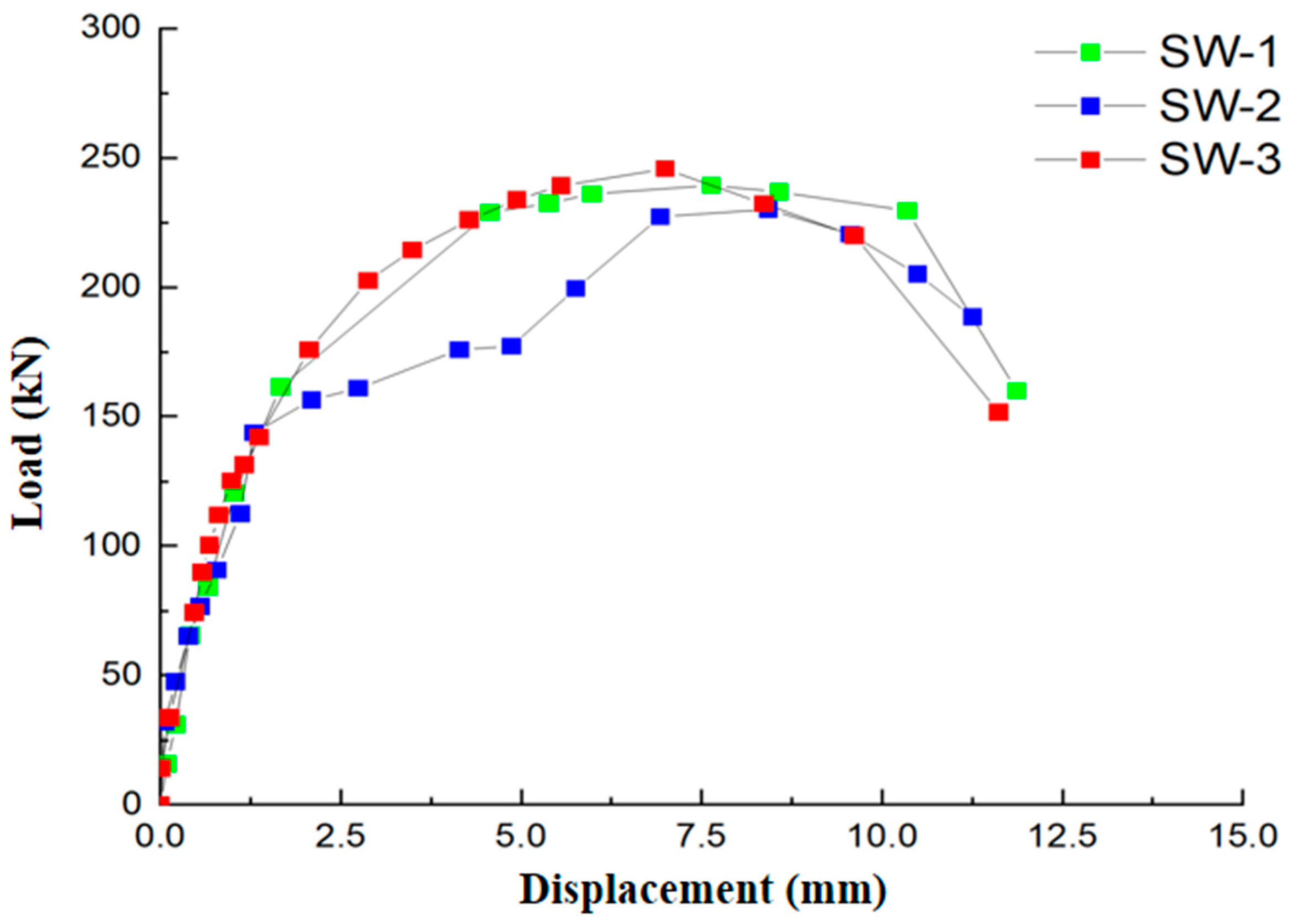

3.3. Load–Displacement Curves of Corroded SRCSWs

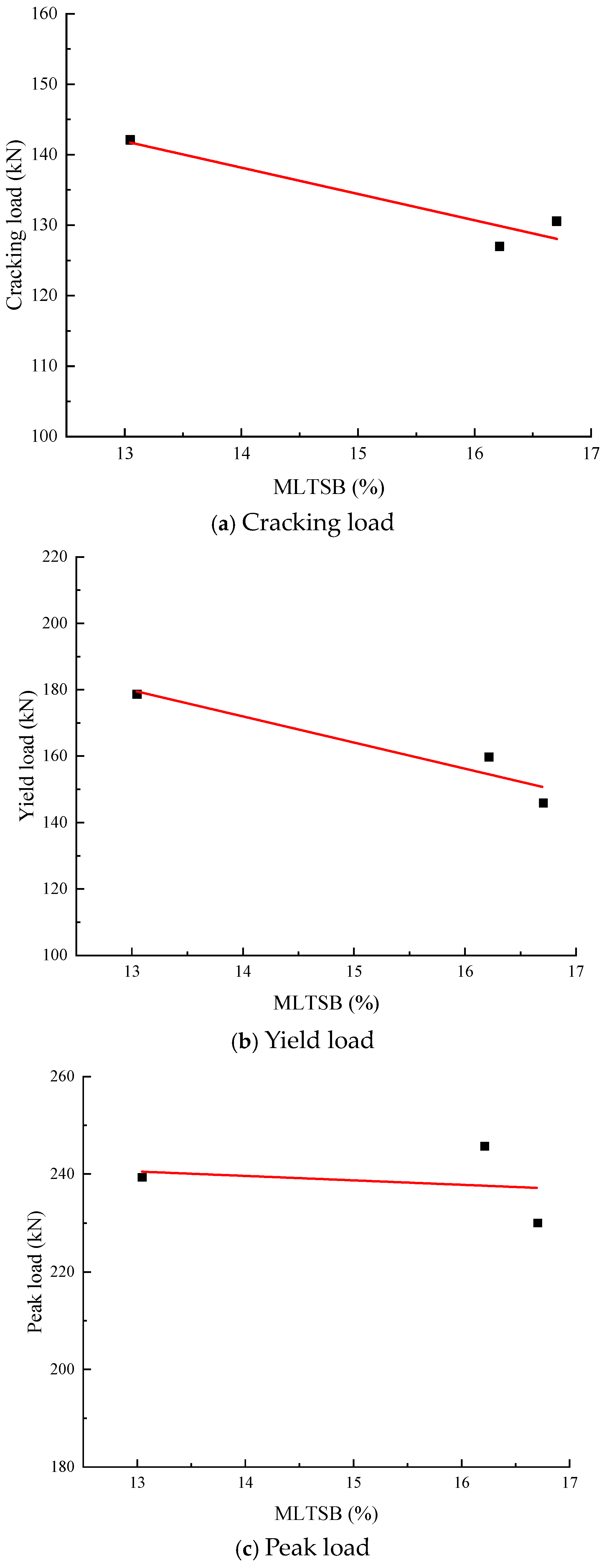

3.4. Relationship Between the Mechanical Properties of the Corroded SRCSWs and the MLTSB

3.5. Relationship Between the Mechanical Properties of Corroded SRCSWs and the Average Width of CICs

4. Conclusions

- (1)

- With an increase in corrosion time, the corrosion-induced cracking area on the SRCSWs increases. When the corrosion time is the same for two investigated structures, the corrosion-induced cracking area on these is approximately equal between the two. The loading failure laws for SRCSWs presenting different corrosion degrees along the base are obviously different. However, the failure mode is always shear failure.

- (2)

- The load–displacement curves of SRCSWs with different degrees of corrosion are basically identical and are linear when the loading is in the elastic stage. Compared to the SW-1, the peak load of SW-2 decreases by 4.0%, while that of SW-3 increases by 2.7%.

- (3)

- As the MLTSB increases from 13.05% to 16.71%, the crack, yield, and peak loads decrease by 8.8%, 22.4%, and 6.8%, respectively. All of them show an approximately linear relationship with the MLTSB, respectively, and the corresponding fitting relations are established.

- (4)

- When the average width of CICs increases from 0.24 mm to 0.40 mm, the crack, yield, and peak loads decrease by 8.8%, 22.4%, and 6.8%, respectively. The crack, yield, and peak loads of SRCSWs with corrosion along the base decrease linearly with the increase in the average width of CICs, and the corresponding fitting relations are established.

- (5)

- The fitting formulas presented in this paper are obtained from a small subset of test results, and, in future research, more SRCSWs with corrosion along the base should be constructed and tested to modify the fitting formulas. Moreover, the seismic properties of SRCSWs with corrosion along the base are not studied in this paper, offering an opportunity for further research.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Liu, H.; Shi, N.; Han, K.; Fu, X.; Fang, Y. Study on the attack of concrete by external sulfate under electric fields. Coatings 2024, 14, 1008. [Google Scholar] [CrossRef]

- Han, M.; Li, J. Enhancement of compressive strength and durability of sulfate-attacked concrete. Buildings 2024, 14, 2187. [Google Scholar] [CrossRef]

- Yuan, W.; Wang, Y.; Zhou, Y.; Yuan, W.; Yao, Y. Effect of biaxial loading path on seismic performance of RC bridge piers with corrosion damage. KSCE J. Civ. Eng. 2023, 27, 5243–5255. [Google Scholar] [CrossRef]

- Li, M.; Shen, D.; Yang, Q.; Cao, X.; Huang, C.; Cui, Z.; Qi, Y. Effect of reinforcement corrosion on the seismic performance of reinforced concrete shear walls. Constr. Build. Mater. 2023, 377, 130977. [Google Scholar] [CrossRef]

- Zheng, S.; Zhou, Y.; Li, Q.; Long, L.; Dong, L.; He, J. Experimental study on aseismic behavior of squat RC shear walls due to chloride ion erosion. Eng. Mech. 2019, 36, 69–78. [Google Scholar]

- Gao, X.; Xu, Z.; Ren, X.; Li, L. Experimental analysis of RC and SPRC squat shear walls. J. Build. Struct. 2024, 93, 109861. [Google Scholar] [CrossRef]

- Long, H.; Chen, L.; Dong, B.; Sun, Y.; Yan, Y.; Chen, C. The electronic properties and surface chemistry of passive film on reinforcement: Effect of composition of simulated concrete pore solution. Constr. Build. Mater. 2022, 360, 129567. [Google Scholar] [CrossRef]

- Mandal, S.; Singh, J.K.; Mallapur, S.; Lee, D.; Park, T. Effect of triethanolamine and sodium hexametaphosphate on formation, growth and breakdown of passive layer in concrete pore solution. J. Build. Eng. 2022, 59, 105113. [Google Scholar] [CrossRef]

- Wang, X.; Ba, M.; Yi, B.; Liu, J. Experimental and numerical investigation on the effect of cracks on chloride diffusion and steel corrosion in concrete. J. Build. Struct. 2024, 86, 108521. [Google Scholar] [CrossRef]

- Liu, Y.; Miao, Z.; Hogan, L.; Zhu, M.; Lu, Y. A new prediction model for residual deformation capacity of corroded steel bars. Eng. Struct. 2024, 318, 118739. [Google Scholar] [CrossRef]

- Qiu, W.; Peng, R.; Jiang, M. Investigation on the prediction of reinforcement corrosion-induced cover time-vary cracking from multi-scale. Structures 2022, 43, 1305–1314. [Google Scholar] [CrossRef]

- Chen, W.; Xu, S.; Zhang, W.; Ma, Z.; Zhang, J.; Zhang, Y.; Zhang, Y. Effect of bidirectional electromigration rehabilitation on corroded reinforcement and surrounding concrete in chloride contaminated concrete. J. Build. Struct. 2024, 93, 109840. [Google Scholar] [CrossRef]

- Dang, V.H.; François, R. Influence of long-term corrosion in chloride environment on mechanical behaviour of RC beam. Eng. Struct. 2013, 48, 558–568. [Google Scholar] [CrossRef]

- Zhang, R.; Castel, A.; François, R. The corrosion pattern of reinforcement and its influence on serviceability of reinforced concrete members in chloride environment. Cem. Concr. Res. 2009, 39, 1077–1086. [Google Scholar] [CrossRef]

- Li, L.; Liu, W.; Zhou, C.; Zeng, Q. Probabilistic assessment of silane impregnation and electrochemical chloride removal treatment on protection effect against steel corrosion in marine concrete structures. Dev. Built Environ. 2024, 17, 100364. [Google Scholar] [CrossRef]

- Yang, L.; Zheng, S.; Zheng, Y.; Dong, L.; Wu, H. Experimental investigation and numerical modelling of the seismic performance of corroded T-shaped reinforced concrete shear walls. Eng. Struct. 2023, 283, 115930. [Google Scholar] [CrossRef]

- Tang, Z.; Zhang, C. Effects of corrosion and pre-fatigue damage on the mechanical properties of HRB400E rebars. J. Constr. Steel Res. 2024, 217, 108641. [Google Scholar] [CrossRef]

- Ren, S.; Gu, Y.; Gao, X.; Gu, S.; Kong, C.; Zeng, S.; Liu, P.; Li, X. Estimating the effects of corrosion pitting morphology on residual fatigue properties of corroded steel based on fractal theory. Int. J. Steel Struct. 2023, 23, 480–492. [Google Scholar]

- Zhou, B.; Wang, H.; Yu, J.; Sun, X. Performance degradation of steel rebar considering corrosion spatial variability in concrete. Constr. Build. Mater. 2024, 411, 134783. [Google Scholar] [CrossRef]

- Zhang, X.; Zheng, S.; Ruan, S.; Hu, J.; Li, Y. Research on seismic performance test and numerical simulation of corroded L-shaped RC shear wall. Eng. Mech. 2024, 40, 213–224. [Google Scholar]

- Zheng, Y.; Kang, X.; Zheng, S.; Zhang, Y.; Liu, X. Study on seismic behavior of corroded reinforced concrete walls in flexural-shear failure. Structures 2024, 67, 107003. [Google Scholar] [CrossRef]

- Yalciner, H.; Kumbasaroglu, A. Experimental study to predict bond-slip behavior of corroded reinforced concrete columns. ACI Struct. J. 2022, 119, 111–128. [Google Scholar]

- Yang, B.; Hu, X.; Qiao, H. Enhancing durability of concrete in saline soil with nano-CaCO3 modification: Investigation and reliability analysis. KSCE J. Civ. Eng. 2024, 28, 3791–3804. [Google Scholar] [CrossRef]

- Ding, F. Mechanical Properties Research of Non-Uniform Corroded Reinforced Concrete Shear Wall Based on UMAT. Master’s Thesis, Xi’an University of Architecture and Technology, Xi’an, China, 2017. [Google Scholar]

- Dong, Y. Research on Seismic Behavior of Uniform Corroded Reinforced Concrete Shear Wall Based on ABAQUS. Master’s Thesis, Xi’an University of Architecture and Technology, Xi’an, China, 2016. [Google Scholar]

- Guo, J. Experimental Study and Finite Element Analysis on the Seismic Behavior of Squat Recycled Concrete Shear Walls. Master’s Thesis, Beijing University of Civil Engineering and Architecture, Beijing, China, 2015. [Google Scholar]

- Farzinpour, A.; Dehcheshmeh, E.M.; Broujerdian, V.; Esfahani, S.N.; Gandomi, A.H. Efficient boosting-based algorithms for shear strength prediction of squat RC walls. Case Stud. Constr. Mater. 2023, 13, e01928. [Google Scholar] [CrossRef]

- Gan, C. Experimental Research on Seismic Behaviors of Squat RC Shear Walls Subjected to Freeze-Thaw Cycles. Master’s Thesis, Xi’an University of Architecture and Technology, Xi’an, China, 2016. [Google Scholar]

- Zheng, S.; Sang, Z.; Zhou, Y. Seismic test and shear strength prediction of squat RC shear walls under acidic environment. Eng. Mech. 2023, 40, 213–224. [Google Scholar]

- Devine, R.D.; Barbachyn, S.M.; Thrall, A.P.; Kurama, Y.C. Effect of aspect ratio, flanges, and material strength on squat reinforced concrete shear walls. ACI Struct. J. 2020, 117, 283–300. [Google Scholar]

- Miao, L.; Jin, L.; Chen, F.; Du, X. Experiment study on seismic performance and size effect in BFRP-RC squat shear walls with different horizontal reinforcement ratios. Eng. Struct. 2023, 295, 116888. [Google Scholar] [CrossRef]

- Rao, G. The Nonlinear Analysis and Performance Research of Low-Rise RC Shear Wall. Master’s Thesis, Hunan University, Changsha, China, 2005. [Google Scholar]

- Shao, W.; Qian, G.; Tong, Y. Research on Reinforced Concrete Squat Shear Walls. J. Xi’an Inst. Metall. Constr. Eng. 1989, 21, 15–23. [Google Scholar]

- Guo, Z.; Tong, Y.; Qian, G. Study on the deformation behaviour and restoring force model of squat shear wall. J. Xi’an Univ. Arch. Technol. 1998, 30, 25–28. [Google Scholar]

- Liu, B.; Guo, Z.; Huang, Q. A practical calculating method for evaluating the shear capacity and lateral stiffness of RC squat shear walls with boundary frame. Sichuan Build. Sci. 2009, 35, 141–144. [Google Scholar]

- Thomson, E.D.; Perdomo, M.E.; Picón, R.; Marante, M.E.; Flórez-López, J. Simplified model for damage in squat RC shear walls. Eng. Struct. 2009, 31, 2215–2223. [Google Scholar] [CrossRef]

- Salonikios, T.N. Shear strength and deformation patterns of R/C walls with aspect ratio 1.0 and 1.5 designed to Eurocode 8 (EC8). Eng. Struct. 2002, 24, 39–49. [Google Scholar] [CrossRef]

- Massone, L.M. Strength prediction of squat structural walls via calibration of a shear-flexure interaction model. Eng. Struct. 2010, 32, 922–932. [Google Scholar] [CrossRef]

- Zheng, S.; Li, Q.; Qin, Q.; Zuo, H.; Dong, L.; Liu, W. Experimental study on seismic behaviors of corroded squat reinforced concrete shear walls. J. Build. Struct. 2019, 40, 79–87. [Google Scholar]

- Zheng, S.; Qin, Q.; Yang, W.; Gan, C.; Zhang, Y.; Ding, S. Experimental research on the seismic behaviors of squat RC shear walls under offshore atmospheric environment. J. Harbin Inst. Technol. 2015, 47, 64–69. [Google Scholar]

- GB 50010; Code for Design of Concrete Structure. China Architecture & Building Press: Beijing, China, 2015.

- JGJ 55; Specification for Mix Proportion Design of Ordinary Concrete. China Architecture & Building Press: Beijing, China, 2011.

- GB 50081; Standard for Test Methods of Concrete Physical and Mechanical Properties. China Architecture & Building Press: Beijing, China, 2019.

- Law, D.W.; Tang, D.; Molyneaux, T.K.C. Impact of crack width on bond, confined and unconfined rebar. Mater. Struct. 2011, 44, 1287–1296. [Google Scholar] [CrossRef]

- Malumbela, G.; Alexander, M.; Moyo, P. Interaction between corrosion crack width and steel loss in RC beams corroded under load. Cem. Concr. Res. 2010, 40, 1419–1428. [Google Scholar] [CrossRef]

- Maaddawy, T.A.E.I.; Soudki, K.A. Effectiveness of impressed current technique to simulate corrosion of steel reinforcement in concrete. J. Mater. Civ. Eng. 2003, 15, 41–47. [Google Scholar] [CrossRef]

- GB 50152; Standard Methods for Testing of Concrete Structures. China Architecture & Building Press: Beijing, China, 1992.

- GB/T 50082; Standard for Test Methods of Long-Term Performance and Durability of Ordinary Concrete. China Architecture & Building Press: Beijing, China, 2009.

- Chen, M.; Liu, X.; Mei, K.; Wang, S.; Liu, J.; Li, Y. Corrosion behavior of steel bar in magnesium oxysulfide cement-based materials: The role of chloride and nitrite. J. Mater. Res. Technol. 2024, 32, 1577–1588. [Google Scholar] [CrossRef]

- Wang, J.; Yuan, Y.; Song, Y.; Wang, Z.; Du, J.; Su, H. Cracking characteristics and axial capacity degradation of precast segmental bridge piers connected with corroded tapered sleeve locking-type splicing. Structures 2024, 65, 106740. [Google Scholar] [CrossRef]

- Qing, Q. Experimental Studies on Seismic Behavior of Corroded Squat RC Shear Walls Under Artificial Climate Environment. Master’s Thesis, Xi’an University of Architecture and Technology, Xi’an, China, 2014. [Google Scholar]

- Hao, C. Research on Seismic Performance of Self-Centering Mortise-Tenon Segmental Pier Based on Cyclic Pseudo-Static Test. Master’s Thesis, Beijing Jiaotong University, Beijing, China, 2022. [Google Scholar]

- Wang, F.; Xue, X.; Hua, J.; Chen, Z.; Huang, L.; Wang, N.; Jin, J. Non-uniform corrosion influences on mechanical performances of stainless-clad bimetallic steel bars. Mar. Struct. 2022, 86, 103276. [Google Scholar] [CrossRef]

- Papadopoulos, M.P.; Apostolopoulos, C.A.; Alexopoulos, N.D.; Pantelakis, S.G. Effect of salt spray corrosion exposure on the mechanical performance of different technical class reinforcing steel bars. Mater. Des. 2007, 28, 2318–2328. [Google Scholar] [CrossRef]

- Li, Y.; Zheng, S.; Dong, L.; Wang, D.; Sang, Z.; Wen, G. Mechanical properties of corroded steel bars on the tensile and buckling considering stirrup constraints. Constr. Build. Mater. 2024, 417, 135181. [Google Scholar] [CrossRef]

- Chai, X.; Shang, H.S.; Zhang, C.W. Bond behavior between corroded steel bar and concrete under sustained load. Constr. Build. Mater. 2021, 310, 125122. [Google Scholar] [CrossRef]

- Shang, H.S.; Zhou, J.H.; Yang, G.T. Study on the bond behavior of corroded steel bars embedded in concrete under the coupled effect of reciprocating loads and chloride ion erosion. Constr. Build. Mater. 2021, 305, 124658. [Google Scholar] [CrossRef]

- Liu, T.; Xu, Z.; Huang, T.; Yang, J.; Huang, Y.; Xu, N.; Pan, C.; Hua, L.; Li, J. Experimental research on the degradation law of the bond performance between steel bars and concrete with rust expansion cracking. Constr. Build. Mater. 2024, 450, 138544. [Google Scholar] [CrossRef]

| Number | Corrosion Time of the Front Side (A Side) | Corrosion Time of the Back Side (B Side) |

|---|---|---|

| SW-1 | 70 days | 0 days |

| SW-2 | 70 days | 42 days |

| SW-3 | 70 days | 70 days |

| Number | Pc/kN | Δy/mm | Py/kN | Pm/kN | Δu/mm | Pu/kN |

|---|---|---|---|---|---|---|

| SW-1 | 142.12 | 2.40 | 178.63 | 239.32 | 10.92 | 203.42 |

| SW-2 | 130.57 | 1.44 | 145.89 | 230.02 | 10.93 | 195.52 |

| SW-3 | 127.00 | 1.73 | 159.76 | 245.69 | 9.94 | 208.83 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Y.; Bi, Z.; Luo, S.; Wang, J. Experimental Study on the Mechanical Properties of Squat RC Shear Walls with Corrosion Along the Base. Buildings 2024, 14, 3409. https://doi.org/10.3390/buildings14113409

Wang Y, Bi Z, Luo S, Wang J. Experimental Study on the Mechanical Properties of Squat RC Shear Walls with Corrosion Along the Base. Buildings. 2024; 14(11):3409. https://doi.org/10.3390/buildings14113409

Chicago/Turabian StyleWang, Yougang, Zhengchao Bi, Sheng Luo, and Jian Wang. 2024. "Experimental Study on the Mechanical Properties of Squat RC Shear Walls with Corrosion Along the Base" Buildings 14, no. 11: 3409. https://doi.org/10.3390/buildings14113409

APA StyleWang, Y., Bi, Z., Luo, S., & Wang, J. (2024). Experimental Study on the Mechanical Properties of Squat RC Shear Walls with Corrosion Along the Base. Buildings, 14(11), 3409. https://doi.org/10.3390/buildings14113409